Agilent technologies TS-8900 User Manual

Agilent TS-8900

Functional Test System

Diagnostics User Guide

Agilent Technologies

Notices

© Agilent Technologies, Inc. 2011, 2012

No part of this manual may be reproduced

in any form or by any means (including

electronic storage and retrieval or translation into a foreign language) without prior

agreement and written consent from Agilent Technologies, Inc. as governed by

United States and international copyright

laws.

Manual Part Number

U8970-90003

Edition

Second Edition, November 2012

Printed in Malaysia

Agilent Technologies Microwave Products

(Malaysia) Sdn. Bhd.

Bayan Lepas Free Industrial Zone

11900 Penang, Malaysia

Technical Assistance

You can find information about technical

and professional services, product support,

and equipment repair and service on the

Web:

http://www.agilent.com/contacts/English/noscript.html

Double-click the link to Tes t & M e a su r e -

ment. Select your country from the

drop-down menus. The Web page that

appears next has contact information specific for your country.

If you do not have access to the Internet,

call one of the numbers in Ta b l e 1 .

Tab le 1 Agilent Call Centers

United States

and Canada:

Europe: (41 22) 780 8111

Japan: Measurement

Latin America: 305 269 7548

Asia-Pacific: (85 22) 599 7777

United States

and Canada:

Te s t a n d

Measurement Call

Center

(800) 452 4844

(toll-free in US)

Assistance Center

(81) 0426 56 7832

Te s t a n d

Measurement Call

Center

(800) 452 4844

(toll-free in US)

Table Of Content

1 Legal Information

Legal Information 1-2

Warranty 1-2

Technology Licenses 1-2

Restricted Rights Legend 1-2

Service And Support 1-3

Agilent On The Web 1-3

Agilent By Phone 1-3

2 Safety and Regulatory Information

Safety Information 2-2

Safety Summary 2-2

Safety Notice 2-2

General 2-2

Environmental Conditions 2-3

Before Applying Power 2-3

Ground The System 2-4

Fuses 2-4

Operator Safety Information 2-4

Safety Symbols and Regulatory Markings 2-5

Electrostatic Discharge (ESD) Precautions 2-7

End of Life: Waste Electrical and Electronic Equipment (WEEE) Directive

2002/96/EC 2-8

3 Running Diagnostics

Overview of Diagnostics Testplans 3-2

Configuring and Running the DGN Testplan 3-3

Configuring and Running the CEDGN Testplan 3-5

Installing the Diagnostic Test Fixture 3-8

Resolving Test Failures 3-12

4 Diagnostic Testing Details

DGN Testplan Description and Flow 4-2

Tes t F i x t u r e De s cr i p t i o n 4-15

U8970-66603 PCA-DIAGNOSTIC NUMBER 1 (Board #1) 4-15

U8970-66604 PCA-DIAGNOSTIC NUMBER 2 (Board #2) 4-16

U8970-66605 PCA-DIAGNOSTIC NUMBER 3 (Board #3) 4-16

TS-8900 Functional Test System Wiring Guide and Hardware Reference iii

U8970-66606 PCA-DIAGNOSTIC NUMBER 4 (Board #4) 4-17

U8970-66607 PCA-DIAGNOSTIC NUMBER 5 (Board #5) 4-17

E6170-61607 CABLE 2X 2X32 IDC PIN 1 TO PIN 1 4-18

E6170-61618 Diagnostic Cable 4-18

E2240-67012 CEDGN LOOPBACK CONNECTOR 4-19

E6170-66520 820OHM LOADED MEZZANINE CARD 4-19

E6170-61619 CABLE-HEAVY DUTY LOAD JUMPER 4-20

CEDGN Testplan Description and Flow 4-21

CEDGN_E878XA_PinMatrix.tpa (Pin Matrix CEDGN Test Flow) 4-22

CEDGN_E6178B_LoadCard.tpa (8 Channel High Power Load Card CEDGN Test

Flow) 4-36

CEDGN_N9377A_LoadCard.tpa (16 Channel Load Card CEDGN Test Flow) 4-42

CEDGN_N9379A_LoadCard.tpa (48 Channel Load Card CEDGN Test Flow) 4-48

CEDGN_E6198B_Utility.tpa (Switch Load Unit Utility CEDGN Test Flow) 4-52

CEDGN_L4451A_LXIDAC.tpa (4 Channel LXI DAC CEDGN Test Flow) 4-55

CEDGN_M9187A_DIO.tpa (DIO CEDGN Test Flow) 4-67

CEDGN_SoftingCAN.tpa (Softing CAN CEDGN Test Flow) 4-78

A Diagnostic Test Fixture Details

Celsior Test Fixture Schematics A-2

Schematic for U8970-66603 PCA-Diagnostic Number 1 (Board #1) A-2

Schematic for U8970-66604 PCA-Diagnostic Number 2 (Board #2) A-3

Schematic for U8970-66605 PCA-Diagnostic Number 3 (Board #3) A-4

Schematic for U8970-66606 PCA-Diagnostic Number 4 (Board #4) A-5

Schematic for U8970-66607 PCA-Diagnostic Number 5 (Board #5) A-6

Schematic for E6170-61618 Diagnostic Cable for 8 Channel Heavy Duty Card A-9

Schematic for E6170-61607 Cable (Cable -2X 2X32 IDC PIN1 to PIN1) A-10

iv TS-8900 Functional Test System Wiring Guide and Hardware Reference

List of Figure

1 Legal Information

2 Safety and Regulatory Information

3 Running Diagnostics

Figure 3-1. Specify the Instruments to be Tested in DGN Testplan 3-4

Figure 3-2. Specify the Instruments to be Tested in CEDGN Testplan 3-7

Figure 3-3. Installing CEDGN Board #1 (U8970-66603) to TC1 and CEDGN Board #3

Figure 3-4. Installing 8-Ch Heavy Duty Card diagnostic cable E6170-61618 on HP2 and

4 Diagnostic Testing Details

Figure 4-1. Generate 5V from Arbitrary Waveform Generator and measure using

Figure 4-2. Test Counter 50 Ohm and Hi Z for Channel1. 4-6

Figure 4-3. Counter measures Arbitrary Waveform Generator output signal

Figure 4-4. Digitizer captures Arbitrary Waveform Generator output signal

Figure 4-5. Measure short by DMM for matrix row 1 and matrix row-n open. 4-12

Figure 4-6. Measure open by DMM for matrix row 1 and matrix row-n open. 4-13

Figure 4-7. CEDGN Board #1 (U8970-66603 PCA- Diagnostic Number 1) 4-15

Figure 4-8. CEDGN Board #2 (U8970-66604 PCA- Diagnostic Number 2) 4-16

Figure 4-9. CEDGN Board #3 (U8970-66605 PCA- Diagnostic Number 3) 4-16

Figure 4-10. CEDGN Board #4 (U8970-66606 PCA- Diagnostic Number 4) 4-17

Figure 4-11. CEDGN Board #5 (U8970-66607 PCA- Diagnostic Number 5) 4-17

Figure 4-12. CEDGN Cable (E6170-61607 Cable 2X 2X32 IDC Pin 1 To Pin 1) 4-18

Figure 4-13. Diagnostic Cable (E6170-61618) for 8 Channel Heavy Duty Card 4-18

Figure 4-14. CEDGN Loopback Connector (E2240-67012) CEDGN test load module for

Figure 4-15. 820OHM Loaded Mezzanine Card (E6170-66520) CEDGN test load module for

Figure 4-16. Heavy Duty Load Card Load Loopback (E6170-61619) CEDGN test load for

Figure 4-17. Pin Matrix Loopback Test 4-25

Figure 4-18. E6175A 8 Channel Load Card Test 4-30

Figure 4-19. U7177A 24 Channel Load Card Test 4-35

Figure 4-20. E6178B 8 Channel High Power Load Card Test 4-41

Figure 4-21. N9377A 16 Channel Load Card Test 4-47

Figure 4-22. N9379A 48 Channel Load Card Test 4-51

(U8970-66605) to TC4 with both boards linked by cable (E6170-61607). 3-9

BNC connectors to Abus1, Abus2, Abus3 and Abus4. 3-11

DMM. 4-4

properties. 4-8

properties. 4-10

E6175A, U7177A, and N9377A 4-19

N9379A 4-19

E6178B 4-20

TS-8900 Functional Test System Wiring Guide and Hardware Reference v

Figure 4-23. E6198B Switch Load Unit Utility Test 4-54

Figure 4-24. L4451A LXI DAC Test 4-57

Figure 4-25. M9185A PXI DAC Output Test 4-63

Figure 4-26. M9185A PXI DAC Trigger Test 4-64

Figure 4-27. M9187A DIO Test 4-69

Figure 4-28. M9216A High Voltage Data Acquisition Test 4-75

A Diagnostic Test Fixture Details

Figure A-1. U8970-66603 PCA-Diagnostic Number 1 (Board #1) A-2

Figure A-2. U8970-66604 PCA-Diagnostic Number 2 (Board #2) A-3

Figure A-3. U8970-66605 PCA-Diagnostic Number 3 (Board #3) A-4

Figure A-4. U8970-66606 PCA-Diagnostic Number 4 (Board #4) A-5

Figure A-5. U8970-66607 PCA-Diagnostic Number 5 (Board #5) A-6

Figure A-6. E6170-61618 Diagnostic Cable for 8 Channel Heavy Duty Card A-9

Figure A-7. E6170-61607 Cable (Cable -2X 2X32 IDC PIN1 to PIN1) A-10

vi TS-8900 Functional Test System Wiring Guide and Hardware Reference

List of Table

1 Legal Information

2 Safety and Regulatory Information

3 Running Diagnostics

4 Diagnostic Testing Details

A Diagnostic Test Fixture Details

Table 1-1. Agilent Call Centers and Regional Headquarters 1-3

Table 2-1. Environment Requirements 2-3

Table 2-2. Safety Symbols and Regulatory Markings 2-5

Table 2-3. Suggested Anti-Static Solutions for Site Planning 2-7

Table 3-1. CEDGN Testplan Description and Flow 3-5

Table 4-1. CEDGN Testplan Description and Flow 4-21

Table A-1. CEDGN Board #2 switch mapping summary A-7

Table A-2. CEDGN Board #5 switch mapping summary A-8

TS-8900 Functional Test System Wiring Guide and Hardware Reference vii

THIS PAGE IS INTENTIONALLY LEFT BLANK.

viii TS-8900 Functional Test System Wiring Guide and Hardware Reference

Agilent TS-8900 Functional Test Sytem

Diagnostics User Guide

1

Legal Information

Warranty 1-2

Technology Licenses 1-2

Restricted Rights Legend 1-2

Service And Support 1-3

Agilent On The Web 1-3

Agilent By Phone 1-3

Agilent Technologies

1-1

1 Legal Information

Legal Information

Warranty

The material contained in this document is provided “as is, ”

and is subject to being changed, without notice, in future

editions. Further, to the maximum extent permitted by

applicable law, Agilent disclaims all warranties, either express

or implied, with regard to this manual and any information

contained herein, including but not limited to the implied

warranties of merchantability and fitness for a particular

purpose. Agilent shall not be liable for errors or for incidental

or consequential damages in connection with the furnishing,

use, or performance of this document or of any information

contained herein. Should Agilent and the user have a separate

written agreement with warranty terms covering the material in

this document that conflict with these terms, the warranty

terms in the separate agreement shall control.

Technology Licenses

The hardware and/or software described in this document are

furnished under a license and may be used or copied only in

accordance with the terms of such license.

Restricted Rights Legend

If software is for use in the performance of a U. S. Government

prime contract or subcontract, Software is delivered and

licensed as “Commercial computer software” as defined in

DFAR 252. 227-7014 (June 1995), or as a “commercial item” as

defined in FAR 2. 101(a) or as “Restricted computer software”

as defined in FAR 52. 227-19 (June 1987) or any equivalent

agency regulation or contract clause. Use, duplication or

disclosure of Software is subject to Agilent Technologies’

standard commercial license terms, and non-DOD Departments

and Agencies of the U. S. Government will receive no greater

than Restricted Rights as defined in FAR 52.

227-19(c)(1-2)(June 1987). U. S. Government users will receive

no greater than Limited Rights as defined in FAR 52. 227-14

(June 1987) or DFAR 252. 227-7015 (b)(2)(November 1995), as

applicable in any technical data.

1-2 TS-8900 Functional Test System Diagnostics User Guide

Service And Support

Any adjustment, maintenance, or repair of this product must be

performed by qualified personnel. Contact your customer

engineer through your local Agilent Technologies Service

Center.

Agilent On The Web

You can find information about technical and professional

services, product support, and equipment repair and service on

the Web: http://www. agilent. com/

Double-click the link to Test & Measurement. Select your country

from the drop-down menus. The Web page that appears next has

contact information specific for your country

Legal Information 1

Agilent By Phone

If you do not have access to the Internet, call one of the

numbers in Table 1-1.

Table 1-1 Agilent Call Centers and Regional Headquarters

United States and Canada: Test and Measurement Call Center

(800) 452 4844 (toll-free in US)

Europe: (41 22) 780 8111

Japan: Measurement Assistance Center

(81) 0426 56 7832

Latin America: 305 269 7548

Asia-Pacific: (85 22) 599 7777

TS-8900 Functional Test System Diagnostics User Guide 1-3

1 Legal Information

Manufacturing Address

Agilent Technologies Microwave Products (Malaysia) Sdn. Bhd.

Bayan Lepas Free Industrial Zone,

11900 Penang,

Malaysia.

1-4 TS-8900 Functional Test System Diagnostics User Guide

Agilent TS-8900 Functional Test System

Diagnostics User Guide

2

Safety and Regulatory Information

Safety Information 2-2

Safety Summary 2-2

Safety Notice 2-2

General 2-2

Environmental Conditions 2-3

Before Applying Power 2-3

Ground The System 2-4

Fuses 2-4

Operator Safety Information 2-4

Safety Symbols and Regulatory Markings 2-5

Electrostatic Discharge (ESD) Precautions 2-7

End of Life: Waste Electrical and Electronic Equipment (WEEE) Directive

2002/96/EC 2-8

Agilent Technologies

2-1

2 Safety and Regulatory Information

CAUTION

WARNING

WARNING

Safety Information

Safety Summary

Safety Notice

The following general safety precautions must be observed during all phases of operation of this instrument. Failure to comply

with these precautions or with specific warnings elsewhere in

this manual violates safety standards of design, manufacture,

and intended use of the instrument. Agilent Technologies, Inc.

assumes no liability for the customer's failure to comply with

these requirements.

A CAUTION notice denotes a hazard. It calls attention to an

operating procedure, practice, or the like, that, if not correctly

performed or adhered to, could result in damage to the product or

loss of important data. Do not proceed beyond a CAUTION notice

until the indicated conditions are fully understood and met.

A WARNING notice denotes a hazard. It calls attention to an operating

procedure, practice, or the like that, if not correctly performed or

adhered to, could result in personal injury or death. Do not proceed

beyond a WARNING notice until the indicated conditions are fully

understood and met.

General

This product is provided with a protective earth terminal. The

protective features of this product may be impaired if it is used

in a manner not specified in the operation instructions.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE. Do not operate the

product in the presence of flammable gases or flames.

2-2 TS-8900 Functional Test System Diagnostics User Guide

WARNING

DO NOT REMOVE RACK PANELS OR INSTRUMENT COVERS. Operating

WARNING

°

°

CAUTION

personnel must not remove any rack panels or instrument covers.

Component replacement and internal adjustments must be made only

by qualified service personnel. Products that appear damaged or

defective should be made inoperative and secured against unintended

operation until they can be repaired by a qualified service personnel.

The protection provided by the TS-8900 system may be impaired if

the system is used in a manner not specified by Agilent.

Environmental Conditions

Safety and Regulatory Information 2

The TS-8900 Functional Test System is designed for indoor use

only. Table 2-1 shows general environmental requirements.

Table 2-1 Environment Requirements

Environment Conditions Requirements

Maximum Altitude 2000 meters

Temperature (Operation) 5 C to 40 C

Maximum Relative Humidity The test system is designed to operate

This product is designed for use in Installation Category II and

Pollution Degree 2, per IEC 61010-1 and 664 respectively.

Before Applying Power

in the range from 5% to 80% relative

humidity (non-condensing).

Verify that the product is set to match the available line voltage

and all safety precautions are taken. Note the external markings

of the instruments described in

Markings

TS-8900 Functional Test System Diagnostics User Guide 2-3

”.

“Safety Symbols and Regulatory

2 Safety and Regulatory Information

WARNING

WARNING

WARNING

Ground The System

Fuses

To minimize shock hazard, the instrument chassis and cover

must be connected to an electrical protective earth ground. The

instrument must be connected to the ac power mains through a

grounded power cable, with the ground wire firmly connected

to an electrical ground (safety ground) at the power outlet. Any

interruption of the protective (grounding) conductor or disconnection of the protective earth terminal will cause a potential

shock hazard that could result in personal injury.

Use only fuses with the required rated current, voltage, and

specified type (normal blow, time delay). Do not use repaired

fuses or short-circuited fuse holders. To do so could cause a

shock or fire hazard.

In order to avoid electrical hazards, all system internal fuses must

be replaced by trained and qualified personnel.

Operator Safety Information

Module connectors and Test Signal cables connected to them

cannot be operator accessible.

M

Cables and connectors are considered inaccessible if a tool (e. g.

screwdriver, wrench, socket, etc. ) or a key (equipment in a

locked cabinet) is required to gain access to a conductive surface connected to any cable conductor (High, Low or Guard).

Assure the equipment under test has adequate insulation

between the cable connections and any operator-accessible parts

(doors, covers, panels shields, cases, cabinets, etc. )

Verify there are multiple and sufficient protective means (rated

for the voltages you are applying) to assure the operator will

NOT come into contact with any energized conductor even if

one of the protective means fails to work as intended. For example, the inner side of a case, cabinet, door cover or panel can be

covered with an insulating material as well as routing the test

2-4 TS-8900 Functional Test System Diagnostics User Guide

Safety symbols

Safety and Regulatory Information 2

cables to the front panel connectors of the module through

non-conductive, flexible conduit such as that used in electrical

power distribution.

Safety Symbols and Regulatory Markings

Symbols and markings on the system, in manuals and on instruments alert you to potential risks, provide information about

conditions, and comply with international regulations. Table 2-2

defines the symbols and markings you may find in a manual or

on an instrument.

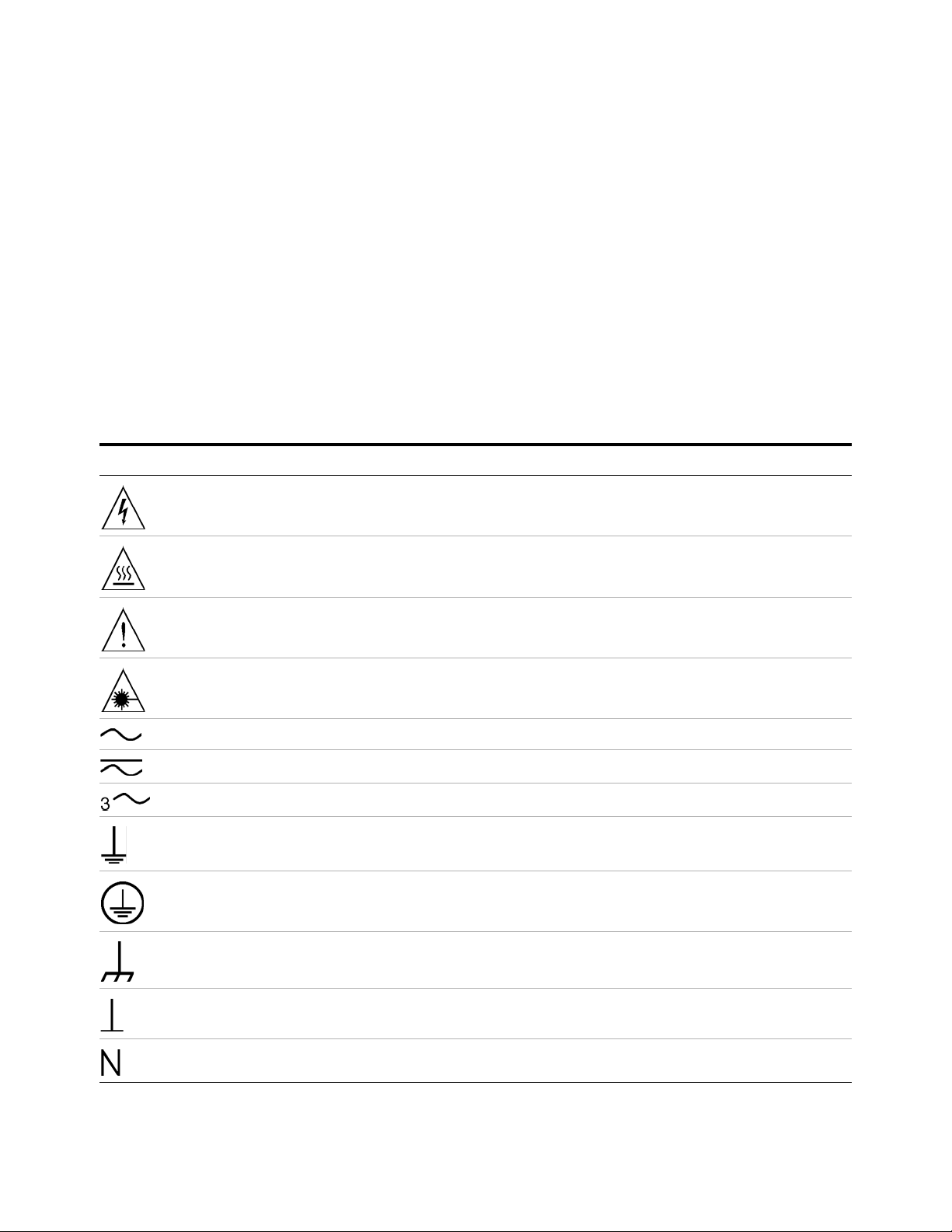

Table 2-2 Safety Symbols and Regulatory Markings

Warning: risk of electric shock.

Warning: hot surface

Caution: refer to accompanying documents.

Laser radiation symbol: marked on products that have a laser output.

Alternating current.

Both direct and alternating current.

Three-phase alternating current.

Earth (ground) terminal

Protective earth (ground) terminal

Frame or chassis terminal

Terminal is at earth potential. Used for measurement and control circuits designed to be operated

with one terminal at earth potential.

Terminal for neutral conductor on permanently installed equipment.

TS-8900 Functional Test System Diagnostics User Guide 2-5

2 Safety and Regulatory Information

Safety symbols

Terminal for line conductor on permanently installed equipment.

Standby (supply); units with this symbol are not completely disconnected from ac mains when

this switch is off. To completely disconnect the unit from ac mains, either disconnect the power

cord, or have a qualified electrician install an external switch.

Regulatory markings

This text indicates that the ISM device complies with Canadian ICES-001. Cet appareil ISM est

conforme à la norme NMB-001 du Canada.

The CSA mark is a registered trademark of the Canadian Standards Association.

The C-tick mark is a registered trademark of the Spectrum Management Agency of Australia. This

signifies compliance with the Australian EMC Framework regulations under the terms of the

Radio Communications Act of 1992.

This instrument complies with the WEEE Directive (2002/96/EC) marking requirement. This

affixed product label indicates that you must not discard this electrical/electronic product in

domestic householdwaste.

The CE mark is a registered trademark of the European Community. If it is accompanied by a year,

it indicates the year the design was proven.

2-6 TS-8900 Functional Test System Diagnostics User Guide

Electrostatic Discharge (ESD) Precautions

CAUTION

Static electricity is destructive to your production process and

the TS-8900. Careless handling and poor site planning can cause

system reliability problems and reduce your product yield. The

system may not be as easily damaged as the modules you will be

testing, but good anti-static planning will help ensure high reliability.

The ESD symbol below indicates areas where ESD caution must

be exercised. This is to prevent damage to instruments and/or

test disruption.

ESD Symbol

Caution: Static Sensitive.

Electrostatic discharge in this area may cause equipment damage or test

disruption.

Safety and Regulatory Information 2

While not an exhaustive list of anti-static precautions, Table 2-3

shows suggestions to consider as you plan your system area:

Table 2-3 Suggested Anti-Static Solutions for Site Planning

Precaution Suggested Solution

Anti-static flooring Plan to use an anti-static floor

covering or mats.

Grounding straps Plan for foot straps in conjunction

with anti-static flooring and wrist

straps for system operators.

The system test rack is secured to the pallet of the shipping crate

and wrapped with a plastic wrap. Do not move the crate or the test

rack and pallet to a static sensitive area until you have removed the

plastic wrap from the test rack.

TS-8900 Functional Test System Diagnostics User Guide 2-7

2 Safety and Regulatory Information

End of Life: Waste Electrical and Electronic Equipment (WEEE) Directive 2002/96/EC

This product complies with the WEEE Directive (2002/96/EC)

marking requirement. The affixed product label (see below)

indicates that you must not discard this electrical/electronic

product in domestic household waste.

Product Category:

With reference to the equipment types in the WEEE directive

Annex 1, this product is classified as a “Monitoring and Control

Instrumentation” product.

Do not dispose in domestic household waste

To return unwanted products, contact your local Agilent office,

or see:

http://www. agilent. com/environment/product

for more information.

2-8 TS-8900 Functional Test System Diagnostics User Guide

Agilent TS-8900 Functional Test System

NOTE

Diagnostics User Guide

3

Running Diagnostics

Overview of Diagnostics Testplans 3-2

Configuring and Running the DGN Testplan 3-3

Configuring and Running the CEDGN Testplan 3-5

Installing the Diagnostic Test Fixture 3-8

Resolving Test Failures 3-12

This chapter describes the overview of diagnostic testplans, DGN

testplan, CEDGN testplan and how to use the diagnostics test fixtures to

verify the operation of system equipment.

Diagnostic testing is intended to verify basic connectivity and instrument

functionality. It does not provide a full functional test of instrumentation

and specifications.

Agilent Technologies

3-1

3 Running Diagnostics

NOTE

Overview of Diagnostics Testplans

The verification strategy incorporates both standard and

optional tests using different testplans. The standard testplan

is shipped with each system. The testplans for the optional

tests are included with the diagnostic test fixtures.

The standard tests verify both the core system instrument

operation and internal test paths. It uses a testplan called

"U8971A_DGN.tpa", simply called "DGN". "DGN" does not

require external hardware, but verifies about 80% of the system

functionality. These testplans are located in directory:

C:\Program Files\Agilent\TS-5000 System Software\testplan\

DGN\

For more detailed description of the "DGN" testplan, go to Diagnostic

Testing Details.

The tests uses the "Customer Engineer Diagnostics" testplans

(file name: "CEDGN *.tpa"), simply called "CEDGN". "CEDGN"

completes the test coverage. It uses optional test hardware that

is supplied with the kit. An understanding of test system

operation and interpreting "CEDGN" test results are required to

execute the tests. These testplans are located in directory:

C:\Program Files\Agilent\TS-5000 System Software\Service\

U8970A\Testplans\

The tests are executed in Agilent TestExec SL and TS-5000

system programming environment, and use both standard and

specialized test actions. The programs can be edited to improve

and/or reduce test coverage. Systems equipped with

non-standard equipment do not have tests incorporated in

either "DGN" or "CEDGN". You have to add tests for those

systems.

3-2 TS-8900 Functional Test System Diagnostics User Guide

Configuring and Running the DGN Testplan

1 Start Agilent Test Exec SL by clicking this icon on the

desktop:

2 Load "U8971A_DGN.tpa" testplan into TestExec SL. "DGN"

Testplans are located in this directory:

C:\Program Files\Agilent\TS-5000 System Software\testplan\

DGN\

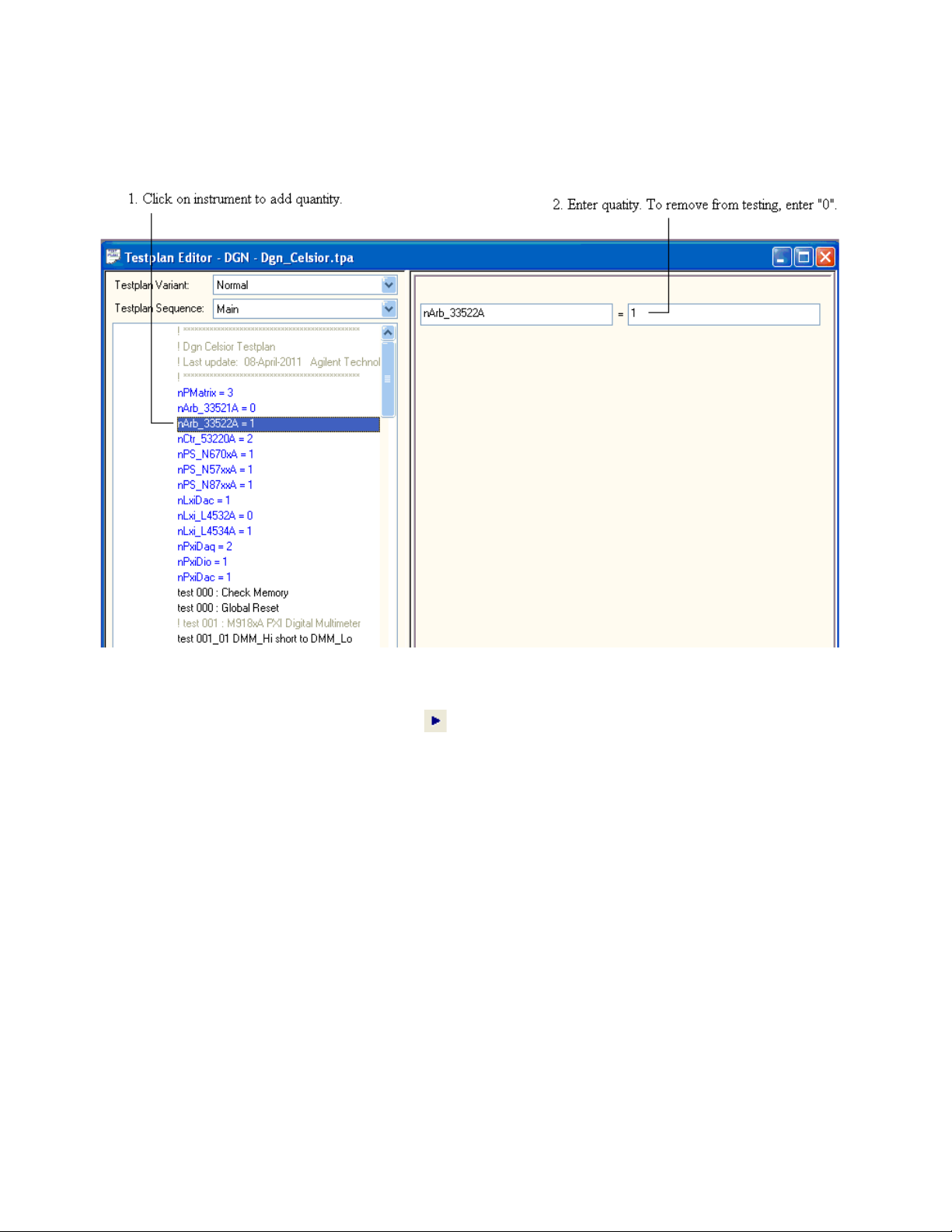

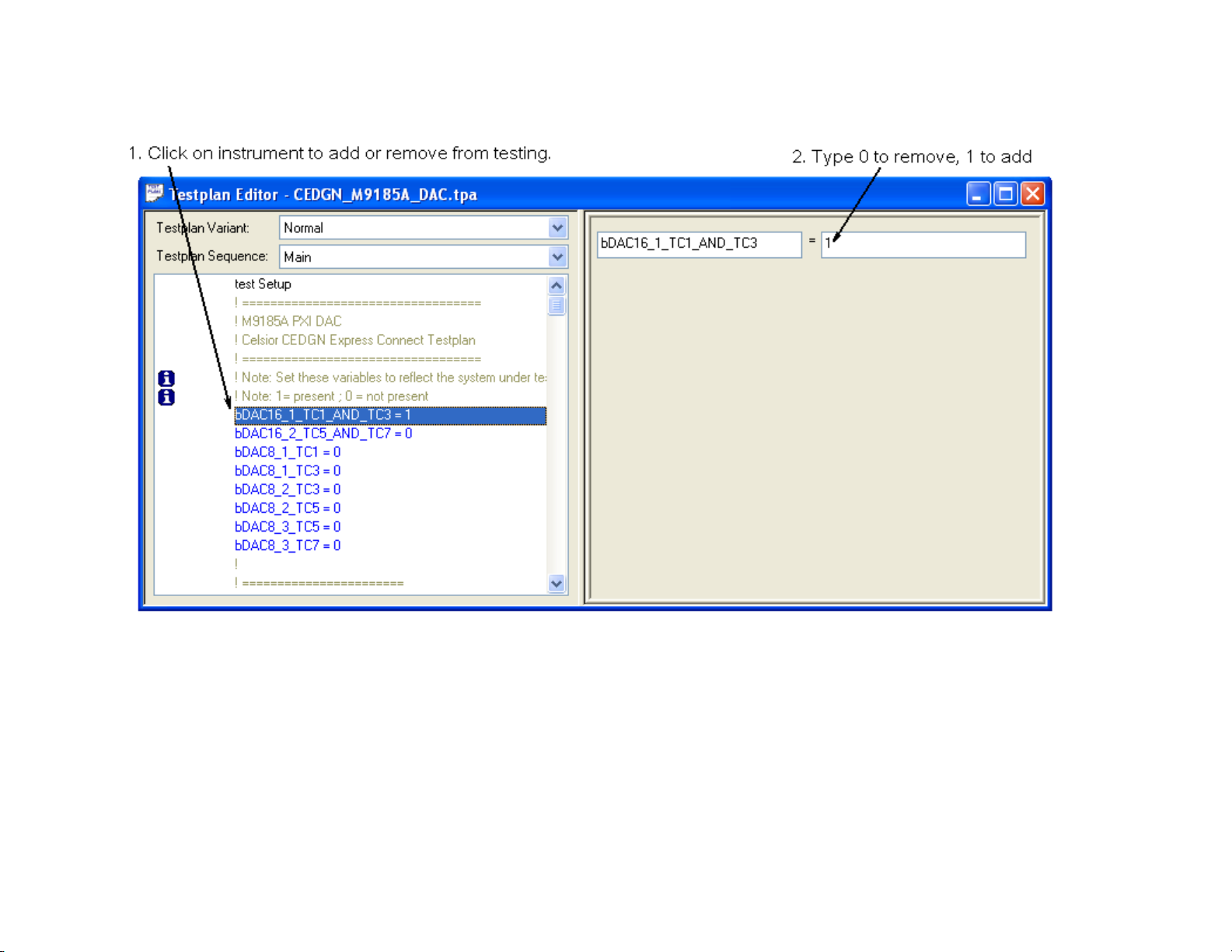

3 Before running the testplan, identify the instrumentation

you want to test in the first lines of the testplan as shown on

Figure 3-1. Place a 1 next to instruments you want to test, a 0

next to those instruments you do not want to test (or that are

not in your system).

Running Diagnostics 3

TS-8900 Functional Test System Diagnostics User Guide 3-3

3 Running Diagnostics

Figure 3-1 Specify the Instruments to be Tested in DGN Testplan

4 Click to run the testplan. The testplan will run tests on

each system instrument configuration specified in step 3 and

display the results of the testing.

3-4 TS-8900 Functional Test System Diagnostics User Guide

Running Diagnostics 3

Configuring and Running the CEDGN Testplan

1 Start Agilent Test Exec SL by clicking this icon on the

desktop:

2 There are multiple testplans for TS-8900 Functional Test

Systems. The each testplan is for specific instrument, module

or card that is accessible at the Express Connect interface.

Tab le 3- 1 CEDGN Testplan Description and Flow

Testplan Filename Topology filename Description

CEDGN_E878XA_PinMatrix.tpa CEDGN_E878XA_PinMatrix.ust SLU E8782A/E8783A Pin Matrix Card CEDGN Test

CEDGN_E6175A_LoadCard.tpa CEDGN_E6175A_LoadCard.ust SLU E6175A 8 Channel Load Card Test

CEDGN_U7177A_LoadCard.tpa CEDGN_U7177A_LoadCard.ust SLU U7177A 24 Channel Load Card CEDGN Test

CEDGN_E6178B_LoadCard.tpa CEDGN_E6178B_LoadCard.ust SLU E6178B 8 Channel Hi Power Load Card Test

CEDGN_N9377A_LoadCard.tpa CEDGN_N9377A_LoadCard.ust SLU N9377A 16 Channel Load Card CEDGN Test

CEDGN_N9379A_LoadCard.tpa CEDGN_N9379A_LoadCard.ust SLU N9379A 48 Channel Load Card CEDGN Test

CEDGN_E6198B_Utility.tpa CEDGN_E6198B_Utility.ust E6198B SLU Mainframe Utility CEDGN Test

CEDGN_L4451A_LXIDAC.tpa CEDGN_L4451A_LXIDAC.ust LXI L4451A 4 Channel DAC CEDGN Test

CEDGN_M9185A_DAC.tpa CEDGN_M9185A_DAC.ust PXI M9185A 8/16 Channel DAC CEDGN Test

CEDGN_M9186A_VI.tpa CEDGN_M9186A_VI.ust PXI M9186A Voltage Current Source CEDGN Test

CEDGN_M9187A_DIO.tpa CEDGN_M9187A_DIO.ust PXI M9187A Digital IO CEDGN Test

CEDGN_M9216A_DAQ.tpa CEDGN_M9216A_DAQ.ust PXI M9216A HV DAQ CEDGN Test

CEDGN_RS232.tpa CEDGN_RS232.ust RS-232 COM port CEDGN Test

CEDGN_SoftingCAN.tpa CEDGN_SoftingCAN.ust Softing CAN CEDGN Test

3 Load the appropriate testplan and its corresponding

topology file based on your installed hardware into TestExec

SL.

Testplans are located in this directory:

C:\Program Files\Agilent\TS-5000 System Software\Service\

U8970A\Testplans

Topology files are located in this directory:

TS-8900 Functional Test System Diagnostics User Guide 3-5

3 Running Diagnostics

C:\Program Files\Agilent\TS-5000 System Software\Service\

U8970A\Ust

4 Load the topology file (*. ust) of the hardware to be tested

and edit the Modules folder content:

• Disable - Check to disable. Uncheck to enable. Depends on

availability of the module in the system.

• Set "Slot #" - Depends on the slot number the card is

installed on the Switch Load Unit. (Applicable to SLU

cards only)

• Set "Instrument Descriptor/Resource" - LXI, PXI, GPIB

module address. Obtained from Agilent IO Libraries Suite.

(VISA Address)

• Set "PCI Slot Number" and "Serial Number" - Depends on

the installed Softing CAN.

Once complete editing, save and close the topology file.

5 Load the testplan together with its corresponding topology

file. Before running the testplan, identify the

instrumentation configuration you want to test in the first

lines of the testplan as shown on Figure 3-2. Place a 1 next to

instrument configuration you want to test, a 0 next to those

instrument configurations you do not want to test (or that

are not in your system).

6 Click to run the testplan. The testplan will run tests on

each system instrument configuration specified in step 5 and

display the results of the testing.

7 Follow the instructions appearing on the display throughout

the test.

8 Repeat step 4 until all instrumentation available in your

system are tested.

3-6 TS-8900 Functional Test System Diagnostics User Guide

TS-8900 Functional Test System Diagnostics User Guide 3-7

Figure 3-2 Specify the Instruments to be Tested in CEDGN Testplan

Running Diagnostics 3

3 Running Diagnostics

Installing the Diagnostic Test Fixture

While running the CEDGN testplan, specific diagnostic test

fixtures are required to install on the Test System Interface

based on the message prompted. Figure 3-3 shows the CEDGN

Board #1 (U8970-66603) to TC1 and CEDGN Board #3

(U8970-66605) to TC4. Both boards are linked by Cable

(E6170-61607). This fixture configuration is used to test the

connectivity and instrumentations functionality in TC4.

3-8 TS-8900 Functional Test System Diagnostics User Guide

Running Diagnostics 3

Figure 3-3 Installing CEDGN Board #1 (U8970-66603) to TC1 and CEDGN Board #3 (U8970-66605) to TC4 with

both boards linked by cable (E6170-61607).

TS-8900 Functional Test System Diagnostics User Guide 3-9

3 Running Diagnostics

Figure 3-4 shows connection of 8-Ch Heavy Duty Card

diagnostic cable E6170-61618. The Positronic connector on HP2

and cable to Abuses. This diagnostic cable is used to test the

connectivity of 8-Ch Heavy Duty Card on HP2.

3-10 TS-8900 Functional Test System Diagnostics User Guide

Loading...

Loading...