Agilent Technologies 6611C, 6613C, 6614C, 6612C User Manual

Service Manual

For Agilent Model 6611C, 6612C, 6613C, 6614C

System DC Power Supply

|

s1 |

Agilent Part No. 5962-8200 |

Printed in Malaysia |

Microfiche No 5962-8201 |

October, 2003 |

Warranty Information

CERTIFICATION

Agilent Technologies certifies that this product met its published specifications at time of shipment from the factory. Agilent Technologies further certifies that its calibration measurements are traceable to the United States National Bureau of Standards, to the extent allowed by the Bureau's calibration facility, and to the calibration facilities of other International Standards Organization members.

WARRANTY

This Agilent Technologies hardware product is warranted against defects in material and workmanship for a period of one year from date of delivery. Agilent Technologies software and firmware products, which are designated by Agilent Technologies for use with a hardware product and when properly installed on that hardware product, are warranted not to fail to execute their programming instructions due to defects in material and workmanship for a period of 90 days from date of delivery. During the warranty period Agilent Technologies will, at its option, either repair or replace products which prove to be defective. Agilent Technologies does not warrant that the operation for the software firmware, or hardware shall be uninterrupted or error free.

For warranty service, with the exception of warranty options, this product must be returned to a service facility designated by Agilent Technologies. Customer shall prepay shipping charges by (and shall pay all duty and taxes) for products returned to Agilent Technologies. for warranty service. Except for products returned to Customer from another country, Agilent Technologies shall pay for return of products to Customer.

Warranty services outside the country of initial purchase are included in Agilent Technologies’ product price, only if Customer pays Agilent Technologies international prices (defined as destination local currency price, or U.S. or Geneva Export price).

If Agilent Technologies is unable, within a reasonable time to repair or replace any product to condition as warranted, the Customer shall be entitled to a refund of the purchase price upon return of the product to Agilent Technologies.

LIMITATION OF WARRANTY

The foregoing warranty shall not apply to defects resulting from improper or inadequate maintenance by the Customer, Customer-supplied software or interfacing, unauthorized modification or misuse, operation outside of the environmental specifications for the product, or improper site preparation and maintenance. NO OTHER WARRANTY IS EXPRESSED OR IMPLIED. AGILENT TECHNOLOGIES. SPECIFICALLY DISCLAIMS THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

EXCLUSIVE REMEDIES

THE REMEDIES PROVIDED HEREIN ARE THE CUSTOMER'S SOLE AND EXCLUSIVE REMEDIES. AGILENT TECHNOLOGIES SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

ASSISTANCE

The above statements apply only to the standard product warranty. Warranty options, extended support contacts, product maintenance agreements and customer assistance agreements are also available. Contact your nearest Agilent Technologies Sales and Service office for further information on Agilent Technologies' full line of Support Programs.

2

Safety Summary

The following general safety precautions must be observed during all phases of operation of this instrument. Failure to comply with these precautions or with specific warnings elsewhere in this manual violates safety standards of design, manufacture, and intended use of the instrument. Agilent Technologies assumes no liability for the customer's failure to comply with these requirements.

WARNING

Servicing instructions are for use by service-trained personnel. To avoid dangerous electrical shock, do not perform any servicing unless you are qualified to do so. Some procedures described in this manual are performed with power supplied to the instrument while its protective covers are removed. If contacted, the energy available at many points may result in personal injury.

BEFORE APPLYING POWER.

Verify that the product is set to match the available line voltage, the correct line fuse is installed, and all safety precautions (see following warnings) are taken. In addition, note the instrument's external markings described under "Safety Symbols"

GROUND THE INSTRUMENT.

Before switching on the instrument, the protective earth terminal of the instrument must be connected to the protective conductor of the (mains) power cord. The mains plug shall be inserted only in an outlet socket that is provided with a protective earth contact. This protective action must not be negated by the use of an extension cord (power cable) that is without a protective conductor (grounding). Any interruption of the protective (grounding) conductor or disconnection of the protective earth terminal will cause a potential shock hazard that could result in personal injury.

FUSES

Only fuses with the required rated current, voltage, and specified type (normal blow, time delay, etc.) should be used. Do not use repaired fuses or short-circuited fuseholders. To do so could cause a shock or fire hazard.

KEEP AWAY FROM LIVE CIRCUITS.

Operating personnel must not remove instrument covers. Component replacement and internal adjustments must be made by qualified service personnel. Do not replace components with power cable connected. Under certain conditions, dangerous voltages may exist even with the power cable removed. To avoid injuries, always disconnect power, discharge circuits and remove external voltage sources before touching components.

DO NOT SERVICE OR ADJUST ALONE.

Do not attempt internal service or adjustment unless another person, capable of rendering first aid and resuscitation, is present. Any adjustment, maintenance, and repair of this instrument while it is opened and under voltage should be avoided as much as possible. When this is unavoidable, such adjustment, maintenance, and repair should be carried out only by a skilled person who is aware of the hazard involved.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT.

Because of the danger of introducing additional hazards, do not install substitute parts or perform any unauthorized modification to the instrument. Return the instrument to an Agilent Technologies Sales and Service Office for service and repair to ensure that safety features are maintained.

SAFETY SYMBOLS

Refer to the table on the following page

WARNING The WARNING sign denotes a hazard. It calls attention to a procedure, practice, or the like, which, if not correctly performed or adhered to, could result in personal injury. Do not proceed beyond a WARNING sign until the indicated conditions are fully understood and met.

Caution The CAUTION sign denotes a hazard. It calls attention to an operating procedure, or the like, which, if not correctly performed or adhered to, could result in damage to or destruction of part or all of the product. Do not proceed beyond a CAUTION sign until the indicated conditions are fully understood and met.

3

|

Safety Symbol Definitions |

Symbol |

Description |

|

Direct current |

|

|

|

Alternating current |

|

|

|

Both direct and alternating current |

|

|

|

Three-phase alternating current |

|

|

|

Earth (ground) terminal |

|

|

|

Protective earth (ground) terminal |

|

|

|

Frame or chassis terminal |

|

|

|

Terminal is at earth potential (Used for measurement and control circuits designed to be |

|

operated with one terminal at earth potential.) |

|

|

|

Terminal for Neutral conductor on permanently installed equipment |

|

|

|

Terminal for Line conductor on permanently installed equipment |

|

|

|

On (supply) |

|

|

|

Off (supply) |

|

|

|

Standby (supply) |

|

Units with this symbol are not completely disconnected from ac mains when this switch |

|

is off. To completely disconnect the unit from ac mains, either disconnect the power |

|

cord or have a qualified electrician install an external switch. |

|

In position of a bi-stable push control |

|

|

|

Out position of a bi-stable push control |

|

|

|

Caution, risk of electric shock |

|

|

|

Caution, hot surface |

|

|

|

Caution (refer to accompanying documents) |

|

|

4

Notice

The information contained in this document is subject to change without notice. Agilent Technologies makes no warranty of any kind with regard to this material, including but not limited to, the implied warranties of merchantability, and fitness for a particular purpose.

Agilent Technologies shall not be liable for errors contained herein or for incidental or consequential damages in connection with the furnishing, performance or use of this material.

This document contains proprietary information which is protected by copyright. All rights are reserved. No part of this document may be photocopied, reproduced, or translated into another language without the prior written consent of Agilent Technologies.

ã Copyright 1998, 2000 Agilent Technologies, Inc.

Printing History

The edition and current revision of this manual are indicated below. Reprints of this manual containing minor corrections and updates may have the same printing date. Revised editions are identified by a new printing date. A revised edition incorporates all new or corrected material since the previous printing date.

Changes to the manual occurring between revisions are covered by change sheets shipped with the manual. In some cases, the manual change applies only to specific instruments. Instructions provided on the change sheet will indicate if a particular change applies only to certain instruments.

Edition 1............................................................... |

June, 1998 |

Edition 2............................................................... |

September, 2000 |

Update 1............................................................... |

October, 2003 |

Instrument Identification

Agilent Technologies power supplies are identified by a 10-digit serial number. The format is described as follows: first two letters indicate the country of manufacture. The next four digits are a code that identify either the date of manufacture or of a significant design change. The last four digits are a sequential number assigned to each instrument.

Item |

Description |

US |

The first two letters indicates the country of manufacture, where US = USA; MY = Malaysia; SG = Singapore. |

3745 |

This is a code that identifies either the date of manufacture or the date of a significant design change. |

0101 |

The last four digits are a unique number assigned to each power supply. |

5

Table of Contents

Warranty Information |

2 |

Safety Summary |

3 |

Notice |

4 |

Printing History |

5 |

Instrument Identification |

5 |

Table of Contents |

6 |

INTRODUCTION |

9 |

Organization |

9 |

Safety Considerations |

9 |

Related Documents |

9 |

Revisions |

10 |

Manual Revisions |

10 |

Firmware Revisions |

10 |

Electrostatic Discharge |

10 |

VERIFICATION AND PERFORMANCE TESTS |

11 |

Introduction |

11 |

Test Equipment Required |

11 |

Measurement Techniques |

12 |

Setup for Most Tests |

12 |

Electronic Load |

13 |

Current-Monitoring Resistor |

14 |

Operation Verification Tests |

14 |

Performance Tests |

14 |

Programming |

14 |

Constant Voltage (CV) Tests |

15 |

CV Setup |

15 |

Voltage Programming and Readback Accuracy |

15 |

CV Load Effect |

15 |

CV Source Effect |

16 |

CV Noise (PARD) |

16 |

Transient Recovery Time |

16 |

Constant Current (CC) Tests |

17 |

CC Setup |

17 |

Current Programming and Readback Accuracy |

17 |

Current Sink (CC-) Operation |

18 |

CC Load and Line Regulation |

18 |

CC Load Effect |

19 |

CC Source Effect |

20 |

CC Noise (PARD) |

20 |

Performance Test Equipment Form |

21 |

Performance Test Record Form |

22 |

TROUBLESHOOTING |

27 |

Introduction |

27 |

Test Equipment Required |

28 |

Overall Troubleshooting |

28 |

Flow Charts |

28 |

Specific Troubleshooting Procedures |

33 |

Power-on Self-test Failures |

33 |

6

CV/CC Status Annunciators Troubleshooting |

34 |

Bias and Reference Supplies |

34 |

J307 Voltage Measurements |

35 |

Manual Fan Speed Control |

36 |

Disabling Protection Features |

36 |

Post-repair Calibration |

37 |

Inhibit Calibration Switch |

37 |

Calibration Password |

37 |

Initialization |

38 |

ROM Upgrade |

38 |

Identifying the Firmware |

38 |

Upgrade Procedure |

38 |

Disassembly Procedures |

39 |

List of Required Tools |

39 |

Cover, Removal and Replacement |

40 |

A2 Interface Board, Removal and Replacement |

40 |

Front Panel Assembly, Removal and Replacement |

40 |

A3 Front Panel Board, Removal and Replacement |

41 |

A1 Main Control Board |

41 |

T1 Power Transformer, Removal and Replacement |

41 |

Line Voltage Wiring |

42 |

PRINCIPLES OF OPERATION |

43 |

|

Introduction |

43 |

|

I/O Interface Signals |

43 |

|

A3 |

Front Panel Circuits |

44 |

A2 |

Interface Circuits |

44 |

Primary Interface |

44 |

|

Secondary Interface |

44 |

|

A1 |

Main Board Circuits |

45 |

Power Circuits |

45 |

|

Control Circuits |

46 |

|

REPLACEABLE PARTS LIST |

49 |

Introduction |

49 |

DIAGRAMS |

53 |

Introduction |

53 |

INDEX |

57 |

7

1

Introduction

Organization

This manual contains information for troubleshooting and repairing Agilent Models 6611C, 6612C, 6613C and 6614C System DC Power Supplies. Hereafter all models will be referred to as the dc power supply.

This manual is organized as follows:

Chapter 1 |

Organization |

Chapter 2 |

Performance tests |

Chapter 3 |

Troubleshooting procedures |

Chapter 4 |

Principles of operation on a block-diagram level |

Chapter 5 |

Replaceable parts |

Chapter 6 |

Diagrams |

Safety Considerations

WARNING: Hazardous voltages exist within the dc power supply chassis.

This dc power supply; is a Safety Class I instrument, which means it has a protective earth terminal. This terminal must be connected to earth ground through a power source equipped with a 3-wire, ground receptacle. Refer to the "Safety Summary" page at the beginning of this manual for general safety information. Before operation or repair, check the dc power supply and review this manual for safety warnings and instructions. Safety warnings for specific procedures are located at appropriate places in the manual.

Related Documents

The following documents are shipped with your dc power supply:

aa User’s Guide, Agilent part number 5962-8194, containing installation, operating, and calibration information

aa Programming Guide, Agilent part number 5962-8198, containing detailed GPIB programming information.

9

1 - Introduction

Revisions

Manual Revisions

If changes have been made to your power supply since the publication of this manual, a yellow Manual Change sheet may be supplied with the manual. It defines the differences between your power supply and the unit described in this manual. The yellow change sheet may also contain information for correcting errors in the manual. Note that because not all changes to the product require changes to the manual, there may be no update information required for your power supply.

Firmware Revisions

You can obtain the firmware revision number by either reading the integrated circuit label, or query the dc power supply using the GPIB *IDN?' query command (See Chapter 3, ROM Upgrade).

Electrostatic Discharge

CAUTION: The dc power supply has components that can be damaged by ESD (electrostatic discharge). Failure to observe standard antistatic practices can result in serious degradation of performance, even when an actual failure does not occur.

When working on the dc power supply, observe all standard, antistatic work practices. These include, but are not limited to:

—Working at a static-free station such as a table covered with static-dissipative laminate or with a conductive table mat (Agilent P/N 9300-0797, or equivalent).

—Using a conductive wrist strap, such as Agilent P/N 9300-0969 or 9300-0970.

—Grounding all metal equipment at the station to a single common ground.

—Connecting low-impedance test equipment to static-sensitive components only when those

components have power applied to them.

—Removing power from the dc power supply before removing or installing printed circuit boards.

10

2

Verification and Performance Tests

Introduction

This document contains test procedures to verify that the dc power supply is operating normally and is within published specifications. There are three types of tests as follows:

Built-in Self Tests |

These tests, run automatically when the power supply is turned on, check most |

|

of the digital circuits and the programming and readback DACs. |

Operation Verification |

These tests verify that the power supply is probably operating normally but do |

|

not check all of the specified operating parameters. |

Performance Tests |

These tests check that the supply meets all of the operating specifications as |

|

listed in the User’s Guide. |

NOTE: The dc power supply must pass the built-in self-tests before calibration or any of the verification or performance tests can be performed. If the supply fails any of the tests or if abnormal test results are obtained, refer to the troubleshooting procedures in Chapter 3. The troubleshooting procedures will determine if repair and/or calibration is required.

Test Equipment Required

Table 2-1 lists the equipment required to perform the verification and performance tests. A test record sheet with specification limits (when test using the recommended test equipment) may be found at the back of this section.

WARNING: |

SHOCK HAZARD. These tests should only be performed by qualified personnel. During the |

|

performance of these tests, hazardous voltages may be present at the output of the supply. |

|

|

11

2 - Verification and Performance Tests

Table 2-1. Test Equipment Required for Verification and Performance Tests

Type |

Specifications |

Recommended Model |

|

Current Monitor Resistor |

15 A (0.1 ohm) 0.04% |

Guildline 9230/15 |

|

DC Power Supply |

Minimum 5 A output current rating |

Agilent 6632B |

|

Digital Voltmeter |

Resolution: 10 nV @ 1V |

Agilent |

3458A or equivalent |

|

Readout: 8 1/2 digits |

|

|

|

Accuracy: 20 ppm |

|

|

Electronic Load |

100V, 5 A minimum, with transient capability |

Agilent |

6060B (60V max.), 6063B |

|

|

(240V) or equivalent |

|

GPIB Controller |

Controller with full GPIB capabilities |

HP Series 300 or equivalent |

|

Resistors |

400 ohm, 5W |

Agilent p/n 0811-1857 |

|

|

1 ohm, 100 W (or 2 ohm adjustable) |

Ohmite D12K2R0 (2 ohm adjustable) |

|

(Load resistors may |

0.6 ohm, 100W (6611C) |

|

|

substitute for electronic |

9 ohm, 100W (6612C) |

|

|

load if load is too noisy |

49 ohm, 100W (6613C) |

|

|

for CC PARD test) |

|

|

|

99 ohm, 100W (6614C) |

|

|

|

|

|

|

|

|

or an appropriate 150W Rheostat |

|

|

Oscilloscope |

Sensitivity: 1 mV |

Agilent |

54504A or equivalent |

|

Bandwidth Limit: 20 MHz |

|

|

|

Probe: 1:1 with RF tip |

|

|

RMS Voltmeter |

True RMS |

Agilent 3400B or equivalent |

|

|

Bandwidth: 20 MHz |

|

|

|

Sensitivity: 100 V |

|

|

Variable-Voltage |

Adjustable to highest rated input voltage |

|

|

Transformer |

range. |

|

|

|

Power: 500 VA |

|

|

Measurement Techniques

Test Setup

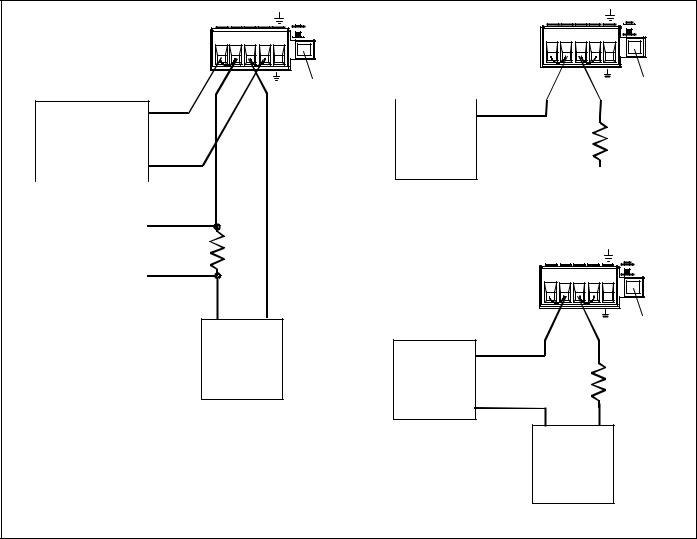

All tests are performed at the rear terminals of the supply as shown in Figure 2-1. Measure the dc voltage directly at the +S and -S terminals. Set the Remote/Local switch to Remote and connect the output for remote sensing. Use adequate wire gauge for the load leads.

12

Verification and Performance Tests - 2

-S |

- |

+ |

+S |

SENSE |

|

Local |

|||||

|

|

|

|

||

NOTE: Connector |

|

|

|

Remote |

|

|

|

|

|

||

is removable |

|

|

|

|

|

+ |

50VDC MAX TO |

|

|||

- |

|

|

|

|

|

Set to

Remote

|

DVM, Scope, or |

- |

|

|

|

|

|

|

RMS voltmeter |

|

|

|

(for CV tests) |

+ |

|

|

|

|

|

|

|

|

|

|

DVM or |

- |

|

|

|

Current |

|

|

RMS voltmeter |

|

|

|

|

monitor |

|

|

|

|

|

|

(for CC tests) |

+ |

|

|

|

|

|

- + Electronic Load (see note)

Note: Use dc supply with same polarity connectons for - CC tests.

Replace electronic load with resistors for CC noise test.

-S |

- |

+ |

+S |

SENSE |

|

||||

|

|

|

|

Local |

|

|

|

|

Remote |

+ |

50VDC MAX TO |

|

||

- |

|

|

|

|

Set to

|

|

Remote |

|

DC |

- |

||

|

|||

|

Load |

||

Ammeter |

|

resistor |

|

|

400 ohm |

||

|

|

+

b.

-S |

- |

+ |

+S |

SENSE |

|

Local |

|||||

|

|

|

|

||

|

|

|

|

Remote |

|

+ |

50VDC MAX TO |

|

|||

- |

|

|

|

|

|

Set to

Remote

DC |

- |

|

Load |

||

Ammeter |

resistor |

|

400 ohm |

||

|

+

- + External

DC supply

a. |

c. |

Figure 2-1. Test Setup

Electronic Load

Many of the test procedures require the use of a variable load capable of dissipating the required power. If a variable resistor is used, switches should be used to either; connect, disconnect, or short the load resistor. For most tests, an electronic load can be used. The electronic load is considerably easier to use than load resistors, but it may not be fast enough to test transient recovery time and may be too noisy for the noise (PARD) tests.

Fixed load resistors may be used in place of a variable load, with minor changes to the test procedures. Also, if computer controlled test setups are used, the relatively slow (compared to computers and system voltmeters) settling times and slew rates of the power supply may have to be taken into account. "Wait" statements can be used in the test program if the test system is faster than the supply.

13

2 - Verification and Performance Tests

Current-Monitoring Resistor

To eliminate output-current measurement error caused by voltage drops in the leads and connections, connect the current monitoring resistor between the -OUT and the load as a four-terminal device. Connect the current-monitoring leads inside the load-lead connections directly at the monitoring points on the resistor element.

Operation Verification Tests

To assure that the supply is operating properly, without testing all specified parameters, perform the turn-on and checkout procedures given in the User’s Guide.

Performance Tests

NOTE: A full Performance Test consists of only those items listed as “Specifications” in Table A-1 of the User’s Guide, and that have a procedure in this document.

The following paragraphs provide test procedures for verifying the supply's compliance with the specifications listed in Table A-1 of the User’s Guide. All of the performance test specifications are entered in the appropriate Performance Test Record Card for your specific model. You can record the actual measured values in the column provided in this card.

Programming

You can program the supply from the front panel keyboard or from a GPIB controller when performing the tests. The test procedures are written assuming that you know how to program the supply either; remotely from a GPIB controller or locally using the control keys and indicators on the supply's front panel. Complete instructions on remote and local programming are given in the User’s Guide and in the Programming Guide.

Table 2-2. Programming and Output Values

Model |

Full scale |

Vmax |

Full Scale |

Imax |

Isink |

OV Max |

|

Voltage |

|

Current |

|

|

|

6611C |

8 |

8.190 |

5 |

5.1187 |

- 3 A |

8.8 |

6612C |

20 |

20.475 |

2 |

2.0475 |

- 1.2 A |

22 |

6613C |

50 |

51.187 |

1 |

1.0238 |

- 0.6 A |

55 |

6614C |

100 |

102.38 |

0.5 |

0.5118 |

- 0.3 A |

110 |

14

Verification and Performance Tests - 2

Constant Voltage (CV) Tests

CV Setup

If more than one meter or if a meter and an oscilloscope are used, connect each to the terminals by a separate pair of leads to avoid mutual coupling effects. For constant voltage dc tests, connect only to +S and -S, since the unit regulates the output voltage that appears between +S and -S, and not between the (+) and (-) output terminals. Use coaxial cable or shielded two-wire cable to avoid noise pickup on the test leads.

Voltage Programming and Readback Accuracy

This test verifies that the voltage programming, GPIB readback and front panel display functions are within specifications. Note that the values read back over the GPIB should be identical to those displayed on the front panel.

a.Turn off the supply and connect a digital voltmeter between the +S and the -S terminals as shown in Figure 2-1a.

b.Turn on the supply and program the supply to zero volts and the maximum programmable current (Imax in Table 2-2) with the load off.

c.Record the output voltage readings on the digital voltmeter (DVM) and the front panel display. The readings should be within the limits specified in the performance test record card for the appropriate model under Voltage Programming and Readback @ 0 Volts. Also, note that the CV annunciator is on. The output current reading should be approximately zero.

d.Program the output voltage to full-scale (See Table 2-2) .

e.Record the output voltage readings on the DVM and the front panel display. The readings should be within the limits specified in the performance test record card for the appropriate model under Voltage Programming and Readback @ Full Scale.

CV Load Effect

This test measures the change in output voltage resulting from a change in output current from full load to no load.

a.Turn off the supply and connect the output as shown in Figure 2-1a with the DVM connected between the +S and -S terminals.

b.Turn on the supply and program the current to the maximum programmable value (Imax) and the voltage to the full-scale value in Table 2-2.

c.Adjust the load for the full-scale current in Table 2-2 as indicated on the front panel display. The CV annunciator on the front panel must be on. If it is not, adjust the load so that the output current drops slightly.

d.Record the output voltage reading on the DVM connected to +S and -S.

e.Open the load and again record the DVM voltage reading. The difference between the DVM readings in steps (d) and (e) is the load effect voltage, and should not exceed the value listed in the performance test record card for the appropriate model under CV Load Effect.

15

2 - Verification and Performance Tests

CV Source Effect

This test measures the change in output voltage that results from a change in ac line voltage from the minimum to maximum value within the line voltage specifications.

a.Turn off the supply and connect the ac power line through a variable voltage transformer.

b.Connect the output as shown in Figure 2-1a with the DVM connected between the +S and the -S terminals. Set the transformer to nominal line voltage.

c.Turn on the supply and program the current to the maximum programmable value (Imax) and the output voltage to the full-scale value in Table 2-2.

d.Adjust the load for the full-scale current value in Table 2-2 as indicated on the front panel display. The CV annunciator on the front panel must be on. If it is not, adjust the load so that the output current drops slightly.

e.Adjust the transformer to the lowest rated line voltage (e.g., 104 Vac for a 115 Vac nominal line voltage input).

f.Record the output voltage reading on the DVM.

g.Adjust the transformer to the highest rated line voltage (e.g., 127 Vac for 115 Vac nominal line voltage input).

h.Record the output voltage reading on the DVM. The difference between the DVM reading is steps (f) and (h) is the source effect voltage and should not exceed the value listed in the performance test record card for the appropriate model under CV Source Effect.

CV Noise (PARD)

Periodic and random deviations (PARD) in the output (ripple and noise) combine to produce a residual ac voltage superimposed on the dc output voltage. CV PARD is specified as the rms or peak-to-peak output voltage in the frequency range specified in the User’s Guide.

a.Turn off the supply and connect the output as shown in Figure 2-1a to an oscilloscope (ac coupled) between the

(+) and the (-) terminals. Set the oscilloscope's bandwidth limit to 20 MHz and use an RF tip on the oscilloscope probe.

b.Turn on the supply and program the current to the maximum programmable value (Imax) and the output voltage to the full-scale value in Table 2-2.

c.Adjust the load for the full-scale current value in Table 2-2 as indicated on the front panel display.

d.Note that the waveform on the oscilloscope should not exceed the peak-to-peak limits in the performance test record card for the appropriate model under CV Noise (PARD).

e.Disconnect the oscilloscope and connect an ac rms voltmeter in its place. The rms voltage reading should not exceed the RMS limits in the performance test record card for the appropriate model under CV Noise (PARD).

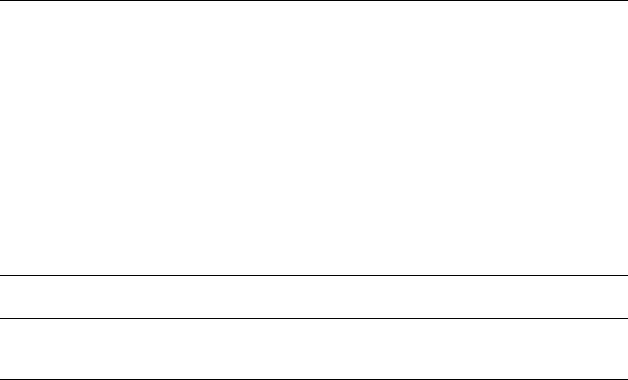

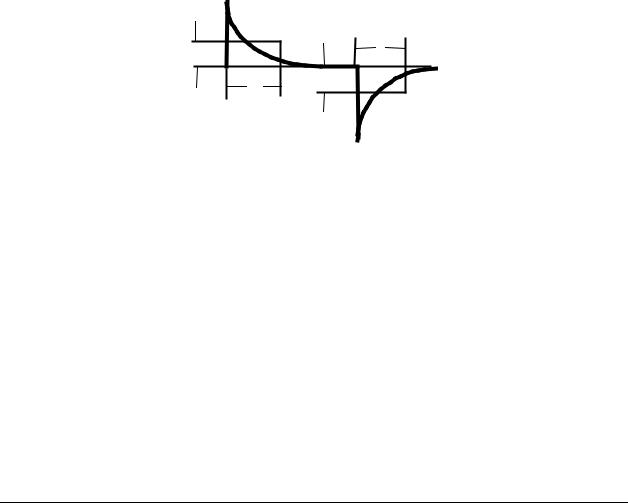

Transient Recovery Time

This test measures the time for the output voltage to recover to within the specified value following a 50% change in the load current.

16

Verification and Performance Tests - 2

tttt

Loading

Transient

v |

t |

v

t

Unloading

Transient

Figure 2-2. Transient Waveform

a.Turn off the supply and connect the output as in Figure 2-1a with the oscilloscope across the +S and -S terminals.

b.Turn on the supply and program the output current to the maximum programmable value (Imax) and the voltage to the full-scale value in Table 2-2.

c.Set the load to the Constant Current mode and program the load current to 1/2 the power supply full-scale rated current.

d.Set the electronic load's transient generator frequency to 100 Hz and its duty cycle to 50%.

e.Program the load's transient current level to the supply's full-scale current value and turn the transient generator on.

f.Adjust the oscilloscope for a waveform similar to that in Figure 2-2.

g.The output voltage should return to within the specified voltage (v) in less than 100uS (t). Check both loading and unloading transients by triggering on the positive and negative slope. Record the voltage at time “t” in the performance test record card under CV Transient Response.

Constant Current (CC) Tests

CC Setup

Follow the general setup instructions in the Measurement Techniques paragraph and the specific instructions given in the following paragraphs.

Current Programming and Readback Accuracy

This test verifies that the current programming and readback are within specification.

a.Turn off the supply and connect the current monitoring resistor across the power supply output and the DVM across the resistor as shown in Figure 2-1a. See "Current Monitoring Resistor" for connection information.

b.Turn on the supply and program the output voltage to 5 V and the current to zero amps. The power supply’s current detector must be set to DC and the programming language mode to SCPI. See the specifications for high range current readback in the User’s Guide if operating with the detector in ACDC or the language in Compatibility mode.

17

2 - Verification and Performance Tests

c.Divide the voltage drop (DVM reading) across the current monitoring resistor by its resistance to convert to amps and record this value (Iout). The readings should be within the limits specified in the performance test record card for the appropriate model under Current Programming @ 0 Amps.

d.Set the current range readback to High and program the output current to 20mA. Repeat step C to get the Iout. Record the current reading on the front panel display. The reading should be within the limits specified in the performance test record card for the appropriate model under Current Readback Accuracy (20mA) Iout.

e.Program the output current to the full-scale value in Table 2-2.

f.Divide the voltage drop (DVM reading) across the current monitoring resistor by its resistance to convert to amps and record this value (Iout). Also, record the current reading that appears on the front panel display. The readings should be within the limits specified in the performance test record card for the appropriate model under Current Programming and Readback @ Full Scale.

Current Sink (-CC) Operation

This test verifies current sink operation and readback.

a.Turn off the supply and connect the output as shown in Figure 2-1a, except connect a dc power supply in place of the electronic load as indicated. Set the DMM to operate in voltage mode.

b.Set the external power supply to 5 V and the current to the full scale current rating of the supply under test as in Table 2-2.

c.Turn on the supply under test and program the output voltage to zero and the current to full scale as in Table 2- 2. The current on the UUT display should be negative and at least 60% of the current rating.

d.Divide the voltage drop across the current monitoring resistor by its resistance to obtain the current sink value in amps and subtract this from the current reading on the display. The difference between the readings should be within the limits specified in the performance test record card under Current Sink Readback.

Low Range Current Readback Accuracy

This test verifies the readback accuracy of the 20 milliampere current range.

a.Turn off the supply and connect the output as shown in Figure 2-1b. Set the DMM to operate in current mode.

b.Turn on the supply under test and set the current range readback to Low. Program the output voltage to zero and the current to the full scale value in Table 2-2. The current on the UUT display should be approximately 0 mA.

c.Record the current reading on the DMM and the reading on the front panel display. The difference between the two readings should be within the limits specified in the performance test record card under 20mA Range Current Readback Accuracy @ 0A.

d.Program the output voltage to 8V and record the current reading on the DMM and the reading on the front panel display. If the meter indicates overrange, lower the 8 volts slightly. The difference between the readings should be within the limits specified in the performance test record card for the appropriate model under 20mA Range Current Readback Accuracy @ +20mA

e.Turn off the supply and connect the output and an external supply as shown in Figure 2-1c. Set the DMM to operate in current mode.

f.Turn on the external supply and program it to 8V and 1 amp. Then program the supply under test to zero volts and 1 amp , except the 6614C is programmed to 0.5 amp . If the meter indicates overrange, lower the voltage of the external supply slightly. The UUT display should read approximately −20 mA.

g.Record the current reading on the DMM and the reading on the front panel display. The difference between the two readings should be within the limits specified in the performance test record card under 20mA Range Current Readback Accuracy @ −20 mA.

18

Loading...

Loading...