SGS Thomson Microelectronics ST92F120V9, ST92F120V9Q, ST92F120V6Q, ST92F120V1Q, ST92F120R9T Datasheet

...

January 2000 1/320

This ispreliminary information on a new product now in development or undergoing evaluation.Details are subject to change without notice.

Rev. 2.1

ST92F120

8/16-BIT FLASH MCU FAMILY

WITH RAM, EEPROM AND J1850 BLPD

PRELIMINARY DATA

■ Register oriented 8/16 bit CORE with RUN,

WFI, SLOW, HALT and STOP modes

■ 0 - 24 MHz Operation (internal Clock), 4.5 - 5.5

Volt voltage range

■ PLL Clock Generator (3-5 MHz crystal)

■ -40

o

C to 105

o

C or -40

o

Cto85

o

C temperature

range

■ Minimum instruction time: 83 ns (24 MHz

internal clock)

■ Internal Memory: Single Voltage FLASH up to

128 Kbytes, RAM 1.5 to 4 Kbytes, EEPROM

512 to 1K bytes

■ 224 general purpose registers (register file)

available as RAM, accumulators or index

pointers

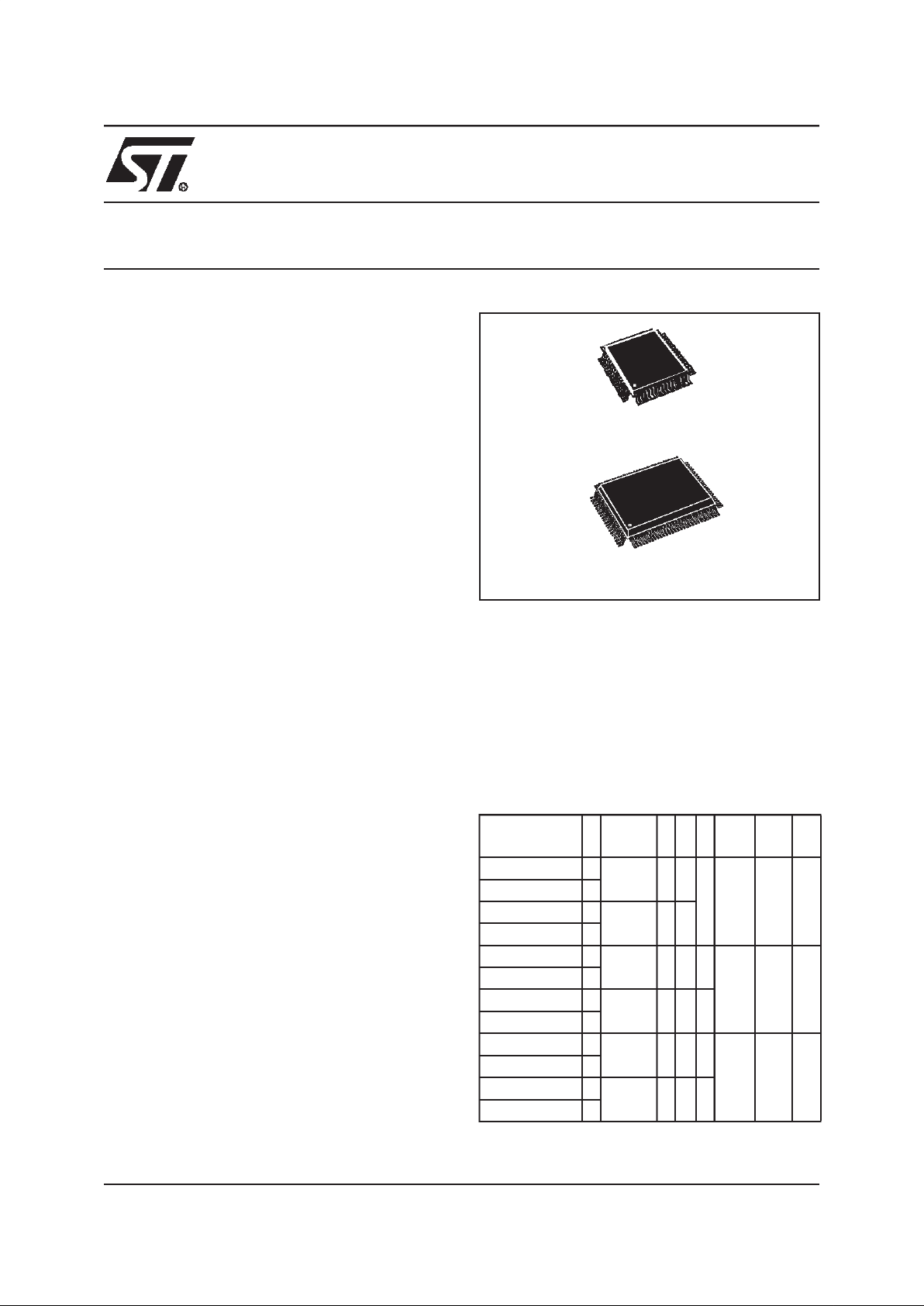

■ TQFP64 or PQFP100 package

■ DMA controller for reduced processor overhead

■ 48 (77 on PQFP100 version) I/O pins

■ 4 external fast interrupts + 1 NMI

■ Up to 16 pins programmable as wake-up or

additional external interrupt with multi-level

interrupt handler

■ 16-bit Timer with 8 bit Prescaler, able to be

used as a Watchdog Timer with a large range of

service time (HW/SW enabling through

dedicated pin)

■ 16-bit Standard Timer that can be used to

generate a time base independent of PLL Clock

Generator

■ Two 16-bit independent Extended Function

Timers (EFTs) with Prescaler, 2 Input Captures

and two Output Compares (PQFP100 only)

■ Two 16-bit Multifunction Timers, with Prescaler,

2 Input Captures and two Output Compares

■ 8-bit Analog to DigitalConverterallowingupto 8

input channelsonTQFP64 or 16 input channels

on PQFP100

■ One or two Serial Communications Interfaces

with asynchronous and synchronous

capabilities. Software Management and

synchronous mode supported

■ Serial Peripheral Interface (SPI) with Selectable

Master/Slave mode

■ J1850 Byte Level Protocol Decoder (JBLPD)

(on some versions only)

■ Full I

2

C multiple Master/Slave Interface

supporting ACCESS BUS

■ Rich InstructionSet with 14 Addressing Modes

■ Division-by-zero trap generation

■ Versatile Development Tools, including

Assembler, Linker, C-Compiler, Archiver,

Source Level Debugger, Hardware Emulators

and Real Time Operating System

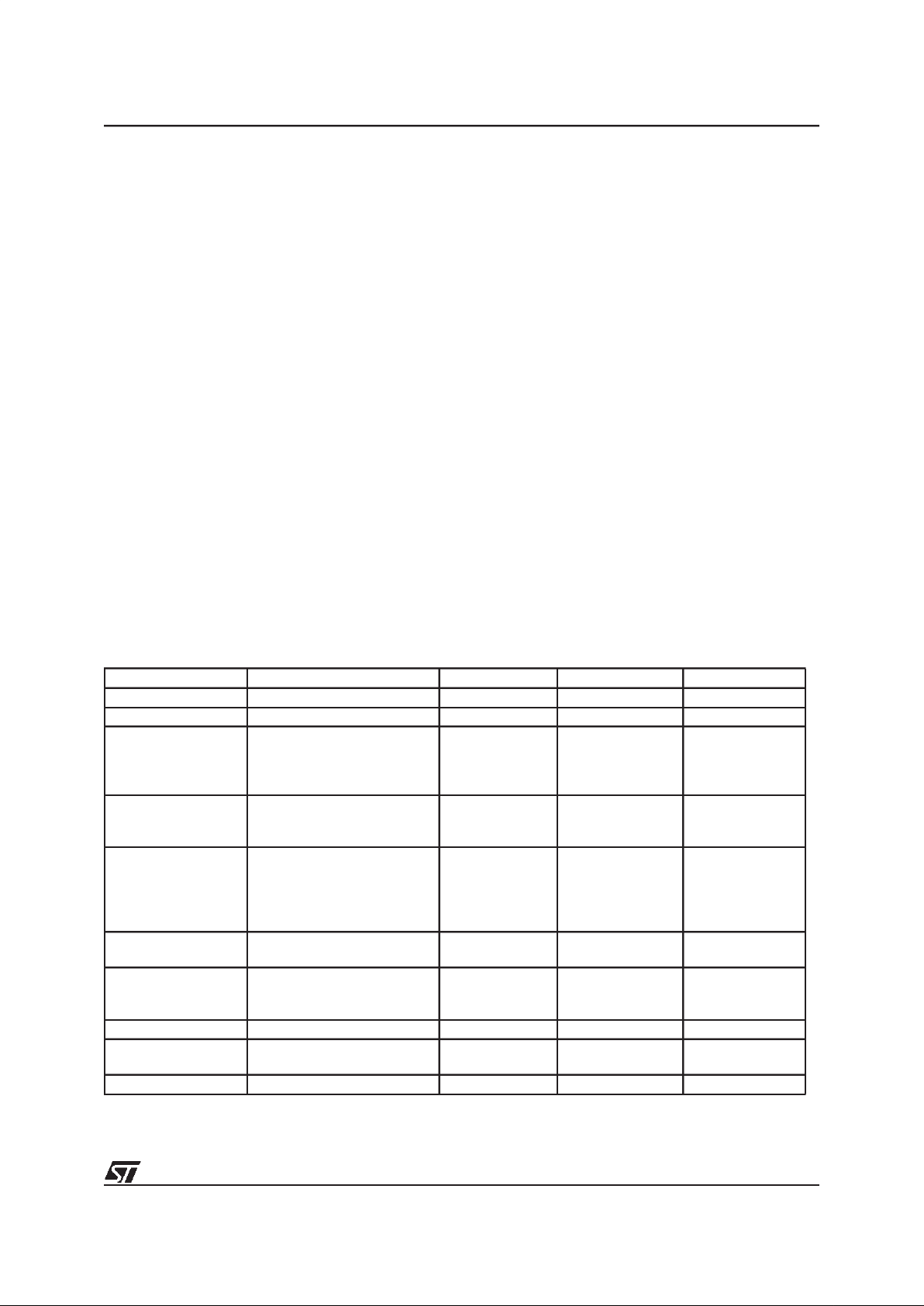

DEVICE SUMMARY

Device

J1850

Pack-

age

EFT

I/Os

SCI

Flash RAM E

ST92F120R6T -

TQFP

64

-48

1 36K 1.5K 512

ST92F120JR6T 1

ST92F120V6Q -

PQFP

100

277

ST92F120JV6Q 1

ST92F120R9T -

TQFP

64

-481

60K 2K 512

ST92F120JR9T 1

ST92F120V9Q -

PQFP

100

2772

ST92F120JV9Q 1

ST92F120R1T -

TQFP

64

-481

128K 4K 1K

ST92F120JR1T 1

ST92F120V1Q -

PQFP

100

2772

ST92F120JV1Q 1

PQFP100

TQFP64

9

2/320

Table of Contents

320

9

1 GENERAL DESCRIPTION . . . . . . ................................................ 7

1.1 INTRODUCTION . . . . . . . . . . . . . ............................................ 7

1.1.1 ST9+ Core . . . . . . . . . ................................................7

1.1.2 External Memory Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1.3 On-chip Peripherals . . . . . . ............................................ 7

1.2 PIN DESCRIPTION . . .................................................... 10

1.2.1 Electromagnetic Compatibility (EMC) . .................................. 10

1.2.2 I/O Port Alternate Functions ...........................................10

1.2.3 Termination of Unused Pins ...........................................10

1.2.4 Avoidance of Pin Damage . . . . . . . . . . . . . . . . . ........................... 11

1.3 I/O PORTS . . . . . . . . . . . . . . . . . . ...........................................19

1.4 OPERATING MODES .. . . . ...............................................24

2 DEVICE ARCHITECTURE . . . . . . . . . . ...........................................25

2.1 CORE ARCHITECTURE . . . . . . . . . . . . . . . . . . ................................25

2.2 MEMORY SPACES . . . . . . . . . . . . . . ........................................ 25

2.2.1 Register File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.2.2 Register Addressing . . . . . . ...........................................27

2.3 SYSTEM REGISTERS . . . . . . . . . . . . . . . . . . . . . . .............................. 28

2.3.1 Central Interrupt Control Register . . . . . ................................. 28

2.3.2 Flag Register . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .................... 29

2.3.3 Register Pointing Techniques . . . . . . . . . . . .............................. 30

2.3.4 Paged Registers . . . . ............................................... 33

2.3.5 Mode Register . . . . . . ...............................................33

2.3.6 Stack Pointers . . . . . . . . . . . . . ........................................34

2.4 MEMORY ORGANIZATION . . . . . . . . . . . . . . . ................................. 36

2.5 MEMORY MANAGEMENT UNIT . . . . . . . . . . .................................. 37

2.6 ADDRESS SPACE EXTENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2.6.1 Addressing 16-Kbyte Pages . . . . . . . . . . . . .............................. 38

2.6.2 Addressing 64-Kbyte Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...........39

2.7 MMU REGISTERS . ...................................................... 39

2.7.1 DPR[3:0]: Data Page Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 39

2.7.2 CSR: Code Segment Register . ........................................41

2.7.3 ISR: Interrupt Segment Register . . . . . . ................................. 41

2.7.4 DMASR: DMA Segment Register . . . . . ................................. 41

2.8 MMU USAGE . . . . . . . . . . . . . . . . . . . . . . . . . . ................................. 43

2.8.1 Normal Program Execution . . . . . . . . . . .................................43

2.8.2 Interrupts . . . . . . . . . . . . . . . . . . . . . . . . ................................. 43

2.8.3 DMA . . . . . . . . . . . . . . . . . . ...........................................43

3 SINGLE VOLTAGE FLASH & EEPROM . . . . . . . . .................................. 44

3.1 INTRODUCTION . . . . . . . . . . . . . ...........................................44

3.2 FUNCTIONAL DESCRIPTION . . . . . ......................................... 45

3.2.1 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........ 45

3.2.2 Software or Hardware EEPROM Emulation (Device dependent option) . ........ 45

3.2.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........................... 46

3.3 REGISTER DESCRIPTION . ............................................... 47

3.3.1 Control Registers . . . . . . . . . . . . . . . . . . . . . .............................. 47

3.3.2 Status Registers . . . . . . . . . . . . . . . . . . . . . . . . . ........................... 50

3.4 WRITE OPERATION EXAMPLE . . . . . . . . .................................... 52

3/320

Table of Contents

9

3.5 EEPROM ..............................................................53

3.5.1 Hardware EEPROM Emulation ........................................53

3.5.2 EEPROM Update Operation . . . . . . . . . . . . .............................. 54

3.6 PROTECTION STRATEGY . ...............................................55

3.6.1 Non Volatile Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ............... 55

3.6.2 Temporary Unprotection .. . . . . . . . . . . .................................57

3.7 FLASH IN-SYSTEM PROGRAMMING . . . . . . . ................................57

3.7.1 First Programming of a virgin Flash . . . . . . . . . . . . . . . . . . . . . . ............... 57

4 REGISTER AND MEMORY MAP ................................................ 59

4.1 INTRODUCTION . . . . . . . . . . . . . ...........................................59

4.2 MEMORY CONFIGURATION .. . . . . . . . . . . . ................................. 59

4.3 ST92F120 REGISTERMAP . . . . . . . . . . . . . ..................................62

5 INTERRUPTS . . ............................................................. 72

5.1 INTRODUCTION . . . . . . . . . . . . . ...........................................72

5.2 INTERRUPT VECTORING ................................................ 72

5.2.1 Divide by Zero trap . . . . . . . . . . . . . . . . . ................................. 72

5.2.2 Segment Paging During Interrupt Routines . . . . . . . . . . . .................... 73

5.3 INTERRUPT PRIORITY LEVELS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.4 PRIORITY LEVEL ARBITRATION . . . ........................................73

5.4.1 Priority level 7 (Lowest) . . . ...........................................73

5.4.2 Maximum depthof nesting . . . . . . . . . . .................................. 73

5.4.3 Simultaneous Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

5.4.4 Dynamic Priority Level Modification . . . . . ................................74

5.5 ARBITRATION MODES . . . . . . . . . . . . . . . . . .................................. 74

5.5.1 Concurrent Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

5.5.2 Nested Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .................... 77

5.6 EXTERNAL INTERRUPTS . . . . . . . . . . . . . . . . . . .............................. 79

5.6.1 Standard External Interrupts . . . . . . . . .................................. 79

5.7 TOP LEVEL INTERRUPT . . . . . . . . . . . . . . . . . ................................81

5.8 ON-CHIP PERIPHERAL INTERRUPTS . . . . . . . . . . . . . . . . . . . . . . . . . . . ...........81

5.9 INTERRUPT RESPONSE TIME . ........................................... 82

5.10INTERRUPT REGISTERS . . ...............................................83

5.11WAKE-UP / INTERRUPT LINES MANAGEMENT UNIT (WUIMU) . . . . . . . . . . . . . . . . . . 86

5.11.1Introduction . . . . ...................................................86

5.11.2Main Features . . . . . . . . . . . . . . . . . . . . ................................. 86

5.11.3Functional Description . . . . . . . ........................................ 87

5.11.4Programming Considerations . . . . . . . .................................. 90

5.11.5Register Description . . . . . . . . . ........................................ 91

6 ON-CHIP DIRECT MEMORY ACCESS (DMA) . . . . .................................. 94

6.1 INTRODUCTION . . . . . . . . . . . . . ...........................................94

6.2 DMA PRIORITY LEVELS . . . ...............................................94

6.3 DMA TRANSACTIONS . . . . . . . . . . . ........................................95

6.4 DMA CYCLE TIME . . . . . . . . . . . . . . . ........................................ 97

6.5 SWAP MODE . . . . . . . . . . . . ...............................................97

6.6 DMA REGISTERS . . . . . . . . . . . . ...........................................98

4/320

Table of Contents

320

1

7 RESET AND CLOCK CONTROL UNIT (RCCU) . . . ................................. 99

7.1 INTRODUCTION . . . . . . . . . . . . . ...........................................99

7.2 CLOCK CONTROL UNIT . . . . . . . ........................................... 99

7.2.1 Clock Control Unit Overview . . . . . . . . . . . . . . . ........................... 99

7.3 CLOCK MANAGEMENT . . . . . . . . . . .......................................101

7.3.1 PLL Clock Multiplier Programming . . . . . . . . ............................. 102

7.3.2 CPU Clock Prescaling . . . . . . . . . . . . . .................................102

7.3.3 Peripheral Clock . . . . . . . . . . . . . . . . . . . . . . . . . .......................... 103

7.3.4 Low Power Modes . . . .............................................. 103

7.3.5 Interrupt Generation . . . . . . . . . ....................................... 103

7.4 CLOCK CONTROL REGISTERS . . . . . . . . . . . . . . ............................. 106

7.5 OSCILLATOR CHARACTERISTICS . . . . . . . . . . . .............................109

7.6 RESET/STOP MANAGER . . . . . . .......................................... 111

7.6.1 Reset Pin Timing . . . . ..............................................112

7.7 STOP MODE . . . . . . . . . . . . . . . . . . . .......................................113

8 EXTERNAL MEMORY INTERFACE (EXTMI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

8.1 INTRODUCTION . . . . . . . . . . . . . ..........................................114

8.2 EXTERNAL MEMORY SIGNALS.. . . . . . . . . . . . . . . . .......................... 115

8.2.1 AS: Address Strobe . . .............................................. 115

8.2.2 DS: Data Strobe ................................................... 115

8.2.3 DS2: Data Strobe 2 . . . . . . . . . .......................................115

8.2.4 RW: Read/Write . . . . . . . . . . . . . . . . . . . . . . ............................. 118

8.2.5 BREQ, BACK: Bus Request, Bus Acknowledge . . . . . . . . . . . . . . . . ..........118

8.2.6 PORT 0 . . . . . . . . . . . . . . . .......................................... 119

8.2.7 PORT 1 . . . . . . . . . . . . . . . .......................................... 119

8.2.8 WAIT: External Memory Wait . . . . . . ................................... 119

8.3 REGISTER DESCRIPTION . .............................................. 120

9 I/O PORTS . . . . . . . . . . . . . . . . . . . . . . . . . . .......................................123

9.1 INTRODUCTION . . . . . . . . . . . . . ..........................................123

9.2 SPECIFIC PORT CONFIGURATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....... 123

9.3 PORT CONTROL REGISTERS . . . . . . . . . . . . . . . . . . .......................... 123

9.4 INPUT/OUTPUT BIT CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

9.5 ALTERNATE FUNCTION ARCHITECTURE . . . . . . . . . . . . . . . . . . . . . . . . ..........128

9.5.1 Pin Declared as I/O . . .............................................. 128

9.5.2 Pin Declared as an Alternate Input . . . . . ...............................128

9.5.3 Pin Declared as an Alternate Function Output . . . . . . . . . . . . . . . . . . . . . ....... 128

9.6 I/O STATUS AFTER WFI, HALT AND RESET . . . . . . . . . . . . . . . . . . . . . . ..........128

10 ON-CHIP PERIPHERALS . . . . . . .............................................. 129

10.1TIMER/WATCHDOG (WDT) . . . . . . . . . . . . . ................................. 129

10.1.1Introduction . . . . ..................................................129

10.1.2Functional Description . . . . . . . .......................................130

10.1.3Watchdog Timer Operation . . . . . . . . . . ................................ 131

10.1.4WDT Interrupts . . . . . . . . . . . . . .......................................133

10.1.5Register Description . . . . . . . . . .......................................134

10.2STANDARD TIMER (STIM) . .............................................. 136

10.2.1Introduction . . . . ..................................................136

10.2.2Functional Description . . . . . . . .......................................137

5/320

Table of Contents

1

10.2.3Interrupt Selection . . . .............................................. 138

10.2.4Register Mapping .. . . . . . . . . . . . . . . . . . . . . . . .......................... 138

10.2.5Register Description . . . . . . . . . .......................................139

10.3EXTENDED FUNCTION TIMER (EFT) . . . . . . ................................ 140

10.3.1Introduction . . . . ..................................................140

10.3.2Main Features . . . . . . . . . . . . . . . . . . . . ................................140

10.3.3Functional Description . . . . . . . .......................................140

10.3.4Interrupt Management . . . . . . . . . . . . . .................................150

10.3.5Register Description . . . . . . . . . .......................................152

10.4MULTIFUNCTION TIMER (MFT) . . . . . . . . . . . . . . . . . . . . . . . . ................... 160

10.4.1Introduction . . . . ..................................................160

10.4.2Functional Description . . . . . . . .......................................162

10.4.3Input Pin Assignment . . . . . ..........................................165

10.4.4Output Pin Assignment . . . . . . ....................................... 169

10.4.5Interrupt and DMA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....... 171

10.4.6Register Description . . . . . . . . . .......................................173

10.5SERIAL COMMUNICATIONS INTERFACE (SCI) . .............................184

10.5.1Introduction . . . . ..................................................184

10.5.2Functional Description . . . . . . . .......................................185

10.5.3SCI Operating Modes . . . . . . . . . . . . . . . . . ............................. 186

10.5.4Serial Frame Format ............................................... 189

10.5.5Clocks And Serial Transmission Rates . . . . ............................. 192

10.5.6SCI Initialization Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....... 192

10.5.7Input Signals . . . . . . . . . . . . . . . . . . . . . . . . ............................. 194

10.5.8Output Signals . . . . . . .............................................. 194

10.5.9Interrupts and DMA . . . . . . . . . . . . . . . . . ...............................195

10.5.10Register Description . .............................................. 198

10.6SERIAL PERIPHERAL INTERFACE (SPI) . . . . . . . . . . . . . . . . . . . . . . . . . ..........209

10.6.1Introduction . . . . ..................................................209

10.6.2Main Features . . . . . . . . . . . . . . . . . . . . ................................209

10.6.3General description . . . . . . ..........................................209

10.6.4Functional Description . . . . . . . .......................................211

10.6.5Interrupt Management . . . . . . . . . . . . . .................................218

10.6.6Register Description . . . . . . . . . .......................................219

10.7 I2C BUS INTERFACE . . . . . . . . . . . . . . . . . . ................................. 221

10.7.1Introduction . . . . ..................................................221

10.7.2Main Features . . . . . . . . . . . . . . . . . . . . ................................221

10.7.3Functional Description . . . . . . . .......................................222

10.7.4I2C State Machine . . . . . . . ..........................................224

10.7.5Interrupt Features . . . .............................................. 229

10.7.6DMA Features . . . . . . .............................................. 230

10.7.7Register Description . . . . . . . . . .......................................232

10.8J1850 BYTE LEVEL PROTOCOL DECODER (JBLPD) . . . . . . . . . . . .............. 243

10.8.1Introduction . . . . ..................................................243

10.8.2Main Features . . . . . . . . . . . . . . . . . . . . ................................243

10.8.3Functional Description . . . . . . . .......................................245

10.8.4Peripheral Functional Modes . . ....................................... 256

10.8.5Interrupt Features . . . .............................................. 257

10.8.6DMA Features . . . . . . .............................................. 259

6/320

Table of Contents

320

1

10.8.7Register Description . . . . . . . . . .......................................263

10.9EIGHT-CHANNELANALOG TO DIGITAL CONVERTER (A/D) . . . . . . . . . . . . . . . . . . . 284

10.9.1Introduction . . . . ..................................................284

10.9.2Functional Description . . . . . . . .......................................285

10.9.3Interrupts . . . . . . . . . . . . . . . . . . . . . . . . . ...............................287

10.9.4Register Description . . . . . . . . . .......................................288

11 ELECTRICAL CHARACTERISTICS . . . . ........................................ 292

12 GENERAL INFORMATION ................................................... 319

12.1PACKAGE MECHANICAL DATA . . . . . . . . . . . . . . . . . ..........................319

7/320

ST92F120 - GENERAL DESCRIPTION

1 GENERAL DESCRIPTION

1.1 INTRODUCTION

The ST92F120 microcontroller is developed and

manufactured by STMicroelectronics using a pro-

prietary n-well HCMOS process. Its performance

derives from the use of a flexible256-register pro-

gramming model for ultra-fast context switching

and real-time event response. The intelligent on-

chip peripherals offload the ST9 core from I/O and

data management processing tasks allowing criti-

cal application tasks to get the maximum use of

core resources. The new-generation ST9 MCU

devices now also support low power consumption

and low voltage operation for power-efficient and

low-cost embedded systems.

1.1.1 ST9+ Core

The advanced Core consists of the Central

Processing Unit(CPU),theRegisterFile, theInter-

rupt and DMA controller, and the Memory Man-

agement Unit. The MMU allows a single linear ad-

dress space of up to4 Mbytes.

Four independent buses are controlled by the

Core: a 16-bit memory bus, an 8-bit register data

bus, an 8-bit register address bus and a 6-bit inter-

rupt/DMA bus which connects the interrupt and

DMA controllersin the on-chip peripherals with the

core.

This multiple busarchitecture makes the ST9 fam-

ily deviceshighlyefficient foraccessing onand off-

chip memory and fast exchange of data with the

on-chip peripherals.

The general-purpose registers can be used as ac-

cumulators, index registers, or address pointers.

Adjacent register pairs make up 16-bit registers for

addressing or 16-bit processing. Although the ST9

has an 8-bit ALU, the chip handles 16-bit opera-

tions, including arithmetic, loads/stores, and mem-

ory/register and memory/memory exchanges.

The powerful I/O capabilities demanded by micro-

controller applications are fulfilled by the

ST92F120 with48(TQFP64) or 77 (PQFP100)I/O

lines dedicated to digital Input/Output. These lines

are grouped into up to ten 8-bit I/O Ports and can

be configuredonabit basis under software control

to provide timing, status signals, an address/data

bus for interfacing to the external memory, timer

inputs and outputs, analog inputs, external inter-

rupts and serial or parallel I/O. Two memory spac-

es are available to support this wide range of con-

figurations: a combined Program/Data Memory

Space and the internal Register File, which in-

cludes the control and status registers of the on-

chip peripherals.

1.1.2 External Memory Interface

PQFP100 devices have a 16-bit external address

bus allowing them to address up to 64K bytes of

external memory. TQFP64 devices have an 11-bit

external address bus for addressing up to 2K

bytes.

1.1.3 On-chip Peripherals

Two 16-bit MultiFunction Timers, each with an 8

bit Prescaler and 12 operating modes allow simple

use for complex waveform generation and meas-

urement, PWM functions and many other system

timing functions by the usage of the two associat-

ed DMA channels for each timer.

On PQFP100 devices, two Extended Function

Timers provide further timing and signal genera-

tion capabilities.

A Standard Timer can be used to generate a sta-

ble time base independent from the PLL.

An I

2

C interface provides fast I

2

C and Access Bus

support.

The SPI is a synchronous serial interface for Mas-

ter and Slave device communication. It supports

single master and multimaster systems.

A J1850 Byte Level Protocol Decoder is available

(on some devices only) for communicating with a

J1850 network.

In addition, there is an16 channel Analog to Digital

Converters with integral sample and hold, fast

conversion time and 8-bit resolution. In the

TQFP64 version only 8 input channels are availa-

ble.

Completing the device are two or one full duplex

Serial Communications Interfaces with an integral

generator, asynchronous and synchronous capa-

bility (fully programmable format) and associated

address/wake-up option, plus two DMA channels.

Finally, a programmable PLL Clock Generator al-

lows the usage of standard 3 to 5 MHz crystals to

obtain a large range of internal frequencies up to

24MHz. Low power Run (SLOW), Wait For Inter-

rupt, low power Wait For Interrupt, STOP and

HALT modes are also available.

9

8/320

ST92F120 - GENERAL DESCRIPTION

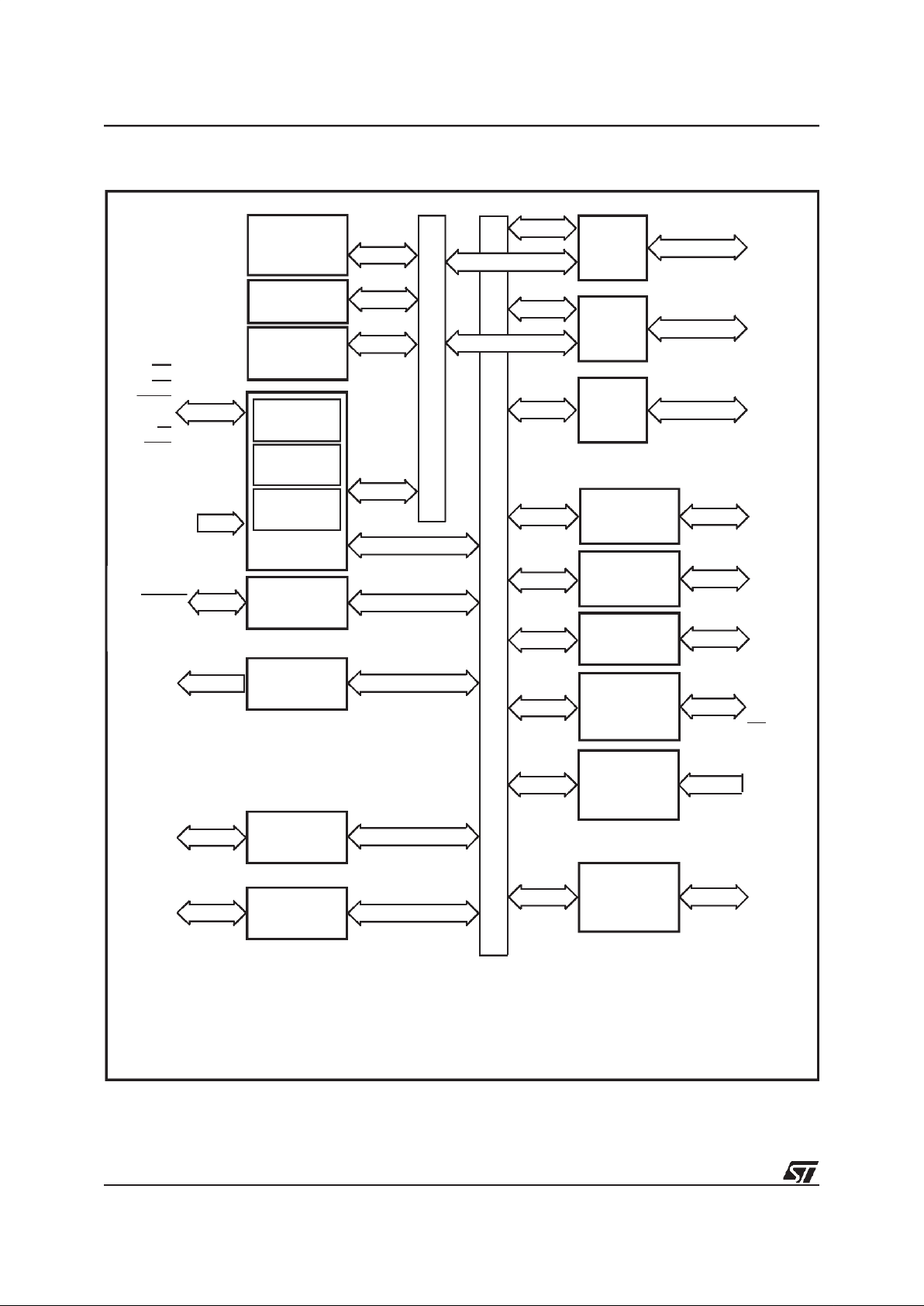

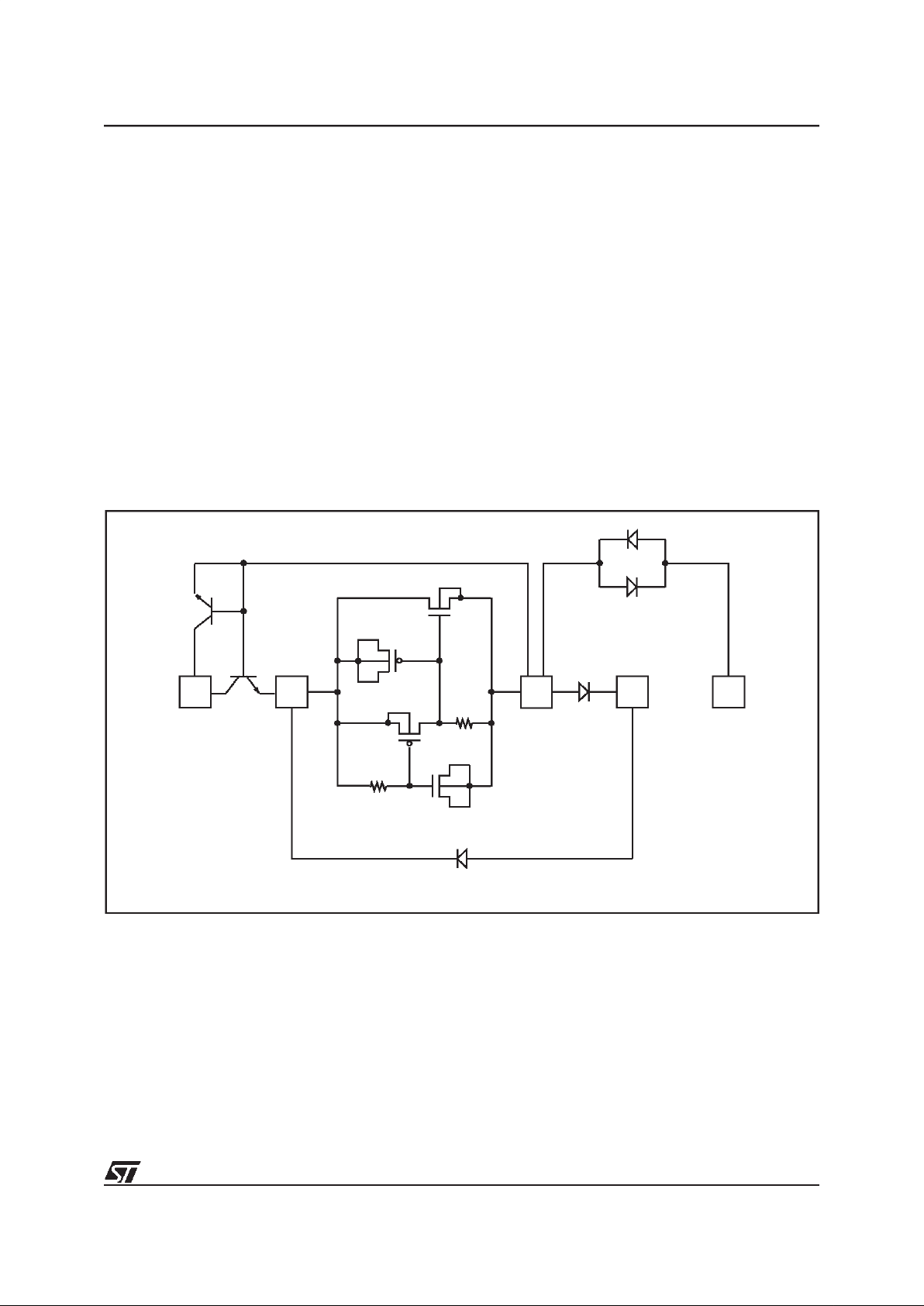

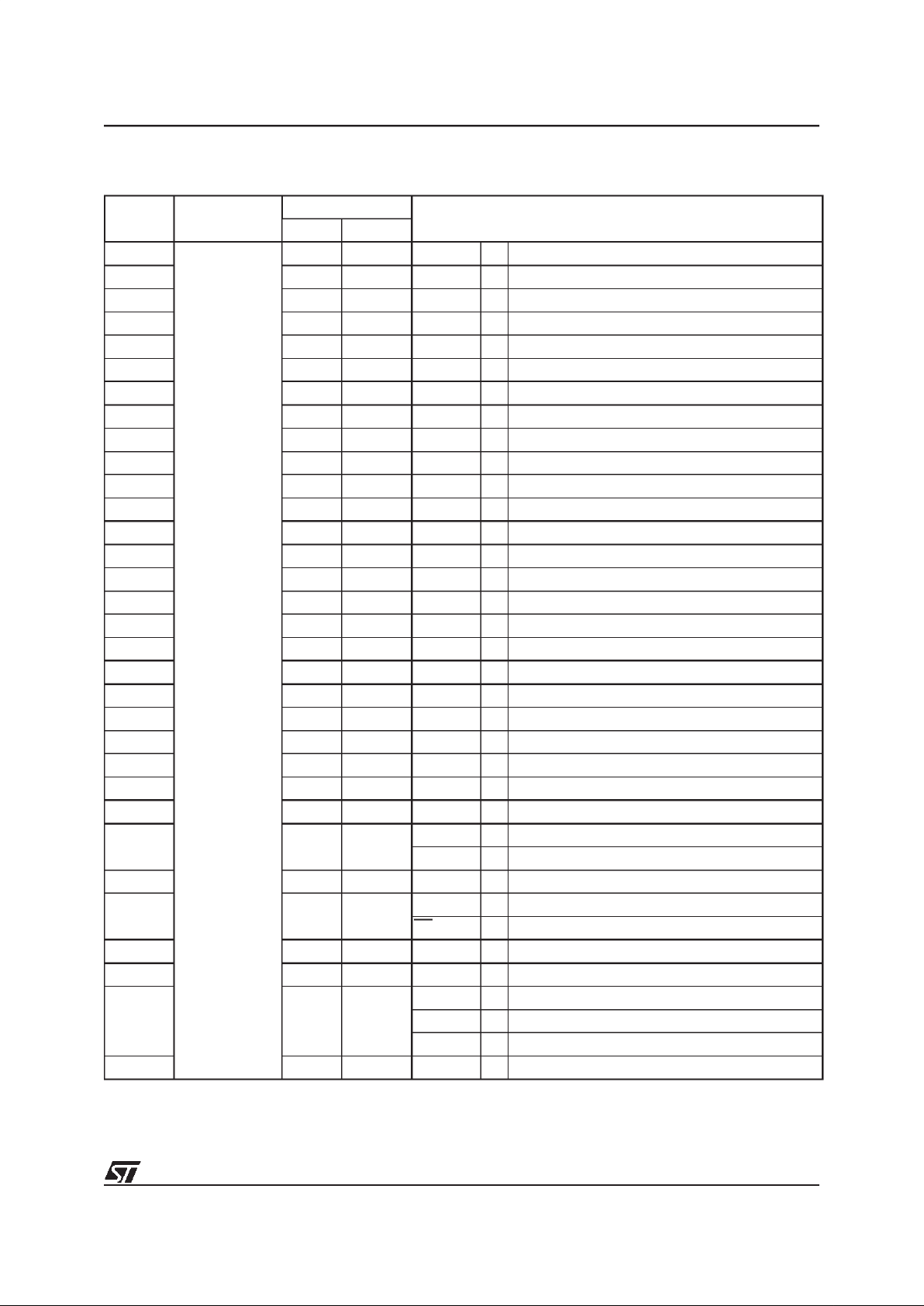

Figure 1. ST92F120JR: Architectural Block Diagram (TQFP64 version)

256 bytes

Register File

RAM

1.5/2/4 Kbytes

ST9 CORE

8/16 bits

CPU

Interrupt

Management

MEMORY BUS

RCCU

Ext.

MEM.

ADDRESS

DATA

Ext. MEM.

AD-

DRESS

REGISTER BUS

WATCHDOG

AS

DS

WAIT

NMI

RW

DS2

MISO

MOSI

SCK

SS

A[10:8]

A[7:0]

D[7:0]

ST. TIMER

SPI

SDAI

SDAO

SCLI

SCLO

I

2

C BUS

SCI 0

FLASH

36/60/128

Kbytes

TXCLK0

RXCLK0

SIN0

DCD0

SOUT0

CLKOUT0

RTS0

WDOUT

HW0SW1

STOUT

All alternate functions (

Italic characters

) are mapped on Port2, Port3, Port4, Port5, Port6,and Port7

Fully Prog.

I/Os

P0[7:0]

P1[2:0]

P2[7:0]

P3[7:4]

P4[7:4]

P5[7:0]

P6[5:2,0]

P7[7:0]

MF TIMER0

TINPA0

TOUTA0

TINPB0

TOUTB0

TINPA1

TOUTA1

TINPB1

TOUTB1

INT[6:0]

WKUP[15:0]

MF TIMER1

EEPROM

512 /1K bytes

OSCIN

OSCOUT

RESET

CLOCK2/8

INTCLK

A/D CONV. 0

A0IN[7:0]

EXTRG

VPWI

VPWO

J1850

JBLPD

(optional)

9

9/320

ST92F120 - GENERAL DESCRIPTION

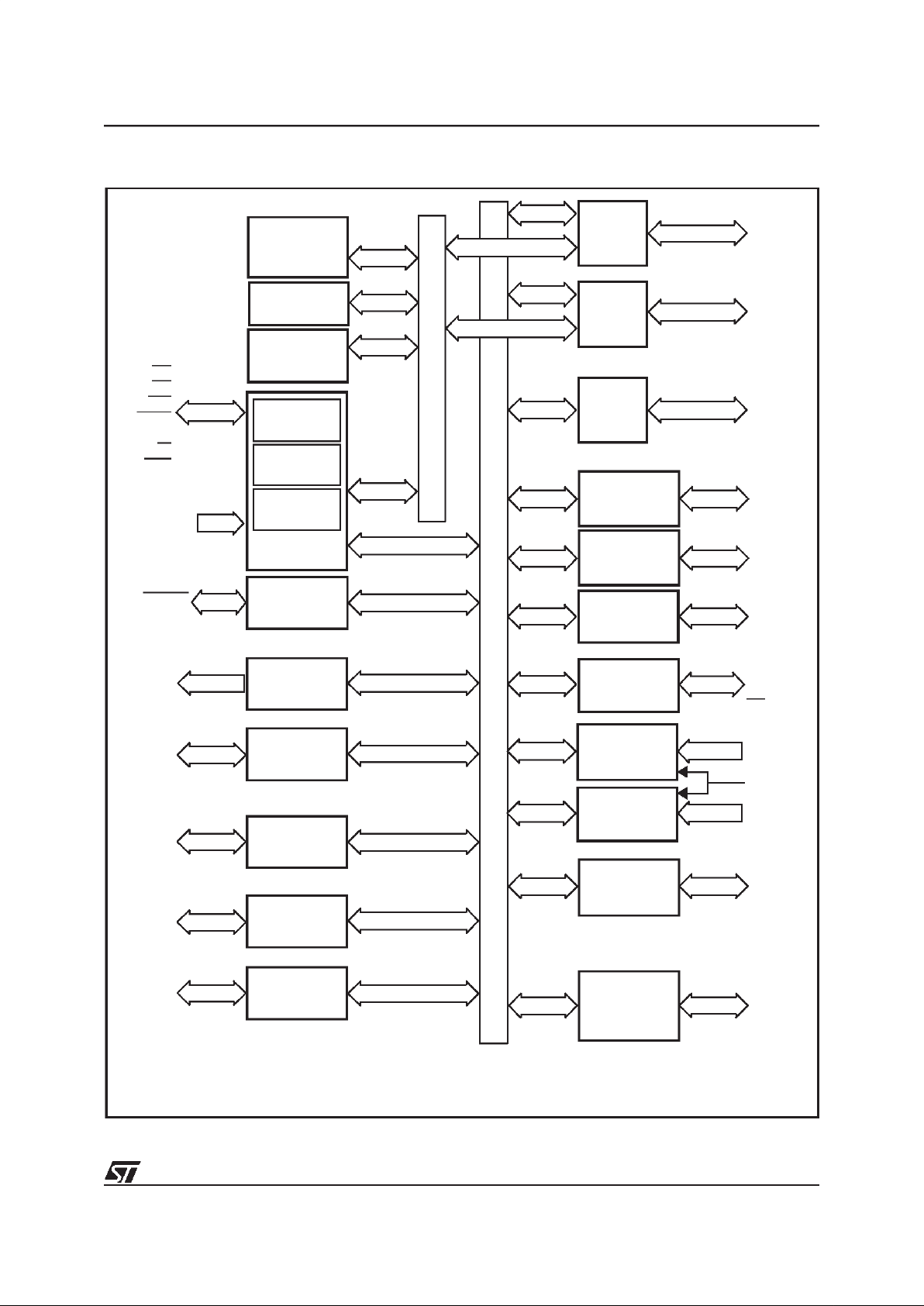

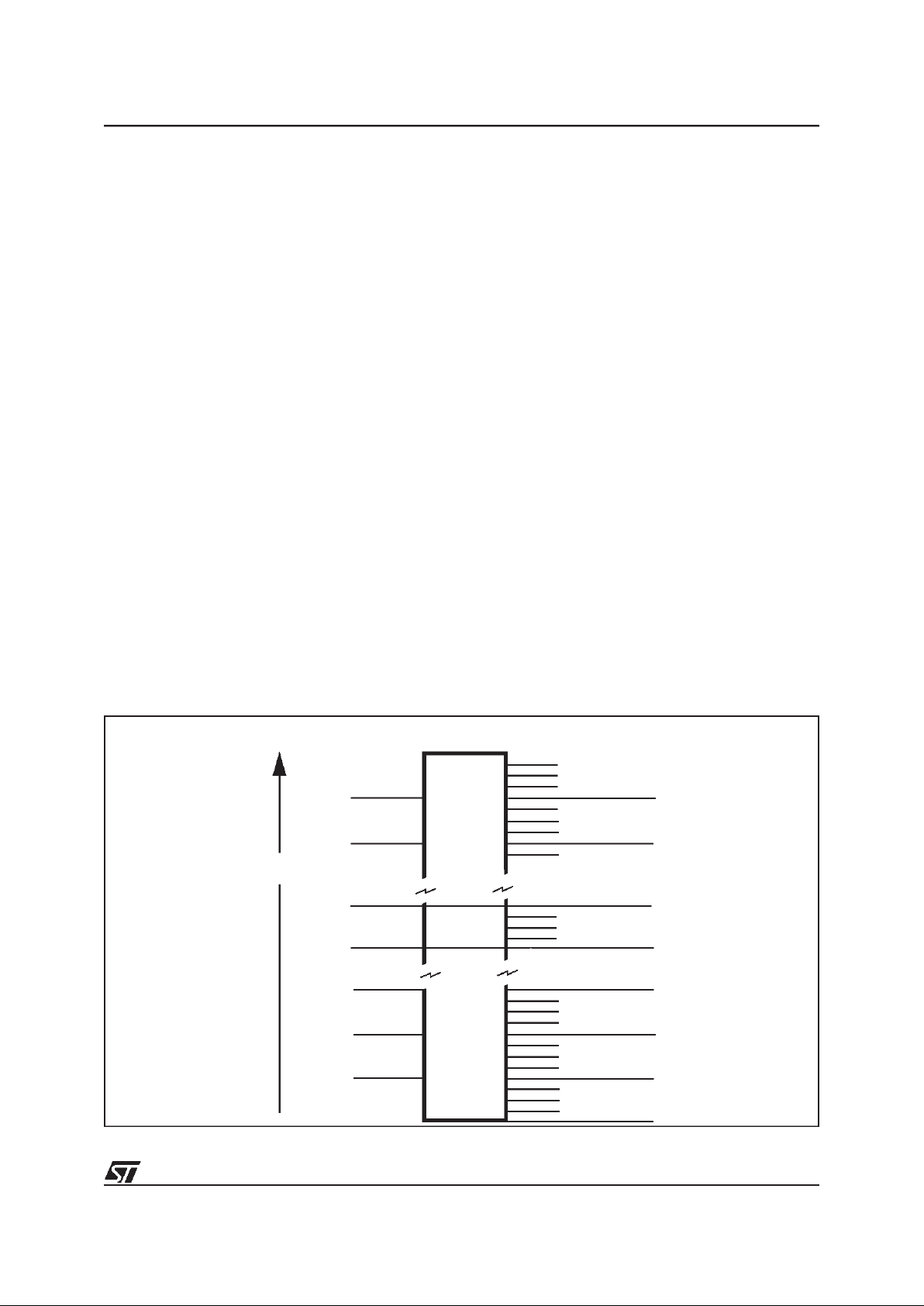

Figure 2. ST92F120JV: Architectural Block Diagram (PQFP100 version)

256 bytes

Register File

ST9 CORE

8/16 bits

CPU

Interrupt

Management

MEMORY BUS

RCCU

REGISTER BUS

WATCHDOG

AS

DS

RW

WAIT

NMI

RW

DS2

MISO

MOSI

SCK

SS

EF TIMER0

ST. TIMER

SPI

SCI 0

TXCLK0

RXCLK0

SIN0

DCD0

SOUT0

CLKOUT0

RTS0

WDOUT

HW0SW1

STOUT

ICAPA0

OCMPA0

ICAPB0

OCMPB0

EXTCLK0

Fully Prog.

I/Os

P0[7:0]

P1[7:0]

P2[7:0]

P3[7:1]

P4[7:0]

P5[7:0]

P6[5:0]

P7[7:0]

P8[7:0]

P9[7:0]

TXCLK1

RXCLK1

SIN1

DCD1

SOUT1

CLKOUT1

RTS1

MF TIMER0

TINPA0

TOUTA0

TINPB0

TOUTB0

ICAPA1

OCMPA1

ICAPB1

OCMPB1

EXTCLK1

TINPA1

TOUTA1

TINPB1

TOUTB1

INT[6:0]

WKUP[15:0]

EF TIMER1

MF TIMER1

SCI 1

*

OSCIN

OSCOUT

RESET

CLOCK2/8

CLOCK2

INTCLK

A/D CONV. 0

A0IN[7:0]

EXTRG

A/D CONV. 1

A1IN[7:0]

SDAI

SDAO

SCLI

SCLO

I

2

C BUS

VPWI

VPWO

J1850

JBLPD

A[7:0]

D[7:0]

A[15:8]

Ext.

MEM.

ADDRESS

DATA

Ext. MEM.

AD-

DRESS

RAM

1.5/2/4 Kbytes

FLASH

36/60/128

Kbytes

EEPROM

512 /1K bytes

(optional)

All alternate functions (

Italic characters

) are mapped on Port2, Port3,Port4, Port5, Port6, Port7, Port8 and Port9

* Available on some versions only

9

10/320

ST92F120 - GENERAL DESCRIPTION

1.2 PIN DESCRIPTION

AS. Address Strobe (output, active low, 3-state).

Address Strobe is pulsed low once at the begin-

ning of each memory cycle. The rising edge of AS

indicates that address, Read/Write (RW), and

Data signals are valid for memory transfers.

DS. Data Strobe (output, active low, 3-state). Data

Strobe provides the timing for data movement to or

from Port 0 for each memory transfer. During a

write cycle, data out is valid at the leading edge of

DS. During a read cycle, Data In must be valid pri-

or to the trailing edge of DS. When the ST9 ac-

cesses on-chip memory, DS is held high during

the whole memory cycle.

RESET. Reset (input, active low). The ST9 is ini-

tialised by the Reset signal. With the deactivation

of RESET, program execution begins from the

Program memory location pointed to by the vector

contained in program memory locations 00h and

01h.

RW. Read/Write (output, 3-state). Read/Write de-

termines the direction of data transfer for external

memory transactions. RW is low when writing to

external memory, and high for all other transac-

tions.

OSCIN, OSCOUT. Oscillator (input and output).

These pins connect a parallel-resonant crystal, or

an external source to the on-chip clock oscillator

and buffer. OSCIN is the input of the oscillator in-

verter and internal clock generator; OSCOUT is

the output of the oscillator inverter.

HW0SW1. When connected to V

DD

through a 1K

pull-up resistor, the software watchdog option is

selected. When connected to V

SS

through a 1K

pull-down resistor, the hardware watchdog option

is selected.

VPWO. This pin is the output line of the J1850 pe-

ripheral (JBLPD). It is available only on some de-

vices. On devices without JBLPD peripheral, this

pin must not be connected.

P0[7:0], P1[2:0] or P1[7:0]

(Input/Output, TTL or

CMOS compatible)

. 11 lines (TQFP64 devices) or

16 lines (PQFP100 devices) providing the external

memory interface for addressing 2K or 64 K bytes

of externalmemory.

P0[7:0], P1[2:0], P2[7:0], P3[7:4], P4.[7:4],

P5[7:0], P6[5:2,0], P7[7:0]

I/O Port Lines (Input/

Output, TTL or CMOS compatible)

. I/O lines

grouped into I/O ports of 8 bits, bit programmable

under software control as general purpose I/O or

as alternate functions.

P1[7:3], P3[3:1], P4[3:0], P6.1, P8[7:0], P9[7:0]

Additional I/O Port Lines available on PQFP100

versions only.

AV

DD

. Analog V

DD

of the Analog to Digital Con-

verter (common for A/D 0 and A/D 1).

AV

SS

. Analog V

SS

of the Analog to Digital Con-

verter (common for A/D 0 and A/D 1).

V

DD

. Main Power Supply Voltage. Four pins are

available on PQFP100 versions, two on TQFP64

versions. The pins are internally connected.

V

SS

. Digital Circuit Ground. Four pins are availa-

ble on PQFP100 versions, two on TQFP64 ver-

sions. The pins are internally connected.

V

PP

. Power Supply Voltage for Flash test purpos-

es. This pin is bonded and must be kept to 0 in

user mode.

V

REG

. 3V regulator output.

1.2.1 Electromagnetic Compatibility (EMC)

To reduce the electromagnetic interference thefol-

lowing features have been implemented:

– A low power oscillator is included with a control-

led gain to reduce EMI and the power consump-

tion in Halt mode.

– Two or Four pairs of digital power supply pins

(V

DD

,V

SS

) are located on each side of the

PQFP100 package (2 pairs on TQFP64).

– Digital and analog power supplies are complete-

ly separated.

– Digital power supplies for internal logic and I/O

ports are separated internally.

– Internal decoupling capacitance is located be-

tween V

DD

and V

SS

.

Note: Each pair of digital V

DD

/V

SS

pins should be

externally connected by a 10 µF chemical pulling

capacitor and a 100 nF ceramic chip capacitor.

1.2.2 I/O Port Alternate Functions

Each pin of the I/O ports of the ST92F120 may as-

sume software programmable Alternate Functions

as shown in Section 1.3.

1.2.3 Termination of Unused Pins

The ST9 deviceis implemented using CMOS tech-

nology; therefore unused pins must be properly

terminated in order to avoid application reliability

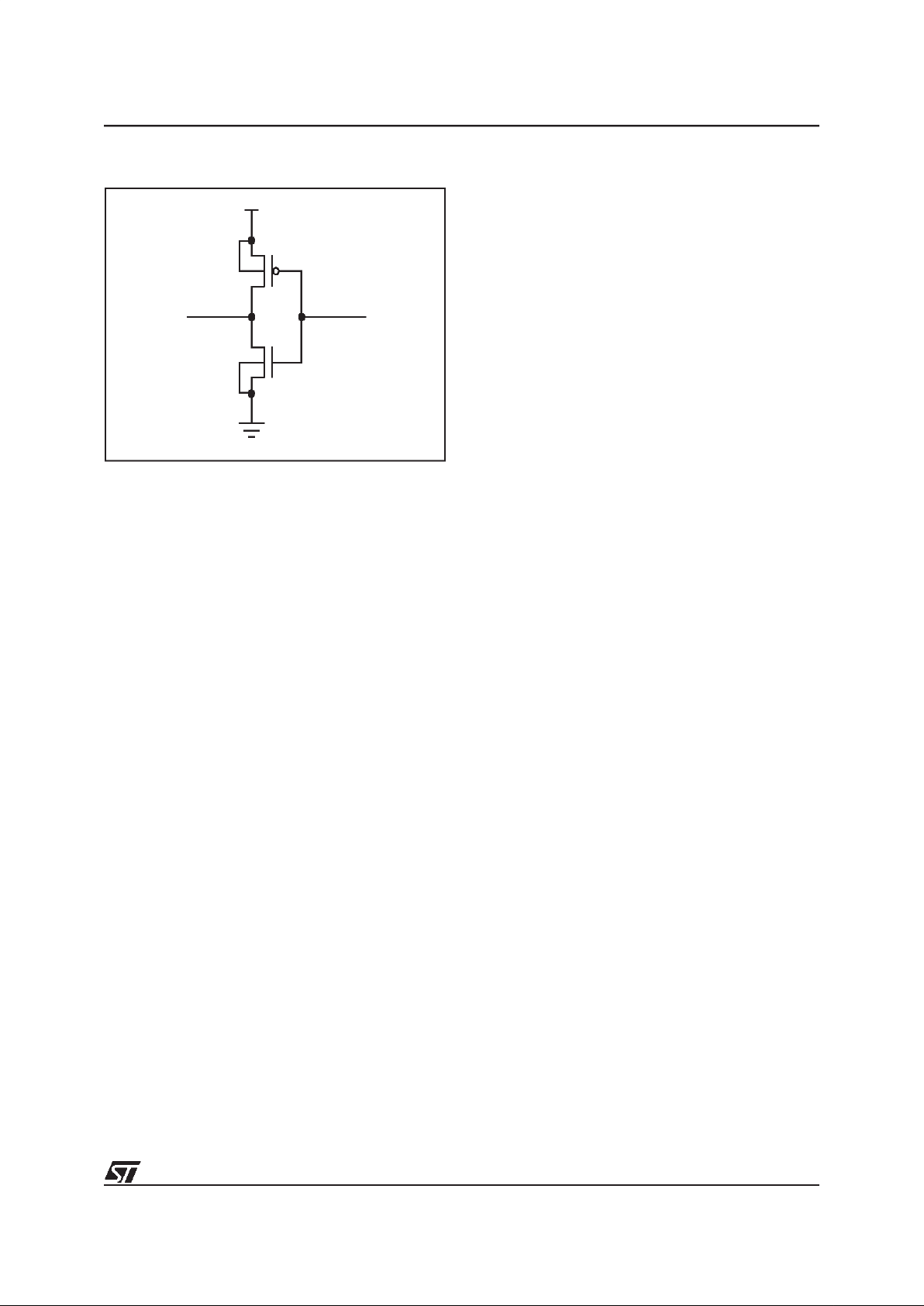

problems. In fact, as shown in Figure 3, the stand-

ard input circuitry is based on the CMOS inverter

structure.

9

11/320

ST92F120 - GENERAL DESCRIPTION

Figure 3. CMOS basic inverter

When an input is kept at logic zero, the N-channel

transistor is off, while the P-channel is on and can

conduct. The opposite occurs when an input is

kept at logic one. CMOS transistors are essentially

linear devices with relatively broad switching

points. During commutation, the input passes

through midsupply, and there is a region of input

voltage values where both P and N-channel tran-

sistors are on. Since normally the transitions are

fast, there is a very short time in which a current

can flow: once the switching is completed there is

no longer current. This phenomenon explains why

the overall current depends on the switching rate:

the consumption is directly proportional to the

number of transistors inside the device which are

in the linear region during transitions, charging and

discharging internal capacitances.

In order to avoid extra power supply current, it is

important to bias input pins properly when not

used. In fact, if the input impedance is very high,

pins can float, when not connected, either to a

midsupply level or can oscillate (injecting noise in

the device).

Depending on the specific configuration of each

I/O pin on different ST9 devices, it can be more or

less critical to leave unused pins floating. For this

reason, on most pins, the configuration after RE-

SET enables an internal weak pull-up transistor in

order to avoid floating conditions. For other pins

this is intrinsically forbidden, like for the true open-

drain pins. In any case, the application software

must program the right state for unused pins to

avoid conflicts with external circuitry (whichever it

is: pull-up, pull-down, floating, etc.).

The suggested method of terminating unused I/O

is to connect an external individual pull-up or pull-

down for each pin, even though initialization soft-

ware can force outputs to a specified and defined

value, during a particular phaseof the RESET rou-

tine there could be an undetermined status at the

input section.

Usage of pull-ups and/or pull-downs is preferable

in place of direct connection to V

DD

or V

SS

. If pull-

up or pull-down resistors are used, inputs can be

forced for test purposes to a different value, and

outputs can be programmed to both digital levels

without generating high current drain due to the

conflict.

Anyway, during system verification flow, attention

must be paid to reviewing the connection of each

pin, in order to avoid potential problems.

1.2.4 Avoidance of Pin Damage

Although integrated circuit data sheets provide the

user with conservative limits and conditions in or-

der to prevent damage, sometimes it is useful for

the hardware system designer to know the internal

failure mechanisms: the risk of exposure to illegal

voltages and conditions can be reduced by smart

protection design.

It is not possible to classify and to predict all the

possible damage resulting from violating maxi-

mum ratings and conditions, due to the large

number of variables that come into play in defining

the failures: in fact, when an overvoltage condition

is applied, the effects on the device can vary sig-

nificantly depending on lot-to-lot process varia-

tions, operating temperature, external interfacing

of the ST9 with other devices, etc.

In the following sections, background technical in-

formation is given in order to help system design-

ers to reduce risk of damage to the ST9 device.

1.2.4.1 Electrostatic Discharge and Latchup

CMOS integrated circuits are generally sensitive

to exposure to highvoltage static electricity, which

can induce permanent damage to the device: a

typical failure is the breakdown of thin oxides,

which causeshigh leakage current and sometimes

shorts.

Latchup is another typical phenomenon occurring

in integrated circuits: unwanted turning on of para-

sitic bipolar structures, or silicon-controlled rectifi-

ers (SCR), may overheat and rapidly destroy the

device. These unintentional structures are com-

posed of P and N regions which work as emitters,

bases and collectors of parasitic bipolar transis-

tors: the bulk resistance of the silicon in the wells

and substrate act as resistors on the SCR struc-

ture. Applying voltages below V

SS

or above V

DD

,

and when the level of current is able to generatea

P

N

INOUT

V

DD

V

SS

1

12/320

ST92F120 - GENERAL DESCRIPTION

voltage drop across the SCR parasitic resistor, the

SCR may be turned on; to turn off the SCR it is

necessary to remove the power supply from the

device.

The present ST9 design implements layout and

process solutions to decrease the effects of elec-

trostatic discharges (ESD) and latchup. Of course

it is not possible to test all devices, due to the de-

structive nature of the mechanism; in order to

guarantee product reliability, destructive tests are

carried out on groups of devices, according to

STMicroelectronics internal Quality Assurance

standards and recommendations.

1.2.4.2 Protective Interface

Although ST9 input/output circuitry has been de-

signed taking ESD and Latchup problems into ac-

count, for those applications and systems where

ST9 pins are exposed to illegal voltages and high

current injections, the user is strongly recommend-

ed to implement hardware solutions which reduce

the risk ofdamage to the microcontroller: low-pass

filters and clamp diodes are usually sufficient in

preventing stress conditions.

The risk of having out-of-range voltages and cur-

rents is greater for those signals coming from out-

side the system, where noise effect or uncon-

trolled spikes could occur with higher probability

than for the internal signals; it must be underlined

that in somecases, adoption of filters or other ded-

icated interface circuitries might affect global mi-

crocontroller performance, inducingundesired tim-

ing delays, and impacting the global system

speed.

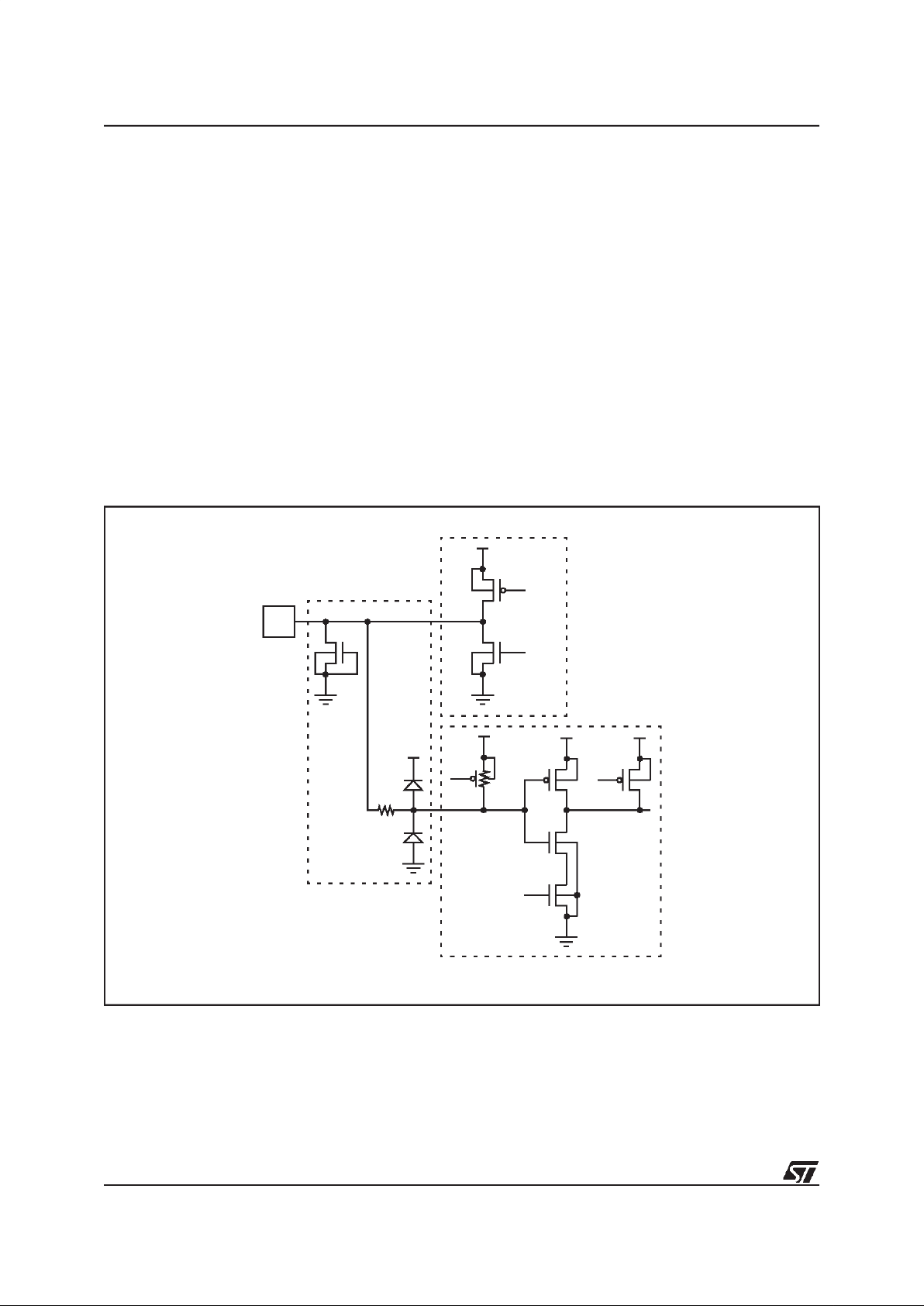

Figure 4. Digital Input/Output - Push-Pull

PIN

OUTPUT

BUFFER

P

N

P

N

N

INPUT

BUFFER

P

ESDPR O TE CT ION

CIRCUITRY

PORTCIRCUITRY

I/O CIRCUITRY

P

EN

EN

1

13/320

ST92F120 - GENERAL DESCRIPTION

1.2.4.3 Internal Circuitry: Digital I/O pin

In Figure 4a schematic representation of an ST9

pin able to operate either as an input or as an out-

put is shown. The circuitry implements a standard

input buffer and a push-pull configuration for the

output buffer. It is evident that although it is possi-

ble to disable the output buffer when the input sec-

tion is used, the MOS transistors of the buffer itself

can still affect the behaviour of the pin when ex-

posed to illegal conditions. In fact, the P-channel

transistor of the output buffer implements a direct

diode toV

DD

(P-diffusionof the drain connected to

the pin and N-well connected to V

DD

), while the N-

channel of the output buffer implements a diode to

V

SS

(P-substrate connected to VSS and N-diffu-

sion of the drain connected to the pin). In parallel

to these diodes, dedicated circuitry is implemented

to protect the logic from ESD events (MOS, diodes

and input series resistor).

The most important characteristic of these extra

devices is that they must not disturb normal oper-

ating modes, while acting during exposure to over

limit conditions, avoiding permanent damage to

the logic circuitry.

All I/O pins can generally be programmed to work

also as open-drain outputs, by simply writing in the

corresponding register of the I/O Port. The gate of

the P-channel of the output buffer is disabled: it is

important tohighlight that physically the P-channel

transistor is still present, so the diode to V

DD

works. In some applications it can occur that the

voltage applied to the pin is higher than the V

DD

value (supposing the external line is kept high,

while the ST9 power supply is turned off): this con-

dition will inject current through the diode, risking

permanent damages to the device.

In any case, programming I/O pins as open-drain

can help when several pins in the system are tied

to the same point: of course software must pay at-

tention to program only one of them as output at

any time, to avoid output driver contentions; it is

advisable to configure these pins as output open-

drain in order to reduce the risk of current conten-

tions.

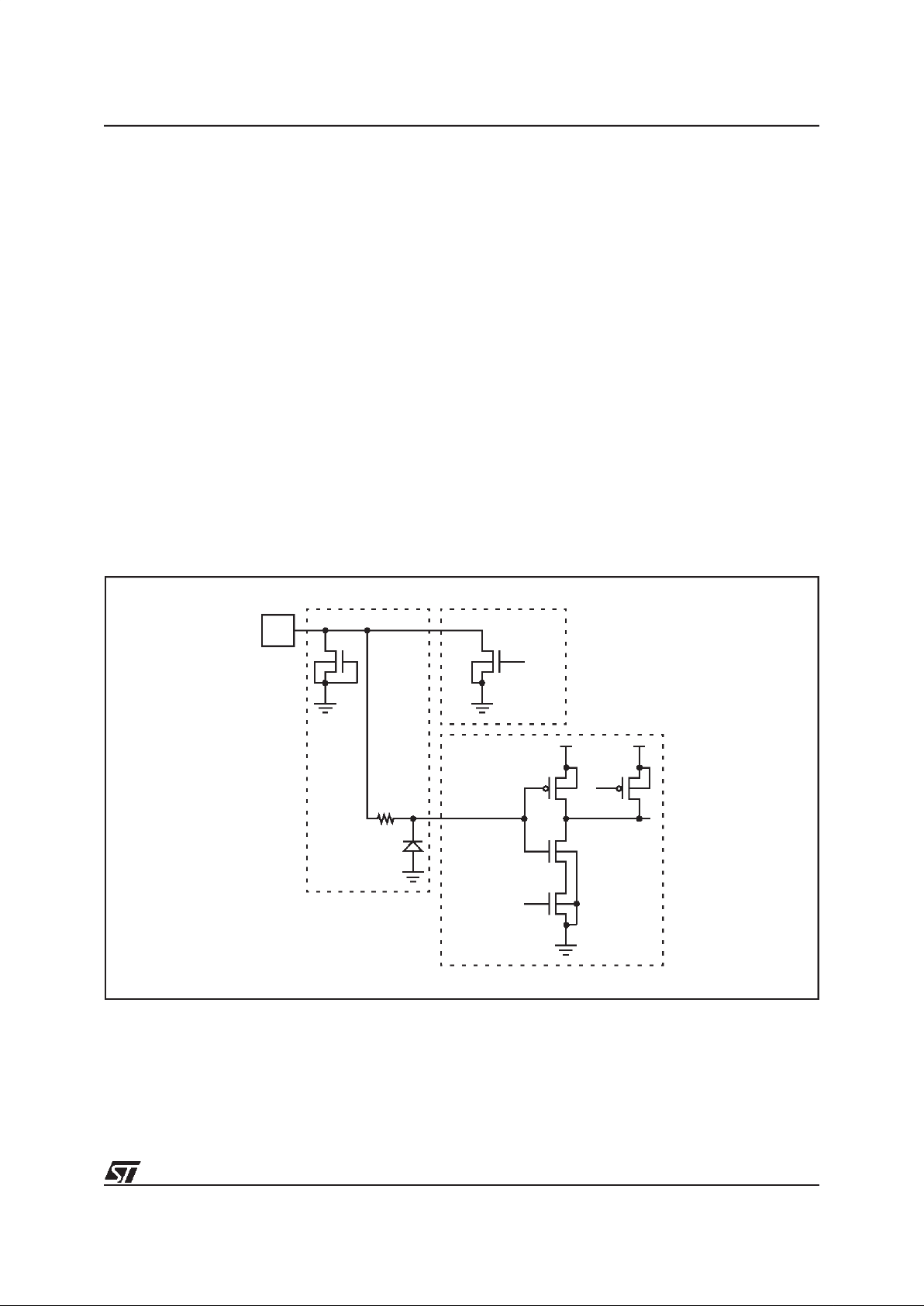

Figure 5. Digital Input/Output - True Open Drain Output

PIN

OUTPUT

BUFFER

N

P

N

N

INPUT

BUFFE R

ESDPROT EC T ION

CIRCUITRY

PORT CIRCUITRY

I/OCIRCUITRY

P

EN

EN

9

14/320

ST92F120 - GENERAL DESCRIPTION

In Figure 6 a true open-drain pin schematic is

shown. In this case all paths to V

DD

are removed

(P-channel driver, ESD protection diode, internal

weak pull-up) in order to allow the system to turn

off the power supply of the microcontroller and

keep the voltage level at the pin high without in-

jecting current in the device. This is a typical con-

dition which can occur when several devices inter-

face a serial bus: if one device is not involved in

the communication, it can be disabled by turning

off its power supply to reduce the system current

consumption.

When an illegal negative voltage level is applied to

the ST9 I/O pins (both versions, push-pull and true

open-drain output) the clamp diode is always

present and active (see ESD protection circuitry

and N-channel driver).

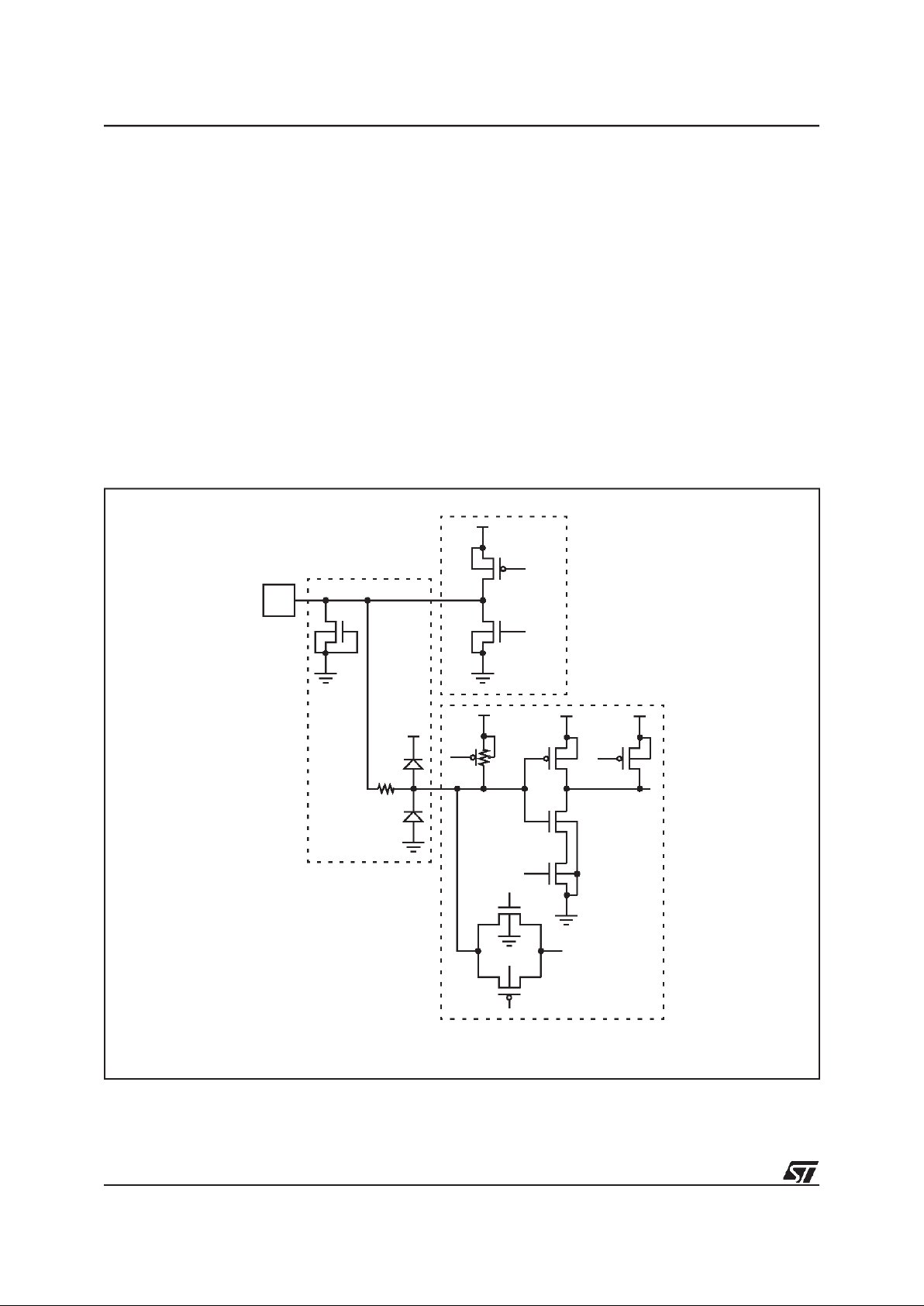

1.2.4.4 Internal Circuitry: Analog Input pin

Figure 6 shows the internal circuitry used for ana-

log input. It is substantially a digital I/O with an

added analog multiplexer for the A/D Converter in-

put signal selection.

The presence of the multiplexer P-channel and N-

channel can affect the behaviour of the pin when

exposed to illegal voltage conditions. These tran-

sistors are controlled by a low noise logic, biased

through AV

DD

and AV

SS

including P-channel N-

well: it is important to always verify the input volt-

age value with respect to both analog power sup-

ply and digital power supply, in order to avoid un-

intended current injections which (if not limited)

could destroy the device.

Figure 6. Digital Input/Output - Push-Pull Output - Analog Multiplexer Input

PIN

OUTPUT

BUFFER

P

N

P

N

N

IN P UT

BUFFER

P

ESDPRO T EC T ION

CIRCUITRY

PORTCIR CUIT RY

I/OCIRCUITRY

P

EN

EN

N

P

AV

DD

9

15/320

ST92F120 - GENERAL DESCRIPTION

1.2.4.5 Power Supply and Ground

As already said for the I/O pins, in order to guaran-

tee ST9 compliancy with respect to QualityAssur-

ance recommendations concerning ESD and

Latchup, dedicated circuits are added to the differ-

ent power supply and ground pins (digital and an-

alog). These structures create preferred paths for

the high current injected during discharges, avoid-

ing damage to active logic and circuitry. It is impor-

tant for the system designer to take this added cir-

cuitry into account, which is not always transpar-

ent withrespect to the relative level of voltages ap-

plied to the different power supply and ground

pins. Figure 7 shows schematically the protection

net implemented on ST9 devices, composedof di-

odes and other special structures.

The clamp structure between the V

DD

and V

SS

pins is designed to be active during very fast tran-

sitions (typical of electrostatic discharges). Other

paths are implemented through diodes: they limit

the possibility of positively differentiating AV

DD

and V

DD

(i.e. AV

DD

>V

DD

); similar considerations

are valid for AV

SS

and V

SS

due to the back-to-

back diode structure implemented between the

two pins. Anyway, it must be highlighted that, be-

cause V

SS

and AV

SS

are connected to the sub-

strate of the silicon die (even though in different ar-

eas of the die itself), they represent the reference

point from which all other voltages are measured,

and it is recommended to never differentiate AV

SS

from V

SS

.

Note: If more than one pair of pins for V

SS

and

V

DD

isavailable on the device, they are connected

internally and the protection net diagram remains

the same as shown in Figure 7.

Figure 7. Power Supplyand Ground configuration

N

P

P

N

V

DD

V

SS

AV

DD

AV

SS

V

PP

9

16/320

ST92F120 - GENERAL DESCRIPTION

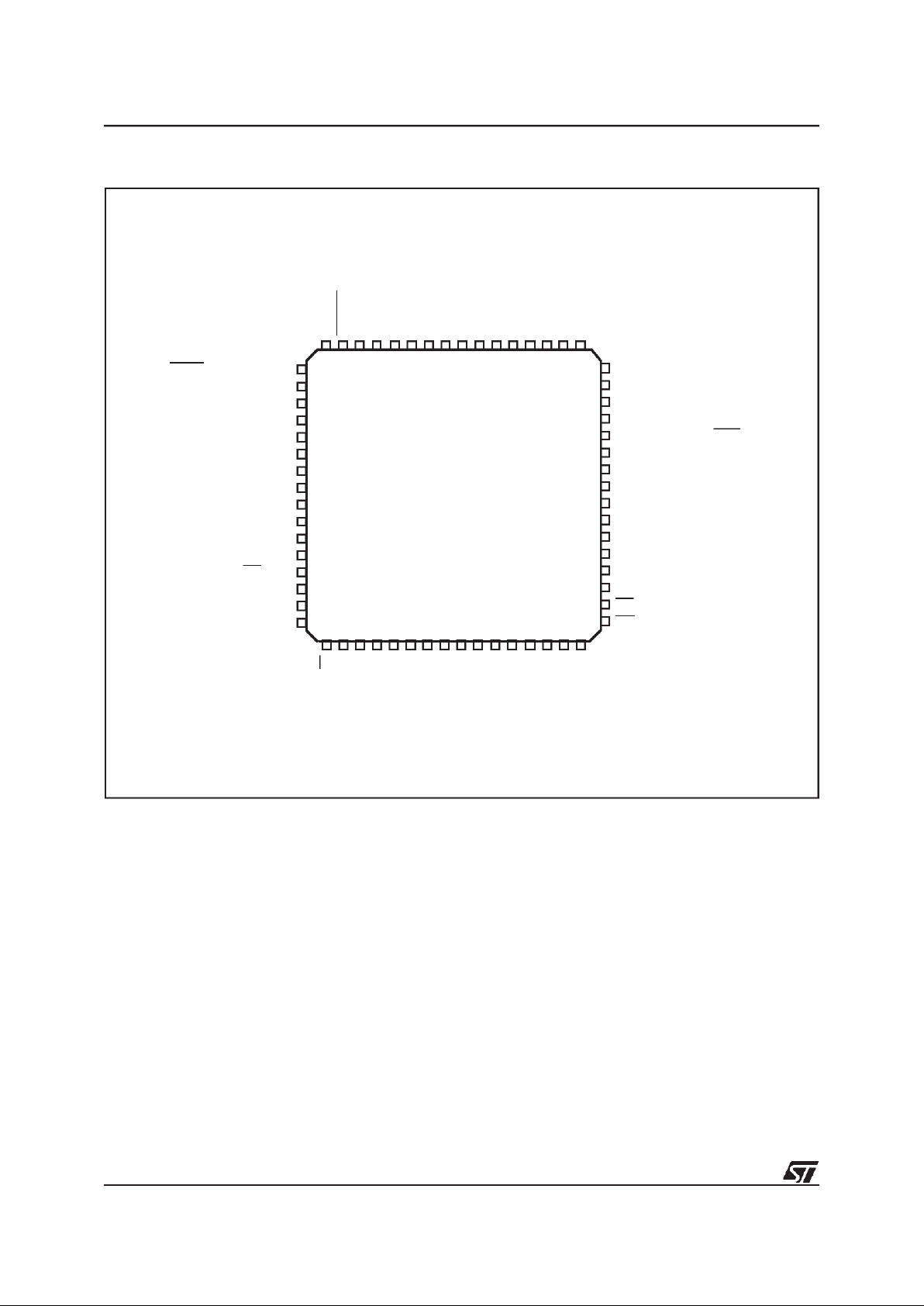

Figure 8. ST92F120: Pin configuration (top-view TQFP64)

* Alternate function forCAN interface, reserved for future use: P5.0/TXCAN0; P5.1/RXCAN0.

** On devices without JBPLD peripheral, this pin must notbe connected.

*** V

PP

must be keptlow in standard operating mode.

WAIT/WKUP5/P5.0*

WKUP6/WDOUT/P5.1*

SIN0/WKUP2/P5.2

SOUT0/P5.3

TXCLK0/CLKOUT0/P5.4

RXCLK0/WKUP7/P5.5

DCD0/WKUP8/P5.6

WKUP9/RTS0/P5.7

EXTCLK1/WKUP4/P4.4

EXTRG/STOUT/P4.5

SDA/P4.6

WKUP1/SCL/P4.7

EXTCLK0/SS/P3.4

MISO/P3.5

MOSI/P3.6

SCK/WKUP0/P3.7

HW0SW1

RESET

OSCOUT

OSCIN

V

DD

V

SS

P7.7/A0IN7/WKUP13

P7.6/A0IN6/WKUP12

P7.5/A0IN5/WKUP11

P7.4/A0IN4/WKUP3

P7.3/A0IN3

P7.2/A0IN2

P7.1/A0IN1

P7.0/A0IN0

AV

SS

AV

DD

VPWO**

P6.5/WKUP10/INTCLK/VPWI

P6.4/NMI

P6.3/INT3/INT5

P6.2/INT2/INT4/DS2

P6.0/INT0/INT1/CLOCK2/8

P0.7/A7/D7

P0.6/A6/D6

P0.5/A5/D5

P0.4/A4/D4

P0.3/A3/D3

P0.2/A2/D2

P0.1/A1/D1

P0.0/A0/D0

AS

DS

RW

TINPA0/P2.0

TINPB0/P2.1

TOUTA0/P2.2

TOUTB0/P2.3

TINPA1/P2.4

TINPB1/P2.5

TOUTA1/P2.6

TOUTB1/P2.7

V

SS

V

DD

V

REG

***V

PP

A8/P1.0

A9/P1.1

A10/P1.2

N.C. = Not connected (no physical bonding wire)

6463 6261 6059585756555453 52515049

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

1718192021222324 29 30313225262728

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

ST92 F12 0

9

17/320

ST92F120 - GENERAL DESCRIPTION

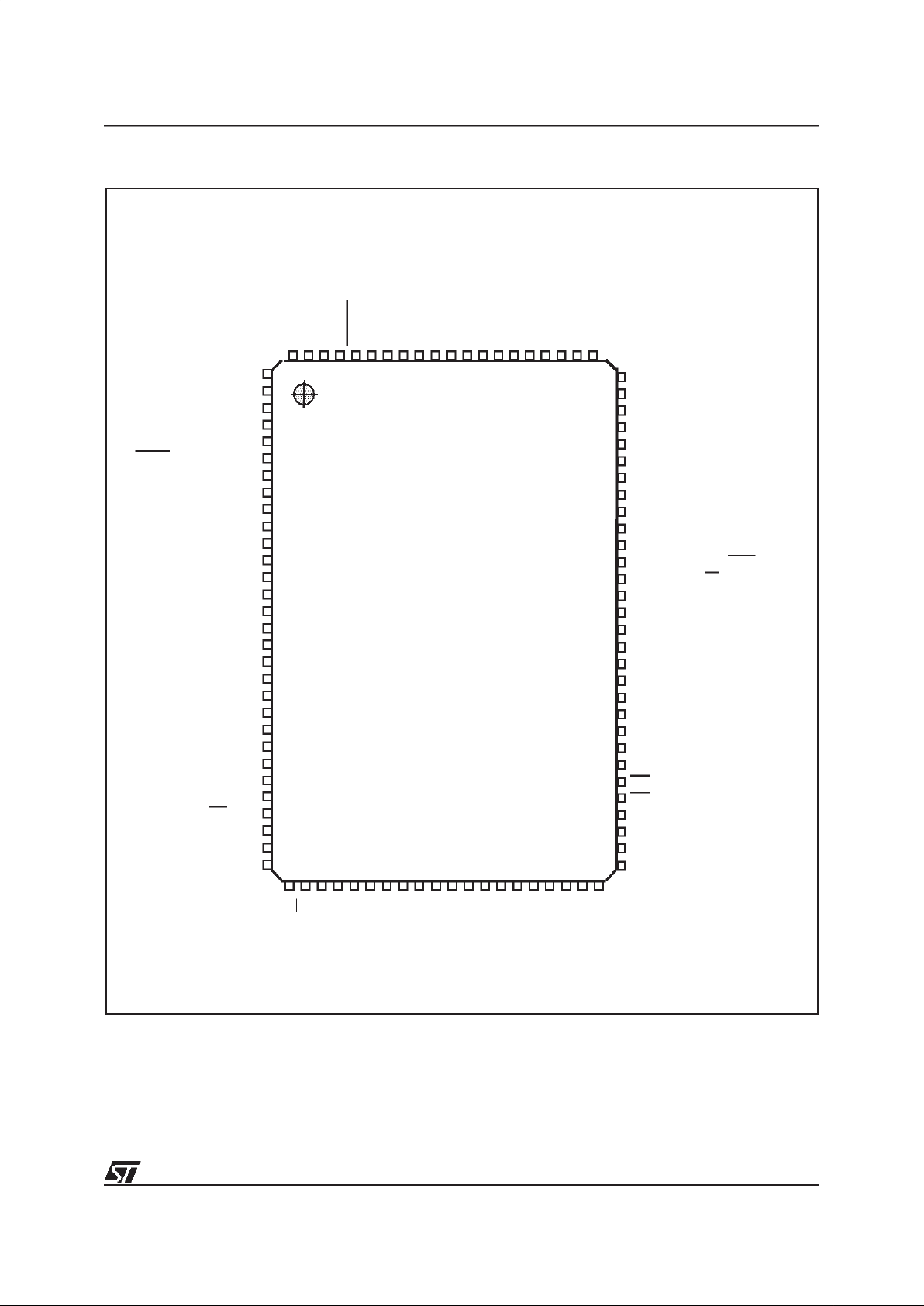

Figure 9. ST92F120: Pin Configuration (top-view PQFP100)

* Alternate function forCAN interface, reserved for future use: P5.0/TXCAN0; P5.1/RXCAN0

** Pin reserved forfuture use: 49- RXCAN1; 50 -TXCAN1

*** V

PP

must be kept low in standard operating mode.

RXCLK1/P9.3

DCD1/P9.4

RTS1/P9.5

CLOCK2/P9.6

P9.7

WAIT/WKUP5/P5.0*

WKUP6/WDOUT/P5.1*

SIN0/WKUP2/P5.2

SOUT0/P5.3

TXCLK0/CLKOUT0/P5.4

RXCLK0/WKUP7/P5.5

DCD0/WKUP8/P5.6

WKUP9/RTS0/P5.7

ICAPA1/P4.0

P4.1

OCMPA1/P4.2

V

SS

V

DD

ICAPB1/OCMPB1/P4.3

EXTCLK1/WKUP4/P4.4

EXTRG/STOUT/P4.5

SDA/P4.6

WKUP1/SCL/P4.7

ICAPB0/P3.1

ICAPA0/OCMPA0/P3.2

OCMPB0/P3.3

EXTCLK0/SS/P3.4

MISO/P3.5

MOSI/P3.6

SCK/WKUP0/P3.7

P9.2/TXCLK1/CLKOUT1

P9.1/SOUT1

P9.0/SIN1

HW0SW1

RESET

OSCOUT

OSCIN

V

DD

V

SS

P7.7/A0IN7/WKUP13

P7.6/A0IN6/WKUP12

P7.5/A0IN5/WKUP11

P7.4/A0IN4/WKUP3

P7.3/A0IN3

P7.2/A0IN2

P7.1/A0IN1

P7.0/A0IN0

AV

SS

AV

DD

P8.7/A1IN0

P8.6/A1IN1

P8.5/A1IN2

P8.4/A1IN3

P8.3/A1IN4

P8.2/A1IN5

P8.1/A1IN6/WKUP15

P8.0/A1IN7/WKUP14

VPWO

P6.5/WKUP10/INTCLK/VPWI

P6.4/NMI

P6.3/INT3/INT5

P6.2/INT2/INT4/DS2

P6.1/INT6/RW

P6.0/INT0/INT1/CLOCK2/8

P0.7/A7/D7

V

DD

V

SS

P0.6/A6/D6

P0.5/A5/D5

P0.4/A4/D4

P0.3/A3/D3

P0.2/A2/D2

P0.1/A1/D1

P0.0/A0/D0

AS

DS

P1.7/A15

P1.6/A14

P1.5/A13

P1.4/A12

V

REG

RW

TINPA0/P2.0

TINPB0/P2.1

TOUTA0/P2.2

TOUTB0/P2.3

TINPA1/P2.4

TINPB1/P2.5

TOUTA1/P2.6

TOUTB1/P2.7

V

SS

V

DD

V

REG

***V

PP

A8/P1.0

A9/P1.1

A10/P1.2

A11/P1.3

**N.C.

**N.C.

1

50

30

ST92F120

N.C. = Not connected (no physical bonding wire)

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

80

51

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

49484746454443424140393837363534333231

81828384858687888990919293949596979899100

9

18/320

ST92F120 - GENERAL DESCRIPTION

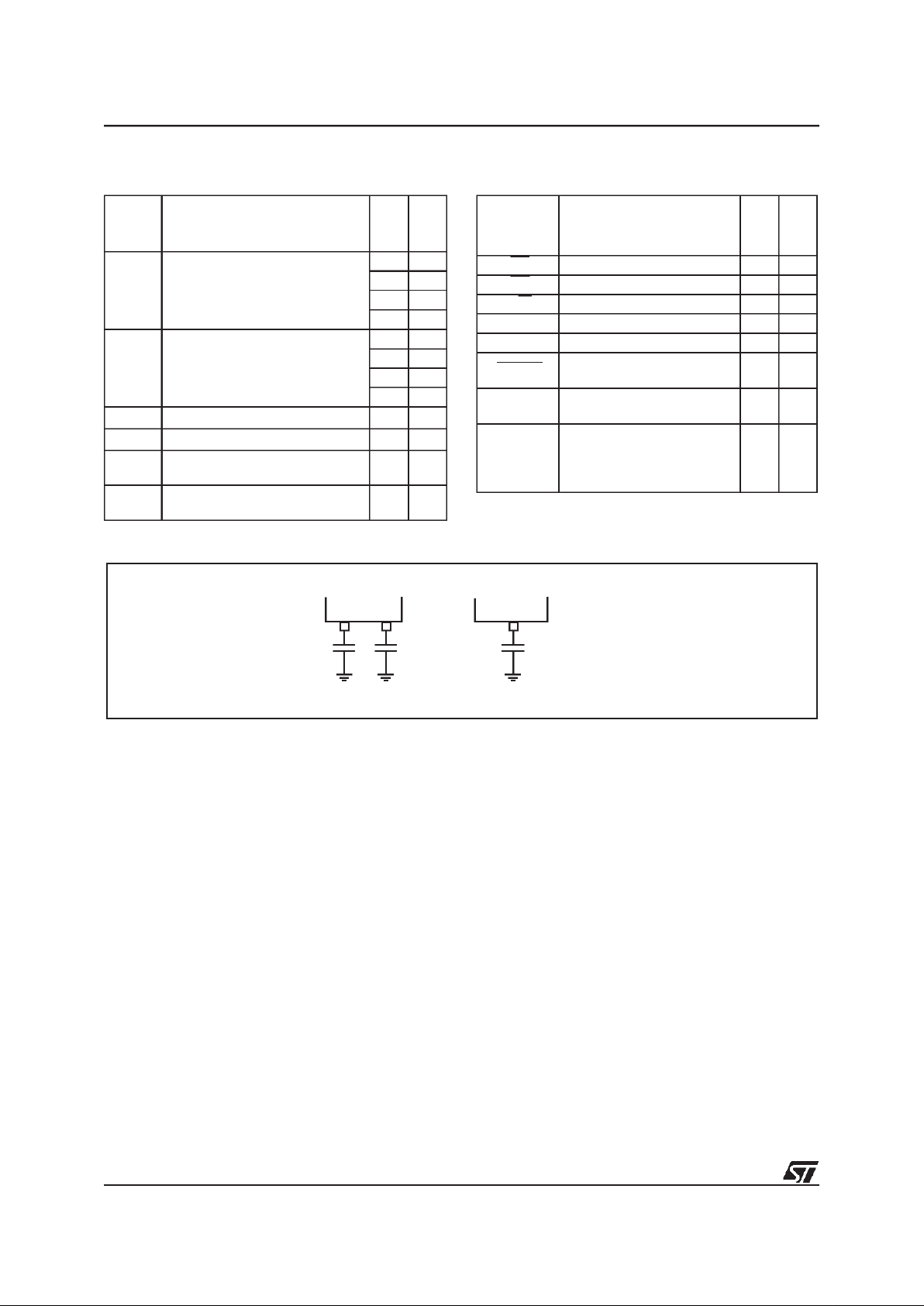

Table 1. ST92F120 Power Supply Pins Table 2. ST92F120 Primary Function Pins

Figure 10. Recommended connections for V

REG

Note : For future compatibility with shrinked versions, the V

REG

pins should be connected to a minimum

of 600 nF (total). Special care should be taken to minimize the distance between the ST9 microcontroller

and the capacitors.

Name Function

QFP64

QFP100

V

DD

Main Power Supply Voltage

( pins internally connected)

-18

27 42

-65

60 93

V

SS

Digital Circuit Ground

(pins internally connected)

-17

26 41

-64

59 92

AV

DD

Analog Circuit Supply Voltage 49 82

AV

SS

Analog Circuit Ground 50 83

V

PP

Must be kept low in standard

operating mode

29 44

V

REG

3V regulator output 28

31

43

Name Function

QFP64

QFP100

AS Address Strobe 34 56

DS Data Strobe 33 55

RW Read/Write 17 32

OSCIN Oscillator Input 61 94

OSCOUT Oscillator Output 62 95

RESET

Reset to initialize theMicro-

controller

63 96

HW0SW1

Watchdog HW/SW enabling

selection

64 97

VPWO

J1850 JBLPD Output. On

devices without JBPLD pe-

ripheral, this pin must not be

connected.

48 73

300 nF 300 nF

QFP100 QFP 64

600 nF

9

19/320

ST92F120 - GENERAL DESCRIPTION

1.3 I/O PORTS

Port 0 and Port 1 provide theexternal memory in-

terface. All the ports of the device can be pro-

grammed as Input/Output or in Input mode, com-

patible with TTL or CMOS levels (except where

Schmitt Trigger is present). Each bit can be pro-

grammed individually (Refer to the I/O ports chap-

ter).

Internal Weak Pull-up

As shown in Table 3, not all input sections imple-

ment a Weak Pull-up. This means that the pull-up

must be connected externally when the pin is not

used or programmed as bidirectional.

TTL/CMOS Input

For all those port bits where no input schmitt trig-

ger is implemented, it is always possible to pro-

gram the input level as TTL or CMOS compatible

by programming the relevant PxC2.n control bit.

Refer I/O Ports Chapter to the section titled “Input/

Output Bit Configuration”.

Schmitt Trigger Input

Two different kind ofSchmitt Trigger circuitries are

implemented: Standard and High Hysteresis.

Standard Schmitt Trigger is widely used (see Ta-

ble 3), while the High Hysteresis one is present on

the NMI and VPWI input function pins mapped on

Port 6 [5:4] (see Table 4).

All inputs which can be used for detecting interrupt

events have been configured with a “standard”

Schmitt Trigger, apart from, as already said, the

NMI pin which implements the “High Hysteresis”

version. In this way, all interrupt lines are guaran-

teed as “level sensitive”.

Push-Pull/OD Output

The output buffer can be programmed as push-

pull or open-drain: attention must be paid to the

fact that the open-drain option corresponds only to

a disabling of P-channel MOS transistor of the

buffer itself: it is still present and physically con-

nected to thepin. Consequentlyit is notpossible to

increase the output voltage on the pin over

V

DD

+0.3 Volt, to avoid direct junction biasing.

Pure Open-drain Output

The user can increase the voltage on an I/O pin

over V

DD

+0.3 Volt where the P-channel MOS tran-

sistor is physically absent: this is allowed on all

“Pure Open Drain” pins. Of course, in this case the

push-pull option is not available and any weak

pull-up must implemented externally.

Table 3. I/O Port Characteristics

Legend: WPU = Weak Pull-Up, OD = Open Drain

Input Output Weak Pull-Up Reset State

Port 0[7:0] TTL/CMOS Push-Pull/OD No Bidirectional

Port 1[7:0] TTL/CMOS Push-Pull/OD No Bidirectional

Port 2[1:0]

Port 2[3:2]

Port 2[5:4]

Port 2[7:6]

Schmitt trigger

TTL/CMOS

Schmitt trigger

TTL/CMOS

Push-Pull/OD

Pure OD

Push-Pull/OD

Push-Pull/OD

Yes

No

Yes

Yes

Input

Input CMOS

Input

Input CMOS

Port 3[2:1]

Port 3.3

Port 3[7:4]

Schmitt trigger

TTL/CMOS

Schmitt trigger

Push-Pull/OD

Push-Pull/OD

Push-Pull/OD

Yes

Yes

Yes

Input

Input CMOS

Input

Port 4.0, Port 4.4

Port 4.1

Port 4.2, Port 4.5

Port 4.3

Port 4[7:6]

Schmitt trigger

TTL/CMOS

TTL/CMOS

Schmitt trigger

Schmitt trigger inside I/O cell

Push-Pull/OD

Push-Pull/OD

Push-Pull/OD

Push-Pull/OD

Pure OD

No

Yes

Yes

Yes

No

Input

Bidirectional WPU

Input CMOS

Input

Input

Port 5[2:0], Port [7:4]

Port 5.3

Schmitt trigger

TTL/CMOS

Push-Pull/OD

Push-Pull/OD

No

Yes

Input

Input CMOS

Port 6[3:0]

Port 6[5:4]

Schmitt trigger

High hysteresis Schmitt trigger

inside I/O cell

Push-Pull/OD

Push-Pull/OD

Yes

Yes (inside I/O cell)

Input

Input

Port 7[7:0] Schmitt trigger Push-Pull/OD Yes Input

Port 8[1:0]

Port 8[7:2]

Schmitt trigger

Schmitt trigger

Push-Pull/OD

Push-Pull/OD

Yes

Yes

Input

Bidirectional WPU

Port 9[7:0] Schmitt trigger Push-Pull/OD Yes Bidirectional WPU

9

20/320

ST92F120 - GENERAL DESCRIPTION

How to Configure the I/O ports

To configure the I/O ports, use the information in

Table 3, Table 4 andthe Port Bit Configuration Ta-

ble in the I/O Ports Chapter (See page 125).

Input Note = the hardware characteristics fixed for

each port line in Table3.

– If Input note = TTL/CMOS, either TTL or CMOS

input level can be selected by software.

– If Input note = Schmitt trigger, selecting CMOS

or TTL input by software has no effect, the input

will always be Schmitt Trigger.

Alternate Functions (AF) = More than one AF

cannot beassigned to an I/O pin at the same time:

An alternate function can be selected as follows.

AF Inputs:

– AF is selected implicitly by enabling the corre-

sponding peripheral. Exception to this areA/Din-

puts which must be explicitly selected as AF by

software.

AF Outputs or Bidirectional Lines:

– In the case of Outputs or I/Os, AF is selected ex-

plicitly by software.

Example 1: SCI input

AF: SIN0, Port: P5.2, Input note: Schmitt Trigger.

Write the port configuration bits:

P5C2.2=1

P5C1.2=0

P5C0.2 =1

Enable the SCI peripheral by software as de-

scribed in the SCI chapter.

Example 2: SCI output

AF: SOUT0, Port: P5.3, Output note:

Push-Pull/OD.

Write the port configuration bits (for AF OUT PP):

P5C2.3=0

P5C1.3=1

P5C0.3 =1

Example 3: External Memory I/O

AF: A0/D0, Port : P0.0, Input Note: TTL/CMOS

Write the port configuration bits:

P0C2.0=1

P0C1.0=1

P0C0.0 =1

Example 4: Analog input

AF: A0IN0, Port : 7.0, Input Note: does not apply

to analog input

Write the port configuration bits:

P7C2.0=1

P7C1.0=1

P7C0.0 =1

9

21/320

ST92F120 - GENERAL DESCRIPTION

Table 4. I/O Port Alternate Functions

Port

Name

General

Purpose I/O

Pin No.

Alternate Functions

TQFP64 PQFP100

P0.0

All ports useable

for general pur-

pose I/O (input,

output or bidirec-

tional)

35 57 A0/D0 I/O Address/Data bit 0

P0.1 36 58 A1/D1 I/O Address/Data bit 1

P0.2 37 59 A2/D2 I/O Address/Data bit 2

P0.3 38 60 A3/D3 I/O Address/Data bit 3

P0.4 39 61 A4/D4 I/O Address/Data bit 4

P0.5 40 62 A5/D5 I/O Address/Data bit 5

P0.6 41 63 A6/D6 I/O Address/Data bit 6

P0.7 42 66 A7/D7 I/O Address/Data bit 7

P1.0 30 45 A8 I/O Address bit 8

P1.1 31 46 A9 I/O Address bit 9

P1.2 32 47 A10 I/O Address bit 10

P1.3 - 48 A11 I/O Address bit 11

P1.4 - 51 A12 I/O Address bit 12

P1.5 - 52 A13 I/O Address bit 13

P1.6 - 53 A14 I/O Address bit 14

P1.7 - 54 A15 I/O Address bit 15

P2.0 18 33 TINPA0 I Multifunction Timer 0 - Input A

P2.1 19 34 TINPB0 I Multifunction Timer 0 - Input B

P2.2 20 35 TOUTA0 O Multifunction Timer 0 - Output A

P2.3 21 36 TOUTB0 O Multifunction Timer 0 - Output B

P2.4 22 37 TINPA1 I Multifunction Timer 1 - Input A

P2.5 23 38 TINPB1 I Multifunction Timer 1 - Input B

P2.6 24 39 TOUTA1 O Multifunction Timer 1 - Output A

P2.7 25 40 TOUTB1 O Multifunction Timer 1 - Output B

P3.1 - 24 ICAPB0 I Ext. Timer 0 - Input Capture B

P3.2 - 25

ICAPA0 I Ext. Timer0 - Input Capture A

OCMPA0 O Ext. Timer0 - Output Compare A

P3.3 - 26 OCMPB0 O Ext. Timer 0 - Output Compare B

P3.4 13 27

EXTCLK0 I Ext. Timer 0 - Input Clock

SS I SPI - Slave Select

P3.5 14 28 MISO I/O SPI - Master Input/Slave Output Data

P3.6 15 29 MOSI I/O SPI - Master Output/SlaveInput Data

P3.7 16 30

SCK I SPI - Serial Input Clock

WKUP0 I Wake-up Line 0

SCK O SPI - Serial Output Clock

P4.0 - 14 ICAPA1 I Ext. Timer 1 - Input Capture A

9

22/320

ST92F120 - GENERAL DESCRIPTION

P4.1

All ports useable

for general pur-

pose I/O (input,

output or bidirec-

tional)

- 15 I/O

P4.2 - 16 OCMPA1 O Ext. Timer1 - Output Compare A

P4.3 - 19

ICAPB1 I Ext. Timer1 - Input Capture B

OCMPB1 O Ext. Timer1 - Output Compare B

P4.4 9 20

EXTCLK1 I Ext. Timer 1 - Input Clock

WKUP4 I Wake-up Line 4

P4.5 10 21

EXTRG I A/D 0 and A/D 1 - Ext. Trigger

STOUT O Standard Timer Output

P4.6 11 22 SDA I/O

I

2

CData

P4.7 12 23

WKUP1 I Wake-up Line 1

SCL I/O

I

2

C Clock

P5.0 1 6

WAIT I External Wait Request

WKUP5 I Wake-up Line 5

P5.1 2 7

WKUP6 I Wake-up Line 6

WDOUT O Watchdog Timer Output

P5.2 3 8

SIN0 I SCI0 - Serial Data Input

WKUP2 I Wake-up Line 2

P5.3 4 9 SOUT0 O SCI0 - Serial Data Output

P5.4 5 10

TXCLK0 I SCI0 - Transmit Clock Input

CLKOUT0 O SCI0 - Clock Output

P5.5 6 11

RXCLK0 I SCI0 - Receive Clock Input

WKUP7 I Wake-up Line 7

P5.6 7 12

DCD0 I SCI0 - Data Carrier Detect

WKUP8 I Wake-up Line 8

P5.7 8 13

WKUP9 I Wake-up Line 9

RTS0 O SCI0 - Request To Send

P6.0 43 67

INT0 I External Interrupt 0

INT1 I External Interrupt 1

CLOCK2/

8

O CLOCK2 divided by 8

P6.1 - 68

INT6 I External Interrupt 6

RW O Read/Write

P6.2 44 69

INT2 I External Interrupt 2

INT4 I External Interrupt 4

DS2 O Data Strobe 2

Port

Name

General

Purpose I/O

Pin No.

Alternate Functions

TQFP64 PQFP100

9

23/320

ST92F120 - GENERAL DESCRIPTION

P6.3

All ports useable

for general pur-

pose I/O (input,

output or bidirec-

tional)

45 70

INT3 I External Interrupt 3

INT5 I External Interrupt 5

P6.4 46 71 NMI I Non Maskable Interrupt

P6.5 47 72

WKUP10 I Wake-up Line 10

VPWI I JBLPD input

INTCLK O Internal Main Clock

P7.0 51 84 A0IN0 I A/D 0 - Analog Data Input0

P7.1 52 85 A0IN1 I A/D 0 - Analog Data Input1

P7.2 53 86 A0IN2 I A/D 0 - Analog Data Input2

P7.3 54 87 A0IN3 I A/D 0 - Analog Data Input3

P7.4 55 88

WKUP3 I Wake-up Line 3

A0IN4 I A/D 0 - Analog Data Input 4

P7.5 56 89

A0IN5 I A/D 0 - Analog Data Input 5

WKUP11 I Wake-up Line 11

P7.6 57 90

A0IN6 I A/D 0 - Analog Data Input 6

WKUP12 I Wake-up Line 12

P7.7 58 91

A0IN7 I A/D 0 - Analog Data Input 7

WKUP13 I Wake-up Line 13

P8.0 - 74

A1IN7 I A/D 1 - Analog Data Input 7

WKUP14 I Wake-up Line 14

P8.1 - 75

A1IN6 I A/D 1 - Analog Data Input 6

WKUP15 I Wake-up Line 15

P8.2 - 76 A1IN5 I A/D 1 - Analog Data Input 5

P8.3 - 77 A1IN4 I A/D 1 - Analog Data Input 4

P8.4 - 78 A1IN3 I A/D 1 - Analog Data Input 3

P8.5 - 79 A1IN2 I A/D 1 - Analog Data Input 2

P8.6 - 80 A1IN1 I A/D 1 - Analog Data Input 1

P8.7 - 81 A1IN0 I A/D 1 - Analog Data Input 0

P9.0 - 98 SIN1 I SCI1 - SerialData Input

P9.1 - 99 SOUT1 O SCI1 - Serial Data Output

P9.2 - 100

TXCLK1 I SCI1 - Transmit Clock input

CLKOUT1 O SCI1 - Clock Input

P9.3 - 1 RXCLK1 I SCI1 - Receive Clock Input

P9.4 - 2 DCD1 I SCI1 - Data Carrier Detect

P9.5 - 3 RTS1 O SCI1 - Request To Send

P9.6 - 4 CLOCK2 O CLOCK2 internal signal

P9.7 - 5 I/O

Port

Name

General

Purpose I/O

Pin No.

Alternate Functions

TQFP64 PQFP100

9

24/320

ST92F120 - GENERAL DESCRIPTION

1.4 OPERATING MODES

To optimize the performance versus the power

consumption of the device, the ST92F120 sup-

ports different operating modes that can be dy-

namically selected depending on the performance

and functionality requirements of the application at

a given moment.

RUN MODE: This is the full speed execution mode

with CPU and peripherals running atthemaximum

clock speed delivered by the Phase Locked Loop

(PLL) of the Clock Control Unit (CCU).

SLOW MODE: Power consumption can be signifi-

cantly reduced by running the CPU and the pe-

ripherals at reduced clock speed using the CPU

Prescaler and CCU Clock Divider.

WAIT FOR INTERRUPT MODE: The Wait For In-

terrupt (WFI) instruction suspends program exe-

cution until an interrupt request is acknowledged.

During WFI, the CPU clock is halted while the pe-

ripheral and interrupt controller keep running at a

frequency depending on the CCU programming.

LOW POWER WAIT FOR INTERRUPT MODE:

Combining SLOW mode and Wait For Interrupt

mode it is possible to reduce the power consump-

tion by more than 80%.

STOP MODE: When the STOP is requested by

executing the STOP bit writing sequence (see

dedicated section on Wake-up Management Unit

paragraph), and if NMI is kept low, the CPU and

the peripheralsstop operating. Operations resume

after a wake-up line is activated (16 wake-up lines

plus NMI pin). See the RCCU and Wake-up Man-

agement Unit paragraphs in the following for the

details. The difference with the HALT mode con-

sists in the way the CPU exits this state: when the

STOP is executed, the status of the registers is re-

corded, and when the system exits from the STOP

mode the CPU continues the execution with the

same status, without a system reset.

When the MCU enters STOP mode the Watchdog

stops counting. After the MCU exits from STOP

mode, the Watchdog resumes counting from

where it left off.

When the MCU exits from STOP mode, the oscil-

lator, which was sleeping too, requires about 5 ms

to restart working properly (at a 4 MHz oscillator

frequency). An internal counter is present to guar-

antee that all operations after exiting STOP Mode,

take place with the clock stabilised.

The counter is active only when the oscillationhas

already taken place. This means that 1-2 ms must

be added to takeinto account the first phase of the

oscillator restart.

HALT MODE: When executing the HALT instruc-

tion, and if the Watchdog is not enabled, the CPU

and its peripherals stop operating and the status of

the machine remains frozen (the clock is also

stopped). A reset is necessary to exit from Halt

mode.

9

25/320

ST92F120 - DEVICE ARCHITECTURE

2 DEVICE ARCHITECTURE

2.1 CORE ARCHITECTURE

The ST9+ Core or Central Processing Unit (CPU)

features a highly optimised instruction set, capable

of handling bit, byte (8-bit) and word (16-bit) data,

as well as BCD and Boolean formats; 14 address-

ing modes are available.

Four independent buses are controlled by the

Core: a 16-bit Memory bus, an 8-bit Register data

bus, an 8-bit Register address bus and a 6-bit In-

terrupt/DMA bus which connects the interrupt and

DMA controllersin the on-chip peripherals with the

Core.

This multiple bus architecture affords a high de-

gree of pipelining and parallel operation, thus mak-

ing the ST9+ family devices highly efficient, both

for numerical calculation, data handling and with

regard to communication with on-chip peripheral

resources.

2.2 MEMORY SPACES

There are two separate memory spaces:

– The Register File, which comprises 240 8-bit

registers, arranged as 15 groups (Group 0 to E),

each containing sixteen 8-bit registers plus up to

64 pages of 16 registers mapped in Group F,

which hold data and control bits for the on-chip

peripherals and I/Os.

– A single linear memory space accommodating

both program and data. All of the physically sep-

arate memoryareas, including the internal ROM,

internal RAM and external memory are mapped

in this common address space. The total ad-

dressable memory space of 4 Mbytes (limited by

the size of on-chip memory and the number of

external address pins) is arranged as 64 seg-

ments of 64 Kbytes. Each segment is further

subdivided into four pages of 16 Kbytes, as illus-

trated in Figure 11.A Memory Management Unit

uses aset of pointer registers to address a22-bit

memory field using 16-bit address-based instruc-

tions.

2.2.1 Register File

The Register File consists of (see Figure 12):

– 224 general purpose registers (Group 0 to D,

registers R0 to R223)

– 6 system registers in the System Group (Group

E, registers R224 to R239)

– Up to 64 pages, depending on device configura-

tion, each containing up to 16 registers, mapped

to Group F (R240 to R255), see Figure 13.

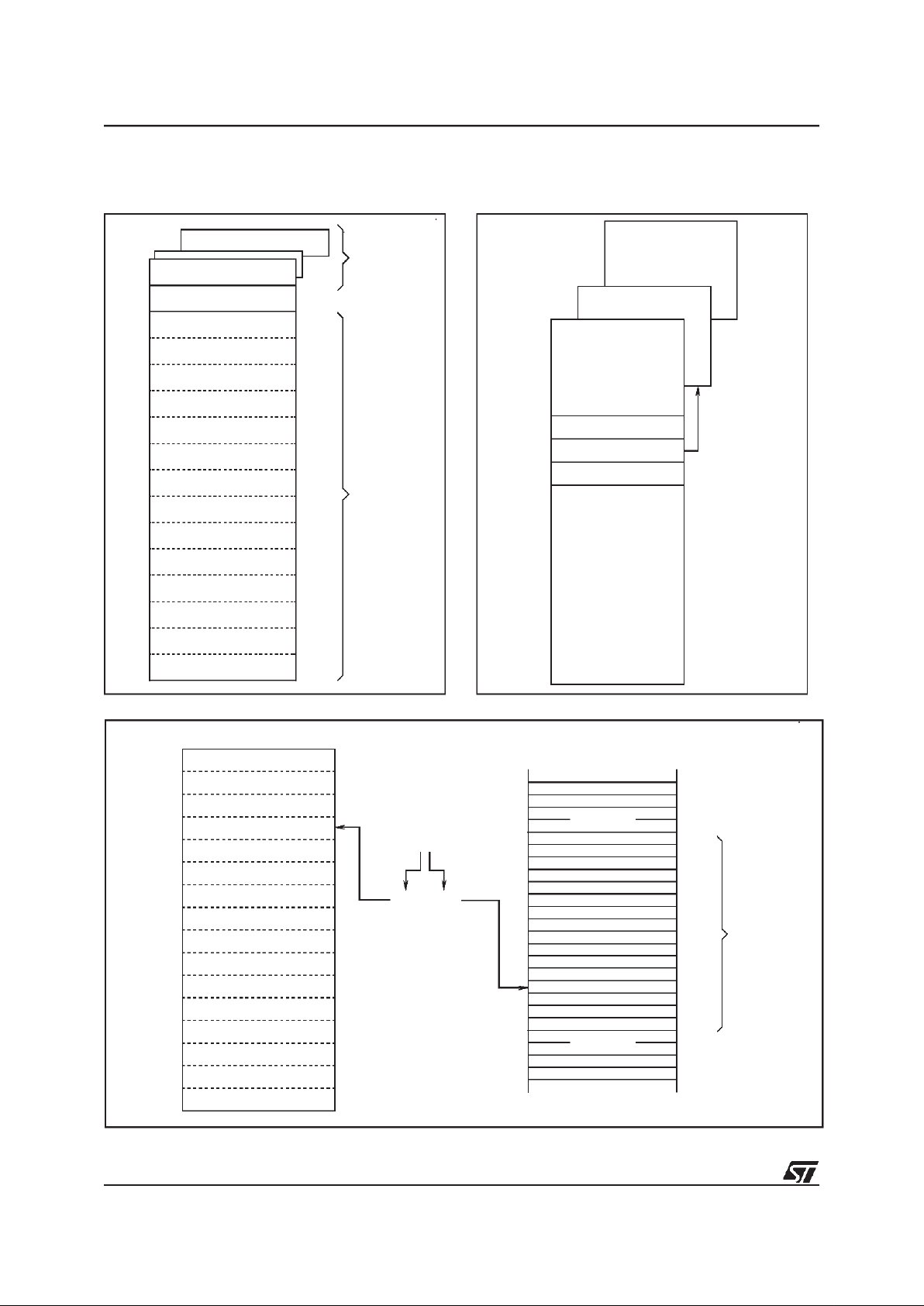

Figure 11. Single Program and Data Memory Address Space

3FFFFFh

3F0000h

3EFFFFh

3E0000h

20FFFFh

02FFFFh

020000h

01FFFFh

010000h

00FFFFh

000000h

8

7

6

5

4

3

2

1

0

63

62

2

1

0

Address 16K Pages 64K Segments

up to 4 Mbytes

Data

Code

255

254

253

252

251

250

249

248

247

9

10

11

21FFFFh

210000h

133

134

135

33

Reserved

132

9

26/320

ST92F120 - DEVICE ARCHITECTURE

MEMORY SPACES (Cont’d)

Figure 12. Register Groups Figure 13. Page Pointer for Group F mapping

Figure 14. Addressing the Register File

F

E

D

C

B

A

9

8

7

6

5

4

3

PAGED REGISTERS

SYSTEM REGISTERS

2

1

0

00

15

255

240

239

224

223

VA00432

UP TO

64 PAGES

GENERAL

REGISTERS

PURPOSE

224

PAGE 63

PAGE 5

PAGE 0

PAGE POINTER

R255

R240

R224

R0 VA00433

R234

REGISTERFILE

SYSTEM REGISTERS

GROUP D

GROUP B

GROUP C

(1100)

(0011)

R192

R207

255

240

239

224

223

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

15

VR000118

00

R195

R195

(R0C3h)

PAGED REGISTERS

9

27/320

ST92F120 - DEVICE ARCHITECTURE

MEMORY SPACES (Cont’d)

2.2.2 Register Addressing

Register File registers, including Group F paged

registers (but excluding Group D), may be ad-

dressed explicitly by means of a decimal, hexa-

decimal or binary address; thus R231, RE7h and

R11100111b represent the same register (see

Figure 14). Group D registers can only be ad-

dressed in Working Register mode.

Note that an upper case “R” is used to denote this

direct addressing mode.

Working Registers

Certain types of instruction require that registers

be specified in the form “rx”, where x is in the

range 0 to 15:these are known as Working Regis-

ters.

Note thata lower case “r” isusedto denote thisin-

direct addressing mode.

Two addressing schemes are available: a single

group of 16 working registers, or two separately

mapped groups,each consisting of 8 working reg-

isters. These groups may be mapped starting at

any 8 or 16 byte boundary in the register file by

means of dedicated pointer registers. This tech-

nique is described in more detail in Section 2.3.3

Register Pointing Techniques, and illustrated in

Figure 15 and in Figure16.

System Registers

The 16 registers in Group E (R224 to R239) are

System registers and may be addressed using any

of the register addressing modes. These registers

are described in greater detail in Section 2.3 SYS-

TEM REGISTERS.

Paged Registers

Up to 64 pages, each containing 16 registers, may

be mapped to Group F. These are addressed us-

ing any register addressing mode, in conjunction

with the Page Pointer register, R234, which is one

of the System registers. This register selects the

page to be mapped to Group F and, once set,

does not need to be changed if two or more regis-

ters on the same page are to be addressed in suc-

cession.

Therefore if the PagePointer, R234, is set to 5,the

instructions:

spp #5

ld R242, r4

will load the contents of working register r4 into the

third register of page 5 (R242).

These paged registers hold data and control infor-

mation relating to the on-chip peripherals, each

peripheral always being associated with the same

pages and registers to ensure code compatibility

between ST9+ devices. The number of these reg-

isters therefore depends on the peripherals which

are present in the specific ST9+ family device. In

other words, pages only exist if the relevant pe-

ripheral is present.

Table 5. Register File Organization

Hex.

Address

Decimal

Address

Function

Register

File Group

F0-FF 240-255

Paged

Registers

Group F

E0-EF 224-239

System

Registers

Group E

D0-DF 208-223

General

Purpose

Registers

Group D

C0-CF 192-207 Group C

B0-BF 176-191 Group B

A0-AF 160-175 Group A

90-9F 144-159 Group 9

80-8F 128-143 Group 8

70-7F 112-127 Group 7

60-6F 96-111 Group 6

50-5F 80-95 Group 5

40-4F 64-79 Group 4

30-3F 48-63 Group 3