Graco Inc 750, 239124, 239092, 239134, 239131 User Manual

...

Instructions–Parts List

Huskyt750 and Huskyt2000

Surge Suppressors

308703G

ENG

For control of pressure fluctuations and acceleration loss, preventing cavitation. For professional use only.

120 psi (0.8 MPa, 8 bar) Maximum Air Input Pressure

120 psi (0.8 MPa, 8 bar) Maximum Fluid Working Pressure

See the Model Numbers on page 12.

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

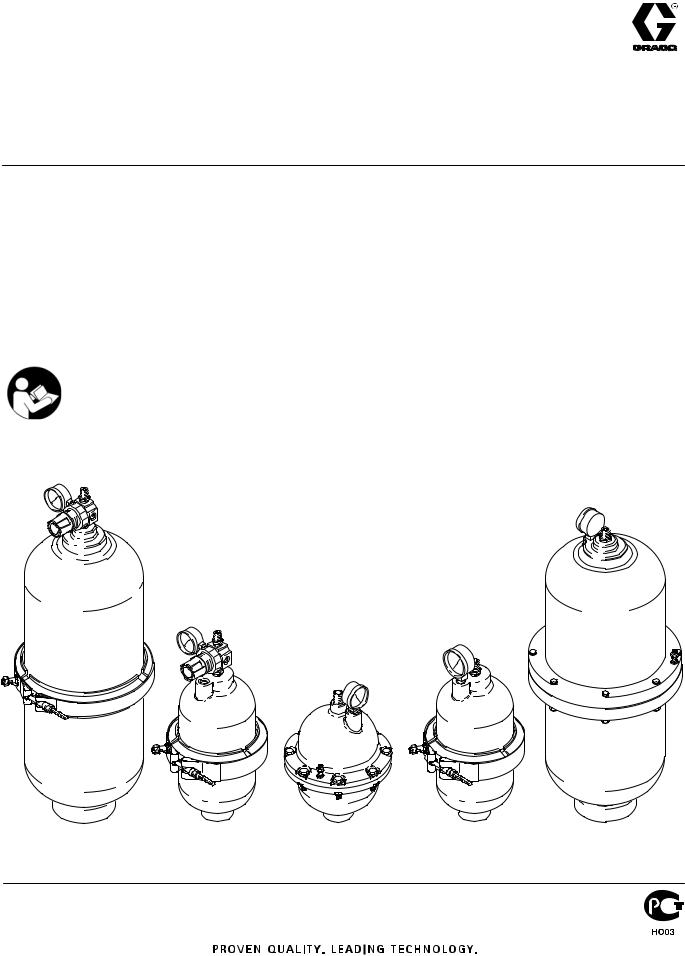

06887 |

06891 |

06888 |

06892 |

06894 |

|

||||

|

|

|

||

Model 239088 Model 239091 |

Model 239095 |

Model 239096 Model 239126 |

||

Table of Contents

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Model Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Parts Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Parts Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Graco Standard Warranty . . . . . . . . . . . . . . . . . . . . . . 18

Graco Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Symbols

Warning Symbol

WARNING

WARNING

This symbol alerts you to the possibility of serious injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

CAUTION

This symbol alerts you to the possibility of damage to or destruction of equipment if you do not follow the instructions.

WARNING

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

INSTRUCTIONS

DThis equipment is for professional use only.

DRead all instruction manuals, tags, and labels before operating the equipment.

DUse the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

DDo not alter or modify this equipment. Use only genuine Graco parts and accessories.

DCheck equipment daily. Repair or replace worn or damaged parts immediately.

DDo not exceed the maximum working pressure of the lowest rated component in your system. This equipment has a 120 psi (0.8 MPa, 8 bar) maximum working pressure and 120 psi (0.8 MPa,

8 bar) maximum incoming air pressure.

DSolvent Compatibility:

–Use fluids and solvents which are compatible with the equipment wetted parts.

–Use only compatible solvents to clean all plastic parts. Many solvents can degrade plastic parts to the point where they could fail.

Refer to the Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

DDo not use hoses to pull equipment.

DDo not lift pressurized equipment.

DComply with all applicable local, state, and national fire, electrical, and safety regulations.

DDo not operate outside the minimum and maximum operating temperature of your surge suppressor unit. See Minimum and Maximum Operating Temperatures on page 7.

2308703

WARNING

TOXIC FLUID HAZARD

Hazardous fluid or toxic fumes can cause serious injury or death if splashed in the eyes or on the skin, inhaled, or swallowed.

DKnow the specific hazards of the fluid you are using.

DStore hazardous fluid in an approved container. Dispose of hazardous fluid according to all local, state and national guidelines.

DAlways wear protective eyewear, gloves, clothing and respirator as recommended by the fluid and solvent manufacturer.

DPipe and dispose of the exhaust air safely, away from people, animals, and food handling areas. If the diaphragm fails, the fluid is exhausted along with the air.

DNever use an acetal pump to pump acids. Take precautions to avoid acid or acid fumes from contacting the pump housing exterior. Stainless steel parts will be damaged by exposure to acid spills and fumes.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result in a fire or explosion and serious injury.

DCharge the surge suppressor with compressed air or nitrogen only. Do not use oxygen. Such use could result in an explosion.

DNever pump flammable fluids with polypropylene units.

DGround the equipment. Refer to Grounding on pages 4 and 5.

DNever use a polypropylene pump or surge suppressor with non-conductive flammable fluids as specified by your local fire protection code. Refer to Grounding on pages 4 and 5 for additional information. Consult your fluid supplier to determine the conductivity or resistivity of your fluid.

DIf there is any static sparking or you feel an electric shock while using this equipment, stop pumping immediately. Do not use the equipment until you identify and correct the problem.

DProvide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid being pumped.

DPipe and dispose of the exhaust air safely, away from all sources of ignition.

DKeep the work area free of debris, including solvent, rags, and gasoline.

DElectrically disconnect all equipment in the work area.

DExtinguish all open flames or pilot lights in the work area.

DDo not smoke in the work area.

DDo not turn on or off any light switch in the work area while operating or if fumes are present.

DDo not operate a gasoline engine in the work area.

308703 3

Installation

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

When pumping flammable fluids, the surge suppressor must be grounded. Before pumping, ground the system as explained below. Also read the section

FIRE OR EXPLOSION HAZARD on page 3.

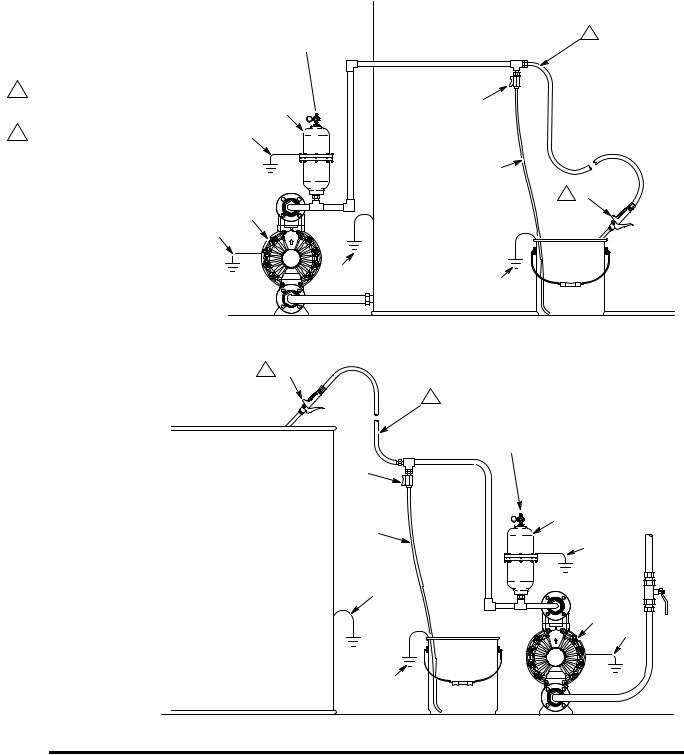

Polypropylene surge suppressors are not conductive. Attaching the ground wire to the grounding lug grounds only the clamp or flange (see Fig. 1). When pumping conductive flammable fluids, always ground the entire fluid system by making sure the fluid has an electrical path to a true-earth ground.

To reduce the risk of static sparking, ground the surge suppressor and all other equipment in the pumping area. Check your local electrical code for detailed grounding instructions for your area and type of equipment. Ground all of this equipment:

DSurge suppressor: Attach a ground wire to the grounding lug (2) as shown in Fig. 1. Connect the clamp end of the ground wire to a true earth ground. To order a ground wire and clamp, order Part No. 222011.

NOTE: To connect the ground wire to the surge suppressor, first remove the copper connector from the non-clamp end of the ground wire and discard it, then push the bare wire through the grounding lug on the surge suppressor.

DFluid supply container: Follow your local code.

23

2

Fig. 1

NOTE: When pumping conductive flammable fluids with a surge suppressor, always ground the entire fluid system. See the WARNING at left. Fig. 2 shows recommended methods of grounding fluid containers during filling. These are only guides; contact your Graco distributor for assistance in grounding your system.

DAir compressor: Follow the manufacturer’s recommendations.

DSolvent pails used when flushing: Follow your local code. Use only grounded metal pails, which are conductive. Do not place the pail on a non-conductive surface, such as paper or cardboard, which interrupts the grounding continuity.

4308703

Installation

Grounding a Surge Suppressor

A Husky pump

B Husky surge suppressor H Fluid drain valve (required) S Dispense valve

T Fluid drain line

W Surge suppressor ground wire (required)

See page 4 for installation instructions.

Y Air motor ground wire (required) Z Container ground wire (required)

1 Hose must be conductive.

2 |

Dispense valve nozzle must be in |

W |

|

contact with the container. |

|||

|

|

A

Y

air supply connection

B

Z

1

H

T

2 S

Z

06895

2 S

1

air supply connection

H

B

T

W

W

Z

A

Y

Z

06896A

Fig. 2

308703 5

Installation

The installations in Fig. 2 are guides for selecting and installing system components. Contact your Graco distributor for assistance in planning a system to suit your needs.

Mounting Automatic and Manual Models

Be sure the mounting surface can support the weight of the pump, surge suppressor, hoses, and accessories, and the stress caused during operation.

DMount the surge suppressor as close to the pump discharge as possible and upstream of equipment such as valves, meters, filters, and so on. The surge suppressor should be installed within 10 pipe diameters of the pump discharge.

DIf you use a flexible connector from the pump to the piping system, the surge suppressor should be mounted to the pump discharge manifold, and the flexible connector should be attached to the surge suppressor tee and system piping.

DBecause pressure is equal in all directions, the surge suppressor can be installed in any position, but the vertical position shown in Fig. 2 is recommended for better draining. Fluids with high specific gravity or high viscosity, settling of heavy material, and possible air entrapment further limit the mounting positions other than those shown in Fig. 2.

NOTE: When you mount a plastic surge suppressor, do not overtighten by using a large pipe wrench near the threads of the fluid inlet. The housing may crack if tightened too much. Hand tightening is recommended.

Connecting Automatic Models

DConnect the 1/4-in air supply hose to the 1/4 npt connection on the top of the surge suppressor.

DThe air pressure to the surge suppressor must be greater than or equal to the pump discharge and/or system pressure. For equal air pressure, you can use a tee in the pump’s air supply line to run an air line to the surge suppressor.

DFor models with elastomer bladders, the tee must be located in the pump’s air supply line before any pump controller or instrumentation such as the filter, regulator, or pump control valve.

DFor models with PTFE bellows, the tee must be located in the pump’s air supply line after any pump controller or instrumentation such as the filter, regulator, or pump control valve.

Connecting Manual Models

DConnect the 1/4-in air supply hose to the brass one-way check valve on the top of the surge suppressor.

DThe air pressure to the surge suppressor must be greater than or equal to the pump discharge and/or system pressure. For equal air pressure, you can use a tee in the pump’s air supply line to run an air line to the surge suppressor.

DThe tee must be located in the pump’s air supply line before any pump controller or instrumentation such as the filter, regulator, or pump control valve.

6308703

Loading...

Loading...