Graco 244115, 244113, 244118, 244117 User Manual

INSTRUCTIONS |

309317 |

|

Rev. B |

This manual contains important warnings and information.

READ AND KEEP FOR REFERENCE.

INSTRUCTIONS

US Patent Pending

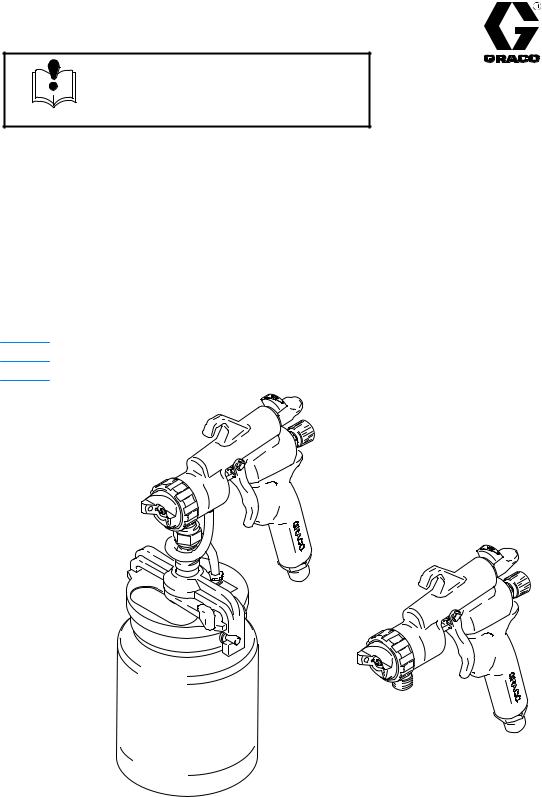

HVLP–Turbine Guns

10 psi (0.07 MPa, .7 bar) Maximum Inlet Air Pressure 50 psi (0.35 MPa, 3.5 bar) Maximum Inlet Fluid Pressure

Related Manuals

309205 – HVLP–Turbine Gun for maintenance and service instructions

309243 – HVLP Turbine

309244 – HVLP Compressor/Cart

T10746

Cup Feed |

Remote Pressure Feed |

|

|

||

Includes 1-quart (1 liter) cup |

Model 244115, without fluid set |

|

Model 244113, without fluid set |

||

Model 244118, with # 3 fluid set |

||

Model 244117, with # 3 fluid set |

||

|

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

ECOPYRIGHT 2001, GRACO INC. Graco Inc. is registered to I.S. EN ISO 9001

Table of Contents

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Identification . . . . . . . . . . . . . . . . . . . . . . . . 4

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Graco Phone Number . . . . . . . . . . . . . . . . . . . . NO TAG

Warning Symbol

WARNING

WARNING

This symbol alerts you to the possibility of serious injury or death if you do not follow instructions.

Caution Symbol

CAUTION

CAUTION

This symbol alerts you to the possibility of damage to or destruction of equipment if you do not follow instructions.

You will need:

Cleaning fluids: a compatible solvent; water–based paint also requires soap and water.

Suggested proper clothing:

• Safety glasses |

• Sturdy boots or shoes |

• Respirator |

• Gloves |

2 309317

Fire and explosion hazard: Solvent and paint fumes can ignite or explode.

DSprayers generate sparks. Keep sprayer at least 20 feet (6 m) from explosive vapors.

DUse in an extremely well ventilated area.

DEliminate all ignition sources; such as pilot lights,

cigarettes and static arcs from plastic drop cloths.

Do not plug or unplug power cords or turn lights on or off in spray area. DGround Sprayer, object being sprayed, paint and

solvent pails. DDo not use 1,1,1-trichloroethane, methylene chlo-

ride, other halogenated hydrocarbon solvents or fluids containing such solvents in pressurized aluminum equipment. Such use could result in a chemical reaction, with the possibility of explosion.

Equipment Misuse Hazard: Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

DBefore operating equipment, read all instruction manuals, tags, and labels.

DCheck equipment daily. Repair or replace worn or damaged parts immediately.

DDo not exceed maximum working pressure (MWPR) of the lowest–rated system component

DUse fluids and solvents that are compatible with the equipment wetted parts. See Specifications on page for this information.

DWear hearing protection when operating this equipment. DDo not “blow back” fluid; this is not an air spray system

DFollow Pressure Relief before cleaning, checking or servicing the equipment.

TOXIC FLUID HAZARD: Hazardous fluid or toxic fumes can cause serious injury or death if splashed in eyes or on skin, inhaled, or swallowed.

DKnow specific hazards of fluid you are using and take protective measures as

recommended by the fluid and solvent manufacturer.

309317 3

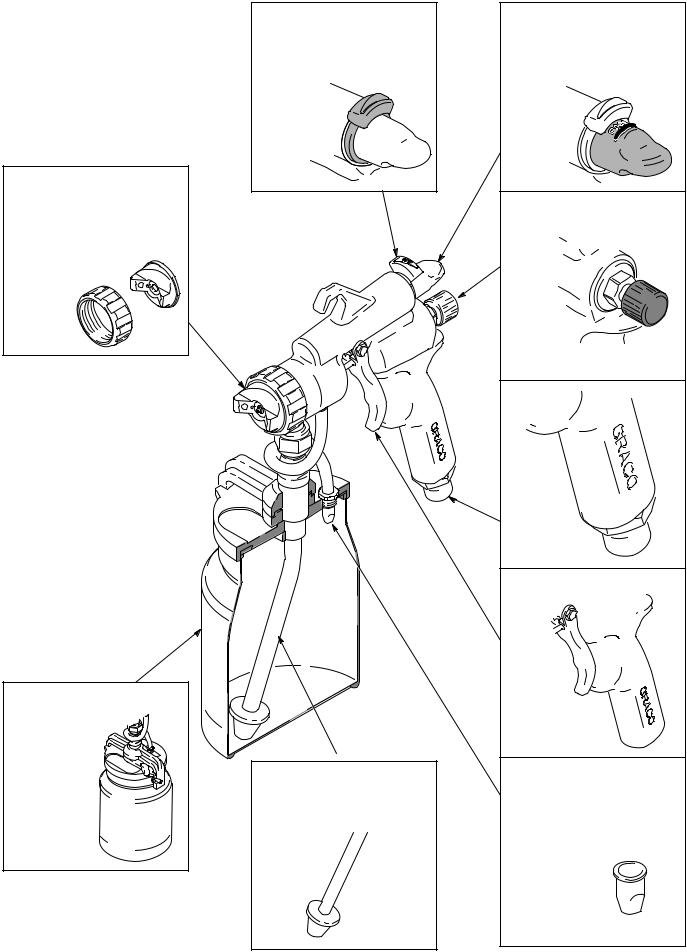

Component Identification

Air flow control – Adjusts TOTAL air flow to spray gun

Pattern Adjustment Knob – Adjusts pattern from fan to round

Air cap/retaining ring – Adjusts

fan direction

Fluid flow/Pattern size control – Adjusts fluid volume

Air inlet

EasyGlidet Trigger

Cup

Duckbill check valve

Swivel tube and strainer

4 309317

PRESSURE RELIEF – Follow this procedure when cleaning, repairing or shuting down sprayer

For Cup Guns

Follow these |

|

|

|

instructions whenever |

1. Turn off turbine. |

2. Unlatch cup |

|

you stop spraying. |

|||

|

|

For Pressure Feed Guns

Follow these instructions whenever you stop spraying.

1. Turn off air supply to the pot.

A  A

A

2. Open pressure relief (A) on |

2 quart |

pot until pressure is completely |

|

relieved. Close relief. |

|

8069A |

02882 |

TIP SELECTION

A Tip consists of a fluid nozzle, and fluid needle. Use the following chart for recommendations.

Fluid Set |

Tip Size |

Fluid Usage |

|

|

|

|

|

#2 |

0.8 mm |

Ink, dye and non–wiping stain. |

|

244123 |

(0.032 in) |

|

|

|

|

|

|

#3 |

1.3 mm |

Water base lacquer, urethane, varnish, stain, and automotive finish. |

|

244124 |

(0.051 in) |

|

|

|

|

|

|

#4 |

1.8 mm |

Lacquer, urethane, varnish, stain, primer, enamel and epoxy. |

|

(0.071 in) |

|

||

244125 |

|

||

|

|

|

|

|

|

|

|

#5 |

2.2 mm |

Lacquer, urethane, varnish, stain, primer, enamel, epoxy and |

|

244126 |

(0.087 in) |

higher output industrial finishes. |

|

|

|

|

|

#6 |

2.5 mm |

Latex, multi–spec, oil wall paint, industrial finishes, buty- |

|

244127 |

(0.098 in) |

rate, and nitrate dope. |

|

|

|

|

|

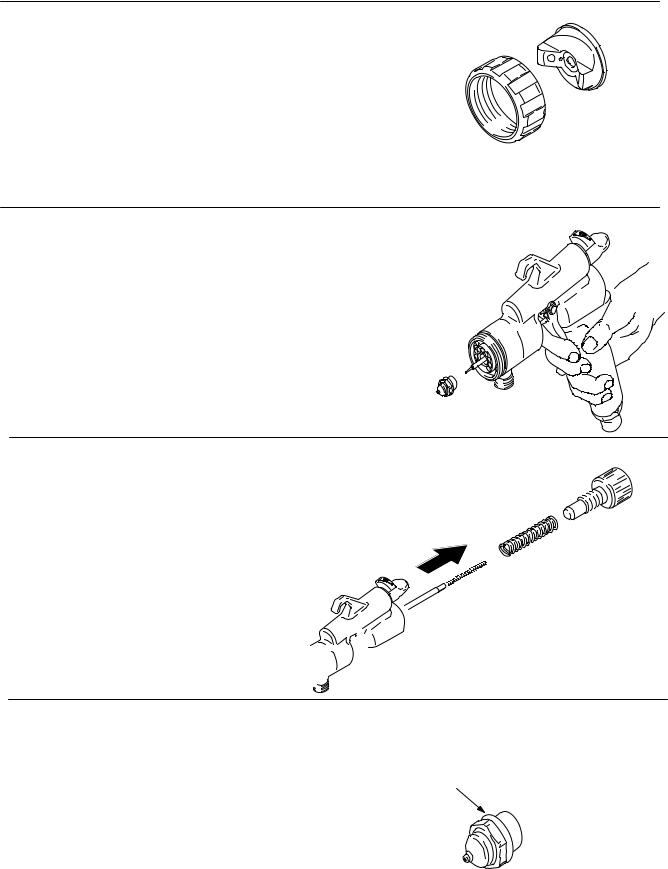

Installing the Fluid Set

CAUTION

CAUTION

Trigger the gun whenever you tighten or remove the nozzle. This keeps the needle seat away from the nozzle seating surface and prevents the seat from being scratched.

309317 5

1.Use your hand to loosen and remove the air cap retaining ring and air cap housing.

2.Test spray pattern and atomization while holding gun about 6 to inches (150 to 200 mm) from test piece.

.

3. While triggering the gun, use your hand to loosen and remove the nozzle.

4. Use your hand to loosen and remove the fluid knob assembly and compression ring from the back of the gun and remove the old needle.

5. Insert the needle assembly in the back of the gun. Reassemble nozzle, air cap housing and air cap retaining ring. Hand tighten.

A

Note: Nozzle should always have an o–ring (A).

6 309317

Loading...

Loading...