Graco 3900, 5900 User Manual

INSTRUCTIONS-PARTS LIST

LineLazert III 3900 and 5900

Airless Paint Stripers

3300 psi (228 bar, 22.8 MPa) Maximum Working Pressure

309414J

LineLazer III 3900

Model |

Series |

Description |

|

|

|

233688 |

A |

Striper with one Gun |

|

|

|

233689 |

A |

Striper with Second Gun Kit |

|

|

|

233664 |

A |

International Striper with one Gun |

|

|

|

233694 |

A |

International Striper with 2nd Gun Kit |

|

|

|

LineLazer III 5900

Model |

Series |

Description |

|

|

|

233690 |

A |

Striper with one Gun |

|

|

|

233691 |

A |

Striper with Second Gun Kit |

|

|

|

233627 |

A |

International Striper with one Gun |

|

|

|

233695 |

A |

International Striper with 2nd Gun Kit |

|

|

|

Important Safety Instructions

Read all warnings and instructions in this manual.

Save these instructions.

ENG

233688

ti1935a

Related Manuals

Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . 309413 Displacement Pump . . . . . . . . . . . . . . . . . 309277 Spray Gun . . . . . . . . . . . . . . . . . . . . . . . . . 309093 Spray Tip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . * PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . 309459 Drain Valve Kit . . . . . . . . . . . . . . . . . . . . . . 308961 Clutch Replacement Kit . . . . . . . . . . . . . . 309890 * for spray tip selection, see page 4

Table of Contents

Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . |

. . 2 |

Displacement Pump . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

Spray Tip Selection Table . . . . . . . . . . . . . . . . . . . . . . . |

. 3 |

Pinion and Drive Housing Assemblies . . . . . . . . . . |

16 |

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 4 |

Parts |

|

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 5 |

LineLazer III 3900/5900 . . . . . . . . . . . . . . . . . . . . . . |

18 |

Repair |

|

Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

Bearing Housing & Connecting Rod . . . . . . . . . . . . |

. 8 |

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

Drive Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 9 |

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

Graco Phone Number . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

Graco Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN |

55440-1441 |

|

|

ECOPYRIGHT 2002, GRACO INC. |

|

|

|

Graco Inc. is registered to I.S. EN ISO 9001

Warnings and Cautions

Warning Symbol

WARNING

WARNING

This symbol alerts you to the possibility of serious injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

CAUTION

This symbol alerts you to the possibility of damage to or destruction of equipment if you do not follow the instructions.

WARNING

WARNING

Fire and explosion hazard: Solvent and paint fumes can ignite or explode.

To help prevent a fire and explosion:

DUse only in an extremely well ventilated area.

DEliminate all ignition sources; such as pilot lights, cigarettes and plastic drop cloths (static arc hazard). Do not plug or unplug power cords or turn lights on or off in spray area.

DGround Sprayer, object being sprayed, paint and solvent pails. DHold gun firmly to side of grounded pail when triggering into pail. DUse only conductive airless paint hose.

DDo not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such solvents in pressurized aluminum equipment. Such use could result in a chemical reaction, with the possibility of explosion.

DDo not fill fuel tank while engine is running or hot. DDo not flush with gasoline.

Fluid injection and high pressure hazard: High pressure spray or leaks can inject fluid into the body.

To help prevent injection, always:

DEngage trigger safety latch when not spraying. DKeep clear of nozzle and leaks.

DNever spray without a tip guard.

DDo PRESSURE RELIEF if you stop spraying or begin servicing sprayer.

DDo not use components rated less than sprayer Maximum Working Pressure.

DNever allow children to use this unit.

If high pressure fluid pierces your skin, the injury might look like “just a cut”. But it is a serious wound! Get immediate surgical treatment.

2 309414

Spray Tip Selection Table

LineLazer Tip Selection Guide. Sprayer is supplied with tip LL5319. For additional applications, use the tip selection table as follows:

Note: the last three digits (LL5319) of the tip part number identifies the line width and tip orifice (opening).

For example: the line width for tip LL5319 is 4 in. as shown in the table below. The tip orifice for tip LL5319 is .019 in.

LineLazer Tip Selection Table |

|

|

||

|

|

|

Used For |

|

Tip Size |

Line Width |

|

||

|

|

Sport court -- light film build |

||

221203* |

2 inches |

|||

|

|

Sport court -- heavy film build |

||

LL5213* |

2 inches |

|||

|

|

Alkyd paints only -- light film build |

||

LL5215* |

4 inches |

|||

|

|

Alkyd paints only -- medium film build |

||

LL5217 |

4 inches |

|||

|

|

Alkyd paints only -- heavy film build |

||

LL5219 |

4 inches |

|||

|

|

Most traffic paints -- light film build |

||

LL5315 |

4 inches |

|||

|

|

Most traffic paints -- medium film build |

||

LL5317 |

4 inches |

|||

|

|

Most traffic paints -- medium film build |

||

LL5319 |

4 inches |

|||

|

|

Most traffic paints -- heavy film build |

||

LL5321 |

4 inches |

|||

|

|

Most traffic paints -- heavy film build |

||

LL5323 |

4 inches |

|||

|

|

Most traffic paints -- heavy film build |

||

LL5327† |

4 inches |

|||

|

|

|

All paints and high solids traffic paints -- light film build |

|

LL5417# |

4 |

-- 8 inches |

||

|

|

|

All paints and high solids |

traffic paints -- medium film build |

LL5419# |

4 |

-- 8 inches |

||

|

|

|

All paints and high solids |

traffic paints -- heavy film build |

LL5421# |

4 |

-- 8 inches |

||

|

|

|

All traffic paints -- light film build |

|

LL5621 |

8 |

-- 12 inches |

||

|

|

|

All traffic paints -- medium film build |

|

LL5623 |

8 |

-- 12 inches |

||

|

|

|

All traffic paints -- medium film build |

|

LL5625 |

8 |

-- 12 inches |

||

|

|

|

All traffic paints -- heavy film build |

|

LL5627 |

8 |

-- 12 inches |

||

* May require 100 mesh filter to minimize tip plugging.

† Best for use with LineDriver.

# Best for cold weather applications.

How to Maximize Line Quality and Reduce Tip Wear. Observe the following suggestions to increase line quality and minimize sprayer tip wear.

1.Select a larger tip orifice and run the sprayer at a reduced operating pressure.

2.Running larger tip sizes (example: use tip LL5321 @ 2000 psi instead of LL5317 @ 3300 psi) will significantly increase tip life and reduce tip plugging. It will also produce a more uniform film build across the line.

309414 3

Maintenance

WARNING

WARNING

INJECTION HAZARD

The system pressure must be manually relieved to prevent the system from starting or spraying accidentally. Fluid

under high pressure can be injected through the skin and cause serious injury. To reduce the risk of an injury from injection, splashing fluid, or moving parts, follow the Pressure Relief Procedure whenever you:

D are instructed to relieve the pressure, D stop spraying,

D check or service any of the system equipment, D or install or clean the spray tip.

Pressure Relief Procedure

1.Lock gun trigger safety.

2.Turn engine ON/OFF switch to OFF.

3.Move pump switch to OFF and turn pressure control knob fully counterclockwise.

4.Unlock trigger safety. Hold metal part of gun firmly to side of grounded metal pail, and trigger gun to relieve pressure.

5.Lock gun trigger safety.

6.Open pressure drain valve. Leave valve open until ready to spray again.

If you suspect that the spray tip or hose is completely clogged, or that pressure has not been fully relieved after following the steps above, VERY SLOWLY loosen tip guard retaining nut or hose end coupling to relieve pressure gradually, then loosen completely. Now clear tip or hose.

CAUTION

CAUTION

For detailed engine maintenance and specifications, refer to separate Honda Engines Owner’s Manual, supplied.

DAILY: Check engine oil level and fill as necessary.

DAILY: Check hose for wear and damage.

DAILY: Check gun safety for proper operation.

DAILY: Check pressure drain valve for proper operation.

DAILY: Check and fill the gas tank.

AFTER THE FIRST 20 HOURS OF OPERATION:

Drain engine oil and refill with clean oil. Reference Honda Engines Owner’s Manual for correct oil viscosity.

WEEKLY: Remove air filter cover and clean element. Replace element, if necessary. If operating in an unusually dusty environment: check filter daily and replace, if necessary.

Repack connecting rod (22) top needle bearing after every pump change.

Replacement elements can be purchased from your local HONDA dealer.

WEEKLY: Check level of TSL in displacement pump packing nut. Fill nut, if necessary. Keep TSL in nut to help prevent fluid buildup on piston rod and premature wear of packings.

AFTER EACH 100 HOURS OF OPERATION:

Change engine oil. Reference Honda Engines Owner’s Manual for correct oil viscosity.

SPARK PLUG: Use only BPR6ES (NGK) or W20EPR--U (NIPPONDENSO) plug. Gap plug to 0.028 to 0.031 in. (0.7 to 0.8 mm). Use spark plug wrench when installing and removing plug.

Caster Wheel

(See letter call-outs in Parts drawing on page 22)

1.Once each year, tighten nut (164m) until spring washer bottoms out. Then back off the nut 1/2 to 3/4 turn.

2.Once each year, tighten nut (62) until it begins to compress spring washer. Then tighten the nut an additional 1/4 turn.

3.Once each month, grease the wheel bearing (F).

4.Check pin (164e) for wear. If pin is worn out, there will be play in the caster wheel. Reverse or replace the pin as needed.

5.Check caster wheel alignment as necessary.

To align: loosen bolt (164t), align wheel and tighten bolt (164t).

4 309414

Troubleshooting

Relieve pressure; page 4.

PROBLEM |

CAUSE |

SOLUTION |

|

|

|

E=XX is displayed |

Fault condition exists |

Determine fault correction from table, page 14. |

|

|

|

Engine won’t start |

Engine switch is OFF |

Turn engine switch ON |

|

|

|

|

Engine is out of gas |

Refill gas tank. Honda Engines Owner’s Manual. |

|

|

|

|

Engine oil level is low |

Try to start engine. Replenish oil, if necessary. |

|

|

Honda Engines Owner’s Manual. |

|

|

|

|

Spark plug cable is disconnected or damaged |

Connect spark plug cable or replace spark |

|

|

plug |

|

|

|

|

Cold engine |

Use choke |

|

|

|

|

Fuel shutoff lever is OFF |

Move lever to ON position |

|

|

|

|

Oil is seeping into combustion chamber |

Remove spark plug. Pull starter 3 to 4 times. |

|

|

Clean or replace spark plug. Start engine. |

|

|

Keep sprayer upright to avoid oil seepage. |

|

|

|

Engine operates, but dis- |

Error code displayed? |

Reference pressure control repair. Page 13. |

placement pump does not |

|

|

operate |

|

|

|

|

|

|

Pump switch is OFF |

Turn pump switch ON. |

|

|

|

|

Pressure setting is too low |

Turn pressure adjusting knob clockwise to |

|

|

increase pressure. |

|

|

|

|

Fluid filter (318) is dirty |

Clean filter. Page 24. |

|

|

|

|

Tip or tip filter is clogged |

Clean tip or tip filter. Manual 309091. |

|

|

|

|

Displacement pump piston rod is stuck due to |

Repair pump. Manual 309277. |

|

dried paint |

|

|

|

|

|

Connecting rod is worn or damaged |

Replace connecting rod. Page 8. |

|

|

|

|

Drive housing is worn or damaged |

Replace drive housing. Page 9. |

|

|

|

|

Electrical power is not energizing clutch field |

Check wiring connections. Page 10. |

|

|

Reference pressure control repair. Page 13. |

|

|

Reference wiring diagram. Page 28. |

|

|

With pump switch ON and pressure turned to |

|

|

MAXIMUM, use a test light to check for power |

|

|

between clutch test points on control board. |

|

|

Remove 7--pin connector from control board |

|

|

and measure resistance across clutch coil. At |

|

|

70_ F, the resistance must be between 1.2 |

|

|

±0.2Ω (LineLazer III 3900); 1.7 ±0.2Ω (Line- |

|

|

Lazer III 5900); if not, replace pinion housing. |

|

|

Have pressure control checked by authorized |

|

|

Graco dealer. |

|

|

|

|

Clutch is worn, damaged, or incorrectly |

Replace clutch. Manual 309890. |

|

positioned |

|

|

|

|

|

Pinion assembly is worn or damaged |

Repair or replace pinion assembly. Manual |

|

|

309890. |

|

|

|

309414 5

Troubleshooting

PROBLEM |

CAUSE |

SOLUTION |

|

|

|

|

|

Pump output is low |

Strainer (31) is clogged |

Clean strainer. Sprayer 233716 strainer is for |

|

|

|

|

use in paint only. |

|

|

|

|

|

|

Piston ball (206) is not seating |

Service piston ball. Manual 309277. |

|

|

|

|

|

|

Piston packings are worn or damaged |

Replace packings. Manual 309277. |

|

|

|

|

|

|

O-ring (227) in pump is worn or damaged |

Replace o-ring. Manual 309277. |

|

|

|

|

|

|

Intake valve ball is not seating properly |

Clean intake valve. Manual 309277. |

|

|

|

|

|

|

Intake valve ball is packed with material |

Clean intake valve. Manual 309277. Do not |

|

|

|

leave 233716 sprayer under pressure for more |

|

|

|

than 5 minutes when spraying texture and not |

|

|

|

actively spraying. |

|

|

|

|

|

|

Engine speed is too low |

Increase throttle setting. Manual 309413. |

|

|

|

|

|

|

Clutch is worn or damaged |

Replace clutch. Manual 309890. |

|

|

|

|

|

|

Pressure setting is too low |

Increase pressure. Manual 309413. |

|

|

|

|

|

|

Fluid filter (318), tip filter or tip is clogged or |

Clean filter. Manual 309413 or 309093. |

|

|

dirty |

|

|

|

|

|

|

|

Large pressure drop in hose with heavy |

Use larger diameter hose and/or reduce overall |

|

|

materials |

length of hose. Use of more than 100 ft of 1/4 |

|

|

|

in. hose significantly reduces performance of |

|

|

|

sprayer. Use 3/8 in. hose for optimum perfor- |

|

|

|

mance (50 ft minimum). |

|

|

|

|

Excessive paint leakage into |

Throat packing nut is loose |

Remove throat packing nut spacer. Tighten |

|

throat packing nut |

|

throat packing nut just enough to stop leakage. |

|

|

|

|

|

|

|

Throat packings are worn or damaged |

Replace packings. Manual 309277. |

|

|

|

|

|

|

Displacement rod is worn or damaged |

Replace rod. Manual 309277. |

|

|

|

|

Fluid is spitting from gun |

Air in pump or hose |

Check and tighten all fluid connections. |

|

|

|

|

Reprime pump. Manual 309413. |

|

|

|

|

|

|

Tip is partially clogged |

Clear tip. Manual 309093. |

|

|

|

|

|

|

Fluid supply is low or empty |

Refill fluid supply. Prime pump. Manual |

|

|

|

309413. Check fluid supply often to prevent |

|

|

|

running pump dry. |

|

|

|

|

Pump is difficult to prime |

Air in pump or hose |

Check and tighten all fluid connections. |

|

|

|

|

Reduce engine speed and cycle pump as |

|

|

|

slowly as possible during priming. |

|

|

|

|

|

|

Intake valve is leaking |

Clean intake valve. Be sure ball seat is not |

|

|

|

nicked or worn and that ball seats well. Reas- |

|

|

|

semble valve. |

|

|

|

|

|

|

Pump packings are worn |

Replace pump packings. Manual 309277. |

|

|

|

|

|

|

Paint is too thick |

Thin the paint according to the supplier’s |

|

|

|

recommendations |

|

|

|

|

|

|

Engine speed is too high |

Decrease throttle setting before priming pump. |

|

|

|

Manual 309413. |

|

|

|

|

Clutch squeaks each time |

Clutch surfaces are not matched to each other |

Clutch surfaces need to wear into each other. |

|

clutch engages |

when new and may cause noise |

Noise will dissipate after a day of run time. |

|

|

|

|

|

High engine speed at no |

Misadjusted throttle setting |

Reset throttle to 3700 engine rpm at no load |

|

load |

|

|

|

|

Worn engine governor |

Replace or service engine governor |

|

|

|

||

|

|

|

|

6 |

309414 |

|

|

Troubleshooting

PROBLEM |

CAUSE |

SOLUTION |

|

|

|

|

|

Gallon counter not working |

Broken or disconnected wire |

Check wires and connections. Replace |

|

|

|

broken wires. |

|

|

|

|

|

|

Bad sensor |

Replace sensor |

|

|

|

|

|

|

Missing magnet |

Replace magnet. Locate in correct spot. |

|

|

|

|

|

Sprayer operates, but display does not |

Bad connection between control board |

Remove display and reconnect |

|

|

and display |

|

|

|

|

|

|

|

Display damaged |

Replace display |

|

|

|

|

|

Distance counter not operating properly |

Trigger sensor not set correctly |

See “Spray icon does not show on dis- |

|

|

|

play when fluid is sprayed” |

|

|

|

|

|

|

Bad wiring connections |

Check connector, and reconnect |

|

|

|

|

|

|

Distance sensor not spaced correctly |

Adjust space between sensor and gear |

|

|

from gear |

to .050 --/+ .020” |

|

|

|

|

|

|

Distance and gear not aligned |

Remove tire, and press in or pull out |

|

|

|

gear to align sensor and gear. |

|

|

|

|

|

|

Gear teeth missing or damaged. |

Replace distance gear/wheel |

|

|

|

|

|

|

Wire cracked or broken |

Replace sensor |

|

|

|

|

|

Mils not calculating |

Distance sensor |

See “Distance counter not operating |

|

|

|

properly” |

|

|

|

|

|

|

Trigger sensor |

See “Spray icon does not show on dis- |

|

|

|

play when fluid is sprayed” |

|

|

|

|

|

|

Gallon counter |

See “Gallon counter not working” |

|

|

|

|

|

|

Bad or damaged control board |

Replace control board |

|

|

|

|

|

Fluid spray starts after spray icon is |

Interrupter (213) is improperly positioned |

Turn screw (215) counterclockwise until |

|

shown on display |

|

spray icon synchronizes with fluid spray |

|

|

|

|

|

Fluid spray starts before spray icon is |

Interrupter (213) is improperly positioned |

Turn screw (215) clockwise until spray |

|

shown on display |

|

icon is synchronized with fluid spray |

|

|

|

|

|

Spray icon does not show on display |

Loose connector |

Check that 5-pin connector and reed |

|

when fluid is sprayed |

|

switch are properly connected |

|

|

|

|

|

|

Interrupter (213) is improperly positioned |

Turn screw (215) counterclockwise until |

|

|

|

spray icon synchronizes with fluid spray |

|

|

|

|

|

|

Reed switch assembly (207) is damaged |

Replace reed switch assembly (207) |

|

|

|

|

|

|

Magnet on assembly (207) is missing |

Replace reed switch assembly (207) |

|

|

|

|

|

|

A connector on wiring harness (58) or on |

Disconnect reed switch and 5-pin con- |

|

|

reed switch (207) is damaged |

nector from back of control board. |

|

|

|

Check continuity between pin 1 on 2-pin |

|

|

|

connector and pin 1 on 5-pin connector. |

|

|

|

Check continuity between pin 2 on 2-pin |

|

|

|

connector and pin 4 on 5-pin connector. |

|

|

|

If there is no continuity in either case, |

|

|

|

replace wiring harness (58). |

|

|

|

If there is continuity in both cases re- |

|

|

|

place reed switch assembly (207). |

|

|

|

|

|

|

Cut or sliced wire |

Replace wiring harness (58) |

|

|

|

|

|

|

Control board is damaged |

Replace control board |

|

|

|

|

|

|

Display is damaged |

Replace display |

|

|

|

|

|

Spray icon is always shown on display |

Interrupter (213) is improperly positioned |

Turn screw (215) clockwise until spray icon |

|

|

|

is synchronized with fluid spray |

|

|

|

|

|

|

Reed switch assembly (207) is damaged |

Replace reed switch assembly (207) |

|

|

|

|

|

|

|

309414 |

7 |

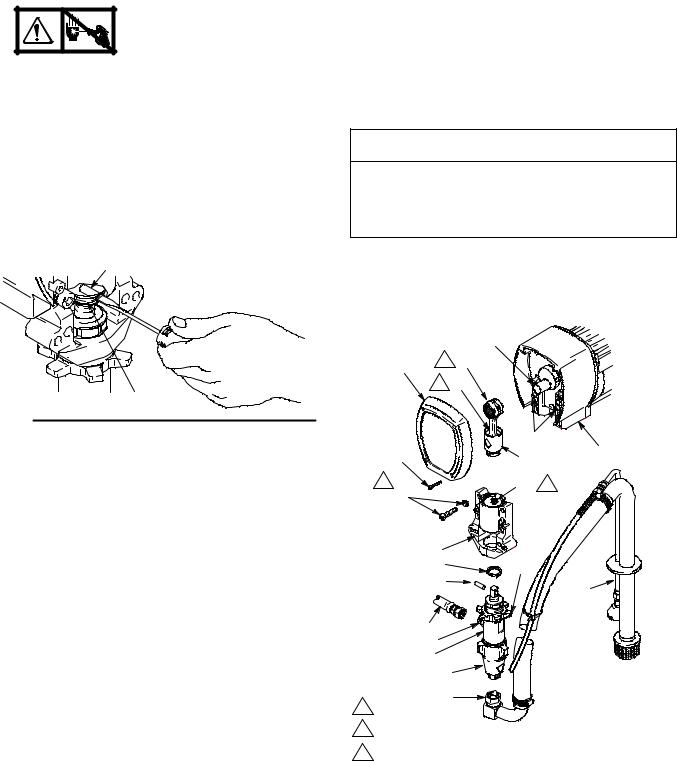

Bearing Housing and Connecting Rod

Removal |

|

1. |

Relieve pressure; page 4. |

|

2.Fig. 2. Remove screws (27) and front cover (92).

3.Unscrew suction tube (12) from pump, hold wrench on pump intake valve (A) to keep pump from loosening.

4.Disconnect pump outlet hose (61) from displacement pump outlet nipple (6).

5.Fig. 1. Use screwdriver to push up retaining spring (95) at top of pump. Push out pin (96).

96

Fig. 1 |

95 |

7675B |

6.Fig. 2. Loosen retaining nut (97). Unscrew and remove displacement pump (119).

7.Remove four screws (26) and lockwashers (25) from bearing housing (94).

8.Pull connecting rod (83) and lightly tap lower rear of bearing housing (94) with plastic mallet to loosen from drive housing (101). Pull bearing housing and connecting rod assembly (83) off drive housing.

9.Inspect crank (B) for excessive wear and replace parts as needed.

Installation

1.Evenly lubricate inside of bronze bearing (C) in bearing housing (94) with high-quality motor oil.

Liberally pack top roller bearing (E), lower bearing

(D) inside connecting rod assembly (83) with bearing grease.

2.Assemble connecting rod (83) and bearing housing (94).

3.Clean mating surfaces of bearing and drive housings.

4.Align connecting rod with crank (B) and carefully align locating pins (F) in drive housing (101) with holes in bearing housing (94). Push bearing housing onto drive housing or tap into place with plastic mallet.

CAUTION

CAUTION

DO NOT use bearing housing screws (26) to align or seat bearing housing with drive housing. Align these parts with locating pins (F), to avoid premature bearing wear.

5.Install screws (26) and lockwashers (25) on bearing housing. Torque evenly to note 3 value in Fig. 2.

6.Refer to Displacement Pump, Installation, page 15.

B

92 |

2 |

E |

|

|

|

|

|

|

2 |

D |

|

27 |

|

F |

101 |

|

83 |

||

|

|

||

|

|

|

|

3 |

|

C 1 |

|

25, 26 |

|

|

|

|

94 |

|

|

|

95 |

97 |

|

|

96 |

|

12g |

|

|

|

61

6

119 A

1 Oil |

12 |

|

ti1965a

2Pack with bearing grease 114819

3LineLazer III 3900: Torque to 200 in-lb (22.6 N¡m) LineLazer III 5900: Torque to 25 ft-lb (34 N¡m)

Fig. 2 |

Model 233701 shown |

|

8 309414

Drive Housing

Removal |

|

1. |

Relieve pressure; page 4. |

|

2.Fig. 3. Remove bearing housing. Do 1. through 8. of Bearing Housing and Connecting Rod procedure on page 8.

3.Fig. 3. Disconnect gallon counter sensor at (A).

Cut tie wrap holding gallon counting sensor wire to clutch wire.

4.Fig. 3. Remove two screws (145) and lockwashers (122).

Installation

1.Liberally apply bearing grease (supplied with replacement gear cluster) to gear cluster (99) and to areas called out by note 3. Use full 0.62 pint (0.29 liter) of grease for LineLazer III 3900 and 0.68 pint (0.32 liter) of grease for LineLazer III 5900.

2.Place bronze colored washer (101g) on shaft protruding from large shaft of drive housing (101). Place silver colored washer (101h) on pinion housing. Align gears and push new drive housing straight onto pinion housing and locating pins (B).

3.Install four screws (102) and lockwashers (122) from pinion housing (183).

4.Install two screws (145) and lockwashers (122).

5.Remove four screws (102) and lockwashers (122) from pinion housing (183).

6.Lightly tap around drive housing (101) to loosen drive housing. Pull drive housing straight off pinion housing. Be prepared to support gear cluster (99), which may also come out.

2 102

122 B

183

5.Fig. 2. Connect gallon counter sensor at (A).

Secure gallon counting sensor wire to clutch wire with a tie wrap.

6.Fig. 3. Install bearing housing. Do 1. through 6. of

Bearing Housing and Connecting Rod procedure on page 8.

|

|

B |

1 |

LineLazer III 3900 only |

1 98 98 |

2 |

Torque to 125 in-lb -- LineLazer III 390099 |

|

|

Torque to 200 in-lb -- LineLazer III 5900 |

|

3 |

Apply remaining grease to these areas |

|

Fig. 3

3

101h

101g

101

250

145 2

100 98

TI0178A

309414 9

Loading...

Loading...