Graco 233711, 233709, 233715, 233714, 233710 User Manual

...

INSTRUCTIONS-PARTS LIST

This manual contains important |

|

warnings and information. |

|

READ AND KEEP FOR REFERENCE. |

|

INSTRUCTIONS |

|

GMaxt 5900 Convertible |

|

Airless Paint Sprayers |

309411E |

|

–For Portable Airless Spraying of Architectural Coatings and Paints –

5.5 HORSEPOWER, GASOLINE POWERED

3300 psi (228 bar, 22.8 MPa) Maximum Working Pressure

Model |

Series |

Description |

|

|

233709 |

A |

Sprayer, gas powered |

|

|

233710 |

A |

Sprayer, gas powered, with RACR X tip, |

|

|

|

|

gun and hose |

|

|

233711 |

A |

Sprayer, gas powered, with electric |

|

|

|

|

motor kit |

|

|

233712 |

A |

Same as 233711 except with ETL |

|

|

|

|

approval to CSA and UL standards |

|

|

233713 |

A |

Sprayer, gas powered, with Lo-Boy |

|

|

|

|

suction set kit |

|

233709 |

|

|

|

|

|

233714 |

A |

Sprayer, gas powered, with RAC X tip, |

|

ti1852a |

|

|

gun and hose and Lo-Boy suction set kit |

|

|

233715 |

A |

Sprayer, gas powered, with Lo-Boy |

|

|

|

|

suction set kit and electric motor kit |

Related Manuals |

|

|

|

|

|

|

|

|

|

Operator . . . . . . . . . . . . . . . . . . . . |

. . . . . . . 309410 |

|

|

|

Displacement Pump . . . . . . . . . . |

. . . . . . . 309277 |

|

|

|

Spray Gun . . . . . . . . . . . . . . . . . . . |

. . . . . . 309639 |

|

|

|

Spray Tip . . . . . . . . . . . . . . . . . . . . . |

. . . . . . 309640 |

|

|

|

AutoClean Kit . . . . . . . . . . . . . . . . . |

. . . . . . 309450 |

|

|

|

PC Board . . . . . . . . . . . . . . . . . . . . |

. . . . . . 309459 |

|

|

|

Electric Motor Kit . . . . . . . . . . . . . . |

. . . . . . 309469 |

|

|

|

Drain Valve Kit . . . . . . . . . . . . . . . . |

. . . . . . 308961 |

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440–1441

COPYRIGHT 2002, GRACO INC. Graco Inc. is registered to I.S. EN ISO 9001

Table of Contents

Component Identification and Function . . . . . . . . . . . |

. 5 |

Parts |

|

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

Basic Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

Pinion Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

Repair |

|

Pressure Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

22 |

Bearing Housing and Connecting Rod . . . . . . . . . . . |

9 |

Wiring Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

Drive Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

Clutch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

Pinion Assembly/Rotor/Field/Shaft/Clutch/Pulley . 11 |

Complete Sprayer . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

|

ON/OFF Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

13 |

Lo-Boy Suction Set Kit . . . . . . . . . . . . . . . . . . . . . . . |

25 |

Pressure Control Repair . . . . . . . . . . . . . . . . . . . . . . |

14 |

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

Displacement Pump Repair . . . . . . . . . . . . . . . . . . . |

16 |

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

|

|

Graco Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

26 |

Warnings and Cautions

Warning Symbol |

|

Caution Symbol |

|

|

|

|

|

|

WARNING |

|

CAUTION |

This symbol alerts you to the possibility of serious injury or death if you do not follow the instructions.

This symbol alerts you to the possibility of damage to or destruction of equipment if you do not follow the instructions.

The wallet-sized warning card provided with this pole gun should be kept with the operator at all times. The card contains important treatment information should a fluid injection injury occur. Additional cards are available at no charge from Graco Inc.

2 309411

WARNING

WARNING

SKIN INJECTION HAZARD

Spray from the spray tip, hose leaks or ruptured components can inject fluid into your body and cause extremely serious injury, including the need for amputation. Splashing fluid in the eyes or on the skin can also cause can also cause serious injury.

DFluid injected into the skin might look like just a cut, but it is a serious injury. Get immediate surgical treatment!

DDo not point the spray tip at anyone or any part of the body.

DDo not put hand or fingers over the spray tip, and do not stop or deflect fluid leaks with your hand, body, glove or rag.

DDo not “blow back” fluid; this is not an air spray system.

DAlways have the tip guard and the trigger guard on the in-line valve when spraying.

DBe sure the trigger safety lever operates before operating the in-line valve.

DLock the trigger safety lever when you stop spraying.

DFollow the Pressure Relief Procedure on page 6 when you are instructed to relieve pressure; stop spraying; check, clean, or service any system equipment; or install or change spray tips.

DTighten all fluid connections before each use.

DCheck the hoses, tubes and couplings daily. Replace worn or damaged parts immediately. Permanently coupled hoses cannot be repaired.

DHandle and route hoses and tubes carefully. Keep hoses and tubes away from moving parts and hot surfaces. Do not use the hoses to pull equipment. Do not expose Graco hoses to temperatures above 150_F (65_C) or below –40_F (–40_C).

TOXIC FLUID HAZARD

Hazardous fluids or toxic fumes can cause a serious injury or death if the fluid is swallowed or splashed in the eyes or on the skin or if the fumes are inhaled.

DKnow the specific hazards of the fluid you are using.

DStore hazardous fluid in an approved container. Dispose hazardous fluid according to all local, state and national guidelines.

DDress appropriately for your application. Wear protective eyewear, noise protection for the ears, a personal respirator, gloves, and clothing.

RECOIL HAZARD

Due to the high pressure fluid emitted, a strong recoil action may occur when you trigger the pole gun. If you are unprepared, your hand could be forced back toward your body or you could lose your balance and fall, resulting in serious injury.

309411 3

WARNING

WARNING

FIRE AND EXPLOSION HAZARD

Improper grounding, poor air ventilation, open flames, or sparks can cause a hazardous condition and result in fire or explosion and serious injury.

DGround the equipment and the object being sprayed.

DProvide fresh air ventilation to avoid the buildup of flammable fumes from solvent or the fluid being sprayed.

DExtinguish all the open flames or pilot lights in the spray area.

DElectrically disconnect all the equipment in the spray area.

DKeep the spray area free of debris, including solvent, rags, and gasoline.

DDo not turn on or off any light switch in the spray area while operating or if fumes are present.

DDo not smoke in the spray area.

DDo not operate a gasoline engine in the spray area.

DIf there is any static sparking while using the equipment, stop spraying immediately. Identify and correct the problem.

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture, malfunction, or start unexpectedly and result INSTRUCTIONS in serious injury.

DThis equipment is for professional use only.

DRead all instruction manuals, tags, and labels before operating the equipment.

DUse the equipment only for its intended purpose. If you are uncertain about the usage, call your distributor.

DDo not alter or modify this equipment. Use only genuine Graco parts and accessories.

DCheck the equipment daily. Repair or replace worn or damaged parts immediately.

DDo not exceed the maximum working pressure of the lowest rated system component. This equipment has a 3600 psi (25 MPa, 248 bar) maximum working pressure.

DRoute the hoses away from the traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose Graco hoses to temperatures above 150_F (65_C) or below –40_F (–40_C).

DDo not use the hoses to pull the equipment.

DUse fluids or solvents that are compatible with the equipment wetted parts. See the Technical Data section of all the equipment manuals. Read the fluid and solvent manufacturer’s warnings.

DFluid hoses must have spring guards on both ends to protect them from rupture caused by kinks or bends near the couplings.

DComply with all applicable local, state and national fire, electrical and other safety regulations.

DWear hearing protection when operating this equipment.

HAZARD OF USING FLUIDS CONTAINING HALOGENATED HYDROCARBONS

Never use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids containing such solvents in this equipment. Such use could result in a serious chemical reaction, with the possibility of explosion, which could cause death, serious injury and/or substantial property damage.

Consult your fluid suppliers to ensure that the fluids being used are compatible with aluminum and zinc parts.

4 309411

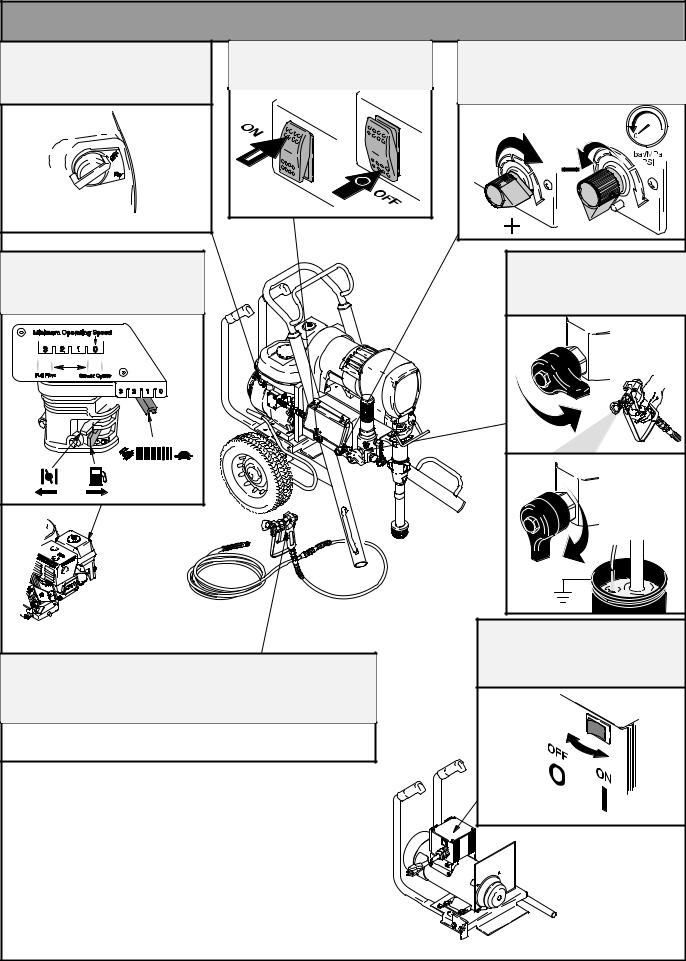

Component Identification and Function |

|

|

Pump On/Off Switch |

Pressure Control |

|

Engine On/Off Switch |

|

|

Engine Controls |

Prime/Drain Valve |

|

ti1852a |

|

|

|

Motor On/Off Switch |

|

Spray Gun Trigger Lock |

|

|

Reference your Spray Gun Manual |

|

|

|

ti1854a |

|

|

309411 |

5 |

Maintenance

WARNING

WARNING

INJECTION HAZARD

System pressure must be manually relieved to prevent system from starting or spraying accidentally. Fluid under high

pressure can be injected through skin and cause serious injury. To reduce risk of injury from injection, splashing fluid, or moving parts, follow Pressure Relief Procedure whenever you:

Dare instructed to relieve pressure,

Dstop spraying,

Dcheck or service any system equipment,

Dor install or clean spray tip.

Pressure Relief Procedure

1.Lock gun safety latch.

2.Turn engine or electric motor ON/OFF switch to OFF.

3.Unplug power supply cord (electric motor).

4.Move pressure control switch to OFF and turn pressure control knob fully counterclockwise.

5.Rotate RAC 5 tip, if used, to reverse position.

6.Unlock gun safety latch. Hold metal part of gun firmly to grounded metal pail. Trigger gun to relieve pressure.

7.Lock gun safety latch.

8.Open pressure drain valve. Leave pressure drain valve open until ready to spray again.

If suspected that spray tip or hose is completely clogged, or that pressure has not been fully relieved after following steps above, VERY SLOWLY loosen tip guard retaining nut or hose end coupling to relieve pressure gradually, then loosen completely. Now clear tip or hose obstruction.

CAUTION

CAUTION

For detailed engine maintenance and specifications, refer to separate engine manual, supplied.

DAILY: Check engine oil level and fill as necessary. Manual 309410.

DAILY: Check that V-belt (60) is centered on pulleys and is not inverted. Replace if worn or damaged.

DAILY: Check and fill gas tank.

DAILY: Check hoses for wear and damage.

DAILY: Check gun safety for proper operation.

DAILY: Check pressure drain valve for proper operation.

AFTER THE FIRST 20 HOURS OF OPERATION AND EACH 100 HOURS THEREAFTER: Change engine oil.

DAILY: Keep TSL in packing nut to help lubricate pump packings. One full squirt of TSL is usually enough.

WEEKLY: Remove cover of air filter (C) and clean element. Replace element, if necessary. If operating in an unusually dusty environment, check filter daily and replace it, if necessary.

Repack connecting rod (22) top needle bearing after every pump change.

Replacement elements can be purchased from your local HONDA dealer.

SPARK PLUG: Use only an BPR6ES (NGK) or W20EPR–U (NIPPONDENSO) plug. Gap plug to 0.028 to 0.031 in. (0.7 to 0.8 mm). Use a spark plug wrench when installing and removing plug.

6 309411

Troubleshooting

Relieve pressure; page 6.

PROBLEM |

CAUSE |

SOLUTION |

|

|

|

|

|

E=XX is displayed |

Fault condition exists |

Determine fault correction from table, page 14. |

|

|

|

|

|

Engine won’t start |

Engine switch is OFF |

Turn engine switch on. |

|

|

|

|

|

|

Engine is out of gas |

Refill gas tank. Honda Engines Owner’s Manual. |

|

|

|

|

|

|

Engine oil level low |

Try to start engine. Replenish oil, if necessary. |

|

|

|

Honda Engines Owner’s Manual. |

|

|

|

|

|

|

Spark plug cable disconnected or |

Connect spark plug cable or replace spark plug. |

|

|

spark plug damaged |

|

|

|

|

|

|

|

Oil seepage into combustion |

Remove spark plug. Pull starter rope 3 or 4 times. |

|

|

chamber |

Clean or replace spark plug. Try to start engine. |

|

|

|

Keep sprayer upright to avoid oil seepage. |

|

|

|

|

|

False tripping of WatchDog |

Operating conditions out of WatchDog |

Turn pressure down. Contact Graco Technical Ser- |

|

system. EMPTY is dis- |

parameters |

vice to adjust WatchDog parameters. |

|

played. Pump does not run. |

Low pump output; page 8. |

Operate without WatchDog active; Manual 309410. |

|

|

|

||

|

|

|

|

Engine operates, but dis- |

Pressure control switch turned OFF |

Turn on. |

|

placement pump doesn’t |

|

|

|

Pressure setting too low |

Increase pressure. |

||

|

|||

|

|

|

|

|

Displacement pump outlet filter dirty |

Clean filter. |

|

|

|

|

|

|

Tip or tip filter clogged |

Clean tip or tip filter. |

|

|

|

|

|

|

Broken drive belt |

Replace belt. |

|

|

|

|

|

|

Displacement pump rod seized by |

Service pump. See page 16. |

|

|

dry paint |

|

|

|

|

|

|

|

Connecting rod worn or damaged |

Replace. See page 9. |

|

|

|

|

|

|

Drive housing worn or damaged |

Replace. See page 10. |

|

|

|

|

|

|

Electrical power is not energizing clutch field |

Check wiring connections. Page 23. |

|

|

|

Reference pressure control repair. Page 14. |

|

|

|

Reference wiring diagram. Page 23. |

|

|

|

With pump switch ON and pressure turned to |

|

|

|

MAXIMUM, use a test light to check for power be- |

|

|

|

tween clutch test points on control board. |

|

|

|

Remove 7–pin connector from control board and |

|

|

|

measure resistance across clutch coil. At 70_ F, |

|

|

|

the resistance must be 1.7 ±0.2Ω; if not, replace |

|

|

|

pinion housing. |

|

|

|

Have pressure control checked by authorized Gra- |

|

|

|

co dealer. |

|

|

|

|

|

|

Clutch is worn, damaged, or incorrectly |

Replace clutch. Page 11. |

|

|

positioned |

|

|

|

|

|

|

|

Pinion assembly is worn or damaged |

Repair or replace pinion assembly. Page 11. |

|

|

|

|

309411 7

PROBLEM |

CAUSE |

SOLUTION |

|

|

|

|

|

Pump output low |

Strainer (31) clogged |

Clean. |

|

|

|

|

|

|

Piston ball (25) not seating |

Service piston ball check. Manual 309277. |

|

|

|

|

|

|

Piston packings worn or damaged |

Replace packings. Manual 309277. |

|

|

|

|

|

|

Displacement pump o-ring (227) is damaged |

Replace o-ring. Manual 309277. |

|

|

|

|

|

|

Intake valve ball not seating properly |

Clean and service. Manual 309277. |

|

|

|

|

|

|

Engine speed is too low |

Increase throttle setting. See Manual 309410. |

|

|

|

|

|

|

V–belt slipping |

Tighten V–belt with tension bar (101). Adjust |

|

|

|

bracket until it takes 15 lb of force to lock |

|

|

|

tension bar down. |

|

|

|

|

|

|

Clutch worn or damaged |

Replace. See page 11. |

|

|

|

|

|

|

Pressure setting is too low |

Increase pressure. Manual 309410. |

|

|

|

|

|

|

Fluid filter (318), tip filter or tip is clogged or |

Clean filter. Manual 309410 or 309091. |

|

|

dirty |

|

|

|

|

|

|

|

Large pressure drop in hose with heavy |

Use larger diameter hose and/or reduce overall |

|

|

materials |

length of hose. Use of more than 100 ft of 1/4 |

|

|

|

in. hose significantly reduces performance of |

|

|

|

sprayer. Use 3/8 in. hose for optimum perfor- |

|

|

|

mance (50 ft minimum). |

|

|

|

|

|

Excessive paint leakage into |

Throat packing nut is loose |

Remove throat packing nut spacer. Tighten |

|

throat packing nut |

|

throat packing nut just enough to stop leakage. |

|

|

|

|

|

|

Throat packings worn or damaged |

Replace packings. Manual 309277. |

|

|

|

|

|

|

Displacement rod worn or damaged |

Replace rod. Manual 309277. |

|

|

|

|

|

Spitting from gun |

Air in fluid pump or hose |

Check and tighten all fluid connections. |

|

|

|

Reprime pump. Manual 309410. |

|

|

|

|

|

|

Tip partially clogged |

Clear tip. Manual 309091. |

|

|

|

|

|

|

Fluid supply is low or empty |

Refill and prime pump. See Startup, Manual |

|

|

|

309410. Check fluid supply often to prevent |

|

|

|

running pump dry. |

|

|

|

|

|

Pump is difficult to prime |

Air leak |

Check and tighten all fluid connections. |

|

|

|

Reduce engine speed and cycle pump as |

|

|

|

slowly as possible during priming. |

|

|

|

|

|

|

Intake valve is leaking |

Shut off pump and relieve pressure. Disas- |

|

|

|

semble and clean intake valve. Be sure ball |

|

|

|

seat is not nicked or worn and that ball seats |

|

|

|

well. Reassemble. |

|

|

|

|

|

|

Worn packings |

Repack pump. Manual 309277. |

|

|

|

|

|

|

Fluid is too thick |

Thin fluid according to supplier’s recommenda- |

|

|

|

tions. |

|

|

|

|

|

|

Engine speed is too high |

Decrease throttle setting before priming pump. |

|

|

|

Manual 309410. |

|

|

|

|

|

Clutch squeaks each time |

Clutch surfaces are not matched to each other |

Clutch surfaces need to wear into each other. |

|

clutch engages |

when new and may cause noise |

Noise will dissipate after a day of run time |

|

|

|

|

|

High engine speed at no |

Misadjusted throttle setting |

Reset throttle to 3700 engine rpm at no load |

|

load |

|

|

|

Worn engine governor |

Replace or service engine governor |

||

|

|||

|

|

|

|

Gallon counter not working |

Bad sensor, broken or disconnected wire |

Check connections. Replace sensor or wire. |

|

|

|

|

|

No display, sprayer operates |

Display damaged or has bad connection |

Check connections. Replace display. |

|

|

|

|

8 309411

Loading...

Loading...