Graco 24F061, 24F059, 24F060, 24C309, 24C308 User Manual

...

Instructions - Parts List

Manuel d’instructions – Liste des pièces Instrucciones – Lista de piezas

Finex™ Gun Pistolet Finex™ Pistola Finex™

312388K

ENG FRA SPA

For the spray application of paints and coatings. Pour la pulvérisation de peintures et de revêtements.

Para la aplicación mediante pulverización de pinturas y revestimientos.

Includes Mini-HVLP, HVLP, and Conventional Styles with Pressure and Gravity Feeds. See page 2 for list of models.

Comprend les styles Mini-HVLP, HVLP et Conventional à alimentation par pression ou par gravité. Voir page 13 pour la liste des modèles.

Incluye Mini-HVLP, HVLP, y Estilos convencionales con alimentación a presión y por gravedad. Consulte la página 24 para ver una lista de modelos.

100 psi (0.7 MPa, 7 bar) Maximum Working Fluid and Air Pressure Pressions maximales de service et pneumatique : 100 psi (0,7 MPa, 7 bars)

Presión máxima de funcionamiento de aire y de fluido de 100 psi (0,7 MPa, 7 bar)

Important Safety Instructions

Read all warnings and instructions in this manual. Save these instructions.

Read all warnings and instructions in this manual. Save these instructions.

Instructions de sécurité importantes

Lire toutes les mises en garde et instructions de ce manuel. Sauvegarder ces instructions.

Lire toutes les mises en garde et instructions de ce manuel. Sauvegarder ces instructions.

Instrucciones importantes de seguridad

Lea todas las advertencias e instrucciones de este manual. Guarde las instrucciones.

Lea todas las advertencias e instrucciones de este manual. Guarde las instrucciones.

English |

page 2 |

|

|

Français |

page 13 |

|

|

Español |

página 25 |

|

|

Pressure Feed |

Gravity Feed |

Alimentation sous pression |

Alimentación por gravedad |

Alimentación a presión |

Alimentation par gravité |

II 2 G

II 2 G

Models

Models

|

|

Needle/Nozzle Size |

Gun Style |

Part No. |

in (mm) |

|

|

|

|

289256 |

0.024 (0.6) |

Gravity Feed |

289257 |

0.031 (0.8) |

289258 |

0.039 (1.0) |

|

Mini-HVLP |

289259 |

0.047 (1.2) |

|

||

|

289260 |

0.055 (1.4) |

|

289242 |

0.039 (1.0) |

Gravity Feed |

289243 |

0.051 (1.3) |

Conventional |

289244 |

0.055 (1.4) |

|

289245 |

0.059 (1.5) |

|

289246 |

0.071 (1.8) |

|

|

|

|

289237 |

0.039 (1.0) |

Gravity Feed |

289238 |

0.051 (1.3) |

289239 |

0.055 (1.4) |

|

HVLP |

289240 |

0.059 (1.5) |

|

||

|

289241 |

0.071 (1.8) |

|

|

Needle/Nozzle Size |

Gun Style |

Part No. |

in (mm) |

|

|

|

|

289247 |

0.039 (1.0) |

Pressure |

289248 |

0.047 (1.2) |

Feed HVLP |

|

|

289249 |

0.055 (1.4) |

|

|

289250 |

0.071 (1.8) |

|

289251 |

0.031 (0.8) |

Pressure |

289252 |

0.039 (1.0) |

Feed |

289253 |

0.047 (1.2) |

Conventional |

|

|

289254 |

0.055 (1.4) |

|

|

289255 |

0.071 (1.8) |

Warnings

The following warnings are for the setup, use, grounding, maintenance, and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbol refers to procedure-specific risk. Refer back to these warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable.

WARNING

WARNING

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

• Use equipment only in well ventilated area.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths (potential static arc).

•Keep work area free of debris, including solvent, rags and gasoline.

•Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

•Ground all equipment in the work area. See Grounding instructions.

•If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until you identify and correct the problem.

•Keep a working fire extinguisher in the work area.

2 |

312388K |

Warnings

WARNING

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

•Do not operate the unit when fatigued or under the influence of drugs or alcohol.

•Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

•Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material, request MSDS forms from distributor or retailer.

•Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

•Do not alter or modify equipment.

•Use equipment only for its intended purpose. Call your distributor for information.

•Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

•Do not kink or over bend hoses or use hoses to pull equipment.

•Keep children and animals away from work area.

•Comply with all applicable safety regulations.

PRESSURIZED EQUIPMENT HAZARD

Fluid from the gun/dispense valve, leaks, or ruptured components can splash in the eyes or on skin and cause serious injury.

•Follow Pressure Relief Procedure in this manual, when you stop spraying and before cleaning, checking, or servicing equipment.

•Tighten all fluid connections before operating the equipment.

•Check hoses, tubes, and couplings daily. Replace worn or damaged parts immediately.

TOXIC FLUID OR FUMES HAZARD

Toxic fluids or fumes can cause serious injury or death if splashed in the eyes or on skin, inhaled, or swallowed.

•Read MSDS’s to know the specific hazards of the fluids you are using.

•Store hazardous fluid in approved containers, and dispose of it according to applicable guidelines.

•Always wear impervious gloves when spraying or cleaning equipment.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or when in the operating area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic fumes, burns, and hearing loss. This equipment includes but is not limited to:

•Protective eyewear

•Clothing and respirator as recommended by the fluid and solvent manufacturer

•Gloves

•Hearing protection

312388K |

3 |

Setup

Setup

Reference numbers and letters in paren-

Reference numbers and letters in paren-  theses in the text refer to numbers and letters in the illustrations.

theses in the text refer to numbers and letters in the illustrations.

Connecting Air Line

1.Install an air pressure regulator on gun air supply line to control air pressure.

2.Install a shutoff valve downstream of the air regulator to shut off gun air.

3.Connect a clean, dry, filtered air supply to air inlet fitting (13). Connect other end to shutoff valve.

Connecting Fluid Supply

Pressure feed guns:

1.To control fluid pressure to the gun, install a fluid regulator on the fluid line.

2.Connect the fluid hose

to the gun fluid inlet,  3/8-18 npsm (R3/8-19) 21 (21).

3/8-18 npsm (R3/8-19) 21 (21).

3.Connect other end to a regulated fluid supply line.

Gravity feed guns:

1.Install fluid filter (24) into fluid inlet (A).

2.Screw on gravity cup.

3.Remove gravity

cup cover and fill A cup with solvent to flush if this is

cup with solvent to flush if this is

first time using equipment. (See

Flushing, page

6.)

1

4.After flushing, fill cup with fluid and attach cover.

5

8-2

8-2

13

4 |

312388K |

Operation

Pressure Relief Procedure

1.Turn off air and fluid supply.

2.Hold a metal part of the gun firmly to a grounded metal pail. Trigger the gun to relieve pressure.

Adjust Spray Pattern

Do not exceed maximum working air pressure shown on front cover. Read warnings.

1.Rotate air cap to change spray pattern direction.

2.For maximum fluid flow and to prevent premature fluid nozzle wear, turn fluid adjustment knob (8-2) counterclockwise until no trigger restriction is felt. Then turn knob out 1/2 turn more.

3.If further fluid flow restriction is needed, use different size needle/nozzle/air cap combination.

If necessary, fluid adjustment knob (8-2) can be turned clockwise to reduce volume of fluid output. However, continuously spraying with fluid adjustment knob closed causes accelerated abrasive wear on fluid needle and trigger/air valve shaft interface.

If fluid adjustment knob (8-2) is turned in

If fluid adjustment knob (8-2) is turned in  all the way, the gun emits only air.

all the way, the gun emits only air.

Operation

4.Pressure Feed only: Adjust fluid pressure to achieve desired fluid flow rate.

5.Test spray pattern and atomization while holding gun about 6 to 8 inches (150 to 200 mm) from test piece.

a.If pattern is too wide, turn pattern adjustment knob (5) clockwise to narrow pattern.

b.To create a round pattern, turn pattern adjustment knob (5) fully clockwise.

c.If pattern is too narrow, turn knob (5) counterclockwise.

d.Check atomization. Increase gun air supply pressure in 5 psi (34 kPa,

0.3 bar) increments until you have the desired atomization.

Applying the Fluid

For the best results:

•Keep gun perpendicular to surface and consistent distance of about 6 to 8 inches

(150 to 200 mm). Do not angle the gun as you spray.

•Use smooth, even strokes, with about 50% overlap.

•HVLP Guns: Use a slightly slower hand movement and make fewer passes than you would with a conventional air spray gun. Take care to avoid runs or sags.

312388K |

5 |

Maintenance

Maintenance

Flushing

Flush before changing colors, before fluid can dry in the equipment, at the end of the day, before storing, and before repairing equipment. Use a solvent that is compatible with gun wetted parts and fluid that will be sprayed.

Gravity Feed Guns:

1.Follow Pressure Relief Procedure, page 5.

2.Dispose of any paint in the cup.

3.Fill the cup with a small amount of solvent.

4.Spray into a grounded metal waste container until clean solvent dispenses.

5.Follow Pressure Relief Procedure, page 5.

Pressure Feed Guns:

1.Follow Pressure Relief Procedure, page 5.

2.Disconnect fluid supply hose and air supply hose from gun.

3.Connect solvent supply hose to gun.

4.Hold metal part of gun against a grounded metal container, trigger, and flush the gun with solvent until all traces of paint are removed from the gun passages.

5.Turn off the solvent supply.

6.Follow Pressure Relief Procedure, page 5.

7.Disconnect solvent supply hose from gun.

Daily Cleaning

CAUTION

•Do not submerge gun in solvent. Solvent dissolves lubricant, dries out packings, and may clog air passages. You can immerse front end of gun in solvent just until cup connection is covered.

•Do not use metal tools to clean air cap holes as this may scratch them and distort the spray pattern.

•Use a compatible solvent.

1.Follow Pressure Relief Procedure, page 5.

2.Clean fluid and air line filters.

3.Check for fluid leakage from gun and fluid hoses. Tighten fittings or replace equipment as needed.

4.Flush gun before changing colors and when you are done spraying.

5.Remove cup and filter and clean them

(gravity feed models only).

6.Remove air cap (1) and nozzle (2) as instructed on page 8 and soak them in compatible solvent.

CAUTION

Trigger gun and use gun tool (27) whenever you tighten or remove nozzle (2) to avoid damaging needle seat and nozzle.

7.Use a rag moistened in solvent to wipe down outside of gun.

8.Before reinstalling air cap and nozzle, clean them and front of gun with a soft-bristle brush dipped into compatible solvent.

Do not use a wire brush or metal tools.

To clean out air cap holes, use a soft implement, such as a toothpick.

9.Lubricate gun.

6 |

312388K |

|

|

Troubleshooting |

|

Troubleshooting |

|

||

|

|

|

|

Problem |

Cause |

Solution |

|

|

|

|

|

|

One side of air cap (1) dirty or |

Clean air cap orifices. See page 6. Blow |

|

|

clogged. |

air through orifices until clean. If air cap |

|

|

|

holes are damaged, replace air cap. |

|

|

|

|

|

|

a. Loose air cap (1). |

a. Tighten. |

|

|

|

|

|

|

b. Dried or damaged air |

b. Rotate air cap 180°. |

|

|

cap (1) or fluid nozzle (2). |

If pattern follows air cap, problem is |

|

|

|

in air cap. Clean and inspect. See |

|

|

|

page 6. If pattern is not corrected, |

|

|

|

replace air cap. |

|

|

|

If pattern does not follow the air cap, |

|

|

|

the problem is with the fluid nozzle. |

|

|

|

Clean and inspect the nozzle. See |

|

|

|

page 6. If the pattern is not corrected, |

|

|

|

replace nozzle. |

|

|

|

|

|

|

a. Atomization air pressure |

a. Reduce air pressure. |

|

|

set too high. |

|

|

|

|

|

|

|

b. Spraying a thin material in |

b. Increase material control by turning |

|

|

too wide of a pattern. |

fluid adjustment knob (8-2) counter- |

|

|

|

clockwise while reducing spray width |

|

|

|

by turning pattern adjustment |

|

|

|

knob (5) clockwise. |

|

|

|

Or increase material viscosity. |

|

|

|

|

|

|

Air getting into paint stream. |

|

|

|

|

|

|

|

a. Cup almost empty. |

a. Fill cup. |

|

|

|

|

|

Spitting |

b. Dry needle packing (3-1, |

b. Loosen packing seat and put a few |

|

|

3-2). |

drops of machine oil on packing (3-1, |

|

|

|

3-2). Retighten seat (4). |

|

|

|

|

|

|

c. Fluid nozzle (2) too loose. |

c. Tighten. |

|

|

|

|

|

|

d. Dried material between |

d. Clean nozzle and front of gun. See |

|

|

nozzle (2) and gun body. |

page 6. |

|

|

|

|

|

|

e. Damaged needle seal. |

e. Replace seal. See page 8. |

|

|

|

|

|

Other spray pattern |

a. Gun not properly adjusted. |

a. See page 5. |

|

problems. |

|

|

|

b. Sluggish needle (10). |

b. Clean and lubricate. |

||

|

|||

|

|

|

|

Unable to get round |

Pattern adjustment knob (5) |

Clean or replace knob. |

|

pattern. |

not seating properly. |

|

|

|

|

|

|

Will not spray. |

a. No air pressure at gun. |

a. Check air supply and air lines. |

|

|

|

|

|

|

b. Cup empty. |

b. Fill cup. |

|

|

|

|

|

|

c. Fluid adjustment knob (8-2) |

c. Adjust knob (8-2) counterclockwise. |

|

|

turned too far clockwise. |

|

|

|

|

|

|

|

d. Fluid too thick for gravity |

d. Thin material. |

|

|

feed. |

|

|

|

|

|

|

312388K |

7 |

Service

Problem |

Cause |

Solution |

|

|

|

|

|

Fluid leaking from |

a. Packing nut (4) loose. |

a. Tighten, but not so tight as to grip |

|

packing nut (4). |

|

needle. |

|

|

|

|

|

|

b. Packing (3-1, 3-2) worn or |

b. Lubricate or replace. |

|

|

dry. |

|

|

|

|

|

|

Fluid nozzle (2) |

a. Dry packing (3-1, 3-2). |

a. Lubricate. |

|

dripping. |

|

|

|

b. Sluggish needle (10). |

b. Clean and lubricate. |

||

|

|||

|

|

|

|

|

c. Packing nut (4) too tight. |

c. Loosen. |

|

|

|

|

|

|

d. Worn fluid nozzle or |

d. Replace. |

|

|

needle. |

|

|

|

|

|

|

Thin, coarse finish. |

a. Gun held too far from |

a. Hold gun about 6 to 8 inches |

|

|

surface. |

(150 to 200 mm) from surface. |

|

|

|

|

|

|

b. Atomization air pressure |

b. Reduce air pressure. |

|

|

set too high. |

|

|

|

|

|

|

Thick, dimpled finish |

Gun held too close to surface. |

Hold gun about 6 to 8 inches |

|

(resembling orange |

|

(150 to 200 mm) from surface. |

|

peel). |

|

|

|

|

|

|

Service

3.Remove fluid adjustment knob (8-2) and spring (9).

4.Pull fluid needle (10) out the back of the gun.

Preparation

1.Flush and clean gun before servicing.

2.Follow Pressure Relief Procedure, page 5.

Air Cap, Nozzle, and Needle

1.Unscrew air cap (1).

2.Trigger gun while you remove the nozzle (2) with gun tool (27).

Trigger gun and use gun tool (27) when-

Trigger gun and use gun tool (27) when-  ever you tighten or remove the nozzle (2) to avoid damage.

ever you tighten or remove the nozzle (2) to avoid damage.

Air Valve and Needle Packings

1.Remove retaining rings (15), pin (16), and trigger (17).

2.Remove packing nut (4) and fluid needle packings (3-1, 3-2).

3.Remove fluid needle guide (7).

4.Remove fluid adjusting guide (8-1).

5.Remove spring (18) and air valve (19).

6.Remove air valve seat (20) and o-rings.

7.Replace parts as needed.

8.Assemble gun in reverse order. Lubricate needle and o-rings. Be sure to trigger gun when installing nozzle (2).

8 |

312388K |

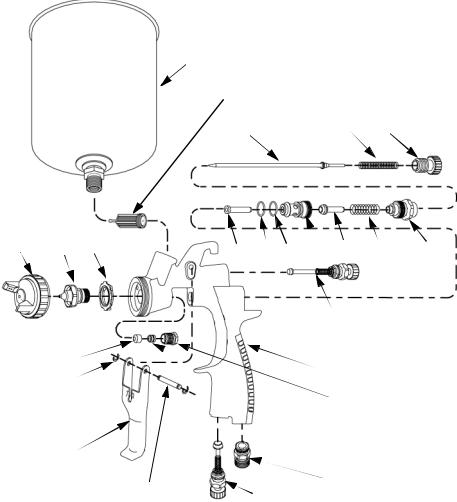

Parts

Parts

Gravity Feed Models

26

26

24

10 |

9 8-2 |

1 |

2 12-2 |

7 6 11 20 19 18 |

|

5 |

|

3-1 |

12-1 |

|

15 |

||

|

||

|

4 |

|

|

3-2 |

|

17 |

|

|

16 |

13 |

|

14 |

||

|

8 -1

-1

ti10444a

Ref. |

Description |

Qty |

1 |

CAP, air |

1 |

2 |

NOZZLE, fluid |

1 |

3-1* |

PACKING, fluid needle |

1 |

3-2* |

PACKING, fluid needle |

1 |

4* |

NUT, packing |

1 |

5* |

KNOB, pattern |

1 |

|

adjustment |

|

6* |

O-RING |

1 |

7* |

GUIDE, fluid needle |

1 |

8-1* |

GUIDE, fluid adjusting |

1 |

8-2* |

KNOB, fluid adjusting |

1 |

9* |

SPRING, fluid needle |

1 |

10 |

NEEDLE, fluid |

1 |

11* |

O-RING |

1 |

12-1 |

BODY, gun |

1 |

12-2* DISTRIBUTOR, air |

1 |

|

13* |

FITTING, air inlet |

1 |

14* |

VALVE, air adjustment |

1 |

15* |

RING, retaining |

2 |

16* |

PIN, trigger |

1 |

17* |

TRIGGER |

1 |

18* |

SPRING, air valve |

1 |

19* |

VALVE, air |

1 |

20* |

SEAT, air valve |

1 |

21 |

CONNECTOR, fluid, |

1 |

|

(pressure feed models |

|

|

only, not shown) |

|

24* |

FILTER, fluid |

1 |

26 |

CUP, gravity, plastic, |

1 |

|

(gravity feed models |

|

|

only) |

|

27 |

TOOL, gun (not |

1 |

|

shown) |

|

312388K |

9 |

Repair Kits

Repair Kits

|

|

Needle, |

|

|

|

|

|

|

|

Nozzle, Air |

Needle |

|

|

|

|

|

|

Cap Kit |

Packing Kit |

Gun Rebuild |

Air |

|

|

|

Needle/ |

(includes |

(includes |

Kit |

Distributor |

|

|

|

Nozzle Size |

parts 1, 2, |

parts 3-1, 3-2 |

(includes parts |

Kit |

Trigger |

|

Gun Style |

in. (mm) |

and 10) |

and 4) |

marked *) |

(pack of 5) |

Repair Kit |

|

|

|

|

|

|

|

|

|

|

0.024 (0.6) |

289286 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Gravity Feed |

0.031 (0.8) |

289287 |

|

|

|

|

|

|

|

|

|

|

|

||

0.039 (1.0) |

289288 |

288890 |

288895 |

24C308 |

24F059 |

||

Mini-HVLP |

|

|

|

|

|

|

|

0.047 (1.2) |

289289 |

|

|

|

|

||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

0.055 (1.4) |

289290 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.039 (1.0) |

289291 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Gravity Feed |

0.051 (1.3) |

289292 |

|

|

|

|

|

|

|

|

|

|

|

||

0.055 (1.4) |

289293 |

288891 |

288896 |

24C309 |

24F061 |

||

Conventional |

|

|

|

|

|

|

|

0.059 (1.5) |

289294 |

|

|

|

|

||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

0.071 (1.8) |

289295 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.039 (1.0) |

289296 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Gravity Feed |

0.051 (1.3) |

289297 |

|

|

|

|

|

|

|

|

|

|

|

||

0.055 (1.4) |

289298 |

288891 |

288896 |

24C309 |

24F060 |

||

HVLP |

|

|

|

|

|

|

|

0.059 (1.5) |

289299 |

|

|

|

|

||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

0.071 (1.8) |

289300 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressure |

0.039 (1.0) |

289301 |

|

|

|

|

|

|

|

|

|

|

|

||

0.047 (1.2) |

289302 |

|

|

|

|

||

Feed |

288891 |

288897 |

24C309 |

24F060 |

|||

|

|

||||||

0.055 (1.4) |

289303 |

||||||

HVLP |

|

|

|

|

|||

|

|

|

|

|

|

||

0.071 (1.8) |

289304 |

|

|

|

|

||

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

0.031 (0.8) |

289305 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.039 (1.0) |

289306 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressure |

0.047 (1.2) |

289307 |

|

|

|

|

|

Feed |

0.055 (1.4) |

289308 |

288891 |

288897 |

24C309 |

24F061 |

|

Conventional |

|

|

|

|

|

|

|

0.071 (1.8) |

289309 |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

0.086 (2.2) |

289677 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.098 (2.5) |

289678 |

|

|

|

|

|

|

|

|

|

|

|

|

10 |

312388K |

|

|

|

|

|

|

Accessories |

|

Accessories |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

Gravity Cup Lid |

Fluid |

|

|

|

Gravity Cup Kits |

PPS |

Gravity Cup |

(for Aluminum |

Filter |

HVLP |

|

Gun Style |

(includes part 26) |

Adapter |

(Aluminum) |

Cup) |

(10 pack) |

Test Kit |

|

|

|

|

|

|

|

|

|

|

|

|

289858 |

289816 |

|

|

|

|

|

|

(125 cc) |

(125 cc) |

|

|

|

Mini-HVLP |

289323 |

289520 |

Standard |

|

24A230 |

24B616 |

|

(125 cc) |

|

|

|||||

|

|

|

|

|

|

||

|

|

|

289859 |

289817 |

|

|

|

|

|

|

(250 cc) |

(250 cc) |

|

|

|

|

|

|

|

|

|

|

|

Conventional |

289322 |

289520 |

289860 |

289818 |

24A230 |

N/A |

|

(600 cc) |

(600 cc) |

(600 cc) |

|||||

|

|

|

|

||||

|

|

|

|

|

|

|

|

HVLP |

289322 |

289520 |

289860 |

289818 |

24A230 |

24B615 |

|

(600 cc) |

(600 cc) |

(600 cc) |

|||||

|

|

|

|

||||

|

|

|

|

|

|

|

|

312388K |

11 |

Loading...

Loading...