Graco 248084, 248082, 248083 User Manual

Operation

TexSpray GTX™ 2000

US Patents D502,532; 7,114,664 |

309915D |

|

- For Water-Based Materials Only-

Model: 248082

Sprayer with Graco Trigger Gun

120 psi (8.27 bar) Maximum Working Air Pressure

120 psi (8.27 bar) Maximum Working Fluid Pressure

Model: 248083

Sprayer with Graco Flex Gun

120 psi (8.27 bar) Maximum Working Pressure

120 psi (8.27 bar) Maximum Working Fluid Pressure

Model: 248084

Sprayer with Graco Pole Gun

120 psi (8.27 bar) Maximum Working Pressure

120 psi (8.27 bar) Maximum Working Fluid Pressure

Read all warnings and instructions.

WL E

308479

310616 model 248082

308603 model 248083 and 248084

309916

Graco Inc. P.O. Box 1441 Minneapolis, MN 55440-1441

Copyright 2003, Graco Inc. is registered to I.S. EN ISO 9001

Warnings

The following Warnings are for the safe setup, use, grounding, maintenance and repair of this equipment. The exclamation point symbol alerts you to a general warning and the hazard symbols refer to procedure-specific risks. Refer back to these Warnings.

Warning

WARNING

WARNING

This symbol alerts you to the possibility of serious injury or death if you do not follow the instructions.

Caution

CAUTION

Alerts you to the possibility of damage or destruction of equipment if you do not follow the instructions.

Warnings

Fire and Explosion Hazard

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

•Use equipment in well ventilated areas only.

•Do not fill fuel tank while motor is running or hot; shut off motor and let it cool. Fuel is flammable and

can ignite or explode if spilled on hot surface.

• Eliminate all ignition sources; such as pilot lights, cigarettes, portable electrical lamps, and plastic drop cloths (potential static arc).

•Keep work area free of debris, including solvent, rags, and gasoline.

•Do not plug or unplug power cords or turn lights on or off when flammable fumes are present.

Carbon Monoxide Hazard

Exhaust contains poisonous carbon monoxide, which is colorless and odorless. Breathing carbon monoxide can cause death. Do not operate in an enclosed area.

Equipment Misuse Hazard

Equipment misuse can cause death or serious injury.

•Do not exceed maximum working pressure or temperature rating of lowest rated system component. See Technical Data, in all equipment manuals.

•Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings.

•Check equipment daily. Repair or replace worn or damaged parts immediately.

•Do not alter or modify this equipment.

•Use the equipment only for its intended purpose. Call your Graco distributor for information.

•For professional use only.

•Route hoses away from traffic areas, sharp edges, moving parts and hot surfaces.

•Do not use hoses to pull equipment.‘

•Comply with all applicable safety regulations.

2 |

309915D |

Warnings

WARNINGS

Burn Hazard

Equipment surfaces and fluid that is heated can become very hot during operation. To avoid severe burns, do not touch hot fluid or equipment. Wait until equipment/fluid has cooled completely.

Pressurized Equipment Hazard

Compressed air can inject in skin. Air tubing rupture can cause injury if disconnected while under pressure. To reduce risk of injury:

•Never exceed maximum working pressure of any attachment.

•Do not direct airstream at body.

•Follow Pressure Relief Procedure, page 6 whenever you are instructed to relieve pressure, stop spraying, service equipment, install or clean spray nozzle or disconnect or connect hose.

Cleaning Solvent Hazard with Plastic Parts

Use only compatible water-based solvents to clean plastic structural or pressure-containing parts. Many solvents can degrade plastic parts to the point where they could fail. Such failure could cause serious injury or property damage. See Technical Data on page 21 of this instruction manual and in all other equipment manuals. Read fluid and solvent manufacturer’s warnings.

Personal Protective Equipment

Wear appropriate protective equipment when operating, servicing or when in the operating area of this equipment to help protect yourself from serious injury, including eye injury, inhalation of toxic fumes, burns and hearing loss. This equipment includes, but is not limited to:

•protective eye wear

•clothing and respirator as recommended by fluid and solvent manufacturer

•hearing protection

•gloves

CAUTION

Water or material remaining in unit when temperatures are below freezing can damage pump and/or delay startup.

To insure water and material are completely drained out of unit:

1.Remove material line from sprayer.

2.Tip sprayer to allow material (water) to flow out of pump inlet.

Before adding material or starting unit in cold weather, run warm water through pump.

309915D |

3 |

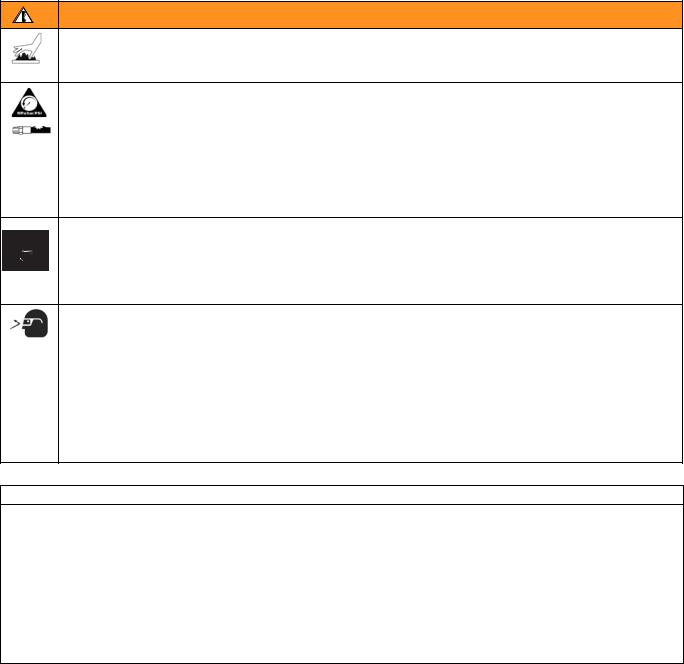

Component Identification

|

Component Identification |

|

|

|

9 |

|

$ |

4 |

|

' |

|

& |

% |

|

|

5 |

3 |

|

|

|

=

:

)

6 (

*

- |

+ |

|

<

WL E

0 |

.

/ 7

/ 7

1

8

4 |

309915D |

Component Identification

|

Component Identification |

|

|

A |

Gas Tank |

|

|

B |

Fuel Valve |

|

|

C |

Choke |

|

|

D |

Throttle Lever |

|

|

E |

Engine ON/OFF Switch |

|

|

F |

Nozzle Storage |

|

|

G |

Hopper |

|

|

H |

Hopper Quick Connect |

|

|

J |

Diaphragm Pump |

|

|

K |

Material Outlet Option 1 |

|

|

L |

Material Outlet Option 2 |

|

|

M |

Air Cooler |

|

|

N |

Gun Air Outlet Quick Connect |

|

|

P |

Air Filter (both sides) |

|

|

Q |

Air Line Quick Connect |

|

|

R |

Engine Starter Cord |

|

|

S |

Motor Lock Knob |

|

|

T |

Material (Pump) Air Pressure Gage and Control Knob |

|

|

U |

Gun Air Pressure Gage and Control Knob |

|

|

V |

Sprayer Quick Connect Air In and Air ON/OFF Valve |

|

|

W |

Pressure Unloader |

|

|

Y |

Gun (see manual 308878)* |

|

|

Z |

Compressor Power Pack |

|

|

* Reference numbers used in gun illustrations coincide with reference numbers shown in gun manual 308878

309915D |

5 |

Pressure Relief Procedure

Pressure Relief Procedure

IMPORTANT

To reduce the risk of injury, follow this Pressure Relief Procedure whenever you:

•Are instructed to relieve pressure

•Stop spraying

•Service equipment

•Install or clean spray nozzle

•Disconnect or connect hose.

OFF |

|

|

ON |

|

|

E |

23 |

ti3903a |

TI3037A |

|

G |

TI

1Turn Engine ON/OFF (E) switch OFF.

2 Open gun air valve (23). |

3 Trigger gun. Spray material back into hopper (G). |

|

|

6 |

309915D |

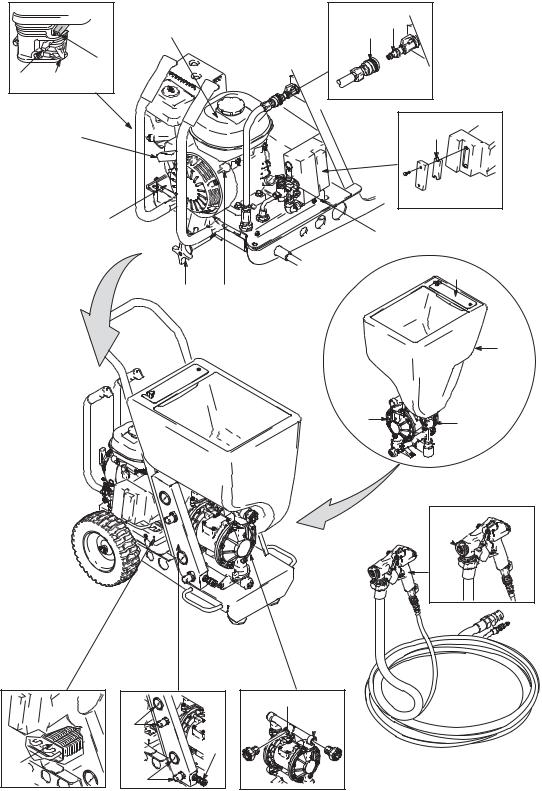

Setup

Setup

Preparation

K

L

23 |

TI3056A |

|

cc

WL E |

A |

ti3908a

dd

dd

N

ti4003a

4 Connect air and material |

5 Connect one end of material |

6 Open gun air valve (23). |

hoses to gun. Tighten |

hose (cc) to material outlet (K |

|

securely). |

or L) and the other end to gun |

|

|

material inlet (bb). |

|

|

NOTE: Material plug must be |

|

|

installed in material outlet (K or |

|

|

L) you are not using. |

|

|

|

|

7Check engine oil level. Add SAE 10W-30 (summer) or 5W-20 (winter) oil, if necessary.

8Fill fuel tank (A) (Fueling, page 13).

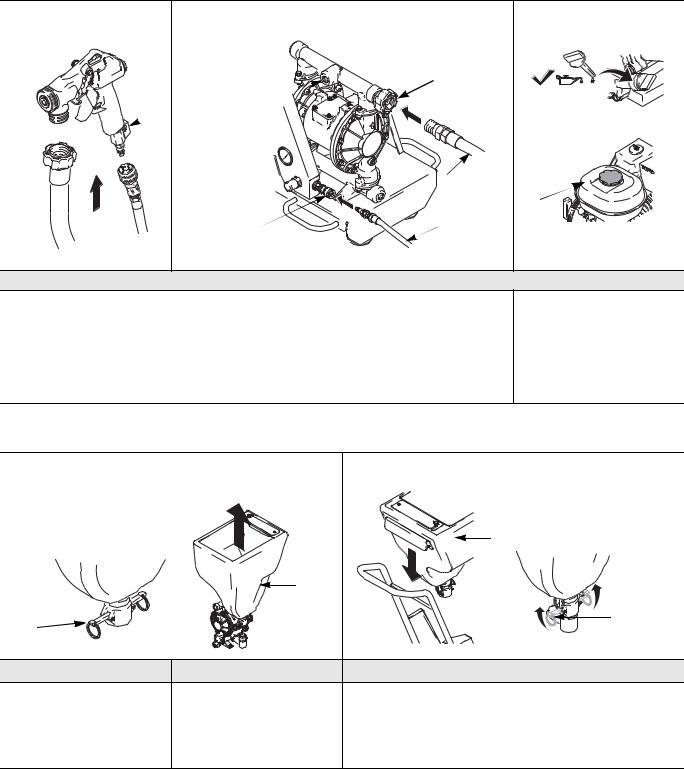

Removing & Installing Hopper

|

|

G |

|

ti3899a |

|

|

G |

|

H |

|

H |

|

|

|

|

|

ti3902a |

|

ti3900a |

ti3925a |

|

Removing Hopper (G) |

Installing Hopper (G) |

The hopper (G) can be removed |

1 Push down 2 latches on each |

2 Position coupler (H) over material outlet and slide hopper (G) |

from cart for cleaning and when |

side of hopper coupler (H). |

straight down, over the fitting as far as it will go, making sure hopper |

using the Siphon Kit 248112, |

|

bracket is positioned over cart handle rod. |

available from your Graco |

Lift hopper (G) straight up, off |

|

distributor. |

of unit. |

Secure latches on each side by pushing them, firmly up, into locked |

|

|

position. |

309915D |

7 |

Loading...

Loading...