Operation & Safety

Manual

Keep this manual with machine at all times.

Suspended Load

Supplement

for

3509, 3513,

4009, 4013

& 4017

31200487

Revised

April 29, 2009

An Oshkosh Corporation Company

Revision Log

Revision Log

October 23, 2008 - A - Original Issue of Manual

April 29, 2009 - B - Revised pages 2-3, 2-4 & 2-5.

REVISION LOG

a31200487

Read This First

Read This First

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and

lessees with the precautions and operating procedures essential for the safe and

proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to

make specification changes without prior notification. Contact JLG Industries, Inc.

for updated information.

Operator Qualifications

The operator of the machine must not operate the machine until this manual has

been read, training is accomplished and operation of the machine has been

completed under the supervision of an experienced and qualified operator.

Operation within the U.S.A. requires training per OSHA 1910.178.

Operators of this equipment must possess a valid, applicable driver’s license, be in

good physical and mental condition, have normal reflexes and reaction time, good

vision and depth perception and normal hearing. Operator must not be using

medication which could impair abilities nor be under the influence of alcohol or any

other intoxicant during the work shift.

In addition, the operator must read, understand and comply with instructions

contained in the following material furnished with the telehandler:

• This Operation & Safety Manual

• Telehandler Safety Manual (as required)

• All instructional decals and plates

• Any optional equipment instructions furnished

The operator must also read, understand and comply with all applicable Employer,

Industry and Governmental rules, standards and regulations.

Modifications

Any modification to this machine must be approved by JLG.

b 31200487

Read This First

This product must comply with all safety related bulletins. Contact JLG Industries,

Inc. or the local authorized JLG representative for information regarding safetyrelated bulletins which may have been issued for this product.

JLG Industries, Inc. sends safety related bulletins to the owner of record of this

machine. Contact JLG Industries, Inc. to ensure that the current owner records are

updated and accurate.

JLG Industries, Inc. must be notified immediately in all instances where JLG

products have been involved in an accident involving bodily injury or death of

personnel or when damage has occurred to personal property or the JLG product.

FOR:

• Accident Reporting and Product Safety Publications

• Current Owner Updates

• Questions Regarding Product Applications and Safety

• Standards and Regulations Compliance Information

• Questions Regarding Product Modifications

CONTACT:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

USA

or Your Local JLG Office

(Addresses on back cover)

In USA:

Toll Free: 1-877-JLG-SAFE (1-877-554-7233)

Outside USA:

Phone: +1-717-485-6591

E-mail:

ProductSafety@JLG.com

c31200487

Read This First

Other Publications Available

For detailed machine operation procedures and safety information, please refer to

the appropriate machine Operation & Safety Manual.

Note: The following standards may be referenced in this manual:

ANSI is compliant to ANSI/ITSDF B56.6

AUS is compliant to AS 1418.19

CE is compliant to EN1459

Refer to the machine Serial Number Plate to identify the applicable compliance

standard.

d 31200487

Table of Contents

TABLE OF CONTENTS

Revision Log

Read This First

Operator Qualifications ...................................................... b

Modifications ...................................................................... b

Other Publications Available .............................................. d

Table of Contents

Section 1 - General Safety Practices

1.1 Hazard Classification System ..............................................1-1

Safety Alert System and Safety Signal Words................1-1

1.2 General Precautions ............................................................1-1

1.3 Operation Safety..................................................................1-2

Electrical Hazards ...........................................................1-2

Tip Over Hazard..............................................................1-3

Travel Hazard .................................................................1-6

Load Falling Hazard ........................................................1-7

Lifting Personnel .............................................................1-8

Driving Hazards on Slopes .............................................1-9

Pinch Points and Crush Hazards ..................................1-10

Fall Hazard....................................................................1-12

Chemical Hazards.........................................................1-13

Table of Contents

Section 2 - Load Management Indicator System (LMIS)

2.1 General ................................................................................2-1

2.2 Control Panel .......................................................................2-2

Display ............................................................................2-3

2.3 Operation .............................................................................2-4

System Start Up ..............................................................2-4

Attachment Selection ......................................................2-5

Lifting Conditions and Alarms .........................................2-6

2.4 Diagnostic Data ...................................................................2-7

Alarms and Warnings......................................................2-7

LMI Values ......................................................................2-7

Pressure Values..............................................................2-8

Angle and Length Transducers.......................................2-8

LMI Status .......................................................................2-9

i31200487

Table of Contents

Section 3 - Machine Operation

3.1 Operating With A Suspended Load..................................... 3-1

Lift Load Safely............................................................... 3-1

Picking Up A Suspended Load....................................... 3-1

Transporting a Suspended Load .................................... 3-2

Leveling Procedure......................................................... 3-2

Placing a Suspended Load............................................. 3-3

Disengaging A Suspended Load .................................... 3-3

Section 4 - Attachments

4.1 Use of the Capacity Chart ................................................... 4-1

Capacity Indicator Locations .......................................... 4-1

Sample Capacity Chart................................................... 4-2

Example.......................................................................... 4-4

Truss Boom .................................................................... 4-5

Section 5 - LMIS Service and Maintenance

5.1 Auto-Diagnostic System ...................................................... 5-1

Alarm Codes................................................................... 5-2

ii 31200487

Section 1 - General Safety Practices

SECTION 1 - GENERAL SAFETY PRACTICES

1.1 HAZARD CLASSIFICATION SYSTEM

Safety Alert System and Safety Signal Words

DANGER

DANGER indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

CAUTION indicates a potentiality hazardous situation which, if not avoided, may

result in minor or moderate injury.

OW0010

OW0021

OW0031

1.2 GENERAL PRECAUTIONS

WARNING

Before operation, read & understand this manual. Failure to comply with the

safety precautions listed in this manual could result in machine damage, property

damage, personal injury or death.

1-131200487

Section 1 - General Safety Practices

1.3 OPERATION SAFETY

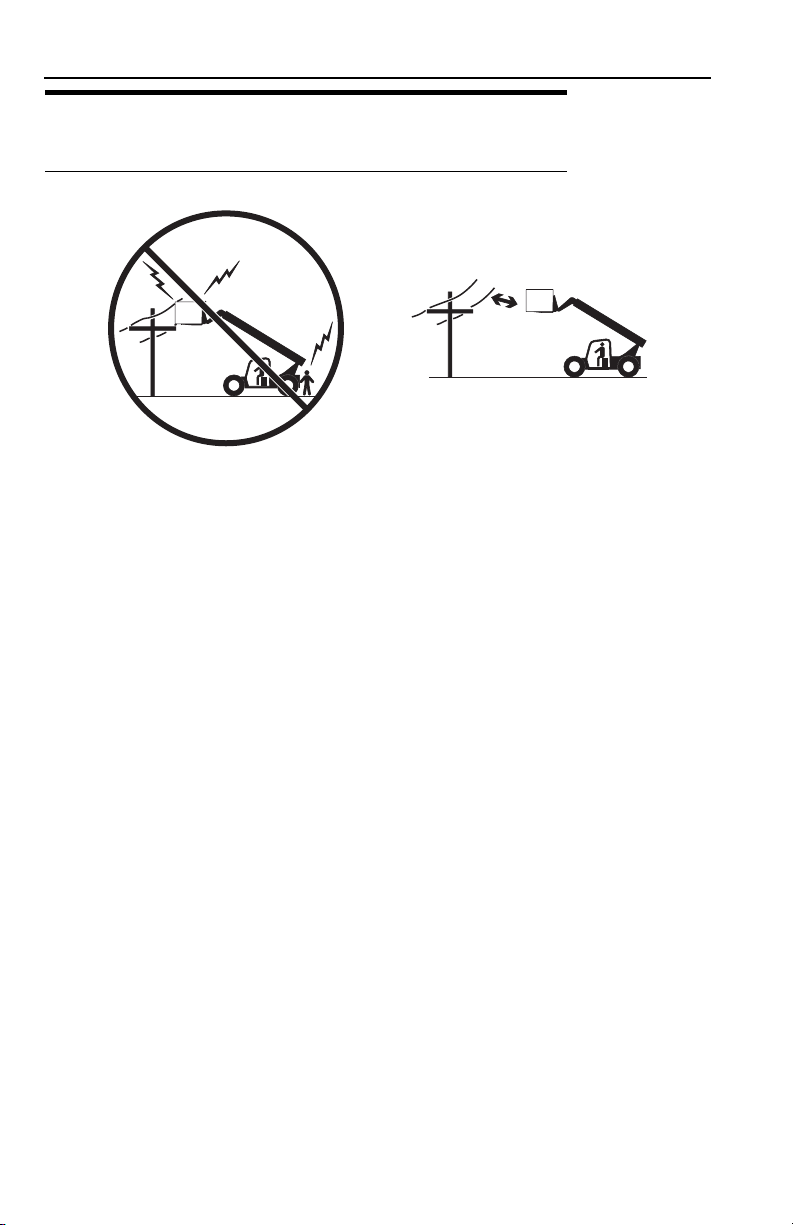

Electrical Hazards

10 FT

(3 M)

OW0040

• This machine is not insulated and does not provide protection from contact or

being near electrical current.

• NEVER operate the telehandler in an area where overhead power lines,

overhead or underground cables, or other power sources may exist without

ensuring the appropriate power or utility company de-energizes the lines.

• Always check for power lines before raising the boom.

• Follow employer, local and governmental regulations for clearance from

powerlines.

1-2 31200487

Section 1 - General Safety Practices

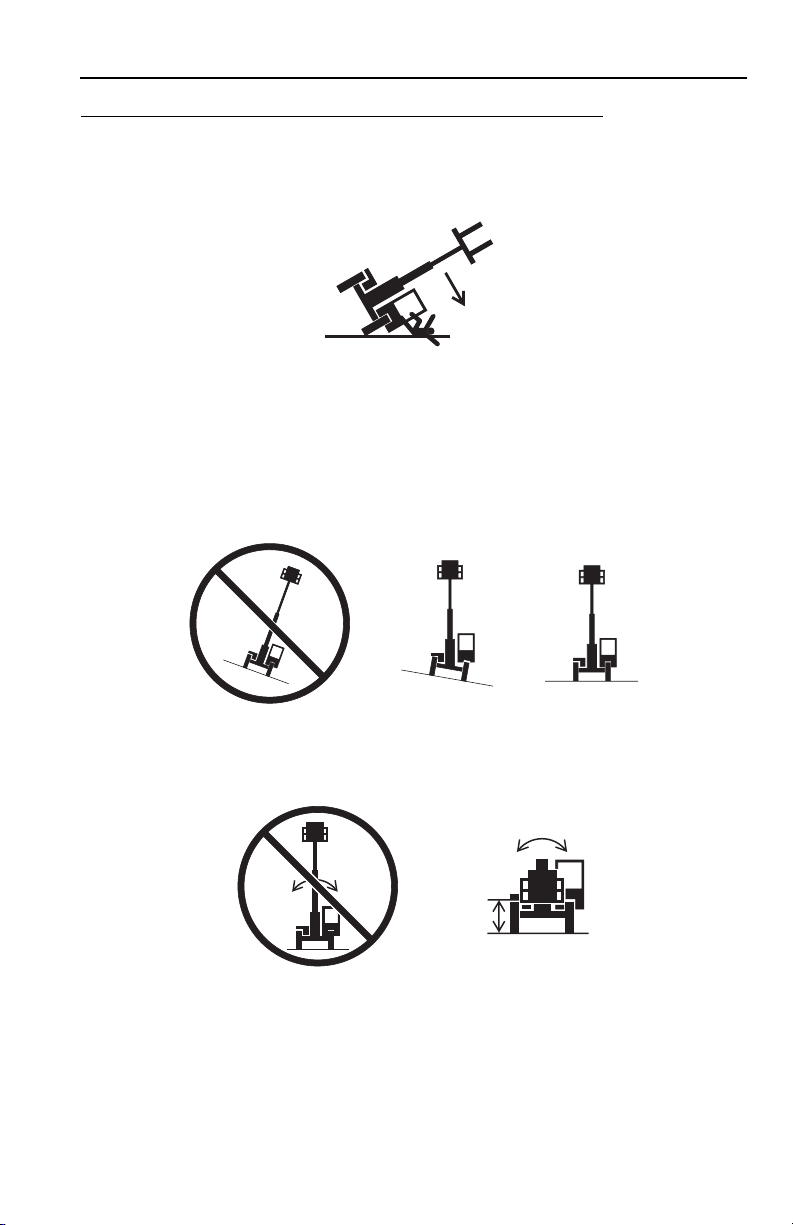

Tip Over Hazard

General

• For additional load requirements, refer to the appropriate capacity chart.

OW0050

• Never use an attachment without the appropriate JLG approved capacity chart

installed on the telehandler.

• Understand how to properly use the capacity charts located in cab.

• DO NOT exceed rated lift capacity.

• Be sure that the ground conditions are able to support the machine.

OW0080

• DO NOT raise boom unless frame is level (0 degrees), unless otherwise noted on

capacity chart.

4 FT

(1,2 M)

OW0100

• DO NOT level machine with boom/attachment above 1,2 m (4 ft).

(AUS - DO NOT level machine with load more than 300 mm (11.8 in) above

ground surface)

1-331200487

Section 1 - General Safety Practices

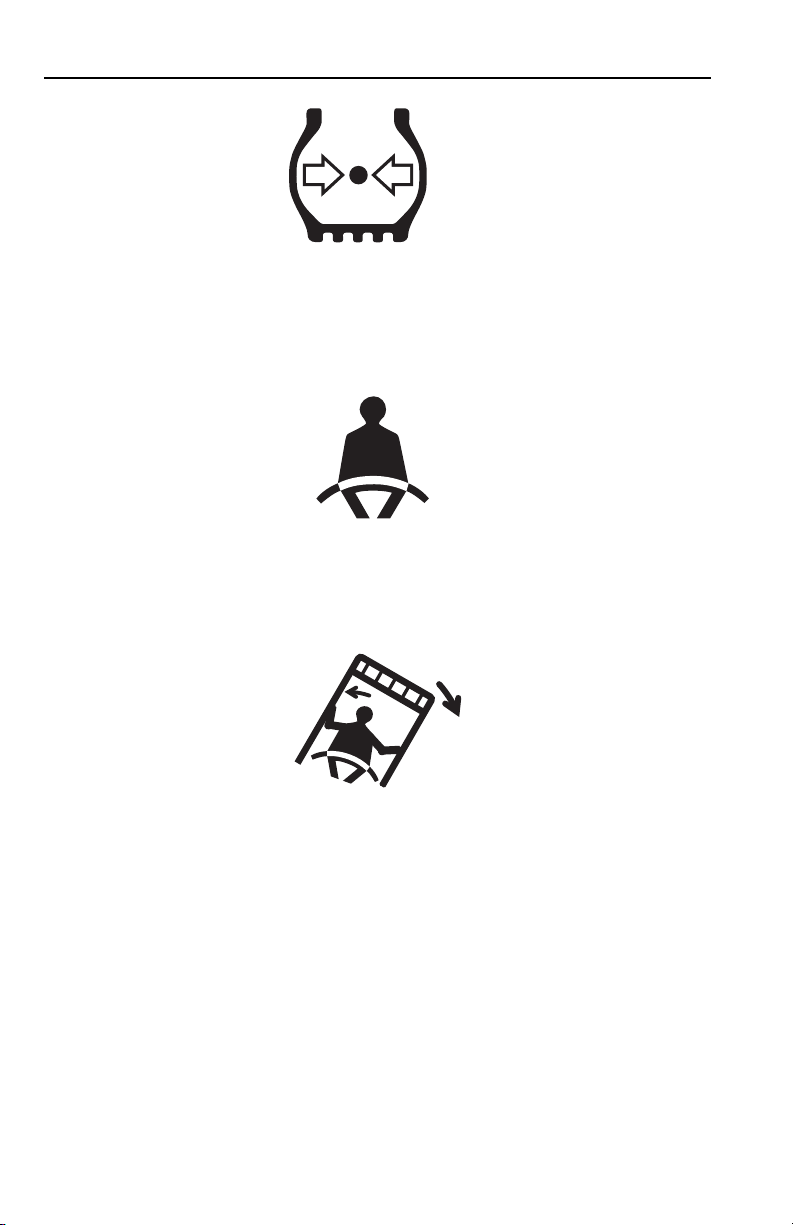

OH2291

• MAINTAIN proper tire pressure at all times. If proper tire pressures are not

maintained, this machine could tip over.

• Refer to manufacturer’s specifications for proper fill ratio and pressure

requirements for tires equipped with ballast.

OH20911

• Always wear the seat belt.

• Keep head, arms, hands, legs and all other body parts inside operator’s cab at all

times.

OH2221

If the telehandler starts to tip over:

• DO NOT JUMP

• BRACE YOURSELF and STAY WITH THE MACHINE

• KEEP YOUR SEAT BELT FASTENED

•HOLD ON FIRMLY

• LEAN AWAY FROM THE POINT OF IMPACT

Trying to escape from a tipping machine could result in death or serious injury.

1-4 31200487

Section 1 - General Safety Practices

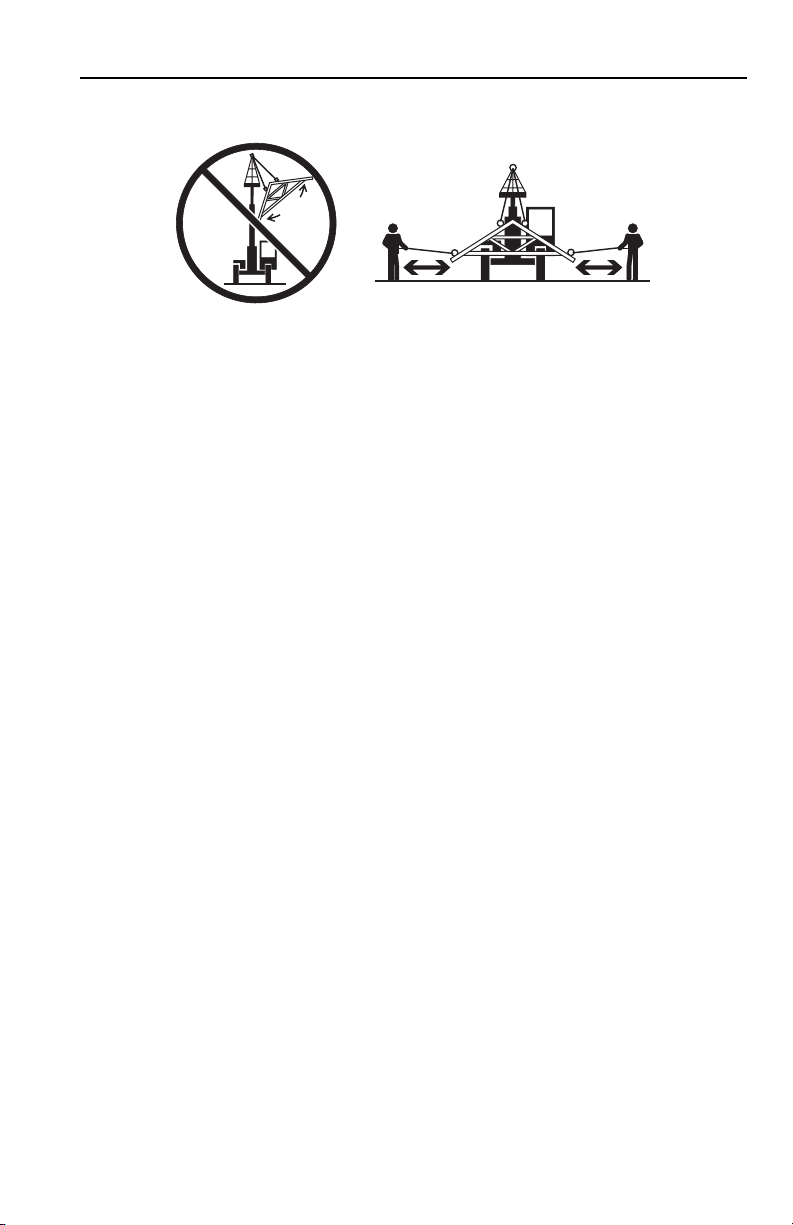

Suspended Load

OW0150

• Tether suspended loads to restrict movement.

• DO NOT raise the load more than 300 mm (11.8 in) above ground surface or the

boom more than 45°.

• Weight of all rigging (slings, etc.) must be included as part of load.

• Start, travel, turn and stop slowly to prevent load from swinging.

• When driving with the boom raised, DO NOT exceed walking speed.

• Beware of wind. Wind can cause a suspended load to swing and cause

dangerous side loads - even with tag lines.

• DO NOT attempt to use telehandler frame-leveling to compensate for load swing.

• Keep heavy part of load closest to attachment.

• Never drag the load; lift vertically.

1-531200487

Section 1 - General Safety Practices

Travel Hazard

2-Wheel Front Steer 4-Wheel Circle Steer 4-Wheel Crab Steer

OAL2030

• Steering characteristics differ between steer modes. Identify the steer mode

settings of the telehandler being operated.

• Ensure that adequate clearance is provided between both rear tail swing and

front fork swing.

• Look out for and avoid other personnel, machinery and vehicles in the area. Use

a spotter if you DO NOT have a clear view.

• Before moving be sure of a clear path and sound horn.

• When driving, retract boom and keep boom/attachment as low as possible while

maintaining visibility of mirrors and maximum visibility of path of travel.

• Always look in the direction of travel.

• Always check boom clearances carefully before driving underneath overhead

obstructions. Position attachment/load to clear obstacles.

• When driving in high speed, use only front wheel steer (if steering modes are

selectable).

1-6 31200487

Section 1 - General Safety Practices

Load Falling Hazard

OW0130

• Never suspend load from forks or other parts of carriage.

• DO NOT burn or drill holes in fork(s).

• Forks must be centered under load and spaced apart as far as possible.

1-731200487

Section 1 - General Safety Practices

Lifting Personnel

OW0170

• When lifting personnel, USE ONLY a JLG approved personnel work platform,

with proper capacity chart displayed in the cab.

OW0190

• DO NOT drive machine from cab when personnel are in platform.

1-8 31200487

Section 1 - General Safety Practices

Driving Hazards on Slopes

OW0200

To maintain sufficient traction and braking capabilities, travel on slopes as follows:

• When unloaded, the rear of the machine is the “heavy end.” Drive with forks

pointed downhill.

• When loaded, the front of the machine is the “heavy end.” Drive with the forks

pointed uphill.

• For additional travel requirements, refer to the appropriate capacity chart.

• To avoid overspeeding the engine and drivetrain when driving down slopes,

downshift to a lower gear and use the service brake as necessary to maintain a

slow speed. DO NOT shift into neutral and coast downhill.

• Avoid excessively steep slopes or unstable surfaces. To avoid tip over DO NOT

drive across excessively steep slopes under any circumstances.

• Avoid turning on a slope. Never engage “inching” or shift to “Neutral” when going

downhill.

• DO NOT park on a slope.

1-931200487

Section 1 - General Safety Practices

Pinch Points and Crush Hazards

Stay clear of pinch points and rotating parts on the telehandler.

• Stay clear of moving parts while engine is running.

OW0220

• Keep clear of steering tires and frame or other objects.

OW0210

OW0230

• Keep clear from under boom.

1-10 31200487

Section 1 - General Safety Practices

OW0240

• Keep clear of boom holes.

OW0250

• Keep arms and hands clear of attachment tilt cylinder.

OW0260

• Keep hands and fingers clear of carriage and forks.

OW0960

• Keep others away while operating.

1-1131200487

Section 1 - General Safety Practices

Fall Hazard

OW0280

• Enter using the proper hand holds and steps provided. Always maintain 3-point

contact when mounting or dismounting. Never grab control levers or steering

wheel when mounting or dismounting the machine.

• DO NOT get off the machine until the shutdown procedure has been performed.

OW0290

• DO NOT carry riders. Riders could fall off machine causing death or serious

injury.

1-12 31200487

Section 1 - General Safety Practices

Chemical Hazards

Exhaust Fumes

• DO NOT operate machine in an enclosed area without proper ventilation.

• DO NOT operate the machine in hazardous environments unless approved for

that purpose by JLG and site owner. Sparks from the electrical system and the

engine exhaust can cause an explosion.

• If spark arrestors are required, ensure they are in place and in good working

order.

Flammable Fuel

OW0300

• DO NOT fill the fuel tank or service the fuel system near an open flame, sparks

or smoking materials. Engine fuel is flammable and can cause a fire and/or

explosion.

Hydraulic Fluid

OW0950

• DO NOT attempt to repair or tighten any hydraulic hoses or fittings while the

engine is running or when the hydraulic system is under pressure.

• Stop engine and relieve trapped pressure. Fluid in the hydraulic system is under

enough pressure that it can penetrate the skin.

• DO NOT use your hand to check for leaks. Use a piece of cardboard or paper to

search for leaks. Wear gloves to protect hands from spraying fluid.

1-1331200487

Section 1 - General Safety Practices

This Page Intentionally Left Blank

1-14 31200487

Section 2 - Load Management Indicator System (LMIS)

SECTION 2 - LOAD MANAGEMENT INDICATOR

SYSTEM (LMIS)

2.1 GENERAL

The LMIS provides visual indication of stability limitations by monitoring suspended

loads compared to predetermined capacity charts.

Note: When using non-suspended load type attachments, capacity charts located

in the operator cab must be used. Refer to the machine Operation & Safety Manual

for details.

2-131200487

Section 2 - Load Management Indicator System (LMIS)

2.2 CONTROL PANEL

The control panel displays information and allows for the selection of different

attachments.

4

3

2

1

+ -

1. UP Button

- Depress to scroll up inside a menu.

2. DOWN Button - Depress to scroll down inside a menu.

3. Display

4. Status Lights

- Shows working data. See page 2-3.

- Progressively illuminate (two green, yellow then red) to indicate

lifting conditions. See page 2-6.

5. ENT Button

6. ESC Button

- Depress to confirm an action.

- Depress to return to previous menu.

5

6

OZ3091

2-2 31200487

Display

Section 2 - Load Management Indicator System (LMIS)

1345 6

2

OFF

a

b

0.0 m

0

t

7

0.0

m

0.0

max

0.0 d

c

d

t

0.0

0.0 m

XXXXX

OZ3410

1. Attachment - Current attachment selection (see page 2-5).

a. OFF - Select when lifting a non-suspended load. Minimal information shown

on display. Capacity charts located in the operator cab must be used.

b. Truss Boom attachment selected.

2. Operating Mode

c. Outriggers fully engaged.

d. Outriggers not engaged.

3. Boom Length - Displays boom length in meters or feet.

4. Bargraph

5. Boom Height

6. Load Percentage - Displays approximate load percentage of the rated capacity.

- Displays approximate percentage of rated capacity.

- Displays boom height in meters or feet.

XXXXX

8

9

10

11

7. Load

8. Boom Angle

9. Rated Capacity

10. Reach

11. Message Display Window - Displays general system information, alarms and

Note: To change display brightness, depress ESC for 2-3 seconds. As the display

cycles through various levels of brightness, depress ENT when the desired

brightness is reached.

- Displays approximate load in metric ton or k-pounds. Load includes

object being lifted and all rigging (slings, etc).

- Displays boom angle in degrees.

- Displays rated capacity in metric ton or k-pounds.

- Displays boom reach from front of tires in meters or feet.

warnings.

2-331200487

Section 2 - Load Management Indicator System (LMIS)

2.3 OPERATION

System Start Up

0

0.0

m

t

0.0

m

0.0

max

0.0

d

t

0.0

0.0

m

ST02 Date

OZ3081

1. When the machine is started the system automatically switches on, performs a

self-test and briefly shows the machine model (1) and LMIS software version (2)

(dd.mm.yy = software date of development).

4

JLGXXXX

0

0.0 m

5

0.0

0.0 d

m

0.0

max

t

2

1

t

0.0

0.0 m

OZ3180

2. The display shows the last used attachment icon (4) and current operating

mode (5).

2-4 31200487

Section 2 - Load Management Indicator System (LMIS)

Attachment Selection

The machine can operate with various attachments, but the appropriate capacity

chart must be selected by the operator. When an attachment is changed, the LMIS

must be manually set to the corresponding attachment capacity chart.

1. Escape out of all menus.

2. Press the UP button.

0.0

max

0

t

t

2

0.0

3

m

0.0

0.0

m

d

0.0

0.0

m

1

XXXXXXXXXXA

OZ3190

3. Press the UP or DOWN button until the part number of the attachment capacity

chart being used is displayed (1).

Note: DO NOT install suspended load type attachments that do not have correct

capacity charts available on the LMIS.

4. Confirm the selection by pressing the ENT button.

5. The correct attachment icon (2) should now be displayed.

Note: Before lifting a load, check that the correct operating mode (3) is displayed.

The system should automatically select the correct operating mode.

XXXX XXXX

WARNING

Never use a suspended load type attachment without the appropriate JLG

supplied capacity chart installed on the LMIS. Failure to use the proper JLG

supplied capacity chart could cause a tip over resulting in death or serious injury.

2-531200487

Section 2 - Load Management Indicator System (LMIS)

Lifting Conditions and Alarms

The control panel and external audible beacon tower (if equipped) display machine

operating conditions.

1

23 4

3

2

1

VIEW OF EXTERNAL AUDIBLE

BEACON TOWER (IF EQUIPPED)

+ -

OZ3121

1. Green Light

2. Yellow Light

0

0.0 m

0.0

0.0 d

0.0 m

t

0.0

m

max

t

0.0

- Illuminates when load is less than rated capacity.

- Illuminates and intermittent alarm sounds when load is

approaching rated capacity.

3. Red Light

- Illuminates and constant alarm sounds when automatic function

cut-out is activated. Certain functions are disabled (i.e. boom lift, extend, etc).

Retract boom to re-enable functions.

4. Bargraph

- See page 2-3.

5. Automatic Function Cut-Out Override

(not illustrated) - Momentarily disables the

automatic function cut-out. Indicator flashes while activated.

Switch/button and indicator locations vary by model. Refer to the machine

Operation & Safety Manual for location details.

Note: Override will only function for 30 seconds. After 30 seconds, boom functions

will cease and the switch/button will need released and depressed again.

WARNING

TIP OVER HAZARD. Exceeding lift capacity of the telehandler could damage the

equipment and/or cause tip over resulting in death or serious injury.

2-6 31200487

Section 2 - Load Management Indicator System (LMIS)

2.4 DIAGNOSTIC DATA

By pressing ENT, the display shows sub-menus. To enter a sub-menu, wait 2-3

seconds on the selected menu.

Alarms and Warnings

The first menu displays the Alarm and Warning Codes.

P01 : Alarms

In this menu, the Alarm code and Warning codes are shown. See page 5-2 for listing

of codes.

Alarms : XXXX

Warning : XXXX

LMI Values

The second menu displays the LMI Values.

P02 : Lmi Values

In this menu the following values are shown:

• P - Differential Pressure (bar).

• W - Weight Lifted (ton).

• M - Max Load (ton).

• Ac - Boom Angle (degree).

• L - Boom Length (meter).

• R - Boom Radius (meter).

P XXX W XXX M XXX

Ac XXX L XXX R XXX

2-731200487

Section 2 - Load Management Indicator System (LMIS)

Pressure Values

The third menu displays Pressure Values.

P03 : Pressures

In this menu the following values are shown:

• P - Differential pressure of the Lift cylinder (bar).

• L - Pressure in the piston side of the Lift cylinder (bar).

• H - Pressure in the rod side of the Lift cylinder (bar).

• p - Differential pressure in the Compensation cylinder (bar).

• l - Pressure in the piston side of Compensation cylinder (bar).

• h - Pressure in rod side of the Compensation cylinder (bar).

P XXX L XXX H XXX

p XXX l XXX h XXX

Angle and Length Transducers

The fourth menu displays information from the cable reel.

P04 : Act 1A

In this menu the following values are shown:

• A - Angle Reading from angle sensor.

• L - Length Reading from length sensor.

• E - Error reading from cable reel.

Act1A A : XXX

E : XX L : XXX

2-8 31200487

Section 2 - Load Management Indicator System (LMIS)

LMI Status

The fifth menu displays information relative to LMI status.

P17 : Lmi Status

P17 : Lmi Status

I0 :OFF

1. Press ESC to enter the sub-menu.

*

X I : value

2. Press ESC to move the (*).

3. Press DOWN to decrease the item selected.

4. Press UP to increase the item selected.

2-931200487

Section 2 - Load Management Indicator System (LMIS)

2-10 31200487

Section 3 - Machine Operation

SECTION 3 - MACHINE OPERATION

3.1 OPERATING WITH A SUSPENDED LOAD

Lift Load Safely

• You must know the weight and load center of every load you lift. If you are not

sure of the weight and load center, check with your supervisor or with the

supplier of the material.

WARNING

TIP OVER HAZARD. Exceeding lift capacity of the telehandler could damage the

equipment and/or cause tip over resulting in death or serious injury.

• Know the rated load capacities (refer to Section 4 - Attachments) of the

telehandler to determine the operating range in which you can safely lift,

transport and place a load.

Picking Up A Suspended Load

• Note the conditions of the terrain. Adjust travel speed and reduce amount of load

if conditions warrant.

• Avoid lifting double-tiered loads.

• Make sure load is clear of any adjacent obstacles.

• NEVER operate telehandler without the appropriate JLG supplied capacity chart

selected on the LMIS.

• Ensure to always properly tether loads to restrict movement.

• Refer to “Use of the Capacity Chart” on page 4-1 for proper lifting guidelines in

addition to the appropriate capacity chart on the machine.

• Only use approved lifting devices rated for the lifting of the load.

• Identify the proper lifting points of the load, taking into consideration the center of

gravity and load stability.

3-131200487

Section 3 - Machine Operation

Transporting a Suspended Load

OZ3160

• Travel in accordance with the requirements set forth in Section 1 - General

Safety Practices and Section 4 - Attachments.

• For additional requirements, refer to the appropriate capacity chart.

Important things to remember:

• Ensure the boom is fully retracted.

• Never raise the load more than 300 mm (11.8 in) above ground surface or the

boom more than 45°.

• The combination of side tilt and load could cause the telehandler to tip over.

• The guide men and operator must remain in constant communication (verbal or

hand) and be in visual contact with the operator at all times.

• Never place the guide men between the suspended load and the telehandler.

• Only transport the load at walking speed (0.4 m/s) or less.

OW0130

Leveling Procedure

1. Position machine in best location to lift or place load.

2. Apply parking brake and move transmission control lever to NEUTRAL.

3. Move boom so load is no more than 300 mm (11.8 in) above ground surface

and/or boom is raised no more than 45°.

4. Observe level indicator to determine whether machine must be leveled prior to

lifting load.

3-2 31200487

Section 3 - Machine Operation

Placing a Suspended Load

Before placing any load be sure that:

• The landing point can safely support the weight of the load.

• The landing point is level; front to back and side to side.

• Use the capacity chart to determine safe boom extension range. See “Use of the

Capacity Chart” on page 4-1.

• Align load at the level load is to be placed, then position boom slowly until load is

just above area where it is to be placed.

• Ensure that the guide men and operator remain in constant communication

(verbal or hand) when placing the load.

Disengaging A Suspended Load

• Never place the guide men between the suspended load and the telehandler.

• Once at the destination of the load, ensure to bring the telehandler to a complete

stop and apply the park brake prior to disengagement of the lifting devices and

the tethers.

3-331200487

Section 3 - Machine Operation

This Page Intentionally Left Blank

3-4 31200487

Section 4 - Attachments

SECTION 4 - ATTACHMENTS

4.1 USE OF THE CAPACITY CHART

To properly use the capacity chart (see page 4-2), the operator must first determine

and/or have the following:

1. A JLG approved attachment.

2. The proper Capacity Chart.

3. Weight of the load being lifted.

4. Load placement information:

a. HEIGHT where the load is to be placed.

b. DISTANCE from the front tires of the telehandler where the load is to be

placed.

5. On the capacity chart, find the line for the height and follow it over to the

distance.

6. The number in the load zone where the two cross is the maximum capacity for

this lift. If the two cross at a division between zones, the smaller number must

be used.

7. For additional operating instructions, refer to the appropriate capacity chart.

The number in the load zone must be equal to or greater than the weight of the load

to be lifted. Determine the limits of the load zone on the capacity chart and keep

within these limits.

Capacity Indicator Locations

ATTACHMENT

IDENTIFICATION

PLATE

ATTACHMENT

CAPACITY

PLATE

BOOM EXTENSION

INDICATOR

LMIS CONTROL PANEL

(inside cab)

AB

OZ3400

4-131200487

Section 4 - Attachments

Sample Capacity Chart

This Capacity Chart may be

used with this model ONLY.

The model of your

telehandler is indicated on

the boom or chassis.

Model XXXX is used for

demonstration purposes only.

XXXX

Boom Extension

Indicator (arc)

Boom Angle

XX

XX

XX

XX

XX

XX

XX

XX

XX

20°

XX

XX

XX

10°

XX

XX

0°

XX

m

XX XX XX XX XX XX XX XX XX XX XX XX

KEEP TRUSS BOOM HORIZONTAL

WITHIN ±XX DEGREES.

XXXXXXXXXX

60°

50°

40°

30°

g

k

X

X

X

g

X

k

X

X

X

g

k

X

X

X

A

These numbers must match the

model/option number stamped

on the attachment ID Plate.

TRAVELLING (PICK & CARRY)

P/N XXXXXXXX

70°

G

F

E

D

C

B

A

g

k

X

g

k

X

X

X

X

X

X

X

REQUIRES LOAD ON HOOK.

MAX TRAVEL WITH RATED LOAD XX M/S.

(WALKING SPEED).

BOOM FULLY RETRACTED.

XX° MAX

MAX BOOM

XX° MAX

LIFTING (STATIONARY)

REQUIRES FIRM SURFACE WITH LOAD ON HOOK.

LEVEL CHASSIS BEFORE LIFTING.

JIB LEVEL WITHIN ±XX°.

X° MAX

X° MAX

SPECIFICATIONS FOR SAFE USE

1. TYRE SIZES:

- XXX/XX-XX XXPLY XX PSI / X BAR.

2. IN-SERVICE WIND SPEED:

- XXM/S (XXKM/H).

3. GROUND CONDITIONS:

- FIRM SURFACES FOR LIFTING.

- SLOPE AND LOAD LISTED ABOVE FOR

BOTH CONFIGURATIONS.

4. STANDARD USED: (AS 1418.19-2007).

Load zones indicate

the maximum weight

that may be safely lifted.

ANGLE XX°

XXXMM

MAX

MAX BOOM

ANGLE XX°

XX° MAX

XXXMM

MAX

MAX BOOM

ANGLE XX°

XXXMM

MAX

X° MAX

TRUSS BOOM

±XX° MAX

OAM2331

Travelling

Information

Lifting

Information

Specifications

for Safe Use

Note: This is a sample capacity chart only! DO NOT use this chart, use the one

located in your operator cab.

WARNING

TIP OVER HAZARD. All loads shown on rated capacity chart are based on

machine being operated within the parameters indicated on the appropriate

capacity chart; proper size tires being properly inflated; and the telehandler being

in good operating condition. Failure to comply could result in death or serious

injury.

4-2 31200487

Section 4 - Attachments

To identify the proper capacity chart on telehandlers equipped with outriggers, refer

to the following icons which may be located on the capacity chart.

• Use when lifting a load with outriggers up.

OW0930

• Use when lifting a load with outriggers down.

OW0940

4-331200487

Section 4 - Attachments

Example

A contractor owns a model xxxx telehandler with a truss boom. He knows this

attachment may be used with his model since:

• The attachment model/option number, matches the attachment number on the

capacity chart.

• The capacity chart is clearly marked for model xxxx and corresponds with

machine configuration being used.

• The capacity chart part number is available and selected on the LMIS.

Below are examples with various conditions the contractor may encounter and

whether or not the load may be lifted.

Load Weight Distance Height OK to Lift

1 400 kg (882 lb) 8 m (26.2 ft) 4 m (13.1 ft) Yes

2 1000 kg (2,205 lb) 6 m (19.7 ft) 9 m (29.5 ft) NO

3 1500 kg (3,307 lb) 4 m (13.1 ft) 6 m (19.7 ft) Yes

4 1250 kg (2,756 lb) 5 m (16.4 ft) 11 m (36.1 ft) NO

P/N XXXXXXXX

Example 4

C

B

A

Example 3

OAM2321

Example 2

Example 1

XXXX

14

13

12

11

10

9

8

7

6

20°

5

4

3

10°

2

1

0°

0

m

11109876543210

50°

40°

30°

500kg

250kg

60°

1.000kg

70°

1.500kg

G

F

E

D

2.000kg

Note: This is a sample capacity chart only! DO NOT use this chart, use the one

located in your operator cab.

4-4 31200487

Section 4 - Attachments

Truss Boom

Description P/N

Truss Boom 2 m - 4000 kg.........................................1001101442

OZ3420

Use Truss Boom Capacity Chart

Suspend loads in accordance with requirements set forth in Section

1 - General Safety Practices.

The joystick (1) controls movement of the boom.

The attachment tilt roller switch (2) controls truss boom tilt.

• Push roller switch down to tilt up.

• Push roller switch up to tilt down.

4-531200487

Section 4 - Attachments

This Page Intentionally Left Blank

4-6 31200487

Section 5 - LMIS Service and Maintenance

SECTION 5 - LMIS SERVICE AND MAINTENANCE

5.1 AUTO-DIAGNOSTIC SYSTEM

The LMIS is equipped with an auto-diagnostic system which is able to detect faulty

pressure transducers, boom angle/length sensors, broken cables or internal

electronic faults.

When the alarm sounds, the display shows an alarm message. If an alarm code

sounds apply the park brake, shift the transmission into “Neutral”, lower forks or

attachment to the ground and shut off the engine. Restart the engine.

If the alarm code persists, refer to “Alarm Codes” on page 5-2. For troubleshooting

information, refer to the appropriate machine service manual.

For additional information, contact your local authorized service distributor.

5-131200487

Section 5 - LMIS Service and Maintenance

Alarm Codes

Alarm

Code

10 Reading pressure of Lift cylinder (bottom side) lower than minimum

11 Reading pressure of the Lift cylinder (bottom side) higher than

12 Reading pressure of the Lift cylinder (rod side) lower than minimum

13 Reading pressure of the Lift cylinder (rod side) higher than maximum

14 Reading pressure of the Compensation cylinder (bottom side) lower

15 Reading pressure of the Compensation cylinder (bottom side) higher

Description

1 Memory Data Not Reliable

2 Angle Sensor 1 reading lower than minimum value

3 Angle Sensor 1 reading higher than maximum value

4 Reading of boom length sensor 1 lower than minimum value

5 Reading of boom length sensor 1 higher than maximum value

value

maximum value

value

value

than minimum value

than maximum value

16 Reading pressure of the Compensation cylinder (rod side) lower than

minimum value

17 Reading pressure of the Compensation cylinder (rod side) higher than

maximum value

120 Canbus time-out from cable reel

121 Internal error from cable reel

5-2 31200487

An Oshkosh Corporation Company

JLG Industries, Inc.

1 JLG Drive

McConnellsburg PA. 17233-9533

USA

Phone: +1-717-485-5161

Customer Support Toll Free: 1-877-554-5438

Fax: +1-717-485-6417

JLG Worldwide Locations

JLG Industries (Australia)

P.O. Box 5119

11 Bolwarra Road

Port Macquarie

N.S.W. 2444

Australia

Phone: +61 265 811 111

Fax: +61 265 810 122

JLG France SAS

Z.I. de Baulieu

47400 Fauillet

France

Phone: +33 (0)5 53 88 31 70

Fax: +33 (0)5 53 88 31 79

JLG Industries (Italia) s.r.l.

Via Po. 22

20010 Pregnana Milanese - MI

Italy

Phone: +39 029 359 5210

Fax: +39 029 359 5845

JLG Industries (Scotland)

Wright Business Centre

1 Lonmay Road

Queenslie, Glasgow G33 4EL

Scotland

Phone: +44 (0)141 781 6700

Fax: +44 (0)141 773 1907

JLG Latino Americana Ltda.

Rua Eng. Carlos Stevenson,

80-Suite 71

13092-310 Campinas-SP

Brazil

Phone: +55 193 295 0407

Fax: +55 193 295 1025

JLG Deutschland GmbH

Max-Planck-Str. 21

D - 27721 Ritterhude-lhlpohl

Germany

Phone: +49 (0)421 69 350 20

Fax: +49 (0)421 69 350 45

JLG Europe B.V.

Polaris Avenue 63

2132 JH Hoofddorp

The Netherlands

Phone: +31 (0)23 565 5665

Fax: +31 (0)23 557 2493

Plataformas Elevadoras

JLG Iberica, S.L.

Trapadella, 2

P.I. Castellbisbal Sur

08755Castellbisbal, Barcelona

Spain

Phone: +34 93 772 4 700

Fax: +34 93 771 1762

JLG Industries (UK) Ltd

Bentley House

Bentley Avenue

Middleton

Greater Manchester

M24 2GP

England

Phone: +44 (0)161 654 1000

Fax: +44 (0)161 654 1001

JLG Equipment Services Ltd.

Rm 1107 Landmark North

39 Lung Sum Avenue

Sheung Shui N.T.

Hong Kong

Phone: +852 2639 5783

Fax: +852 2639 5797

JLG Polska

UI. Krolewska

00-060 Warsawa

Poland

Phone: +48 (0)914 320 245

Fax: +48 (0)914 358 200

JLG Sverige AB

Enkopingsvagen 150

Box 704

SE - 176 27 Jarfalla

Sweden

Phone: +46 (0)850 659 500

Fax: +46 (0)850 659 534

Loading...

Loading...