siemens 611 User Manual

-

SIMODRIVE 611 digital/ SINUMERIK 840D/810D

Drive Functions

Function Manual

Valid for

Control

SINUMERIK 840D

SINUMERIK 840DE (export version)

SINUMERIK 840D powerline

SINUMERIK 840DE powerline

SINUMERIK 810D

SINUMERIK 810DE (export version)

SINUMERIK 810D powerline

SINUMERIK 810DE powerline

Drive

SIMODRIVE 611 digital

05/2010 Edition

Operational Messages/ |

|

Alarm Responses |

DB1 |

Diagnostic Functions |

DD1 |

Speed Control Loop |

DD2 |

Extended Drive Functions |

DE1 |

Enables |

DF1 |

Encoder Parameterization DG1 |

|

Parameters for |

|

Linear Motors |

DL1 |

Calculating Motor/Power |

|

Section/Controller Data |

DM1 |

Current Control Loop |

DS1 |

Monitoring Functions/ |

|

Limits |

DÜ1 |

Abbreviations |

A |

Explanation of Terms |

B |

List of Drive Machine Data |

C |

Drive Functions |

D |

Index |

|

3ls |

SINUMERIK documentation |

Printing history

Brief details of this edition and previous editions are listed below.

The status of each edition is shown by the code in the ”Remarks” columns.

Status code in the ”Remarks” column:

A . . . . . New documentation.

B . . . . . Unrevised reprint with new Order No. C . . . . . Revised edition with new status.

If factual changes have been made on the page since the last edition, this is indicated by a new edition coding in the header on that page.

Edition |

Order No. |

Remarks |

12.95 |

6SN1 197--0AA80--0BP0 |

A |

07.96 |

6SN1 197--0AA80--0BP1 |

C |

08.97 |

6SN1 197--0AA80--0BP2 |

C |

12.97 |

6SN1 197--0AA80--0BP3 |

C |

12.98 |

6SN1 197--0AA80--0BP4 |

C |

08.99 |

6SN1 197--0AA80--0BP5 |

C |

10.00 |

6SN1 197--0AA80--0BP6 |

C |

09.01 |

6SN1 197--0AA80--0BP7 |

C |

12.01 |

6SN1 197--0AA80--0BP8 |

C |

12.02 |

6SN1 197--0AA80--1BP0 |

C |

03.04 |

6SN1 197--0AA80--1BP1 |

C |

10.04 |

6SN1 197--0AA80--1BP2 |

C |

11.05 |

6SN1 197--0AA80--1BP3 |

C |

08.06 |

6SN1 197--0AA80--1BP4 |

C |

03.07 |

6SN1 197--0AA80--1BP5 |

C |

11.07 |

6SN1 197--0AA80--1BP6 |

C |

08.08 |

6SN1 197--0AA80--1BP7 |

C |

12.08 |

6SN1 197--0AA80--1BP8 |

C |

06.09 |

6SN1 197--0AA80--2BP0 |

C |

05.10 |

6SN1 197--0AA80--2BP1 |

C |

Trademarks

All products mentioned may be trademarks or product designations of Siemens AG or their suppliers, whose use by third parties for their own purposes may infringe the rights of the trademark owners.

|

We have checked that the contents of this document correspond to |

|

the hardware and software described. Nevertheless, differences |

|

might exist and therefore we cannot guarantee that they are |

|

completely identical. The data in this document is regularly checked |

|

and the necessary corrections are included in subsequent editions. |

|

Suggestions for improvement are also welcome. |

Siemens AG 1995 - 2010 All rights reserved. |

Subject to change without prior notice. |

Printed in the Federal Republic of Germany |

Siemens-Aktiengesellschaft |

068.0986 |

Preface |

Preface

Structure of the documentation

Target group

Benefits

Standard scope

The SIMODRIVE 611 documentation is structured in 2 levels:

S General documentation

S Manufacturer/Service documentation

Information on the following topics is available at

http://www.siemens.com/motioncontrol/docu:

SOrdering documentation

Here you can find an up--to--date overview of publications.

SDownloading documentation

Links to more information for downloading files from Service & Support.

SResearching documentation online

Information on DOConCD and direct access to the publications in DOConWEB.

SIndividually compiling documentation on the basis of Siemens contents with the My Documentation Manager (MDM), refer to http://www.siemens.com/mdm

My Documentation Manager provides you with a range of features for generating your own machine documentation.

STraining and FAQs

Information on our range of training courses and FAQs (frequently asked questions) is available via the page navigation.

This document addresses engineers and technologists (employed with the machinery construction OEM), commissioning engineers (commissioning the system/machine), programmers. The brochure contains a detailed description of the scope of functions offered by SINUMERIK 840D/810D controllers and SIMODRIVE 611 digital drives.

This publication describes the functions so that the target group understands these functions and can appropriately select them. It provides the target group with the information required to implement the functions.

Should you wish for additional information or should exceptional problems arise that are not addressed in sufficient detail in this manual, you can request the required information from your local Siemens office.

The scope of the functionality described in this document can differ from the scope of the functionality of the drive system that is actually supplied. Other functions not described in this documentation might be able to be executed in the drive system. However, no claim can be made regarding the availability of these functions when the equipment is first supplied or in the event of servicing. Additions or revisions made by the machine manufacturer are documented by the machine manufacturer.

This document does not purport to cover all details or variations in equipment, nor to provide for every possible contingency to be met in connection with installation, operation or maintenance.

The contents of this document are not part of an earlier or existing contract or agreement nor do they change this. The Purchase Agreement contains the complete and exclusive obligations of Siemens. Any statements contained herein neither create new warranties nor modify the existing warranty.

Siemens AG 2010 All Rights Reserved |

iii |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Preface |

1208..0806 |

Technical Support If you have any technical questions, please contact our hotline:

|

Europe/Africa |

|

|

Phone |

+49 180 5050 222 |

|

|

Fax |

+49 180 5050 223 |

|

|

Internet |

http://www.siemens.com/automation/support-request |

|

|

|

Americas |

|

|

Phone |

+1 423 262 2522 |

|

|

Fax |

+1 423 262 2200 |

|

|

mailto:techsupport.sea@siemens.com |

|

|

|

|

Asia/Pacific |

|

|

|

|

Phone |

+86 1064 757 575 |

|

|

|

|

Fax |

+86 1064 747 474 |

|

|

|

|

mailto:support.asia.automation@siemens.com |

||

|

|

|

|

|

|

Note

Questions regarding documentation

Country--specific telephone numbers for technical support can be found on the Internet: http://www.automation.siemens.com/partner

Calls are subject to charge, e.g. 0.14 €/min. on the German landline network. Tariffs of other phone providers may differ.

If you have any queries (suggestions, corrections) in relation to this documentation, please fax or e--mail us:

Fax +49 9131 98 2176

E-mail mailto:docu.motioncontrol@siemens.com

Internet address

Certificates

Notes on how to use this manual

Up--to--date information about our products can be found on the Internet at the following address:

http://www.siemens.com/simodrive

You will find the certificates for the products described in this documentation on the Internet: http://www.support.automation.siemens.com

under the Product/Order No. 15257461

or at the relevant branch office of the A&D MC group of Siemens AG.

All declarations of conformity and certificates such as CE, UL, etc., relate to the system components described in the corresponding Configuration Manuals/Catalogs and are, therefore, only valid if these components are used in the device or system.

This Function Manual is structured as follows:

S General contents

SDescriptions of functions in alphabetical order according to the function description codes

S Appendix with list of abbreviations, terms and references

iv |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

116058.1009786 |

Preface |

Edition of the documentation?

Software release?

What’s new?

S Index

SList of machine data with cross references to the corresponding description of functions

Note

The following information is provided on each page:

Part of Description of Functions/Publication/Chapter -- Page

There is a fixed relationship between the edition of the documentation and the software release of the drive functions.

S The first edition (12/1995) describes the functionality of SW 1.0.

SThe 03/2007 edition describes the functionality of SW 1.0 to 6.x.

What are the essential new functions that have been added for SW 6.08.18? -- 10 current setpoint filters (not CCU3) (DD2)

-- Expansion of dynamic energy management (DE1)

-- Thermal motor model (not CCU3) (DÜ1)

SThe 11/2007 edition describes the functionality of SW 1.0 to 6.x.

What are the essential new functions that have been added for SW 6.08.19 to SW 6.08.21?

-- Monitoring of the direction of the axis motion (DM1) -- Motor ground fault test (DÜ1)

-- VDC_min_controller (DÜ1)

SThe 08/2008 edition describes the functionality of SW 1.0 to 6.x.

What are the essential new functions that have been added for SW 6.08.22 to SW 6.08.25?

-- FDD operation with field weakening (DE1)

SThe 06/2009 edition describes the functionality of SW 1.0 to 6.x.

What are the essential new functions that have been added for SW 6.08.26 to SW 6.08.27?

-- Removing the limitations for the combination – brakes/ground fault/RLI -- Ground fault with a linear motor

-- Increased peak current for power units –0JA

SThe 05/2010 edition describes the functionality of SW 1.0 to 6.x.

What are the essential new functions that have been added for SW 6.08.28? -- Correction of the reference value for MD 1266 “Thermal motor load”

-- “Thermal motor load” signal in DAC

-- Data set changeover for absolute value encoders possible

Siemens AG 2010 All Rights Reserved |

v |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Preface |

08..0806 |

Safety information

!indicates that death or serious injury will result if proper precautions are not taken.Danger

!indicates that death or serious injury may result if proper precautions are not taken.Warning

!indicates that minor personal injury may result if proper precautions are not taken.

Caution

without a safety alert symbol, indicates that property damage can result if proper precautions are not taken.

Notice

means an undesirable result or state can occur if the corresponding instruction is not followed.Caution

|

In the event of a number of levels of danger prevailing simultaneously, the warn- |

|

ing corresponding to the highest level of danger is always used. If a warning |

|

notice is used with the safety alert symbol to warn against injury, this same no- |

|

tice may also include a warning regarding property damage. |

Qualified |

Setup and operation of the device/equipment/system in question must only be |

personnel |

performed using this documentation. Only qualified personnel should be al- |

|

lowed to commission and operate the device/system. For the purpose of the |

|

safety information in this documentation, a “qualified person” is someone who is |

|

authorized to energize, ground, and tag equipment, systems, and circuits in |

|

accordance with established safety procedures. |

Proper use |

Please note the following: |

!Siemens products must only be used for the applications specified in the catalog and in the technical documentation. If third--party products and components are used, they must be recommended or approved by Siemens. To ensure trouble--free and safe operation of the products, they must be appropriately transported, stored, assembled, installed, commissioned,

operated and maintained. The permissible ambient conditions must be adhered to. The notes in the associated documentation must be complied with.Warning

vi |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

08.06 |

Preface |

Explanation of symbols

Order data option

In this documentation you will find the symbol shown on the left with a reference to an ordering data option. The function described will only be able to be used if the control contains the designated option.

Machine manufacturer

This pictorial symbol always appears in this document to indicate that the machine manufacturer can affect or modify the function described. See machine manufacturer’s specifications.

Technical information

Notations

Explanation for abbreviations used in Chap. 4 and 5

Default value

Value range (minimum and maximum value)

Effectiveness of changes

The following notations and abbreviations are used in this document:

S Machine data --> MD: MD_NAME (German name)

S Setting data --> SD: SD_NAME (German name)

S The symbol ” ” means ”corresponds to”.

The data/signals that are important for each function are described in Chapters 4 and 5 of each Description of Functions. Certain terms and abbreviations, which are used in these tabular descriptions, are explained here.

The machine data/setting data is preset to this value during startup. If default values for the channels differ, this is indicated by ”/”.

Specifies the input limits. If no value range is specified, the data type determines the input limits and the field is marked ” ”.

Changes made to machine data, setting data, etc. do not take immediate effect in the control. The conditions for such changes to take effect are always indicated. The possible options are listed in order of priority below:

S |

POWER ON (po) |

”RESET” key on front panel of NCU module, |

|

|

or disconnection/reconnection of power supply |

S |

NEW_CONF (cf) |

-- Reconfiguration of the PLC interface |

|

|

-- ”RESET” key on control unit, or |

S |

RESET (re) |

”RESET” key on control unit or |

S |

Immediately (im) |

after the value has been entered. |

Siemens AG 2010 All Rights Reserved |

vii |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Preface |

08.06 |

Protection level |

Protection levels 0 to 7 have been used. The lock for protection levels 0 to 3 |

||

|

(4 to 7) can be canceled by entering the correct password (setting the correct |

||

|

keyswitch position). The operator only has access to information protected by |

||

|

one particular level and the levels below it. The machine data is assigned differ- |

||

|

ent protection levels by default. |

|

|

|

Only the write protection level appears in the table. However, there is a fixed |

||

|

assignment between write and read levels: |

|

|

|

|

|

|

|

Write protection level |

|

Read protection level |

|

|

|

|

|

0 |

|

0 |

|

|

|

|

|

1 |

|

1 |

|

|

|

|

|

2 |

|

4 |

|

|

|

|

|

References: |

/BA/, Operating Manual |

|

|

|

|

/FB/, A2, Various Interface Signals |

Unit |

The unit refers to the default setting for the machine data |

||

|

SCALING_FACTOR_USER_DEF_MASK and |

||

|

SCALING_FACTOR_USER_DEF. |

||

|

If a physical unit has not been assigned to the MD, ”--” appears in the field. |

||

Data type |

The following data types are used in the control: |

||

|

S |

DOUBLE |

|

|

|

Real values or integers |

|

|

|

input limits from +/--4.19*10--307 to +/--1.67*10308 |

|

|

S |

DWORD |

|

|

|

Integers |

|

|

|

input limits from --2.147*109 to +2.147*109 |

|

|

S |

BOOLEAN |

|

|

|

Possible input values: true or false/0 or 1 |

|

|

S |

BYTE |

|

|

|

Integers from --128 to +127 |

|

|

S |

STRING |

|

|

|

Comprising a max. of 16 ASCII characters (upper case letters, numbers |

|

|

|

and underscores) |

|

Data management The explanations of the PLC interface in the individual Descriptions of Functions assume a theoretical maximum number of components:

S 4 mode groups (corresponding signals stored in DB11, ...)

S 8 channels (corresponding signals stored in DB21, ...)

S 18 axes (corresponding signals stored in DB31, ...)

For details of the actual number of components which can be implemented with each software version, please refer to

References: /FB/, K1, Mode Groups, Channels, Program Operation

J

viii |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

058.1006

SIMODRIVE 611D/SINUMERIK 840D/810D

Drive Functions

Operational Messages/Alarm Responses (DB1)

1 |

Product Brief . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/1-3 |

|

2 |

Detailed Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/2-5 |

|

|

2.1 |

Pulse suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/2-5 |

|

2.2 |

Relay functions/operational messages . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/2-7 |

|

2.2.1 |

Threshold torque for Md < Mdx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/2-9 |

|

2.2.2 |

Minimum speed for |nact| < nmin . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/2-10 |

|

2.2.3 |

Threshold speed for nact < nx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/2-12 |

|

2.2.4 |

Speed in the setpoint range for nact = nset . . . . . . . . . . . . . . . . . . . . |

DB1/2-12 |

|

2.3 |

Filter for the current and torque display . . . . . . . . . . . . . . . . . . . . . . . |

DB1/2-13 |

|

2.4 |

Alarm response, suppressing alarms . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/2-15 |

3 |

Supplementary Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/4-21 |

|

4 |

Data Descriptions (MD, SD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/4-21 |

|

5 |

Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/5-23 |

|

6 |

Example |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/7-29 |

7 |

Data Fields, Lists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/7-29 |

|

|

7.1 |

Pulse suppression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/7-29 |

|

7.2 |

Relay functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/7-29 |

|

7.2.1 |

Threshold torque for Md < Mdx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/7-29 |

|

7.2.2 |

Minimum speed for |nact| < nmin . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/7-30 |

|

7.2.3 |

Threshold speed nact < nx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/7-30 |

|

7.2.4 |

Speed in the setpoint range, nact = nset . . . . . . . . . . . . . . . . . . . . . . |

DB1/7-30 |

|

7.3 |

Filter for current and torque display . . . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/7-30 |

|

7.4 |

Alarm response, suppressing alarms . . . . . . . . . . . . . . . . . . . . . . . . . |

DB1/7-31 |

Siemens AG 2010 All Rights Reserved |

DB1--i |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

0508..1006

Space for your notes

DB1--ii |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

08.06 |

Operational Messages/Alarm Responses (DB1) |

|

1 Product Brief |

Product Brief |

1 |

Pulse suppression when the servo enable is canceled

Signaling functions/ operational messages

Signal exchange via system variables

Alarm response, suppressing alarms

When the drive servo enable is canceled (using terminal 64, initiated from the NC, PLC or under fault conditions), the drive decelerates along the torque limit with speed setpoint = 0, until the speed falls below the creep speed or the timer has expired. The pulses are then suppressed.

Torque and speed messages can be output to the PLC as a function of limit settings. Operational messages can also be seen in the service displays.

Machine data can be used to configure the ”Drive load”, ”Drive torque setpoint” and ”Actual current values of axis/spindle” signals with the PT1 smoothing filter.

System variables can be used to read drives signals via the part program:

S Drive load ($AA_LOAD), described in /FBA/ DD1

S Drive torque setpoint ($AA_TORQUE)

S Active drive power ($AA_POWER)

S Actual current values of axis/spindle ($AA_CURR)

Further information about programming:

References: /PGA/ Programming Manual Advanced, Chapters 1 and 15.

User--configured monitoring functions are available. Alarms can be suppressed and the shutdown response to a fault/error condition can be set (immediate pulse disable or the drive servo enable canceled).

J

Siemens AG 2010 All Rights Reserved |

DB1/1-3 |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Operational Messages/Alarm Responses (DB1) |

0508..1006 |

1 Product Brief |

|

Space for your notes

DB1/1-4 |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

08.06 |

Operational Messages/Alarm Responses (DB1) |

|

2.1 Pulse suppression |

Detailed Description |

2 |

2.1Pulse suppression

1403 |

PULSE_SUPPRESSION_SPEED |

|

|

Cross reference: |

|

|

|

|

|

|

- |

|

Creep speed, pulse suppression |

|

Relevant: |

Protection level: |

|

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

rev/min |

0.0 |

0.0 |

7 200.0 |

FLOAT |

Immediately |

|

MSD: 2.0 |

|

|

|

|

|

|

|

|

|

|

The default setting depends on the motor type (FDD ¹ 0, MSD ¹ 2) and is parameterized during startup using the drive configuration. The default value 0 means that the machine data is inactive. Pulses are now exclusively suppressed via machine data

MD 1404: PULSE_SUPPRESSION_DELAY.

When the drive servo enable is canceled (this is possible using terminal 64, from the NC or in the event of an error), the drives decelerate along their torque limit. If the speed actual value falls below the specified speed threshold during shutdown, the pulse enable is suppressed and the drives coast down.

The pulses are deleted before this if the timer, set in MD 1404, has expired.

The functionality of machine data MD 1403 is necessary, if the overshoot is to be suppressed when zero speed is reached after the drive servo enable signal has been canceled.

Note

When the PLC cancels the servo enable interface signal, the NC and drives are sequentially shut down with different, adjustable delay times.

Axis--specific MD 36620: SERVO_DISABLE_DELAY_TIME and MD 36060: STANDSTILL_VELO_TOL.

If the drive develops a fault or terminal 64 is deactivated, then the drive is only shut down with MD 1403 and MD 1404.

References: /FB, A2/ Description of Functions

Siemens AG 2010 All Rights Reserved |

DB1/2-5 |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Operational Messages/Alarm Responses (DB1) |

|

1108.07.06 |

|||

2.1 Pulse suppression |

|

|

|

|

|

|

|

|

|

|

|

1404 |

PULSE_SUPPRESSION_DELAY |

|

|

Cross reference: |

|

|

|

|

|

|

- |

|

Timer, pulse suppression |

|

Relevant: |

Protection level: |

|

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

ms |

100.0 |

0.0 |

8388607.0 |

FLOAT |

Immediately |

|

MSD: 5 000.0 |

|

|

|

|

|

|

|

|

|

|

The default setting depends on the motor type

(FDD ¹ 100, MSD ¹ 5,000) and is parameterized during startup using the drive configuration.

Enter the timer for pulse suppression (pulse enable = 0). After the drive servo enable signal has been canceled (this is possible using terminal 64, from the NC or in the event of an error), the control pulses of the power section transistors are cancelled on the drive side after an adjustable delay.

The pulses will already have been suppressed if the speed threshold set in MD 1403: PULSE_SUPPRESSION_SPEED has previously been undershot.

Note

When the PLC cancels the servo enable interface signal, the NC and drives are shut down sequentially with different, adjustable delay times.

If MD 1605 > MD 1404 is not selected, alarm ”300608 Speed controller output limited” is output when the drive servo enable is canceled.

MD 1404 must also be selected as > MD 36610.

Axis--specific MD 36620: SERVO_DISABLE_DELAY_TIME and MD 36060: STANDSTILL_VELO_TOL.

If the drive develops a fault or terminal 64 is deactivated, then the drive is only shut down with MD 1403 and MD 1404.

References: /FB, A2/ Description of Functions

DB1/2-6 |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

08.06 |

Operational Messages/Alarm Responses (DB1) |

|

2.2 Relay functions/operational messages |

2.2Relay functions/operational messages

1002 |

MONITOR_CYCLE_TIME |

|

|

Cross reference: |

|

|

|

|

|

|

- |

|

Monitoring cycle |

|

|

Relevant: |

Protection level: |

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

31.25 s |

3 200 |

128 |

3 200 |

UNS.WORD |

POWER ON |

810D: The relay functions, heatsink and motor temperature monitoring are calculated in this cycle. The value entered must be an integral multiple of

32 x MD 1000 (in order to avoid a parameterization error). The default monitoring time is 20 ms.

MD 1002 = K x 32 x MD 1000 |

K = 1, 2, 3,... |

840D/611D: The heatsink and motor temperature monitoring are calculated in this cycle. The relay functions are calculated in the position controller cycle. The value entered must be a multiple of 4 ms (in order to avoid a parameterization error). The default monitoring time is 100 ms.

MD 1002 = K x 128 |

K = 1, 2, 3,...25 |

Note

The computation time in the interrupt level must not be exceeded, as this would cause the drive to shut down (system error).

Machine data must be the same in all axes of a controller plug--in, i.e., the same value must be entered in all axes on the 810D, and in both module axes with a 611D dual--axis module.

Siemens AG 2010 All Rights Reserved |

DB1/2-7 |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Operational Messages/Alarm Responses (DB1) |

|

|

|

|

08.06 |

|||||

2.2 Relay functions/operational messages |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

1012 |

FUNC_SWITCH |

|

|

|

|

|

Cross reference: |

|||

|

|

|

|

|

|

|

|

- |

|

|

|

Function switch |

|

|

|

|

Relevant: |

Protection level: |

|||

|

|

|

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Unit: |

Default: |

|

Minimum: |

|

Maximum: |

Data type: |

Active: |

|

||

Hex |

0004 |

|

0000 |

|

00B5 |

WORD |

Immediately |

|||

|

|

|

|

|

|

|

|

|

||

|

Entering the configuration for the power--up functionality. |

|

|

|

||||||

Table 2-1 |

Function switch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Bit No. |

Description |

|

|

Note |

|

|

Default setting |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FDD |

MSD |

|

|

|

|

|

|

|

|

|

||

Bit 0 |

Ramp--function--generator tracking |

|

0 |

= Not active |

|

|

0 |

0 |

||

840D only |

|

|

|

|

1 |

= active |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 1 |

Reserved |

|

|

|

|

|

|

0 |

0 |

|

|

|

|

|

|

|

|

|

|

||

Bit 2 |

Drive ready |

|

|

0 |

= The drive is ready if no alarms are |

|

1 |

1 |

||

|

Interface: |

|

|

|

present |

|

|

|

|

|

|

”DRIVE READY” DB31, ... DBX 93.5 |

|

1 |

= The drive is ready if the conditions |

|

|

|

|||

|

|

|

|

|

|

below are present simultaneously: |

|

|

|

|

|

|

|

|

|

|

-- No alarm |

|

|

|

|

|

|

|

|

|

|

-- Terminal 663 = 1 (810D)/(611D |

|

|

|

|

|

|

|

|

|

|

module) |

|

|

|

|

|

|

|

|

|

|

|

||||

|

IS ”611D--Ready” DB10 DBX 108.6 |

|

All of the existing drives signal ”drive |

|

|

|

||||

|

|

|

|

|

ready”, terminal 63 and terminal 64 |

|

|

|

||

|

|

|

|

|

of the infeed/regenerative feedback |

|

|

|

||

|

|

|

|

|

module are energized, independently of |

|

|

|

||

|

|

|

|

|

S1.2 ”Ready/fault”. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Bit 3 |

Relay functions active |

|

0 |

= Deactivate relay function |

|

0 |

1 |

|||

|

(always active for 840D, |

|

1 |

= Activate relay function |

|

|

|

|||

|

function available with SW 2.4 and |

|

|m| < mdx |

|

|

|

|

|||

|

higher for 810D CCU2, |

|

| nact | < nmin |

|

|

|

|

|||

|

not available for 810DE CCU1) |

|

| nact | < nx |

|

|

|

|

|||

|

|

|

|

|

nact = nset, ramp--up function complete |

|

|

|

||

Bit 4 |

Parameterizing faults |

|

|

0 |

= (default). A parameterization error |

|

0 |

0 |

||

840D only |

|

|

|

|

leads to shutdown (servo disable). |

|

|

|

||

|

|

|

|

|

1 |

= A parameterization error leads to a |

|

|

|

|

|

|

|

|

|

warning signal on the screen. |

|

|

|

||

|

|

|

|

|

|

|

|

|

||

Bit 5 |

”Hide error I_RLI_ERR” |

|

|

|

|

|

0 |

0 |

||

|

|

|

|

|

|

|

|

|

|

|

Bit 6 |

Reserved |

|

|

|

|

|

|

0 |

0 |

|

|

|

|

|

|

|

|

|

|||

Bit 7 |

Pre--assigned, pre--control speed (AM) |

|

0 |

= The drive brings the motor directly to |

|

0 |

0 |

|||

840D only |

for pulse suppression and re--enable of |

|

the current setpoint speed. |

|

|

|

||||

|

the drive on a motor, which is still rotat- |

|

|

|

|

|

|

|

||

|

ing |

|

|

1 |

= The drive decelerates the motor to- |

|

|

|

||

|

|

|

|

|

wards speed 0 and then accelerates to |

|

|

|

||

|

|

|

|

|

the current setpoint speed. |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Bits 8 --15 |

Reserved |

|

|

|

|

|

|

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

DB1/2-8 |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

08.06 |

Operational Messages/Alarm Responses (DB1) |

2.2 Relay functions/operational messages

2.2.1Threshold torque for Md < Mdx

Note

On the SINUMERIK 810D CCU2, the relay functions must be activated by setting bit 3 in MD 1012.

1428 |

TORQUE_THRESHOLD_X[n] 0...7 index of parameter set |

|

Cross reference: |

||

|

|

|

|

|

- |

|

Threshold torque |

|

|

Relevant: |

Protection level: |

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

% |

90.0 |

0.0 |

100.0 |

FLOAT |

Immediately |

|

|

|

|

|

|

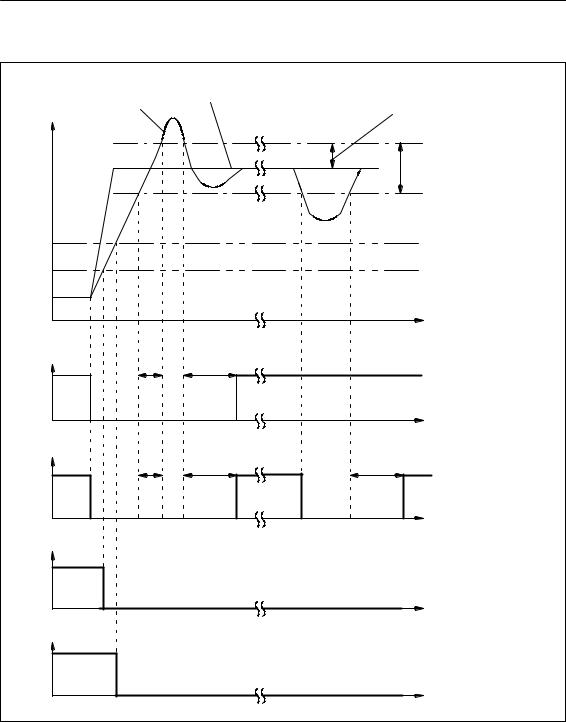

The machine data specifies the torque limit, which when exceeded deactivates the PLC interface signal ”Md < Mdx” DB 31, ... DBX 94.3. The value entered refers to the actual torque limit. Analog to this value, above the rated speed in the constant power range (field weakening operation), the maximum permissible torque is dependent on the operating point. Thus, a decreasing threshold torque characteristic is obtained as a function of 1/n; from the stall torque onwards, this becomes a 1/n2 characteristic.

|

MD 1235 |

Mstall |

|

M |

|

|

|

Plimit |

|

|

|

|

|

|

|

|

n |

|

|

MD 1230 |

|

|

Power limitation |

|

Mlimit |

|

|

Current torque limit |

|

|

|

|

|

|

|

|

|

1/n |

|

|

Threshold |

1/n2 |

|

|

torque = Mdx |

||

|

|

|

n |

Fig. 2-1 Threshold torque characteristic for Md < Mdx signal

The ”Md < Mdx” signal is latched in the active status as long as the interface signal ”Ramp--up function complete” DB31, ... DBX 94.2 is not active. If

”ramp--up function complete” is active, a delay time (MD 1429) is applied before the Md < Mdx” signal can become inactive.

Siemens AG 2010 All Rights Reserved |

DB1/2-9 |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Operational Messages/Alarm Responses (DB1) |

|

0308..0706 |

|||

2.2 Relay functions/operational messages |

|

|

|

||

|

|

|

|

|

|

1429 |

TORQUE_THRESHOLD_X_DELAY |

|

|

Cross reference: |

|

|

|

|

|

|

- |

|

Delay time Md < Mdx signal |

|

Relevant: |

Protection level: |

|

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

ms |

800.0 |

0.0 |

1 000.0 |

FLOAT |

Immediately |

|

|

|

|

|

|

The delay time, which must expire before the ”Md < Mdx” signal can become inactive following the ”Ramp--up function complete” signal, is entered. As long as ”ramp--up function complete” is not active and the delay time has still not expired, the ”Md < Mdx” signal is set to ”HIGH”, regardless of the torque.

2.2.2Minimum speed for |nact| < nmin

Note

On the SINUMERIK 810D CCU2, the relay functions must be activated by setting bit 3 in MD 1012.

1418 |

SPEED_THRESHOLD_MIN [n] |

|

|

Cross reference: |

|

|

|

|

|

|

- |

|

nmin for |nact|< nmin signal |

|

Relevant: |

Protection level: |

|

|

[drive parameter set]: 0 ... 7 |

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

rev/min |

5.0 |

0.0 |

100,000.0) |

FLOAT |

Immediately |

|

SLM: 0.3 |

|

|

|

|

|

|

|

|

|

|

The threshold speed is entered for monitoring purposes. If the actual speed falls

below the set threshold speed (absolute value), IS ”|nact|<nmin” DB 31, ... DBX 94.4 is signaled to the PLC, see Fig. 2-2.

DB1/2-10 |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

08.06 |

Operational Messages/Alarm Responses (DB1) |

||

|

2.2 |

Relay functions/operational messages |

|

Speed actual value |

Speed setpoint |

MD 1426: |

|

nset |

|||

nact |

|||

SPEED_DES_EQ_ACT_TOL |

|||

Speed |

|

||

|

|

||

n |

|

|

|

|

|

Speed tolerance band |

|

MD 1417 |

|

|

|

nx |

|

|

|

MD 1418 |

|

|

|

nmin |

|

|

|

IS ”Ramp--up |

|

Time |

|

function complete” |

|

|

|

1=active |

T < TD |

T > TD |

|

|

|

|

|

||

|

! thus no |

! Signal |

|

|

|

signal |

that is |

|

|

0=inactive |

|

interlocked |

|

|

|

|

|

|

|

NST |

|

|

|

Time |

”nact = nset” |

|

|

|

|

1=active |

T < TD |

T > T |

T > T |

TD= Drive MD 1427: |

|

||||

|

! thus no |

D |

D |

SPEED_DES_EQ_ACT_DELAY |

|

! Alarm |

! Alarm |

||

|

signal |

|

|

|

0=inactive |

|

|

|

Time |

NST |

|

|

|

|

|

|

|

|

|

”|nact | < nmin” |

|

|

|

|

1=active |

|

|

|

|

0=inactive |

|

|

|

|

NST |

|

|

|

Time |

|

|

|

|

|

”|nact | < nx” |

|

|

|

|

1=active |

|

|

|

|

0=inactive |

|

|

|

|

|

|

|

|

Time |

Fig. 2-2 Interface signals (IS)

Siemens AG 2010 All Rights Reserved |

DB1/2-11 |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Operational Messages/Alarm Responses (DB1) |

0308..0706 |

2.2 Relay functions/operational messages |

|

2.2.3Threshold speed for nact < nx

Note

On the SINUMERIK 810D CCU2, the relay functions must be activated by setting bit 3 in MD 1012.

1417 |

SPEED_THRESHOLD_X[n] 0...7 index of parameter set |

|

Cross reference: |

||

|

|

|

|

|

- |

|

nx for |nact|< nx message |

|

Relevant: |

Protection level: |

|

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

rev/min |

6,000.0 |

0.0 |

100 000.0 |

FLOAT |

Immediately |

|

SLM: 120.0 |

|

|

|

|

|

|

|

|

|

|

The threshold speed is entered for monitoring purposes. If the actual speed falls below the selected threshold speed (absolute value), a signal is sent to the PLC (IS ”nact<nx” DB 31, .. DBX 94.5), see Fig. 2-2.

2.2.4Speed in the setpoint range for nact = nset

Note

On the SINUMERIK 810D CCU2, the relay functions must be activated by setting bit 3 in MD 1012.

1426 |

SPEED_DES_EQ_ACT_TOL[n] 0...7 index of parameter set |

|

Cross reference: |

||

|

|

|

|

|

- |

|

Tolerance band for nact = nset signal |

|

Relevant: |

Protection level: |

|

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

rev/min |

20.0 |

0.0 |

10,000.0 |

FLOAT |

Immediately |

|

SLM: 1.0 |

|

|

|

|

|

|

|

|

|

|

Enter the response value for the tolerance band of the PLC status signals

IS ”nact = nset” DB 31, ... DBX 94.6 and

IS ”Ramp--up function complete” DB 31, ... DBX 94.2.

The ”nact = nset” signal becomes active if the speed actual value enters the selected tolerance band associated with the speed setpoint and remains within

this band at least for the delay time (MD 1427). The signal becomes inactive immediately when the tolerance band is exited.

Although the ”ramp--up function complete” signal becomes active simultaneously with the ”nact = nset” signal, it is latched in the active state until the next setpoint change, even if the speed actual value exits the tolerance band. The ”ramp--up function complete” signal becomes inactive immediately if the setpoint changes, see Fig. 2-2.

DB1/2-12 |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

08.06 |

|

|

|

Operational Messages/Alarm Responses (DB1) |

||

|

|

|

|

2.3 Filter for the current and torque display |

||

|

|

Functionality in SW 3.40/04 and higher |

|

|

||

|

|

As long as the controller signals adjustment of the speed setpoint, the tolerance |

||||

|

|

band is ”frozen” at the last setpoint value. The signal is deleted when the set- |

||||

|

|

point moves outside of the tolerance band. In this way, no signals are produced |

||||

|

|

if the setpoint value changes within the tolerance band. |

|

|||

|

|

See also ”Ramp--up timing”, MD 1723: ACTUAL_RAMP_TIME. |

||||

|

|

|

|

|

|

|

1427 |

SPEED_DES_EQ_ACT_DELAY |

|

|

Cross reference: |

||

|

|

|

|

|

|

- |

|

Delay time nact=nset signal |

|

Relevant: |

Protection level: |

||

|

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

|

Unit: |

Default: |

|

Minimum: |

Maximum: |

Data type: |

Active: |

ms |

200.0 |

|

0.0 |

500.0 |

FLOAT |

Immediately |

|

|

|

|

|

|

|

The delay time, after which the ”nact = nset” signal should respond after entering the tolerance band (MD 1426), is entered here, see Fig. 2-2.

2.3Filter for the current and torque display

Filter for the current actual-value display

1250 |

ACTUAL_CURRENT_FILTER_FREQ |

|

|

Cross reference: |

|

|

|

|

|

|

- |

|

Frequency limit, current actual--value smoothing |

Relevant: |

Protection level: |

||

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

Hz |

100.0 |

0.0 |

8 000.0 |

FLOAT |

Immediately |

|

|

|

|

|

|

Enter the 3 dB frequency limit fo for q--axis current actual--value smoothing (PT1 low pass) for the display. The time constant T1 of the PT1 filter is obtained from the formula T1 = 1 /(2 π fo). It is displayed in machine data MD 1708:

ACTUAL_CURRENT.

The filter is calculated in the current controller cycle.

This machine data has no effect on the closed--loop control.

Note

The filter is disabled when values < 1 Hz are entered.

Siemens AG 2010 All Rights Reserved |

DB1/2-13 |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Operational Messages/Alarm Responses (DB1) |

|

08.06 |

||||

2.3 Filter for the current and torque display |

|

|

|

|||

|

|

Filter for the torque-setpoint display |

|

|

||

|

|

|

|

|

|

|

1251 |

LOAD_SMOOTH_TIME |

|

840D only |

Cross reference: |

||

|

|

|

|

|

|

- |

|

Time constant, motor utilization |

|

Relevant: |

Protection level: |

||

|

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

|

Unit: |

Default: |

|

Minimum: |

Maximum: |

Data type: |

Active: |

ms |

0.0 |

|

0.0 |

1 000.0 |

FLOAT |

Immediately |

|

|

|

|

|

|

|

Smoothing means that the motor load (MD 1722) can be displayed more smoothly on the HMI.

The filter is calculated in the position controller cycle.

Note

Enter ”0” to deactivate the filter.

1252 |

TORQUE_FILTER_FREQUENCY |

|

|

Cross reference: |

|

|

|

|

|

|

- |

|

Frequency limit, torque--setpoint smoothing |

Relevant: |

Protection level: |

||

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

Hz |

100.0 |

0.0 |

8 000.0 |

FLOAT |

Immediately |

|

|

|

|

|

|

Enter the 3 dB frequency limit fo for torque--setpoint smoothing (PT1 low pass) for the display. The time constant T1 of the PT1 filter is obtained from the formula T1 = 1 /(2 S π S fo).

The filter is calculated in the speed controller cycle.

This machine data has no effect on the closed--loop control.

Note

The filter is disabled when values < 1 Hz are entered.

DB1/2-14 |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

083.067 |

Operational Messages/Alarm Responses (DB1) |

|

2.4 Alarm response, suppressing alarms |

2.4Alarm response, suppressing alarms

1600 |

ALARM_MASK_POWER_ON |

|

|

Cross reference: |

|

|

|

|

|

|

- |

|

Concealable alarms (POWER ON) |

|

Relevant: |

Protection level: |

|

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

Hex |

0 |

0 |

83BE |

UNS.WORD |

Immediately |

|

|

|

|

|

|

POWER ON alarms can be suppressed using this machine data. If the corresponding bit = 0, the appropriate monitoring function is active. The default setting is active for all monitoring functions.

Table 2-2 |

Concealable POWER ON alarms |

|

|

|

|

|

|

Bit No. |

|

Description |

Alarm No. |

|

|

|

|

Bit 0 |

|

Internal error -- cannot be concealed |

|

|

|

|

|

Bit 1 |

|

Measuring--circuit error, absolute current value1) |

300501 |

Bit 2, 840D only |

Measuring--circuit error, phase current R1) |

300502 |

|

Bit 3, 840D only |

Measuring--circuit error, phase current S1) |

300503 |

|

Bit 4 |

|

Measuring--circuit error, motor measuring |

300504 |

|

|

system |

|

|

|

|

|

Bit 5 |

|

Measuring--circuit error, absolute track, motor |

300505 |

|

|

measuring system |

|

|

|

|

|

Bit 6 |

|

-- |

|

|

|

|

|

Bit 7 |

|

Synchronization error, rotor position |

300507 |

|

|

|

|

Bit 8 |

|

Zero--mark monitoring, motor measuring system |

300508 |

|

|

|

|

Bit 9 |

|

Drive converter limit frequency exceeded |

300509 |

|

|

|

|

Bit 10 |

|

Error in the center frequency measurement -- |

300510 |

|

|

cannot be concealed |

|

|

|

|

|

Bit 11 |

|

Measured--value memory active -- |

300511 |

|

|

cannot be concealed |

|

|

|

|

|

Bit 12 |

|

-- |

|

|

|

|

|

Bit 13 |

|

-- |

|

|

|

|

|

Bit 14 |

|

-- |

|

|

|

|

|

Bit15 |

|

Heatsink temperature exceeded |

300515 |

|

|

|

|

1) The power section could be destroyed if these alarms are suppressed.

Note

POWER ON alarms can only be acknowledged using a hardware reset.

Siemens AG 2010 All Rights Reserved |

DB1/2-15 |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Operational Messages/Alarm Responses (DB1) |

08.06 |

2.4 Alarm response, suppressing alarms |

|

!Important

The power section or the machine mechanical system could be destroyed if the POWER ON alarms are suppressed.

1601 |

ALARM_MASK_RESET |

|

|

|

|

|

|

Cross reference: |

||

|

|

|

|

|

|

|

|

|

- |

|

|

Concealable alarms (Reset) |

|

|

|

|

Relevant: |

|

Protection level: |

||

|

|

|

|

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

|

|

|

|

|

|

Unit: |

Default: |

|

Minimum: |

|

Maximum |

|

Data type: |

|

Active: |

|

Hex |

0000 |

|

0000 |

|

|

FFFF |

|

UNS.WORD |

|

Immediately |

|

|

|

|

|

|

|

|

|

||

|

|

Reset alarms can be suppressed or disabled using this machine data. The |

||||||||

|

|

alarm is active if the corresponding bit = 0. All alarms are active by default. |

||||||||

|

|

Table 2-3 |

Concealable reset alarms |

|

|

|

||||

|

|

|

|

|

|

|

|

|||

|

|

Bit No. |

|

Description |

|

|

Alarm No. |

|||

|

|

|

|

|

|

|

||||

|

|

Bit 0 |

|

Cannot be concealed using software interlock |

|

|

||||

|

|

|

|

|

(configuring error) |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 1 |

|

-- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 2 |

|

-- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 3 |

|

-- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 4 |

|

-- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 5 |

|

-- |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

Bit 6, 840D only |

Flux controller output limited |

|

|

300606 |

||||

|

|

|

|

|

|

|||||

|

|

Bit 7, 840D only |

Current controller output limited |

|

300607 |

|||||

|

|

|

|

|

|

|

||||

|

|

Bit 8 |

|

Speed controller output limited |

|

300608 |

||||

|

|

|

|

|

|

|

||||

|

|

Bit 9 |

|

Encoder limit frequency exceeded |

|

300609 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 10 |

|

-- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 11 |

|

-- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 12 |

|

-- |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

Bit 13 |

|

Max. permissible motor temperature exceeded |

|

300613 |

||||

|

|

|

|

|

|

|

||||

|

|

Bit 14 |

|

Motor temperature exceeded |

|

300614 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Bit 15 |

|

-- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Reset alarms can be acknowledged via the reset key.

!Important

The power section could be destroyed if the reset alarms are suppressed.

DB1/2-16 |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

083.067 |

|

|

Operational Messages/Alarm Responses (DB1) |

||

|

|

|

2.4 Alarm response, suppressing alarms |

||

|

|

|

|

|

|

1612 |

ALARM_REACTION_POWER_ON |

|

|

Cross reference: |

|

|

|

|

|

|

- |

|

Configurable shutdown responses for PO alarms |

Relevant: |

Protection level: |

||

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum |

Data type: |

Active: |

Hex |

2FBC |

0000 |

FFFF |

UNS.WORD |

Immediately |

|

MSD: FFFF |

|

|

|

|

|

|

|

|

|

|

Input bit field to changeover the actual POWER ON alarm. The following can be selected: Shutdown response ”pulse disable”, bit = 1 or ”servo disable”,

bit = 0 (shutdown via MD 1403/MD 1404). The default setting is dependent on the motor type (FDD/SLM 2FBC, MSD FFFF) and is initialized during startup on the basis of the drive configuration.

!Important

It is possible to disable or conceal alarms via machine data

MD 1600 ALARM_MASK_POWER_ON, which means that they are then no longer active.

Table 2-4 |

Configurable POWER ON alarms |

|

|

|

|

|

|

|

|

|

|

Bit No. |

|

Description |

Alarm No. |

Default setting |

|

|

|

|

|

|

|

|

|

|

|

FDD/ |

MSD |

|

|

|

|

SLM |

|

|

|

|

|

|

|

Bit 0 |

|

Pulse disable for system error |

|

0 |

1 |

|

|

|

|

|

|

Bit 1 |

|

Not configurable (measuring--circuit error, absolute current) |

300501 |

0 |

1 |

|

|

|

|

|

|

Bit 2 |

|

-- |

|

1 |

1 |

|

|

|

|

|

|

Bit 3 |

|

-- |

|

1 |

1 |

|

|

|

|

|

|

Bit 4 |

|

Not configurable (measuring--circuit error, motor measuring |

300504 |

1 |

1 |

|

|

system) |

|

|

|

|

|

|

|

|

|

Bit 5 |

|

Not configurable (measuring--circuit error, motor measuring |

300505 |

1 |

1 |

|

|

system, optical encoder) |

|

|

|

|

|

|

|

|

|

Bit 6 |

|

Pulse disable for NC sign of life |

300500 |

0 |

1 |

|

|

|

(from |

|

|

|

|

|

SW 4.2 |

|

|

|

|

|

300506) |

|

|

|

|

|

|

|

|

Bit 7 |

|

810D: Not configurable |

300507 |

1 |

1 |

|

|

(synchronization error, rotor position) |

|

|

|

|

|

For 840D: Pulse disable, synchronization error, rotor position |

|

|

|

|

|

(valid up to SW 2) |

|

|

|

|

|

|

|

|

|

Bit 8 |

|

Pulse disable for zero--mark monitoring, motor measuring |

300508 |

1 |

1 |

|

|

system |

|

|

|

|

|

|

|

|

|

Bit 9 |

|

Pulse disable for converter limit frequency exceeded |

300509 |

1 |

1 |

|

|

|

|

|

|

Bit 10 |

|

Not configurable (speed too high during ramp--up) |

|

1 |

1 |

|

|

|

|

|

|

Bit 11 |

|

Not configurable (trace ran during ramp--up) |

|

1 |

1 |

|

|

|

|

|

|

Bit 12 |

|

-- |

|

0 |

1 |

|

|

|

|

|

|

Bit 13 |

|

Not configurable (ground fault test detected) |

300513 |

1 |

1 |

|

|

|

|

|

|

Bit 14 |

|

-- |

|

0 |

1 |

|

|

|

|

|

|

Bit 15 |

|

Pulse disable for heatsink temperature exceeded |

300515 |

0 |

1 |

|

|

|

|

|

|

Siemens AG 2010 All Rights Reserved |

DB1/2-17 |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Operational Messages/Alarm Responses (DB1) |

|

08.06 |

|||

2.4 Alarm response, suppressing alarms |

|

|

|

||

|

|

|

|

|

|

1613 |

ALARM_REACTION_RESET |

|

|

Cross reference: |

|

|

|

|

|

|

- |

|

Configurable shutdown responses for reset alarms |

Relevant: |

Protection level: |

||

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum |

Data type: |

Active: |

Hex |

0100 |

0000 |

FFFF |

UNS.WORD |

Immediately |

|

MSD: FFFF |

|

|

|

|

Input bit field for changeover of the respective 611D reset alarm. The following shutdown responses can be selected: Pulse disable (bit = 1) or servo disable (bit = 0) (shutdown via MD 1403/MD 1404). The default setting is dependent on the motor type (FDD 0100, MSD FFFF) and is initialized during startup based on the drive configuration.

!Important

It is possible to disable or conceal alarms via

MD 1601: ALARM_MASK_RESET, which means that they are then no longer active.

Table 2-5 |

Configurable reset alarms |

|

|

|

|

|

|

|

|

|

|

Bit No. |

|

Description |

Alarm No. |

Default setting |

|

|

|

|

|

|

|

|

|

|

|

FDD/ |

MSD |

|

|

|

|

SLM |

|

|

|

|

|

|

|

Bit 0 |

|

Pulse disable for configuration error |

3007xx |

0 |

1 |

|

|

|

|

|

|

Bit 1 |

|

-- |

|

0 |

1 |

|

|

|

|

|

|

Bit 2 |

|

-- |

|

0 |

1 |

|

|

|

|

|

|

Bit 3 |

|

-- |

|

0 |

1 |

|

|

|

|

|

|

Bit 4 |

|

Pulse disable motor encoder not calibrated |

300604 |

0 |

1 |

|

|

|

|

|

|

Bit 5 |

|

-- |

|

0 |

1 |

|

|

|

|

|

|

Bit 6 |

|

-- |

|

0 |

1 |

|

|

|

|

|

|

Bit 7 |

|

-- |

|

0 |

1 |

|

|

|

|

|

|

Bit 8 |

|

Pulse disable controller output limited |

300608 |

1 |

1 |

|

|

|

|

|

|

Bit 9 |

|

Pulse disable when an alarm occurs: Encoder frequency |

300609 |

0 |

1 |

|

|

exceeded |

|

|

|

|

|

|

|

|

|

Bit 10 |

|

-- |

|

0 |

1 |

|

|

|

|

|

|

Bit 11 |

|

-- |

|

0 |

1 |

|

|

|

|

|

|

Bit 12 |

|

-- |

|

0 |

1 |

|

|

|

|

|

|

Bit 13 |

|

Pulse disable when an alarm occurs: Max. permissible motor |

300613 |

0 |

1 |

|

|

temperature exceeded |

|

|

|

|

|

|

|

|

|

Bit 14 |

|

Pulse disable when an alarm occurs: Motor temperature |

300614 |

0 |

1 |

|

|

exceeded |

|

|

|

|

|

|

|

|

|

Bit 15 |

|

-- |

|

0 |

1 |

|

|

|

|

|

|

DB1/2-18 |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

083.067 |

|

|

Operational Messages/Alarm Responses (DB1) |

||

|

|

|

2.4 Alarm response, suppressing alarms |

||

|

|

|

|

|

|

1731 |

CL1_PO_IMAGE |

|

|

|

Cross reference: |

|

|

|

|

|

- |

|

Image, PO alarm register |

|

Relevant: |

Protection level: |

|

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

-- |

0 |

0 |

65 535 |

UNS. WORD |

Immediately |

|

|

|

|

|

|

This machine data is used to display the internal POWER ON alarm register. MD 1600: ALARM_MASK_POWER_ON is not taken into account for this diagnostic data.

Suppressed POWER ON alarms (MD 1600) are also displayed If bit n is set to 1, alarm 300500 + n is displayed.

1732 |

CL1_RES_IMAGE |

|

|

|

Cross reference: |

|

|

|

|

|

- |

|

Image, RES alarm register |

|

Relevant: |

Protection level: |

|

|

|

|

|

FDD/MSD/SLM |

2/4 |

|

|

|

|

|

|

Unit: |

Default: |

Minimum: |

Maximum: |

Data type: |

Active: |

-- |

0 |

0 |

65 535 |

UNS. WORD |

Immediately |

|

|

|

|

|

|

This machine data is used to display the internal alarm reset register. MD 1601:

ALARM_MASK_RESET is not taken into account for this diagnostic data.

Suppressed RESET alarms (MD 1601) are also displayed

If bit n is set to 1, alarm 300600 + n is displayed.

Note

This display value is only reset by an NC--side reset (software reset).

J

Siemens AG 2010 All Rights Reserved |

DB1/2-19 |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Operational Messages/Alarm Responses (DB1) |

0508..1006 |

2.4 Alarm response, suppressing alarms |

|

Space for your notes

DB1/2-20 |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

08.06 |

Operational Messages/Alarm Responses (DB1) |

|

4 Data Descriptions (MD, SD) |

Supplementary Conditions |

3 |

None |

|

|

J |

Data Descriptions (MD, SD) |

4 |

See Chapter 2

J

Siemens AG 2010 All Rights Reserved |

DB1/4-21 |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Operational Messages/Alarm Responses (DB1) |

0508..1006 |

4 Data Descriptions (MD, SD) |

|

Space for your notes

DB1/4-22 |

Siemens AG 2010 All Rights Reserved |

SIMODRIVE 611 digital/SINUMERIK 840D/810D Drive Functions (FBA) -- 05/2010 Edition |

Loading...

Loading...