siemens 611 User Manual

SIMODRIVE 611 digital

HLA module

Description of Functions

Valid for

Series 6SN11-

03.06 Edition

General Information

Configuration

Start-up

Firmware Drive Functions

Hardware Drive Functions

Hydraulics Diagnostics

Peripherals/Accessories

Servicing

Hydraulics

Abbreviations

Terminology

References

EC Declaration of

Conformity

Index

1

2

3

4

5

6

7

8

A B C D

E F

3ls |

SINUMERIK→ Documentation |

|

Revision history

Brief details of this edition and previous editions are listed below.

The status of each edition is indicated by the code in the “Remarks” column.

Status code in the “Remarks” column:

A . . . . . New documentation.

B . . . . . Unmodified reprint with new order number C . . . . . Revised version with new edition status.

If the technical subject matter shown on the page has changed compared to the previous edition status, this is indicated by the changed edition status in the header of the respective page.

Edition |

Order no. |

Remarks |

02/99 |

6SN1197-0AB60-0BP0 |

A |

08/99 |

6SN1197-0AB60-0BP1 |

C |

04/00 |

6SN1197-0AB60-0BP2 |

C |

10/03 |

6SN1197-0AB60-0BP3 |

C |

03/06 |

6SN1197-0AB60-0BP4 |

C |

Trademarks

All products are registered trademarks of Siemens AG. Other names in this publication might be trademarks whose use by a third party for his own purposes may violate the rights of the registered holder.

|

Other functions not described in this documentation might be |

|

executable in the control. This does not, however, represent an |

|

obligation to supply such functions with a new control or when |

|

servicing. |

|

We have checked that the contents of this document correspond to |

|

the hardware and software described. Nevertheless, differences |

|

might exist and therefore we cannot guarantee that they are |

|

completely identical. The information given in this publication is |

|

reviewed at regular intervals and any corrections that might be |

|

necessary are made in subsequent editions. We welcome all |

|

recommendations and suggestions. |

♥ Siemens AG, 2006. |

Subject to change without prior notice |

Printed in Germany |

Siemens Aktiengesellschaft. |

1032.06993 |

Preface |

Preface

Structure of the documentation

Target group

Benefits

Technical support

Instructions when reading

The SIMODRIVE documentation is subdivided into 2 parts:

SGeneral Documentation

SManufacturer/Service Documentation

The function manual of the HLA module is part of the

SIMODRIVE/SINUMERIK documentation.

A list of documents, updated on a monthly basis, is available on the Internet for the available languages at:

http://www.siemens.com/motioncontrol

Select “Support” ––> “Technical Documentation” ––> “Overview of Documents”

The Internet version of the DOConCD (DOConWEB) is available at: http://www.automation.siemens.com/doconweb

You can find information on the training courses offered and FAQs (frequently asked questions) on the Internet under: http://www.siemens.com/motioncontrol (under “Support”)

This document does not purport to cover all details or variations in equipment, nor to provide for every possible contingency to be met in connection with installation, operation or maintenance.

The contents of this document are not part of an earlier or existing contract or agreement nor do they change this. The sales contract contains the entire obligation of Siemens. The warranty conditions specified in the contract between the parties is the sole warranty of Siemens. Any statements contained herein neither create new warranties nor modify the existing warranty.

This documentation is intended for use by machine manufacturers and servicing personnel who use the “HLA modules”.

The function manual enables the target group to configure and operate the SIMODRIVE 611 digital drive with hydraulic module.

If you have any questions, please contact the following hotline:

A&D Technical Support Tel.: +49 (0) 180 5050 – 222

Fax: +49 (0) 180 5050 – 223

E-Mail: mailto:adsupport@siemens.com

Internet: http://www.siemens.com/automation/support-request

Questions on the manual

If you have any questions (suggestions, corrections) regarding this documentation, please fax or e-mail us at:

|

Fax: +49 (0) 9131/98 – 63315 |

|

E-mail: mailto:motioncontrol.docu@siemens.com |

Fax form |

Refer to the feedback sheet at the end of the documentation |

Certificates |

You will find the certificates for the products described in this documentation |

|

under: |

|

http://intra1.erlf.siemens.de/qm/home/index.html |

♥ Siemens AG, 2006. All rights reserved |

iii |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

Preface |

1002..0399 |

Objectives

Information for using this manual

Definition of qualified personnel

Software version

This Description of Functions provides the information required to configure and start up the hydraulic drive module.

SChapter 2 describes the procedures for configuring the electric and hydraulic components.

SChapter 3 shows how the hydraulic drive is started up with the support of a menu-driven user interface.

SThe firmware and the HLA module hardware functionality are explained in Chapters 4 and 5.

SChapter 6 explains how to check and interpret status displays and alarms (hydraulic diagnostics).

SChapter 7 describes the accessories required, e.g. measuring systems and cables.

SAppendix A contains general information and an explanation of the hydraulic system functionality.

Note

Hydraulics In this document, information about specific hydraulic functions refers to functions provided by Bosch Rexroth AG.

The following guide information is provided to help you reference information in this Description of Functions:

SGeneral table of contents

SHeader line (as orientation):

–The main chapter is in the upper header line

–The second line of the header is the subsection number

SAppendix with

–Abbreviations, Terms and List of References

–Index

For the purpose of this manual and product labels, a “qualified person” is one who is familiar with the installation, mounting, start-up and operation of the equipment and the hazards involved.

STrained and authorized to energize/de-energize, circuits and equipment in accordance with established safety procedures.

STrained in the proper care and use of protective equipment in accordance with established safety procedures.

SFirst aid training.

The SW versions specified in this documentation refer to the SINUMERIK 840D control system and the HLA module.

The Description of Functions applies only to the software versions specified. When a new software version is released, the Description of Functions for that version must be ordered.

iv |

♥ Siemens AG, 2006. All rights reserved |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

1032.06993 |

Preface |

Safety information/ instructions

This documentation contains information that must be observed to ensure your personal safety and to prevent material damage. The instructions for your personal safety are marked by a warning triangle. Instructions relating solely to material damage are not marked by a warning triangle. Depending on the degree of hazard, the warning information is shown as follows in decreasing sequence:

Danger

!indicates that death or severe personal injury will result if proper precautions are not taken.

Warning

!indicates that death or severe personal injury may result if proper precautions are not taken.

Caution

!With a warning triangle indicates that minor personal injury can result if proper precautions are not taken.

Caution

Without warning triangle indicates that material damage can result if proper precautions are not taken.

Notice

indicates that an undesirable result or state may arise if the relevant note is not observed.

Note

In the context of this document, it is advisable to take note of the warning information.

Intended use |

Note the following: |

Warning

!The unit may be used only for the applications described in the catalog and the technical description, and only in combination with the equipment, components and devices of other manufacturers where recommended or permitted by Siemens. To ensure trouble-free and safe operation of the product, it must be transported, stored and installed as intended and maintained and operated with care.

♥ Siemens AG, 2006. All rights reserved |

v |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

Preface |

100203..06993 |

Danger and warning information

Danger

!Commissioning should not start until you have ensured that the machine in which the components described here are to be installed complies with Directive 98/37/EC.

Only appropriately qualified personnel may commission/start up this equipment.

This personnel must take into account the technical customer documentation belonging to the product and be knowledgeable and observe the specified information and instructions on the hazards and warnings.

When electrical devices are operated, the electrical circuits automatically conduct a dangerous voltage.

Dangerous mechanical movements may occur in the system during operation.

All of the work carried-out on the electrical machine or system must be carried-out with it in a no-voltage condition.

Warning

!Perfect, safe and reliable operation of the equipment assumes that it has been professionally transported, stored, mounted and installed as well as carefully operated and serviced.

In addition to the danger and warning information provided in the technical customer documentation, applicable national, local, and system-specific regulations must be taken into account.

For special versions of the machines and equipment, the information in the associated catalogs and quotations applies.

! |

Caution |

|

When attaching the connecting cables, you must ensure that: |

||

|

S They are not damaged, |

|

|

S |

they are not stressed, |

|

S |

they cannot come into contact with rotating parts. |

|

|

|

Warning

!All of the SIMODRIVE unit connections must be withdrawn or disconnected when the electrical equipment on the machines is subject to a voltage test (EN 60204-1 (VDE 0113-1), Point 20.4).

This is necessary, as the SIMODRIVE insulation has already been tested, and should not be subject to a new test (additional voltage stressing).

vi |

♥ Siemens AG, 2006. All rights reserved |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

1032.06993 |

Preface |

Warning

!The information and instructions in all of the documentation supplied and any other instructions must always be observed to eliminate hazardous situations and damage.

SFor special versions of the machines and equipment, the information in the associated catalogs and quotations applies.

SFurthermore, all of the relevant national, local land plant/system-specific regulations and specifications must be taken into account.

SAll work should be undertaken with the system in a no-voltage condition!

Caution

When using mobile radios (e.g. cellular phones, mobile phones, 2-way radios) with a transmission power of > 1 W close to the equipment (< 1.5 m) the function of the equipment can be disturbed.

Caution

As part of routine tests, the devices undergo a voltage test in accordance with EN 50178. During voltage testing of electrical equipment on industrial machines in accordance with EN 60204-1, Section 19.4, all SIMODRIVE device connections must be disconnected/removed. This is necessary in order to avoid damaging the SIMODRIVE devices.

♥ Siemens AG, 2006. All rights reserved |

vii |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

Preface |

1002..0399 |

ESDS information Electro Static Discharge Sensitive Devices and instructions

Some parts, such as individual components, integrated circuits or modules, could be damaged by electrostatic fields or electrostatic discharge during handling, testing or transport. These components are referred to as ESDS (ElectroStatic Discharge Sensitive Devices).

Handling ESDS modules:

SWhen handling devices which can be damaged by electrostatic discharge, personnel, workstations and packaging must be well grounded!

SElectronic components should only be touched when absolutely necessary.

SPersonnel may only touch components if

–they are continuously grounded through ESDS wristlets,

–they wear ESDS shoes, ESDS shoe grounding strips in conjunction with an ESDS floor surface.

SModules must only be placed on conductive surfaces (table with ESD surface, conductive ESD foam, ESD packaging, ESD transport container).

SModules may not be brought close to data terminals, monitors or television sets (minimum clearance to the screen > 10 cm).

SDo not bring ESD-sensitive modules into contact with chargeable and highly-insulating materials, such as plastic sheets, insulating table tops or clothing made of synthetic materials.

SMeasuring work may only be carried out on the components if

–the measuring instrument is properly grounded (e.g. equipment grounding conductor), or

–when floating measuring equipment is used, the probe is briefly discharged before making measurements (e.g. a bare-metal control housing is touched).

SOnly touch control components, option modules and memory modules at the front panel or at the edge of the PC boards.

J

viii |

♥ Siemens AG, 2006. All rights reserved |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

03.06

Table of Contents

1 |

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-13 |

|

|

1.1 |

Application examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-13 |

|

1.2 |

Comparison of electric and hydraulic drive systems . . . . . . . . . . . . . |

1-14 |

|

1.3 |

Structure of an electro-hydraulically controlled drive axis . . . . . . . . |

1-16 |

|

1.3.1 |

Machine commutation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-16 |

|

1.3.2 |

Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-17 |

|

1.3.3 |

Control valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-17 |

|

1.3.4 |

Valve amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-17 |

|

1.3.5 |

Shut-off valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-17 |

|

1.3.6 |

Position measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-17 |

|

1.3.7 |

SINUMERIK 840D/SIMODRIVE 611 digital . . . . . . . . . . . . . . . . . . . . |

1-18 |

|

1.3.8 |

Hydraulic power unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

1-18 |

2 |

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-19 |

|

|

2.1 |

Configuring steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-19 |

|

2.1.1 |

Procedure for configuring electrical components . . . . . . . . . . . . . . . |

2-19 |

|

2.1.2 |

Procedure for configuring hydraulic components . . . . . . . . . . . . . . . |

2-20 |

|

2.2 |

Integration in SINUMERIK 840D/SIMODRIVE 611 digital . . . . . . . . |

2-22 |

|

2.2.1 |

System overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-22 |

|

2.2.2 |

Required FW packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-27 |

|

2.2.3 |

Hardware requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-27 |

|

2.3 |

Configuring the hydraulic drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-28 |

|

2.3.1 |

Cylinder selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-28 |

|

2.3.2 |

Selection of servo solenoid valves . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-30 |

|

2.3.3 |

Selection of shut-off valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-37 |

|

2.3.4 |

Natural frequency of the hydraulic drive . . . . . . . . . . . . . . . . . . . . . . . |

2-40 |

|

2.3.5 |

Hydraulic power unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-41 |

|

2.4 |

Interconnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-43 |

|

2.4.1 |

Internal power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-43 |

|

2.4.2 |

External power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

2-43 |

|

2.4.3 |

Grounding concept/electromagnetic compatibility (EMC) . . . . . . . . |

2-46 |

3 |

Start-up . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-47 |

|

3.1 |

Overview of start-up process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-47 |

|

3.2 |

Drive configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-49 |

|

3.3 |

Modify drive machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-50 |

|

3.4 |

Valve selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-51 |

|

3.5 |

Cylinder selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-54 |

|

3.6 |

Mounting/supply data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-55 |

|

3.7 |

Measuring system data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-56 |

|

3.8 |

Modifying data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-57 |

|

3.9 |

Fine adjustment and optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-60 |

♥ Siemens AG, 2006. All rights reserved |

ix |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

0302..0699

|

3.9.1 |

Control direction, travel direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-60 |

|

3.9.2 |

Offset adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-62 |

|

3.9.3 |

Velocity adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-63 |

|

3.9.4 |

Referencing data for HLA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-65 |

|

3.9.5 |

Controller optimization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-66 |

|

3.9.6 |

Controller adaptation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-71 |

|

3.9.7 |

Hydraulic/electrical interpolation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-72 |

|

3.10 |

File functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-73 |

|

3.11 |

Start-up functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-74 |

|

3.11.1 |

Measuring function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-75 |

|

3.11.2 |

Function generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-82 |

|

3.11.3 |

Circularity test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-86 |

|

3.11.4 |

Servo trace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-86 |

|

3.11.5 |

DAC parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-87 |

|

3.12 |

User views . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-88 |

|

3.13 |

Display options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-89 |

|

3.14 |

Configuring an OEM valve list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-90 |

|

3.15 |

System variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3-92 |

4 |

Firmware Drive Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-93 |

|

|

4.1 |

Block diagram of closed-loop control . . . . . . . . . . . . . . . . . . . . . . . . . |

4-93 |

|

4.2 |

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-95 |

|

4.2.1 |

Function overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-95 |

|

4.2.2 |

Parameter set changeover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-96 |

|

4.3 |

Closed-loop velocity control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-97 |

|

4.3.1 |

Velocity adaptation/feedforward control . . . . . . . . . . . . . . . . . . . . . . . |

4-97 |

|

4.3.2 |

Velocity controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-104 |

|

4.3.3 |

Dynamic stiffness control (DSC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-112 |

|

4.4 |

Closed-loop force control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-113 |

|

4.4.1 |

Force limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-115 |

|

4.4.2 |

Static friction injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-116 |

|

4.4.3 |

Force controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-117 |

|

4.5 |

Manipulated voltage output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-122 |

|

4.5.1 |

Characteristic compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-122 |

|

4.5.2 |

Control output filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-128 |

|

4.5.3 |

Manipulated voltage limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-130 |

|

4.6 |

Supply unit data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-131 |

|

4.7 |

Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-132 |

|

4.8 |

Cylinder drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-134 |

|

4.9 |

Drive data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-135 |

|

4.10 |

Position measuring system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-138 |

|

4.11 |

Pressure sensor system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-143 |

|

4.12 |

Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-144 |

|

4.13 |

Monitoring functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-150 |

x |

♥ Siemens AG, 2006. All rights reserved |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

032.0699

|

4.13.1 |

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-150 |

|

4.13.2 |

Variable signaling functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-152 |

|

4.14 |

Service functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-157 |

|

4.14.1 |

Min/max display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-157 |

|

4.14.2 |

Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-158 |

|

4.14.3 |

Diagnostic machine data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-159 |

|

4.15 |

Parameters table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4-163 |

5 |

Hardware Drive Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-173 |

|

|

5.1 |

Interface overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-173 |

|

5.1.1 |

Measurement system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-176 |

|

5.1.2 |

Pressure sensor system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-177 |

|

5.1.3 |

Control valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-178 |

|

5.1.4 |

Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-179 |

|

5.1.5 |

Test sockets (diagnostics) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-180 |

|

5.1.6 |

Bus interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-181 |

|

5.2 |

System environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-182 |

|

5.3 |

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-183 |

|

5.3.1 |

Climatic and mechanical environmental conditions in operation . . . |

5-183 |

|

5.3.2 |

Shippingand storage conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-184 |

|

5.3.3 |

Stress caused by contaminants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5-185 |

6 |

Hydraulics Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6-187 |

|

7 |

Peripherals/Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-217 |

|

|

7.1 |

Measurement systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-217 |

|

7.1.1 |

Encoders, linear scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-217 |

|

7.1.2 |

Cable diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-220 |

|

7.2 |

BERO (X432) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-224 |

|

7.3 |

Pressure sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-225 |

|

7.3.1 |

Sensor systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-225 |

|

7.3.2 |

Connection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7-229 |

|

7.4 |

Connection diagrams for servo solenoid valves . . . . . . . . . . . . . . . . |

7-230 |

8 |

Servicing |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8-235 |

|

8.1 |

Areas of responsibility at Siemens/Bosch Rexroth . . . . . . . . . . . . . . |

8-235 |

|

8.2 |

Hotline and contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8-236 |

A |

Hydraulics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-237 |

|

|

A.1 |

Closed-loop proportional valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-237 |

|

A.1.1 |

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-237 |

|

A.1.2 |

Directly-controlled servo solenoid valves, sizes 6 and 10 . . . . . . . . |

A-245 |

|

A.1.3 |

Pilot-controlled servo solenoid valves, sizes 10 and 16 . . . . . . . . . . |

A-247 |

|

A.1.4 |

HR servo solenoid valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-250 |

|

A.2 |

Cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

A-252 |

♥ Siemens AG, 2006. All rights reserved |

xi |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

0302..0699

B |

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

B-255 |

|

C |

Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

C-257 |

|

D |

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

D-259 |

|

|

D.1 |

Electrical applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

D-259 |

|

D.2 |

Hydraulic applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

D-259 |

E |

EC Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

E-261 |

|

F |

Index . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

Index-265 |

xii |

♥ Siemens AG, 2006. All rights reserved |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

General Information |

1 |

1.1Application examples

Applications |

The NCU 573.2 of the SINUMERIK 840D is capable of handling axis |

|

configurations of a maximum of 31 axes on up to 10 different channels. This |

|

functional sophistication makes the SINUMERIK 840D an increasingly popular |

|

system for the automation of rotary indexing machines. These machines are |

|

often highly compact in design and frequently equipped with hydraulic axes |

|

(cylinders and servo solenoid valves). The hydraulics module (HLA module) |

|

provides a means of controlling hydraulic axes directly from the SINUMERIK |

|

840D system via the digital drive bus. |

|

The HLA module is a control unit belonging to the modular SIMODRIVE 611 |

|

converter system mounted in a 50 mm carrier module (universal empty hous- |

|

ing). |

|

The gating and closed-loop control electronics for operating controlled hydraulic |

|

drives are integrated in the HLA module. |

|

From the point of view of the manufacturer of modern servo solenoid valves, an |

|

innovative step in the field of hydraulic drive systems has been taken by treating |

|

electric and hydraulic drives as equally important components and integrating |

|

them into a standard NC. |

Objective |

Hydraulic and electric drives are equally important, and are also available for |

|

combinations within an interpolating grouping. |

Interfaces

SFirmware

The communications -interface is compatible with SIMODRIVE 611 SRM(FD)/ARM(MSD) for supported services. Code and data structure is analogous to SIMODRIVE 611 SRM(FD)/ARM(MSD). The hydraulics software is stored as a separate program code in the control system.

SHardware

Integration into the SIMODRIVE 611 system is compatible with SIMODRIVE 611 digital SRM(FD)/ARM(MSD). Essentially, this involves the following interfaces:

–Drive bus

–Equipment bus

–Power supply concept

♥ Siemens AG, 2006. All rights reserved |

1-13 |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

1 General Information |

1002..0399 |

1.2 Comparison of electric and hydraulic drive systems |

|

1.2Comparison of electric and hydraulic drive systems

Table 1-1 |

Comparison of electric and hydraulic drive systems |

|

|

||||

|

|

|

|

|

|

|

|

Criterion |

|

|

Direct electric drive |

|

Electric drive with |

|

Hydraulic drive |

|

|

|

|

|

leadscrew |

|

|

|

|

|

|

|

|||

Power density / |

S Low weight and |

S |

Servo motor and |

S Cylinder and servo sole- |

|||

mounting |

|

S |

reduced spatial re- |

|

leadscrew large and |

|

noid valve are light-weight |

space require- |

|

|

heavy. |

|

and compact. |

||

|

quirements of the |

|

|

||||

ments |

|

|

|

Problematic with lim- |

S Transfer of E motor to hy- |

||

|

|

electric part on the |

S |

||||

|

|

|

|||||

|

|

|

machine table. |

|

ited mounting space. |

|

draulic power unit. |

|

|

|

|

||||

Mass inertia of |

Low mass of electric part |

Servomotor and leads- |

Piston and piston rod have |

||||

moving parts |

|

on machine table. |

crew have high mass mo- |

very low mass |

|||

|

|

|

|

ment of inertia. |

|

|

|

|

|

|

|

|

|

|

|

Operational |

|

In principle, service life |

S |

Shock sensitive. |

S |

Protected against overload |

|

safety, service |

only depends |

S |

Service life limited by |

|

by pressure limitation. |

||

life |

|

on the linear guides. |

|

|

|

||

|

|

leadscrew. |

S |

Sturdy, insensitive to |

|||

|

|

|

|

|

|||

|

|

|

|

S |

Sudden failure |

|

shocks. |

|

|

|

|

|

|

|

|

|

|

|

|

|

possible. |

S Cylinder seals and valve |

|

|

|

|

|

|

|

|

control edges have a long |

|

|

|

|

|

|

|

service life. |

|

|

|

|

|

|

S |

Wear warning. |

|

|

|

|

|

|

||

Service |

|

Simple replacement |

Expensive replacement |

S |

Simple error diagnosis |

||

|

|

|

|

and repair of leadscrew by |

S |

Simple replacement and |

|

|

|

|

|

specialists. |

|

repair of valves and cylin- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ders. |

|

|

|

|

|

|||

Energy storage |

Peak requirement must |

Peak requirement must be |

S |

Compensation of energy |

|||

|

|

be installed as no storage |

installed as no storage is |

|

requirement peaks by hy- |

||

|

|

is possible. |

possible. |

|

draulic accumulator. |

||

|

|

|

|

|

|

S Rapid traverse in differen- |

|

|

|

|

|

|

|

|

tial circuit. |

|

|

|

|

|

|

S Reduction of installed ca- |

|

|

|

|

|

|

|

|

pacity. |

|

|

|

|

|

|||

Maximum |

|

Peak thrust per unit area |

Limitation for high forces. |

Practically unlimited |

|||

forces |

|

approx. 40 to 80 kN/m2 |

|

|

(cylinder-φ, pmax=700 bar) |

||

Load stiffness |

Very good; |

S |

Elasticity under large |

S Oil compressibility is com- |

|||

|

|

Servo gain can be set |

|

forces. |

|

pensated as a control |

|

|

|

10–100 times higher than |

S |

Elasticity of leadscrew |

|

function (I component). |

|

|

|

on the other two drives. |

|

|

|

||

|

|

|

is largely compen- |

S Good zero overlap quality |

|||

|

|

|

|

|

|||

|

|

|

|

|

sated as a control |

|

of valve ensures very high |

|

|

|

|

|

function. |

|

rigidity under load. |

|

|

|

|

||||

Maximum ve- |

Up to 500 m/min |

vmax=hs @ ωmax/2π |

30...300 m/min |

||||

locity |

|

|

|

hs=thread lead |

(depending on which cylinder |

||

|

|

|

|

ωmax=max. motor speed |

seal kit is used) |

||

Maximum |

|

Unlimited |

v 6 m |

v 3 m |

|||

travel path |

|

|

|

|

|

|

|

|

|

|

|

|

|||

Collision |

|

Mechanically difficult |

Mechanically possible |

Mechanically possible |

|||

protection |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-14 |

♥ Siemens AG, 2006. All rights reserved |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

02.99 |

|

|

|

|

|

|

|

|

1 General Information |

|

|

|

|

1.2 Comparison of electric and hydraulic drive systems |

|||||

Table 1-1 |

Comparison of electric and hydraulic drive systems |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

Criterion |

|

Direct electric drive |

|

Electric drive with |

|

Hydraulic drive |

|||

|

|

|

|

|

leadscrew |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Noise |

|

Noise produced by |

|

Noise produced by servo- |

|

S Flow through valve may |

|||

|

|

linear guides |

|

motor and leadscrew |

|

|

produce noise. |

||

|

|

|

|

|

|

|

|

|

S Pump noise of |

|

|

|

|

|

|

|

|

|

hydraulic power unit. |

|

|

|

|

|

|

|

|

|

|

Acceleration |

|

max. 45 g |

|

max. 1 g |

|

|

max. 2 g |

||

characteristics |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drive cooling |

|

Absolutely essential |

|

Required only at high |

|

|

Required in some cases, in |

||

|

|

|

|

|

speeds |

|

|

power unit only |

|

|

|

|

|

|

|

|

|

|

|

Sensitivity to |

|

High |

|

Low |

|

|

Low |

||

ferromagnetic |

|

|

|

|

|

|

|

|

|

swarf |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Table 1-2 |

Analogy of characteristic data |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Electrical |

|

|

|

Hydraulic |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Speed |

|

|

|

|

|

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

Velocity |

|

|

|

Velocity |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

Current |

|

|

|

Flow rate |

||

|

|

|

|

|

|

|

|

||

|

|

|

DC link voltage |

|

|

|

System pressure |

||

|

|

|

|

|

|

|

|

||

|

|

|

Power |

|

|

|

Flow rate @ valve pressure differential |

||

|

|

|

|

|

|

|

|||

|

|

|

Transistor/power section |

|

Valve |

|

|||

|

|

|

|

|

|

|

|

||

|

|

|

Motor |

|

|

|

Drive cylinder |

||

|

|

|

|

|

|

|

|

|

|

♥ Siemens AG, 2006. All rights reserved |

1-15 |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

1 General Information |

02.99 |

1.3 Structure of an electro-hydraulically controlled drive axis

1.3Structure of an electro-hydraulically controlled drive axis

SINUMERIK 840D, |

|

|

SIMODRIVE 611 digital |

|

|

with HLA module |

Servo solenoid value with |

|

|

valve amplifier (OBE) |

|

|

Machine commutation |

|

Shut-off valve |

|

|

|

Position |

measuring |

Hydraulic power unit |

system |

|

Fig. 1-1 Construction of an electro-hydraulically controlled drive axis

1.3.1Machine commutation

Guide mechanism Straight line movement of machine slides and tables is accomplished with minimum friction and maximum precision by hydrodynamic and hydrostatic slideways or roller slideways.

Friction |

A certain degree of friction can be very useful for damping oscillations. |

However, excessive friction, especially pronounced transitions from static to sliding friction, has a negative effect on the control result and impairs control loop stability.

1-16 |

♥ Siemens AG, 2006. All rights reserved |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

02.99 |

1 General Information |

1.3 |

Structure of an electro-hydraulically controlled drive axis |

1.3.2Cylinder

Construction |

The cylinder represents the simplest form of a linear motor and can easily be |

|

integrated into machine guidance. The cylinder normally has a piston rod at one |

|

end. |

Quality criteria |

The following are critical quality criteria |

Sthe surface quality of barrel and piston rod and

Sthe seals and guides (low-friction, servo quality...).

1.3.3Control valve

Task |

This is the control element in the closed control loop system and forms the elec- |

|

tro-hydraulic converter. |

Function |

The valve steadily converts electrical signals into hydraulic flow. |

|

Its quality is defined by static and dynamic parameters, such as |

Szero overlap

Shysteresis

Slimit frequency, etc.

1.3.4Valve amplifier

This circuit contains the power electronics for the solenoid in the servo solenoid valve, which adjusts the valve spool position.

The position controller in the valve amplifier (on-board electronics – OBE) controls the position of the valve spool proportionally to the output value (U=0..."10 V).

1.3.5Shut-off valve

Shut-off valves are used to add safety functions to a valve control with servo solenoid valve. Shut-off valves can prevent uncontrolled motion of the cylinder.

1.3.6Position measuring system

Task |

The position measuring system supplies the actual value for the position of the |

|

moving machine element. |

♥ Siemens AG, 2006. All rights reserved |

1-17 |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

1 General Information |

02.99 |

1.3 Structure of an electro-hydraulically controlled drive axis |

|

Function |

The velocity is acquired by continuous differentiation of the distance over time. |

|

Various systems are available depending on the level of accuracy required. |

Highest accuracy requirements are achieved by digital systems (glass scale with photoelectric evaluation circuit) mounted directly on the machine.

The most widely used digital incremental systems require a reference point approach at the beginning of a machining operation.

1.3.7SINUMERIK 840D/SIMODRIVE 611 digital

SINUMERIK control systems and SIMODRIVE drive systems are specially designed for machine tools, manipulators and special-purpose machines.

The numerical control processes the machine program and converts it into control commands. It also monitors command execution continuously.

The control structures for the electro-hydraulic control loop and the interfaces to

Sthe shut-off valve,

Sthe servo solenoid valve,

Sthe position measuring system and

Sthe central processing unit

are all provided by the HLA module.

The HLA module is an integral component of the SINUMERIK 840D and

SIMODRIVE 611 digital systems.

A range of different modules with graded scope of functions is provided to allow the SINUMERIK 840D NCU system to be tailored to a wide range of functional requirements of machines. This allows optimal adaptation to the machine and machining task, as well as allowing for equipping standardized machine series.

1.3.8Hydraulic power unit

This unit supplies hydraulic energy.

It is installed remotely from the drive axis. Accumulators are employed to compensate for strongly fluctuating hydraulic energy requirements and to minimize the installed power.

J

1-18 |

♥ Siemens AG, 2006. All rights reserved |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

Configuration |

2 |

2.1Configuring steps

2.1.1Procedure for configuring electrical components

The procedure for configuring an HLA module is divided into steps in such a way that the user is guided through the full range of relevant settings, from the required force, to the hydraulics components, and finally the HLA and its encoder evaluation circuitry. This initial configuring phase may be followed by a second in some cases, in which the corresponding circuit recommendations and EMC measures are taken into account.

The functions of SIMODRIVE components are described with keywords in this

Planning Guide. Limit values for functions may be specified in some cases.

For further details (e.g. characteristics), please refer to the Installation and

Start-Up Guides for SIMODRIVE 611 digital and SINUMERIK 840 digital.

Further configuring instructions and detailed ordering information can be found in Catalogs NC 60 and NC Z.

Phase 1

Selection of hydraulic |

|

|

|

|

|

|

|

|

Section 2.3 |

||||

components |

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

and publication from Rexroth |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

Dimensioning of incoming |

|

|

|

|

|

|

Section 2.2 |

|||||

|

mains supply |

|

|

|

|

|

|

||||||

|

|

|

|

and publication 6SN1197-0AA00 |

|||||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

Dimensioning of |

|

|

|

|

|

Section 2.2 |

|||||

|

|

power modules |

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

and publication 6SN1197-0AA00 |

|||||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

Dimensioning of external |

|

|

|

|

Section 2.4 |

|||||

|

|

|

power supply |

|

|

|

|

||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

Dimensioning of closed- |

|

|

|

Chapter 4 |

|||||

|

|

|

|

loop control components |

|

|

|

||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

Dimensioning of position |

|

Section 7.1 |

|||||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

sensor (measuring system) |

|

||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 2-1 Configuring steps in start-up sequence

♥ Siemens AG, 2006. All rights reserved |

2-19 |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

2 Configuration |

1002..0399 |

2.1 Configuring steps |

|

Phase 2

Recommended circuits |

|

|

Section 2.4 |

EMC measures |

|

|

|

|

|

|

|

|

|

|

|

Block diagrams/ |

|

Section 2.2 |

connection diagrams |

|

|

|

|

Abbreviations,

Appendix

terms and index

Fig. 2-2 2. Configuring phase

2.1.2Procedure for configuring hydraulic components

Hydraulically controlled drives are normally configured by the technical sales and marketing personnel of the hydraulics supplier (e.g. Bosch

Rexroth, see Chapter 8) in close co-operation with the machine manufacturer.

This configuring phase is divided into the following steps:

SSelection of the cylinder on the basis of forces and velocities required and the cylinder mounting conditions in the machine

(see Subsection 2.3.1).

SSelection of the servo solenoid valves on the basis of the cylinder data, forces, velocities and dynamic requirements (see Subsection 2.3.2, 2.3.3).

SSelection of the position measuring system and optionally the pressure sensors with regard to the measuring range, accuracy and linearity (see Section 7.1, 7.3).

SDimensioning of the hydraulic power unit, taking all loads into account (see Subsection 2.3.5).

SCalculation of the natural frequency of the drive for an initial assessment of whether the expected control result can be achieved (see Subsection 2.3.4).

SIn difficult cases, it may be worthwhile carrying out a dynamic simulation of the drive as an aid to configuration.

The basic data required to design a system are obtained from a questionnaire.

2-20 |

♥ Siemens AG, 2006. All rights reserved |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

02.99 |

2 Configuration |

|

2.1 Configuring steps |

Questionnaire |

Design of hydraulic NC axes |

|

Hydraulic NC axes |

|

||

|

Design of systems with linear motions |

|

||

Company: |

|

|

Contact person: |

|

Address: |

|

|

Department: |

|

|

|

|

Phone: |

|

Machine: |

|

|

|

|

Axis: |

Function/designation: |

|

|

|

|

Straight-cut control: |

|

Continuous-path control: |

|

Drive specification |

|

|

|

|

Cylinder dimensions [mm] |

|

Accuracy requirements |

|

|

Piston diameter: |

|

Positioning precision [ m] |

|

|

1. rod diameter: |

|

from rapid traverse: |

|

|

2. rod diameter: |

|

from feedrate: |

|

|

Stroke: |

|

|

Path accuracy: |

|

Cylinder mounting position: |

|

Velocity |

|

|

|

|

|

tolerance [mm/min]: |

|

051-001/ |

|

|

|

|

Connection: |

|

|

Position |

incremental, |

Valve cylinder |

|

|

measuring system |

output signal ... |

Pipe/Hose length [mm]: |

|

Make: |

|

|

Pipe/Hose diameter [mm]: |

|

Type: |

|

|

Moved mass [kg]: |

|

Other: |

|

|

Machining forces [N] |

|

Resolution [ m]: |

|

|

Piston advance: |

|

|

|

|

Piston retraction: |

|

|

|

|

Slide guide friction |

|

NC control system |

|

|

|

: |

|

Make: |

SIEMENS |

|

FR [N]: |

|

Type: |

840D |

Pump pressure [bar]: |

|

|

|

|

Velocities [m/min] |

|

|

|

|

Rapid traverse advance: |

|

|

|

|

Rapid traverse retract: |

|

|

|

|

Machining feed advance: |

|

|

|

|

Machining feed retract: |

|

|

|

|

Acceleration rates [m/s2] |

|

|

|

|

Max. acceleration: |

|

|

|

|

Max. delay: |

|

|

|

|

Processed by: |

Dept.: |

No. of pages: |

Date: |

|

♥ Siemens AG, 2006. All rights reserved |

2-21 |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

2 Configuration |

02.99 |

2.2 Integration in SINUMERIK 840D/SIMODRIVE 611 digital |

|

2.2Integration in SINUMERIK 840D/SIMODRIVE 611 digital

2.2.1System overview

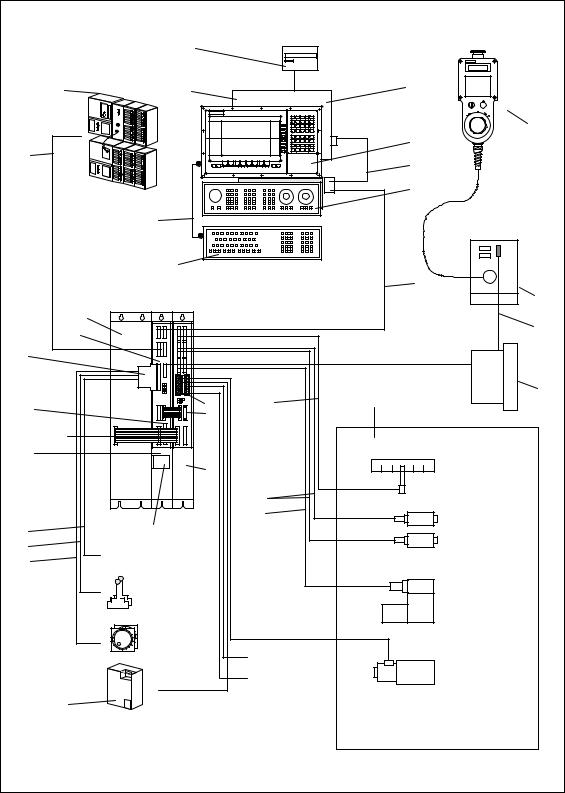

Components |

A complete SINUMERIK 840 digital control system with HLA module consists of |

||||

|

various individual components. These are listed below. |

||||

|

Table 2-1 |

Components of SINUMERIK 840 digital control with HLA module (number, |

|||

|

|

|

component, description) |

||

|

|

|

|

|

|

|

No. |

|

Component |

|

Description |

|

in |

|

|

|

|

|

Fig. |

|

|

|

|

|

2-3 |

|

|

|

|

|

|

|

|

|

|

|

A |

NCU box |

S |

Enclosure for NC CPU |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

NC CPU |

S |

Central processing unit of 840D, |

|

|

|

|

|

|

|

|

|

|

|

S Execution of NC program, |

|

|

|

|

|

S Contains modules with e.g. PLC, communications |

|

|

|

|

|

|

functions |

|

|

|

|

S NCU 573.2 includes a fan module |

|

|

B1 |

Cable distributor |

S |

For insertion in NCU |

|

|

|

|

|

|

|

|

|

|

|

||

|

C1) |

Operator panel |

S Display, keyboard, power supply unit and |

||

|

|

|

|

|

operator controls for NC |

|

|

|

|

|

|

|

D1) |

MMC module |

S |

Operator panel calculator (integrated in panel), |

|

|

|

|

|

|

|

|

|

|

|

S MMC 103 with hard disk |

|

|

E |

Mains supply module |

Reference: /PJ1/ SIMODRIVE 611 |

||

|

|

(MS) |

|

|

|

|

|

|

|

|

|

|

F1) |

Machine control panel |

S |

Machine operation |

|

|

|

|

|

|

|

|

|

|

|

||

|

G11) |

ISA adapter |

S Allows AT modules to be used in conjunction with |

||

|

|

|

|

|

the MMC module MMC103 (mounted in operator |

|

|

|

|

|

panel) |

|

|

|

|

|

|

|

G2 |

Full keyboard for CNC |

S |

Full keyboard for connection to MMC module |

|

|

1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G3 |

Memory card (PCMCIA) |

S |

Contains the system program, |

|

|

|

|

|

|

|

|

|

|

|

S can be slotted into the NCU 561.2, 571.2, 572.2, |

|

|

|

|

|

|

573.2 |

|

|

|

|

|

|

|

G4 |

Diskette unit (accessory) |

S |

Built-in unit for connection to MMC module |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H1 to |

Cable |

|

Reference: /Z/, Catalog of Accessories NC Z |

|

|

H 9 |

|

|

|

|

|

|

|

|

|

|

|

H10 |

Cable |

|

See Chapter 7, Peripherals/Accessories |

|

|

to |

|

|

|

|

|

H12 |

|

|

|

|

|

|

|

|

|

|

|

I |

SIMODRIVE hydraulic |

S |

Closed-loop control of hydraulic drive |

|

|

|

module (HLA module) |

|

||

|

|

S |

Actuation of servo solenoid valve |

||

|

|

|

|

|

|

|

|

|

|

||

|

|

50 mm carrier module |

Holder for HLA closed-loop control plug-in module |

||

|

|

(universal empty housing) |

(see Fig. 2-6) |

||

|

|

|

|

|

|

|

I1 |

Phoenix cable connection |

S |

Shut-off valve |

|

|

|

|

|

|

|

|

|

|

|

S External 24 V supply |

|

|

|

|

|

S BERO input |

|

|

|

|

|

S “Power enable” |

|

|

J |

SIMATIC components |

Reference: /S7H/, Manual |

||

|

|

|

|

||

|

K |

Terminator |

Terminator for drive bus (inserted in last module in |

||

|

|

|

|

drive grouping) |

|

|

|

|

|

|

|

2-22 |

♥ Siemens AG, 2006. All rights reserved |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

0210.9903 |

|

|

|

|

2 Configuration |

|

|

|

2.2 Integration in SINUMERIK 840D/SIMODRIVE 611 digital |

||

|

Table 2-1 |

Components of SINUMERIK 840 digital control with HLA module (number, |

|||

|

|

|

component, description) |

||

|

|

|

|

|

|

|

No. |

|

Component |

|

Description |

|

in |

|

|

|

|

|

Fig. |

|

|

|

|

|

2-3 |

|

|

|

|

|

|

|

|

|

|

|

L1) |

Handheld unit |

S |

Connect HHU to K bus via MPI |

|

|

|

|

|

|

|

|

|

|

|

S Handwheel, EMERGENCY STOP button, key-ac- |

|

|

|

|

|

|

tuated switch, override, agreement buttons, dis- |

|

|

|

|

|

play, unassigned keys |

|

|

|

|

|

|

|

M1) |

Distributor box |

S |

For linking the hand-held unit to the MPI bus |

|

|

|

|

|

|

|

|

|

|

|

S Connection for EMERGENCY STOP circuit, en- |

|

|

|

|

|

|

able keys, handwheel, 24 V DC |

|

|

|

|

|

|

|

N |

Cable distributor |

S |

24V supply for connection to MPI connector |

|

|

|

|

|

|

|

|

|

|

|

||

|

O |

Hydraulic drive |

References: |

||

|

|

|

|

/BR1/, “Servo solenoid valves” catalog |

|

|

|

|

|

|

/BR2/, “Sensors and electronics” catalog |

|

|

|

|

|

/BR3/, “Adapter plate valves” catalog |

|

|

|

|

|

|

|

P |

External 24 V supply |

S |

SITOP stabilized power supply modules |

|

|

|

|

|

|

|

|

|

|

|

Reference: SITOP catalog |

|

|

|

|

|

Order No. E860060-K2410-A101-A4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

1)A description of these components can be found in:

References: /BH/, Operator Components Manual

Note

An HLA module must never be operated directly on a SIMODRIVE monitoring module, i.e. it must always be connected via a mains infeed module.

For information about connecting further additional SIMODRIVE monitoring modules in configurations with several HLA modules, please refer to the Planning Guide for SIMODRIVE 611 Converters /PJU/.

In a multi-tier configuration, all the infeed supply units must be connected simultaneously.

♥ Siemens AG, 2006. All rights reserved |

2-23 |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

2 Configuration |

02.99 |

2.2 Integration in SINUMERIK 840D/SIMODRIVE 611 digital

|

|

|

Floppy |

|

|

|

|

G4 |

|

|

|

J |

|

G1 |

|

MMC CPU |

D |

|

|

|

|||

|

|

|

|

||

|

|

|

|

|

|

S7–300 |

|

|

|

|

|

|

|

|

|

|

L |

|

|

|

|

|

C |

H1 |

|

|

|

|

H5 |

|

|

|

|

|

|

|

|

MCP |

|

|

F |

|

|

|

|

|

|

|

|

H4 |

|

|

|

|

|

G2 |

|

|

|

|

|

|

|

|

H6 |

|

|

|

|

|

M |

E |

|

|

|

|

(GND) |

|

|

|

|

H8 |

|

B |

|

|

|

|

|

|

|

|

|

|

|

B1 |

|

|

|

|

|

|

|

I1 |

|

O |

N |

G3 |

|

H10 |

|

||

|

|

|

|||

|

K |

|

|

|

|

|

|

|

|

|

|

Device bus |

|

|

|

|

|

A |

|

|

|

|

Position sensing |

|

|

I |

|

|

|

|

|

|

|

|

|

|

MS |

NCU HLA |

|

|

|

|

|

module |

H11 |

|

|

|

|

|

|

|

|

|

|

|

H12 |

|

Pressure sensor A |

H2 |

Battery and plug-in fan |

|

|

Pressure sensor B |

|

unit |

|

|

|

||

H3 |

|

|

|

||

|

|

|

|

||

Digital I/O |

|

|

|

||

H9 |

|

|

|

||

(high-speed NC I/O) |

|

|

|

||

|

|

|

|

||

|

|

Measure- |

|

|

Servo solenoid |

|

|

ment (2x) |

|

|

|

|

|

|

|

valve |

|

|

|

|

|

|

|

|

|

Handwheel |

BERO |

|

|

|

|

(2x) (1x of M) |

|

|

|

|

|

inputs |

|

|

|

|

|

|

|

Shutoff valve |

|

SITOP power |

|

|

Enable |

|

|

(external PS) |

|

|

|

|

|

|

|

|

|

|

|

P |

External 26.5 V |

|

Note: |

|

|

|

|

|

|||

|

supply |

|

|

Display of hydraulics for one axis |

|

Fig. 2-3 System components

2-24 |

♥ Siemens AG, 2006. All rights reserved |

SINUMERIK 840D/SIMODRIVE 611 digital, HLA Module (FBHLA) – 03.06 Edition |

02.99 |

2 Configuration |

2.2 Integration in SINUMERIK 840D/SIMODRIVE 611 digital

|

|

|

|

|

|

|

|

|

|

|

|

|

Servo solenoid |

Servo solenoid valve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

valve |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

Pressure |

Pressure sensor A |

|

|

|

|

|

|

|

|

|

|

O |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

B |

|

|

|

|

|

|

|

|

sensor A |

Pressure sensor B |

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressure |

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

sensor B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Position sensing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Position sensing |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shutoff valve |

|

|

Shutoff valve |

|

|

|

|

Hydraulic drive, axis 1 |

|

Hydraulic drive, axis 2 |

|||

|

|

Axis 1 |

HLA |

|

|

Axis 2 |

|

|

Position |

–X101 |

–X102 |

|

|

Position |

|

|

measuring |

|

|

|

|

measuring |

|

|

system |

|

|

|

B |

system |

|

|

|

B |

|

|

|

|

|

|

|

O |

–X111 |

–X112 |

|

O |

|

|

Pressure sensor |

|

|

Pressure sensor |

|||

|

|

|

|

|

|||

|

Servo solenoid |

–X121 |

–X122 |

|

|

Servo solenoid |

|

|

valve |

|

|

|

|

valve |

|

|

|

X431 |

|

|

|

X432 |

|

|

|

|

|

–X35 |

|

|

|

|

|

|

–X34 |

|

|

|

|

M |

+ |

Functional ground |

|

|

M |

+ |

Functional ground1) |

PV1 |

Shutoff valve, axis 1 |

|

|

PV2 |

Shutoff valve, axis 2 |

||

MV1 |

– |

Reserved, do not use! |

|

|

MV2 |

– |

Reserved, do not use! |

C1 |

+ |

X1141 |

X1341 |

C2 |

|

||

P24 |

External 26.5 V supply |

B1 |

|

BERO input, axis 1 |