Operation & Safety

An Oshkosh Corporation Company

Manual

Original Instructions

Keep this manual with machine at all times.

Telehandler

Personnel Work

Platform

31200160

Revised

June 15, 2012

CALIFORNIA PROPOSITION 65

BATTERY WARNING

Battery posts,

terminals and related

accessories contain

lead and lead compounds,

chemical known to the

State of California

to cause cancer and

reproductive harm.

WASH HANDS

AFTER HANDLING!

CALIFORNIA PROPOSITION 65

EXHAUST WARNING

Diesel Engine exhaust and

some of its constituents

are known to the State of

California to cause cancer,

birth defects and other

reproductive harm.

Revision Log

Revision Log

January 2, 2007 - A - Original Issue of Manual

March 22, 2007 - B - Revised pages 3-1, 4-4 and 6-1.

February 14, 2008 - C - Revised pages 1-1, 1-2, 2-1, 2-4, 4-2, 4-3 and 4-4.

December 10, 2008 - D - Revised covers and pages c & 5-1.

June 15, 2012 - E - Revised covers and pages 1-5, 1-11, 2-1, 2-4, 3-4, 4-2 & 5-1.

REVISION LOG

a31200160

Read This First

Read This First

This manual is a very important tool! Keep it with the machine at all times.

The purpose of this manual is to provide owners, users, operators, lessors, and

lessees with the precautions and operating procedures essential for the safe and

proper machine operation for its intended purpose.

Due to continuous product improvements, JLG Industries, Inc. reserves the right to

make specification changes without prior notification. Contact JLG Industries, Inc.

for updated information.

Telehandler Operator and Platform Occupant Qualifications

The telehandler operator and platform occupants must read and understand this

manual.

The telehandler operator must read and understand the telehandler Operation &

Safety Manual and any optional equipment instructions prior to operation.

The operator must also read, understand and comply with all applicable Employer,

Industry and Governmental rules, standards and regulations.

Modifications

Any modification to the platform must be approved by the platform

manufacturer.

b 31200160

Read This First

This product must comply with all safety related bulletins. Contact JLG Industries,

Inc. or the local authorized JLG representative for information regarding safetyrelated bulletins which may have been issued for this product.

JLG Industries, Inc. sends safety related bulletins to the owner of record of this

machine. Contact JLG Industries, Inc. to ensure that the current owner records are

updated and accurate.

JLG Industries, Inc. must be notified immediately in all instances where JLG

products have been involved in an accident involving bodily injury or death of

personnel or when damage has occurred to personal property or the JLG product.

FOR:

• Accident Reporting and Product Safety Publications

• Current Owner Updates

• Questions Regarding Product Applications and Safety

• Standards and Regulations Compliance Information

• Questions Regarding Product Modifications

CONTACT:

Product Safety and Reliability Department

JLG Industries, Inc.

13224 Fountainhead Plaza

Hagerstown, MD 21742

USA

or Your Local JLG Office

(Addresses on back cover)

In USA:

Toll Free: 1-877-JLG-SAFE (1-877-554-7233)

Outside USA:

Phone: +1-717-485-6591

E-mail: ProductSafety@JLG.com

c31200160

Read This First

This Page Intentionally Left Blank

d 31200160

Table of Contents

TABLE OF CONTENTS

Revision Log

Read This First

Telehandler Operator and Platform

Occupant Qualifications ..................................................... b

Modifications ...................................................................... b

Table of Contents

Section 1 - General Safety Practices

1.1 Hazard Classification System ..............................................1-1

Safety Alert System and Safety Signal Words................1-1

1.2 General Precautions ............................................................1-2

1.3 Operation Safety ..................................................................1-3

Electrical Hazards ...........................................................1-3

Tip Over Hazard..............................................................1-4

Load Falling Hazard ........................................................1-6

Pinch Points and Crush Hazards ....................................1-7

Fall Hazard......................................................................1-9

Chemical Hazards.........................................................1-11

Section 2 - Pre-Operation and Inspection

2.1 Pre-Operation Check and Inspection...................................2-1

2.2 Safety Decals - JLG Supplied Personnel Work Platform.....2-2

Quick Switch Mounted .................................................... 2-2

Fork Mounted..................................................................2-4

2.3 Walk-Around Inspection.......................................................2-5

2.4 Warm-Up and Operational Checks ......................................2-6

Warm-Up Check ............................................................. 2-6

Operational Check .......................................................... 2-6

Table of Contents

Section 3 - Operation

3.1 Platform Operation...............................................................3-1

Lifting/Lowering Personnel..............................................3-1

3.2 Use of the Capacity Chart ....................................................3-2

Example ..........................................................................3-2

3.3 Loading and Securing for Transport .................................... 3-4

i31200160

Table of Contents

Section 4 - Types of Personnel Work Platforms

4.1 Approved Personnel Work Platforms .................................. 4-1

Quick Switch Mounted - JLG Supplied ........................... 4-1

Fork Mounted ................................................................. 4-1

4.2 Unapproved Personnel Work Platforms .............................. 4-2

4.3 Platform Installation ............................................................. 4-3

Quick Switch Mounted - JLG Supplied ........................... 4-3

Fork Mounted ................................................................. 4-4

Section 5 - Emergency Procedures

5.1 Emergency Lowering of Boom ............................................ 5-1

5.2 Incident Notification ............................................................. 5-1

Section 6 - Specifications

6.1 Product Specifications - JLG Supplied Personnel

Work Platform...................................................................... 6-1

Performance ................................................................... 6-1

Dimensions of Platform .................................................. 6-1

Index

Inspection, Maintenance and Repair Log

ii 31200160

Section 1 - General Safety Practices

DANGER

OW0010

WARNING

OW0021

CAUTION

OW0031

SECTION 1 - GENERAL SAFETY PRACTICES

1.1 HAZARD CLASSIFICATION SYSTEM

Safety Alert System and Safety Signal Words

DANGER indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

WARNIN G indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION indicates a potentiality hazardous situation which, if not avoided, may

result in minor or moderate injury.

1-131200160

Section 1 - General Safety Practices

OAB0050

1.2 GENERAL PRECAUTIONS

WARNING

Before operation, read & understand this manual. Failure to comply with the

safety precautions listed in this manual could result in machine damage, property

damage, personal injury or death.

• DO NOT use the telehandler with platform attached for any purpose other than

positioning personnel, their tools and equipment.

• DO NOT place boom or platform against any structure to steady the platform or

to support the structure.

• Operator must remain in cab and keep platform occupants in direct line of sight.

• Prior to lifting personnel, platform occupants and telehandler operator must

establish means of communication.

1-2 31200160

1.3 OPERATION SAFETY

OAB0010

Electrical Hazards

• This machine is not insulated and does not provide protection from contact or

proximity to electrical current.

Voltage Range

(Phase to Phase)

0 to 50 KV 10 ft (3 m)

Over 50 KV to 200 KV 15 ft (5 m)

Over 200 KV to 350 KV 20 ft (6 m)

Over 350 KV to 500 KV 25 ft (8 m)

Over 500 KV to 750 KV 35 ft (11 m)

Over 750 KV to 1000 KV 45 ft (14 m)

Note: This requirement shall apply except where employer, local or

governmental regulations are more stringent.

• Maintain safe distance from electrical lines, apparatus or any energized

(exposed or insulated) parts according to the Minimum Safe Approach Distance

(MSAD).

• Allow for machine movement and electrical line swaying.

• Maintain a clearance of at least 10 ft (3 m) between any part of the machine and

its occupants, their tools and equipment from any electrical line or apparatus

carrying up to 50,000 volts. One foot additional clearance is required for every

additional 30,000 volts or less.

• The minimum safe approach distance may be reduced if insulating barriers are

installed to prevent contact and the barriers are rated for the voltage of the line

being guarded. These barriers shall not be part of (or attached to) the machine.

The minimum safe approach distance shall be reduced to a distance within the

designed working dimensions of the insulating barrier. This determination shall

be made by a qualified person in accordance with the employer, local or

governmental requirements for work practices near energized equipment.

MINIMUM SAFE APPROACH

DISTANCE (MSAD)

1-331200160

Section 1 - General Safety Practices

OAB0020

OAB0030

OAB0040

OH2291

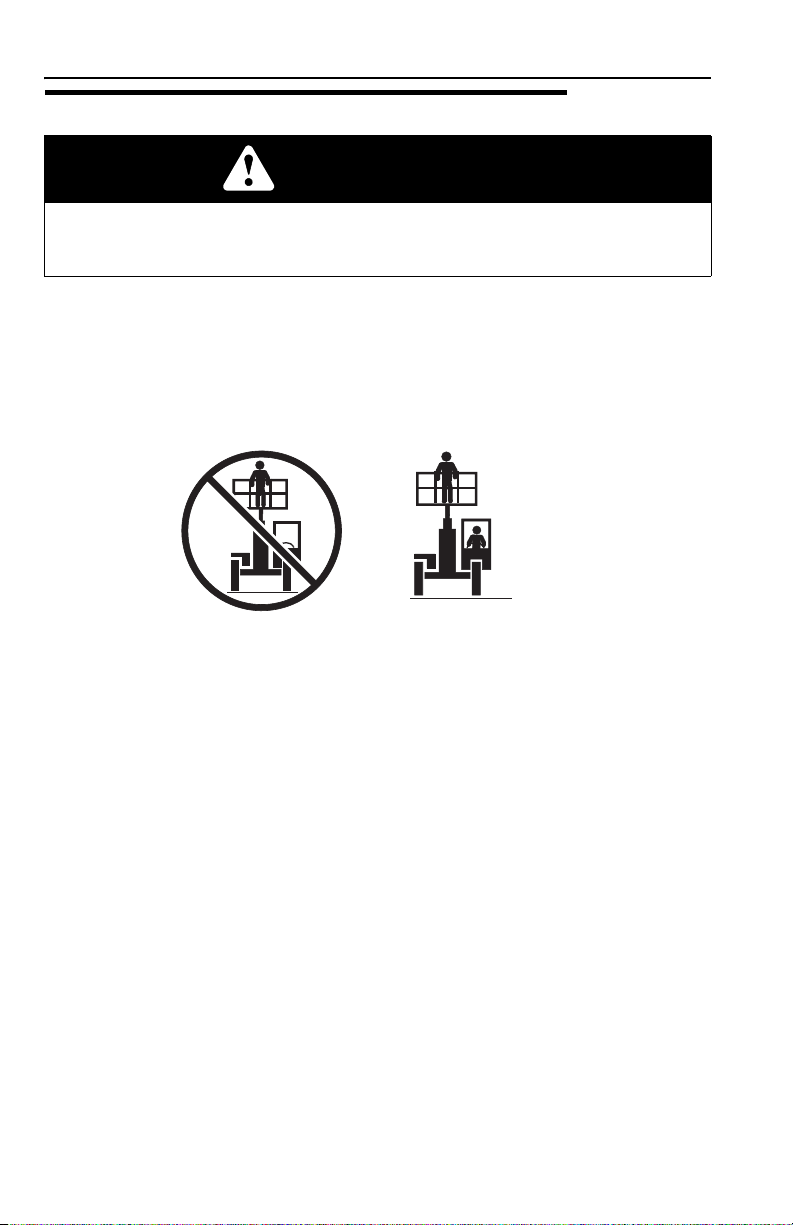

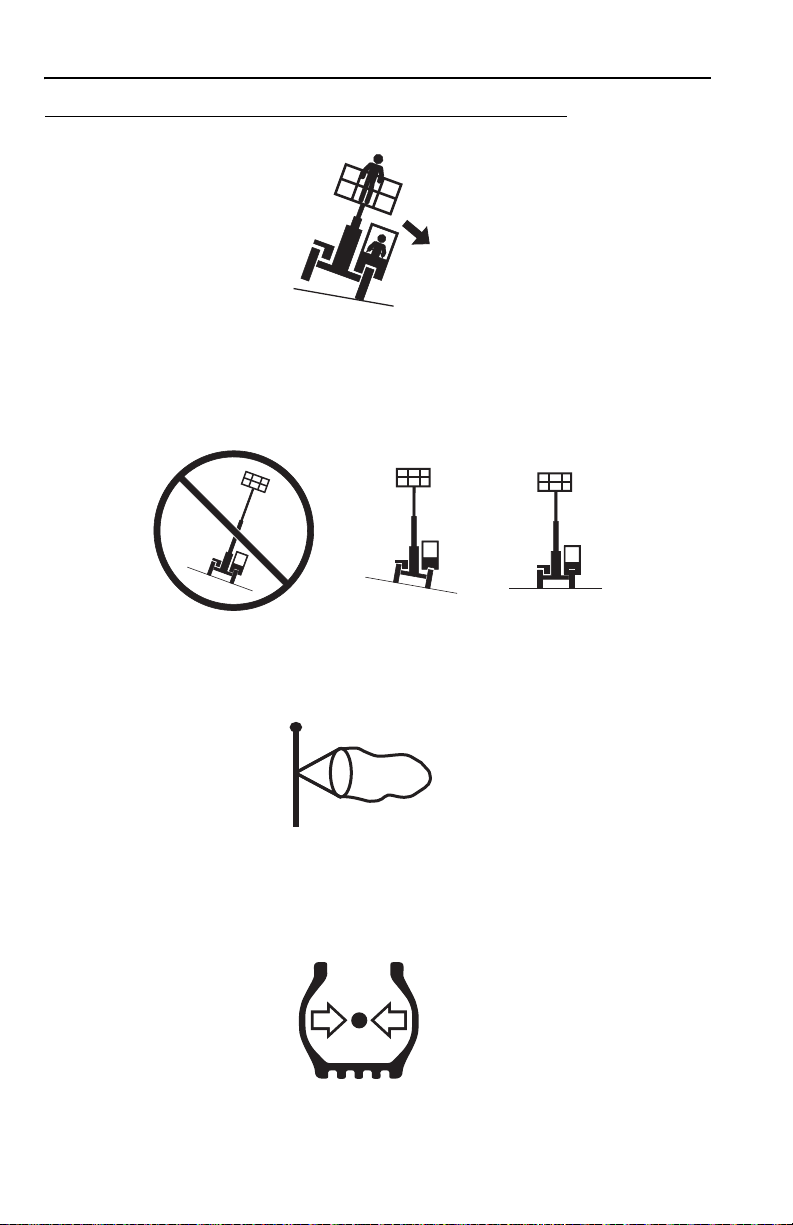

Tip Over Hazard

• DO NOT exceed rated lift capacity. Distribute loads evenly on platform floor.

• Be sure that the ground conditions are able to support the machine.

• DO NOT raise boom unless frame is level (0 degrees).

• DO NOT lift personnel during thunderstorms, strong winds or other inclement

weather.

• MAINTAIN proper tire pressure at all times. If proper tire pressures are not

maintained, this machine could tip over.

1-4 31200160

Section 1 - General Safety Practices

OW0170

OW01

90

OAB0070

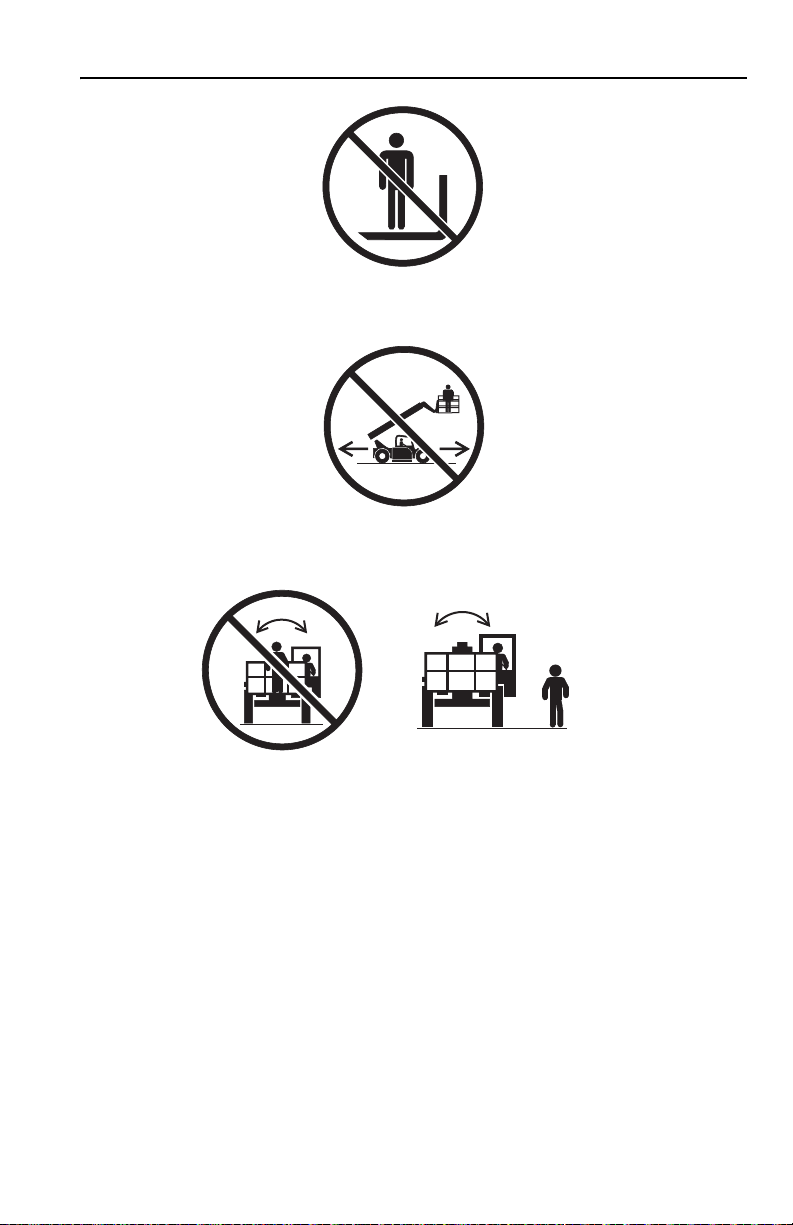

• USE ONLY an approved personnel work platform.

• DO NOT drive machine from cab when personnel are in platform.

• Never level the machine when the platform is occupied.

1-531200160

Section 1 - General Safety Practices

OZ1350

Load Falling Hazard

• Never suspend load from platform or supports.

• DO NOT carry materials directly on platform railing unless approved by the

platform manufacturer.

• Always ensure that power tools are properly stowed and never left hanging by

their cord from the platform work area.

1-6 31200160

Section 1 - General Safety Practices

OW0210

OW0220

OW0230

OW0240

Pinch Points and Crush Hazards

Stay clear of pinch points and rotating parts on the telehandler.

• Stay clear of moving parts while engine is running.

• Keep clear of tires and platform or other objects.

• Keep clear from under boom.

• Keep clear of boom holes.

1-731200160

Section 1 - General Safety Practices

OW0250

O

AB0170

O

AB0060

OZ1310

• Keep arms and hands clear of attachment tilt cylinder.

• During operation, keep all body parts inside platform railing.

• Keep others away while operating.

• Approved head gear must be worn by all platform personnel.

• Check work area for clearances overhead, on sides and bottom of platform when

lifting or lowering platform. Always look in direction of movement.

• Be sure that operators of other overhead and floor level machines are aware of

the machine’s presence. Disconnect power to overhead cranes.

1-8 31200160

Section 1 - General Safety Practices

OZ1290

OZ1300

Fall Hazard

• During operation, occupants in the platform must wear a full body harness with a

lanyard attached to an authorized lanyard anchorage point. Attach only one

lanyard per lanyard anchorage point.

• DO NOT use damaged harnesses, deceleration devices or lanyards.

• Before operating the machine, make sure all gates are closed and fastened in

their proper position.

• Keep both feet firmly positioned on the platform floor at all times. Never use

ladders, boxes, steps, planks or similar items on platform to provide additional

reach.

• Use hand rails, if equipped, to maintain balance while platform is in motion.

• Never use the boom assembly to enter or leave the platform.

• Use extreme caution when entering or leaving platform. Be sure that the boom is

fully lowered. Face the machine, maintain three point contact with the machine,

using two hands and one foot or two feet and one hand during entry and exit.

• Platform-to-structure transfers at elevated positions are discouraged. Where

transfer is necessary, enter/exit through the gate only with the platform within 1 ft

(0,3 m) of a safe and secure structure. 100% tie-off is also required in this

situation utilizing two lanyards. One lanyard must be attached to the platform

with the second lanyard attached to the structure. The lanyard connected to the

platform must not be disconnected until such time as the transfer to the structure

is safe and complete.

• Avoid accumulation of debris on platform floor. Keep mud, oil, grease and other

slippery substances from footwear and platform deck.

1-931200160

Section 1 - General Safety Practices

OAB0160

• Never tilt the platform when the platform is occupied.

1-10 31200160

Section 1 - General Safety Practices

OW0300

OW0950

Chemical Hazards

Exhaust Fumes

• DO NOT operate machine in an enclosed area without proper ventilation.

• DO NOT operate the machine in hazardous environments unless approved for

that purpose by JLG and site owner. Sparks from the electrical system and the

engine exhaust can cause an explosion.

Flammable Fuel

• DO NOT fill the fuel tank or service the fuel system near an open flame, sparks

or smoking materials. Engine fuel is flammable and can cause a fire and/or

explosion.

Hydraulic Fluid

• DO NOT attempt to repair or tighten any hydraulic hoses or fittings while the

engine is running or when the hydraulic system is under pressure.

• Stop engine and relieve trapped pressure. Fluid in the hydraulic system is under

enough pressure that it can penetrate the skin.

• DO NOT use your hand to check for leaks. Use a piece of cardboard or paper to

search for leaks. Wear gloves to protect hands from spraying fluid.

Welding

• DO NOT use machine as a ground for welding.

• When performing welding or metal cutting operations, precautions must be taken

to protect the chassis from direct exposure to weld and metal cutting spatter.

1-1131200160

Section 1 - General Safety Practices

This Page Intentionally Left Blank

1-12 31200160

Section 2 - Pre-Operation and Inspection

SECTION 2 - PRE-OPERATION AND INSPECTION

2.1 PRE-OPERATION CHECK AND INSPECTION

Note: Complete all required maintenance before operating unit.

WARNING

FALL HAZARD. Use extreme caution when checking items beyond your normal

reach. Use an approved ladder.

A pre-operation check & inspection of the telehandler is to be completed first. Refer

to the Operation & Safety Manual supplied with telehandler.

The pre-operation check & inspection, performed at beginning of each work shift or

at each change of operator, should include the following:

1. Cleanliness - Check all surfaces for foreign objects.

2. Structure - Inspect the platform structure for dents, damage, weld or parent

metal cracks or other discrepancies.

3. Safety Decals - Ensure all safety decals are legible and in place. Clean or

replace as required. See page 2-2 for details.

4. Operation & Safety Manual - Operation & Safety manual located in platform

manual holder.

5. Walk-Around Inspection - See page 2-5 for details.

6. Operational Check - Once the walk-around inspection is complete, perform a

warm-up and operational check (see page 2-6) in an area free of overhead and

ground level obstructions.

WARNING

If the telehandler does not operate properly, immediately bring machine to a stop,

lower boom and platform to ground and stop engine. Determine cause and

correct before continued use.

2-131200160

Section 2 - Pre-Operation and Inspection

OAB0120

1704277 B

1704277

90553032

ATTACH LANYARD HERE

9055-3032

90553026

90553031

90553033

406 MILL AVE. S.W. NEW PHILADELPHIA, OHIO MADE IN U. S. A.

DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE

PROPER GRADALL MATERIAL HANDLER/PERSONNEL WORK

PLATFORM CAPACITY CHART DISPLAYED IN CAB.

9055-3033

ATTACHMENT

SERIAL NUMBER

WEIGHT

CAPACITY

HYD. PRESSURE

9055-3026 REV. A

READ AND UNDERSTAND THE FOLLOWING PRIOR TO LIFTING PERSONNEL.

WHEN LIFTING PERSONNEL USE ONLY A GRADALL MANUFACTURED

PERSONNEL WORK PLATFORM.

ALL PERSONNEL IN PLATFORM MUST WEAR A FULL BODY HARNESS WITH

LANYARD ATTACHED TO A DESIGNATED ANCHORAGE POINT.

READ AND UNDERSTAND PERSONNEL WORK PLATFORM USER'S MANUAL

BEFORE OCCUPYING PERSONNEL WORK PLATFORM.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY OR DEATH.

4

-

R

IG

H

T

4

-

R

IG

H

T

9055-3031 REV. A

MAXIMUM OCCUPANCY THREE (3) PEOPLE.

DO NOT USE PERSONNEL WORK PLATFORM

WITHOUT THE PROPER GRADALL MATERIAL

HANDLER/PERSONNEL WORK PLATFORM

CAPACITY CHART DISPLAYED IN CAB.

FAILURE TO COMPLY COULD RESULT IN

SERIOUS INJURY OR DEATH.

VIEW OF LANYARD

ANCHORAGE POINT

BEFORE S/N 2005108-01

SIDE VIEW

OF PLATFORM

S/N 2005108-01 & AFTER

2.2 SAFETY DECALS - JLG SUPPLIED PERSONNEL WORK PLATFORM

Ensure all DANGER, WARNING, CAUTION and instructional decals and proper

capacity charts are legible and in place. Clean and replace as required.

Quick Switch Mounted

Before S/N 2006058-01

2-2 31200160

S/N 2006058-01 & After

OAB0090

1701509

1701509

1704277 B

1704277

1706892

1706892A

All occupants must wear full body

harness with lanyard attached to

designated anchorage point.

Fallingfrom

platform

couldresult

indeath or

serious

injury.

1706893

1706893A

Operator and occupants

must read and understand

personnel work platform

operator and safety manual

prior to lifting personnel.

TIP OVER

HAZARD

Death or

serious

injury could

result from

tip over.

= +

MAX Capacity

2000 lbs

MAX 3

90553033

406 MILL AVE. S.W. NEW PHILADELPHIA, OHIO MADE IN U. S. A.

DO NOT USE PERSONNEL WORK PLATFORM WITHOUT THE

PROPER GRADALL MATERIAL HANDLER/PERSONNEL WORK

PLATFORM CAPACITY CHART DISPLAYED IN CAB.

9055-3033

ATTACHMENT

SERIAL NUMBER

WEIGHT

CAPACITY

HYD. PRESSURE

4

-R

IG

H

T

4

-R

IG

H

T

VIEW OF LANYARD

ANCHORAGE POINT

Section 2 - Pre-Operation and Inspection

2-331200160

Section 2 - Pre-Operation and Inspection

OAB0192

1704277 B

1704277

1707063

1701509

1701509

1001092482A

Operator and occupants

must read and understand

personnel work platform

operatorand safety manual

priorto lifting personnel.

TIPOVER

HAZARD

Deathor

serious

injurycould

resultfrom

tipover.

=+

MAXCapacity

1000lbs

MAX 2

1001092482 - ENGLISH

1001096020 - FRENCH

1001096023 - ISO

1001092481A

PlatformFalling

offmachine

couldresult

indeath or

serious

injury.

Alwaysensure

platformretaining pins are

properlyinstalled behind

heelof forks.

1001092481 - ENGLISH

1001096019 - FRENCH

1001096021 - ISO

1706892 - ENGLISH

1001096024 - FRENCH

1001096025 - ISO

1706892A

All occupants must wear full body

harness with lanyard attached to

designated anchorage point.

Fallingfrom

platform

couldresult

indeath or

serious

injury.

Fork Mounted

2-4 31200160

Section 2 - Pre-Operation and Inspection

23

4

-

R

I

G

H

T

4

-

R

I

G

H

T

1

OAB0080

2.3 WALK-AROUND INSPECTION

Begin your platform walk-around inspection at item 1, as noted below. Continue

checking each item in sequence.

INSPECTION NOTE: On all components, make sure there are no loose or missing

parts, that they are securely fastened and no visible leaks or excessive wear exists

in addition to any other criteria mentioned. Inspect all structural members including

attachment and railing for cracks, excessive corrosion and other damage.

1. Platform

• Properly installed, see “Platform Installation” on page 4-3.

• Rail connections properly secure, undamaged and no missing hardware.

• Applicable Operation & Safety Manual located in manual holder.

2. Platform Gate - Clean, undamaged and closes properly.

-

3. Platform Support

Inspection Note.

(Quick Switch Mounted Personnel Work Platform) - See

2-531200160

Section 2 - Pre-Operation and Inspection

2.4 WARM-UP AND OPERATIONAL CHECKS

Warm-Up Check

Warm-up and operational checks of the telehandler are to be completed before

entering the platform. Refer to the Operation & Safety Manual supplied with

telehandler.

Operational Check

After engine warms, perform an operational check:

1. Horn must be audible from platform with engine running.

2-6 31200160

Section 3 - Operation

SECTION 3 - OPERATION

3.1 PLATFORM OPERATION

• JLG recommends the user comply with local, provincial and federal regulations

as they pertain to telehandler mounted personnel work platforms.

• Capacities and range limits for the telehandler change depending on the platform

in use.

• Separate attachment instructions must be kept in manual holder in cab with this

Operation & Safety Manual. An additional copy must be kept with the attachment

if it is equipped with a manual holder.

• For fork mounted platforms, the combined weight of the platform, load and

personnel shall not exceed one-third of the capacity at the related load center

position as indicated on the capacity chart for the attachment on which the

personnel work platform is being used.

Lifting/Lowering Personnel

• Secure work area.

• Without personnel in the platform, perform a simulated lift with designated signal

person on ground as spotter to assure adequate telehandler range and

attachment clearances.

• With the park brake applied, lift/lower personnel only at their request and in

accordance with the requirements set forth in Section 1 - General Safety

Practices and Section 4 - Types of Personnel Work Platforms. The operator shall

always sound horn to alert personnel prior to lifting/lowering the platform and

operate the joystick slowly and cautiously.

3-131200160

Section 3 - Operation

3.2 USE OF THE CAPACITY CHART

Example

A contractor owns a model xxxxx telehandler with a 48" Carriage. He knows his fork

mounted platform may be used with his model/attachment since it follows the

requirements set forth in “Approved Personnel Work Platforms” on page 4-1.

The contractor knows the platform’s capacity of 1,000 lb (454 kg) can handle the

occupant’s weight of 450 lb (204 kg) and the load also being lifted of 150 lb (68 kg).

The contractor also knows the platform weighs 400 lb (181 kg).

The following are examples with various conditions the contractor may encounter

and whether or not the platform may be lifted.

Load Weight (including

platform, load & personnel)

1 1000 lb (454 kg) 20 ft (6,1 m) 10 ft (3,0 m) Yes

2 1000 lb (454 kg) 28 ft (8,5 m) 16 ft (4,9 m) NO

3 1000 lb (454 kg) 22 ft (6,7 m) 24 ft (7,3 m) NO

4 1000 lb (454 kg) 8 ft (2,4 m) 30 ft (9,1 m) Yes

Distance Height OK to Lift

3-2 31200160

Section 3 - Operation

XXXXXXXX

48" & 72"

CARRIAGES

MODEL

XXXXX

USE WITH:

1234-5678 48" CARRIAGE

8765-4321 72" CARRIAGE

RATED CAPACITY @ 2 FT. LOAD CENTER

48'

44'

40'

36'

32'

28'

24'

20'

16'

12'

8'

4'

0'

-4'

-8'

1

2

3

4

5

6

69°

60°

50°

40°

30°

20°

10°

0°

-6°

9000 LBS

7000 LBS

6000 LBS

5000 LBS

4000 LBS

3000 LBS

2000 LBS

1100 LBS

DEDUCT 350 LBS

FROM ALL CAPACITIES

WHEN MACHINE IS

EQUIPPED WITH WINCH

36'

0'4'8'

12'16'20'24'28'32'

OABO180

Example 1

Example 4

Example 2

Example 3

Note: This is a sample capacity chart only! DO NOT use this chart, use the one

located in your operator cab.

3-331200160

Section 3 - Operation

4

-

R

I

G

H

T

4

-

R

I

G

H

T

OAB0130

3.3 LOADING AND SECURING FOR TRANSPORT

1. If attached to telehandler, refer to the Operation & Safety Manual supplied with

telehandler for securing telehandler.

2. Secure platform with strap as shown in figure.

Note: The user assumes all responsibility for choosing the proper method of

transportation and tie-down devices, making sure the equipment used is capable of

supporting the weight of the attachment/machine being transported and that all

manufacturer’s instructions and warnings, regulations and safety rules of their

employer, the Department of Transportation and/or any other local, state or federal/

provincial laws are followed.

3-4 31200160

Section 4 - Types of Personnel Work Platforms

SECTION 4 - TYPES OF PERSONNEL WORK

PLATFORMS

4.1 APPROVED PERSONNEL WORK PLATFORMS

Quick Switch Mounted - JLG Supplied

To determine if a quick switch personnel work platform is approved for use on the

specific telehandler you are using, perform the following prior to installation.

• The attachment model/option number on the attachment identification plate must

match the attachment number on a capacity chart located in the operator cab.

• The model on the capacity chart must match the model telehandler being used.

If any of the above conditions are not met, do not use the platform. The telehandler

may not be equipped with the proper capacity chart or the platform may not be

approved for the model telehandler being used. Contact JLG or the local distributor

for further information.

Fork Mounted

Fork mounted personnel work platforms must comply with the design requirements

of platforms for elevating personnel as outlined in the current revision of ITSDF

B56.6 Safety Standard for Rough Terrain Forklift Trucks.

Note: Compliance to OSHA regulations does not necessarily indicate compliance to

ITSDF B56.6.

If the platform does not meet the design requirements of the B56.6 Standard, do not

use the platform.

Contact JLG Product Safety Department at 1-877-554-7233 or the local distributor

for additional information.

4-131200160

Section 4 - Types of Personnel Work Platforms

4.2 UNAPPROVED PERSONNEL WORK PLATFORMS

Do not attach any type of personnel work platform that is not manufactured by JLG

to the Quick Switch.

Do not use fork mounted personnel work platforms that do not meet the design

requirements. See “Fork Mounted” on page 4-1.

Do not use unapproved platforms for the following reasons:

• Range and capacity limitations for “will fit,” homemade, altered, or other

non-approved platforms cannot be established.

• An overextended or overloaded telehandler can tip over with little or no warning

and cause serious injury or death to the operator and/or those working nearby.

• The ability of a non-approved platform to perform its intended function safely

cannot be assured.

WARNING

Use only approved personnel work platforms. Platforms which have not been

approved for use with your telehandler could cause machine damage or an

accident.

4-2 31200160

Section 4 - Types of Personnel Work Platforms

OAB0140

4-

R

IG

H

T

4-

R

IG

H

T

1

2

3

4

5

6

4

6

5

GRADALL & JLG

G-SERIES

GRADALL

C-SERIES &

D-SERIES

4.3 PLATFORM INSTALLATION

Quick Switch Mounted - JLG Supplied

Verify the personnel work platform is properly installed. Refer to the Operation &

Safety Manual supplied with telehandler for complete installation instructions.

1. Personnel Work Platform

2. Pivot Pin Recess

3. Saddle

4. Quick Switch

5. Lock Pin

6. Retaining Pin

WARNING

CRUSH HAZARD. Always be certain that personnel work platform is properly

positioned on boom and is secured by lock pin and retaining pin. Failure to

ensure proper installation could permit platform/load to disengage causing death

or serious injury.

4-331200160

Section 4 - Types of Personnel Work Platforms

OAB0150

G-SERIES

C-SERIES &

D-SERIES

• Attachment pin engaged in platform pin recess. Lock pin engaged fully and

secured with retainer pin. Saddles swung down and pinned in place.

Fork Mounted

JLG fork mounted personnel work platforms must attach to the forks by installing a

pin behind the heel of each fork. Prior to use, ensure each pin is installed and

secured.

For fork mounted platforms not manufactured by JLG, follow the personnel work

platform manufacturer’s instructions for installation.

DO NOT use fork mounted personnel work platforms with attachments capable of

independent motion (i.e. side tilt, swing and mast carriages) without disabling the

independent motion feature(s).

4-4 31200160

Section 5 - Emergency Procedures

SECTION 5 - EMERGENCY PROCEDURES

5.1 EMERGENCY LOWERING OF BOOM

In the event of total loss of engine power, hydraulic pump failure or if platform or

boom becomes jammed or snagged in overhead structures or equipment with an

elevated load, the situation must be properly evaluated and dealt with on an

individual basis. Contact your local Authorized Distributor or JLG Service

Department for specific instructions.

Secure the telehandler using the following procedures:

1. Rescue platform occupants.

2. Clear the area around telehandler of all personnel.

3. Engage the parking brake. Place the transmission control lever in “NEUTRAL”.

4. Block all four wheels.

5. Section off a large area under the boom with string or tape to restrict any

personnel from entering this area.

5.2 INCIDENT NOTIFICATION

JLG Industries, Inc. must be notified immediately of any incident involving a JLG

product. Even if no injury or property damage is evident, the factory should be

contacted by telephone and provided with all necessary details.

In USA:

Toll Free: 1-877-JLG-SAFE (1-877-554-7233)

8:00am to 4:45pm EST

Outside USA:

Phone: +1-717-485-6591

E-mail:

ProductSafety@JLG.com

Failure to notify the manufacturer of an incident involving a JLG Industries product

within 48 hours of such an occurrence may void any warranty consideration on that

particular machine.

Important:

Following any accident, thoroughly inspect the machine and test all functions from

cab controls. Do not lift above 10 ft (3 m) until all damage has been repaired, if

required, and all controls are operating correctly.

5-131200160

Section 5 - Emergency Procedures

This Page Intentionally Left Blank

5-2 31200160

Section 6 - Specifications

SECTION 6 - SPECIFICATIONS

6.1 PRODUCT SPECIFICATIONS - JLG SUPPLIED PERSONNEL WORK PLATFORM

For telehandler specifications refer to the Operation & Safety Manual supplied with

telehandler.

Performance

Quick Switch Mounted

Maximum Platform Capacity........................................................ 2000 lb (907 kg)

Fork Mounted

Maximum Platform Capacity........................................................ 1000 lb (454 kg)

Required Fork Length..................................................................48 in (1219 mm)

Dimensions of Platform

Quick Switch Mounted (including quick switch)

106” Platform

Platform Overall Height.......................................................53.8 in (1367 mm)

Platform Overall Width........................................................64.3 in (1633 mm)

Platform Overall Depth ........................................................106 in (2692 mm)

96” Platform

Platform Overall Height.......................................................53.8 in (1367 mm)

Platform Overall Width........................................................64.3 in (1633 mm)

Platform Overall Depth ..........................................................96 in (2438 mm)

Fork Mounted

Platform Overall Height ...............................................................49 in (1255 mm)

Platform Overall Width............................................................53.75 in (1365 mm)

Platform Overall Depth ..............................................................101 in (2565 mm)

6-131200160

Section 6 - Specifications

This Page Intentionally Left Blank

6-2 31200160

Index

Index

C

Capacity Chart.................................. 3-2

Example...................................... 3-2

Chemical Hazards.......................... 1-11

D

Decals .............................................. 2-2

Dimensions....................................... 6-1

E

Electrical Hazards ............................ 1-3

Emergency Lower of Boom .............. 5-1

Emergency Procedures.................... 5-1

F

Fall Hazard....................................... 1-9

G

General Precautions......................... 1-2

H

Hazard Classification System........... 1-1

I

Incident Notification.......................... 5-1

P

Performance .....................................6-1

Pinch Points and Crush Hazards ......1-7

Platform

Installation ...................................4-3

Operation.....................................3-1

Pre-Operation Check and

Inspection..........................................2-1

S

Safety Decals....................................2-2

Safety Practices ................................1-1

Safety Signal Words .........................1-1

Securing For Transport .....................3-4

Specifications....................................6-1

T

Tip Over Hazard................................1-4

W

Walk-Around Inspection....................2-5

Warm-Up...........................................2-6

L

Lifting/Lowering Personnel............... 3-1

Load Falling Hazard ......................... 1-6

M

Minimum Safe Approach

Distance ........................................... 1-3

O

Operation.......................................... 3-1

Operational Check............................ 2-6

131200160

Index

2 31200160

Inspection, Maintenance and Repair Log

Inspection, Maintenance and Repair Log

Serial Number ______________________________

Date Comments

Inspection, Maintenance and Repair Log

Date Comments

Hand Signals

OY1090

O

Y1100

OY1110

O

Y1120

OY1130

O

Y1140

OY1150

OY1160

OY1170

OY1180

OY1190

EMERGENCY STOP - With both

arms extended laterally, hands

open downward, move arms back

and forth.

RAISE BOOM - With either arm

extended horizontally, fingers

closed, point thumb upward.

EXTEND BOOM - With both

hands clenched, point thumbs

outward.

STOP - With either arm extended

laterally, hand open downward,

move arm back and forth.

LOWER BOOM - With either arm

extended horizontally, fingers

closed, point thumb downward.

RETRACT BOOM - With both

hands clenched, point thumbs

inward.

STOP ENGINE - Draw thumb or

forefinger across throat.

MOVE SLOWLY - Place one hand

motionless in front of hand giving

motion signal. (Raise load slowly

shown)

THIS FAR TO GO - With hands

raised and open inward, move

hands laterally, indicating distance

to go.

TILT FORKS UP - With one arm

held at side, extend other arm

upward at about 45 degrees.

TILT FORKS DOWN - With one

arm held at side, extend other arm

downward at about 45 degrees.

Special Signals - When signals for auxiliary equipment functions or conditions not

covered are required, they shall be agreed upon in advance by the operator and

signalman.

JLG Industries, Inc.

An Oshkosh Corporation Company

31200160

1 JLG Drive

McConnellsburg PA. 17233-9533

USA

Phone: +1-717-485-5161

Customer Support Toll Free: 1-877-554-5438

Fax: +1-717-485-6417

JLG Worldwide Locations

JLG Industries (Australia)

P.O. Box 5119

11 Bolwarra Road

Port Macquarie

N.S.W. 2444

Australia

Ph o n e: +6 1 2 658 11111

Fax: +61 2 65813058

JLG France SAS

Z.I. de Baulieu

47400 Fauillet

France

Phone: +33 (0)5 53 88 31 70

Fax: +33 (0)5 53 88 31 79

JLG Industries (Italia) s.r.l.

Via Po. 22

20010 Pregnana Milanese - MI

Italy

Phone: +39 029 359 5210

Fax: +39 029 359 5845

Plataformas Elevadoras

JLG Iberica, S.L.

Trapadella, 2

P.I. Castellbisbal Sur

08755Castellbisbal, Barcelona

Spain

Phone: +34 93 772 4 700

Fax: +34 93 771 1762

JLG Latino Americana Ltda.

Rua Antonia Martins Luiz, 580

Distrito Industrial João Narezzi

13347-404 Indaiatuba - SP

Brazil

Phone: +55 19 3936 8870

Fax: +55 19 3935 2312

JLG Deutschland GmbH

Max-Planck-Str. 21

D - 27721 Ritterhude-lhlpohl

Germany

Phone: +49 (0)421 69 350 20

Fax: +49 (0)421 69 350 45

JLG Europe B.V.

Polaris Avenue 63

2132 JH Hoofddorp

The Netherlands

Phone: +31 (0)23 565 5665

Fax: +31 (0)23 557 2493

JLG Sverige AB

Enkopingsvagen 150

Box 704

SE - 176 27 Jarfalla

Sweden

Phone: +46 (0)850 659 500

Fax: +46 (0)850 659 534

www.jlg.com

JLG Industries (UK) Ltd

Bentley House

Bentley Avenue

Middleton

Greater Manchester

M24 2GP - England

Phone: +44 (0)161 654 1000

Fax: +44 (0)161 654 1001

JLG Equipment Services Ltd.

Rm 1107 Landmark North

39 Lung Sum Avenue

Sheung Shui N.T.

Hong Kong

Phone: +852 2639 5783

Fax: +852 2639 5797

JLG Polska

UI. Krolewska

00-060 Warsawa

Poland

Phone: +48 (0)914 320 245

Fax: +48 (0)914 358 200

Loading...

Loading...