Model

BS E N ISO 9001 CertificateN o. 6917

M45A

M45AJ

E45A

E45AJ

CORPORATE OFFICE

JLG INDUST RIES, INC.

1 JLG Drive

McConnellsburg, PA 17233-9533

USA

Telephone: (717) 485-5161

Fax: (717) 485-6417

Issued: August 5, 1999 PRINTED IN U.S.A. 3120884

Updated: Fe bruary 15, 2000

EUROPEAN OFFICE

JLG INDUSTRIES (EUROPE)

Kilmartin Place,

T a nnoc hs ide Park,

Uddingston, Scotland, G71 5PH

Telephone: 01698 811005

Fax: 0169 8 811055

AUSTRALIAN OFFICE

JLG INDUSTRIES (AUSTRALIA)

P.0. Box 972

11 Bolwarra Road

Port MacQuarie

N.S.W. 44

Australia

Telephone: 1 (065) 811111

SERVICE & MAINTENANCE

INTRODUCTION

SECTION A. INTRODUCT ION - MAINT ENA NCE SA FETY

PRECAUTIONS

A GENERAL

This section contains the general s afety precaution s

which must be observed during maintenance of the aerial

platform. It is of utmost importance that maintenance personnel pay strict attention to these warnings and precautions to avoid possible injury to themsel ves or others, or

damage to the equipment. A maintenance program must

be followed to ensure that the machine is safe to operate.

MODIFICATION OF THE MACHINE WITHOUT CERTIFICATION BY

A RESPONSIBLE AUTHORITY THAT THE MACHINE IS AT LEAST

AS SAFE AS ORIGINALLY MANUFACTURED, IS A SAFETY VIOLATION.

The specific precautions to be observed during maintenance are inserted at the appropriate point in the manual.

These precautions are, for the most part, those that apply

when servicing hydraulic and larger machine component

parts.

Your safety, and that of others, is the first considerat ion

when engaging in the maintenance of equipment. Always

be conscious of weight. Never atte mpt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support

is provided.

SINCE THE MACHINE MANUFACTURER HAS NO DIRECT CONTROL OVER THE FIELD INSPECTION AND MAINTENANC E,

SAFETY IN THIS AREA RESPONSIBILITY OF THE OWNER/OPERATOR.

B HYDRAULIC SYSTEM SAFETY

It should be noted that the machines hydraulic systems

operate at extremely high potentially dangerous pressures. Every effort should b e made to reli eve any s ystem

pressure prior to discon nectin g or removin g any portio n of

the system.

C MAINTENANCE

FAILURE TO COMPLY WITH SAFETY PRECAUTIONS LISTED IN

THIS SECTION MAY RESULT IN MACHINE DAMAGE, PERSONNEL

INJURY OR DEATH AND IS A SAFETY VIOLATION.

• NO SMOKING IS MANDATORY. NEVER REFUEL DURING ELECTRICAL STORMS. ENSURE THAT FUEL

CAP IS CLOSED AND SECU RE AT ALL OTHER

TIMES.

• REMOVE ALL RINGS, WATCHES AND JEWELRY

WHEN PERFORMING ANY MAINTENANCE.

• DO NOT WEAR LONG HAIR UNRESTRAINED, OR

LOOSE-FITTING CLOTHING AND NECKTIES WHICH

ARE APT TO BECOME CAUGHT ON OR ENTANGLED

IN EQUIPMENT.

• OBSERVE AND OBEY ALL WARNINGS AND CAUTIONS ON MACHINE AND IN SERVICEMANUAL.

• KEEP OIL, GREASE, WATER, ETC. WIPED FROM

STANDING SURFACES AND HAND HOLDS.

• USE CAUTION WHEN CHECKING A HOT, PRESSURIZED COOLANT SYSTEM.

• NEVER WORK UNDER AN ELEVATED BOOM UNTIL

BOOM HAS BEEN SA FELY RESTRAINED FROM ANY

MOVEMENT BY BLOCKING OR OVERHEAD SLING,

OR BOOM SAFETY PROP HAS BEEN ENGAGED.

• BEFORE MAKING ADJUSTMENTS, LUBRICATING OR

PERFORMING ANY OTHER MAINTENANCE, SHUT

OFF ALL POWER CONTROLS.

• BATTERY SHOULD ALWAYS BE DISCONNECTEDDURING REPLACEMENT OF ELECTRICAL COMPONENTS.

• KEEP ALL SUPPORT EQUIPMENT AND ATTACHMENTS STOWED IN THEIR PROPER PLACE.

• USE ONLY APPROVED, NONFLAMMABLE CLEANING

SOLVENTS.

Relieve system pressure by cycling the applicable control

several times with the engine stopped and ignition on, to

direct any line pressure back into the reservoir. Pressure

feed lines to system components can then be disconnected with minimal fluid loss.

3120884 – JLG Lift – A-1

INTRODUCTION

REVISON LOG

August 5, 1999 - Original Issue

2-40 - Updated 8-30-99

1-1 and 1-2 - Updated 10-7-99

2-50 - Updated 10-7-99

2-52 thru 2-54 - Updated 10-7-99

1-1 - Updated 2-15-00

3-1 - Updated 2-15-00

3-5 - Updated 2-15-00

3-16 - Updated 2-15-00

A-2 – JLG Lift – 3120884

TABLE OF CONTENTS

TABLE OF CONTENTS

SUBJECT - SECTION, PARAGRAPH PAGE NO.

SECTION A - INTRODUCTION - MAINTENANCE SAFETY PRE CAU TIONS

A General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

B Hydraulic System Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

C Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

SECTION 1 - SPECIFICATIONS

1.1 Capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.2 Component Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.3 Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

1.4 Function Speeds (M45A/E45A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.5 Function Speeds (M45AJ/E45AJ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1.6 Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.7 Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1.8 Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.9 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1.10 Major Component Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.11 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1.12 Serial Number Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

SECTION 2 - PROCEDURES

2.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.2 Servicing and Maintenance Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

2.3 Lubrication Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2.4 Battery Maintenance and Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

2.5 Cylinders - Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2.6 Cylinder Checking Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

2.7 Cylinder Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2.8 Cylinder Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2.9 Wear Pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

2.10 Boom Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

2.11 Rotator - Helac. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

2.12 Boom Limit Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

2.13 Articulating Jib Boom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

2.14 Swing Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

2.15 Mid and Lower Lift Cylinder Bleeding Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

2.16 Boom Synchronizing Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

2.17 Dri v e Hub. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

2.18 Drive Brake - Mico. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

2.19 Pins and Gar-max Bearing Repair Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

2.20 Speed Sensor Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

2.21 Footswitch Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

2.22 Positrac/Tilt module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

2.23 Pressure Setting Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

2.24 JLG Control System Analyzer Kit Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45

2.25 Gene r ator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-70

2.26 Preventive Maintenance and Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-76

SECTION 3 - TROUBLESHOOTING

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.2 Troubleshooting.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3.3 Hydraulic Circuit Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

3120884 – JLG Lift – i

TABLE OF CONTENTS

LIST OF FIGURES

FIGURE NO. TITLE PAGE NO.

1-1. Serial Number Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-2. Torque Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1-3. Lubrication Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

2-1. On Board Generator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

2-2. Batteries and Battery Charger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

2-3. Cylinder Barrel Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2-4. Capscr e w Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2-5. Cylinder Rod Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2-6. Tapered Bushing Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-9

2-7. Gar-Max Bearing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2-8. Rod Seal Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2-9. Wiper Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2-10. Installation of Head Seal Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2-11. Piston Seal Kit Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2-12. Tapered Bushing Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1 2

2-13. Seating the Tapered Bearing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2-14. Poly-Pak Piston Seal Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2-15. Rod Assembly Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1 3

2-16. Upper Boom Lift Cylinder Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2-17. Mid Boom Lift Cylinder Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2-18. Lower Boom Lift Cylinder Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2-19. Upper Telescope Cylinder Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2-20. Wear Pad Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

2-21. Platform Components and Attaching Hardware (M45A & E45A). . . . . . . . . . . . . . . . . . . . . . . . . .2-18

2-22. Location of Components - Boom Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

2-23. Rotator Assembly (Helac). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

2-24. Removing End Cap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

2-25. Removing Shaft from Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

2-26. Removing Sleeve from Housing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-23

2-27. Actuator Timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

2-28. Boo m Limit Switches. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

2-29. Location of Component s - Articulating Ji b Boom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-26

2-30. Swing Bearing Feeler Gauge Check. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

2-32. Swi ng Bearing Tolerance Measuring Po in t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

2-31. Swing Bearing Tolerance Boom Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

2-33. Swing Bearing Torquing Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

2-34. Swi ng Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-31

2-35. Dri v e Hub - Cutaway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

2-36. Drive Brake - Mico. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-35

2-37. Speed Sensor Orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

2-38. Frame Mounted Electrical Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-38

2-39. Steering Components and Spindles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-39

2-40. Dri v e Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-40

2-41. Tilt Sensor Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

2-42. Jib Valve Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-42

2-43. Brake/Steer Valve Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-43

2-44. Mai n Valve Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4 4

2-45. Control Module Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-45

2-46. Analyzer Flow Chart - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-61

2-47. Analyzer Flow Chart - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-62

2-48. Generator Componen t s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-71

2-49. Generator System Analyzer Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-74

ii – JLG Lift – 3120884

TABLE OF CONTENTS

LIST OF FIGURES (continued)

FIGURE NO. TITLE PAGE NO.

3-1. Electrical Components Installation - Sheet 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2 0

3-2. Electrical Components Installation - Sheet 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

3-3. Platform Electrical Schematic - Sheet 1 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

3-4. Platform Electrical Schematic - Sheet 2 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

3-5. Turntable Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-24

3-6. Frame Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

3-7. On Board Generator Electrical Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

3-8. Hydraulic Schematic - M45A/E45A - Sheet 1 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

3-9. Hydraulic Schematic - M45A/E45A - Sheet 2 of 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

3-10. Hydraulic Schematic - M45AJ/E45AJ - Sheet 1 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-30

3-11. Hydraulic Schematic - M45AJ/E45AJ - Sheet 2 of 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-31

LIST OF TABLES

TABLE NO. TITLE PAGE NO.

1-1 Torque Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-2 Hydraulic Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-3 Lubrication Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-4 Mobil DTE 11M Specs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-5 Cylinder Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-6 Major Component Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-7 Critical Stability Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-8 Lubrication Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

2-1 Cylinder Head and Tapered Bushing Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

2-2 Cylinder Piston Nut Torque Specifications) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2-3 Holding Valve Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2-4 Wear Pad Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-17

2-4 Pressure Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-42

2-5 Personality Ranges/Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-50

2-6 Machine Setup Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-53

2-7 JLG Control System Flash Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-54

2-8 Help Descriptions and Fault Flash Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-55

2-9 DIAGNOSTICS - Menu Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-63

2-10 System Test Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-65

2-11 System Test Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-66

2-12 RBS Prestart Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-72

2-13 RBS Startup Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-72

2-14 RBS Shutdown Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-72

2-15 Generator System Flash Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-73

2-16 Preventive Maintenance and Inspection Schedule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-77

3-1 Platform Assembly - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2 Boom Assembly - Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3-3 Turntable Assembly - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3-4 Chassis Assembly - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

3-5 Hydraulic System - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-15

3-6 Electrical System - Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-17

3120884 – JLG Lift – iii

TABLE OF CONTENTS

This Page Left Blank Intentionally .

iv – JLG Lift – 3120884

SECTION 1. SPECIFICATIONS

SECTION 1 - SPECIFICATIONS

1.1 CAPACITIES

Hydraulic Oil Tank

19 liters (5 gallons)

Generator Fuel Ta nk

15.1 liters (4 gallons)

Drive Axle

Torque Hubs - 0.5 liters (19 oz.)

1.2 COMPONENT DATA

Battery Charger

Input, 110 VAC,60 HZ

Output, 48 VDC (25 Amps)

Batteries (8)

6 Volt, 370 AmpHour (20 hour rate)

Drive System

Drive Motor - 48 VDC, 12.5 H.P. @ 3200 rpm. continuous,

rotation - reversible

Drive Brake- spring-applied, hydraulic all y release d

Tires - IN240/55-17.5 pneumatic or foam filled

Tire Pressure - 6.2 Bar (90 psi)

1.3 PERFORMANCE DATA

Travel Speed

5.2 kph (3.2 mph)

Gradeability

30% (16.7 degrees)

Turning Radius (Inside)

0.61 m (2ft. 0 in.)

Turning Radius (Curb to Curb)

3.15 m (10 ft. 4 in.)

Tail Swing (Any Position)

0

Upper Boom Speed

Lift Up - 27 seconds

Lift Down - 26 seconds

Lower Boom Speed

Lift Up - 30 seconds

Lift Down - 24 seconds.

Swing Speed - 360 Degrees

90 seconds / rev.

Hydraulic Pump/Electric Motor Assembly

Motor - 48 VDC, 2.14 H.P. @ 2700 rpm.

Pump - 1.6 cm[3]/rev. (0.098 in.[3]/rev.)

Pump Output - 11.2 lpm (2.96 gpm) @ 222 Bar (3200 psi)

Machine Weight

E45A - 5,811 kg (12,800 lb.)

M45A - 5,811 kg (12,800 lb.)

E45AJ - 6690 kg (14,750 lb.)

M45AJ - 6690 kg (14,750.)

Max. Tire Load

M45A, E45A - 2,767 kg (6100 lbs.).

M45AJ, E45AJ - 3,130 kg (6900 lbs.)

Updated 2-15-00

3120884 – JLG Lift – 1-1

SECTION 1 - SPECIFICATIONS

Ground Bearing Pressure

M45A, E45A - 6.2 Bar (95 psi)

M45AJ, E45AJ - 7.6 Bar (110 psi)

Machine Height (stowed)

M45A, E45A - 1.99 m (6 ft. 6.25 in.)

M45AJ, E45AJ - 2.0 m (6ft. 7 in.)

Machine Length (stowed)

M45A, E45A - 5.69 m (18 ft. 8.0 in.)

M45AJ, E45AJ - 6.45 m (21 ft. 2 in.)

Up and Over Platform Height

M45A, E45A - 7.49 m (24 ft. 7 in.)

M45AJ, E45AJ - 7.7 m (25 ft. 3in.)

Horizontal Reach @ Maximum Up and Over

M45 A, E45A - 7.0 m (23 ft. 1 in.)

M45AJ, E45AJ - 7.24 m (23 ft. 9 in.)

Machine Width

1.75 m (5 ft. 9 in.)

Wheel Base

2.00 m (6 ft. 7.0 in.)

Working Height

15.54 m (51 ft. 0 in.)

1.4 FUNCTION SPEEDS (M45A/E45A)

Lift Up - 30-24 seconds

Lift Down - 29-23 seconds

Tower Lift Up - 33-27 seconds

Tower Lift Down - 26-22 seconds

Telescope Out - 18-14 seconds

Telescope In - 28-23 seconds

Swing Left 360° - 81-67 seconds*

Swing Right 360° - 81-67 seconds*

Rotate Left 180° - 17-14 seconds

Rotate Right 180° - 18-15 seconds

High Drive - Fwd. & Rev. (60.9 m) - 42-44 seconds**

above Horiz. - Fwd. & Rev. (15.2 m) - 67-71 seconds**

Drive

*Swing Left to Swing Right should be within 10% of each other.

**Drive Forward to Drive Reverse should be within 10% of each

other.

1.5 FUNCTION SPEEDS (M45AJ/E45AJ)

Lift Up - 30-24 seconds

Lift Down - 29-23 seconds

Tower Lift Up - 33-27 seconds

Tower Lift Down - 26-22 seconds

Platform Height

13.72 m (45 ft. 0 in.)

Track Width

1.51 m (5 ft. 0 in.)

Ground Clearance

M45, E45 - 0.22 m (8.5 in.)

M45AJ, E45AJ - 0.20 m (8 in.)

System Voltage

48 volts

Battery Life per Charge

7 hours continuous

Jib Up - 25-26 seconds

Jib Down - 24-25 seconds

Telescope Out - 12-9 seconds

Telescope In - 19-15 seconds

Swing Left 360° - 81-67 seconds*

Swing Right 360° - 81-67 seconds*

Rotate Left 180° - 17-14 seconds

Rotate Right 180° - 18-15 seconds

High Drive - Fwd. & Rev. (60.9 m) - 42-44 seconds**

above Horiz. - Fwd. & Rev. (15.2 m) - 107-112 seconds**

Drive

*Swing Left to Swing Right should be within 10% of each other.

**Drive Forward to Drive Reverse should be within 10% of each

other.

Battery Recharge Time

Charger - 17 hours from full discharg e

Generator - 6.2 hours

Updated 10-7-99

1-2 – JLG Lift – 3120884

SECTION 1 - SPECIFICATIONS

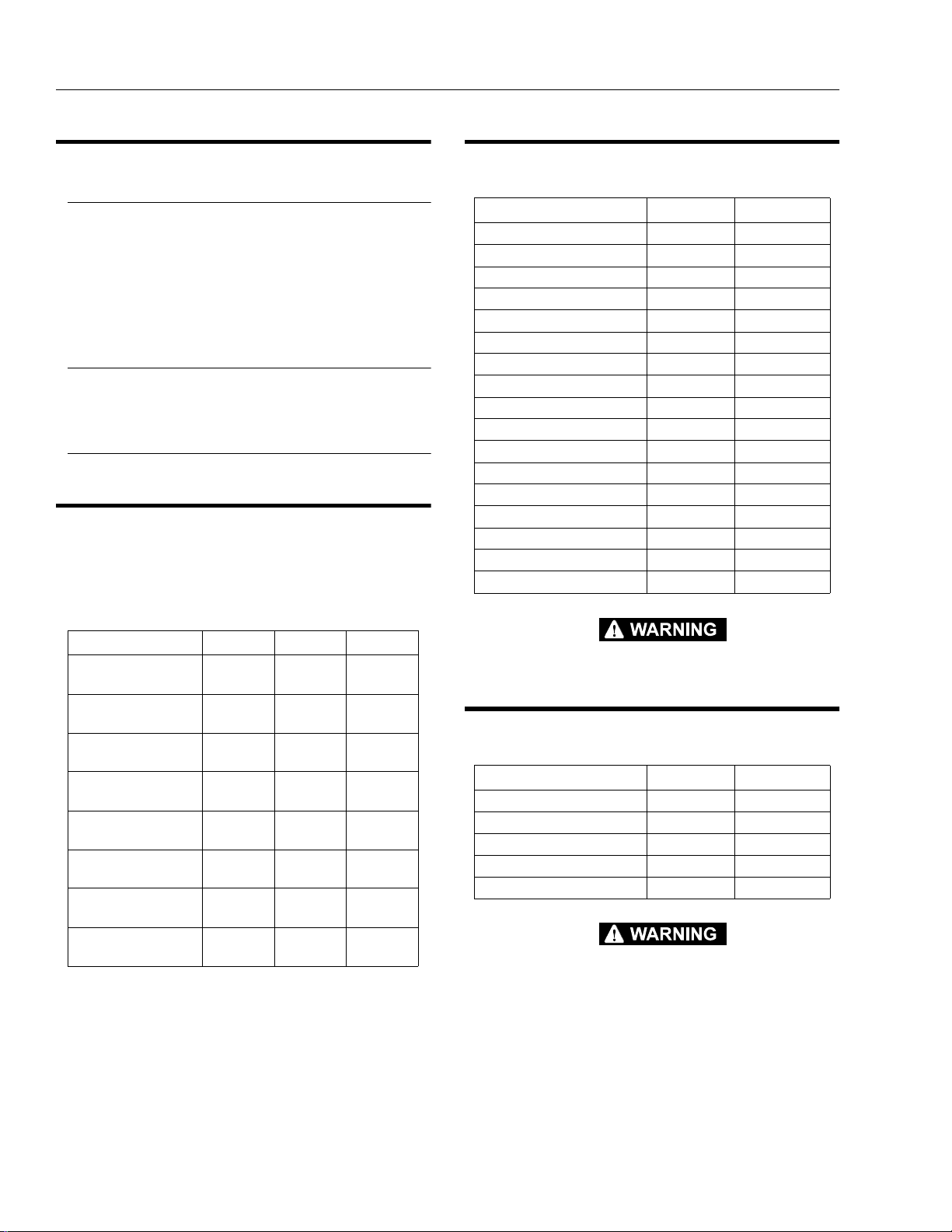

1.6 TORQUE SPECIFICATIONS

Table 1-1.Torque Requirements

Description Torque V alue Interval Hours

Wheel Lugs 170 ft. lbs.

(230 Nm)

Swing Bearing

(Dry)

Swing Bearing

((Loctite)

* Check swing bearing bolts for security after first

50 hours of operation and every 600 hours thereafter.

220 ft. lbs.

(298 Nm)

240 ft. lbs.

(326 Nm)

150

50/600*

50/600*

1.7 LUBRICATION

Hydraulic Oil

Table 1-2.Hydraulic Oil

Hydraulic System

Operating

Temperature Range

+0 to + 180 F

(-18 to +83 C)

+0 to + 210 F

(-18 to +99 C)

+50 to + 210 F

(+10 to +99 C

NOTE: Hydraulic oils must have anti-wear qualities at least

to API Service Classification GL-3, and sufficient

chemical stability for mobile hydraulic system service.

Aside from JLG recommendations, it is not advisable

to mix oils of different brands or types, as they may

not contain the same required additives or be of

comparable viscos ities. If use of hydraulic oil ot her

than Mobil DTE 11M is desired, contact JLG Industries for proper recommendations.

S.A.E. Viscosity

Grade

10W

10W-20, 10W30

20W-20

Lubrication Specifications

Table 1-3.Lubrication Specifications.

KEY SPECIFICATIONS

MPG Multipurpose Grease having a minimum dripping point of

350 degrees F. Excellent water resistance and adhesive

qualities; and being of extreme pressure type (Timken OK

40 pounds minimum).

EPGL Extreme Pressure Gear Lube (oil) meeting API Service

Classification GL-5 or Mil-Spec Mil-L-2105.

HO Hydraulic Oil. Mobil DTE-11M

OG* Open Gear Lube - Tribol Molub-Alloy 936 Open Gear Com-

pound. (JLG Part No. 3020027)

BG* Bearing Grease (JLG Part No. 3020029) Mobilith SHA 460.

LL Synthetic Lithium Lubricant, Gredag 741 Grease. (JLG

Part No. 3020022)

EO Engine (crankca se) Oil. Gas - API SF/SG cl ass, MIL-L-

2104. Diesel - API CC/CD class, MIL-L-2104B/MIL-L2104C.

*MPG may be substituted for these lubricants, if necessary, but service intervals will be reduced.

NOTE: Refer to Lubrication Chart, Figure1-2, for specific

lubrication procedures.

Table 1-4. Mobil DTE 11M Specs

ISO Viscosity Grade #15

Gravity API 31.9

Pour Poi nt, Max -40 F (-40 C)

Flash Point, Min. 330 F (166 C)

Viscosity

at 40° C 15 cSt

at 100° C 4.1 cSt

at 100° F 80 SUS

at 210° F 43 SUS

cp at -30° F 3.200

Viscosity Index 140

3120884 – JLG Lift – 1-3

SECTION 1 - SPECIFICATIONS

Table 1-5.Cylinder Specifications

Cylinder Bore Stroke Rod Dia.

Upper Lift

Cylinder

3.00

(76.2)

28.3125

(719.1)

1.50

(38.1)

Mid Lift Cylinder 3.00

(76.2)

21.25

(539.7)

1.50

(38.1)

Lower Lift Cylinder 4.00

(101.6)

23.25

(590.5)

2.25

(57.1)

T elescope Cylinder 2.00

(50.8)

92

(2337)

1.25

(31.8)

Master Cylinder 2.00

(50.8)

9.375

(238.1)

1.00

(25.4)

Slave Cylinder 2.00

(50.8)

9.375

(238.1)

1.00

(25.4)

Rotator Cylinder 1.875

(47.6)

15.250

(387.3)

1.00

(25.4)

Steer Cylinder

(Double Rod)

2.50

(63.5)

4.06

(103.1)

1.75

(44.5)

1.8 PRESSURE SETTINGS

Main Valve

Upper Lift Down Relief - 38 bar (550 psi)

Mid/Lower Lift Down Relief - 117 bar (1700 psi)

Telescope In Relief - 148 bar (2150 psi)

Platform Level Up Relief - 172 bar (2500 psi)

Platform Level Down Relief - 83 bar (1200 psi)

Steer/Brake Valve

Steer Relief - 159 bar (2300 psi)

Main Relief - 221 bar (3200 psi)

Jib Valve

Jib Relief (Up and Down) - 103 bar (1500 psi)

1.9 CYLINDER SPECIFICATIONS

NOTE: All dimensions are given in inches (in.), with the met-

ric equivalent, millimeters (mm), given in parentheses.

1.10 MAJOR COMPONENT WEIGHTS

Table 1-6.Major Component Weights

Component LB. KG.

Platform and Support 215 97.5

Upper Boom Complete 810 367

Mid Boom Complete 550 249

Lower Boom Complete 550 249

Upper Lift Cylinder 89 40

Mid Lift Cylinder 95 43

Lower Lift Cylinder 110 50

T elescope Cy linder 85 38 .5

Upper Upright 225 102

Lower Uprig ht 97 44

Turntable 948 430

Battery Box (incl. batteries) 600 272

Chassis (w/ pneu. tires) 4,295 1948

Chassis (w/ foam-filled tires) 4,695 2130

Counterweight 3850 1746

Machine Complete (E45A) 14,000 6356

Machine Complete (M45A) 14,300 6492

SELECT LIFTING EQUIPMENT WITH CAPACITY CAPABLE OF

SAFELY SUPPORTING WEIGHT.

1.11 CRITICAL STABILITY WEIGHTS

Table 1-7.Critical Stability Weights

Component LB. KG.

Counterweight 3850 1746

Tire & Wheel (foam-filled) 207 94

Platform (4ft [1.2 m]) 90 41

1-4 – JLG Lift – 3120884

Platform (5 ft. [1.5 m]) 100 45

Battery (each) 120 54

DO NOT REPLACE ITEMS CRITICAL TO STABILITY WITH ITEMS

OF DIFFERENT WEIGHT OR SPECIFICATION (FOR EXAMPLE:

BATTERIES, FILLED TIRES, PLATFORM) DO NOT MODIFY UNIT

IN ANY WAY TO AFFECT STABILITY.

SECTION 1 - SPECIFICATIONS

1.12 SERIAL NUMBER LOCATIONS

For machine identification, a serial number plate is affixed

to the left rear of frame, in front of left rear wheel. If the

serial number plate is damaged or missi ng, the machine

serial number is stamped on the top left side of the frame

and the top left side of the turntable. In addition, the serial

number is stamped on top of the end of the upper boom,

mid boom, and lower boom at the left rear of the booms.

Figure 1-1. Serial Number Locations

3120884 – JLG Lift – 1-5

SECTION 1 - SPECIFICATIONS

Figure 1-2. Lubrication Diagram

1-6 – JLG Lift – 3120884

Table 1-8. Lubrication Chart

SECTION 1 - SPECIFICATIONS

Interval Hours

3 Months

150 hrs

6 Months

300 hrs

1 Year

600 hrs

2 Years

1200 hrs

Comments

Components

Number/Type

Lube Points

Capacity Lube

Lubrication

Swing Bearing

1

Swing Bearing /

2

Worm Gear Teeth*

Hydraulic Fluid (Oil)

3

Hydraulic Filter

4

Wheel Drive Hub

5

Wheel Bearing

6

Spindles/Bushing

7

Boom Pivot Pins/

8

Bushing

Engine

9

NOTES: KEY TO LUBRIC ANTS

Lubrication intervals are base d on machine operation under nor mal conditions. For machines used in multi shift operations and/or ex posed to hostile

environments or conditions, l ubrication frequencies must be increased accordingly .

* If necessary install grease fitt ings into worm gear housing and grease bea rings.

1 Grease Fittin g or by

brush

Spray On A/R Mobiltac

Fill Cap 15 liters (tank) HO X Check o il every 10 hou rs of operation.

N/A N/A N/A X Replace filter element after first 50 hours and

Fill Plug/Hal f Full 0.5 liter (1/2 Full) EPGL X Check o il level at side plug on hub dail y.

Repack A/R MPG X

N/A A/R LL At Spindle/Bushing Repl acement Coat I.D. of bushings pri or to installin g king

N/A A/R LL At boom pivot pin s/bushing re placement Coat I.D. of bushi ngs prior to in stalling pins.

Fill Cap R efer to Engi ne

A/R MPG X More freq uent lubricati on intervals may b e

X More freq uent lubricati on intervals may be

375NC

EO Check daily . Change in acco rdance with

Manual

EPGL

required

required.

Change oil every 1 200 hours of opera tion.

every 300 hours t hereafter .**

Change after fir st 150 hours then e very 1200

hours of operatio n.

pins.

engine manual.

EO

Engine Oil

Extreme Pressure Ge ar Lube

HO

Hydraulic Fluid (Mobil DTE-11M)

MPG

Multi-Purpose Gre ase

Synthetic Lithiu m Lubricant

LL

DO NOT OVERGREASE BEARINGS. OVERGREASING BEARINGS WILL RESULT IN

BLOWING OUTER SEAL IN HOUSING.

** Under certain conditions, it may be necessary to replace the h ydraulic filter on a more frequent basis. A common symptom of a dirty filter is sluggishness experienced in hydraulic func tions.

3120884 – JLG Lift – 1-7

SECTION 1 - SPECIFICATIONS

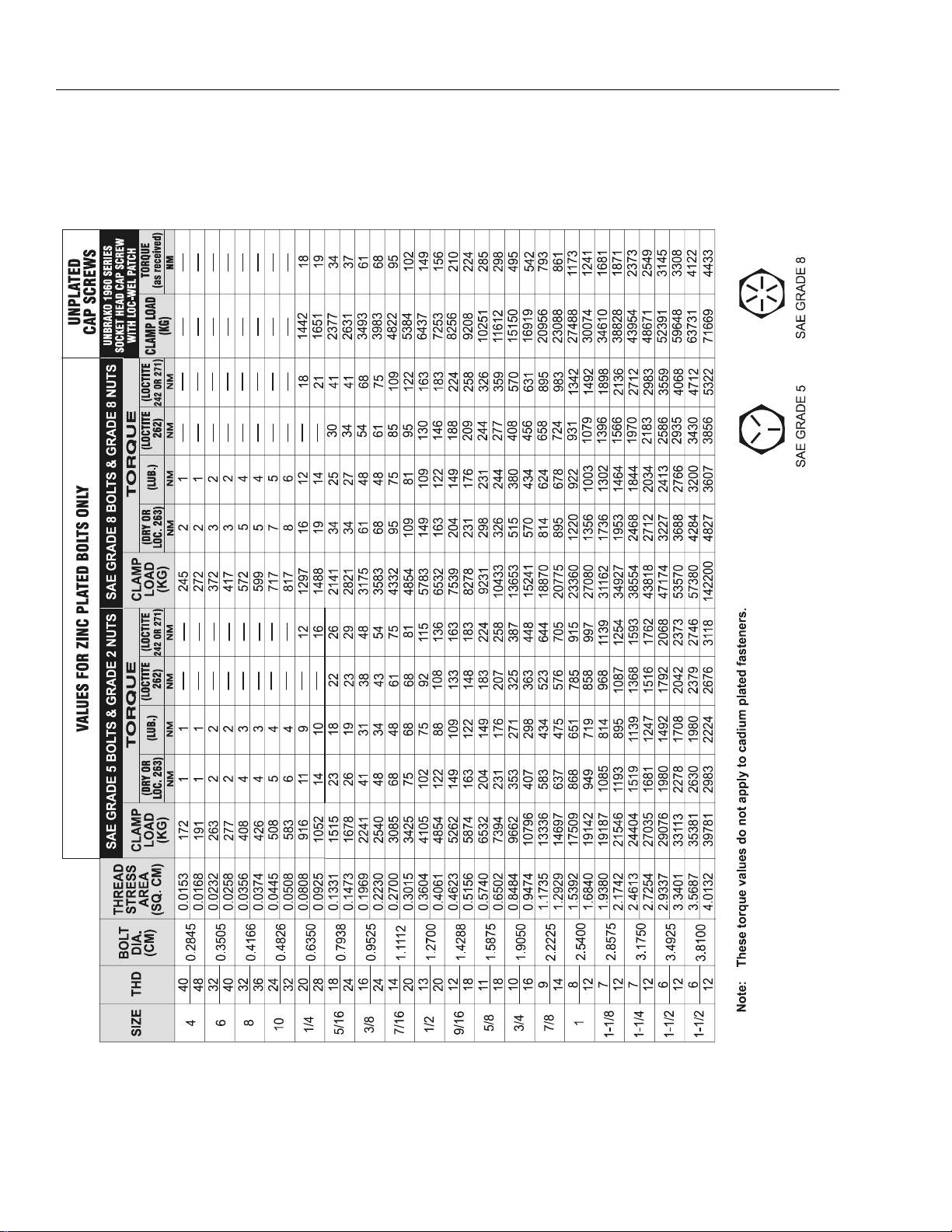

Figure 1-3. Torque Chart

1-8 – JLG Lift – 3120884

SECTION 2. PROCEDURES

SECTION 2 - PROCEDURES

2.1 GENERAL

This section provides information necessary to per form

maintenance on the aerial platform. Descriptions, techniques and specific procedures are designed to provide

the safest and most efficient maintenance for use by personnel responsible for ensuring the correct installation

and operation of machine components and systems.

WHEN AN ABNORMAL CONDITION IS NOTED AND PROCEDURES

CONTAINED HEREIN DO NOT SPECIFICALLY RELATE TO THE

NOTED IRREGULARITY, WORK SHOULD BE STOPPED AND

TECHNICALLY QUALIFIED GUIDANCE OBTAINED BEFORE WORK

IS RESUMED.

The maintenance procedures included consist of servicing and component rem oval and installation, disassembly,

and assembly, inspection, lubrication and cleaning. Information on any special tools or test equipment is also provided where applicable.

2.2 SERVICING AND MAINTENANCE

GUIDELINES

General

The following inf ormation is prov ided to a ssist you in t he

use and application of servicing and maintenance procedures contained in this chapter.

Safety and Workmanship

Your safety and that of others is the first consideration

when engaging in the maintenance of equipment. Always

be conscious of weight. Never atte mpt to move heavy

parts without the aid of a mechanical device. Do not allow

heavy objects to rest in an unstable position. When raising

a portion of the equipment, ensure that adequate support

is provided.

and fittings themselves. As soon as a line or component is disconnected, cap or cover all openings to

prevent entry of foreign matter.

3. Clean and inspect all parts during servicing or maintenance, and assure that all passages and openings

are unobstructed. Cover all parts to keep them

clean. Be sure all parts are clean before they are

installed. New parts should remain in their containers until they are ready to be used.

Component Removal and Installation

1. Use adjustable lifting devices, whenever possible, if

mechanical assistance is required. All slings (chains,

cables, etc.) should be parallel to each other and as

near perpend icular as possibl e to top of par t being

lifted.

2. Should it be necessary to remove a c omponent on

an angle, keep in mind that the capacity of an eyebolt or similar bracket lessens, as th e an gle between

the supporting structure and the component

becomes less than 90 degrees.

3. If a part resists removal, check to see whether all

nuts, bolts, cables, brackets, wiring, etc. have been

removed and that no adjacent parts are interfering.

Component Disassembly and Reassembly

When disassembling or r e assembling a compon ent, complete the procedural steps in sequence. Do not part ially

disassemble or assemble one part, then start on another.

Always recheck your work to assure that nothing has been

overlooked. Do not make any adjustments, ot her than

those recommended, without obtaining proper approval.

Pressure Fit Parts

When assembling pressure fit parts, use an “anti-seize” or

molybdenum disulfid e base co mpound to l ubricate the

mating surface.

Cleanliness

1. The most important single item in preserving the

long service life of a machine is to keep dirt and foreign materials out of the vital components. Precautions have been taken to safeguard against this.

Shields, covers, seals and filters are provided to

keep oil supplies clean; however, these items must

be maintained on a s chedu led ba sis i n o rder to func tion properly.

2. At any time when hydraulic oil lines are disconnected, clear adjacent areas as well as the openings

3120884 – JLG Lift – 2-1

SECTION 2 - PROCEDURES

Bearings

1. When a bearing is removed, cover it to keep out dirt

and abrasives. Clean bearings in nonflammable

cleaning solvent and allow to drip dry. Compressed

air can be used but do not spin the bea ring.

2. Discard bearings if the races and balls (or rollers)

are pitted, scored or burned.

3. If bearing is found to be serviceable, apply a light

coat of oil and wrap it in clean (waxed) paper. Do not

unwrap reusable or new bearings until they are

ready to be installed.

4. Lubricate new or used serviceable bearings before

installation. When pressing a bearing into a retainer

or bore, apply pressure to the outer race. If the bearing is to be in sta lled on a sh aft, apply pres su re to the

inner race.

Gaskets

Check that holes in gaskets align with openings in the

mating parts. If it becomes necessary to hand fabricate a

gasket, use gasket material or stock of equivalent material

and thickness. Be sure to cut holes in the right location as

blank gaskets can cause serious system damage.

Bolt Usage and Torque Application

1. Use bolts of proper length. A bolt which is too long

will bottom before the head is tight against its related

part. If a bolt is too short, there will not be enough

thread area to engage and hold the part properly.

When replacing bolts, use only those having the

same specifications of the original, or one which is

equivalent.

Hydraulic Lines and Electrical Wiring

Clearly mark or tag hydraulic lines and electrical wiring, as

well as their receptacles, when discon nec ting or removing

them from the unit. This will assure that they are correctly

reinstalled.

Hydraulic System

1. Keep the system clean. If evidence of metal or rubber particles are found i n the hydraulic system, drain

and flush the entire system.

2. Disassemble and reassemble parts on clean work

surface. Clean all metal parts with non-flammable

cleaning solvent. Lubricate components, as

required, to aid assembly.

Lubrication

Service applicable components with the amount, type,

and grade of lubricant recommended in this man ual, at

the specified interval. When recommended lubricants are

not available, consult your local supplier for an equivalent

that meets or exceeds the specifications listed.

Batteries

Clean batteries using a non-metallic brush and a solution

of baking soda and water. Rinse with clean water. After

cleaning, thoroughly dry batteries and coat terminals with

an anti-corrosion compound.

Lubrication and Servicing

Components and assemblies requiring lubrication and

servicing are shown in Lubricati on Chart.

2. Unless specific torque requirements are given within

the text, standard torque values should be used on

heat treated bolts, studs and steel nuts, in accordance with recommended shop practices.

2-2 – JLG Lift – 3120884

SECTION 2 - PROCEDURES

2.3 LUBRICATION INFORMATION

Hydraulic System

1. The primary enemy of a hydraulic system is contamination. Contaminants enter the system by various

means, e.g.; inadequate hydr aulic oil, allowi ng moisture, grease, filings, sealing componen ts, sand, etc.

to enter when performing maintenance, or by permitting the pump to cavitate due to insufficient system warm-up.

2. The design and manufacturing tolerances of the

component working parts are very close, therefore,

even the smallest amount of dirt or foreign matter

entering a system can cause wear or damage to the

components and generally results in faulty operation. Every precaution must be taken to keep

hydraulic oil clean, including reserve oil in storage.

Hydraulic system filters should be checked,

cleaned, and/or replaced at the specified intervals

required in Section 1. Always examine filters for evidence of metal particles.

3. Cloudy oils indicate a high moisture content which

permits organic gr ow t h, res ulting in oxidation or corrosion. If this conditi on occurs, the system mu st be

drained, flushed, and refilled with clean oil.

4. It is not advisable to mix oils of different brands or

types, as they may not contain the same required

additives or be of comparable viscosities. Good

grade mineral oils, with viscosities suited to the

ambient temperatures in which the machine is operating, are recommended for use.

NOTE: Metal particles may appear in the oil or filters of new

machines due to the wear-in of meshing components.

Hydraulic Oil

1. Refer to Section 1 for recommendations for viscosity

ranges.

2. JLG recommends Mobil DTE-11 Hydra ulic O il, wh ich

has an SAE viscosity of 10W and a viscosity index of

140.

NOTE: Start-up of hydraulic system with oil temperatures

below -29 degrees C. is not recommended. If it is

necessar y to sta r t the sy ste m in a sub- zero envi ron ment, it will be necessary to heat the oil with a low

density 100VAC heater to a minimum temperature of

-29 degrees C.

sesses the same antiwear and rust protection ch aracteristics as mineral oils, but will not adversely

affect ground water or the environment when spilled

or leaked in small amounts. Mobil EAL224H has a

viscosity of 34 cST at 40° C and a viscosity index of

213. The operating range of this oil is -18° C to +83°

C.

IT IS RECOMMENDED THAT MOBIL EAL224H HYDRAULIC OIL BE

STORED ABOVE FREEZING (0 C) AS THE OIL MAY APPEAR

CLOUDY AFTER EXPOSURE TO LOW TEMPERATURES FOR

EXTENDED PERIODS OF TIME. THE CLOUDINESS WILL DISAPPEAR

WHEN THE OIL IS WARME D TO AT L EAST 1 0 C AND AG ITATED. DO

NOT ATTEMPT TO "THIN" THE OIL WITH NO.2 DIESEL FUEL. FOR

BEST RESULTS, STORE THE OIL ABOVE FREEZING.

NOTE: Accidentally mixing Mobil EAL224 H hydraulic oil wi th

other mineral oils will cause no loss of performance

characteristics. However, biodegradability may be

reduced and toxicity may be increased, depending

on the oil and level of contamination.

Changing Hydraulic Oil

1. Use of any of the recommended hydraulic oils eliminates the need for changing the oil on a regular

basis. However, filter elements must be changed

after the first 50 hours of operation and every 300

hours thereafter. If it is necessary to change the oil,

use only those oils meeting or ex ceeding the specifications appearing in this manual. If unable to obtain

the same type of oil supplied with the machine, consult local supplier for assistance in selecting the

proper equivalent. Avoid mixing petroleum and synthetic base oils. JLG Industries recommends ch an ging the hydraulic oil every two years.

2. Use every precaution to keep the hydraulic oil clean.

If the oil must be poured from the original container

into another, be sure to clean all possible contaminants from the service container. Always clean the

mesh element of the filter and replace the cartridge

any time the system oil is changed.

3. While the unit is shut dow n, a good preventive maintenance measure is to make a thorough inspection

of all hydraulic components, lines, fittings, etc., as

well as a functional check of each system, before

placing the machine back in service.

3. Some machines may be specially equipped with

Mobil EAL224H biodegradable and non-toxic

hydraulic oil. This oil is vegetable oil based and pos-

3120884 – JLG Lift – 2-3

SECTION 2 - PROCEDURES

Lubrication Specifications

Specified lubricants, as recommended by the component

manufacturers, are always th e best choice, however,

multi-purpose greases usually have the qualities which

meet a variety of single purpose requirements. Should

any question arise regarding the use of greases in maintenance stock, consul t your local supp lier for eval uation.

Refer to Section 1 for an expl anation of the lub ricant ke y

designations appearing in the Lubrication Chart.

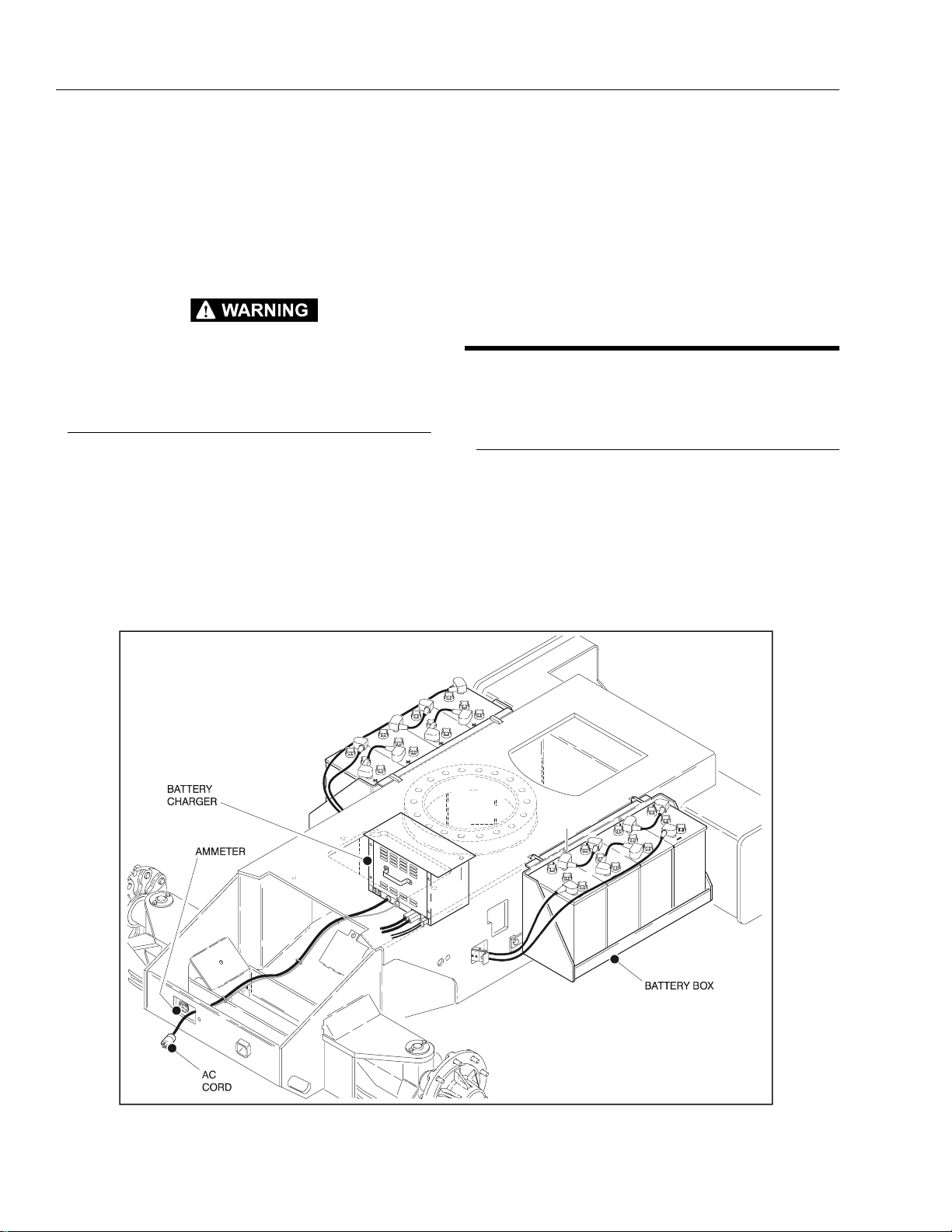

2.4 BATTERY MAINTENANCE AND

CHARGING

Battery Maintenance, Qu arterly

1. Open battery compartment cover to allow access to

battery terminals and vent caps.

WHEN ADDING WATER TO BATTERIES, ADD WATER UNTIL ELECTROLYTE COVERS PLATES. DO NOT CHARGE BATTERIES

UNLESS ELECTROLYTE COVERS THE PLATES.

NOTE: When adding distilled water to batteries , no n-metalli c

containers and/or funnels must be used.

To avoid electrolyte overflow, add distilled water to

batteries after charging.

When adding water to the battery, fill only to level

indicated or 9.5 mm above separators.

3. Remove battery cables from each battery post one

at a time, negative first. Clean cables with acid neutralizing solution (e.g. baking soda and water or

ammonia) and wire brush. Replace cables and/or

cable clamp bolts as re quired.

4. Clean battery post with wire brush then re-connect

cable to post. Coat non-contact surfaces with mineral grease or petroleum jelly.

5. When all cables and terminal posts have been

cleaned, ensure all cables are properly positioned

and do not get pinched. Close battery compartment

cover.

6. Start hydraulic system and ensure that it functions

properly.

Optional On Board Generator

EXHAUST GAS HAZARD. RUN THE GENERATOR IN A WELL VENTILATED AREA ONLY.

WHEN THE GENERATOR EN ABLE CONTROL LOCATED IN T HE

PLATFORM CONTROL BOX IS IN THE ON POSITION AND THE

GROUND EMERGENCY STOP SWITCH IS ON (PULLED OUT), THE

GENERATOR WILL START AUTOMATICALLY WHEN THE BATTERIES REACH A LOW-CHARGE STATE, AUTOMATICALLY

CHARGING THE BATTERIES. THE GENERATOR WILL A LSO

AUTOMATICALLY STAR T IF THE G ENERATOR ST ART BATTERY

IS LOW.

2. Remove all vent caps and inspect electrolyte level of

each cell. Electrolyte level should be to the ring

approximately one inch from top of battery. Fill batteries with distilled water only. Replace and secure

all vent caps.

2-4 – JLG Lift – 3120884

SECTION 2 - PROCEDURES

Figure 2-1. On Board Generator

3120884 – JLG Lift – 2-5

SECTION 2 - PROCEDURES

NOTE: The engine will automatically shut down under the

following conditions:

High Engine Oil Temperature

Low Engine Oil Pressure

Engine Overspeed

Generator Overvoltage

Batteries fully charged

TO AVOID INJURY FROM AN EXPLOSION, DO NOT SMOKE OR

ALLOW SPARKS OR A FLAME NEAR BATTERY DURING SERVICING. ALWAYS WEAR EYE AND HAND PROTECTION WHEN SERVICING BATTERIES.

Battery Charging (On Board Charger)

1. For maximum battery life:

a. Avoid completely discharging the batteries.

b. Fully charge the batteries each day the machine

is used.

c. Charge the batteries at available times between

charging.

d. Be sure the battery fluid covers the battery

plates before charging, but to avoid overflow, do

not top off the fluid level until charging.

2. To charge the batteries, connect the charger to a

115 volt source with a 15 amp minimum capacity.

3. The Charger will shut off automatically when the batteries are fully charged.

4. The charge cycle is complete when the ammeter

reads 0 amps. Any reading indicates the charge

cycle is not complete.

5. Depleted batteries will take approximately 17 hours

to charge.

2.5 CYLINDERS - THEORY OF OPERATION

Upper Boom Lift, Mid Boom Lift, Lower

Boom Lift, T e lescope, Slave, Master , Rotator,

and Steer

A double acting cylinder is one that requires oil flow to

operate the cylinder rod in both directions. Directing oil

(by actuating the corresponding control valve to the piston side of the cylinder) forces the piston to travel toward

the rod end of the barrel, extending the cylinder rod (piston attached to rod). When the oil flow is stopped, movement of the rod will stop. By directing oil to the rod side of

the cylinder, the piston will be forced in the opposite direction and the cylinder rod will retract.

Figure 2-2. Batteries and Battery Charger

2-6 – JLG Lift – 3120884

Holding valves are used in the Lift circuits to prevent

retraction of the cylin der rod should a hydr aulic line rupture or leak develop between t he cylin der and it s relat ed

control valve.

2.6 CYLINDER CHECKING PROCEDURES

NOTE: Cylinder checks must be performed any time a cylin-

der component is repl ac ed o r wh en im pro pe r syste m

operation is suspected.

Cylinder Without Counterbalance Valves

(Steer, Master, and Rotate)

1. Using all applicable safety precautions, activate

hydraulic system and fully extend cylinder to be

checked. Shut down hydraulic system.

2. Carefully disconnect hydraulic ho se from retra ct port

of cylinder. There will be initial weeping of hydraulic

fluid which can be caught in a suitable container.

After initial discharge, there should be no further

leakage from the retract port.

3. Activate hydraulic system, and activate cylinder

extend function.

4. If cylinder retract port leakage is less than 6-8 drops

per minute, carefully reconnect hose to retract port

and retract cylinder. If leakage continues at a rate of

6-8 drops per minute or more, cylinder repairs must

be made.

5. With cylinder fully retracted, shut down motor and

carefully disconnect hydraulic hose from cylinder

extend port.

6. Activate hydraulic system and activate cylinder

retract function. Check extend port for leakage.

7. If extend port leakage is less than 6-8 drops per

minute, carefully reconnect hose to extend port,

then activate cylinder through one complete cycle

and check for leaks. If leakage continues at a rate of

6-8 drops per minute or more, cylinder repairs must

be made.

Cylinders With Single Counterbalanc e Valve

(Upper Lift Cylinder)

SECTION 2 - PROCEDURES

WHEN WORKING ON THE UPPER BOOM LIFT CYLINDER RAISE

THE UPPER BOOM TO HORIZONTAL AND PLACE A BOOM PROP

APPROXIMATELY 2.5 CM BELOW THE MAIN BOOM. IF WORKING

ON LOWER BOOM LIFT CYLINDER, RAISE LOWER BOOM HALFWAY, FULLY ELEVATE UPPER BOOM AND ATTACH OVERHEAD

CRANE TO THE UPRIGHT FOR SUPPORT, LEAVING APPROXIMATELY 2.5 CM OF SLACK IN CHAIN O R SLING FOR TEST PURPOSES.

2. After completing the above, shut down hydraulic

system and allow machine to si t for 10-15 minutes.

This is done to relieve pressure in the hydraulic

lines. Carefully remove hydraulic hoses from appropriate cylinder port block.

3. There will be initial weeping of hydraulic fluid, which

can be caught in a suitable container. After the initial

discharge, there should not be any further leakage

from the ports. If leakage continues at a rate of 6-8

drops per minute or more, the following cylinder

repairs must be made. If the retract port is leaking,

the piston is leaking, the piston seals are defective

and must be replaced. If the extend port is leaking,

the counterbalance is defective and must be

replaced.

4. If no repairs are necessary or when repairs have

been made, carefully reconnect hydraulic hoses to

the appropriate ports.

5. Remove boom prop/overhead crane, activate

hydraulic sy s t e m and run cyl inder throug h complete

cycle to check for leaks and operation.

Cylinders With Dual Counterb alance Valve

(Lower Lift, Mid Lift, Telescope, and Sla ve

Cylinders)

OPERATE ALL FUNCTIONS FROM GROUND CONTROL STATION

ONLY.

1. Using all applicable safety precautions, activate

hydraulic system.

WHEN WORKING ON THE UPPER BOOM LIFT CYLINDER RAISE

THE UPPER BOOM TO HORIZONTAL AND PLACE A BOOM PROP

OPERATE ALL FUNCTIONS FROM GROUND CONTROL STATION

ONLY.

1. Using all applicable safety precautions, activate

hydraulic system.

APPROXIMATELY 2.5 CM BELOW THE MAIN BOOM. IF WORKING

ON LOWER BOOM LIFT CYLINDER, RAISE LOWER BOOM HALFWAY, FULLY ELEVATE UPPER BOOM AND ATTACH OVERHEAD

CRANE TO THE UPRIGHT FOR SUPPORT, LEAVING APPROXIMATELY 2.5 CM OF SLACK IN CHAIN O R SLING FOR TEST PURPOSES.

3120884 – JLG Lift – 2-7

SECTION 2 - PROCEDURES

2. When working on the platform slave cylinder, stroke

platform slave level cylinder forward until platform

sits at a 45 degree angle.

3. After completing the above, shut down hydraulic

system and allow machine to sit f or 10-15 minutes.

This is done to relieve pressure in the hydraulic

lines. Carefully remove hydraulic hoses from appropriate cylinder port block.

4. There will be initial weeping of hydraulic fluid, which

can be caught in a suitable container. After the initial

discharge, there should not be any further leakage

from the ports. If leakage continues at a rate of 6-8

drops per minute or more, the following cylinder

repairs must be made. If the retract port is leaking,

the piston is leaking, the piston seals are defective

and must be replaced. If the extend port is leaking,

the counterbalance is defective and must be

replaced.

5. To check piston seals, carefully remove the counterbalance valve from the retract port. After initial discharge there should not be any further leakage from

the ports. If leakage occurs at a rate of 6-8 drops per

minute or more, the piston seals are defective and

must be replaced.

6. If no repairs are necessary or when repairs have

been made, carefully reconnect hydraulic hoses to

the appropriate ports.

7. Remove boom prop/overhead crane, activate

hydraulic system and run cylinder through complete

cycle to check for leaks and operation.

source. Adequa te ly s upport the cylinder rod, if applicable.

3. If applicable, remove the cartridge-type holding

valve and fittings from the cylinder port block. Discard o-rings.

4. Place the cylinder barrel into a suitable holding fixture.

Figure 2-3. Cylinder Barrel Support

5. Mark cylinder head and barrel with a center punch

for easy realignment. Using an allen wrench, loosen

the cylinder head retainer cap screws, and remove

cap screws from cylinder barrel.

2.7 CYLINDER REPAIR

NOTE: The following are general procedures that apply to

all of the c ylinde rs on th is mac hine. Pr ocedur es that

apply to a specific cylinder will be so noted.

Disassembly

DISASSEMBLY OF THE CYLINDER SHOULD BE PERFORMED ON

A CLEAN WORK SURFACE IN A DIRT FREE WORK AREA.

1. Connect a suitable auxiliary hydraulic power source

to the cylinder port block fitting.

DO NOT FULLY EXTEND CYLINDER TO THE END OF STROKE.

RETRACT CYLINDER SLIGHTLY TO AVOID TRAPPING PRESSURE.

2. Operate the hydraulic power source and extend the

cylinder. Shut down and disconnect the power

NOTE: St eps 6 applies only t o the lower lift and tele scope

6. Using a spanner wrench, loosen the end cap or

7. Attach a suitable pulling device to the cylinder rod

2-8 – JLG Lift – 3120884

Figure 2-4. Capscrew Removal

cylinders.

head retainer, and remove from cylinder barrel.

port block end or cylinder rod end, as applicable.

EXTREME CARE SHOULD BE TAKEN WHEN REMOVING THE CYLINDER ROD, HEAD, AND PISTON. AVOID PULLING THE ROD OFFCENTER, WHICH COULD CAUSE DAMAGE TO THE PISTON AND

CYLINDER BARREL SURFACES.

8. With the barrel clamped securely, apply pressure to

the rod pulling device and carefully withdraw the

complete rod assembly from the cylinder barrel.

SECTION 2 - PROCEDURES

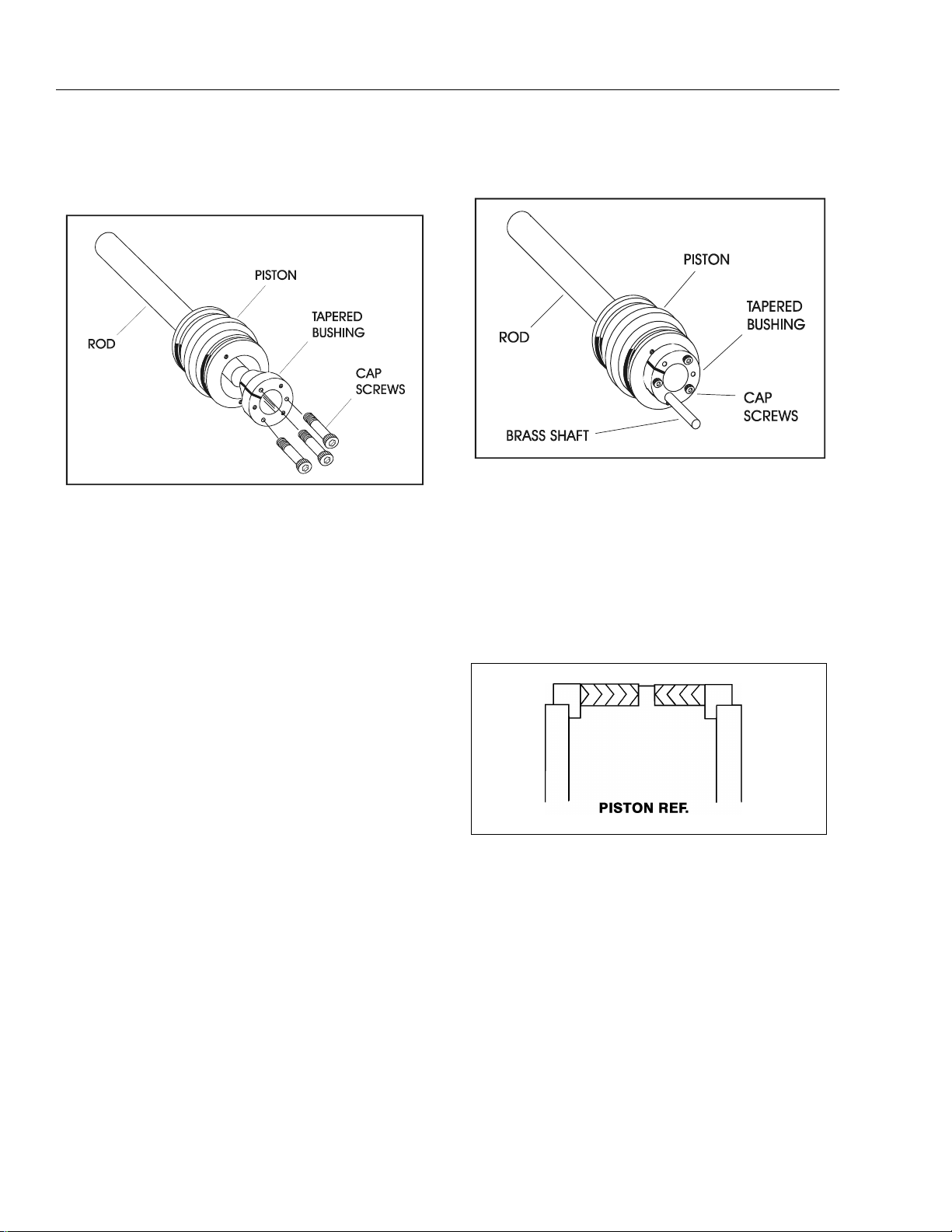

12. Remove the bushing from the piston.

Figure 2-6. Tapered Bushing Removal

13. Screw the piston CCW, by hand, and remove the

piston from cylinder rod.

14. Remove and discard the piston o-rings, seal rings,

and backup rings.

Figure 2-5. Cylinder Rod S upport

9. Using suitable protection, clamp the cylinder rod in

a vise or similar holding fixture as close to the piston

as possible.

10. Loosen and remove the cap screw(s), i f applicable,

which attach the tapered bushing to the piston.

11. Insert the cap screw(s) in the threaded holes in the

outer piece of the tapered bushing. Progressively

tighten the cap screw(s) until the bushing is loose

on the piston.

15. Remove piston spa cer, if applicable, from the rod.

16. Remove the rod from the holding fixture. Remove

the cylinder head gland an d retainer plate, if app licable. Discard the o-rings, back-up rings, rod seals,

and wiper seals.

Cleaning and Inspection

1. Clean all parts thoroughly in an approved cleaning

solvent.

2. Inspect the cylinder rod for scoring, tapering, ovality,

or other damage. If necessary, dress rod with

Scotch Brite or equivalent. Replace rod if necessary.

3. Inspect threaded portion of rod for excessive damage. Dress threads as necessary.

4. Inspect inner surface of cylinder barrel tube for scoring or other damage. Check inside diameter for

tapering or ovality. Replace if necessary .

5. Inspect threaded portion of b arrel fo r dam age. Dress

threads as necessary.

6. Inspect pist on surface f or damage and s coring and

for distortion. Dress piston surface or replace piston

as necessary.

7. Inspect threaded portion of piston for damage.

Dress threads as necessary.

8. Inspect seal and o-ring grooves in piston for burrs

and sharp edges. Dress applicable surfaces as necessary.

3120884 – JLG Lift – 2-9

SECTION 2 - PROCEDURES

Figure 2-7. Gar-Max Bearing Installation

9. Inspect cylinder head inside diameter for scoring or

other damage and for ovality and tapering. Replace

as necessary.

10. Inspect threaded portion of head for damage. Dress

threads as necessary.

11. Inspect seal and o-ring grooves in head for burrs

and sharp edges. Dress applicable surfaces as necessary.

12. Inspect cylinder head outside diameter for scoring

or other damage and ovality and tapering. Replace

as necessary.

13. If applicable, inspect rod and barrel bearings for

signs of correct excessive wear or damage. Replace

as necessary.

a. Thoroughly clean hole, (steel bushing) of burrs,

dirt etc. to facilitate bearing installation.

b. Inspect steel bushing for wear or other damage.

If steel bushing is worn o r damaged, rod/bar rel

must be replaced.

c. Lubricate inside of the steel bushing with WD40

prior to bearing installation.

d. Using an arbor of the correct size, carefully

press the bearing into steel bushing.

Assembly

NOTE: Prior to cylinder assembly, ensure that the proper

cylinder seal kit is us ed . Se e your JLG Parts Manua l.

Apply a light film of hydraulic oil to all components

prior to assembly.

1. A speci al tool is use d to install a new rod seal into

the applicable cylinder head gland groove.

NOTE: Install pin into the Gar-Max bearing dry. Lubrication

is not required with nickel plated pins and bearings.

14. Inspect travel limiting collar or spacer for burrs and

sharp edges. If necessary, dress inside diameter

surface with Scotch Brite or equivalent.

15. If applic able, inspect port block fitt ings and holdi ng

valve. Replace as necessary.

16. Inspect the oil ports for blockage or the presence of

dirt or other foreign material. Repair as necessary.

17. If applicable, inspect piston rings for cracks or other

damage. Replace as nece s sa ry.

Figure 2-8. Rod Seal Installation

WHEN INSTALLING "POLY-PAK" PISTON SEALS, ENSURE SEALS

ARE INSTALLED PROPERLY. REFER TO WIPER SEAL INSTALLATION FOR CORRECT SEAL ORIENTATION. IMPROPER SEAL

INSTALLATION COULD RESULT IN CYLINDER LEAKAGE AND

IMPROPER CYLINDER OPERATION.

2. Use a soft mallet to tap a new wiper seal into the

applicable cylinder head gland groove. Install a new

wear ring into the applicable cylinder head gland

groove.

Figure 2-9. Wiper Seal Installation

2-10 – JLG Lift – 3120884

SECTION 2 - PROCEDURES

3. Place a new o-ring and back-up seal in the applicable outside diameter groove of the cylinder head.

Figure 2-10. Installation of Head Seal Kit

4. Install washer ring onto rod, careful ly instal l the head

gland on the rod, ensuring that the wiper and rod

seals are not damaged or dislodged. Push the head

along the rod to the rod end, as applicable.

5. Carefully slide the piston spacer on the rod.

6. If applicable, correctly place new o-ring in the inner

piston diameter gr oove. (The backup ring side facing the O-ring is grooved.)

7. If applicable, correctly place new seals and guide

lock rings in the outer piston diameter groove. (A

tube, with I.D. slightly larger than the O.D.of the piston is recommended to install the solid seal.)

NOTE: The backup rings for the solid seal have a radius on

one side. This side faces the solid seal.(See magnified insert in Figure 2-11.)The split of seals and

backup rings are to be positioned so as not to be in

alignment with each other.

Figure 2-11. Piston Seal Kit Installation

8. Using suitable protection, clamp the cylinder rod in

a vise or similar holding fixture as close to piston as

possible.

9. Carefully thread the piston on the cylinder rod hand

tight, ensuring that the o-ring and back-up rings are

not damaged or dislodged.

10. Thread piston onto rod until it abuts the spacer end

and install the tapered bushing.

NOTE: When installing the tapered bushing, piston and ma t-

ing end of rod must be free of oil.

WHEN REBUILDING THE STEER, LOWER LIFT, LEVEL CYLINDER,

OR UPPER LIFT CYLINDER, APPLY LOCTITE #242 TO TAPERED

BUSHING BOLTS, THEN TIGHTEN SECURELY.

3120884 – JLG Lift – 2-11

SECTION 2 - PROCEDURES

Figure 2-12. Tapered Bushing Installation

11. Assemble the tapered bushing loosely into the piston and insert JLG capscrews (not vendor capscrews) through the drilled holes in the bushing and

into the tapped holes in the piston.

12. Tighten the capscrews evenly and progressively in

rotation to the specified torque value. (See T able 2-1,

Cylinder Head and Tapered Bushing Torque Specifications.)

13. After the screws have been torqued, tap the tapered

bushing with a hammer (500 to 750 gram) and brass

shaft (approximately 19 mm in diameter) as follows;

b. Tap each space once; this means the tapered

bushing is tapped 3 times as there are 3 spaces

between the capscrews.

Figure 2-13. Seating the Tapered Bearing

14. Retorque the capscrews evenly and progressively in

rotation to the specified torque value. (See Table 2-1,

Cylinder Hea d an d Tapered Bushing Torque Specifications.)

15. Remove the cylinder rod from the holding fixture.

16. Place new guide locks and seals in the applicable

outside diameter grooves of the cylinder piston.

(See Figure 2-11., Piston Seal Kit Installation)

a. Place the shaf t against the cylinder rod and in

contact with the bushing in the spaces between

the capscrews.

Figure 2-14. Poly-Pak Piston Seal Installat ion

2-12 – JLG Lift – 3120884

SECTION 2 - PROCEDURES

17. Position the cylinder barrel in a suitable holding fixture.

EXTREME CARE SHOULD BE TAKEN WHEN INSTALLING THE

CYLINDER ROD, HEAD, A ND PISTON. AVOID PULLING TH E ROD

OFF-CENTER, WHICH COULD CAUSE DAMAGE TO THE PISTON

AND CYLINDER BARREL SURFACES.

18. With barrel clamped securely, and while adequately

supporting the rod, insert the piston end into the

barrel cylinder. Ensure that the piston loading o-ring

and seal ring are not damaged or dislodged.

19. Continue pushing the rod into the barrel until the cylinder head gland can be inserted into the barrel cylinder.

20. Secure the cylinder head gland using the washer

ring and socket head bolts.

Table 2-1.Cylinder Head and Tapered Bushing Torque

Specifications

Description

E.A.R. Cylinder

Level Cylinder (M45AJ)

Master Cylinder

(M45AJ)

Table 2-2. Cylinder Piston Nut Torque Specifications)

Description

Upper

Lift Cylinder

Mid

Lift Cylinder

Head Torque V alue

(Wet)

30 ft. lbs

(41 Nm)

30 ft. lbs

(41 Nm)

30 ft. lbs.

(41 Nm)

Nut Torque

Valve (Wet)

200 ft. lbs.

(270 Nm)

400 ft. lbs.

(542 Nm)

Tapered Bushing

Torque Value (Wet)

5 ft. lbs.

(7 Nm)

5 ft. lbs.

(7 Nm)

5 ft. lbs.

(7 Nm)

Setscrew

Torque Value

(Dry)

100 in. lbs.

(11 Nm)

100 in. lbs.

(11 Nm)

Figure 2-15. Rod Assembly Installation

21. After the cylinder has been reassembled, the rod

should be pushed all the way in (fully retracted) prior

to the reinstallation of any holding valve or valves.

22. If applicable, install the cartridge-type holding valve

and fittings in the rod port block, using new o-rings

as applicable. (See Table 2-3, Holding Valve Torque

Specifications).

IF THE CYLINDER IS TO BE TESTED PRIOR TO INSTALLATIO N ON

THE MACHINE, EXTREME CARE SHOULD BE USED TO INSURE

THAT THE OUTER END OF THE ROD IS SUPPORTED. USE

EITHER A TRAVELING OVERHEAD HOIST, FORK-LIFT, OR O THER

MEANS TO SUPPORT THE OVERHANGING WEIGHT OF THE

EXTENDING ROD.

Lower

Lift Cylinder

Level Cylinder (M45 A) 80 ft. lbs.

Master Cylinder

(M45A)

Table 2-3. Holding Valve Torque Specificatio ns

Description Torque Value

SUN - 7/8 HEX M20 X 1.5 THDS. 30-35 ft. lbs.

SUN - 1 1/8 HEX 1 -14 UNS THDS. 45-50 ft. lbs.

SUN - 1 1/4 HEX M36 X 2 THDS. 150-160 ft. lbs.

RACINE - 1 1/8 HEX 1 1/16 - 12 THDS. 50-55 ft. lbs.

RACINE - 1 3/8 HEX 1 3/16 - 12 THDS. 75-80 ft. lbs.

400 ft. lbs.

(542 Nm)

(108 Nm)

80 ft. lbs.

(108 Nm)

100 in. lbs.

(11 Nm)

100 in. lbs.

(11 Nm)

100 in. lbs.

(11 Nm)

(41-48 Nm)

(61-68 Nm)

(204-217 Nm)

(68-75 Nm)

(102-109 Nm)

RACINE - 1 7/8 HEX 1 5/8 - 12 THDS. 100-110 ft. lbs.

(136-149 Nm)

3120884 – JLG Lift – 2-13

SECTION 2 - PROCEDURES

Figure 2-16. Upper Boom Lift Cy linder Removal

2.8 CYLINDER REMOVAL AND

INSTALLATION

Upper (Main) Boom Lift Cylinder Removal

1. Place the machine on a flat and level surface. Place

the Upper Boom in a horizontal position. Place

Lower and Mid Booms 5 degree above horizontal.

Shut down machine and prop boom.

2. Tag, disco nnec t a nd ca p th e up per boom lift cylind er

hydraulic lines and ports.

3. Remove the hardware securing the cylinder rod

attach pin #1 to the boom. Using a suitable brass

drift, drive out the cylinder rod attach pin #1.

3. Remove cylinder port plugs and hydraulic line caps

and correctly attach lines to cylinder ports.

4. With function speed switch at its slowest setting,

extend the cylinder rod until attach pin hole aligns

with those in boom. Using a suitable drift, drive the

cylinder rod attach pin #1 through the aligned

holes. Secure the pin in place with pin retaining

hardware.

5. Cycle cylinder completely to check for proper functioning. Place boom in stowed position. Check

hydraulic fluid level and adjust accordingly.

Mid Boom Lift Cylinder Removal

1. Place machine on flat and level surface. Place the

Upper Boom in a horizontal position. Place the Mid

Boom in a 10 degree elevated position. Support

Upper Boom with a prop. Support upright with an

overhead cran e.

2. Using slings, restrain the lower lift cylinder.

3. Remove the hardware securing the cylinder rod

attach pin #3 to the boom. Using an appropriate

brass drift, drive out the cylinder rod attach pin #3.

4. Secure the cylinder with suitable slings or supports

as required. Remove the hardware securing the barrel end attach pin #2. Using a suitable brass drift,

drive out the barrel end attach pin #2.

5. Remove the cylinder from the boom and place in a

suitable work area.

Upper (Main) Boom Lift Cylinder In stallation

NOTE: Coat I.D. of bushings with specified lubricant prior to

installing pins.

1. Install Lift Cylinder in place using suitable slings or

supports, aligning attach pin mounting holes on

upright.

2. Using a suitable drift, drive the barrel end attach pin

#2 through the mounting holes in the lift cylinder

and upright. Secure in place with pin retaining hardware.

Figure 2-17. Mid Boom Lift Cylinder Removal

4. Tag, disconnect and cap the lift cylinder hydraulic

lines and ports.

5. Remove the hardware securing the barrel end attac h

pin #4 to the boom. Using an appropriate brass

drift, drive out the cylinder barrel pin #4.

6. Carefully remove cylinder from boom. Place in a

suitable work area.

2-14 – JLG Lift – 3120884

SECTION 2 - PROCEDURES

Mid Boom Lift Cylinder Installation.

NOTE: Co at I. D. of bushings wit h spe cif ied l ubr ic ant pr ior t o

installing pins.

1. With the booms positioned and supported, place

cylinder in position and secure in place using slings.

2. Install the cylinder barrel pin #4, being sure to align

the hole in the cylinder barrel pin with the retaining

pin screw hole. When holes alig n, in s t all hard ware.

3. Correctly install hydraulic lines to cylinder as previously tagged. Extend cylinder rod slowly until attach

pin hole aligns with those in boom.

4. Using a suitable brass drift, drive the cylinder rod

attach pin #3 through the aligned holes. Secure the

pin in place using retaining hardw are.

5. Remove boom prop and overhead crane. Take the

lift cylinder through one complete cycle to assure

correct functioning. Place boom in stowed position.

Check hydraulic fluid and adjust accordingly.

Lower Boom Lift Cylinder Removal

1. Place machine on flat and level surface. Place the

Upper Boom in a horizontal position. Place the Mid

and Lower Booms in a 10 degree elevated position.

Support Upper Boom with a prop. Support upright

with an overhead crane.

2. Using slings, restrain the lower lift cylinder.

4. Tag, disconnect and cap the lift cylinder hydraulic

lines and ports.

5. Remove the hardware securing the barrel end attac h

pin #6 to the boom. Using an appropriate brass

drift, drive out the cylinder barrel pin #6.

6. Carefully remove cylinder from boom. Place in a

suitable work area.

Lower Boom Lift Cylinder Installation

NOTE: Co at I. D. of bushings wi th spe cif ied lubr ic ant pr io r to

installing pins.

1. With the booms positioned and supported, place

cylinder in position and secure in place using slings.

2. Install the cylinder barrel pin #6, being sure to align