Graco 205626, 222095, 222065 User Manual

Instructions – Parts List

10:1 Fire–Ballr 425 Pump

For pumping non–corrosive and non–abrasive oils and lubricants only.

180 psi (12.4 bar) Maximum Incoming Air Pressure

1800 psi (124 bar) Maximum Fluid Working Pressure

Model 205626, Series K

Universal Pump

Model 222065, Series C

55-Gallon Drum Cover-Mount Pump

Model 222095, Series C

55-Gallon Drum Bung-Mount Pump

Important Safety Instructions.

Read all warnings and instructions in this manual.

Save these instructions.

Model 205626 shown

GRACO INC. P.O. BOX 1441 MINNEAPOLIS, MN 55440-1441

Copyright 1996, Graco Inc. is registered to I.S. EN ISO 9001

308655J

TI1071

Table of Contents

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 2 |

Parts Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

Mounting Hole Layout . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

Air Motor and Throat Service . . . . . . . . . . . . . . . . . . . . . |

9 |

Performance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

Displacement Pump Service . . . . . . . . . . . . . . . . . . . . |

13 |

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

14 |

Graco Phone Number . . . . . . . . . . . . . . . . . . . . . . . . . . |

18 |

Symbols

Warning Symbol

WARNING

WARNING

This symbol alerts you to the possibility of serious injury or death if you do not follow the instructions.

Caution Symbol

CAUTION

CAUTION

This symbol alerts you to the possibility of damage to or destruction of equipment if you do not follow the instructions.

WARNING

WARNING

EQUIPMENT MISUSE HAZARD

Equipment misuse can cause the equipment to rupture or malfunction and result in serious injury.

DThis equipment is for professional use only.

DRead all instruction manuals, tags, and labels before you operate this equipment.

DUse the equipment only for its intended purpose. If you are not sure, call your Graco distributor.

DDo not alter or modify this equipment.

DCheck equipment daily. Repair or replace worn or damaged parts immediately.

DDo not exceed the maximum working pressure stated on the equipment or in the Technical Data for your equipment. Do not exceed the maximum working pressure of the lowest rated component in your system.

DUse fluids and solvents which are compatible with the equipment wetted parts. Refer to the Technical Data section of all equipment manuals. Read the fluid and solvent manufacturer’s warnings.

DDo not use 1,1,1–trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or fluids that contain such solvents in pressurized aluminum equipment. Such use could result in a chemical reaction, with the possibility of explosion.

DHandle hoses carefully. Do not pull on hoses to move equipment.

DRoute hoses away from traffic areas, sharp edges, moving parts, and hot surfaces. Do not expose Graco hoses to temperatures above 82_C (180_F) or below –40_C (–40_F).

DDo not lift pressurized equipment.

DComply with all applicable local, state, and national fire, electrical, and safety regulations.

2 308655J

WARNING

WARNING

SKIN INJECTION HAZARD

Fluid from the dispensing valve, leaks, or ruptured components can inject fluid into your body and cause extremely serious injury, including the need for amputation. Fluid splashed in the eyes or on the skin can also cause serious injury.

DFluid injected into the skin may look like just a cut, but it is a serious injury. Get immediate surgical treatment.

DDo not point the dispensing valve at anyone or at any part of the body.

DDo not put your hand or fingers over the end of the dispensing valve.

DDo not stop or deflect leaks with your hand, body, glove or rag.

DUse only extensions and no-drip tips that are designed for use with your dispensing valve.

DTighten all fluid connections before you operate this equipment.

DCheck the hoses, tubes, and couplings daily. Replace worn or damaged parts immediately. Do not repair high pressure couplings; you must replace the entire hose.

HAZARDOUS FLUIDS

Improper handling of hazardous fluids or inhaling toxic fumes can cause extremely serious injury, even death, due to splashing in the eyes, ingestion, or bodily contamination.

DKnow the specific hazards of the fluid you are using.

DStore hazardous fluid in an approved container. Dispose of hazardous fluid according to all local, state, and national guidelines.

DAlways wear protective eyewear, gloves, clothing, and respirator as recommended by the fluid and solvent manufacturer.

FIRE AND EXPLOSION HAZARD

Improper grounding, poor ventilation, open flames or sparks can cause a hazardous condition and result in a fire or explosion and serious injury.

DGround the equipment. Refer to Grounding on page 6.

DIf there is any static sparking or you feel an electric shock while you use this equipment, stop dispensing immediately. Do not use the equipment until you identify and correct the problem.

DProvide fresh air ventilation to avoid the buildup of flammable fumes from solvents or the fluid being dispensed.

DDo not smoke in the dispensing area.

MOVING PARTS HAZARD

Moving parts can pinch or amputate your fingers.

DKeep clear of all moving parts when you start or operate the pump.

DBefore you service this equipment, follow the Pressure Relief Procedure on page 7 to prevent the equipment from starting unexpectedly.

308655J 3

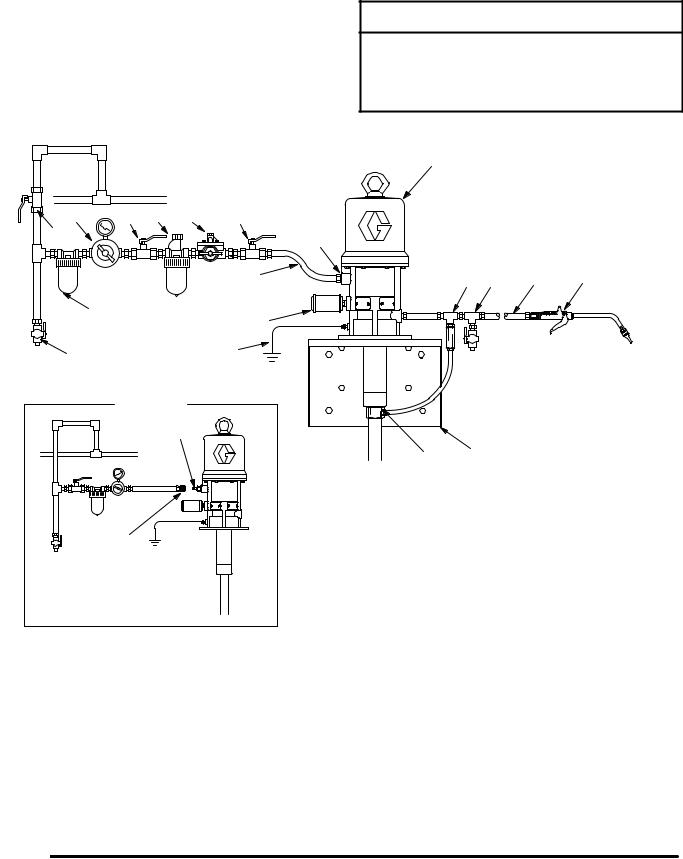

Installation

The typical installation shown in Fig.1 is only a guide to help you select and install a pump; it is not an actual system design. Contact your Graco distributor for assistance in designing a system to suit your needs.

C A N D A

A

E

R

B

Z

F Y

DETAIL A

L

M

For Portable Applications

KEY

ABleed-type master air valve

(required, Part No. 107142)

BAir line filter

CAir regulator and gauge

DPump runaway valve

EAir inlet

FBall valve (for releasing collected moisture)

GPump

HDrain valve (required, Part No. 210658)

JDispensing valve (model 222411 shown)

KThermal relief kit (required, Part No. 240429)

CAUTION

CAUTION

Always mount the pump firmly to a bracket or a tank cover. Never operate the pump while it is not mounted. Such use could damage the pump and fittings.

G

K H P J

TI0890

S T

LMale quick-disconnect fitting

MFemale quick-disconnect coupler

NAir line lubricator

P Fluid hose

RElectrically conductive air hose (218093 shown)

Use at least 1/2 in. (13 mm) ID to supply an adequate volume of air to the air motor.

SFluid inlet

TWall-mounting bracket (Part No. 238245)

YGround wire (required, Part No. 222011)

ZMuffler

06038

Fig. 1

4 308655J

Installation

System Accessories

CAUTION

CAUTION

Do not hang the air accessories directly on the air inlet (E). The fittings are not strong enough to support the accessories and may cause one or more to break. Provide a bracket on which to mount the accessories.

NOTE: Install the following accessories in the order shown in Fig. 1.

WARNING

WARNING

Four accessories are required in your system: an air shut-off valve/air bleed device, fluid drain valve, thermal relief kit, and ground wire. These accessories help reduce the risk of serious bodily injury including fluid injection, splashing in the eyes or on the skin, injury from moving parts if you are adjusting or repairing the pump, and explosion from static sparking.

The air bleed device relieves air trapped between it and the air motor after the air supply is shut off. Trapped air can cause the air motor to cycle unexpectedly, causing serious bodily injury if you are adjusting or repairing the pump. Use either a bleed-type master air valve (A) or a quick-discon- nect coupler (M) and fitting (L). Install near the pump air inlet, within easy reach of the pump.

The fluid drain valve (H) assists in relieving fluid pressure in the displacement pump, hoses, and dispensing valve. Triggering the valve to relieve pressure may not be sufficient.

The thermal relief kit assists in relieving pressure in the pump, hose, and dispensing valve due to heat expansion.

The ground wire reduces the risk of static sparking.

DScrew the muffler (5) into the 3/4-in. npt muffler port, and tighten it using a wrench on the flats of the muffler near the male threads.

DInstall an air line lubricator (N) for automatic air motor lubrication.

DInstall the air regulator (C) to control pump speed and pressure.

DInstall an air line filter (B) to remove harmful dirt and contaminants from your compressed air supply.

DInstall a bleed-type master air valve (A) to isolate the accessories for servicing. See Fig. 1. To order a bleed-type master air valve, order Part No. 107142.

As an alternative to a bleed-type master air valve, you can install an air line quick disconnect coupler

(M) and fitting (L) to serve as an air-bleed device. See Detail A in Fig. 1.

DInstall a ball valve (F), at the end of a line drop, as shown in Fig. 1, for releasing moisture that collects in the line.

DInstall a drain valve (H) near the pump fluid outlet to relieve fluid pressure in the hoses and gun when opened. To order a fluid drain valve, order Part No. 210658.

DInstall a pump runaway valve (D) to shut off the air to the pump if the pump accelerates beyond the pre-adjusted setting, which can be caused by a depleted fluid supply. A pump that runs too fast can be seriously damaged. To order a 3/4-in. npt(f) inlet and outlet pump runaway valve, order Part No. 215362.

DInstall a thermal relief kit (K) on the dispensing valve side of the pump. To order a 1600 psi

(110 bar) thermal relief kit, order Part No. 240429.

DInstall a suitable fluid hose (P) and dispensing valve (J).

Wall Mount

The pump shown in Fig. 1 is a wall-mounted universal pump, Model 205626. To order the wall-mounting bracket shown, order Part No. 238245.

Cover Mount

Pump Model 222065 is designed for mounting directly on a 55-gallon drum cover. When the pump is mounted to a closed-head drum, be sure you loosen the vent plug on the drum cover to prevent a vacuum in the drum. For cover mounting, see the Mounting Hole Layout on page 16.

Bung Mount

Pump model 222095 is designed for bung mounting on a 55-gallon drum. The bung adapter (153) is shown in the Parts Drawing on page 15.

308655J 5

Installation

Grounding

Proper grounding is an essential part of maintaining a safe system.

To reduce the risk of static sparking, ground the pump. Check your local electrical code for detailed grounding instructions for your area and type of equipment. Be sure to ground this equipment:

DPump: Use a ground wire and clamp as shown in Fig. 2.

DAir and Fluid hoses: Use only electrically conductive hoses.

DAir compressor: Follow the manufacturer’s recommendations.

DFluid supply container: Follow the local code.

DObject being lubricated: Follow the local code.

DTo maintain grounding continuity when flushing or relieving pressure, always hold a metal part of the valve firmly to the side of a grounded metal pail, then trigger the valve.

To ground the pump, remove the ground screw (Z) and insert through the eye of the ring terminal at end of the ground wire (Y). Fasten the ground screw back onto the pump and tighten securely. Connect the other end of the ground wire to a true earth ground. See Fig. 2. To order a ground wire and clamp, order Part No. 222011.

Y

Z

Fig. 2 |

TI1052 |

|

6 308655J

Loading...

Loading...