YAMAHA XT660R User Manual

2007

XT660R(W)

XT660X(W)

SUPPLEMENTARY

SERVICE MANUAL

5VK-F8197-E2

FOREWORD

This Supplementary Service Manual has been prepared to introduce new service and data for the XT660R(W)/XT660X(W) 2007. For complete service information procedures it is necessary to use this Supplementary Service Manual together with the following manual.

XT660R(S)/XT660X(S) 2004 SERVICE MANUAL: 5VK1-AE1

XT660R(W)/XT660X(W) 2007

SUPPLEMENTARY

SERVICE MANUAL ©2006 by MBK Industrie First edition, July 2006 All rights reserved.

Any reproduction or unauthorized use without the written permission of MBK Industrie

is expressly prohibited.

EAS00002

NOTICE

This manual was produced by MBK Industrie primarily for use by Yamaha dealers and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manual. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha vehicles should have a basic understanding of mechanics and the techniques to repair these types of vehicles. Repair and maintenance work attempted by anyone without this knowledge is likely to render the vehicle unsafe and unfit for use.

Yamaha is continually striving to improve all its models. Modifications and significant changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and will appear in future editions of this manual where applicable.

NOTE:

Designs and specifications are subject to change without notice.

EAS00004

IMPORTANT MANUAL INFORMATION

Particularly important information is distinguished in this manual by the following.

WARNING

WARNING

CAUTION:

NOTE:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Failure to follow WARNING instructions could result in severe injury or death to the motorcycle operator, a bystander or a person checking or repairing the motorcycle.

A CAUTION indicates special precautions that must be taken to avoid damage to the motorcycle.

A NOTE provides key information to make procedures easier or clearer.

EAS00007

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic. Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check procedures are laid out with the individual steps in sequential order.

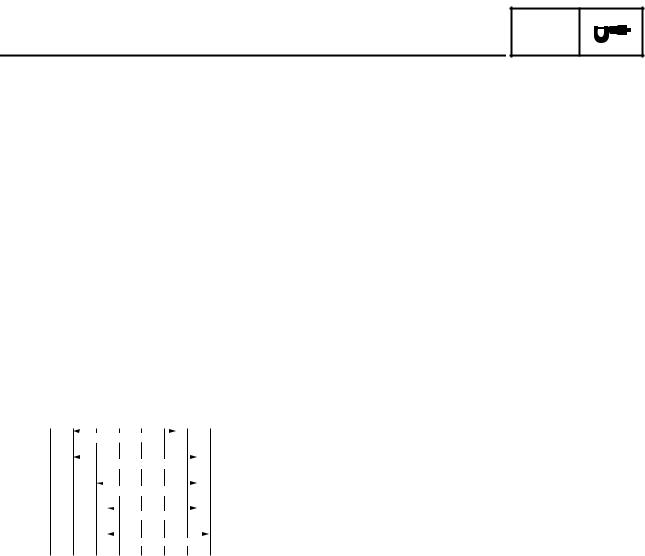

1 The manual is divided into chapters. An abbreviation and symbol in the upper right corner of each page indicate the current chapter.

Refer to “SYMBOLS”.

2 Each chapter is divided into sections. The current section title is shown at the top of each page, except in Chapter 3 (“PERIODIC CHECKS AND ADJUSTMENTS”), where the sub-section title(s) appears.

3Sub-section titles appear in smaller print than the section title.

4To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each removal and disassembly section.

5Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates a disassembly step.

6Symbols indicate parts to be lubricated or replaced. Refer to “SYMBOLS”.

7A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of parts, notes in jobs, etc.

8Jobs requiring more information (such as special tools and technical data) are described sequentially.

1 |

|

2 |

|

|

GEN |

|

SPEC |

|

|

INFO |

|

|

|

|

|

|

|

|

|

3 |

|

4 |

|

|

CHK |

|

CHAS |

|

|

ADJ |

|

|

|

|

|

|

|

|

|

5 |

|

6 |

|

|

ENG |

|

COOL |

|

|

7 |

|

8 |

|

|

FI |

|

ELEC |

– |

+ |

9 |

|

0 |

|

|

TRBL |

|

|

|

|

SHTG |

|

|

|

|

A |

|

B |

|

|

C |

|

D |

|

|

|

|

|

T |

|

|

|

|

. |

|

|

|

|

R |

|

|

|

|

. |

|

E |

F |

G |

|

|

H |

I |

J |

|

|

E |

|

G |

M |

|

K |

L |

M |

|

|

B |

|

LS |

M |

|

N |

|

O |

|

|

LT |

|

New |

|

|

|

|

|

|

|

EAS00008

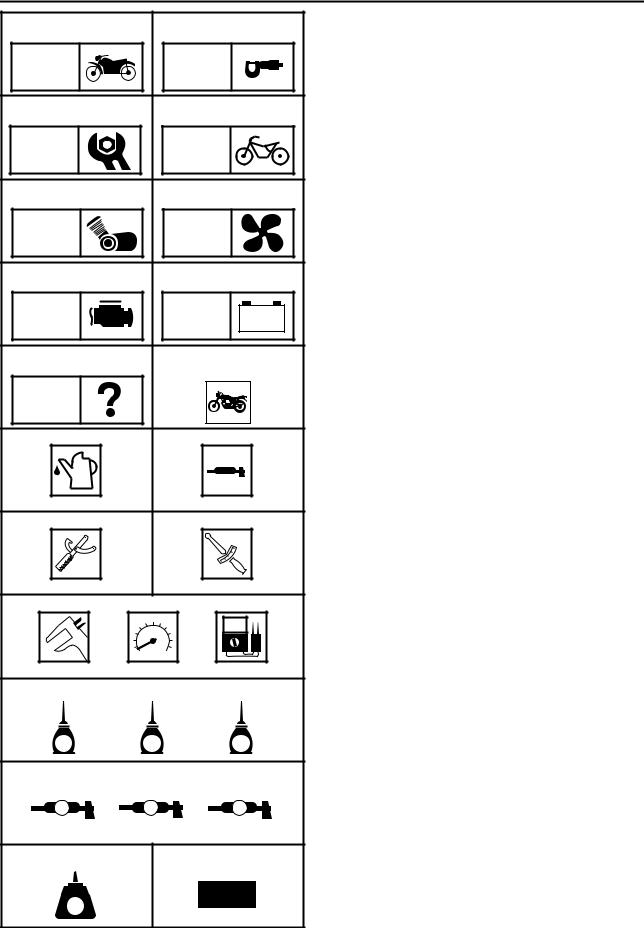

SYMBOLS

The following symbols are not relevant to every vehicle.

Symbols 1 to 9 indicate the subject of each chapter.

1 General information

2Specifications

3Periodic checks and adjustments

4Chassis

5Engine

6Cooling system

7Fuel injection system

8Electrical system

9Troubleshooting

Symbols 0 to G indicate the following.

0 Serviceable with engine mounted A Filling fluid

BLubricant

CSpecial tool

DTightening torque

EWear limit, clearance

FEngine speed

GElectrical data

Symbols H to M in the exploded diagrams indicate the types of lubricants and lubrication points.

H Engine oil

I Gear oil

JMolybdenum-disulfide oil

KWheel-bearing grease

LLithium-soap-based grease

MMolybdenum-disulfide grease

Symbols N to O in the exploded diagrams indicate the following.

N Apply locking agent (LOCTITE®)

O Replace the part

CONTENTS |

|

SPECIFICATIONS .............................................................................................. |

1 |

GENERAL SPECIFICATIONS ..................................................................... |

1 |

ENGINE SPECIFICATIONS......................................................................... |

2 |

CHASSIS SPECIFICATIONS....................................................................... |

6 |

ELECTRICAL SPECIFICATIONS ................................................................ |

8 |

TIGHTENING TORQUE ............................................................................... |

8 |

ENGINE TIGHTENING TORQUES ....................................................... |

8 |

CHASSIS TIGHTENING TORQUES ..................................................... |

8 |

CABLE ROUTING ........................................................................................ |

9 |

PERIODIC CHECKS AND ADJUSTMENTS.................................................... |

22 |

COWLING AND COVER ............................................................................ |

22 |

COVER ................................................................................................ |

22 |

COWLING ............................................................................................ |

23 |

FUEL TANK................................................................................................ |

24 |

CHASSIS.................................................................................................... |

26 |

ADJUSTING THE DRIVE CHAIN SLACK............................................ |

26 |

CHECKING THE TIRES ...................................................................... |

28 |

CHASSIS .......................................................................................................... |

32 |

REAR WHEEL, BRAKE DISC, AND REAR WHEEL SPROCKET ............. |

32 |

REAR WHEEL ..................................................................................... |

32 |

REMOVING THE REAR WHEEL (XT660R) ........................................ |

34 |

REMOVING THE REAR WHEEL (XT660X) ........................................ |

35 |

INSTALLING THE REAR WHEEL (XT660R)....................................... |

35 |

INSTALLING THE REAR WHEEL (XT660X)....................................... |

36 |

SWINGARM AND DRIVE CHAIN............................................................... |

38 |

ENGINE ............................................................................................................ |

41 |

ENGINE REMOVAL ................................................................................... |

41 |

EXHAUST PIPES AND MUFFLERS.................................................... |

41 |

CYLINDER HEAD ...................................................................................... |

42 |

CYLINDER AND PISTON .......................................................................... |

44 |

COOLING SYSTEM.......................................................................................... |

46 |

RADIATOR ................................................................................................. |

46 |

FUEL INJECTION SYSTEM............................................................................. |

48 |

FUEL INJECTION SYSTEM....................................................................... |

48 |

WIRING DIAGRAM .............................................................................. |

49 |

FAIL-SAFE ACTION TABLE ................................................................ |

50 |

DIAGNOSTIC MODE ........................................................................... |

52 |

TROUBLESHOOTING DETAILS ......................................................... |

58 |

ELECTRICAL SYSTEM.................................................................................... |

71 |

ELECTRICAL COMPONENTS................................................................... |

71 |

XT660R(W)/XT660X(W) 2007 WIRING DIAGRAM

|

|

|

|

|

|

|

|

GENERAL SPECIFICATIONS |

|

SPEC |

|

||

|

|

|

|

|

|

|

|

SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

||

GENERAL SPECIFICATIONS |

|

|

|

|

||

|

|

|

|

|

|

|

Item |

|

Standard |

|

|

|

Limit |

|

|

|

|

|

||

Model code |

|

XT660R: 5VK8 (Europe) |

|

|

---- |

|

|

|

5VK9 (AUS) |

|

---- |

||

|

|

XT660X: 10S1 (Europe) |

|

---- |

||

|

|

10S2 (AUS) |

|

---- |

||

|

|

|

|

|

|

|

Dimensions |

|

|

|

|

|

|

Overall length |

|

2,240 mm (88.2 in) (XT660R) |

|

---- |

||

|

|

2,175 mm (85.6 in) (XT660X) |

|

---- |

||

Overall width |

|

845 mm (33.3 in) (XT660R) |

|

---- |

||

|

|

860 mm (33.9 in) (XT660X) |

|

---- |

||

Overall height |

|

1,230 mm (48.4 in) (XT660R) |

|

---- |

||

|

|

1,170 mm (46.1 in) (XT660X) |

|

---- |

||

Seat height |

|

865 mm (34.1 in) (XT660R) |

|

---- |

||

|

|

875 mm (34.4 in) (XT660X) |

|

---- |

||

Wheelbase |

|

1,505 mm (59.3 in) (XT660R) |

|

---- |

||

|

|

1,490 mm (58.7 in) (XT660X) |

|

---- |

||

Minimum ground clearance |

|

210 mm (8.27 in) (XT660R) |

|

---- |

||

|

|

205 mm (8.07 in) (XT660X) |

|

---- |

||

Minimum turning radius |

|

2,400 mm (94.5 in) |

|

---- |

||

|

|

|

|

|

|

|

– 1 –

ENGINE SPECIFICATIONS SPEC

ENGINE SPECIFICATIONS

|

|

|

|

|

Item |

Standard |

Limit |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine |

|

|

|||||||||||||

Engine type |

Liquid-cooled, 4-stroke, SOHC |

---- |

|||||||||||||

Displacement |

660 cm3 |

---- |

|||||||||||||

Cylinder arrangement |

Forward-inclined single cylinder |

---- |

|||||||||||||

Bore × stroke |

100.0 × 84.0 mm (3.94 × 3.31 in) |

---- |

|||||||||||||

Compression ratio |

10.00 : 1 |

---- |

|||||||||||||

Engine idling speed |

1,400 ~ 1,500 r/min |

---- |

|||||||||||||

Water temperature |

80 °C (176 °F) |

---- |

|||||||||||||

Oil temperature |

55 ~ 65 °C (131 ~ 149 °F) |

---- |

|||||||||||||

Standard compression pressure |

650 kPa (6.5 kg/cm2, 92.4 psi) |

---- |

|||||||||||||

(at sea level) |

at 800 r/min |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine oil |

|

|

|||||||||||||

Lubrication system |

Dry sump |

---- |

|||||||||||||

Recommended oil |

|

|

|||||||||||||

-20 -10 0 10 20 30 40 50 ˚C |

SAE 10W30, SAE 10W-40, SAE 15W40, |

---- |

|||||||||||||

SAE 20W40 or SAE 20W-50 |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SAE 10W-30 |

|

|

|

|

Refer to the chart for engine oil grade. |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

SAE 10W-40 |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

SAE 15W-40 |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

SAE 20W-40 |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

SAE 20W-50 |

|

|

||||||||

Recommended engine oil grade |

API service SG type or higher, JASO |

---- |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

standard MA |

|

Quantity |

|

|

|||||||||||||

Total amount |

2.90 L (2.55 Imp qt, 3.07 US qt) |

---- |

|||||||||||||

Periodic oil change |

2.50 L (2.20 Imp qt, 2.64 US qt) |

---- |

|||||||||||||

With oil filter replacement |

2.60 L (2.29 Imp qt, 2.75 US qt) |

---- |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oil pump |

|

|

|||||||||||||

Oil pump type |

Trochoid |

---- |

|||||||||||||

Inner-rotor-to-outer-rotor-tip clear- |

0.03 ~ 0.08 mm (0.0012 ~ 0.0031 in) |

0.16 mm |

|||||||||||||

ance |

|

(0.0063 in) |

|||||||||||||

Outer-rotor-to-oil-pump-housing |

0.09 ~ 0.15 mm (0.0035 ~ 0.0059 in) |

0.22 mm |

|||||||||||||

clearance |

|

(0.0087 in) |

|||||||||||||

Oil-pump-housing-to-inner-rotor-and- |

0.03 ~ 0.08 mm (0.0012 ~ 0.0031 in) |

0.15 mm |

|||||||||||||

outer-rotor clearance |

|

(0.0059 in) |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– 2 –

|

|

|

|

|

|

|

|

|

|

|

ENGINE SPECIFICATIONS |

|

SPEC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

Standard |

|

|

Limit |

|||

|

|

|

|

|

|

|

|

Camshaft |

|

|

|

|

|

||

Drive system |

Chain drive (left) |

---- |

|

||||

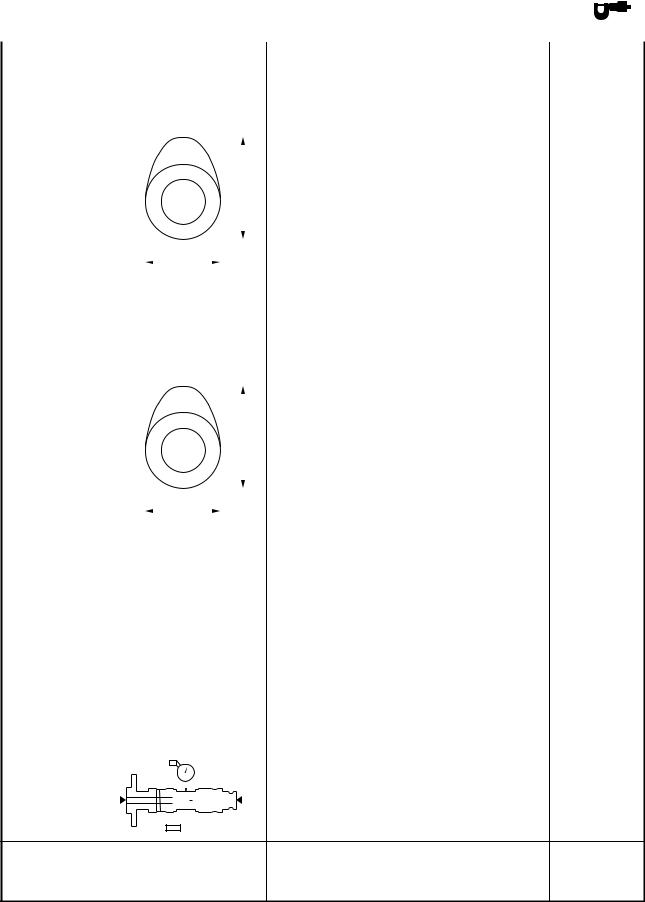

Intake camshaft lobe dimensions |

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Measurement A |

43.488 ~ 43.588 mm (1.7121 ~ 1.7161 in) |

43.388 mm |

||||||

|

|

|

|

|

|

|

|

(1.7082 in) |

Measurement B |

36.959 ~ 37.059 mm (1.4551 ~ 1.4590 in) |

36.859 mm |

||||||

|

|

|

|

|

|

|

|

(1.4511 in) |

Exhaust camshaft lobe dimensions |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

Measurement A |

|

|

|

43.129 ~ 43.229 mm (1.6980 ~ 1.7019 in) |

43.029 mm |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(1.6941 in) |

Measurement B |

|

|

|

37.007 ~ 37.107 mm (1.4570 ~ 1.4609 in) |

36.907 mm |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(1.4530 in) |

Valve timing |

|

|

|

|

|

||||||||||

Intake - open (B.T.D.C.) |

25° |

---- |

|||||||||||||

Intake - closed (A.B.D.C.) |

55° |

---- |

|||||||||||||

Exhaust - open (B.B.D.C.) |

60° |

---- |

|||||||||||||

Exhaust - closed (A.T.D.C.) |

20° |

---- |

|||||||||||||

Overlap angle “A” |

45° |

---- |

|||||||||||||

Maximum camshaft runout |

---- |

0.040 mm |

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(0.0016 in) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Timing chain |

|

|

Model/number of links |

98XRH2010/126 |

---- |

Tensioning system |

Automatic |

---- |

– 3 –

ENGINE SPECIFICATIONS SPEC

Item |

Standard |

Limit |

|

|

|

|

|

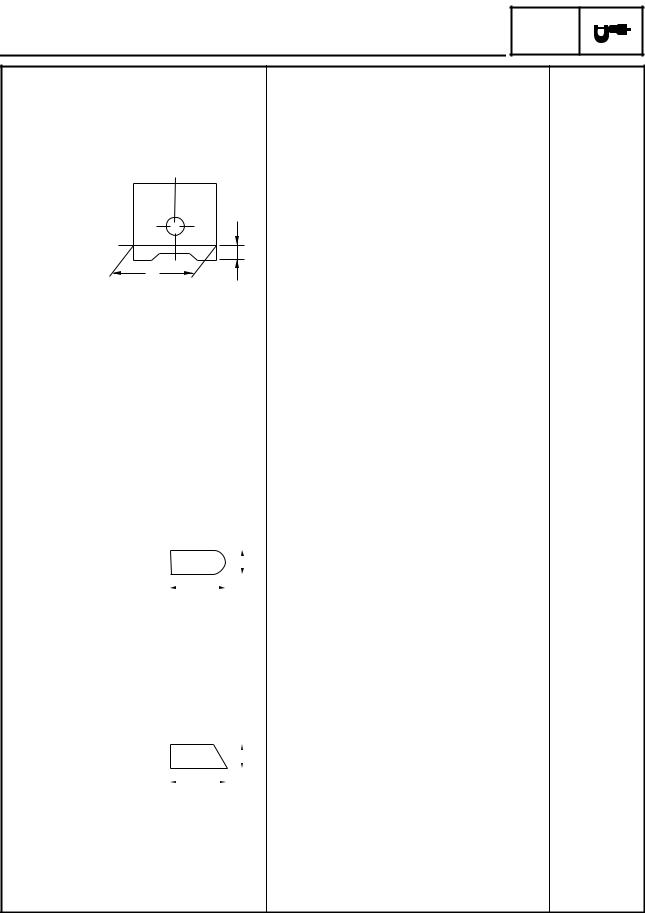

Piston |

|

|

|

Piston-to-cylinder clearance |

0.030 ~ 0.055 mm (0.0012 ~ 0.0022 in) |

0.13 mm |

|

|

|

|

(0.0051 in) |

Diameter D |

99.955 ~ 99.970 mm (3.9352 ~ 3.9358 in) |

---- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H |

|

|

||

D |

|

|

|||||||||

Height H |

10.0 mm (0.39 in) |

---- |

|||||||||

Piston pin bore (in the piston) |

|

|

|||||||||

Diameter |

23.004 ~ 23.015 mm (0.9057 ~ 0.9061 in) |

23.045 mm |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

(0.9073 in) |

Offset |

0.50 mm (0.0197 in) |

---- |

|||||||||

Offset direction |

Intake side |

---- |

|||||||||

Piston pin |

|

|

|||||||||

Outside diameter |

22.991 ~ 23.000 (0.9052 ~ 0.9055 in) |

22.971 mm |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

(0.9044 in) |

Piston-pin-to-piston-pin-bore clear- |

0.004 ~ 0.024 mm (0.0002 ~ 0.0009 in) |

0.074 mm |

|||||||||

ance |

|

(0.0029 in) |

|||||||||

Piston rings |

|

|

|||||||||

Top ring |

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

Ring type |

Barrel |

---- |

|||||||||

Dimensions (B × T) |

1.20 × 3.80 mm (0.047 × 0.150 in) |

---- |

|||||||||

End gap (installed) |

0.20 ~ 0.35 mm (0.0079 ~ 0.0138 in) |

0.60 mm |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

(0.0236 in) |

Ring side clearance |

0.030 ~ 0.080 mm (0.0012 ~ 0.0031 in) |

0.13 mm |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

(0.0051 in) |

2nd ring |

|

|

|||||||||

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

T |

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||

Ring type |

Taper |

---- |

|||||||||

Dimensions (B × T) |

1.20 × 4.00 mm (0.047 × 0.157 in) |

---- |

|||||||||

End gap (installed) |

0.35 ~ 0.50 mm (0.0138 ~ 0.0197 in) |

0.85 mm |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

(0.0335 in) |

Ring side clearance |

0.030 ~ 0.070 mm (0.0012 ~ 0.0028 in) |

0.13 mm |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

(0.0051 in) |

– 4 –

ENGINE SPECIFICATIONS SPEC

Item |

Standard |

Limit |

||||||||

|

|

|

|

|

|

|

|

|

|

|

Oil ring |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Dimensions (B × T) |

2.50 × 3.40 mm (0.098 × 0.134 in) |

---- |

||||||||

End gap (installed) |

0.20 ~ 0.70 mm (0.0079 ~ 0.0276 in) |

---- |

||||||||

Ring side clearance |

0.060 ~ 0.150 mm (0.0024 ~ 0.0059 in) |

---- |

||||||||

|

|

|

|

|

|

|

|

|

|

|

Throttle body |

|

|

||||||||

Model/manufacturer × quantity |

44EHS/MIKUNI × 1 |

---- |

||||||||

Intake vacuum pressure |

37.6 ~ 40.2 kPa |

---- |

||||||||

|

|

|

|

|

|

|

|

|

(282 ~ 302 mmHg, 11.1 ~ 11.9 inHg) |

|

Throttle cable free play (at the flange |

3.0 ~ 5.0 mm (0.12 in ~ 0.20 mm) |

---- |

||||||||

of the throttle grip) |

|

|

||||||||

ID mark |

5VK8 10 |

---- |

||||||||

Throttle valve size |

#50 |

---- |

||||||||

|

|

|

|

|

|

|

|

|

|

|

– 5 –

CHASSIS SPECIFICATIONS SPEC

CHASSIS SPECIFICATIONS

Item |

Standard |

Limit |

|

|

|

Rear wheel |

|

|

Wheel type |

Spoke wheel |

---- |

Rim |

|

|

Size |

17M/C × MT2.75 (XT660R) |

---- |

|

17M/C × MT4.25 (XT660X) |

---- |

Material |

Aluminum |

---- |

Wheel travel |

200.0 mm (7.87 in) (XT660R) |

---- |

|

191.0 mm (7.52 in) (XT660X) |

---- |

Wheel runout |

|

|

Maximum radial wheel runout |

---- |

2.0 mm |

|

|

(0.08 in) |

Maximum lateral wheel runout |

---- |

2.0 mm |

|

|

(0.08 in) |

Wheel axle bending limit |

---- |

0.25 mm |

|

|

(0.01 in) |

|

|

|

Front tire |

|

|

Tire type |

With tube |

---- |

Size |

90/90-21M/C 54S, 90/90-21M/C 54T |

---- |

|

(XT660R) |

|

|

120/70R 17M/C 58 H, 120/70ZR 17M/C |

---- |

|

58W, 120/70ZR 17M/C 58W (XT660X) |

|

Model/manufacturer |

TOURANCE FRONT/METZELER, |

---- |

|

SIRAC/MICHELIN (XT660R) |

|

|

DRAGON/PIRELLI, SPORTEC M1/ |

---- |

|

METZELER, RADIAL PILOT SPORT/ |

|

|

MICHELIN (XT660X) |

|

Tire pressure (cold) |

|

|

0 ~ 90 kg (0 ~ 198 lb) |

200 kPa (2.00 kgf/cm, 29 psi) (XT660R) |

---- |

|

210 kPa (2.10 kgf/cm, 30 psi) (XT660X) |

---- |

90 (198 lb) ~ Maximum load* |

200 kPa (2.00 kgf/cm, 29 psi) (XT660R) |

---- |

|

220 kPa (2.20 kgf/cm, 31 psi) (XT660X) |

---- |

|

* Load is the total weight of the cargo, |

|

|

rider, passenger and accessories. |

|

Off-road riding |

200 kPa (2.00 kgf/cm, 29 psi) (XT660R) |

---- |

Minimum tire tread depth |

---- |

1.6 mm |

|

|

(0.063 in) |

|

|

|

– 6 –

CHASSIS SPECIFICATIONS SPEC

Item |

Standard |

Limit |

|

|

|

Rear tire |

|

|

Tire type |

With tube |

---- |

Size |

130/80-17M/C 65S, 130/80-17M/C 65T |

---- |

|

(XT660R) |

|

|

160/60R 17M/C 69H, 160/60ZR 17M/C |

---- |

|

69W, 160/60ZR 17M/C 69W (XT660X) |

|

Model/manufacturer |

TOURANCE/METZELER, SIRAC A/ |

---- |

|

MICHELIN (XT660R) |

|

|

DRAGON/PIRELLI, SPORTEC M1/ |

---- |

|

METZELER, RADIAL PILOT SPORT/ |

|

|

MICHELIN (XT660X) |

|

Tire pressure (cold) |

|

|

0 ~ 90 kg (0 ~ 198 lb) |

200 kPa (2.00 kgf/cm, 29 psi) (XT660R) |

---- |

|

210 kPa (2.10 kgf/cm, 30 psi) (XT660X) |

---- |

90 (198 lb) ~ Maximum load* |

225 kPa (2.25 kgf/cm, 33 psi) (XT660R) |

---- |

|

230 kPa (2.30 kgf/cm, 33 psi) (XT660X) |

---- |

|

* Load is the total weight of the cargo, |

|

|

rider, passenger and accessories. |

|

Off-road riding |

200 kPa (2.00 kgf/cm, 29 psi) (XT660R) |

---- |

Minimum tire tread depth |

---- |

1.6 mm |

|

|

(0.063 in) |

|

|

|

– 7 –

ELECTRICAL SPECIFICATIONS/ |

|

|

|

|

||||||||

|

SPEC |

|

||||||||||

|

|

TIGHTENING TORQUE |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

ELECTRICAL SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

Item |

|

|

|

|

Standard |

|

|

|

|

Limit |

||

|

|

|

|

|

|

|

|

|

|

|

||

System voltage |

|

12 V |

|

|

|

|

|

|

|

|

---- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ignition system |

|

|

|

|

|

|

|

|

|

|

|

|

Ignition system type |

|

Transistorized coil ignition (digital) |

|

---- |

||||||||

Ignition timing |

|

5.0° BTDC at 1,450 r/min |

|

|

---- |

|||||||

Advancer type |

|

Electric |

|

|

|

|

|

|

|

---- |

||

Crankshaft position senor resistance/ |

192 ~ 288 Ω at 20 °C (68 °F) |

|

|

---- |

||||||||

color |

|

blue/yellow–green/white |

|

|

|

|

|

|||||

Transistorized coil ignition unit |

|

TBDF36/DENSO |

|

|

|

|

---- |

|||||

model/manufacturer |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TIGHTENING TORQUE |

|

|

|

|

|

|

|

|

|

|

|

|

ENGINE TIGHTENING TORQUES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Part to be tightened |

Part name |

Thread |

Q’ty |

Tightening torque |

Remarks |

|||||||

|

|

|

|

|

||||||||

|

size |

Nm |

|

m · kg |

|

ft · lb |

||||||

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

O2 sensor |

|

— |

|

M18 |

1 |

45 |

|

4.5 |

32 |

|

|

|

O2 sensor protector |

|

Bolt |

|

M6 |

2 |

10 |

|

1.0 |

7.2 |

|

|

|

CHASSIS TIGHTENING TORQUES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

Part to be tightened |

|

|

|

Thread |

Tightening torque |

Remarks |

||||||

|

|

|

size |

|

|

|

|

|

||||

|

|

|

Nm |

|

m · kg |

|

ft · lb |

|||||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

Engine mounting: |

|

|

|

|

|

|

|

|

|

|

|

|

Engine upper bracket and frame |

|

|

|

M10 |

65 |

|

6.5 |

47 |

|

|

||

Engine front bracket and frame |

|

|

|

M10 |

65 |

|

6.5 |

47 |

|

|

||

Engine front bracket and engine |

|

|

|

M10 |

65 |

|

6.5 |

47 |

|

|

||

Engine and frame |

|

|

|

M10 |

65 |

|

6.5 |

47 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

– 8 –

|

|

|

|

|

|

CABLE ROUTING |

|

SPEC |

|

|

|

|

|

|

EAS00035 |

|

|

|

|

|

|

|

|

|

CABLE ROUTING |

|

|

|

|

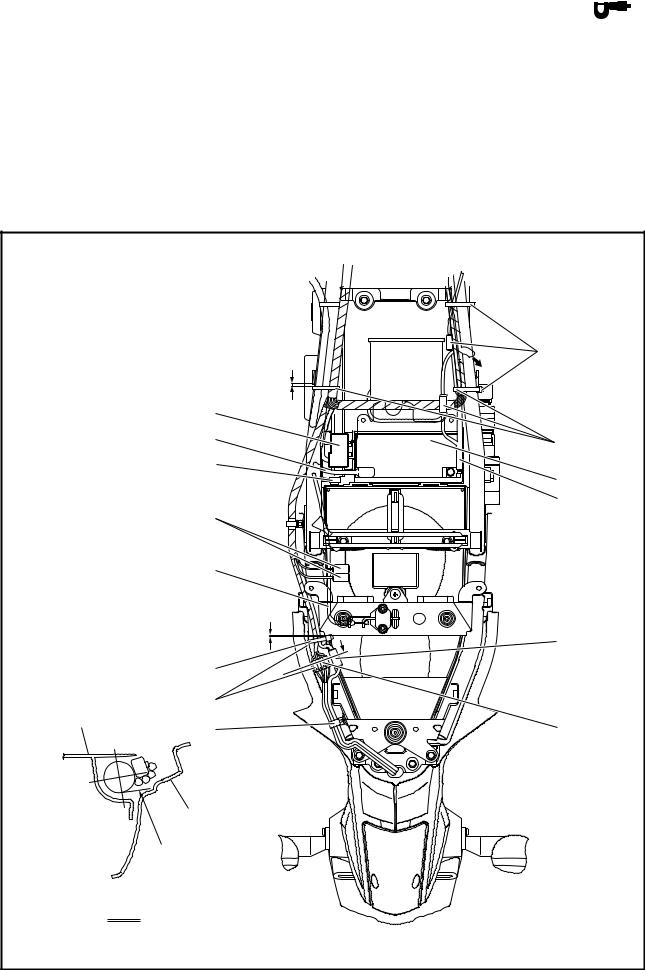

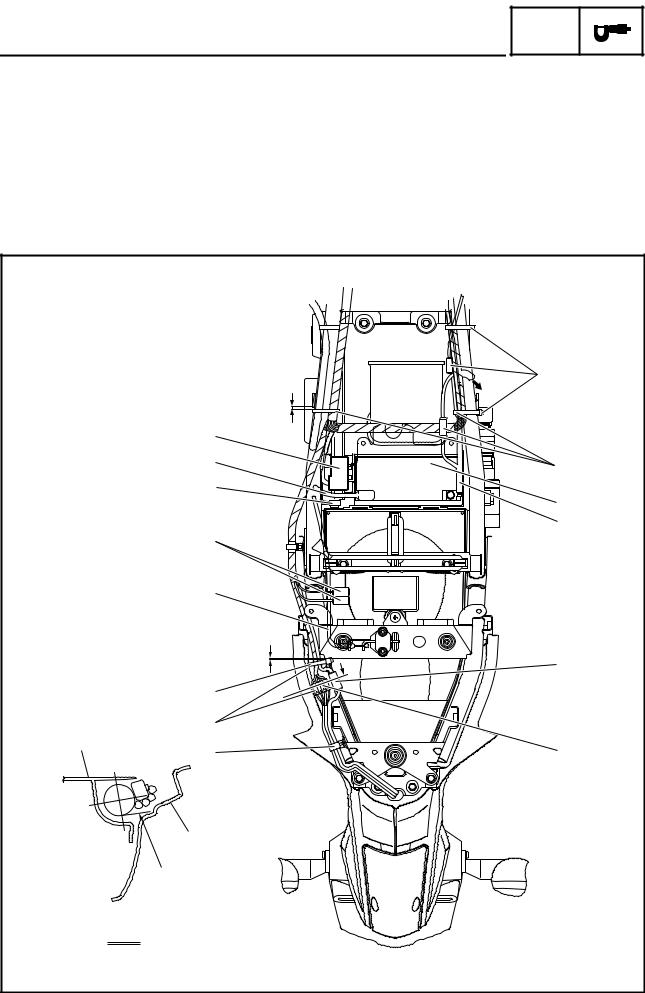

1 Front turn signal light lead (right) |

È Fasten the sub-wire harness and meter assem- |

|||

2 Meter assembly lead |

bly lead with a plastic band. Fasten the sub-wire |

|||

3 Auxiliary light lead |

harness at the white tape. Face the end of the |

|||

4 Front turn signal light lead (left) |

plastic band forward. |

|||

5 Headlight lead |

É Make sure that there is no slack in the meter |

|||

6 Sub-wire harness |

assembly lead between the meter assembly and |

|||

|

the plastic band. The rubber boot on the meter |

|||

|

assembly can be bent as shown. |

|||

|

|

|

|

|

|

|

|

|

|

– 9 –

CABLE ROUTING SPEC

ÊPlace the slack of the left and right front turn signal light leads between the headlight assembly

and front cowling assembly.

ËFasten the left and right front turn signal light leads to the headlight stay with a plastic locking tie, and then cut off the excess end of tie.

ÌPass the left and right front turn signal light leads in front of the headlight stay.

ÍOnly the left side is shown in this illustration. Route the right front turn signal light lead in the same way.

ÎPass the left and right front turn signal light leads between the headlight stay and front fork protector.

Ï XT660R

Ð0 ~ 5 mm (0 ~ 0.20 in) for both left and right sides

Ñ XT660X

– 10 –

|

|

|

|

|

|

|

CABLE ROUTING |

|

SPEC |

|

|

|

|

|

|

|

|

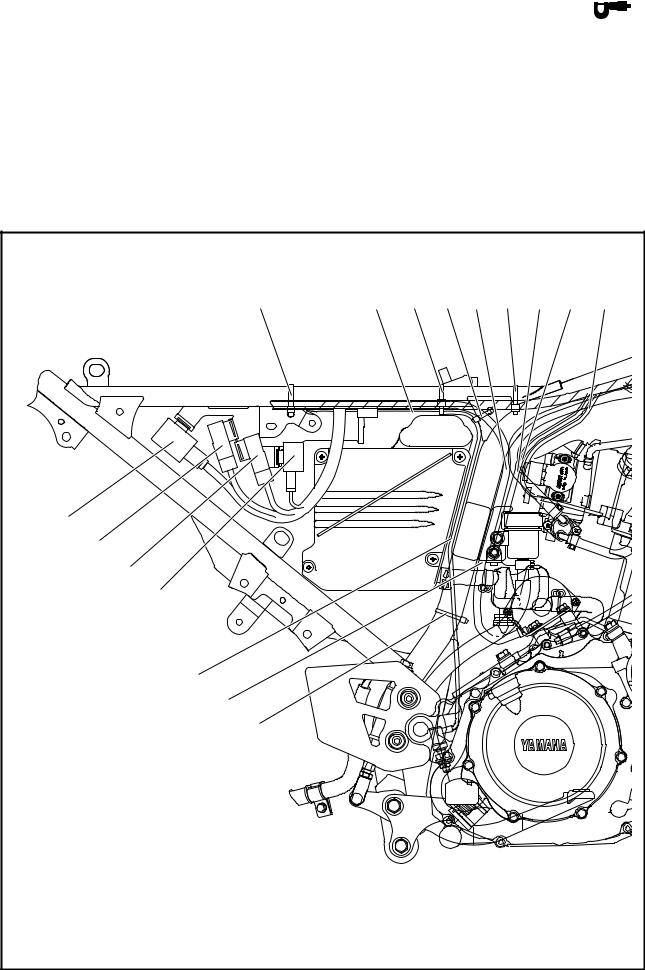

1 Rear brake light switch lead |

|

|

|

|

|

È Fasten the wire harness and negative battery |

|||||

2 Negative battery lead |

lead to the frame with a plastic locking tie. |

||||

3 Lean angle cut-off switch lead |

É Fasten the wire harness, negative battery lead, |

||||

4 Throttle position sensor lead |

and rear brake light switch lead to the frame with |

||||

5 Coolant temperature sensor lead |

a plastic locking tie. |

|

|

|

|

6 Turn signal/hazard relay |

Ê Fasten the rear brake light switch lead to the |

||||

7 Headlight relay |

frame with a plastic locking tie. |

||||

8 Radiator fan motor relay |

Ë Fasten the wire harness to the frame at the |

||||

9 Relay unit |

white tape with a plastic locking tie. |

||||

È |

1 |

É |

Ê |

2 |

Ë |

3 |

4 |

5 |

9 |

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

Í |

|

|

|

|

|

|

|

|

Ì |

|

|

|

|

|

|

|

|

Ê |

|

|

|

|

|

|

|

|

|

– 11 – |

|

|

|

|

|

|

|

CABLE ROUTING SPEC

ÌRoute the negative battery lead behind the lean angle cut-off switch bracket.

ÍRoute the rear brake light switch lead between the air filter case and the frame.

È |

1 |

É |

Ê |

2 |

Ë |

3 |

4 |

5 |

9 |

|

|

|

|

|

|

|

|

8 |

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

6 |

|

|

|

|

|

|

|

|

Í |

|

|

|

|

|

|

|

|

Ì |

|

|

|

|

|

|

|

|

Ê |

|

|

|

|

|

|

|

|

|

– 12 – |

|

|

|

|

|

|

|

CABLE ROUTING SPEC

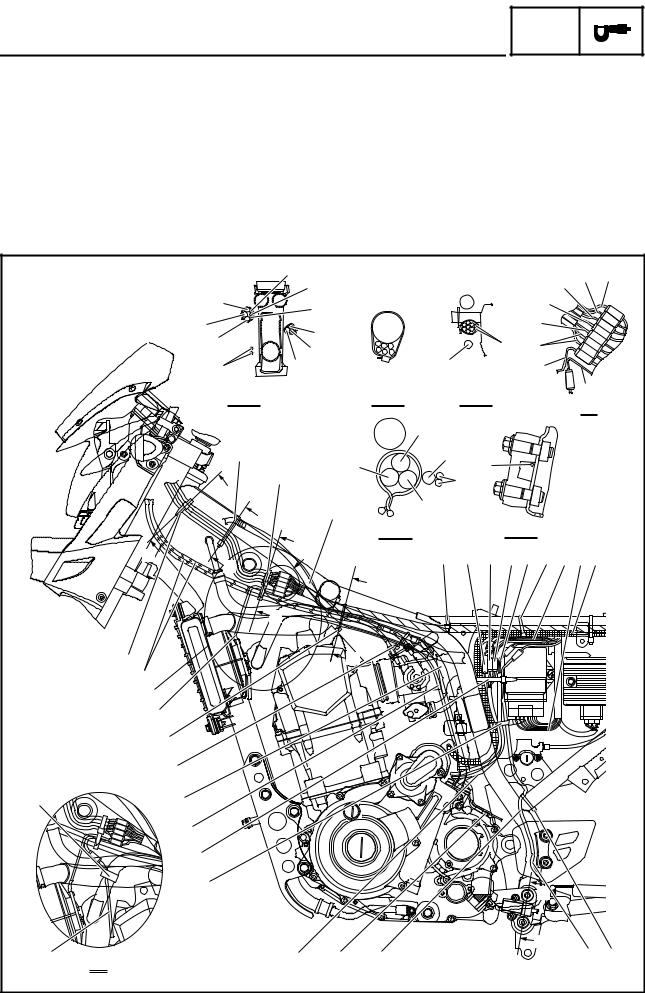

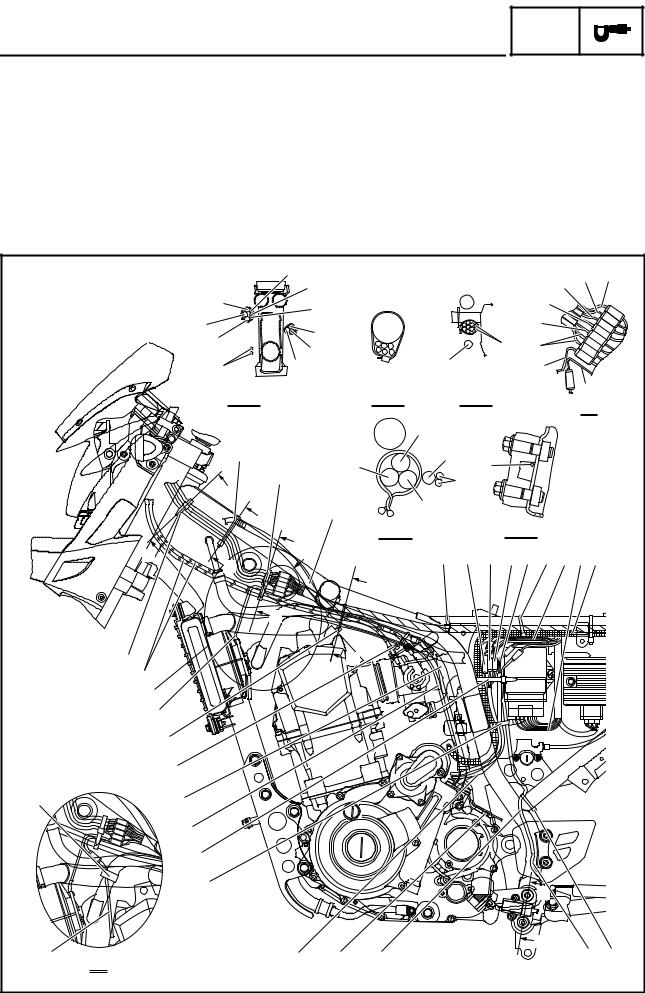

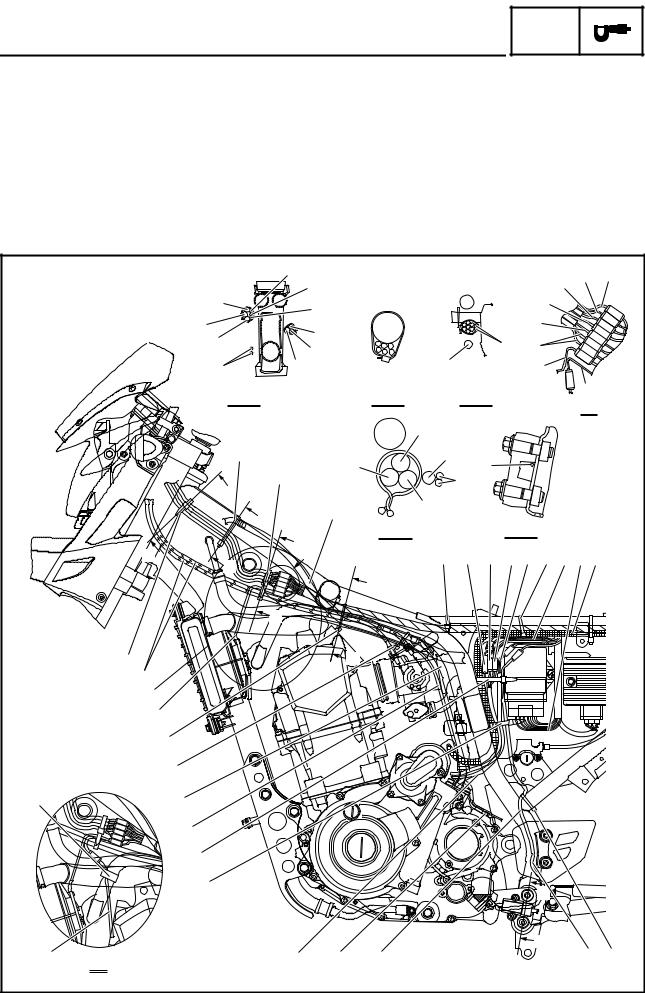

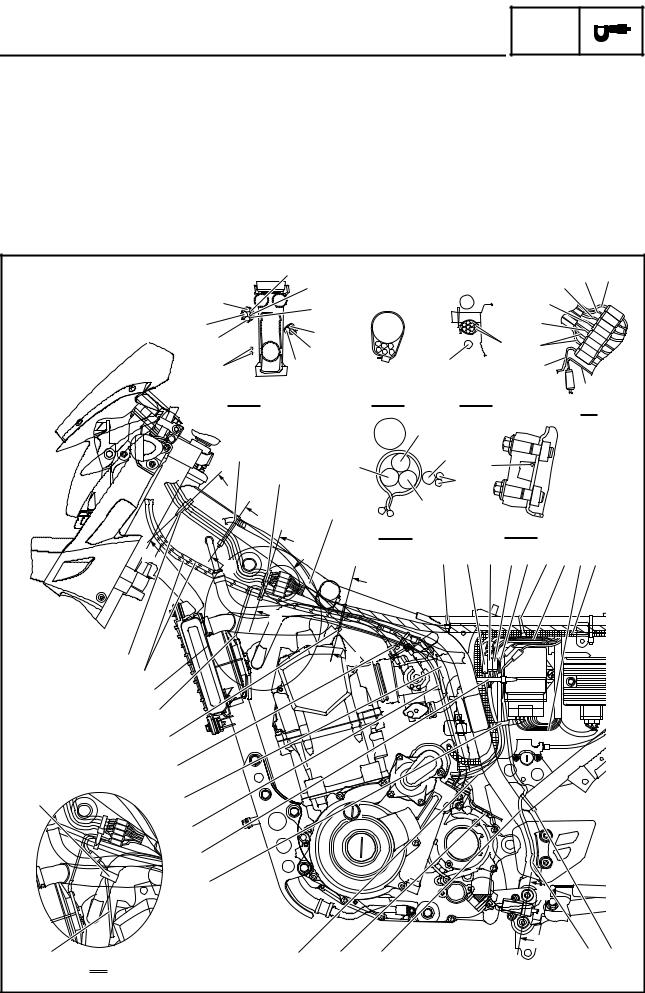

1 Neutral switch connector |

0 A.C. magneto lead |

K Immobilizer unit lead |

2 Crankshaft position sensor |

A Oil tank breather hose |

L Clutch cable |

coupler |

B Oil delivery hose 2 |

M Main switch lead |

3 A.C. magneto coupler |

C Radiator fan motor lead |

N O2 sensor lead |

4 Speed sensor lead |

D Throttle cable |

O Air-filter-to-air-cut-off-valve |

5 Intake air temperature sensor |

E Headlight lead |

hose |

lead |

F Meter assembly lead |

P Wire harness |

6 ECU lead |

G Left handlebar switch lead |

|

7 Starter motor lead |

H Right handlebar switch lead |

|

8 Sidestand switch lead |

I Front brake light switch lead |

|

9 Speed sensor |

J Clutch switch lead |

|

|

|

H |

|

|

|

G I J |

|

|

I |

|

|

|

|

|

G |

J |

|

|

|

H |

|

|

|

|

|

|

|

|

F |

K |

|

|

|

E |

|

|

|

|

|

||

|

E |

|

|

|

D F |

|

|

L |

|

|

|

||

|

|

|

|

|

||

|

|

|

B |

|

|

|

|

D |

M |

|

|

C |

|

|

A-A |

|

|

B-B |

C-C |

N |

|

|

|

D |

|||

|

|

|

|

|

|

|

|

|

|

|

P |

|

|

|

È |

É |

O |

A |

8 |

|

|

A |

|

D |

|

||

|

|

|

|

|

|

|

|

|

B |

Ê |

B |

|

|

|

|

E-E |

|

F-F |

||

|

|

C |

|

|

||

|

|

|

|

|

|

|

|

A |

D |

|

Ë 1 2 34 Ì 567 |

||

|

B |

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

Ó |

|

E |

|

|

|

|

D |

|

|

|

|

|

|

G |

|

|

|

|

|

|

C |

|

|

|

|

|

|

Ò |

|

|

|

|

|

|

Ñ |

|

|

|

|

|

Ô |

B |

|

|

|

|

|

|

A |

|

|

|

|

|

|

Ð |

|

|

|

|

|

|

Ï |

|

|

|

|

F |

|

|

|

|

|

|

|

N |

|

|

|

|

|

F |

G |

0 |

9 |

8 |

|

Î Í |

|

|

|

|

|

|

|

|

|

|

– 13 – |

|

|

|

|

CABLE ROUTING SPEC

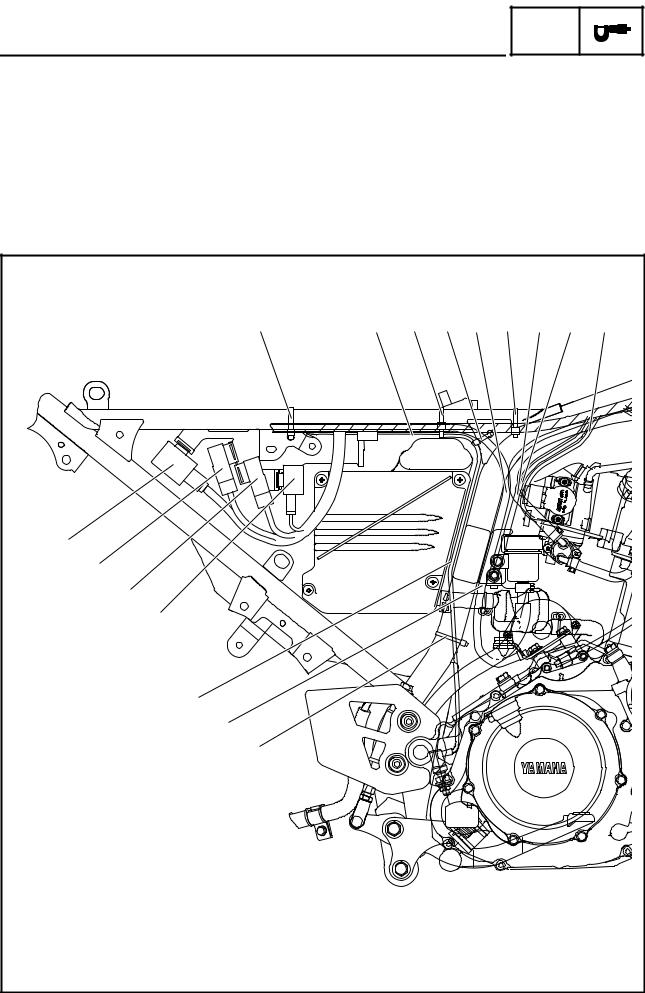

ÈFasten the left handlebar switch lead, right handlebar switch lead, headlight lead, meter assembly lead, front brake light switch lead, and clutch switch lead to the frame with a plastic locking tie. To fasten the leads, connect the couplers, and then turn the handlebar completely to the right.

ÉFasten the left handlebar switch lead, right handlebar switch lead, headlight lead, meter assembly lead, front brake light switch lead, clutch switch lead, radiator fan motor lead, and throttle cables with a plastic band. To fasten the leads and cables, connect the couplers, and then turn the handlebar completely to the right.

ÊRoute the oil tank breather hose on the outside of the throttle cables.

|

|

H |

|

|

|

G I J |

|

|

I |

|

|

|

|

|

G |

J |

|

|

|

H |

|

|

|

|

|

|

|

|

F |

K |

|

|

|

E |

|

|

|

|

|

||

|

E |

|

|

|

D F |

|

|

L |

|

|

|

||

|

|

|

|

|

||

|

|

|

B |

|

|

|

|

D |

M |

|

|

C |

|

|

A-A |

|

|

B-B |

C-C |

N |

|

|

|

D |

|||

|

|

|

|

|

|

|

|

|

|

|

P |

|

|

|

È |

É |

O |

A |

8 |

|

|

A |

|

D |

|

||

|

|

|

|

|

|

|

|

|

B |

Ê |

B |

|

|

|

|

E-E |

|

F-F |

||

|

|

C |

|

|

||

|

|

|

|

|

|

|

|

A |

D |

|

Ë 1 2 34 Ì 567 |

||

|

B |

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

Ó |

|

E |

|

|

|

|

D |

|

|

|

|

|

|

G |

|

|

|

|

|

|

C |

|

|

|

|

|

|

Ò |

|

|

|

|

|

|

Ñ |

|

|

|

|

|

Ô |

B |

|

|

|

|

|

|

A |

|

|

|

|

|

|

Ð |

|

|

|

|

|

|

Ï |

|

|

|

|

F |

|

|

|

|

|

|

|

N |

|

|

|

|

|

F |

G |

0 |

9 |

8 |

|

Î Í |

|

|

|

|

|

|

|

|

|

|

– 14 – |

|

|

|

|

CABLE ROUTING SPEC

ËFasten the wire harness to the frame at the white tape with a plastic locking tie.

ÌFasten the starter motor lead to the frame with a plastic locking tie.

ÍFasten the sidestand switch lead to the frame with a plastic locking tie.

ÎRoute the sidestand switch lead at the front end of the left side heel plate.

ÏFasten the neutral switch lead, crankshaft position sensor lead, sidestand switch lead, speed sensor lead, starter motor lead, and A.C. magneto lead with a plastic band.

ÐFasten the neutral switch lead, crankshaft position sensor lead, sidestand switch lead, speed sensor lead, and starter motor lead with a plastic

band.

ÑFasten the air-filter-to-air-cut-off-valve hose, oil tank breather hose, and oil delivery hose 2 with a plastic clamp.

|

|

H |

|

|

|

G I J |

|

|

I |

|

|

|

|

|

G |

J |

|

|

|

H |

|

|

|

|

|

|

|

|

F |

K |

|

|

|

E |

|

|

|

|

|

||

|

E |

|

|

|

D F |

|

|

L |

|

|

|

||

|

|

|

|

|

||

|

|

|

B |

|

|

|

|

D |

M |

|

|

C |

|

|

A-A |

|

|

B-B |

C-C |

N |

|

|

|

D |

|||

|

|

|

|

|

|

|

|

|

|

|

P |

|

|

|

È |

É |

O |

A |

8 |

|

|

A |

|

D |

|

||

|

|

|

|

|

|

|

|

|

B |

Ê |

B |

|

|

|

|

E-E |

|

F-F |

||

|

|

C |

|

|

||

|

|

|

|

|

|

|

|

A |

D |

|

Ë 1 2 34 Ì 567 |

||

|

B |

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

Ó |

|

E |

|

|

|

|

D |

|

|

|

|

|

|

G |

|

|

|

|

|

|

C |

|

|

|

|

|

|

Ò |

|

|

|

|

|

|

Ñ |

|

|

|

|

|

Ô |

B |

|

|

|

|

|

|

A |

|

|

|

|

|

|

Ð |

|

|

|

|

|

|

Ï |

|

|

|

|

F |

|

|

|

|

|

|

|

N |

|

|

|

|

|

F |

G |

0 |

9 |

8 |

|

Î Í |

|

|

|

|

|

|

|

|

|

|

– 15 – |

|

|

|

|

CABLE ROUTING SPEC

ÒFasten the wire harness, air-filter-to-air-cut-off- valve hose, and oil delivery hose 2 with a plastic

clamp.

ÓFasten the left handlebar switch lead, right handlebar switch lead, headlight lead, meter assembly lead, front brake light switch lead, and clutch switch lead with a plastic band.

Turn the handlebar completely to the right, and then fasten the left handlebar switch lead, right handlebar switch lead, headlight lead, meter assembly lead, front brake light switch lead, and clutch switch lead next to the steering head pipe with the plastic band. Be sure to connect the couplers before fastening the leads.

ÔFasten the O2 sensor lead and air-filter-to-air- cut-off-valve hose with a holder as shown in the illustration.

|

|

H |

|

|

|

G I J |

|

|

I |

|

|

|

|

|

G |

J |

|

|

|

H |

|

|

|

|

|

|

|

|

F |

K |

|

|

|

E |

|

|

|

|

|

||

|

E |

|

|

|

D F |

|

|

L |

|

|

|

||

|

|

|

|

|

||

|

|

|

B |

|

|

|

|

D |

M |

|

|

C |

|

|

A-A |

|

|

B-B |

C-C |

N |

|

|

|

D |

|||

|

|

|

|

|

|

|

|

|

|

|

P |

|

|

|

È |

É |

O |

A |

8 |

|

|

A |

|

D |

|

||

|

|

|

|

|

|

|

|

|

B |

Ê |

B |

|

|

|

|

E-E |

|

F-F |

||

|

|

C |

|

|

||

|

|

|

|

|

|

|

|

A |

D |

|

Ë 1 2 34 Ì 567 |

||

|

B |

|

|

E |

|

|

|

|

|

|

|

|

|

|

|

C |

|

|

|

|

|

Ó |

|

E |

|

|

|

|

D |

|

|

|

|

|

|

G |

|

|

|

|

|

|

C |

|

|

|

|

|

|

Ò |

|

|

|

|

|

|

Ñ |

|

|

|

|

|

Ô |

B |

|

|

|

|

|

|

A |

|

|

|

|

|

|

Ð |

|

|

|

|

|

|

Ï |

|

|

|

|

F |

|

|

|

|

|

|

|

N |

|

|

|

|

|

F |

G |

0 |

9 |

8 |

|

Î Í |

|

|

|

|

|

|

|

|

|

|

– 16 – |

|

|

|

|

|

|

|

|

|

|

|

|

CABLE ROUTING |

|

SPEC |

|

|

|

|

|

|

|

|

|

|

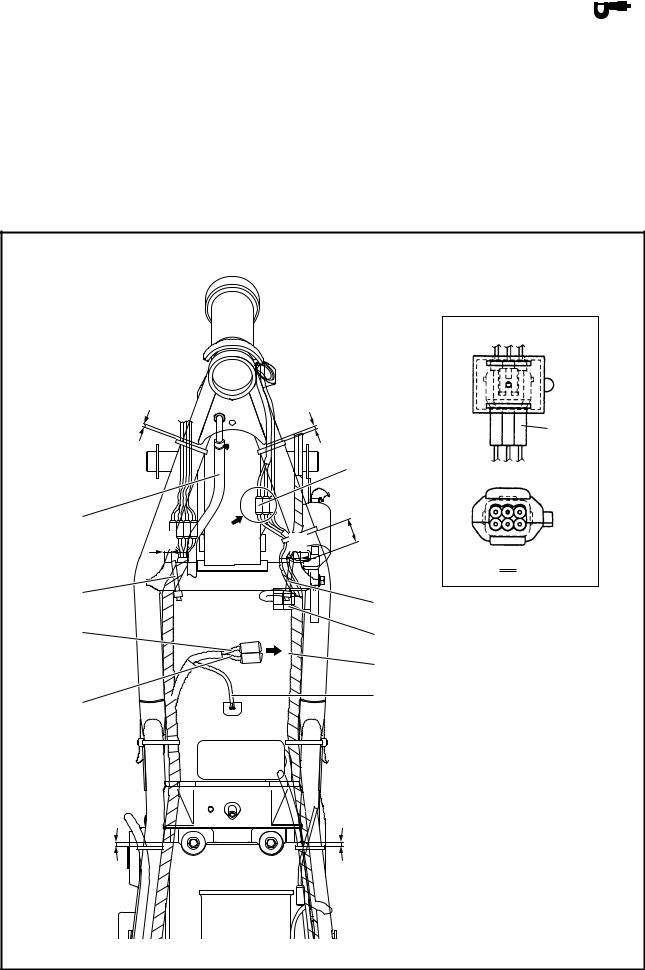

1 Immobilizer unit coupler |

|

|

|

|

|

|

È 0 |

~ 10 mm (0 ~ 0.39 in) |

|||||

2 Intake air temperature sensor |

É 30 ~ 40 mm (1.18 ~ 1.57 in) |

|||||

3 Fuel injector lead |

Ê 5 |

~ 15 mm (0.20 ~ 0.59 in) |

||||

4 Fuel pump lead |

Ë Fasten the wire harness to the frame with a plas- |

|||||

5 Fuel sender lead |

tic locking tie. |

|||||

6 Oil tank breather hose |

Ì To the fuel tank |

|||||

|

Í 0 |

~ 5 mm (0 ~ 0.20 in) |

||||

|

Î Europe, ZA |

|||||

Î

È |

È |

1 |

|

|

|

|

|

1 |

6 |

|

É |

A |

|

|

Ê |

Ê |

|

|

|

A |

Ë |

|

Ë |

|

|

|

5 |

|

2 |

|

|

|

|

|

Ì |

4 |

|

3 |

|

|

Í |

Í |

– 17 –

|

|

|

|

|

|

|

CABLE ROUTING |

|

SPEC |

|

|

|

|

|

|

|

|

1 Battery |

|

|

|

|

|

È Fasten the tail/brake light lead with two plastic |

|||||

2 Negative battery lead |

locking ties so that the coupler is positioned to |

||||

3 Tail/brake light coupler |

the inside of where the relays (turn signal/hazard |

||||

4 Rear turn signal light connector |

relay, headlight relay, radiator fan motor relay, |

||||

5 Seat lock cable |

and relay unit) branch off from the wire harness. |

||||

6 Anti-theft alarm coupler |

É To relays (turn signal/hazard relay, headlight |

||||

7 Fuse box 2 |

relay, radiator fan motor relay, and relay unit) |

||||

8 Positive battery lead |

|

|

|

|

|

9 Fuse box 1 |

|

|

|

|

|

0 Rear fender |

|

|

|

|

|

A Rear fender cover |

|

|

|

|

|

0

A-A

È

|

É |

|

Ï |

9 |

|

8 |

Ê |

|

|

7 |

|

|

1 |

|

2 |

6 |

|

5 |

|

Î |

A |

3 |

|

Í A

A

Ì |

|

Ë |

4 |

A

Ð

– 18 –

CABLE ROUTING SPEC

ÊFasten the wire harness with plastic locking ties, making sure to install the ties around the taped

sections of the harness. Do not install the plastic locking ties around the sections of the leads that are not covered by the tape and do not fasten the negative battery lead coupler.

ËFasten the rear turn signal light leads and tail/ brake light lead with a lead holder.

ÌConnect the couplers so that they are not pinched between the rear fender and rear fender cover.

ÍFasten the wire harness to the frame with a plastic locking tie.

Î 0 ~ 5 mm (0 ~ 0.20 in) Ï 0 ~ 10 mm (0 ~ 0.39 in)

ÐThe tail/brake light coupler and the rear turn signal light lead should not be lower than the line shown in the illustration.

0

A-A

È

|

É |

|

Ï |

9 |

|

8 |

Ê |

|

|

7 |

|

|

1 |

|

2 |

6 |

|

5 |

|

Î |

A |

3 |

|

Í A

A

Ì |

|

Ë |

4 |

A

Ð

– 19 –

Loading...

Loading...