YAMAHA XVZ13TF(L) 1999 SERVICE MANUALS

EAS00001

XVZ13TF (L)

SERVICE MANUAL

1999 by Yamaha Motor Co., Ltd.

First edition, January 1999

All rights reserved. Any reproduction or

unauthorized use without the written

permission of Yamaha Motor Co., Ltd

is expressly prohibited.

NOTE:

CAUTION:

EAS00003

NOTICE

This manual was produced by the Y amaha Motor Company , Ltd. primarily for use by Y amaha dealers

and their qualified mechanics. It is not possible to include all the knowledge of a mechanic in one manu-

al. Therefore, anyone who uses this book to perform maintenance and repairs on Yamaha vehicles

should have a basic understanding of mechanics and the techniques to repair these types of vehicles.

Repair and maintenance work attempted by anyone without this knowledge is likely to render the ve-

hicle unsafe and unfit for use.

This model has been designed and manufactured to perform within certain specifications in regard to

performance and emissions. Proper service with the correct tools in necessary to ensure that the ve-

hicle will operate as designed. If there is any question about a service procedure, it is imperative that

you contact a Y amaha dealer for any service information changes that apply to this model. This policy

is intended to provide the customer with the most satisfaction from his vehicle and to conform with fed-

eral environmental quality objectives.

Y amaha Motor Company, Ltd. is continually striving to improve all its models. Modifications and signifi-

cant changes in specifications or procedures will be forwarded to all authorized Y amaha dealers and

will appear in future editions of this manual where applicable.

This Service Manual contains information regarding periodic maintenance to the emission control

system. Please read this material carefully.

Designs and specifications are subject to change without notice.

EAS00004

IMPORTANT INFORMATION

Particularly important information is distinguished in this manual by the following notations.

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR

SAFETY IS INVOLVED!

Failure to follow WARNING instructions could result in severe injury or death

to

the motorcycle operator, a bystander or a person inspecting or repairing the

motorcycle.

A CAUTION indicates special precautions that must be taken to avoid damage

to the motorcycle.

NOTE: A NOTE provides key information to make procedures easier or clearer.

12

4

5

7

3

8

6

EAS00007

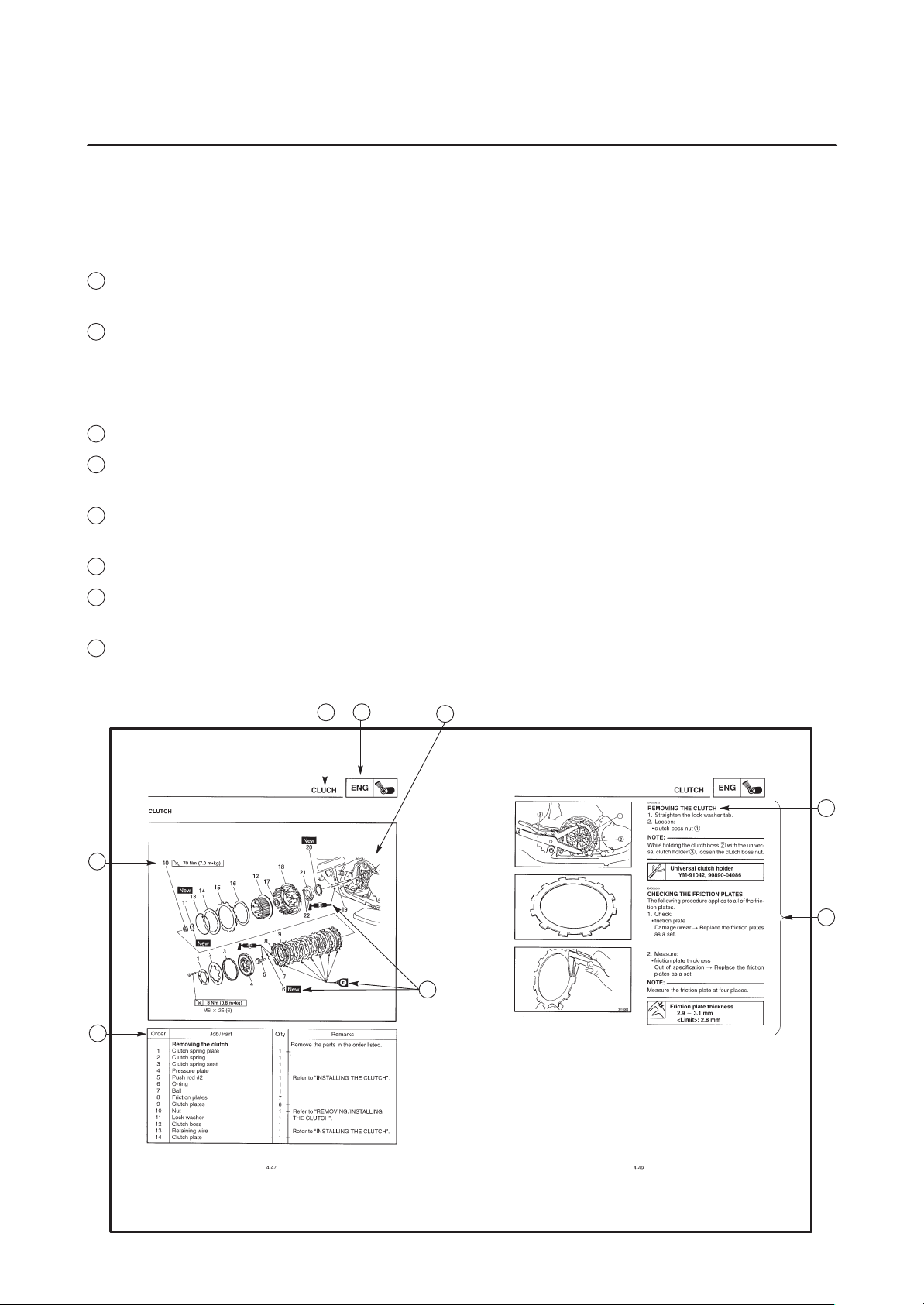

HOW TO USE THIS MANUAL

This manual is intended as a handy , easy-to-read reference book for the mechanic. Comprehensive

explanations of all installation, removal, disassembly , assembly , repair and inspection procedures are

laid out with the individual steps in sequential order.

1

The manual is divided into chapters. An abbreviation and symbol in the upper right corner of each

page indicate the current chapter. Refer to “SYMBOLS” on the following page.

2

Each chapter is divided into sections. The current section title is shown at the top of each page,

except in Chapter 3 (“Periodic Inspections and Adjustments”), where the sub-section title(-s) appear.

(In Chapter 3, “Periodic Inspection and Adjustments”, the sub-section title appears at the top of each

page, instead of the section title.)

3

Sub-section titles appear in smaller print than the section title.

4

To help identify parts and clarify procedure steps, there are exploded diagrams at the start of each

removal and disassembly section.

5

Numbers are given in the order of the jobs in the exploded diagram. A circled number indicates a

disassembly step.

6

Symbols indicate parts to be lubricated or replaced (see “SYMBOLS”).

7

A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc.

8

Jobs requiring more information (such as special tools and technical data) are described sequen-

tially .

22

1

3

5

7

9

2

4

8

6

24 25

2321

19 2018

16 1715

1413

11 12

10

GEN

INFO

SPEC

ENG

CARB

ELECCHAS

COOL

CHK

ADJ

TRBL

SHTG

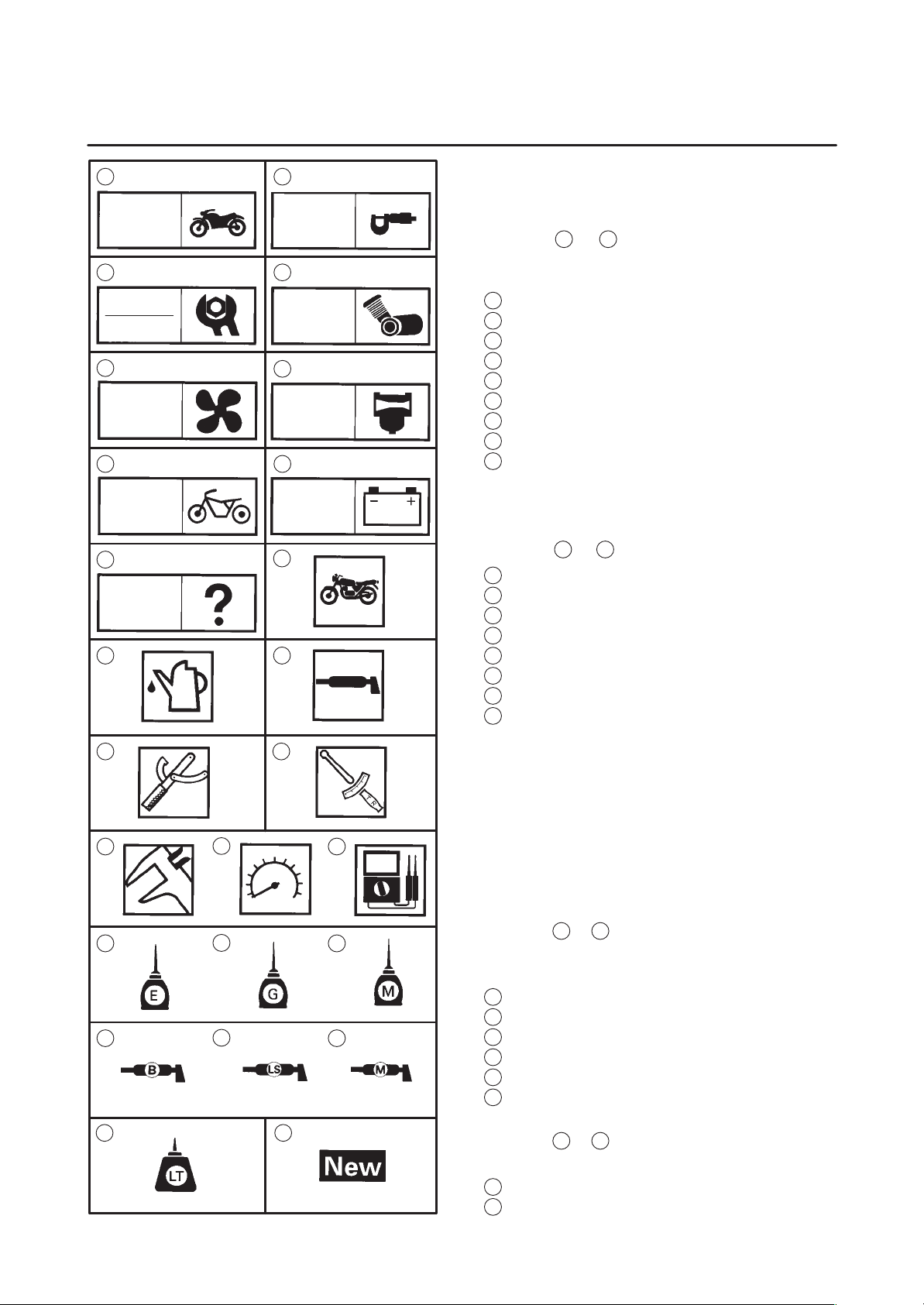

EAS00008

SYMBOLS

The following symbols are not relevant to every

vehicle.

Symbols

1

to

9

indicate the subject of each

chapter.

1

General information

2

Specifications

3

Periodic inspections and adjustments

4

Engine

5

Cooling system

6

Carburetor(-s)

7

Chassis

8

Electrical system

9

Troubleshooting

Symbols

10

to

17

indicate the following.

10

Serviceable with engine mounted

11

Filling fluid

12

Lubricant

13

Special tool

14

Tightening torque

15

Wear limit, clearance

16

Engine speed

17

Electrical data

Symbols

18

to

23

in the exploded diagrams indi-

cate the types of lubricants and lubrication

points.

18

Engine oil

19

Gear oil

20

Molybdenum disulfide oil

21

Wheel bearing grease

22

Lithium soap base grease

23

Molybdenum disulfide grease

Symbols

24

to

25

in the exploded diagrams indi-

cate the following:

24

Apply locking agent (LOCTITE

R

)

25

Replace the part

GENERAL INFORMATION

SPECIFICATIONS

PERIODIC INSPECTIONS AND

ADJUSTMENTS

ENGINE

COOLING SYSTEM

CARBURETORS

CHASSIS

ELECTRICAL SYSTEM

TROUBLESHOOTING

GEN

INFO

1

SPEC

2

3

ENG

4

COOL

5

CARB

6

CHAS

7

ELEC

8

TRBL

SHTG

9

CHK

ADJ

EAS00012

TABLE OF CONTENTS

GEN

INFO

1

GEN

INFO

CONTENTS

GENERAL INFORMATION

MOTORCYCLE IDENTIFICATION 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VEHICLE IDENTIFICATION NUMBER 1-1. . . . . . . . . . . . . . . . . . . . . . . . .

MODEL CODE 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FEA TURES 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CRUISE CONTROL 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIGITAL SPEEDOMETER 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AUDIO SYSTEM 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IMPORTANT INFORMATION 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PREPARATION FOR REMOVAL AND DISASSEMBLY 1-13. . . . . . . . . .

REPLACEMENT PARTS 1-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GASKETS, OIL SEALS AND O-RINGS 1-13. . . . . . . . . . . . . . . . . . . . . . . .

LOCK WASHERS/PLATES AND COTTER PINS 1-14. . . . . . . . . . . . . . . .

BEARINGS AND OIL SEALS 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CIRCLIPS 1-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CHECKING THE CONNECTIONS 1-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIAL TOOLS 1-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GEN

INFO

1-1

MOTORCYCLE IDENTIFICATION

GEN

INFO

EAS00014

GENERAL INFORMATION

MOTORCYCLE IDENTIFICATION

EAS00017

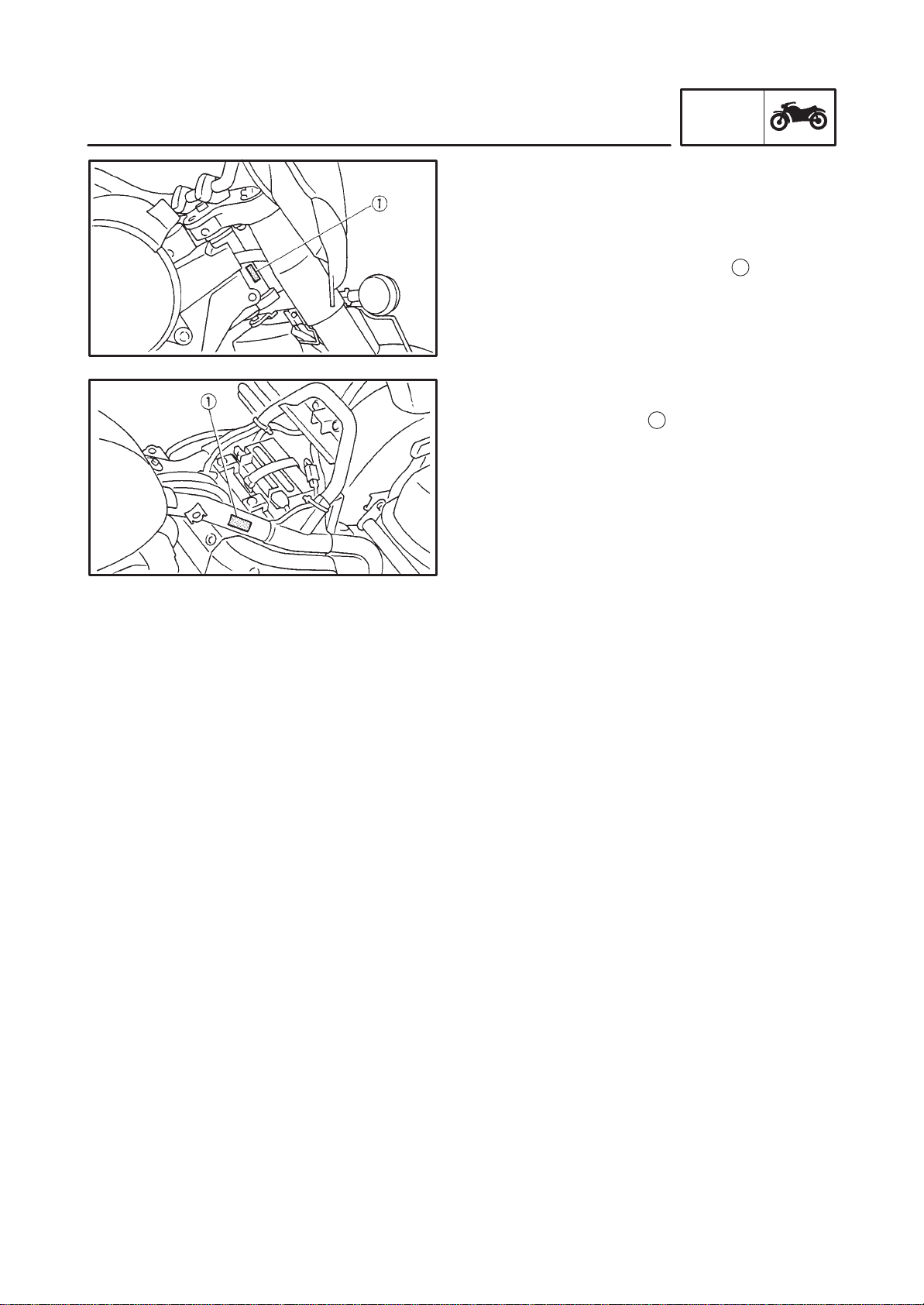

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number

1

is stamped

into the right side of the steering head.

EAS00018

MODEL CODE

The model code label

1

is affixed to the frame.

This information will be needed to order spare

parts.

1-2

FEATURES

GEN

INFO

CAUTION:

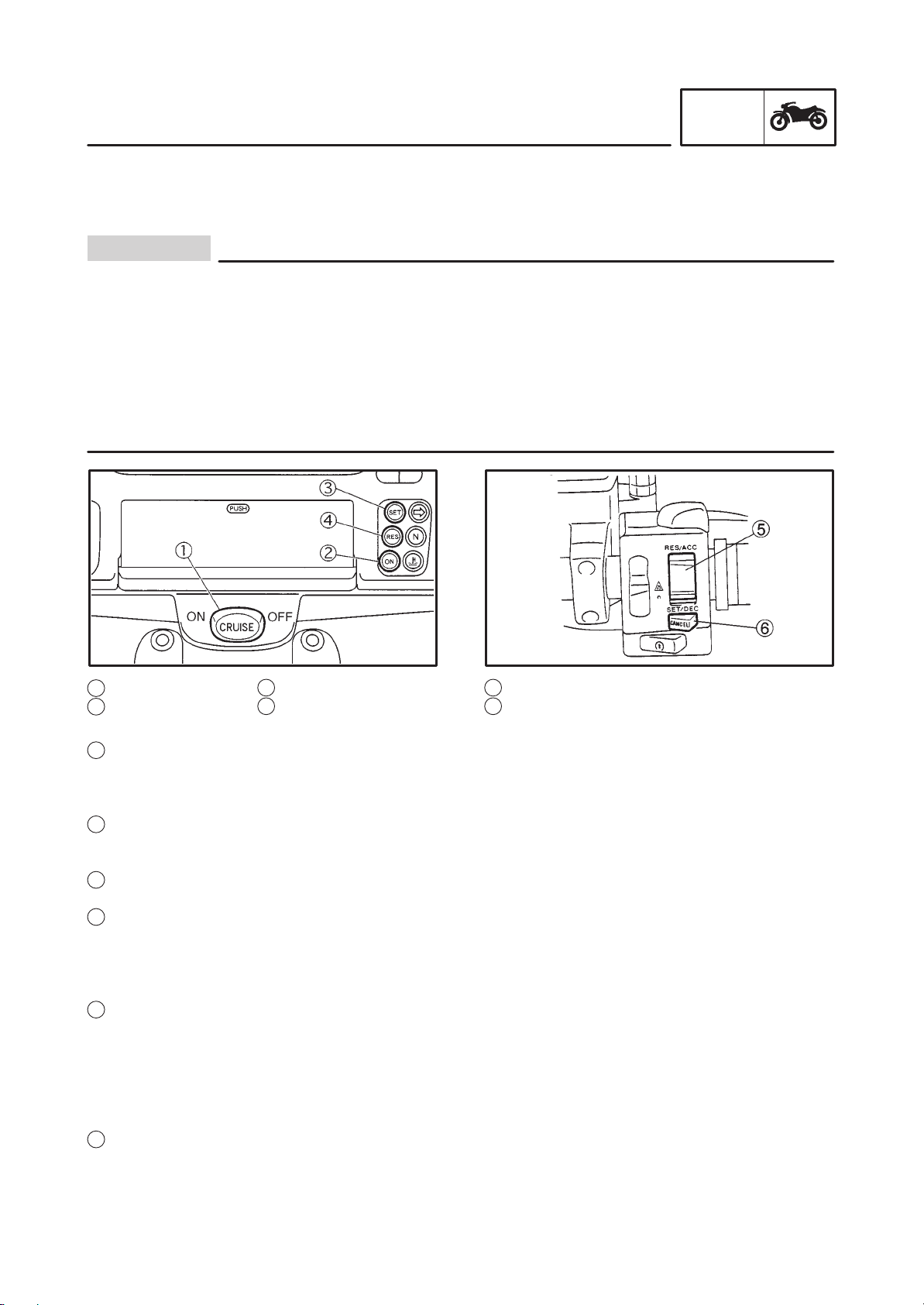

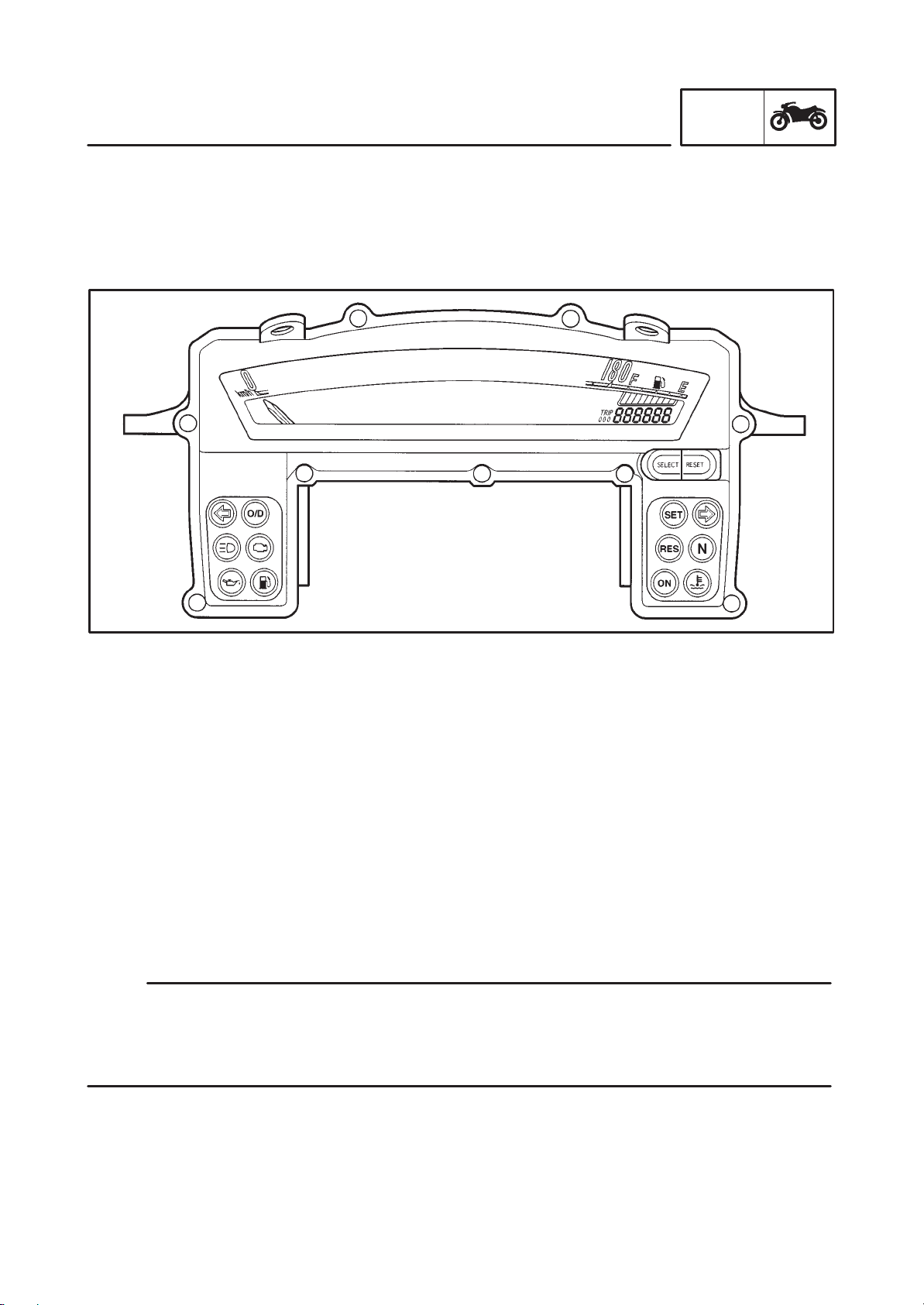

3 “SET” indicator light

4 “RES” indicator light

5 Cruise control switch

6 “CANCEL” switch

EAS00019

FEATURES

CRUISE CONTROL

This motorcycle is equipped with cruise control which designed to maintain a set speed.

Giving a severe load like using as a trailer/tractor or driving on a steep slope could remove the

cruise control.

Do not set the cruise control while idling the rear tires for the preparation.

Do not disassemble the vacuum pump.

Never remove the cruise control actuator rubber cover. When putting it back, bolts or other

parts will be caught and the cruise control wire can be locked.

Do not remove the air cleaner cover of the vacuum pump in order not to cause a malfunction in

cancellation of the cruise control by dirt, trash etc.

Do not drive without holding the steering wheel whether the cruise control is ON or OFF.

1

“CRUISE” switch

2

“ON” indicator light

Cruise control switch functions

1

“CRUISE” switch

Push this switch to “ON” when the cruise control system is preset. The “ON” indicator light will come on.

Once the switch is released it will return to the center (Hold) position.

To cancel the cruise control system, push the switch to “OFF” or main switch to the “OFF” position.

2

“ON” indicator light

This indicator light comes on when the cruise control systems preset (when “ON” is selected by the

“CRUISE” switch).

3

“SET” indicator light

This indicator light comes on when the motorcycle is operating at a set speed.

4

“RES” indicator light

This light comes on when the set speed, which is cancelled by any steps, is memorized and when the

operating speed is in the range of approx. 50-130 km/h.

If the resume system is operated while this light is on, it continues flashing until the speed returns to that

memorized.

5

Cruise control switch

This switch is capable of the following controls.

Refer to the “Operation chart” for details.

Set speed ride

Minute adjustment of set speed

Consecutive adjustment of set speed

“RESUME” system

6

“CANCEL” switch

Push this switch to cancel the set speed ride in the cruise control system.

1-3

FEATURES

GEN

INFO

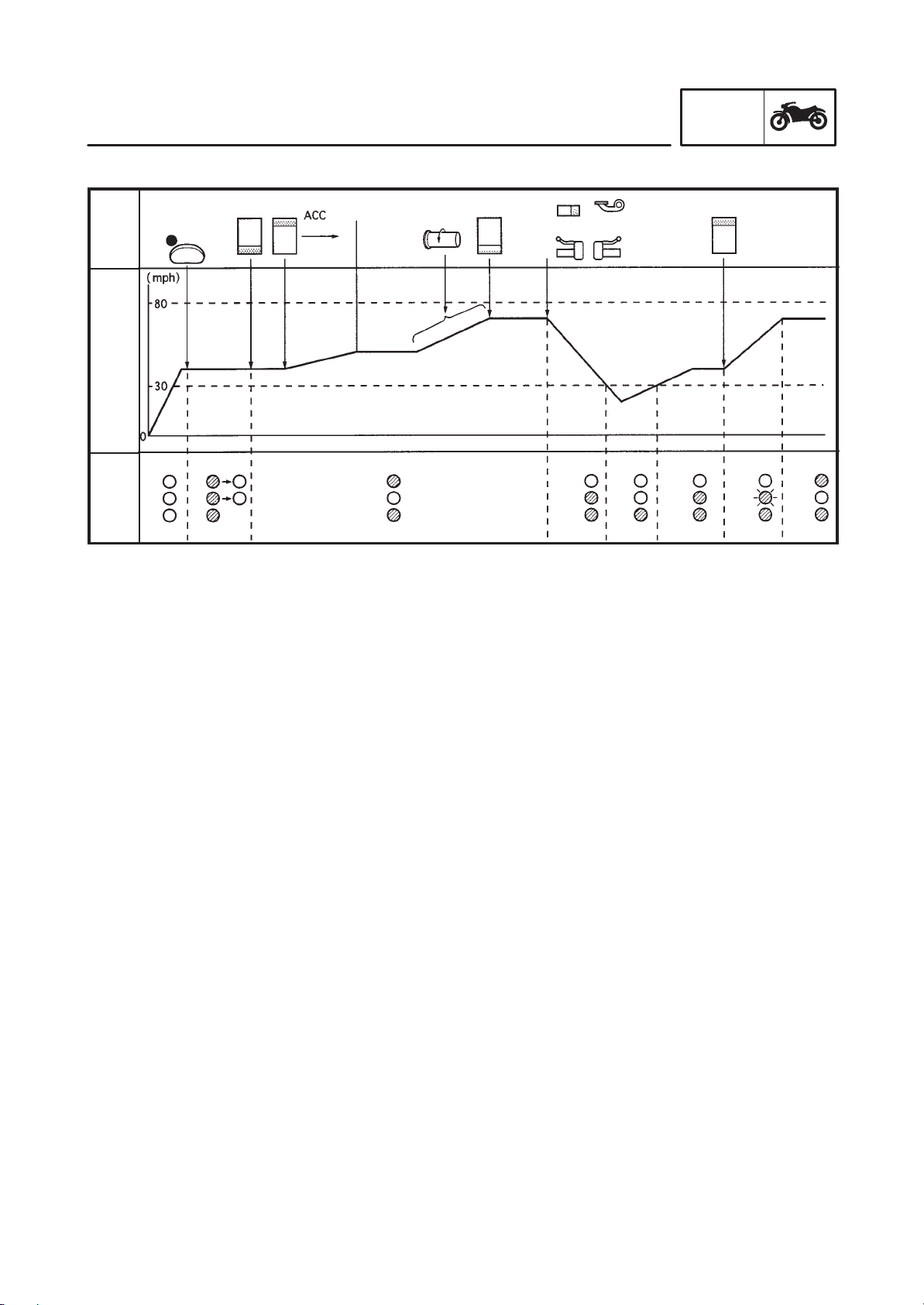

SET

CRUISE

SET

RES

ON

(After1.4sec)

SET

RES

ON

SET

RES

ON

Flash

Out of range

Out of range

Mannual

acceleration

cancel

Rear brake

Clutch

SET Front brake

Resume

Cruise SW

ON

Operation chart

Opera-

tion

Speed

Indica-

tor

Cruise control function

1) The cruise control can only be activated when riding in 4th, 5th gear and traveling between the

speed of 50 and 130 km/h.

2) To operate the system, the “CRUISE” switch should be turned “ON”.

3) When push the cruise control switch to “SET”, the cruise control system will be set the set speed.

4) By pushing (in shorter than 0.5 seconds), the control switch in the direction of either “ACC” or “DEC”,

the set speed can be changed in increments or decrements of approximately 1.6 km/h.

5) If the control switch is held in the “ACC” or “DEC” position (longer than 0.5 seconds), the speed can

be successively increased or decreased slowly.

6) The cruise control will be deactivated if the front or rear brake is applied or if the clutch is disengaged

or if the “CANCEL” switch is pushed.

7) After canceling, the speed is returned to the one set before the cancellation by pushing the control

switch once in the “RES” direction.

8) Auto cruise function is canceled;

a. In case of current speed drops 8 km/h less than the originally set speed.

b. In case of gear position is moved to gears other than of 4th, 5th.

c. In case of systems fines any faulty signal in the following systems.

Control unit

Actuator cable

Logical error in cut off signal

Error signal in speed sensor signal

Error signal in engine revolution

Cruise control switch lead (“SET”/“RES”)

9) When main switch is cut off once, “resume” is canceled.

1-4

FEATURES

GEN

INFO

NOTE:

DIGITAL SPEEDOMETER

This speedometer is equipped with:

An odometer

Two trip odometers

A fuel reserve trip meter

A clock

Odometer and trip meter modes

1) Selecting a mode

Push the “SELECT” button to change between the odometer mode “ODO” and the trip odometer

modes “TRIP 1” and “TRIP 2” in the following order.

“ODO” “TRIP 1” “TRIP 2” “ODO”

If the fuel level indicator light comes on, the odometer display will automatically change to the fuel re-

serve trip meter mode “TRIP F” and start counting the distance traveled from that point.

Push the “SELECT” button to change between the fuel reserve tripmeter, trip odometer and odometer

modes in the following order:

“TRIP F” “TRIP 1” “TRIP 2” “ODO” “TRIP F”

2) Resetting a meter

T o reset a trip odometer to 0.0, select it by pushing the “SELECT” button and push the “RESET” button.

To reset the fuel reserve trip meter, select it by pushing the “SELECT” button and push the “RESET”

button. The display will return to prior mode (“ODO”, “TRIP 1” or “TRIP 2”).

If you do not reset the fuel reserve trip meter manually , it will automatically reset and retum to “TRIP 1”

after refueling and the motorcycle has traveled both 5km.

If the fuel reserve trip meter appears, and a different mode was NOT selected prior to resetting the fuel

reserve trip meter, the display always returns to the “TRIP 1” mode.

If the fuel reserve trip meter appears, and a different mode was selected prior to resetting the fuel

reserve trip meter, the display automatically returns to the prior mode.

1-5

FEATURES

GEN

INFO

NOTE:

Clock mode

To change the display to the clock mode, push both the “SELECT” and “RESET” buttons.

To change the display back to odometer mode, push the “RESET” button.

1) To set the clock

a. Push both the “SELECT” and “RESET” buttons for at least two seconds.

b. When the hour digits start flashing, push the “RESET” button to set the hours.

c. Push the “SELECT” button and the minute digits will start flashing.

d. Push the “RESET” button to set the minutes.

e. Push the “SELECT” button to start the clock.

After setting the clock, be sure to push the “SELECT” button before turning the main switch to “OFF”,

otherwise the clock will not be set.

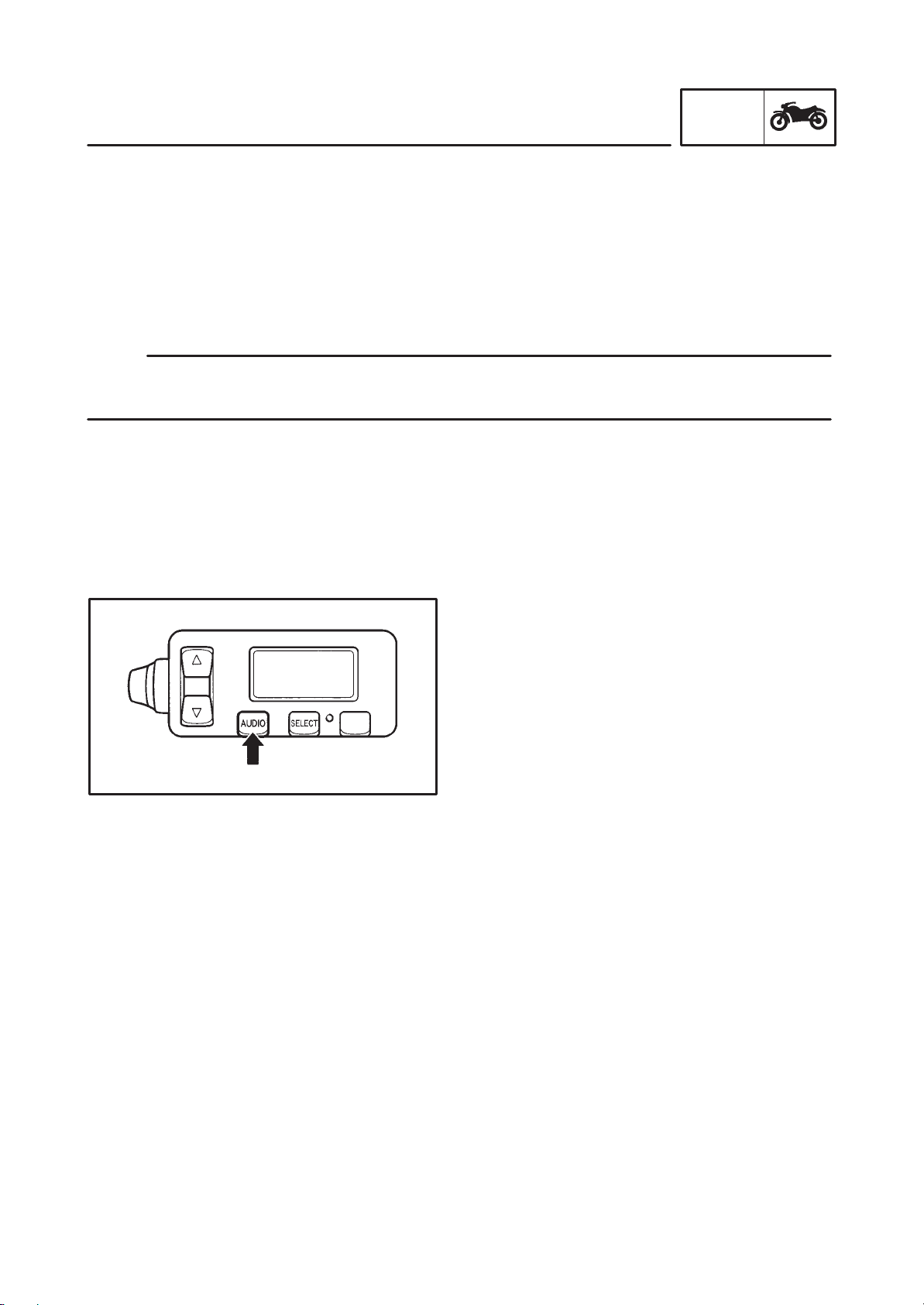

AUDIO SYSTEM

1. POWERING ON/OFF THE AUDIO SYS-

TEM

Turning on/off the audio system

Turn the main switch to the “ACC” or “ON” posi-

tion.

To turn on the power for the audio system,

push the audio button “AUDIO”.

To turn off the audio system, push the audio

button “AUDIO” continuously for 1 second or

more.

1-6

FEATURES

GEN

INFO

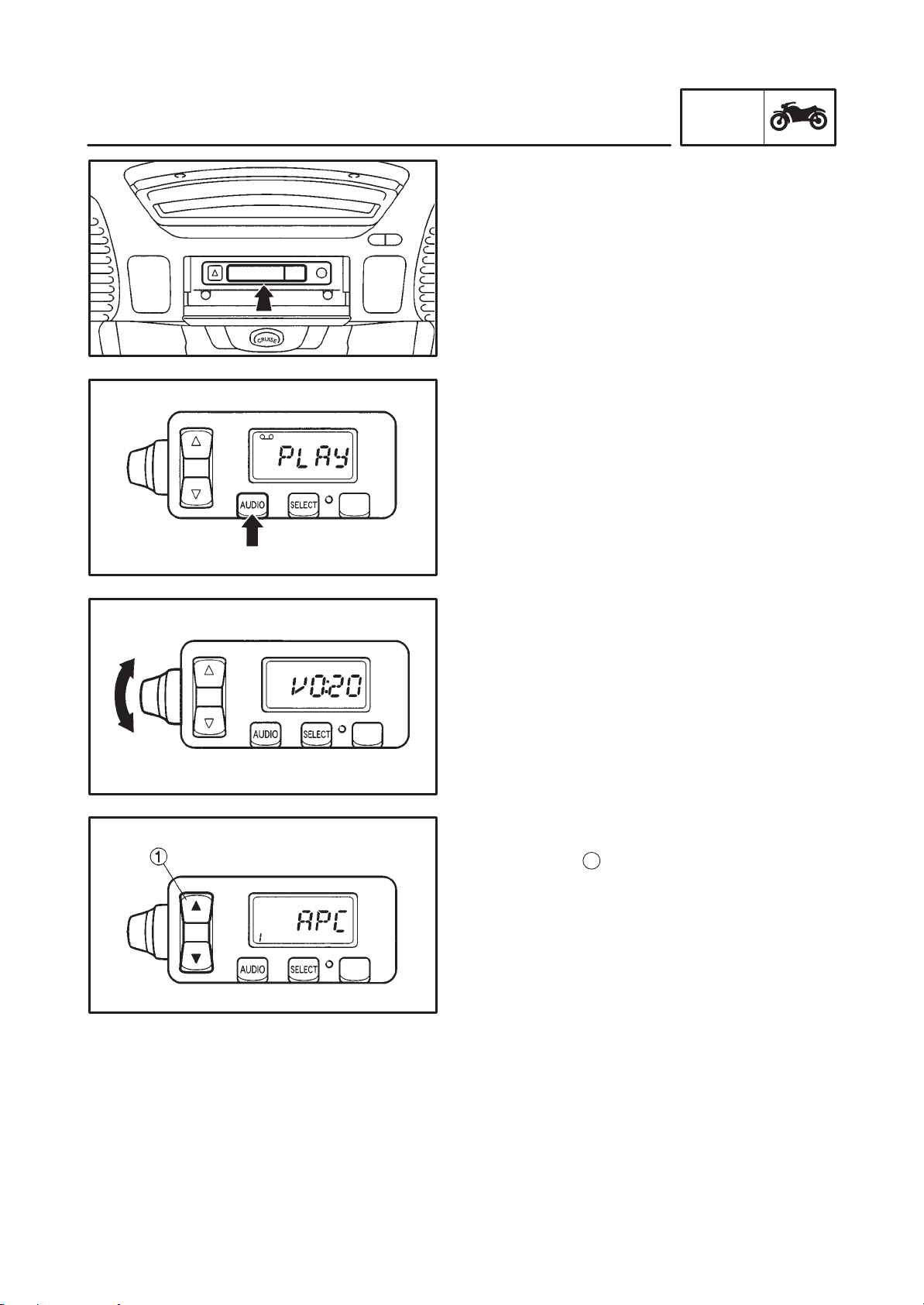

2. CASSETTE DESK OPERATION

The cassette tape deck has the following func-

tions.

Song search

Change tape play direction

Dolby noise reduction

Blank tape skip

a. Turn the main switch to the “ACC” or “ON”

position and push the “AUDIO”button to turn

on the power.

b. Insert a cassette tape into the cassette deck.

c. If a tape is aleady loaded in the cassette

deck, push the “AUDIO” button until “PLAY”

appears.

The tape will start playing.

d. Turn the volume control knob to set the vol-

ume level. The volume level can be set from

0 to 30.

Track searching

To search for a song on the tape, push the up-

down switch

1

for less than one second. The

“APC” (auto program control) indicator will ap-

pear in the display.

Push the witch once for each song to be skipped.

Pushing the switch in direction “n” will search in

the forward direction.

Pushing the switch in direction “o” will search in

the reserve direction.

When searching in the forward direction, the num-

ber of song that are being skipped will appear.

(i.e., “1”, meaning one track is being skipped)

When searching the reverse direction, the num-

ber of song that are being skipped will appear

along with a minus sign before the number. (i.e.,

“-1”, meaning one song is being skipped)

The maxmum number of songs that can be

skipped in either direction is 9.

To stop a searching operation, push the up-

down button in the opposite direction that it was

originally pushed.

1-7

FEATURES

GEN

INFO

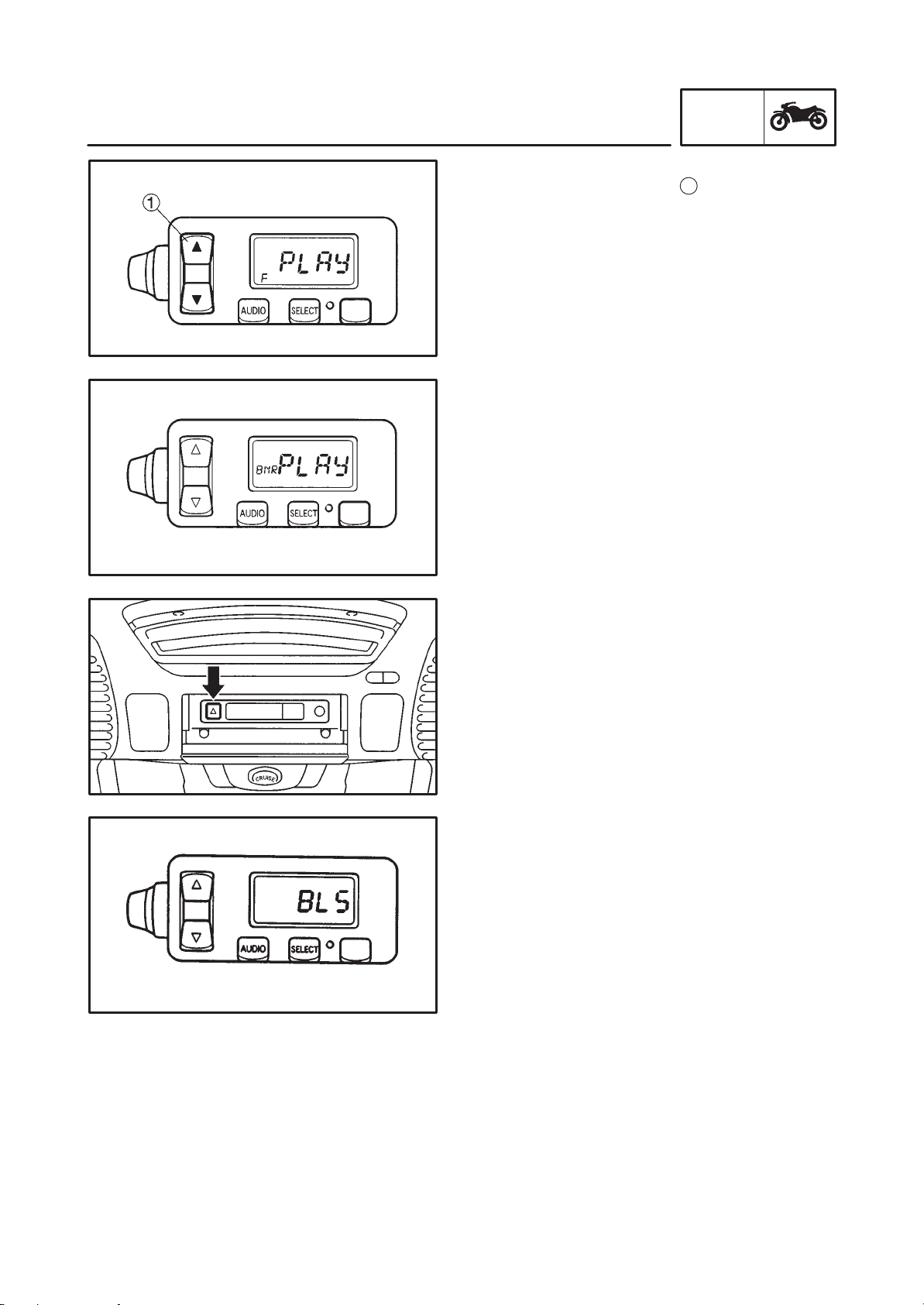

Reserving tape play direction

Push the up-down button

1

in either direction

for more than one second to reverse tape play .

When the tape is playing the forward direction,

the “F” indicator will appear.

When the tape is playing in the reverse direc-

tion, the “R” indicator will appear.

Dolby noise reduction

The Dolby noise reduction can be turned on or

off by pushing the “EJECT” button for at least

two seconds.

When the noise reduction is on, the “BNR” indi-

cator appears in the display.

Ejecting the cassette tape

Push the “EJECT” button to eject the tape from

the cassette dack.

Blank skipping

When there is a blank portion on the cassette

tape the “BLS” indicator light will come on and

the cassette deck automatically fast forwards

the tape to the next track.

1-8

FEATURES

GEN

INFO

TAPE FM1 FM2 FM3

AUX. CD(option) AM

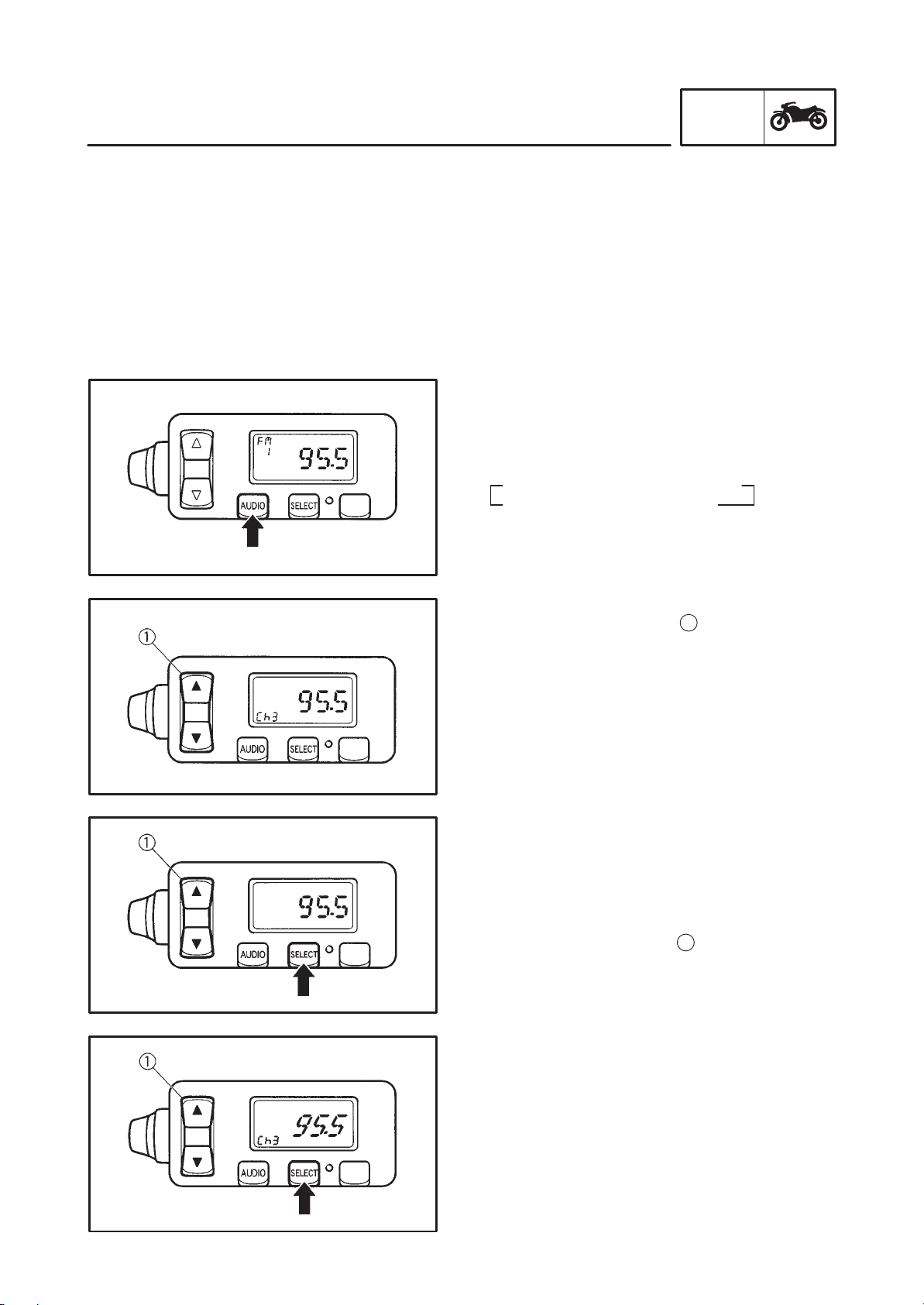

3. RADIO OPERATION

The radio has the following functions.

Switching the receiving band

Switching the receiving station

Automatic tuning (Seek)

Manual tuning

Programing preset stations in memory

Automatic writing of stations in memory (Auto

store operation)

Switching the receiving bands

This radio system has 3 bands for FM and 1

band for AM. Select a band by pushing the “AU-

DIO” button for less than 1 second.

The display will change as follows.

Automatic tuning (Seek operation)

Push the up-down switch

1

in either direction

and hold it for as least 1 second.

The tuner will automatically stop at the first sta-

tion that has a strong enough radio wave.

Manually turning

When a radio wave is too weak to be picked up

automatically, it can be selected manually as

follows.

Push the “SELECT” button until “RADIO” sta-

tion appears.

Push the up-down switch

1

for less than 1 se-

cond in either direction and the ferequency will

change in 0.1 MHz steps for FM and in 9 kHz for

AM.

Presetting station in memory

Station can be preset either automatically or

manually. 6 stations can be set for each band.

Preset station either manually or automatically

by the following procedure.

a. Select the station desired to be preset.

b. Push the “SELECT” button for as least 2 se-

conds unitl the radio frequency and the chan-

nel “Ch” start flashing.

1-9

FEATURES

GEN

INFO

NOTE:

c. Push the up-down switch

1

in either direc-

tion to select the channel number to be set for

the current station. (Ch1, Ch2, Ch3, Ch4,

Ch5 and Ch6)

d. Press the “SELECT” button to programing

the channel in memory.

Repeat this procedure for the remaining sta-

tions desired to be preset in the memory.

Stations can be also be automatically preset by

the following procedure.

a. Push the “SELECT” button until the radio fre-

quency and the channel “Ch” start flashing.

b. Push the up-down button in either direction

for at least 1 second to automatically tune in

a station.

c. When the desired station is found, push the

up-down switch for less than one second to

select the channel number to be set for that

station.

d. Push the “SELECT” button to programing the

channels in memory.

e. Repeat this procedure for the remaining sta-

tions desived to be preset in memory.

Programing preset stations in memory auto-

matically

Setting up to 6 channels can be made by the fol-

lowing procedure.

Stations will be starting from the station preset

at chanel 6.

It is recommended to use this function only in

areas with strong radio frequencies.

a. Push the “SELECT” button until the radio fre-

quency and the channel “Ch” start flashing.

b. Push the up-down switch

1

in either direc-

tion to select channel “A”.

c. Press the “SELECT” button to start the ran-

dom channel selection and the tuner will au-

tomatically write the channels in memory.

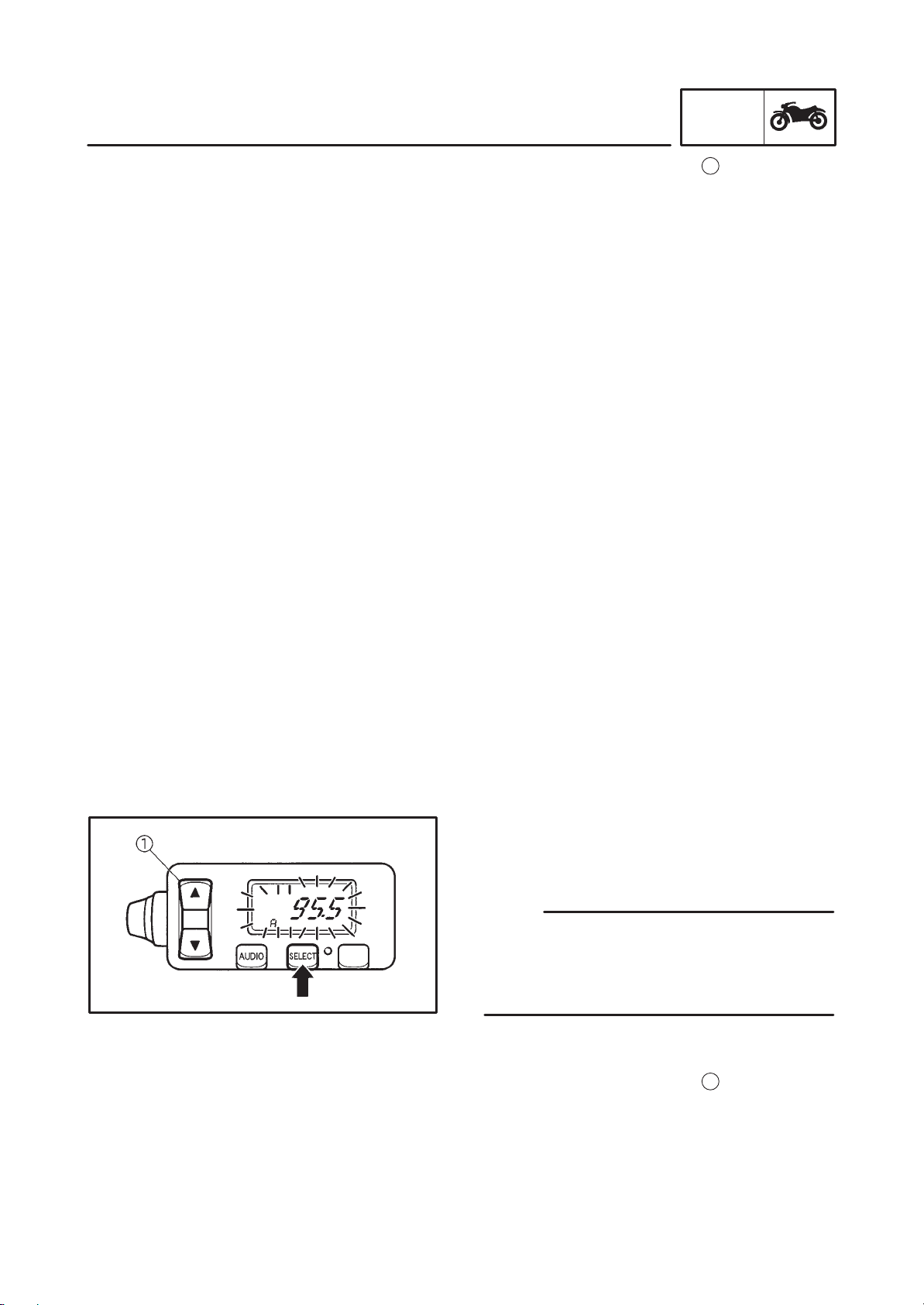

1-10

FEATURES

GEN

INFO

TAPE FM1 FM2 FM3

AUX. CD(option) AM

OUTPUT BASS TREB FADE

RADIO station AVC INT.VOL

“AUX” (Auxiliary) operation

Auxiliary audio equipment can be used to play

through the audio system.

a. Insert the output plug of the auxiliary equip-

ment into the jack located at the right side of

the dassette deck.

b. Push the “AUDIO” button until “AUX” ap-

pears and the auxiliary equipment can be

used to play through the audio system.

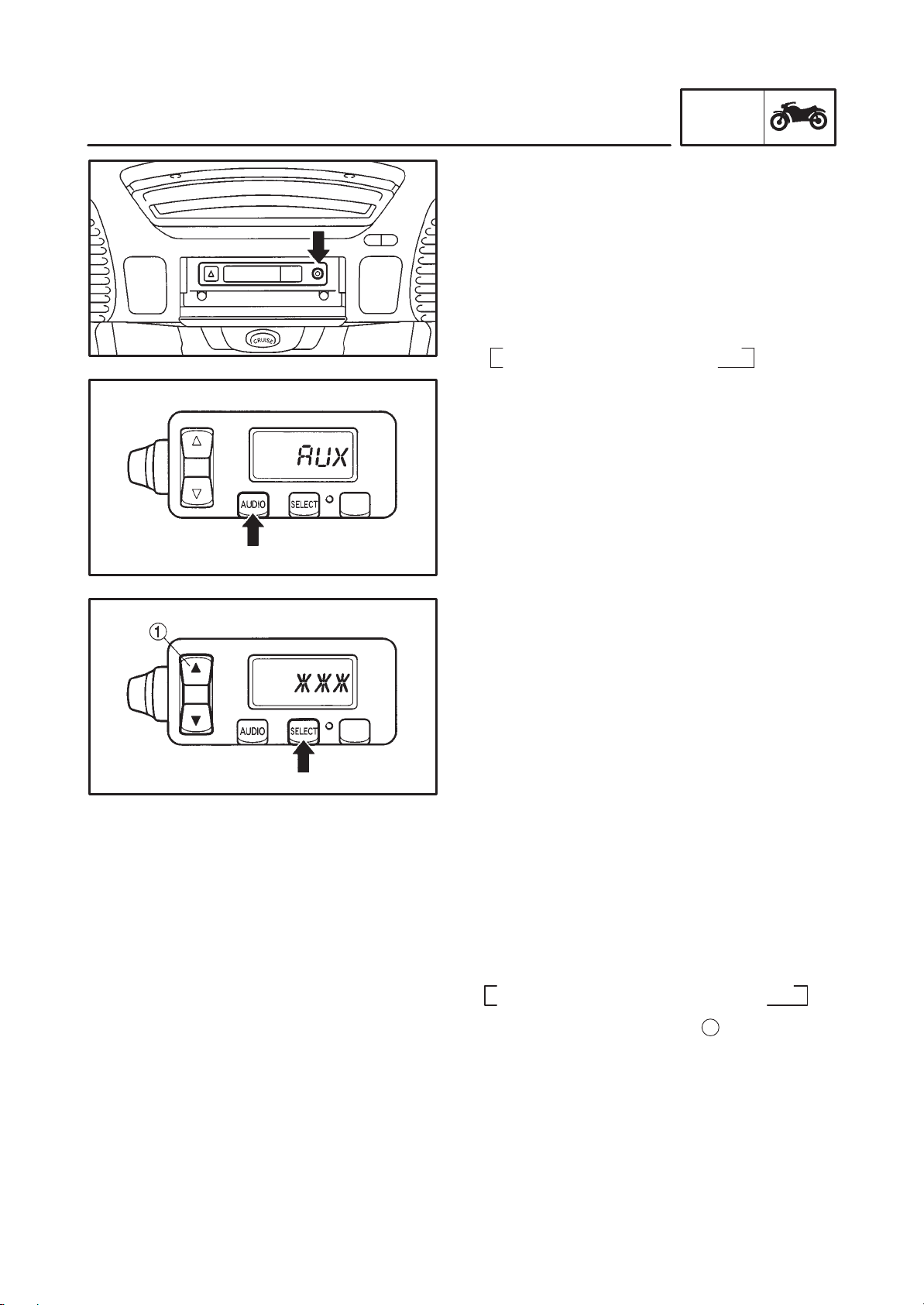

5. BASIC SETTINGS

AUDIO system

The following settings can be made in the audio

system.

Selecting output between speakers and a head-

set assembly

Controlling bass level

Controlling treble level

Controlling fader (balance between the front

and the rear speakers)

Controlling intercom volume level

Changing auto volume level

Setting procedure

The following setting procedures apply to the

audio system, auxiliary mode and CD Changer.

a. Select the desired setting mode by pushing

the “SELECT” button. On each press of the

button, the mode changes as follows.

Audio system

b. Push the up-down switch

1

in either direc-

tion to change the setting for any mode.

1-11

FEATURES

GEN

INFO

NOTE:

Selecting the output for speaker or headset

(optional)

To select the output for speaker or headset,

push the “SELECT” button and the “SP” (speak-

er) or “HS” (headset) indicator will appear. To

change between speaker and headset, push

the up-down switch

1

in either direction.

The speaker and headset cannot be used the

same time.

Controlling the bass level

a. To control the bass level, push the “SELECT”

button until the “BASS” indicator appears.

b. Push the up-down switch

1

in either direc-

tion to change the level.

Controllingthe treble level

a. To control the treble level, push the “SE-

LECT” button until the “TREB” indicator ap-

pears.

b. Push the up-down switch

1

in either direc-

tion to change the level.

The treble level can be set from –6 to +6.

Controlling the fader (balance between front

and rear speakers)

a. To control the fader , push the “SELECT” but-

ton until the “FAD” indicator appears.

b. Push the up-down switch

1

in either direc-

tion to change the balance.

The fader level can be adjusted from F9 to

R9.

Controlling the intercom volume level

a. To control the intercom volume level, push

the “SELECT” button until the “IC:” indicator

appears.

b. Push the up-down switch

1

in either direc-

tion to change the volume level.

The intercom volume level can be set from 0

to 20.

1-12

FEATURES

GEN

INFO

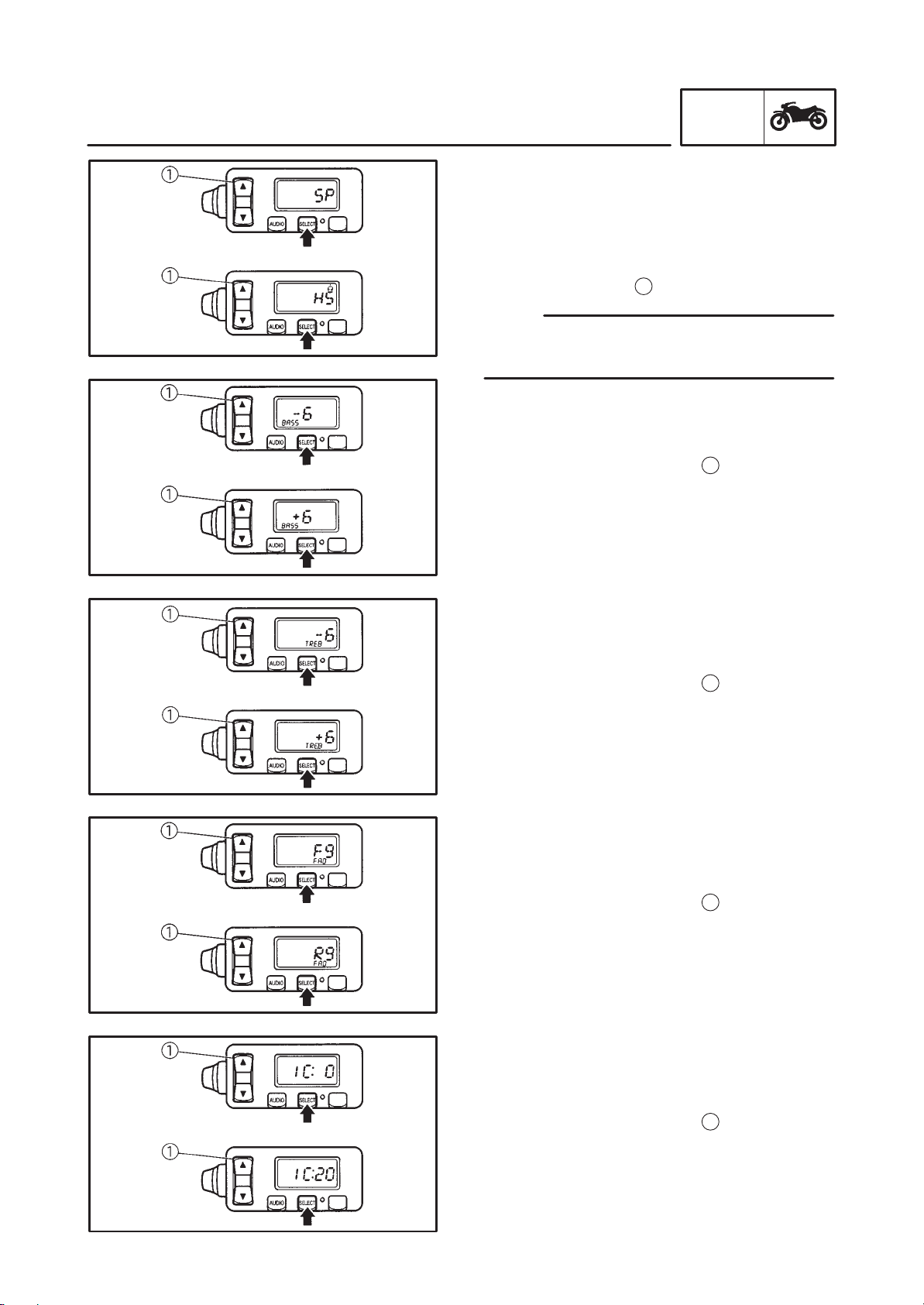

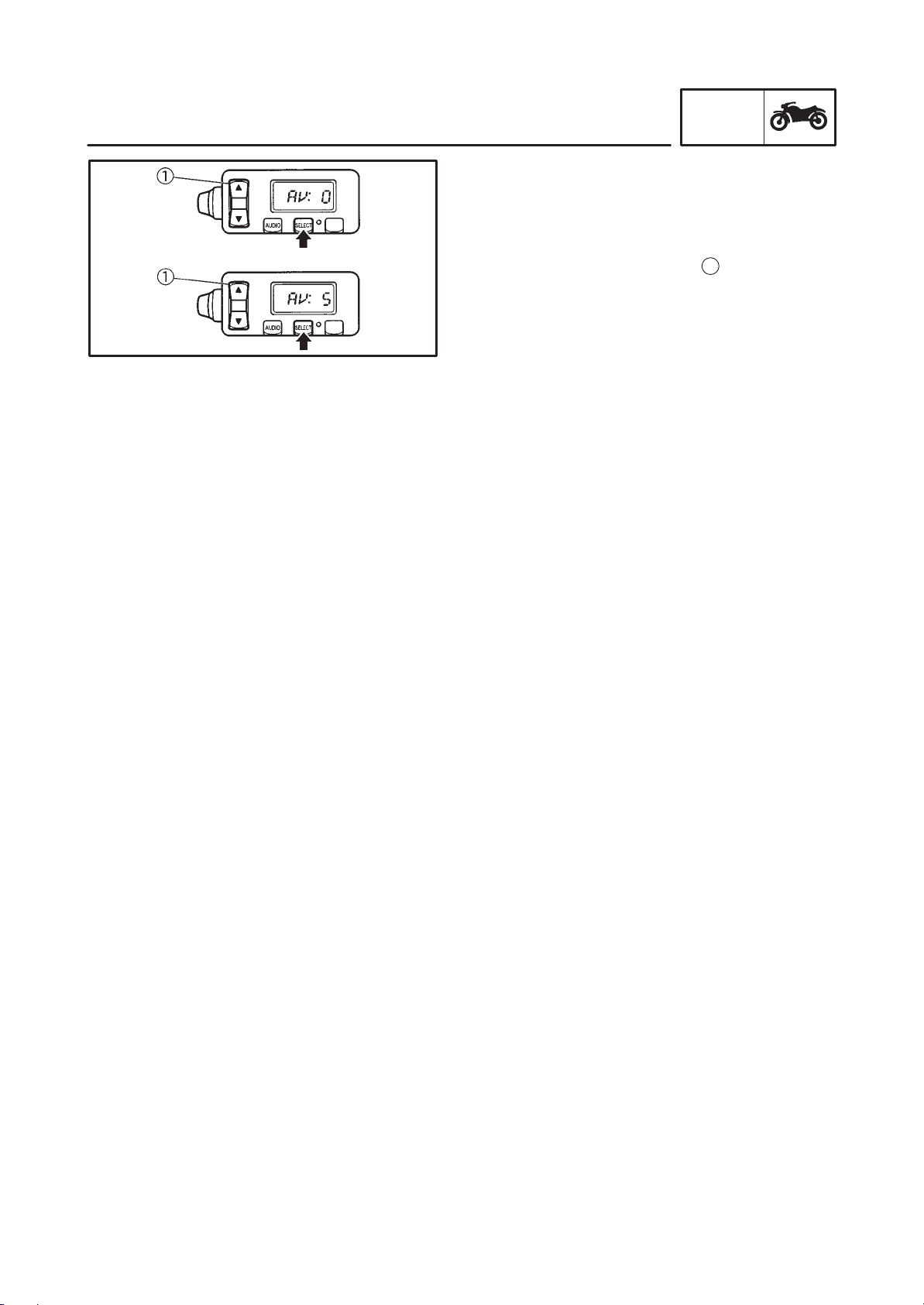

Changing the level for auto volume control

system

a. To control the level for the auto volume con-

trol system, push the “SELECT” button untill

the “AV:” indicator appears.

b. Push the up-down switch

1

in either direc-

tion to change the volume level.

The auto volume control rate of compensa-

tion can be adjusted from 0 to 5.

1-13

IMPORTANT INFORMATION

GEN

INFO

EAS00020

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND DIS-

ASSEMBLY

1. Before removal and disassembly, remove all

dirt, mud, dust and foreign material.

2. Use only the proper tools and cleaning

equipment.

Refer to the “SPECIAL TOOLS” section.

3. When disassembling, always keep mated

parts together. This includes gears, cylin-

ders, pistons and other parts that have been

“mated” through normal wear.

Mated parts must always be reused or re-

placed as an assembly.

4. During disassembly, clean all of the parts

and place them in trays in the order of disas-

sembly . This will speed up assembly and al-

low for the correct installation of all parts.

5. Keep all parts away from any source of fire.

EAS00021

REPLACEMENT PARTS

1. Use only genuine Yamaha parts for all re-

placements. Use oil and grease recom-

mended by Yamaha for all lubrication jobs.

Other brands may be similar in-function and

appearance, but inferior in quality.

EAS00022

GASKETS, OIL SEALS AND O-RINGS

1. When overhauling the engine, replace all

gaskets, seals and O-rings. All gasket sur-

faces, oil seal lips and O-rings must be

cleaned.

2. During reassembly, properly oil all mating

parts and bearings and apply grease onto

the oil seal lips.

1-14

IMPORTANT INFORMATION

GEN

INFO

CAUTION:

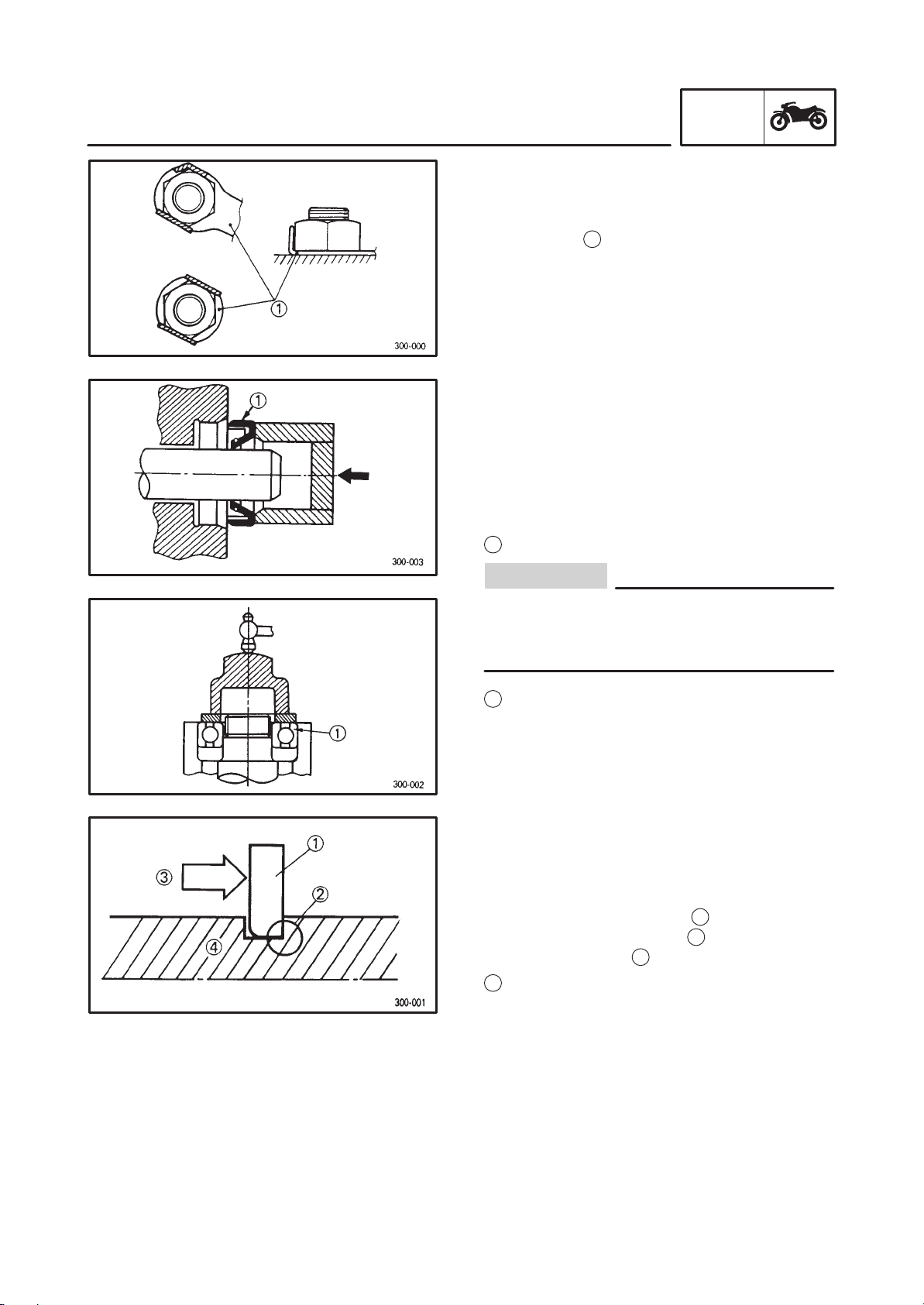

EAS00023

LOCK WASHERS/PLATES AND COTTER

PINS

1. After removal, replace all lock wash-

ers/plates

1

and cotter pins. After the bolt or

nut has been tightened to specification, bend

the lock tabs along a flat of the bolt or nut.

EAS00024

BEARINGS AND OIL SEALS

1. Install bearings and oil seals so that the

manufacturer’s marks or numbers are vis-

ible. When installing oil seals, apply a light

coat of lithium soap base grease onto the oil

seal lips. Oil bearings liberally when instal-

ling, if appropriate.

1

Oil seal

Do not spin the bearing with compressed air

because this will damage the bearing sur-

faces.

1

Bearing

EAS00025

CIRCLIPS

1. Before reassembly , check all circlips careful-

ly and replace damaged or distorted circlips.

Always replace piston pin clips after one use.

When installing a circlip

1

, make sure that

the sharp-edged corner

2

is positioned op-

posite the thrust

3

that the circlip receives.

4

Shaft

1-15

CHECKING THE CONNECTIONS

GEN

INFO

NOTE:

NOTE:

NOTE:

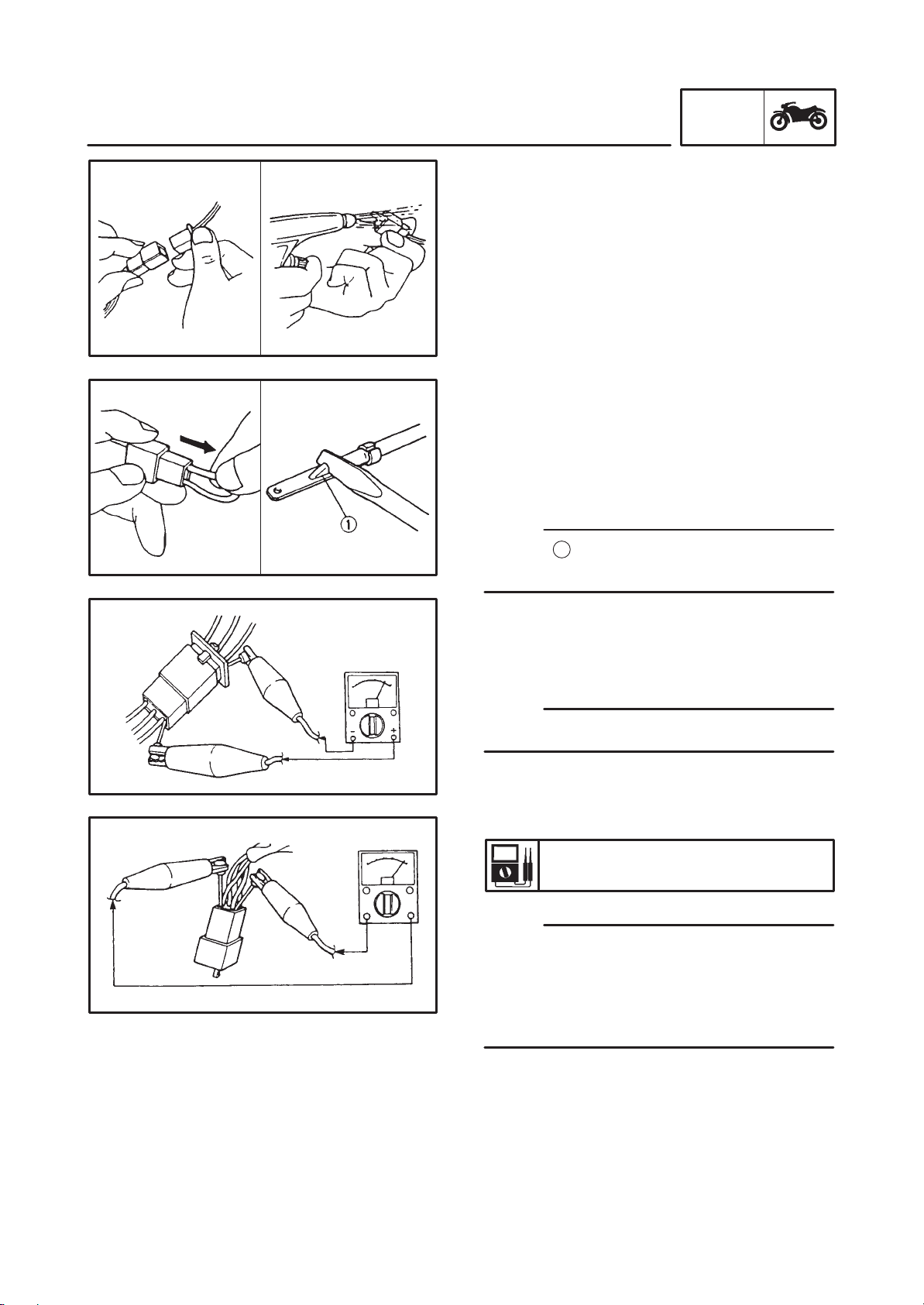

EAS00026

CHECKING THE CONNECTIONS

Check the leads, couplers, and connectors for

stains, rust, moisture, etc.

1. Disconnect:

lead

coupler

connector

2. Check:

lead

coupler

connector

Moisture Dry with an air blower.

Rust/stains Connect and disconnect sev-

eral times.

3. Check:

all connections

Loose connection Connect properly.

If the pin

1

on the terminal is flattened, bend it

up.

4. Connect:

lead

coupler

connector

Make sure that all connections are tight.

5. Check:

continuity

(with a pocket tester)

Pocket tester

YU-03112,90890-03112

If there is no continuity, clean the terminals.

When checking the wire harness, perform

steps 1 to 3.

As a quick remedy, use a contact revitalizer

available at most part stores.

1-16

SPECIAL TOOLS

GEN

INFO

EAS00027

SPECIAL TOOLS

The following special tools are necessary for complete and accurate tune-up and assembly . Use only

the appropriate special tools as this will help prevent damage caused by the use of inappropriate tools

or improvised techniques. Special tools, part umbers or both may differ depending on the country.

When placing an order, refer to the list provided below to avoid any mistakes.

P/N.YM-, YU-

FOr US, CDN

YS-, YK- ACC-

P/N.90890-

Except for US, CDN

Tool No.

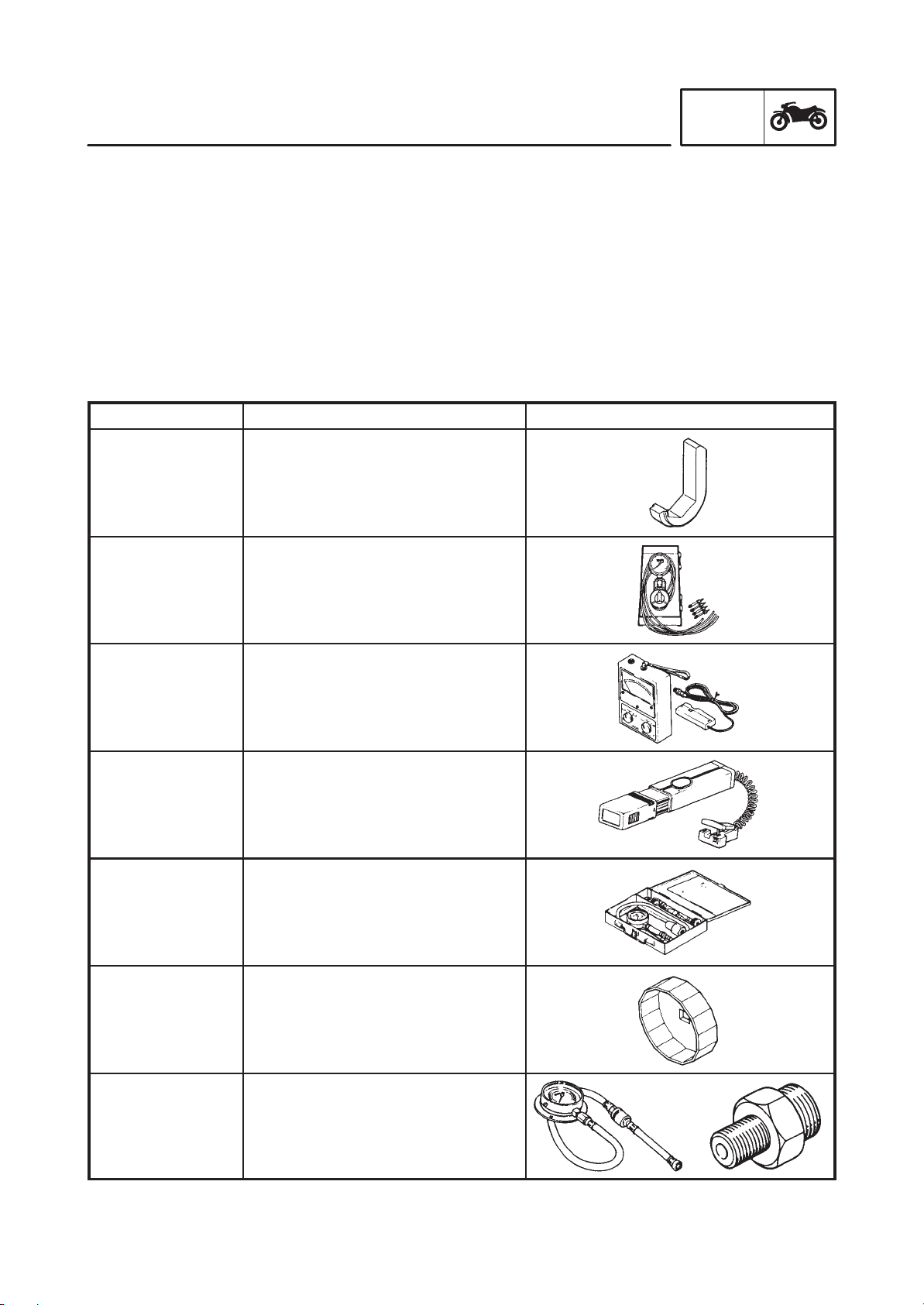

Tool name/Usage Illustration

YM-33961

90890-04105

Tappet adjusting tool

This tool is needed to rotate the

camshaft for access to the valve lift-

er and valve pad

YU-08030-A

90890-03094

Vacuum gauge

This gauge is needed for carburetor

synchronization.

YU-08036-A

90890-031 13

Engine tachometer

This tool is needed for observing en-

gine rpm.

YU-33277-A

90890-03141

Timing light

This tool is necessary for checking

ignition timing.

YU-33223

90890-03081

Compression gauge/Set

These tools are needed to measure

engine compression.

YU-38411

90890-01426

Oil filter wrench

This tool is needed to remove and

install the oil filter.

Gauge

90890-03153

Adapter

90890-03124

Pressure gauge/adapter

These tools are needed to measure

engine oil pressure.

1-17

SPECIAL TOOLS

GEN

INFO

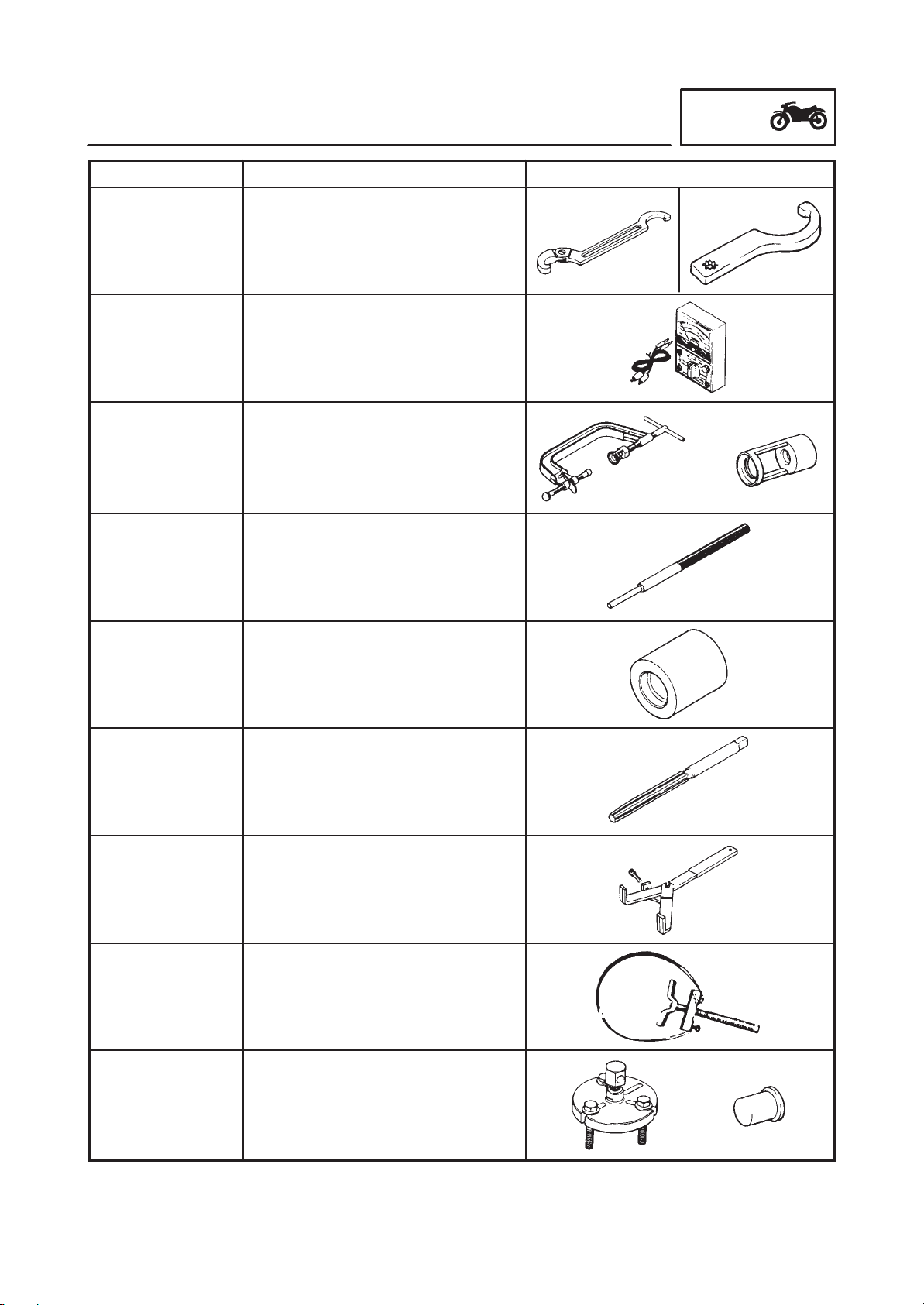

Tool No. Tool name/Usage Illustration

YU-01268

90890-01268

YU-33975

90890-01403

Ring nut wrench

This tool is needed to loosen and

tighten the steering stem ring nut.

YU-03112

90890-03112

Pocket tester

This instrument is needed for check-

ing the electrical system.

Compressor

YM-04019

90890-04019

Adapter

YM-01253-1

90890-04114

Valve spring compressor/adapter

These tools are needed to remove

and install the valve assemblies.

YM-4064-A

90890-04064

Valve guide remover (6.0 mm)

This tool is needed to remove and

install the valve guide.

YM-04065-A

90890-04065

Vale guide installer (6.0 mm)

This tool is needed to install the

valve guide.

YM-04066

90890-04066

Valve guide reamer (6.0 mm)

This tool is needed to rebore the

new valve guide.

YM-91042

90890-04085

Universal clutch holder

This tool is needed to hold the clutch

when removing or installing the

clutch boss nut.

YS-01880

90890-01701

Sheave holder

This tool is needed to hold the rotor

when removing or installing the rotor

bolt.

Puller

YU-33270

90890-01362

Adapter

YM-33282

90890-04089

Flywheel puller/adapter

These tools are needed to remove

the rotor.

1-18

SPECIAL TOOLS

GEN

INFO

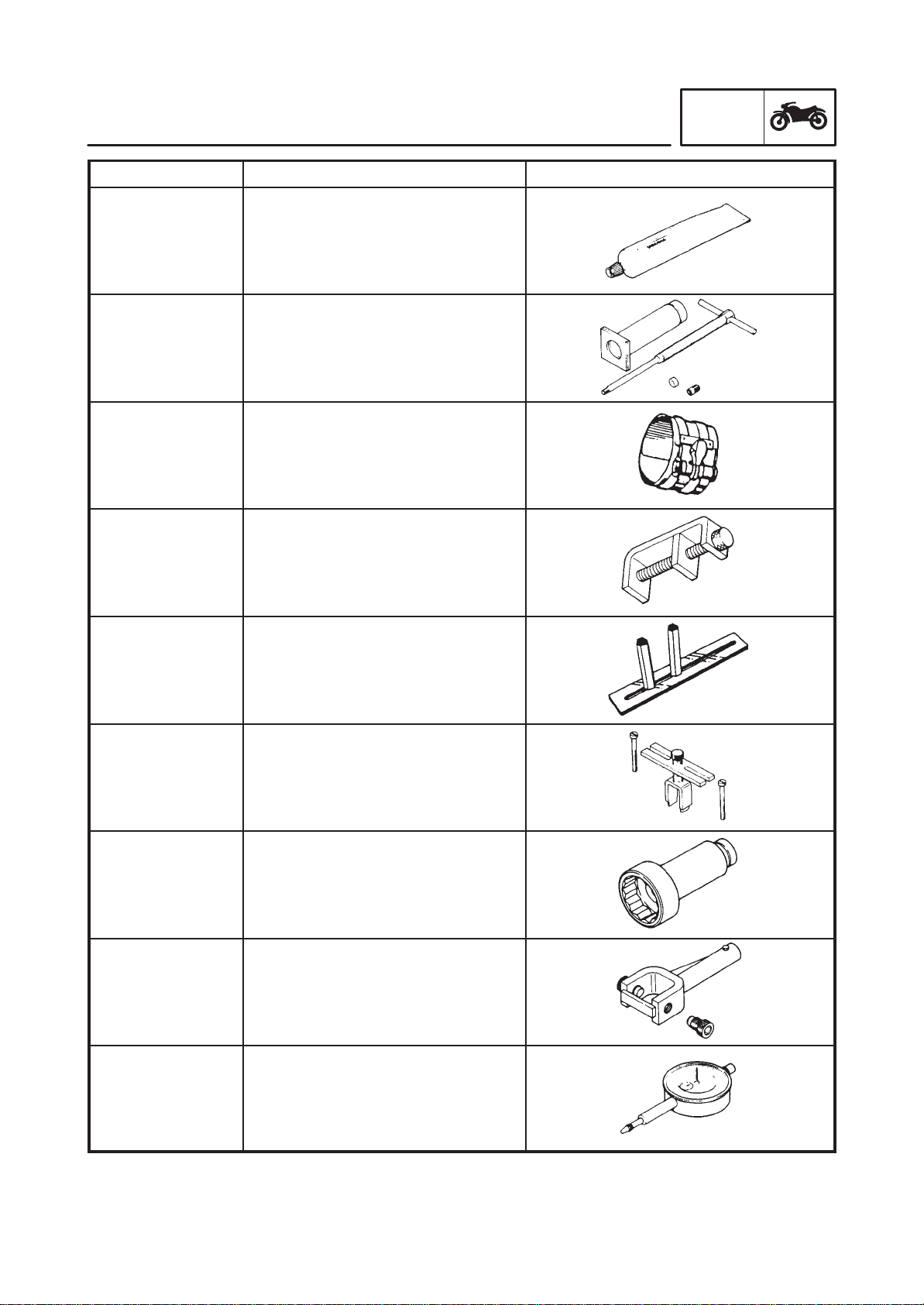

Tool No. Tool name/Usage Illustration

ACC-1100-15-01

90890-85505

Quick gasket

Yamaha Bond No.1215

This sealant (bond) is used on

crankcase mating surfaces, etc.

YU-01304

90890-01304

Piston pin puller

This tool is used to remove the pis-

ton pin.

YM-8037

90890-05158

Piston ring compressor

This tool is used to compress the

piston rings when installing the pis-

ton into the cylinder.

YM-33286

90890-04090

Damper spring compressor

This tool is needed when removing

or installing the damper spring.

YM-33222

Middle drive gear holder

This tool is needed to remove and

install the middle drive pinion gear.

This tool is also used for the gear

backlash adjustment.

90890-04080

Middle drive gear holder

This tool is needed for the gear

backlash adjustment.

YM-04054

90890-04054

Offset wrench (55 mm)

This tool is needed when removing

or installing the middle drive gear

nut.

YM-04062

90890-04062

Universal joint holder

This tool is needed when removing

or installing the driven pinion gear

nut.

YU-03097

90890-03097

Dial gauge

This tool is used to measure the

middle gear backlash.

1-19

SPECIAL TOOLS

GEN

INFO

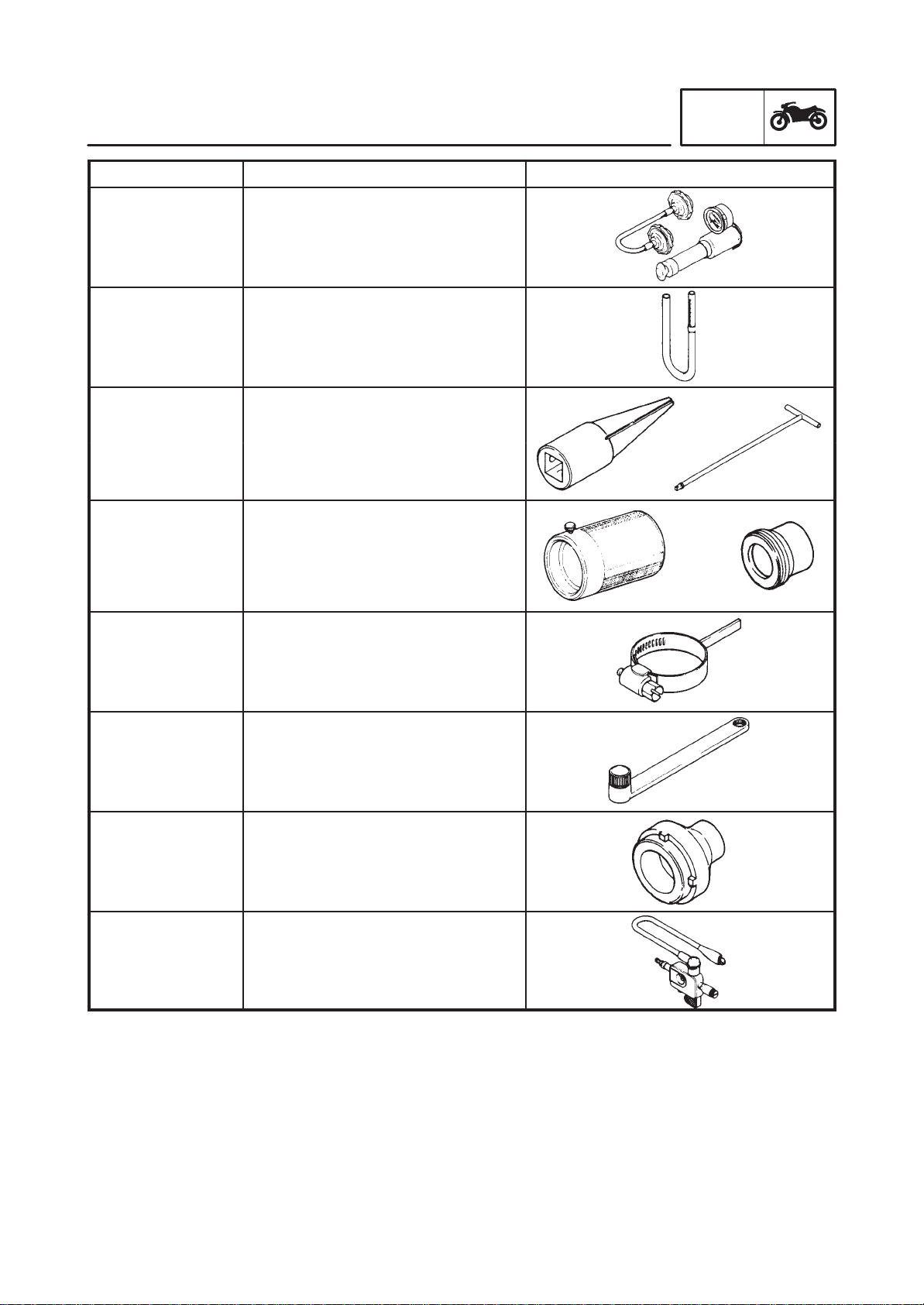

Tool No. Tool name/Usage Illustration

Tester

YU-24460-01

90890-01325

Adapter

YU-33984

Radiator cap tester/adapter

This tester and its adapter are need-

ed for checking the cooling system.

YM-01312-A

90890-01312

Fuel level gauge

This gauge is used to measure the

fuel level in the float chamber.

Rod holder

YM-01300-1

90890-01294

Damper rod holder/T-handle

T-handle

YM-01326

90890-01326

These

tools

are

needed

to

loosen

and tighten the damper rod holding

bolt.

Weight

YM-33963

90890-01367

Adapter

YM-8020

90890-01374

Fork seal driver weight/adapter

These tools are needed when instal-

ling the slide metal, oil seal and dust

seal into the fork.

YM-01230

90890-01230

Final gear backlash band

This tool is needed when measuring

final gear backlash.

YM-01229

90890-01229

Coupling gear/middle shaft tool

This tool is needed when removing

or installing the coupling gear nut.

YM-04050

90890-04050

Bearing retainer wrench

This tool is needed when removing

or installing the final drive shaft

bearing.

YM-34487

90890-06754

Dynamic spark tester

Ignition checker

Loading...

Loading...