Schneider Electric T300 User Manual

MV Network Management

Easergy

T300

Remote Terminal Unit for distribution networks

User Manual

Safety information

Hazard Categories and Special Symbols

Read these instructions carefully and look at the equipment to become familiar with

the device before trying to install, operate, service or maintain it. The following

special messages may appear throughout this bulletin or on the equipment to warn

of potential hazards or to call attention to information that clarifies or simplifies a

procedure.

The addition of either symbol to a “Danger” or “Warning” safety label indicates

that an electrical hazard exists which will result in personal injury if the

instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER

DANGER indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE

NOTICE is used to address practices not related to physical injury. The safety alert symbol

shall not be used with this signal word.

Please Note

Electrical equipment should be installed, operated, serviced, and maintained only by

qualified personnel. No responsibility is assumed by Schneider Electric for any

consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the construction,

installation, and operation of electrical equipment and has received safety training to

recognize and avoid the hazards involved.

2

NT00378-EN-03

Safety information

Legal information

The Schneider Electric brand and any registered trademarks of Schneider Electric

Industries SAS referred to in this guide are the sole property of Schneider Electric SA and

its subsidiaries. They may not be used for any purpose without the owner's permission,

given in writing. This guide and its content are protected, within the meaning of the French

intellectual property code (Code de la propriété intellectuelle français, referred to hereafter

as "the Code"), under the laws of copyright covering texts, drawings and models, as well

as by trademark law. You agree not to reproduce, other than for your own personal,

noncommercial use as defined in the Code, all or part of this guide on any medium

whatsoever without Schneider Electric’s permission, given in writing. You also agree not

to establish any hypertext links to this guide or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial

use of the guide or its content, except for a non-exclusive license to consult it on an "as is"

basis, at your own risk. All other rights are reserved.

As standards, specifications and designs change from time to time, please ask for

confirmation of the information given in this publication.

FCC Part 15

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception which can be determined by turning the equipment off and on, the

user is encouraged to try to correct interference by one or more of the following

measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on circuit different from that to which the

- Consult the dealer or an experienced radio/TV technician for help.

This device complies with FCC RF radiation exposure limits set forth for general

population. This device must be installed to provide a separation distance of at least 20cm

from all persons and must not be co-located or operating in conjunction with any other

antenna or transmitter.

receiver is connected.

NT00378-EN-03

3

Easergy T300 Contents

1

GENERAL DESCRIPTION ................................................................................................................................. 6

1.1 FUNCTIONAL DESCRIPTION .................................................................................................................................... 6

1.2 DESCRIPTION OF T300 MODULES .......................................................................................................................... 7

1.2.1 HU250 Module – CPU and Communication Gateway ............................................................................. 7

1.2.2 SC150 Module – Switch Control Unit ...................................................................................................... 7

1.2.3 LV150 Module – Low Voltage measuring Unit ......................................................................................... 8

1.2.4 PS50 Module – Backup Power Supply for severe environments ............................................................ 8

1.2.5 PS25 Module – Backup Power Supply for monitoring and control solutions ........................................... 8

1.3 T300 INTERNAL ARCHITECTURE ............................................................................................................................ 9

1.4 T300 CONFIGURATION PRINCIPLE ....................................................................................................................... 10

1.4.1 Engineering in Easergy Builder ............................................................................................................. 10

1.4.2 Management of RBAC and security policy ............................................................................................ 12

1.5 INITIAL START-UP ............................................................................................................................................... 13

2 CONNECTING TO THE T300 WEB SERVER .................................................................................................. 14

3 OVERVIEW OF THE T300 WEB SERVER ...................................................................................................... 15

3.1 DATA CONSULTATION AND MONITORING PAGES ................................................................................................... 17

3.1.1 Home Page ............................................................................................................................................ 17

3.1.2 Substation Page ..................................................................................................................................... 18

3.1.3 System Page .......................................................................................................................................... 24

3.1.4 Data Pages ............................................................................................................................................ 26

3.2 MEASUREMENTS ................................................................................................................................................. 29

3.2.1 Measurements Pages ............................................................................................................................ 29

3.3 DIAGNOSTIC FILES .............................................................................................................................................. 33

3.3.1 Events Page ........................................................................................................................................... 33

3.3.2 System Page .......................................................................................................................................... 34

3.3.3 Cyber-Security Page .............................................................................................................................. 34

3.4 TRACES .............................................................................................................................................................. 35

3.4.1 Protocol Traces ...................................................................................................................................... 35

3.5 SYSTEM CYBER-SECURITY .................................................................................................................................. 36

3.5.1 Users and roles ...................................................................................................................................... 36

3.5.2 Centralized authentication with RADIUS ............................................................................................... 40

3.6 DEVICE SYNCHRONIZATION ................................................................................................................................. 45

3.6.1 Clock Page ............................................................................................................................................. 45

3.7 IP INTERFACES ................................................................................................................................................... 46

3.7.1 IP Configuration Page ............................................................................................................................ 46

3.8 DIAL-UP MODEM SETTINGS ................................................................................................................................. 51

3.8.1 Modems Configuration Page ................................................................................................................. 51

3.9 UPGRADING THE FIRMWARE ................................................................................................................................ 53

3.9.1 Firmware Page ....................................................................................................................................... 53

3.10 MANAGING THE CONFIGURATION .................................................................................................................... 55

3.10.1 Configuration Page ................................................................................................................................ 55

4 T300 SETTINGS ............................................................................................................................................... 59

4.1 HU250 MODULE SETTINGS ................................................................................................................................. 60

4.1.1 Local I/O ................................................................................................................................................. 60

4.1.2 SCADA Protocols ................................................................................................................................... 64

4.1.3 Master Protocols .................................................................................................................................... 64

4.1.4 Configuring the Physical Ports ............................................................................................................... 65

4.1.5 Synchronization ..................................................................................................................................... 69

4.2 SC150 MODULE SETTINGS ................................................................................................................................. 71

4.2.1 MV Current and Voltage Sensors .......................................................................................................... 72

4.2.2 Switch Control ........................................................................................................................................ 76

4.2.3 Front panel voltage indication ................................................................................................................ 84

4.2.4 MV Voltage Monitoring ........................................................................................................................... 85

4.2.5 Fault current Detection ........................................................................................................................... 88

4.2.6 Fault Current validation and indication ................................................................................................ 104

4.2.7 MV Power Measurement Settings ....................................................................................................... 110

4.2.8 MV Power Quality Settings .................................................................................................................. 111

4.2.9 Automation Settings ............................................................................................................................. 112

4

NT00378-EN-03

Easergy T300 Contents

4.3

LV150 MODULE SETTINGS ................................................................................................................................ 114

4.3.1 LV Current and Voltage Sensors ......................................................................................................... 115

4.3.2 Front panel voltage indication .............................................................................................................. 118

4.3.3 LV Voltage Monitoring .......................................................................................................................... 119

4.3.4 Broken Phase Conductor Detection .................................................................................................... 122

4.3.5 LV Power Measurement Settings ........................................................................................................ 124

4.3.6 Power Quality Settings ......................................................................................................................... 125

4.4 PS50 MODULE SETTINGS ................................................................................................................................. 126

4.5 COMMISSIONING TESTS .................................................................................................................................... 127

5 OPERATION ................................................................................................................................................... 128

5.1 INDICATIONS AND ACTIONS ON THE FRONT PANEL ................................................................................................... 128

5.2 TESTING THE LEDS ON THE FRONT PANEL ......................................................................................................... 134

5.3 LOCAL/REMOTE MODE ...................................................................................................................................... 134

5.3.1 Automation Enabled ............................................................................................................................. 135

5.4 SWITCH COMMANDS ......................................................................................................................................... 135

5.5 OTHER COMMANDS .......................................................................................................................................... 135

5.6 BLMON UTILITY ................................................................................................................................................ 136

5.6.1 Accessing BLMon ............................................................................................................... ................. 136

5.6.2 Using BLMon........................................................................................................................................ 137

6 MAINTENANCE .............................................................................................................................................. 138

6.1 DIAGNOSTIC LEDS ON THE FRONT PANEL .......................................................................................................... 139

6.2 POWERING DOWN THE EQUIPMENT .................................................................................................................... 143

6.3 BATTERY MAINTENANCE ................................................................................................................................... 143

6.3.1 Replacing the Battery ........................................................................................................................... 143

6.3.2 Battery Care and Storage .................................................................................................................... 143

6.4 REPLACING THE HU250, SC150 OR LV150 MODULE ......................................................................................... 144

6.4.1 Addressing the SC150 and LV150 Modules ........................................................................................ 144

6.4.2 Checking the Firmware Version ........................................................................................................... 144

6.4.3 Importing a Stored Configuration ......................................................................................................... 144

6.5 REPLACING A BOX MODEM ................................................................................................................................ 145

6.6 REPLACING THE PS50 MODULE ........................................................................................................................ 145

6.6.1 Addressing the PS50 Module .............................................................................................................. 145

6.6.2 Commissioning .................................................................................................................................... 145

6.7 REPLACING THE PS25 MODULE ........................................................................................................................ 145

7 APPENDIX A - GENERAL CHARACTERISTICS .......................................................................................... 146

7.1 HU250 ............................................................................................................................................................ 146

7.2 SC150 ............................................................................................................................................................. 147

7.3 LV150 ............................................................................................................................................................. 148

7.4 HU250, SC150 AND LV150 ............................................................................................................................. 149

7.5 PS50 ............................................................................................................................................................... 150

7.6 PS25 ............................................................................................................................................................... 152

8 ANNEXE B: LIST OF POTENTIAL ISSUE CODES ....................................................................................... 153

8.1 SC150 POTENTIAL ISSUE CODES ON SWITCH CONTROL ....................................................................................... 153

9 APPENDIX C: GLOSSARY ............................................................................................................................ 154

9.1 ABBREVIATIONS AND DEFINITIONS ..................................................................................................................... 154

10 APPENDIX D: INVERSE DEFINITE MINIMUM TIME (IDMT) CURVES ........................................................ 157

NT00378-EN-03

5

Presentation General description

DANGER

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR

ARC FL ASH

Wear your personal protective equipment (PPE) and

comply with the safe electrical work practices. See

NFPA 70E in the USA or applicable local standards.

This unit must be installed and serviced only by

qualified electrical personnel.

Turn off all power supplying this unit before working

on or inside the unit.

Always use a properly rated voltage sensing device to

confirm that the power is off.

A live current transformer secondary circuit must not

be opened without turning off the primary side of the

transformer and short-circuiting transformer secondary

circuit first.

Replace all devices, doors and covers before turning

on power to this unit.

Failure to follow these instructions will result in

death or serious injury.

WARNING

LOSS OF CONTROL

The designer of any control scheme must consider the

potential failure modes of control paths and, for certain

critical control functions, provide a means to achieve a

safe state during and after a path failure. Example:

Emergency Stop.

Separate or redundant control paths must be provided

for critical control functions.

System control paths may include communication

links. Consideration must be given to the implications

of anticipated transmission delays or failures of the

link.

Failure to follow these instructions can result in

death or serious injury.

1 General description

1.1 Functional description

Easergy T300 features a modular architecture designed for applications in MV

network substations.

The T300 offers the following functions:

Management of the open/close motor mechanism on MV switchgear,

compatible with any MV switch

Detection of ammetric and directional fault currents on the MV

network: operational on any neutral system with or without the presence of

distributed power and including fault current algorithms based on the

following international standards:

o Phase overcurrent and ground fault detection (ANSI 50/51,

ANSI 50N/51N)

o Directional overcurrent and ground fault detection (ANSI 67/67N)

Two fault current detection methods are used:

o Definite time (DT) curve

o Inverse definite minimum time (IDMT) curve

MV network voltage and current monitoring, for the following functions:

MV current measurement using standard current sensors, compatible

MV voltage measurement using the following voltage sensors:

MV power measurement according to standard IEC61557-12

Quality

LV network voltage monitoring, for the following functions:

LV current measurement using standard current sensors, compatible

LV voltage measurement via a Voltage adapter measuring directly the

LV power measurement according to IEC 61557-12.

Quality of the LV power supply delivered according to the principles of

Transformer monitoring:

Monitoring, remote indication, and local display of T300 and

Integrated automation functions in the SC150 modules (Sectionalizer)

o Undervoltage detection (ANSI 27)

o Overvoltage detection (ANSI 59)

o Neutral overvoltage detection (ANSI 59N)

o Voltage broken conductor detection (ANSI 47)

o Undercurrent detection (ANSI 37)

with standard IEC 61869-2, according to three possible configurations:

o 3 phase CTs

o 1 core balance CT

o 3 phase CTs + 1 core balance CT

o LPVT (low power voltage transformer) conforming to standard

IEC 60044-7

o Standard MV/LV VTs with secondary from 57 Vac to 220 Vac

conforming to IEC 61869-3 (requires a VT adapter)

o VPIS (voltage presence indicating system) with voltage

output (VPIS-VO)

o VDS (voltage detecting system) indicator with voltage output

(standard IEC 61243-5)

o PPACS external capacitive divider mounted at the head of the

MV cable

of the MV power supply delivered, according to the principles of

IEC 61000-4-30 class S (up to harmonic 15), for T300 RTUs equipped

with LPVT and VT sensors

o Undervoltage detection (ANSI 27)

o Overvoltage detection (ANSI 59)

o Neutral overvoltage detection (ANSI 59N)

o Voltage broken conductor detection (ANSI 47)

with IEC61869-2, according to two possible configurations:

o 3 phase CTs

o 3 phase cores + 1 neutral measuring sensor

voltage on the LV network.

IEC 61000-4-30 class S (up to harmonic 15).

o Temperature monitoring with threshold alarm

o Measurement of current peaks

substation data

6

NT00378-EN-03

Presentation General description

Easergy HU250 module

Easergy SC150 module

Recording of time- and date-stamped events in logs (SOE)

Battery-backed power supply with several hours independent operation

in the event of an AC line outage

Local or remote communication over 1 or more communication

channels: local communication with auxiliary equipment; remote

communication with the remote control center (SCADA system).

The following modems are managed on the communication ports:

o 2G/3G and 3G/4G (standard EU and US versions)

o RS232/RS485

Communication protocols for communicating with the control center or

with other devices:

o IEC 60870-5-101 slave and IEC 60870-5-104 master and slave

o DNP3 master and slave

o Modbus master and slave

o IEC 61850 client and server.

Device time synchronization, can be set:

o Via the communication protocol

o Via the SNTP server

IEC 61131-3 PLC (IsaGRAF®) including text and graphics editors for

executing specific custom applications in the following programming

languages:

o SFC: Sequential Function Chart

o FBD: Function Block Diagram

o LD: Ladder Diagram

o ST: Structured Text

o IL: Instruction List

1.2 Description of T300 Modules

Easergy T300 comprises several communicating modules.

1.2.1 HU250 Module – CPU and Communication

Gateway

The T300 HU250 module manages the following functions:

User database and access rights administration

Remote communication with the control center (SCADA system) via the

protocols (IEC 60870-5-101/IEC 60870-5-104/IEC 61850) and the secure

protocol (DNP3)

Local communication with other substations (inter-device communication)

Flexible communication media (Ethernet, 2G, 3G, 4G)

Communication gateway for the T300 modules

LAN communication for third-party devices (IED) in master protocols

(Modbus, IEC 60870-5-104, IEC 61850, DNP3)

Access to local and remote configuration for all T300 modules

Web server with local and remote access

Integrated automation function with execution of programmable logic

control

Remote/local operation of global functions, enabling/disabling of PLC

function

For more information regarding installing, connection, and use of HU250

module, refer to the HU250 Installation Guide (ref: NHA77925-xx).

1.2.2 SC150 Module – Switch Control Unit

The T300 SC150 module manages the following functions:

Control and monitoring of all switch types

Detection of ammetric and directional fault currents:

o Detection of Ammetric phase overcurrent and ground fault

o Detection of Directional phase overcurrent and ground fault

Detection of broken phase conductor

Current measurements using standard current transformers

MV Voltage measurements using different types of sensor: LPVT, VT,

VDS, VPIS, and external capacitive divider installed on the MV cables

MV Power measurement in accordance with standard IEC 61557-12

MV Power quality according to the principles of IEC 61000-4-30 class S

(up to harmonic 15)

Special integrated automation function: sectionalizer

For more information regarding installing, connection, and use of SC150

module, refer to the SC150 Installation Guide (ref: NHA91857-xx).

NT00378-EN-03

7

Presentation General description

1.2.3 LV150 Module – Low Voltage measuring Unit

The T300 LV150 module manages the following functions:

Current measurements using standard current transformers

LV Voltage measurements using Voltage adaptor

LV Power measurement in accordance with standard IEC 61557-12

LV Power quality according to the principles of IEC 61000-4-30 class S

(up to harmonic 15)

Detection of broken phase conductor

For more information regarding installing, connection, and use of LV150

module, refer to the LV150 Installation Guide (ref: NHA92575-xx).

Easergy LV150 module

Easergy PS50 module

Easergy PS25 module

1.2.4 PS50 Module – Backup Power Supply for

severe environments

The PS50 is the default power supply for the T300. It supplies power to the

system and allows, through a battery-backup power supply, continuity of

operation for the equipment listed below in the event of a power outage:

Motor mechanism for the MV switches and circuit breakers

Transmission interfaces (radio, modem, etc.)

T300 electronic modules

Third-party devices, such as protection relays, fault current passage

indicators, and other electronic equipment installed in the MV substation

The PS50 module can communicate on an RS485 Modbus link with the HU250

module to exchange information managed by the PS50 power supply. This

communication also makes it possible to set the PS50 module from the T300

web server.

For more information regarding installing, connection, and use of PS50 module,

refer to the PS50 Installation Guide (ref: NT00375-xx).

1.2.5 PS25 Module – Backup Power Supply for

monitoring and control solutions

The PS25 module is the dedicated power supply for monitoring and control

solutions of MV electrical networks using a T300. The PS25 module provides a

single 12 V or 24 V supply voltage to the system (depending on the model). It

has a battery-backup power supply which in the event of a power outage

enables operation of:

T300 electronic modules

Measurement and monitoring functions

The PS25 module does not include any communication. It operates

autonomously. Set up is done directly on the product.

For more information regarding installing, connection, and use of PS25 module,

refer to the PS25 Installation Guide (ref: NT00376-xx).

8

NT00378-EN-03

Presentation General description

1.3 T300 Internal Architecture

The diagram below shows an example internal architecture for a T300 RTU

comprising 1 HU250, 1 SC150, 1 LV150 and 1 PS50 module.

Architectures may differ depending on the application; there may be more

SC150 and LV150 modules, or some of the other components shown may not

be required (e.g. there may be just the HU250 module or the PS50 module may

be replaced with another type of power supply, etc.).

Since the T300 is modular, mutliple architectures are possible.

This diagram shows the various internal links between the component modules.

The HU250 is the central interface for internal communication between all the

modules as well as for external communication.

NT00378-EN-03

9

Presentation General description

T300 configuration steps

T300

Default

configuration

Easergy Builder

Custom

configuration

Web serveur

Custom

configuration

with application

parameter settings

Configuration backup to

PC or in Easergy Builder

1.4 T300 Configuration Principle

The T300 is delivered with a default factory configuration corresponding to the

options ordered.

This initial configuration should then be customized to adapt it to the user

application and requirements.

There are some tools for this purpose:

Easergy Builder: Engineering tool for adding or customizing specific

operational options adapted to the application. Easergy Builder generates a

custom configuration for the T300 based on the initial configuration modified by

the addition of these options.

SAT: engineering tool for defining / changing the equipment's security policy

and roles assigned to users.

T300 Web server: Commissioning tool for the end user. Using the

configuration set up in Easergy Builder and loaded onto the equipment, the

user can set the parameters for the T300 application program via the Web

server. This step consists in customizing the parameters of the various

functions, such as fault current detection, communication, switch control,

measurement, etc.

In contrast to Easergy Builder, the Web server does not allow functions to be

added to the equipment. It only allows parameters to be set and customized

for the application associated with the functions already selected.

1.4.1 Engineering in Easergy Builder

Before using the equipment, a certain number of functions need to be configured in

Easergy Builder. These functions are not included in the factory configuration as

they depend on the customer application.

The functions that requiered to be added/modified in Easergy Builder are listed

below:

1.4.1.1 Adding/Deleting Channel and Modems

The setting of Channels and existing modems in the default configuration can be

done via the T300 Web server. However, the addition or replacement of modems or

the creation of Channels for the SCADA link, can only be done via Easergy Builder.

Refer to the Easergy Builder User Manual for more details on these custom

settings.

1.4.1.2 T300 Synchronization

The default configuration does not include device synchronization.

The choice of synchronization source can only be configured in Easergy Builder.

The Web server only allows the synchronization parameters to be set once the

function has been configured in Easergy Builder.

There are three possibilities for synchronizing the RTU:

Automatically by the communication protocol (via the SCADA)

Through an SNTP server, if the RTU is connected to an IP network.

By GPS satellites, if the HU250 module includes a 4G modem with GPS

option.

You can define two channels of synchronization, the primary device and the

secondary device.

The secondary device will be used if the primary device is unavailable.

Instructions on how to configure synchronization are given in the T300 Quick Start

Guide (NT00383-xx). Refer to this document for more information.

10

NT00378-EN-03

Presentation General description

1.4.1.3 Sequence of Events (SOE)

An events file is automatically created in the T300 default configuration. This file

corresponds to standard use of the equipment and includes a number of data for

which events are generated on change of states.

The engineering phase is to modify or add additional variables to the file or to create

additional events files (eg measures backup file), or to change the default storage

files.

The total capacity of event files is limited to maximum 4 files.

Easergy Builder allows the management, creation or modification of these events

files.

Note that this management cannot be done via the Web server. The Web server

can only be used to operate these events files, i.e. consulting, downloading, or

deleting them.

Instructions on how to configure the SOE option are given in the T300 Quick Start

Guide (NT00383-xx). Refer to this document for more information.

1.4.1.4 The Master and Slave protocols

The default configuration of the equipment is provided without addressing for the

protocol since it must be adapted to the SCADA type used or the type of slave to

include in the configuration.

The Master protocols:

For Master protocols, the engineering phase is to create first of all slave devices in

the system and the data that will be associated to these Devices. The data to create

depend on the application and the connected device type.

The addressing protocol will have to be set for all the data you wish to report the

statements on the T300.

The list of master protocols that can be used is as follows:

o IEC 60870-5-104

o DNP3

o Modbus

o IEC 61850 Client

The Slave protocols:

For slave protocols, the engineering phase consists of selecting in the system

database, the datas that have to be reported to the SCADA and then to define the

corresponding protocol addressing.

The list of slave protocols that can be used is as follows:

o IEC 60870-5-101

o IEC 60870-5-104

o DNP3

o Modbus

o IEC 61850 Server

Instructions on how to configure the Master and Slave protocol addresses are given

in the T300 Quick Start Guide (NT00383-xx). Refer to this document for more

information.

NT00378-EN-03

1.4.1.5 Personalization of LEDs

Some indicators used in front panel of the product and external lights can be

customized to define the data that will trigger the lighting of these LEDs. This

operation is made during the engineering phase via Easergy Builder advanced tool.

It is possible to customize the colors of the LEDs and set the I/O filter parameters

via the Web server (see the Local I/O section).

Note that the same operations can also be carried out in Easergy Builder.

Instructions on how to assign the LEDs are given in the T300 Quick Start Guide

(NT00383-xx). Refer to this document for more information.

11

Presentation General description

1.4.1.6 Management of specific commands

A specific management function related to the switch controls voltage can be

configured in the engineering phase via Easergy Builder.

Instructions on how to configure this specific command management option are

given in the Easergy Builder User Manual. Refer to this document for more

information.

1.4.1.7 Calculation Formulae

The calculation formulae are used to carry out math, combinational logic operations

or others on T300 data in order to perform specific personalized functions.

These Calculation formulaes can be created via Easergy Builder.

The list of operations available are given in the Easergy Builder User Manual.

Refer to this document for more information related to the calculation formulae.

1.4.1.8 IEC 61131-3 PLC

An IEC 61131-3 programming tool (IsaGRAF® platform) is available with the T300

for developing PLC programs.

This IsaGRAF® platform is an external software tool to be installed on a PC.

It is used to develop specific custom applications in the following programming

languages:

o SFC: Sequential Function Chart

o FBD: Function Block Diagram

o LD: Ladder Diagram

o ST: Structured Text

o IL: Instruction List

Before developing and using a PLC program in the HU250, the interface must first

be created with IsaGRAF® in Easergy Builder to define the links and the

relationship between these 2 elements and the CoreDB.

Instructions on how to configure the interface with IsaGRAF® in Easergy Builder

are given in the Easergy Builder User Manual. Refer to this document for more

information.

1.4.2 Management of RBAC and security policy

The T300 is provided with a standard security policy and a default RBAC (roles

assigned to a number of predefined users).

The T300 security policy is managed by a special tool - SAT (Security

Administration Tool).

The SAT can be used during the engineering phase to redefine or change the

system access restrictions, including the access rights and responsibilities, via an

RBAC (Role-Based Access Control) model.

Radius protocol provides also the capability to have a generalized and unique

authentication policy on a dedicated server, rather than to define them locally on the

various T300s of the network.

The commissioning phase done in the Web server will be only limited to adding or

deleting users, to modify their associated passwords, and to assign or modify one or

more of the roles pre-defined in the SAT to these users.

See the Managing Users and Roles section for more information on how to set

these parameters.

Instructions on how to configure the security policy in the SAT are given in the SAT

User Manual. Refer to this document for more information.

12

NT00378-EN-03

Installation Start-Up the unit

1.5 Initial Start-Up

Instructions relating to starting up the equipment are described in the T300 Quick

Start Guide (reference NT00383-xx).

Refer to this document to get the following information:

How to install Easergy Builder

First local connection to the T300

o Connecting to the T300 Web server via an Ethernet network

o Connecting to the T300 Web server via a WI-FI network

Configuring the SC150 and LV150 modules IP addresses

Overview of Easergy Builder

How to import a T300 configuration into Easergy Builder

How to import a saved tar.gz T300 configuration into Easergy Builder

How to customize the T300 configuration in Easergy Builder

How to synchronize the T300

How to send a configuration to the T300 via Easergy Builder.

NT00378-EN-03

13

Connecting to the T300 Overview of the T300 Web Server

HU250 module

Connection of a

configuration/consultation/maintenance PC to one of

the available ETH port.

Ethernet cable for the PC-T300 link

2 Connecting to the T300 Web Server

Easergy T300 needs a connection from a PC, tablet, or smartphone to

be able to configure, consult, or carry out maintenance on the equipment:

This can be via a WI-FI or Ethernet connection (via the HU250 module).

Equipment Required for the T300 Connection

The T300 needs a PC with Windows XP, 7, or more recent operating system, and a

web browser, such as Internet Explorer (version 10 minimum), Mozilla Firefox, or

Google Chrome. It also needs:

An Ethernet port (RJ45) on the PC to connect to the T300 via an

Ethernet network or direct PC-T300 access

WI-FI access on the PC to connect to the T300

Note: The choice of WI-FI or Ethernet access to the T300 is up to the user.

There is no difference in operation between the 2 types of link. However, Wi-Fi is

considered as a Local access mode and Ethernet a remote access mode, with the

possibilities that relate to these two modes.

The T300 parameters and data are accessed directly via a web browser.

No other additional software is required to access the embedded Web server.

Principle of the T300 Embedded Web Server

The T300 includes an embedded server that initializes automatically as soon as

the connection is established with the T300.

The data displayed by the T300 via this embedded server is presented in the

form of HTML pages.

Different pages and subpages can be accessed by the user depending on

their user rights. The HTML pages displaying the data managed by the T300 are

refreshed in real time to help ensure they show the most up-to-date status

information.

Access and connection are secured by a login and password.

From the embedded server you can:

Modify the fault current detection, communication, automation fucntion, or

system parameters

Note: The T300 is supplied with default parameters that can be modified

as required by the user.

View the states managed by the T300 (indicators, events, potential issues,

measurements, counters, etc.)

Save the T300 configuration to file or download it from a file already saved

on the PC

Send remote control orders to the T300

Transfer diagnostics logs in .csv file format compatible with Excel

Load a new version of the T300 application firmware (to the HU250 or the

SC150 and LV150 modules)

IP Addresses for Connection to the T300

As standard, the T300 integrates IP addresses for the local Ethernet connection

from a PC as well as for WI-FI access. The following characteristics are needed

to establish these connections:

Default T300 Ethernet port address: https://192.168.0.254

WI-FI access:

WI-FI SSID = EasergyT300

Password = EasergyT300

WI-FI IP address = https://192.168.2.254

Note: To prevent conflicts and for security purposes, it is advisable to configure a

single and unique SSID for each T300. Refer to the corresponding section in this

manual for information on how to change these parameter settings.

The default connection parameters are general purpose, but it is possible to modify

them to meet your network specifications.

Connecting to the T300 Web Server

Instructions on how to connect to the T300 web server are not given in this manual.

Refer to the T300 Quick Start Guide (reference NT00383-xx), for detailed

instructions on how to connect via Ethernet or WI-FI.

14

NT00378-EN-03

Connecting to the T300 Overview of the Web Server

Home page – T300 Web server

Substation page – T300 Web server

MV Measurement page – T300 Web server

3 Overview of the T300 Web Server

The T300 Web server is the local and remote user interface for consulting and monitoring

T300 operating, maintenance, and application configuration data.

Once the username and password have been entered, all data in the HTML pages can

be viewed simply by clicking on the links in the ribbon at the top of the screen.

This ribbon contains 5 menus:

HOME:

The information on this page identifies the MV substation to which the user is

connected. Some of this information can be filled in by the user:

o The substation's GPS coordinates

o A location map is created automatically and updated using the GPS data (if there is

an Internet connection).

o Notes added by the user

o The product ID with the option to add images

MONITORING & CONTROL:

This menu is used to view the T300 status, monitor substation data, and control the

breaking device:

o Graphical representation of the substation and switchgear with electrical symbols

o Display of T300 status in the form of a data point list with the values associated

with each type (state, command data, analog data, setpoint values)

o Option to set command and setpoint data parameters manually from the Web

server and to assign a specific preset value (for security purposes, each

command must be confirmed by the user)

Note: The user can modify command data via the Web server:

- Via the WI-FI network only if the T300 is in local mode

- Via the LAN or WAN only if the T300 is in remote mode

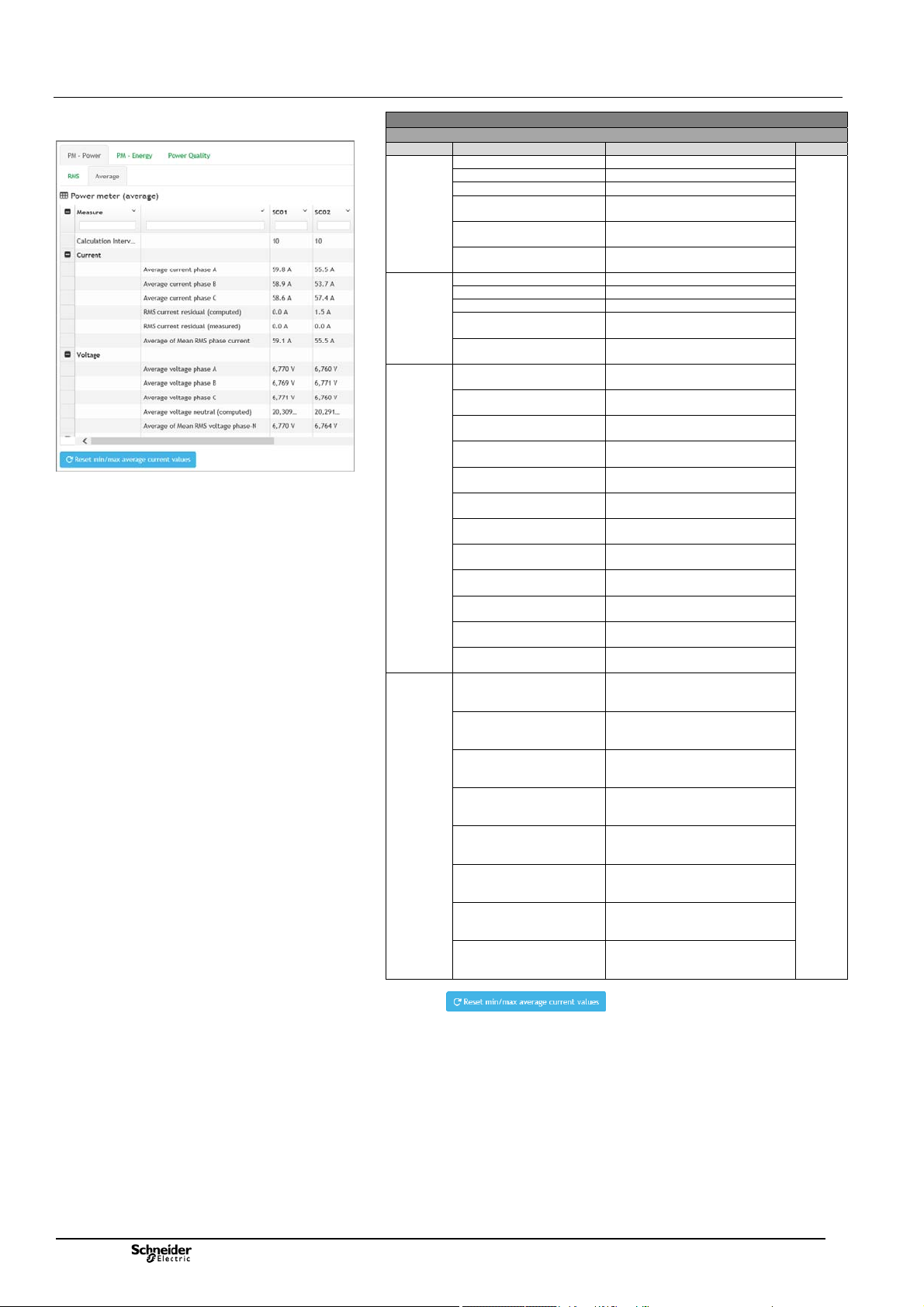

MV/LV MEASUREMENTS

This page is used to view the different measurements performed by the T300

(display of some measurements according to the options of the unit):

o Current measurements on each phase, residual current and mean current

o Average of the currents on each phase, the calculated or measured residual

current and the average current

o Phase-to-neutral and phase-to-phase voltage measurements on each phase and

indication of residual voltage and mean voltage measurements

o Average of the voltages on each phase, the calculated neutral voltage and the

phase-to-neutral average voltage

o Active, reactive, and apparent power measurements on each phase

o Average of the active, reactive and apparent power on each phase and of the

total power

o Power factor measurement on each phase

o Active, reactive, and apparent energy measurements on each phase

o Power quality measurement (statistics and counters for the vol

sags, and swells on the MV network)

o Minimum and Maximum recorded for current averages, per day, week, month

and year.

o Harmonic distortions on each phase current and the average of the three phases.

o Harmonic distortions on each phase voltage and the average of the three

phases.

o Harmonic magnitude 1 on each phase current.

o Harmonic magnitude 1 on each phase voltage.

o Harmonic 1 current and voltage on the average of the three phases.

o Harmonic angle 1 on each phase current.

o Harmonic angle 1 on each phase voltage.

tage interruptions,

NT00378-EN-03

15

Connecting to the T300 Overview of the Web Server

Diagnostic/Events page – T300 Web server.

HU01 Settings page – T300 Web server.

SC01 Settings page – T300 Web server.

LV01 Settings page – T300 Web server.

DIAGNOSTICS:

This menu is used to view the data logs recorded in real time by the T300. Events

are time-stamped with a 1 ms resolution.

Recording of events: Data changes are recorded in log files according to the

configuration.

The recording mode must be configured using the Easergy Builder configuration

tool:

o It is possible to define up to 4 log files (events).

o The size and name of each log file are configurable.

o Any data can be assigned to a log file.

Note: By default, only the Events log is created, with a capacity of 2,000 events.

Log files can be downloaded locally or remotely. For all logs, when the storage cap

acity is reached, the most recent event erases the oldest event from the list.

MAINTENANCE:

This menu helps with maintenance of the T300 by supplying the relevant information

or by allowing configuration of the standard RTU applications:

o Users: managing the roles and passwords associated with each user.

o Clock: Synchronization of the device date and time

o IP configuration: Definition of the IP addresses of the LAN, WAN, and WI-FI

networks or the T300 router function

o Modem configuration: Configuration of the modem communication

parameters, for the modems providing remote access, such as the 3G or 4G

modem

o Firmware: Information relating to the firmware for each module (version, date,

and time) with the option to update it

o Configuration: Information relating to the device configuration with the option

to import/export the configuration in file format or saving/importing it into

SETTINGS:

dedicated slot spaces in the device.

There are several pages dedicated to configuring the various functions for each T300

module:

o HU250: Configuration of the HU250 module parameters:

o SCADA protocol (slave) (Modbus, IEC 60870-5-101 and 104, DNP3)

o Master protocol (Modbus, IEC60870-5-104, DNP3)

o Physical port (RS485 for PS50 link, RS232/485 modem box, etc.)

o Synchronization

o SC0x: Configuration of the parameters of each SC150 module:

o Current and voltage measurement sensors

o Switch controls

o Current and voltage presence/absence detection

o Fault current indication

o Fault current detection

o Broken conductor detection

o MV Measurements

o MV Power quality

o Sectionalizer automation function.

o PS50: Configuration of the parameters of each PS50 module:

Power supply input monitoring

o

o Battery

o Remote control order monitoring

o Back-up power supply management.

o LV0x: Configuration of the parameters of each LV150 module:

o Current and voltage measurement sensors

o LV Voltage monitoring

o Broken conductor detection

o LV Measurements

o LV Power quality.

16

NT00378-EN-03

Commissioning Data Consultation and

Monitoring Pages

Home page – Web server

3.1 Data Consultation and

Monitoring Pages

3.1.1 Home Page

Accessed via: Home page

Once the username and password have been entered to access the

T300 Web server, the Home page is displayed automatically.

This page contains the following general information about the MV substation:

Device Information: It is possible to add the names of the operators who

have used or configured the equipment or a specific custom note that can be

viewed each time a connection is established to this substation.

Location: The GPS coordinates for the MV substation location

(latitude, longitude, and altitude) can be entered here.

If these coordinates are defined and there is an Internet connection,

a Google map automatically appears in the Home page.

It is possible to download another image manually by clicking the button

next to the map. Then simply browse to select the relevant image file and

click Upload to upload the map:

Factory Information: This gives the product ID and the version of the

software loaded on the HU250 module.

It is also possible to include an image of the MV substation or a particular

device here for identification purposes.

To do this, click the , button to select the relevant file and click Upload to

upload the image:

NT00378-EN-03

17

Commissioning Data Consultation and

Monitoring Pages

Monitoring & Control/Substation page – Web server

Extended data display for the HU250 module

3.1.2 Substation Page

Accessed via: Monitoring & Control/Substation page

The Substation page provides an overview of the information relating to the

MV substation managed by the T300:

The overall status of the T300 HU250 module (local/remote control,

state of the automation function, etc.)

The overall status of the power supplies managed by the PS50 module

Information related to the MV switches and the associated measurements,

with a graphical representation per channel (by SC150 module)

The Low Voltage measurements managed by each LV150 module.

Information displayed for the HU250 Module

This graphical representation corresponds to the information displayed and

the actions that are possible on the HU250 module, namely:

Indication of Local/Remote operation (this can be changed using the

pushbutton on the HU250 module)

Reset button to clear the fault current indication

Automation function status (ON/OFF or locked), with the option to activate

the automation function (by clicking the button) and to reset the automation

function lock (by clicking the button)

Indication of the ambient temperature, if there is a PT100 temperature sensor

connected to the HU250 module

Extended display for the HU250 Module

By clicking on the graphical representation of the HU250 above, an additional

representation appears on the right-hand side of the screen indicating the

states of all the digital I/O:

By clicking the button, the user has the option to change the

state of the associated digital output:

Note: the labels of the displayed states can eventually be customized by changing

the description of the corresponding data points in CoreDb via Easergy Builder.

Refer to the Easergy Builder User's Manual for more information.

18

NT00378-EN-03

Commissioning Data Consultation and Monitoring

pages

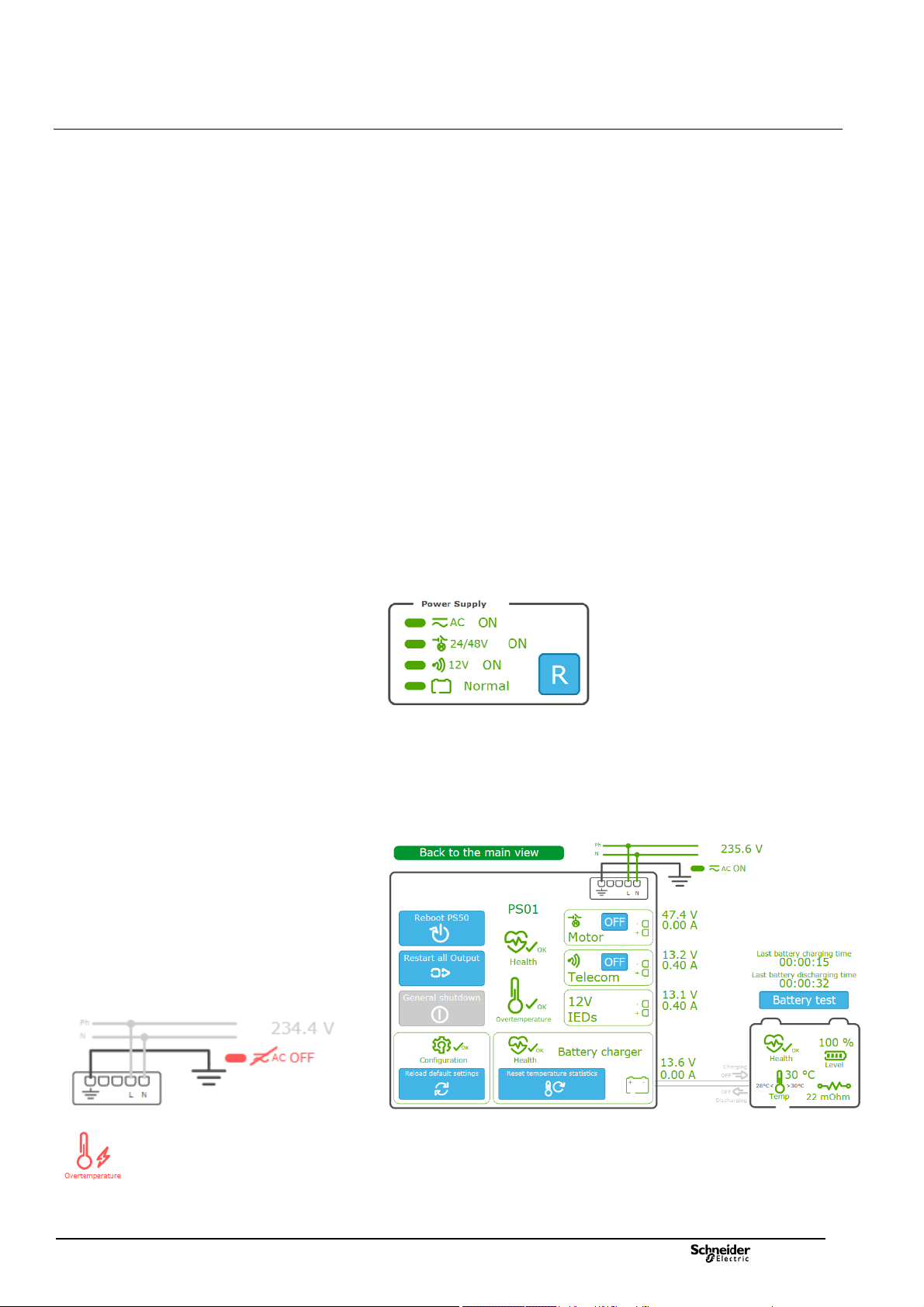

Information displayed for the PS50 Module

This graphical representation contains the following information:

The status of the power supplies managed by the PS50 module, respectively:

The AC line supply

The 24/48 VDC power supply for the switch motor mechanism

The 12 VDC power supply for the transmission equipment

The battery

A Reset button for restarting the power supplies in the event of an outage

following a potential issue on one of the outputs

Power supply shutdown

A power supply shutdown occurs when the mains power supply has been switched

off for a long time, in order to limit the time on the backup power supply (battery).

This power interruption preserves the capacity of the battery and its lifetime.

Battery backup saving can be enabled or disabled by configuration.

When this function is enabled, as soon as the MV network is switched off, the

battery takes over the power supply for a configurable maximum period Backup

time duration (default: 16 hours).

Beyond this period, an immediate alarm General shutdown is activated and then

Power supply is switched off automatically. The power supply is also switched off if

the battery reachs low level and then PS50 module enters sleep mode until the AC

network voltage returns.

From this sleep mode, the 24/48 V & 12 V power supply outputs can be

reactivated temporarily when the PS50 module is reset (Reset button

the External Reset digital input of the PS50 module is activated. The power

supply is switched off again and permanently if it reach the critical discharge

threshold (< 10.8 V).

Extended display for the PS50 Module

By clicking on the graphical representation of the PS50 above, additional

information appears on the right-hand side of the screen including states,

measurements, and the possible actions.

) or when

Examples of potential issues displayed in red

NT00378-EN-03

Under normal conditions, the information is displayed in green. In the event of an

anomaly, the information is displayed in orange or red depending on the severity of

the condition.

19

Commissioning Data Consultation and Monitoring

pages

A Reboot PS50 button for restarting the PS50 module. This action performs a complete reboot of

the T300 device.

The extended information included in the detailed view of the PS50 module is

described in the table below:

A Restart all outputs button for restarting all outputs. This may reset the outputs to their initial state

if this is possible and if the anomaly is temporary.

A General shutdown button that can only be activated if there is no AC line supply and power is

supplied by the battery only. Click this button to switch all T300 power supplies to standby mode

and thereby conserve battery power. It is possible to exit standby mode, either manually by pressing

the Reset button on the front of the PS50, or automatically when the AC line supply is restored.

A Reload default settings button for clearing the current parameters and returning to the

PS50 module default parameters.

A Health symbol indicating the overall state of the PS50 and an Overtemperature symbol indicating

the state of the PS50 module thermal protection.

A symbol indicating the state of the 24/48 V switch motor mechanism power supply with an

ON/OFF button for turning this power supply on or off.

A voltage measurement and a consumption measurement are also displayed for this power supply.

A symbol indicating the state of the 12 V transmission power supply with an ON/OFF button for

turning this power supply on or off.

A voltage measurement and a consumption measurement are also displayed for this power supply.

A symbol indicating the state of the general 12 V power supply for the T300 modules and IEDs.

A voltage measurement and a consumption measurement are also displayed for this power supply.

This section displays the overall state of the battery charger with a Reset temperature

statistics button to clear the stored minimum and maximum battery temperatures.

A voltage measurement and a consumption measurement are also displayed for the battery.

A symbol for the presence/absence of the AC line supply with the corresponding voltage

measurement.

Two time indications and a button:

Last battery charging time: Duration of the battery's last charging period

Last battery discharging time: Duration of the battery's last discharging period

Battery test button for activating the battery test immediately. The battery test is theoretically

conducted automatically depending on the period defined in the Automatic test

interval parameter (default setting: 1 day).

Note : The button is not displayed if the battery is disconnected, if battery

potential issue is detected, or if the AC supply is missing.

A graphical representation of the overall status of the battery, including:

Overall battery health indication

Percentage battery charge remaining

Internal resistance measurement in mOhm

The temperature measured in the PS50 operating environment (measurement made internally

in the PS50 box) with an indication of the minimum and maximum values recorded since the

last statistics reset (see

An indication of whether the battery is charging or discharging via arrows showing the direction

of the current. The measurement indicated at the charger level (see

value for this current.

)

) gives a measurement

20

NT00378-EN-03

Commissioning Data Consultation and Monitoring

r

r

r

pages

Information displayed for the SC150 modules

Each switch managed by a SC150 module is represented graphically with the

following indications:

Position of the switch (open or closed)

Position of the ground switch (open or closed)

Presence of the MV voltage (ON or OFF)

Display of the RMS current and voltage measurements for each phase

Indication of the presence of a fault current by a red flash and an arrow

indicating the direction of the fault current (for directional fault current detection):

o Green arrow = in the direction of the busbar

o Red arrow = in the direction of the network

Button for editing the graphics parameters associated

with switches

Window for setting the parameters of the graphic

objects associated with a switch

Graphical representation of the Switch

It is possible to customize the graphical representation of each switch by clicking

the button at the top of the page.

Click the edit button that appears in the page to access the graphic

parameters for the switch you want to customize.

A window appears offering the following choices:

Parameter Possible choices Description

SC Position on the bus

Switch type

Line output

VT presence

CT presence

Bay name Name given to the channel

Not connected

On the left

On the right

In the middle

Disconnector

Load switch

Switch disconnector

Circuit breaker

Not any output

Cable

LV0x

No

Yes

No

Yes

Choice of position of the switch on

the busbar:

No link with the busbar

On the left

On the right

In the middle

Choice of switchgear represented:

Disconnector

Load switch

Switch disconnector

Circuit breake

Choice for the representation of

the line downstream of the switch

Choice of whether or not to display

the voltage measurement

transforme

Choice of whether or not to display

the current measurement

transforme

NT00378-EN-03

21

Commissioning Data Consultation and Monitoring

pages

Dummy switch

position

Dummy switch position LED on the front panel of the

SC150 module

Extended display for the SC150 module

By clicking on the graphical representation of the switch, additional information

appears on the right-hand side of the screen including counters

and measurements:

Information relating to the switch is displayed in the same way as in the

standard representation. There is also an option to send a command to the

switch by clicking the or button (depending on its

actual position). The graphical representation of the switch is automatically

updated as soon as the change of state is detected.

The general fault current counters representing the total number of phase-to-

phase and phase-to-ground (earth) fault currents detected are displayed by type

(transient, semi-permanent, and permanent), with the option to reset the counter

values by clicking the Reset button .

The detected phase-to-phase fault current counters are displayed by type

(transient, semi-permanent, and permanent), with the option to change the values

by clicking the Edit button.

The detected phase-to-ground (earth) fault current counters are displayed by

type (transient, semi-permanent, and permanent), with the option to change the

values by clicking the Edit button.

The number of operations counted on the switch is given, with the option to

change the value by clicking the Edit button .

The T300 includes the option to configure 2 sets of fault current detection

parameters (with specific values for each set) in the Settings section of the Web

server (see the corresponding section in this manual). The option is given here to

select which set of parameters to apply to fault current detection by clicking or

. The active group is indicated by a green LED.

A Simulation section that is used to test a command on a dummy switch

without actually actuating it (this can be useful to test T300-SCADA

communication when it is not physically possible to operate the switch due to an

interruption on the MV network). To do this, click on the or

retransmission of the change of state remotely (e.g. at the SCADA end). The

position of the dummy switch changes state in this Simulation section of the

application but the actual position of the MV switch (indicated in

change.

After a command is sent to the dummy switch, its position is indicated for

30 seconds on the first customized LED on the SC150 module.

button to operate dummy switch and, for instance, check the

) does not

The instantaneous current measurements for each phase as well as the

residual current

The instantaneous voltage measurements for each phase.

22

NT00378-EN-03

Commissioning Data Consultation and Monitoring

pages

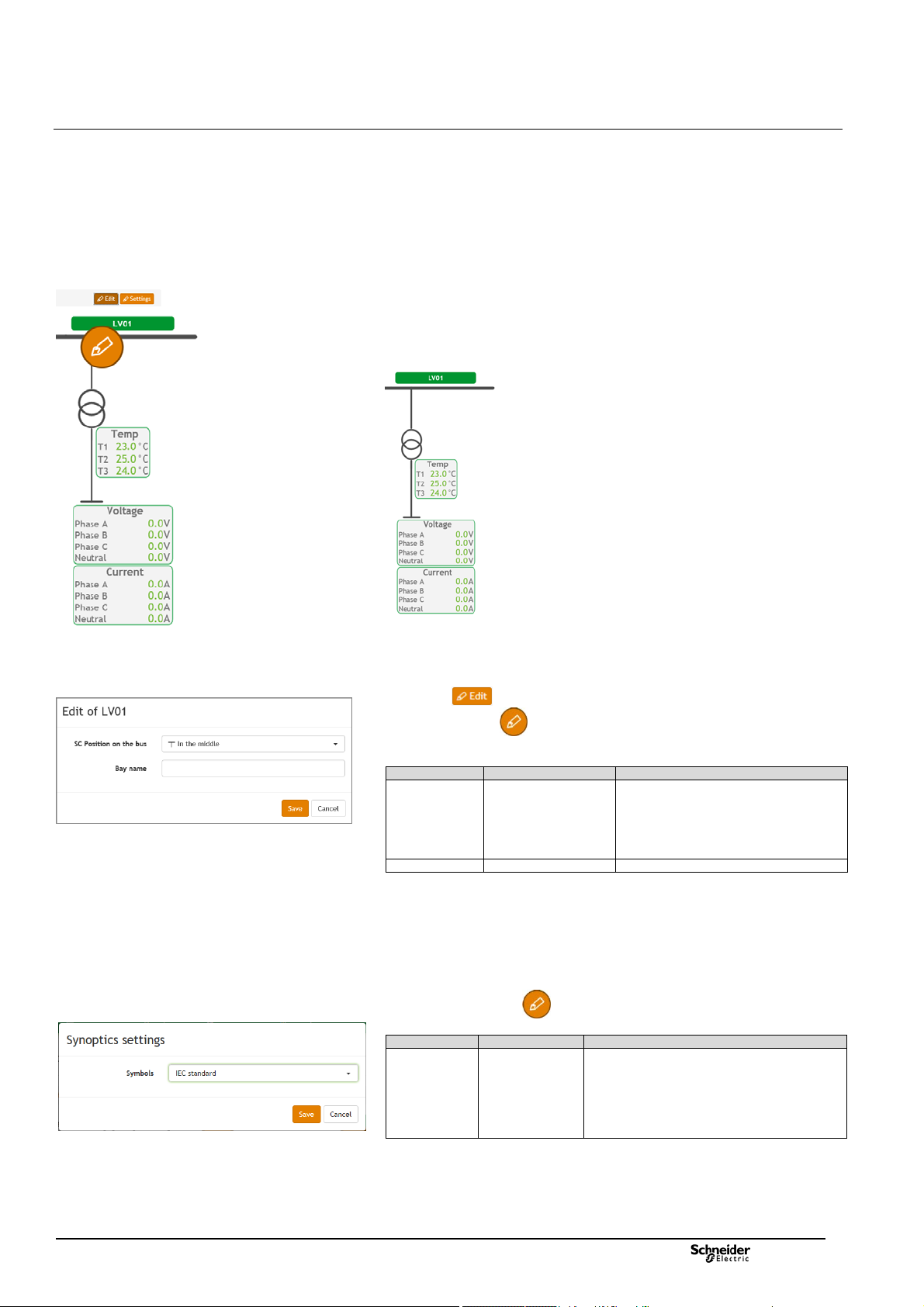

Information displayed for the LV150 modules

Each LV150 module has its own graphical representation including the display of

the following information:

The temperature measurements provided by the three PT100 sensors

connected to the LV150

The LV current measurements on each phase and neutral

The LV voltage measurements on each phase and neutral.

Note: The neutral current measurement displayed corresponds to a measured

value in case the 3-phase + neutral sensors mounting is used and to a calculated

value (by summing all 3 phases) when the neutral is not connected.

Button for editing the graphics parameters associated

with LV150

Window for setting the parameters of the graphic

objects associated with LV150

Window for selecting the standard for the graphical

representations

Graphical representation of LV150:

It is possible to customize the graphical representation of each LV150 module by

clicking the button at the top of the page.

Click the edit button that appears in the page to access the graphic

parameters for the LV150 you want to customize.

A window appears offering the following choices:

Parameter Possible choices Description

LV Position on

the bus

Bay name Name given to the channel

Synoptics settings

Click the settings button to define the type of graphical representation to

apply for the objects displayed in the page's synoptics:

Parameter Possible choices Description

Symbols

Not connected

On the left

On the right

In the middle

IEC standard

ANSI standard

Choice of position of the LV150 on the

busbar:

No link with the busbar

On the left

On the right

In the middle

The standard used relates to the representation of

the switchgear, voltage and current transformers,

and the ground switch:

Objects represented in accordance with the IEC

standard.

Objects represented in accordance with the

ANSI standard.

NT00378-EN-03

23

Commissioning Data Consultation and Monitoring

pages

Monitoring & Control/Physical view page – Web server

Overall HU250 module status

Overall PS50 module status

3.1.3 System Page

Accessed via: Monitoring & Control/System page

This page provides a general overview of the system. The states of the various

items (modules) are given by symbols indicating a correct operation or potential

issue conditions. The indications given by theses states are detailed by module

here after.

HU250 Module Status

This representation includes:

The status of the Wi-Fi access and the K7 3G/4G modem with a 5-bar GSM

signal strength indicator, and indication of the IP address if connected to the

mobile network.

The status of the HU250 module itself, including the configuration, the PLC,

the GPS reception, the synchronization of equipment and a percentage value

representing the CPU usage level.

Note: The GPS reception symbol indicates the satus of GPS reception with a

color:

- gray: unconfigured or invalid GPS reception.

- green: operational GPS reception.

- red: GPS reception potential issue.

Note 2: A GPS reception issue causes a loss of synchronization and the

corresponding symbol becomes red.

PS50 Module Status

This representation includes:

An indication of the type of link used for the internal HU250-PS50 link (RS485

in Modbus protocol).

The status of the PS50 module, the charger, and the battery, as well as the

overall status of the internal Modbus RS485 link.

LV150 and SC150 Modules Status

This representation includes:

An indication of the type of link used for the internal link between HU250

module and SC150/LV150 modules (Ethernet LAN in IEC 60870-5-104 protocol).

The status of the SC150 and LV150 modules, including for each the status of

the configuration and synchronization, as well as the overall status of the internal

IEC 60870-5-104 Ethernet LAN.

Overall SC150 and LV150 modules status

24

NT00378-EN-03

Commissioning Data Consultation and Monitoring

pages

Example of a pop-up window displayed for the

Configuration section of a module

Example of a pop-up window displayed for the

Synchronization section of a HU250 module and

SC150/LV150 module

Example of a pop-up window displayed for the Modem

section of a module

Example of shortcuts available by clicking on the

module representation

Extended display

By passing the mouse over some graphical elements of the modules in the System

page, a "pop up" window appears giving additional indications.

This additional display concerns the following:

1. Configuration: By passing the mouse over the Conf element of a module,

the system indicates the following informations:

The minimum software required for compatibility with the module

configuration.

The options installed on the module (eg details of installed power

2. Synchronization: By passing the mouse over the Synchro element of a

3. Modem: by passing the mouse over the graphical representation of a 3G/4G

measurement options).

module, the system gives the following indications:

For the HU250 module:

o Status of the two synchronization sources (primary and secondary).

For the SC150 and LV150 modules:

o Status of the module time synchronization and status of the

synchronization source generating this synchronization.

o Status of the "1Hz" module synchronization as well as the status of

this synchronization 1Hz signal. This synchronization allows all the

SC150 and LV150 modules to be synchronized to the same 1 Hz

frequency top generated by the HU250 module.

modem, the system indicates the following informations:

Type of modem installed (2G, 3G or 4G modem).

Received GSM signal strength, numbered from 0 to 99:

o 0 to 10: insufficient GSM reception

o 11 to 31: correct GSM reception

o 99: undetectable GSM signals.

The IP address obtained for the T300, assigned by the mobile operator.

The modem IMEI code, allowing identification of the equipment

connecting to the mobile network.

Shortcut to pages

By clicking on the graphical representation of a module, a pop-up window appears

giving the possibility to access directly certain pages of the Web server linked to

this module, like shortcuts or quick accesses.

Depending on the type of module, quick access can be of different types:

PS50: shortcuts to the PS50 module configuration page (Settings page) and

the PS50 module status display page (Subview of PS page).

Other modules: shortcuts to the system events page (Diagnostics-

>System page) and the module settings page (Settings page).

NT00378-EN-03

25

Commissioning Data Consultation and Monitoring

pages

Monitoring & Control / Status page – Web server

3.1.4 Data Pages

Accessed via: Monitoring & Control/Status-Command-Analog-Setpoint page

There are 4 pages in the T300 Web server for viewing status and measurement

data or for sending commands:

Status page: For viewing the status of the digital data

Command page: For sending change of state commands based on the

digital data

Analog page: For viewing measurement values

Setpoint page: For forcing parameter values

Each page has the same format, with the following information displayed on

the screen:

The data refresh period can be configured in 1 of 3 ways:

o Fast: Data is refreshed every second

o Normal: Data is refreshed every 4 seconds

o Slow: Data is refreshed every 10 seconds

It is also possible to set a filter to display data by Source or Destination to limit

the amount of data displayed on screen:

The description of a data item is displayed over 3 main columns:

o Point name Internal name of the data item in CoreDb (database)

o Description Data label

o Value Value of the data item

By clicking the button associated with the Value field, you can manually

edit the state or value of a Command or Setpoint data item:

Note: For switch control, it is advisable to use the interface in the Substation view.

26

NT00378-EN-03

Commissioning Data Consultation and Monitoring

pages

Example of Analog data display

Similarly, for a Status or Analog data item, you can force its status or value.

However, this type of data is only processed in read mode; forcing is only

applied in simulation.

To do this, the actual data item must first be locked by clicking the Locking option.

Once the data is locked, the button associated with the Value field then

becomes accessible and can be used to change its status or value in

simulation mode.

Note: The modified value also impacts the remote retransmission at the

SCADA end. This allows you, for instance, to simulate the state of a variable

and to test its retransmission at the SCADA end, without affecting the actual

equipment operation.

Disabling the Locking option cancels the simulation and returns to the actual

status or value of the data item.

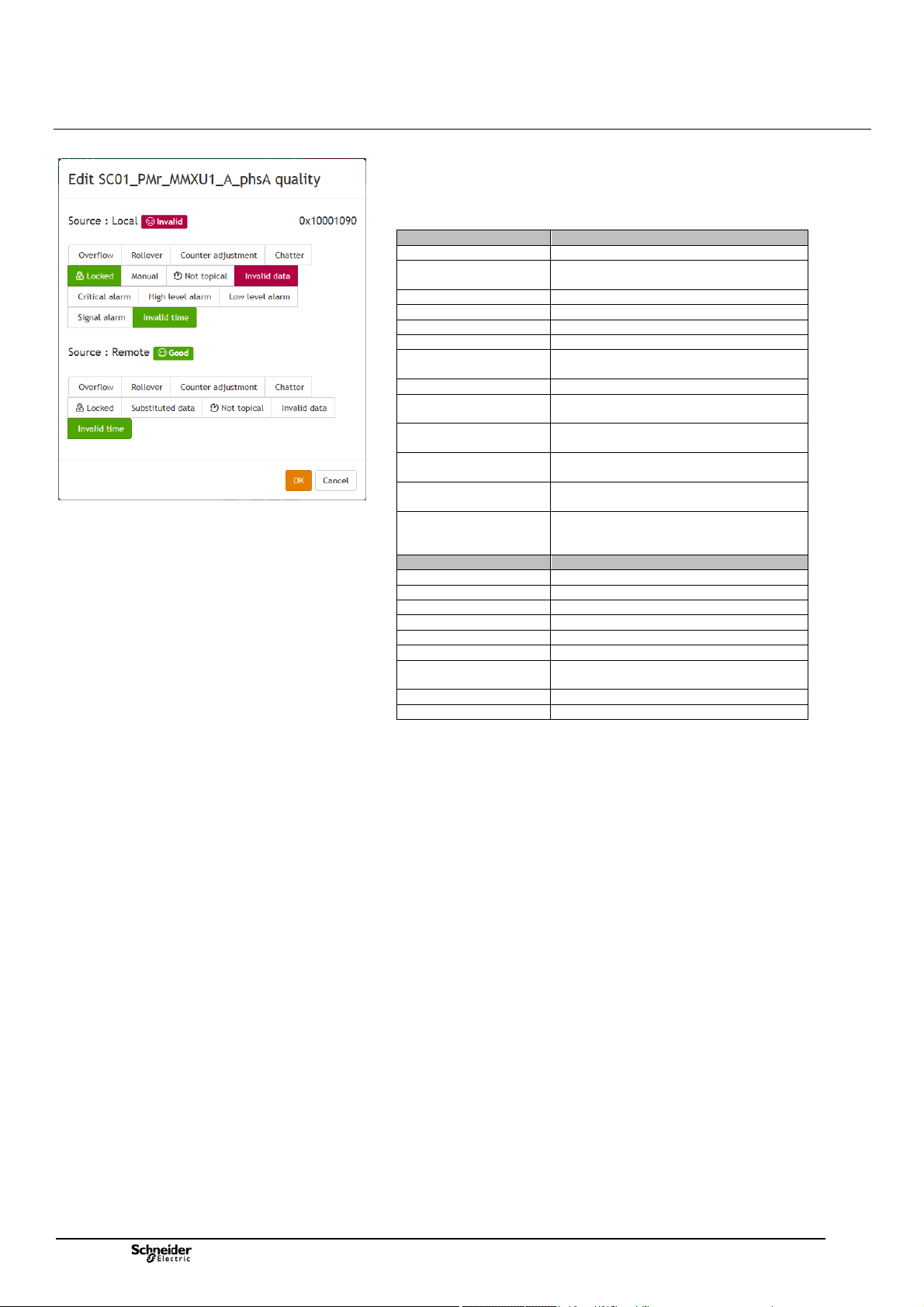

Two icons displayed in the Quality column provide an indication of the data

processing quality. The quality of a data item can give an indication of the

validity of the status or value entered on the Web server page.

This quality is indicated for the following 2 sources:

o Local source: Reflects the quality of the data item from the viewpoint

of its processing at the HU250 end

o Remote source: Reflects the quality of the data item sent by the

information source (device) processing the data (e.g. SC150, PS50, etc.)

NT00378-EN-03

In the same way as for a change of state or value for Status or Analog