Kodak DirectView CR-825, DirectView CR-850 Diagnostics

© EASTMAN KODAK COMPANY, 2005 |

HEALTH GROUP |

|

Publication No. DG4825-1 |

|

10DEC05 |

|

Supersedes DG4825-1 |

|

20JUL04 |

Confidential |

|

Restricted |

|

Information |

|

DIAGNOSTICS for the

Kodak DirectView CR 825/850 SYSTEMS

Service Codes: 5634, 4825

Important

Important

Qualified service personnel must repair this equipment.

H177_0500GC

DIAGNOSTICS

10DEC05 DG4825-1 Page

2 of 180

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and makes no warranty, express or implied, with respect to this information. Kodak shall not be liable for any loss or damage, including consequential or special damages, resulting from any use of this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic |

|

discharge. Use caution to prevent damage during all service procedures. |

|

Table of Contents |

|

Description |

Page |

Using the Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

System Service Diagnostic Screen. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

10 |

Functions of the “System Service Diagnostic” Screen . . . . . . . . . . . . . . . . . . . |

12 |

Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

Individual Component Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

Component Control: Step . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

Light Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

31 |

Slow Scan Current and Velocity Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

Laser Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

35 |

Galvo Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

36 |

PMT Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

39 |

GALVO PLOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

40 |

Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

43 |

AUTOLOOPER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

45 |

MCPU Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

47 |

Diagnostic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

49 |

Checking the Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

49 |

Checking the Error Frequency Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

50 |

Checking the Actuation Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

51 |

Storing the Error Logs on a Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

52 |

Clearing the Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

53 |

Installing Files from a Disk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

54 |

Displaying the Software Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

55 |

Downloading Software to the BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

56 |

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

57 |

DIAGNOSTICS

10DEC05 DG4825-1 Page

3 of 180

Overview. . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

57 |

CASSETTE LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

58 |

|

10006 |

- CASSETTE REAR SENSOR S3 did not detect CASSETTE . . . . . |

58 |

10007 |

- CASSETTE REAR SENSOR S3 did not detect loading of |

|

CASSETTE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

58 |

|

10008 |

- CASSETTE REAR SENSOR S3 did not clear . . . . . . . . . . . . . . . . . |

59 |

10009 |

- CASSETTE LOAD SENSOR S2 did not clear . . . . . . . . . . . . . . . . . |

60 |

10014 |

- CASSETTE REAR SENSOR S3 blocked on load . . . . . . . . . . . . . . |

61 |

10016 |

- Load CASSETTE: Retry attempt . . . . . . . . . . . . . . . . . . . . . . . . . . . |

61 |

10017 |

- Eject CASSETTE: Retry attempt . . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

10019 |

- Eject CASSETTE: Timeout error . . . . . . . . . . . . . . . . . . . . . . . . . . . |

62 |

10020 |

- Malfunction at CASSETTE ENTRY SENSOR S1 . . . . . . . . . . . . . . |

63 |

10021 |

- MSC BOARD A1: Software malfunction . . . . . . . . . . . . . . . . . . . . . |

63 |

10022 |

- MSC BOARD A1: Software malfunction . . . . . . . . . . . . . . . . . . . . . |

64 |

10024 |

- MSC BOARD A1: Software malfunction . . . . . . . . . . . . . . . . . . . . . |

64 |

10029 |

- READER detected the CASSETTE BAR CODE label as backward |

64 |

10030 |

- READER did not read the CASSETTE BAR CODE . . . . . . . . . . . . |

64 |

LATCH/UNLATCH CAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

66 |

|

11001 |

- DUPLEX CAM did not move to Home Position . . . . . . . . . . . . . . . |

66 |

11002 |

- DUPLEX CAM did not move to “PINCH” position. . . . . . . . . . . . . |

66 |

11003 |

- DUPLEX CAM did not move to “CLAMP/UNLATCH” position. . . |

66 |

11004 |

- DUPLEX CAM did not move to “UNCLAMP/LATCH” position. . . |

66 |

11005 |

- DUPLEX CAM did not move to “UNPINCH” position . . . . . . . . . . |

66 |

11006 |

- CAM OUTER SENSOR S11 did not detect position of |

|

DUPLEX CAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

66 |

|

11007 |

- CAM INNER SENSOR S10 did not detect Home Position for DUPLEX |

|

CAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

66 |

|

11009 |

- DUPLEX CAM: Move failed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

67 |

11010 |

- DUPLEX CAM: Software command failed on the MSC BD . . . . . |

67 |

11014 |

- DUPLEX CAM: Timeout Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

67 |

11015 |

- Move command failed because SLOW SCAN not at Home Position 67 |

|

11016 |

- MSC BOARD A1: Software Error for DUPLEX CAM . . . . . . . . . . . |

67 |

11017 |

- MSC BOARD A1: Software Error for DUPLEX CAM . . . . . . . . . . . |

68 |

11018 |

- DUPLEX CAM did not move to next position . . . . . . . . . . . . . . . . |

68 |

11019 |

- DUPLEX CAM did not move to “PINCH” position. . . . . . . . . . . . . |

68 |

11020 |

- DUPLEX CAM did not move to “UNLATCH” position. . . . . . . . . . |

68 |

11021 |

- DUPLEX CAM did not move to “LATCH” position . . . . . . . . . . . . |

69 |

11022 |

- DUPLEX CAM did not move to “UNPINCH” position . . . . . . . . . . |

69 |

SLOW SCAN AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

69 |

|

12001 |

- SLOW SCAN EXTRACTION BAR did not move to Home Position |

69 |

12002 |

- EXTRACTION BAR REFERENCE SENSOR S9 failed to activate . |

70 |

12003 |

- PLATE PRESENT SENSOR S5 did not detect PLATE . . . . . . . . . |

70 |

DIAGNOSTICS

10DEC05 DG4825-1 Page

4 of 180

12004 |

- PLATE PRESENT SENSOR S5 failed to activate. . . . . . . . . . . . . . |

71 |

12009 |

- Caution! SLOW SCAN MOTOR drawing too much power . . . . . . |

71 |

12012 |

- SLOW SCAN AY: Timeout Error . . . . . . . . . . . . . . . . . . . . . . . . . . . |

72 |

12013 |

- SLOW SCAN AY: Timeout error . . . . . . . . . . . . . . . . . . . . . . . . . . . |

72 |

12014 |

- MSC BOARD A1: Software Error for SLOW SCAN . . . . . . . . . . . . |

72 |

12100 |

- SLOW SCAN CONTROLLER BOARD A6: Software Error . . . . . . |

72 |

12101 |

- SLOW SCAN a velocity malfunction during scan . . . . . . . . . . . . . |

73 |

12102 |

- SLOW SCAN stopped during scan . . . . . . . . . . . . . . . . . . . . . . . . . |

73 |

12103 |

- SLOW SCAN stopped during scan . . . . . . . . . . . . . . . . . . . . . . . . . |

73 |

12104 |

- SLOW SCAN: Timeout while moving to SENSOR S9 . . . . . . . . . . |

73 |

12107 |

- SLOW SCAN: +24 V DC malfunction during scan. . . . . . . . . . . . . |

74 |

12108 |

- SLOW SCAN stopped during scan . . . . . . . . . . . . . . . . . . . . . . . . . |

74 |

12109 |

- SLOW SCAN stopped during scan . . . . . . . . . . . . . . . . . . . . . . . . . |

74 |

12110 |

- SLOW SCAN did not communicate with the MOTION SYSTEM |

|

CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

74 |

|

12111 |

- SLOW SCAN did not move. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

74 |

12112 |

- SLOW SCAN did not move. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

75 |

12113 |

- SLOW SCAN CONTROLLER BOARD A6: NVRAM malfunctioned |

75 |

12115 |

- SLOW SCAN CONTROLLER BOARD A6: Software Error . . . . . . |

75 |

12116 |

- SLOW SCAN CONTROLLER BOARD A6 did not communicate with |

|

MSC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

75 |

|

12120 |

- SLOW SCAN did not move. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

76 |

12121 |

- SLOW SCAN did not move. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

76 |

12122 |

- SLOW SCAN COIL BOARD A7 malfunctioned. . . . . . . . . . . . . . . . |

76 |

12123 |

- SLOW SCAN CONTROLLER BOARD A6: Software Error . . . . . . |

76 |

12124 |

- SLOW SCAN CONTROLLER BOARD A6: Software Error . . . . . . |

76 |

12125 |

- SLOW SCAN COIL BOARD A7 malfunctioned. . . . . . . . . . . . . . . . |

77 |

12126 |

- Caution! SLOW SCAN MOTOR is overheated . . . . . . . . . . . . . . . . |

77 |

12130 |

- SLOW SCAN CONTROLLER BOARD A6: Software Error . . . . . . |

77 |

12131 |

- SLOW SCAN CONTROLLER BOARD A6 did not communicate with |

|

MSC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

77 |

|

12132 |

- SLOW SCAN CONTROLLER BOARD A6 did not communicate with |

|

MSC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

78 |

|

12201 |

- SLOW SCAN CONTROLLER BOARD A6: Programming Error . . |

78 |

12202 to 12260 - SLOW SCAN CONTROLLER BOARD A6: “Memory |

|

|

Command” Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

78 |

|

12896 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Reset . . . |

80 |

12901 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . |

80 |

12902 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . |

80 |

12903 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . |

81 |

12904 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . |

81 |

12905 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . |

81 |

DIAGNOSTICS

10DEC05 DG4825-1 Page

5 of 180

12906 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . |

81 |

12907 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . |

82 |

12908 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . |

82 |

12911 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . |

82 |

12913 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . |

82 |

12914 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . |

83 |

12915 |

- SLOW SCAN CONTROLLER BOARD A6: Unexpected Retry . . . . |

83 |

12930 |

- SLOW SCAN: Unexpected Retry during Current Test . . . . . . . . . |

83 |

12931 |

- SLOW SCAN: Unexpected Retry during Velocity Test . . . . . . . . . |

83 |

12941 |

- Unexpected Retry during Communication to MOTION SYSTEM |

|

CONTROL BD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

|

ERASE LAMPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

|

13001 |

- 13008 ERASE LAMP PAIRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

84 |

13009 |

- All ERASE LAMPS malfunctioned . . . . . . . . . . . . . . . . . . . . . . . . . . |

85 |

13010 |

- Erase time exceeds maximum allowed. . . . . . . . . . . . . . . . . . . . . . |

86 |

13011 |

- Command to Erase did not occur . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

13012 |

- MSC BOARD A1: Invalid Command for ERASE LAMPS . . . . . . . |

86 |

13013 |

- MSC BOARD A1: Software failure during erase . . . . . . . . . . . . . . |

86 |

13899 |

- General Erase Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

86 |

|

14001 |

- SLOW SCAN: Malfunction of 24 V Power . . . . . . . . . . . . . . . . . . . |

86 |

14002 |

- STEPPER: Malfunction of 24 V Power . . . . . . . . . . . . . . . . . . . . . . |

87 |

14003 |

- CAM MOTOR M1: Low Power Malfunction. . . . . . . . . . . . . . . . . . . |

87 |

14005 |

- Front DOOR Open . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

87 |

14006 |

- DUPLEX CAM: Initialization Error due to the PLATE PRESENT |

|

SENSOR S5 reading blocked when the SLOW SCAN AY is in the home |

|

|

position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

|

14008 |

- SLOW SCAN: Initialization Error . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

14009 |

- DUPLEX CAM: Initialization Error . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

14010 |

- Slow Scan Async Reset Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

88 |

DATA PATH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

|

15001 |

- MCPU BOARD A2: Fatal Error in Software . . . . . . . . . . . . . . . . . . |

89 |

15002 |

- MCPU BOARD A2: Fatal Error in Software . . . . . . . . . . . . . . . . . . |

89 |

15003 |

- MCPU BOARD A2: Communications Error in Software . . . . . . . . |

89 |

15005 |

- LASER: Reference Error. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

89 |

15006 |

- Communications Error between MCPU BD A2 and GALVO BD A4 |

90 |

15007 |

- Communications Error between MCPU BD A2 and GALVO BD A4 |

91 |

15008 |

- Start of Scan Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

91 |

15012 |

- Communications Error between MCPU BOARD A2 and the PC . |

91 |

15013 |

- Image Quality Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

92 |

15014 |

- LASER power not calibrated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

92 |

15015 |

- PLATE not calibrated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

92 |

DIAGNOSTICS

10DEC05 DG4825-1 Page

6 of 180

15016 |

- The LASER reference voltage is too high . . . . . . . . . . . . . . . . . . . |

93 |

15017 |

- PLATE not calibrated . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

93 |

15018 |

- There was an error reading or writing to the PCMCIA card . . . . |

93 |

15040 |

- Communications Error Between MCPU and the PC . . . . . . . . . . . |

93 |

15800 |

- Image resent at NT reboot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

94 |

15900 |

- NT rejected image at end of scan. Retransmission being |

|

attempted . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

94 |

|

Calibration |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

95 |

16001 |

- Calibration Error: Did not find START OF SCAN position . . . . . . |

95 |

16002 |

- Calibration Error: Did not find Offset . . . . . . . . . . . . . . . . . . . . . . . |

95 |

16003 |

- Calibration Error: Did not find Amplitude . . . . . . . . . . . . . . . . . . . |

95 |

16005 |

- Calibration Error: Routine did not receive image in the time |

|

allowed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

96 |

|

16006 |

- Calibration Error: Did not acquire image . . . . . . . . . . . . . . . . . . . . |

97 |

16010 |

- Possible Light Leak. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

97 |

16011 |

- Imaging System Error occurred during Initialization . . . . . . . . . . |

97 |

16012 |

- PMT/DAS BOARD A5: Calculation Error occurred during |

|

Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

97 |

|

16013 |

- Imaging System contains out-of-range noise . . . . . . . . . . . . . . . . |

98 |

16014 |

- Imaging System did not zero or PMT did not calibrate . . . . . . . . |

98 |

16016 |

- Malfunctioning PMT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

99 |

16017 |

- Possible Light Leak. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

99 |

16018 |

- Possible Light Leak. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

99 |

16019 |

- Calibration could not find offset, rotate GALVO counterclockwise |

99 |

16020 |

- Calibration could not find offset, rotate GALVO clockwise . . . . . |

99 |

16021 |

- Malfunctioning PMT1: Gain out of range . . . . . . . . . . . . . . . . . . . . |

100 |

16022 |

- Malfunctioning PMT2: Gain out of range . . . . . . . . . . . . . . . . . . . . |

100 |

“Self Test” for the MASTER CENTRAL PROCESSING UNIT . . . . . . . . . . . . . . . |

101 |

|

19001 |

- Check GALVO COMMUNICATIONS CABLE . . . . . . . . . . . . . . . . . . |

101 |

19002 |

- Check PMT BOARD CABLE and power . . . . . . . . . . . . . . . . . . . . . |

101 |

19003 |

- Check the power to the GALVO BOARD . . . . . . . . . . . . . . . . . . . . |

101 |

19004 |

- GALVO AGC reference is too high. Suggest check if GALVO |

|

connected and/or adjust AGC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

101 |

|

19005 |

- Check the GALVO reference (too low) . . . . . . . . . . . . . . . . . . . . . . |

102 |

19006 |

- Memory self test failed. Replace the MCPU BOARD . . . . . . . . . . |

102 |

19009 |

- The LASER diode off power is too high. . . . . . . . . . . . . . . . . . . . . |

102 |

19010 |

- The LASER diode on power is too low . . . . . . . . . . . . . . . . . . . . . |

102 |

19011 |

- PMT BOARD ramp test failed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

103 |

MOTION SYSTEM CONTROL BOARD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

103 |

|

22000 |

- MSC BOARD A1: Fatal Software Error . . . . . . . . . . . . . . . . . . . . . . |

103 |

22001 |

- MSC BOARD A1: Memory did not erase during Download . . . . . |

103 |

22002 |

- MSC BOARD A1: Error during download of MSC Software. . . . . |

103 |

DIAGNOSTICS

10DEC05 DG4825-1 Page

7 of 180

22003 - MSC BOARD A1: Checksum of Main Application failed . . . . . . . 104 22004 - MSC BOARD A1: RAM Test failed. . . . . . . . . . . . . . . . . . . . . . . . . . 104 22005 - MSC BOARD A1: Error during download of MSC Software. . . . . 105 22006 - MSC BOARD A1: Error during download of MSC Software. . . . . 105 22007 - MSC BOARD A1: Error during download of MSC Software. . . . . 105 22008 - MSC BOARD A1: Error during download of MSC Software. . . . . 105 22009 - MSC BOARD A1: Error during download of MSC Software. . . . . 106 22010 - MSC BOARD A1: Error during download of MSC Software. . . . . 106 22011 - MSC BOARD A1: Error during download of MSC Software. . . . . 107

MOTION SYSTEM CONTROL BOARD RTXC . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

29001 - 29008 - MSC BOARD A1: Software malfunctioned . . . . . . . . . . . . 107 MOTION SYSTEM CONTROL BOARD SYSTEM. . . . . . . . . . . . . . . . . . . . . . . . . . 108 30002 - 30033 - MSC BOARD A1: Software malfunctioned . . . . . . . . . . . . 108 Communications for the MOTION SYSTEM CONTROL BOARD . . . . . . . . . . . . 110

32001 - Communications malfunctioned between MCPU and

SSC BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

32002 - MSC BOARD A1: Internal Communications Error. . . . . . . . . . . . . 110 32003 - MSC BOARD A1: Internal Communications Error. . . . . . . . . . . . . 110 32004 - Communications Error between MCPU and SSC BOARDS . . . . . 110 32005 - Communications Error between MCPU and SSC BOARDS . . . . . 111

Shutdown Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

47001 - Communications to MCPU BD failed during Shut Down . . . . . . . 112 47002 - Internal communications failure . . . . . . . . . . . . . . . . . . . . . . . . . . . 112 47003 - Internal communications to UPS failed . . . . . . . . . . . . . . . . . . . . . 112 47500 - 47504 - Internal communications to UPS failed . . . . . . . . . . . . . . 112 47510 - 47511 - Internal communications failure to UPS1 . . . . . . . . . . . . . 112 47520 - 47522 - Internal communications failure to UPS1 . . . . . . . . . . . . . 113

47550 - The BATTERY in UPS1 is too low. System will be shutdown in 1 minute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

47551 - Unable to establish communications with UPS1 . . . . . . . . . . . . . 113

47950 - Display only - no Log Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113 47951 - Display only - no Log Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113 47952 - Display only - no Log Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114 47960 - Display only - no Log Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114 47961 - Display only - no Log Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114 47962 - Display only - no Log Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

DISK MANAGER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

49000 - HARD DISK is full. DISK MANAGER not able to remove images 115 49001 - Image Files have been deleted . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

55100 - Error on the Options Diskette or this is not a valid Options

Diskette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

DIAGNOSTICS

10DEC05 DG4825-1 Page

8 of 180

55101 - Could not open files on the Options Diskette. Try another Options Diskette. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

55102 - Pentium III identification not enabled on this Pentium III class machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

55103 - Could not open files on the Options Diskette . . . . . . . . . . . . . . . . 117 55104 - Error updating the options on the CR 825/850 SYSTEM . . . . . . . 117 55105 - Could not allocate essential memory . . . . . . . . . . . . . . . . . . . . . . . 117 55106 - The Options on this diskette are already enabled on this system 117 55107 - This Options Diskette has been used on another device . . . . . . 117 55109 - Error occurred while trying to update the Options on the UNIT . 117 55110 - Could not determine what product we are running on . . . . . . . . 118 55111 - The Options Diskette is not valid for this product . . . . . . . . . . . . 118 55112 - Error obtaining Adapter Name on Pentium 4 class machine . . . 118

55113 - Error obtaining MAC address for card name specified in AdapterName in General Equipment on Pentium 4 class machine . . . 118

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119 Initialization Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119 “Power-On Self-Test” (POST) Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119 Software Loading Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 Application Software Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 Dark TOUCH SCREEN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121 Image Quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Checkout Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122 CASSETTE HANDLING AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122 DUPLEX CAM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122 CAM MOTOR M1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 PLATE PRESENT SENSOR S5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129 INTERLOCK SWITCH S8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132 EXTRACTION BAR SENSOR S9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134 HOOKS on the EXTRACTION BAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136 CAM SENSORS S10 and S11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137 BOARDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139 MOTION SYSTEM CONTROL BOARD A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

MASTER CENTRAL PROCESSING UNIT BOARD A2 . . . . . . . . . . . . . . . . . 140

DIGITIZER BOARD A3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143 GALVO BOARD A4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145 PMT/DAS BOARD A5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

SLOW SCAN CONTROLLER BOARD A6 and COIL BOARD A7 . . . . . . . . 148

LASER DRIVER BOARD A17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154 POWER SUPPLY PS1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154 TRANSFORMER T1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

DIAGNOSTICS

10DEC05 DG4825-1 Page

9 of 180

UNINTERRUPTED POWER SUPPLY UPS1. . . . . . . . . . . . . . . . . . . . . . . . . . 158 System Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 Test Points and LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163 MOTION SYSTEM CONTROL BOARD A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

MASTER CENTRAL PROCESSING UNIT BOARD A2 . . . . . . . . . . . . . . . . . 166

DIGITIZER BOARD A3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169 GALVO BOARD A4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171 PMT/DAS BOARD A5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173 SLOW SCAN CONTROLLER BOARD A6 . . . . . . . . . . . . . . . . . . . . . . . . . . . 175 LASER DRIVER BOARD A17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

LASER DRIVER PREREGULATOR BOARD A18 . . . . . . . . . . . . . . . . . . . . . 179

|

DIAGNOSTICS |

Using the Diagnostics |

||

|

|

|

|

|

10DEC05 |

|

Section 1: Using the Diagnostics |

|

|

DG4825-1 |

|

|

|

|

|

|

|

|

|

Page |

|

|

|

|

10 of 180 |

|

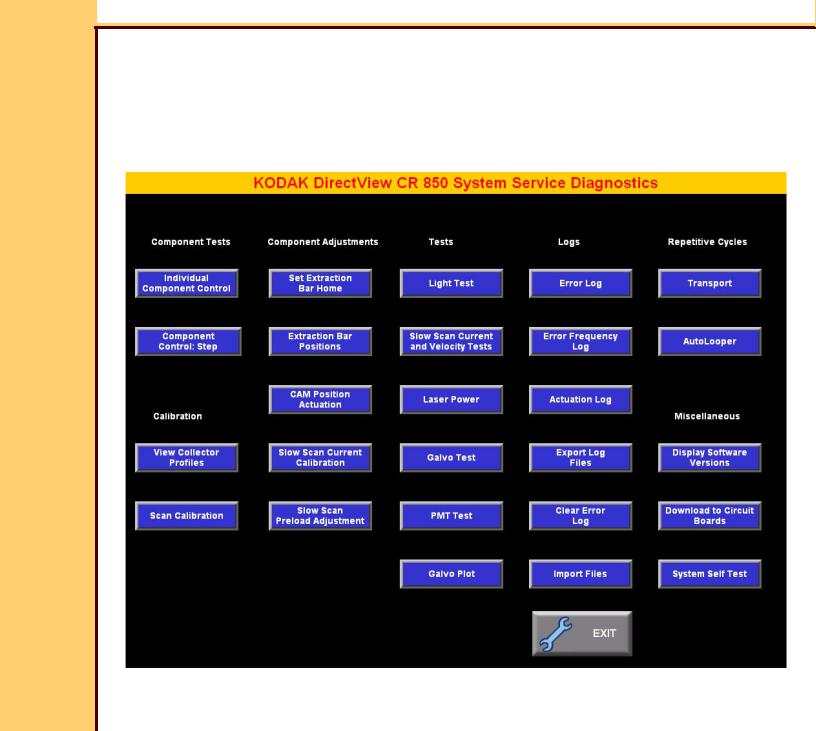

System Service Diagnostic Screen |

|

|

|

|

|

|

|

Important

Important

For systems with Software Version ≥ 4.1, you must have a “Session ID” for access to

“Service Functions” and “Diagnostics”. See SERVICE BULLETIN 843.

1At the main menu, touch:

•[Service Functions]

•[ENTER]

•[Diagnostics]

2Does the “System Service Diagnostics” screen display?

Yes |

No |

|

|

Advance to the test or procedure. Continue with Step 3.

3Check that the TX and RX LEDs are blinking on the MASTER CENTRAL PROCESSING

UNIT BOARD A2 and on the NETWORK CARD in the computer.

4At the main menu, touch [Service Functions].

5At the main menu, touch:

•[Service Functions]

•[ENTER]

•[EXIT TO DESKTOP]

6Select My Computer>Control Panel>Network>Protocols.

7Double-click [TCP/IP Protocol].

8Select [ADAPTER 1].

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

11 of 180

9Check the “IP Address” of the NETWORK CARD that is connected to the MASTER

CENTRAL PROCESSING UNIT BOARD A2:

“IP Address” |

192.168.0.1 |

|

|

“Subnet Mask” |

255.255.255.0 |

|

|

“Default Gateway” |

|

|

|

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

12 of 180

Functions of the “System Service Diagnostic” Screen

Table 1 Component Tests

BUTTON |

Description |

|

|

[Individual Component Control]

Important

Important

For the test procedure, see Individual Component

Control.

Allows you to actuate and check the status of:

•CAM MOTOR

•SLOW SCAN

•ERASE LAMPS

•CASSETTE DRIVE MOTOR

[Component Control: Step]

Important

Important

For the test procedure, see Component Control: Step.

Allows you to check the status of the components by executing the following steps:

1.Loading the CASSETTE

2.Loading the PLATE

3.Scanning the PLATE

4.Erasing the PLATE

5.Ejecting the PLATE

6.Ejecting the CASSETTE

|

DIAGNOSTICS |

|

|

Using the Diagnostics |

||

|

|

|

|

|

|

|

10DEC05 |

|

Table 2 |

Calibration |

|

|

|

DG4825-1 |

|

|

|

|

||

Page |

|

|

|

|

|

|

13 of 180 |

|

|

BUTTON |

|

Description |

|

|

|

|

|

|

|

|

|

|

[View Collector Profiles] |

|

|

|

|

|

|

|

|

Important |

||

|

|

|

|

For the procedure, see Calibration for the CR 825/850 SYSTEM. |

||

|

|

|

|

|

|

|

Displays the COLLECTOR PROFILE for each size of CASSETTE, including:

•number of steps from “HOME” to “START OF SCAN”

•“OFFSET” - Number of pixels from “START” to the diagnostic image

•“Amplitude” - Number of pixels from “OFFSET” to the last pixel of the diagnostic image

•PMT 1 - 2: Correction value of each PMT for gain adjustment

[Scan Calibration]

Caution

•All COVERS must be installed when using this option.

•For the procedure, see Calibration for the CR 825/850 SYSTEM.

•Completes the calibration of:

–GALVO

–PMT 1

–PMT 2

•Starts a COLLECTOR PROFILE for all sizes of STORAGE

PHOSPHOR PLATES.

• |

Allows calibration of the PLATES exposed at 20 mR ± 5 mR. |

• |

Displays the date and time of the last successful calibration. |

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

14 of 180

Table 3 Component Adjustments

BUTTON |

Description |

|

|

[Set Extraction Bar Home] |

|

|

|

Important |

|

|

For the procedure, see EXTRACTION BAR HOME |

|

|

POSITION. |

|

|

|

|

|

Allows you to set and check the home position of the |

|

|

EXTRACTION BAR: |

|

|

• [FINE NUDGE UP] |

|

|

• [FINE NUDGE DOWN] |

|

|

• [COARSE NUDGE UP] |

|

|

• [COARSE NUDGE DOWN] |

|

|

• [SAVE] - Sets the selected home position |

|

|

• [CANCEL] - Resets the home position to the last |

|

|

recorded value |

|

|

|

|

[Extraction Bar Positions] |

Allows you to move the EXTRACTION BAR to: |

|

|

• [HOME] |

|

|

• [UPPER PLATE GUIDE POSITION] |

|

|

• [LOWER PLATE GUIDE POSITION] |

|

|

• [ERASE] |

|

|

• [RETURN TO HOME] |

|

|

• [NUDGE UP] |

|

|

• [NUDGE DOWN] |

|

|

|

DIAGNOSTICS |

|

Using the Diagnostics |

|||

|

10DEC05 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DG4825-1 |

|

BUTTON |

|

|

Description |

|

|

Page |

|

|

|

|

|

|

|

|

[CAM Position Actuation] |

|

|

|

|

|

|

15 of 180 |

|

|

|

|

|

|

|

|

|

|

|

Important |

||

|

|

|

|

|

See the checkout of the DUPLEX CAM. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Allows you to check the status of the CASSETTE |

||

|

|

|

|

|

HANDLING AY by rotating the DUPLEX CAM to: |

||

|

|

|

|

|

• [HOME CAM] |

||

|

|

|

|

|

• [HOOKS UP POSITION] |

||

|

|

|

|

|

• [PINCH POSITION] |

||

|

|

|

|

|

• [UNPINCH POSITION] |

||

|

|

|

|

|

• [UNLATCH POSITION] |

||

|

|

|

|

|

• [LATCH POSITION] |

||

|

|

|

|

|

Allows you to reset the DUPLEX CAM after jams: |

||

|

|

|

|

|

• [FINE JOG FORWARD] |

||

|

|

|

|

|

• [FINE JOG REVERSE] |

||

|

|

|

|

|

• [COARSE JOG FORWARD] |

||

|

|

|

|

|

• [COARSE JOG REVERSE] |

||

|

|

|

|

|

• [Return PLATE to CASSETTE] |

||

|

|

|

|

|

• [HOME SLOW SCAN] |

||

|

|

|

|

|

|

|

|

|

|

|

[Slow Scan Current Calibration] |

|

|

|

|

|

|

|

|

|

Important |

||

|

|

|

|

|

For the procedure, see Calibration for the CR 825/850 |

||

|

|

|

|

|

SYSTEM. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Completes the calibration of the SLOW SCAN MOTOR for |

||

|

|

|

|

|

the correct current at all 3 phases of the MOTOR. |

||

|

|

|

|

|

|

|

|

|

|

|

[Slow Scan Preload |

|

Moves the SLOW SCAN AY. This allows you to make |

||

|

|

|

Adjustment] |

|

adjustments to the SLOW SCAN AY. |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

16 of 180

Table 4 Tests

BUTTON |

Description |

|

|

[Light Test]

Important

Important

For the test procedure, see Light Test.

•Checks for excessive light to the PMTs during the loading of a CASSETTE.

•Allows you to:

–actuate or deactuate the high voltage of the PMTs

–“AUTO-ZERO” the PMTs

•Tests the signal for noise.

[Slow Scan Current and |

|

Velocity Tests] |

Caution |

•An increase in current might indicate that a bind is occurring in the SLOW SCAN AY.

•For the test procedure, see Slow Scan Current and Velocity Tests.

•Drives the SLOW SCAN AY to the limits in both directions.

•Displays for the SLOW SCAN AY:

–speed variation

–current

–“Start of Scan”

–“End of Scan”

|

DIAGNOSTICS |

Using the Diagnostics |

||

|

|

|

|

|

10DEC05 |

|

|

|

|

DG4825-1 |

|

BUTTON |

Description |

|

Page |

|

|

|

|

|

[Laser Power] |

|

|

|

17 of 180 |

|

|

|

|

|

|

|

Important |

|

For the test procedure, see Laser Power.

Allows you to:

•check the power of the LASER DIODE

•set the power values for a new LASER DIODE

[Galvo Test]

Important

Important

For the test procedure, see Galvo Test.

Allows you to:

•set the “Amplitude” of the GALVO

•check the response of the LASER DIODE

[PMT Test]

Important

Important

For the test procedure, see PMT Test.

Checks the function of the 2 PMTs.

[Galvo Plot]

Important

Important

For the test procedure, see GALVO PLOT.

Allows you to:

•check:

–response of the GALVO

–automatic gain control - AGC

–2.5 V reference

•set the GALVO without an OSCILLOSCOPE

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

18 of 180

Table 5 Logs

BUTTON |

Description |

|

|

[Error Logs]

Important

Important

For the procedure, see Checking the Error Logs.

Allows you to check:

•error code and description

•date and time

•CASSETTE ID

•scan count

[Error Frequency Log]

Important

Important

For the procedure, see Checking the Error Frequency

Log.

Allows you to:

•check:

–frequency of each error code

–date and time of last error

•collate error codes by:

–date

–error number

–frequency

|

DIAGNOSTICS |

|

Using the Diagnostics |

||

|

|

|

|

|

|

10DEC05 |

|

|

|

|

|

DG4825-1 |

|

BUTTON |

|

Description |

|

Page |

|

|

|

|

|

|

[Actuation Log] |

|

|

|

|

19 of 180 |

|

|

|

|

|

|

|

|

Important |

||

|

|

|

For the procedure, see Checking the Actuation Logs. |

||

|

|

|

|

|

|

Allows you to check:

•“SCAN CYCLES” - This value cannot be reset

•“BATCH ERASE CYCLES” - The number of times that the “Batch Erase” function was used

•“TOTAL POWER-ON HOURS”

•“LASER DIODE SCAN CYCLES”

•“LASER HOURS (estimated)”

•“LASER HOURS LAST CLEARED”

[Export Log Files]

Important

Important

For the procedure, see Storing the Error Logs on a Disk.

Records onto a FLOPPY DISKETTE:

•“Actuation Logs”

•error logs

•parameters of the SLOW SCAN

|

DIAGNOSTICS |

|

Using the Diagnostics |

||

|

|

|

|

|

|

10DEC05 |

|

|

|

|

|

DG4825-1 |

|

BUTTON |

|

Description |

|

Page |

|

|

|

|

|

|

[Clear Error Log] |

|

|

|

|

20 of 180 |

|

|

|

|

|

|

|

|

Important |

||

|

|

|

For the procedure, see Clearing the Error Logs. |

||

|

|

|

|

|

|

•Clears all the errors from the error logs.

•Displays the date when the error logs were last cleared.

[Import Files]

Important

Important

For the procedure, see Installing Files from a Disk.

Record from a FLOPPY DISKETTE onto the CR 825/

850 SYSTEM:

•“Actuation Logs”

•parameters of the SLOW SCAN

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

21 of 180

Table 6 “Repetitive Cycles”

BUTTON |

Description |

|

|

[AutoLooper]

Important

•During the test, the “Light Test” is disabled to allow operation with the PANELS removed.

•For the test procedure, see AUTOLOOPER.

•Automatically processes the CASSETTE to check if it is reliable.

•Completes a test cycle including scanning and erasing.

•Disables the “Patient Data” for the test.

•Displays status screens for the SENSORS.

[Transport]

Important

Important

For the test procedure, see Transport.

•Uses a CASSETTE to test the operation of loading.

•Displays status of the SENSORS at each step.

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

22 of 180

Table 7 Miscellaneous

BUTTON |

Description |

|

|

[Download to Circuit Boards]

Important

Important

For the procedure, see Downloading Software to the

BOARDS.

Allows you to download the necessary software to all the

BOARDS from the HARD DRIVE.

[Display Software Versions]

Important

Important

For the procedure, see Displaying the Software Versions.

Displays the software version number for:

•MASTER CENTRAL PROCESSING UNIT BOARD A2

•MOTION SYSTEM CONTROL BOARD A1

•MOTION SYSTEM CONTROL BOARD BOOT

•SLOW SCAN CONTROLLER BOARD BOOT

•SLOW SCAN CONTROLLER BOARD FIXED Application

•SLOW SCAN CONTROLLER BOARD PRODUCT Application

•DIGITIZER BOARD

•MEDICAL IMAGING MANAGER

•DIAGNOSTICS

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

23 of 180

[System Self Test]

Important

Important

For the test procedure, see MCPU Self Test.

Completes the following diagnostic tests:

•“GALVO BOARD COMMUNICATION” - Checks the connection of the CABLE between:

–GALVO BOARD A4

–MASTER CENTRAL PROCESSING UNIT BOARD A2

•“GALVO REFERENCE” - Reads the GALVO AGC

CHANNEL connected to the reference voltage of the GALVO.

•“GALVO MOTOR” - Reads the voltage of the GALVO

AGC to check for problems with the GALVO.

•“GALVO SWEEP” - Checks the functions of reading and writing of the REGISTERS on the GALVO BOARD A4.

•“LASER OFFSET”

•“PMT BOARD TEST” - Checks the connection of the CABLE between:

–MASTER CENTRAL PROCESSING UNIT BOARD A2

–PMT/DAS BOARD A5

•“MASTER CENTRAL PROCESSING UNIT BOARD

MEMORY TEST” - Checks for errors in the reading and writing of data to each of the image buffers.

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

24 of 180

Diagnostic Tests

Individual Component Control

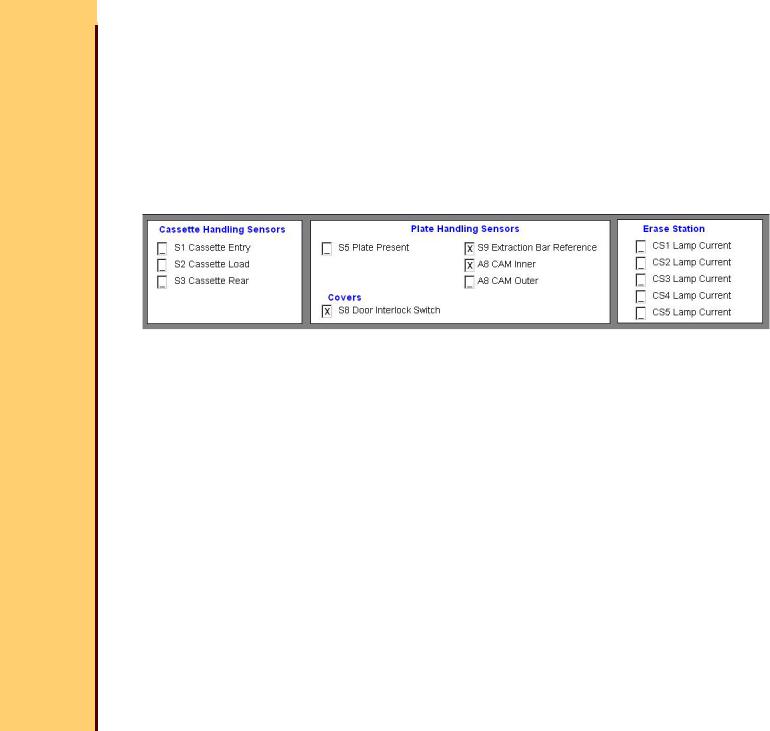

1 At the “Service System Diagnostic” screen, touch [Individual Component Control].

2 Touch [LATCH Position].

3 Check the status of the SENSORS.

|

DIAGNOSTICS |

Using the Diagnostics |

||

|

|

|

|

|

10DEC05 |

4 Does the status of the SENSORS match? |

|

|

|

DG4825-1 |

|

|

||

Page |

|

|

|

|

|

Yes |

No |

|

|

25 of 180 |

|

|

||

|

|

|

|

|

Continue with Step 5. 1. Check the error logs. See Checking the Error Logs.

2.See the Error Codes to determine the possible cause and action for the problem.

3.Continue with Step 5.

5 Touch [UNLATCH Position].

6Check the status of the SENSORS.

7Does the status of the SENSORS match?

Yes |

No |

|

|

Continue with Step 8. 1. Check the error logs See Checking the Error Logs.

2.See the Error Codes to determine the possible cause and action for the problem.

3.Continue with Step 8.

8 Touch [HOOKS Position].

9 Check the status of the SENSORS.

|

DIAGNOSTICS |

|

Using the Diagnostics |

||

|

|

|

|

|

|

10DEC05 |

10 |

Does the status of the SENSORS match? |

|||

DG4825-1 |

|||||

Page |

|

|

|

|

|

26 of 180 |

|

Yes |

|

No |

|

|

|

Continue with Step 11. |

1. |

Check the error logs. See Checking the Error Logs. |

|

|

|

|

2. |

See the Error Codes to determine the possible cause |

|

|

|

|

|

and action for the problem. |

|

|

|

|

3. |

Continue with Step 11. |

|

|

11 |

|

|

|

|

|

Touch [PINCH Position]. |

|

|

|

|

12Check the status of the SENSORS.

13Does the status of the SENSORS match?

Yes |

|

No |

Continue with Step 14. |

1. |

Check the error logs. See Checking the Error Logs. |

|

2. |

See the Error Codes to determine the possible cause |

|

|

and action for the problem. |

|

3. |

Continue with Step 14. |

|

|

|

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

27 of 180

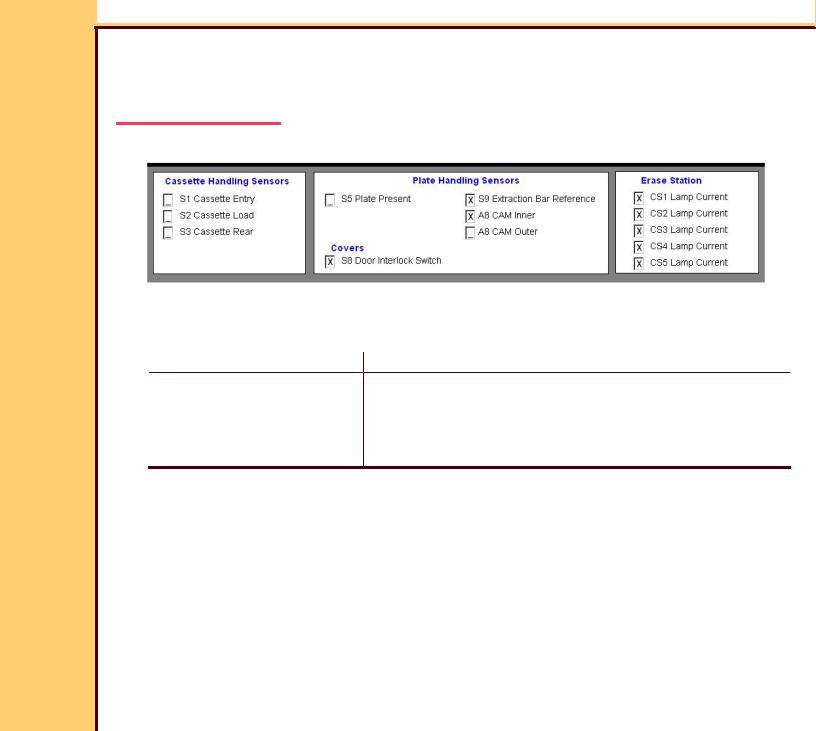

Important

Important

The ERASE LAMPS energize for approximately 2 - 10 seconds. The marks display in the

“Erase Station” check boxes while the ERASE LAMPS are energized.

14 Touch [ERASE LAMPS ON].

15Check the status of the SENSORS.

16Does the status of the SENSORS match?

Yes |

No |

|

|

Continue with the next test. 1. Check the error logs. See Checking the Error Logs.

2.See the Error Codes to determine the possible cause and action for the problem.

3.Advance to the next test.

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

28 of 180

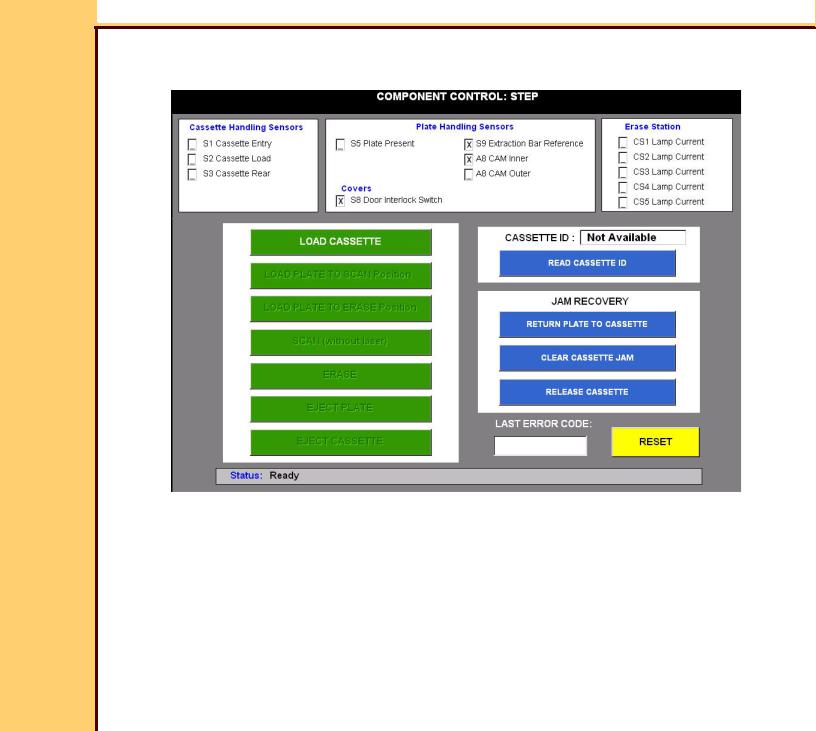

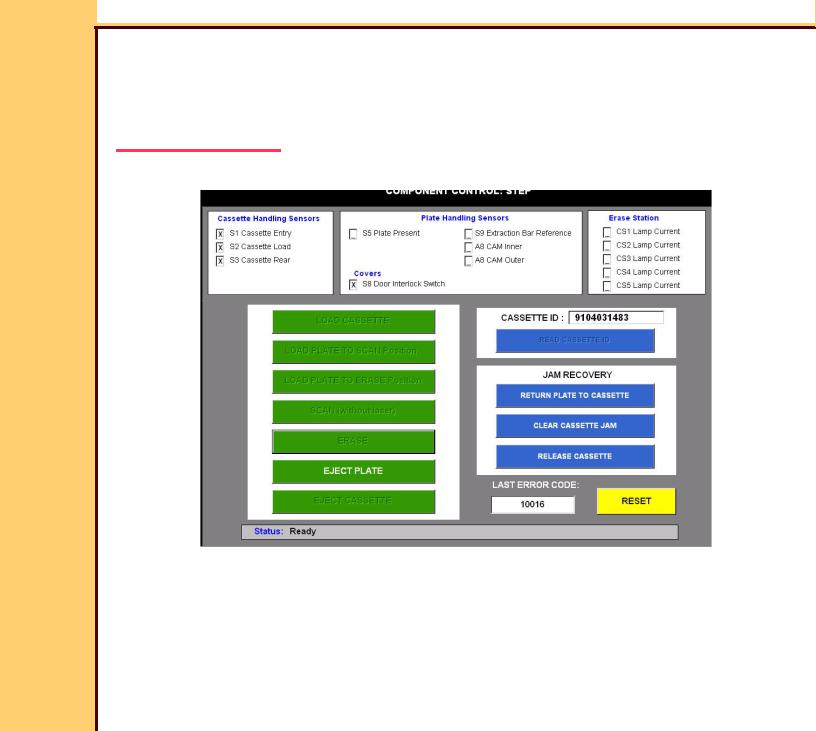

Component Control: Step

1 On the “System Service Diagnostic” screen, touch [Component Control: Step].

2Insert the CASSETTE into the CR 825/850 SYSTEM.

3Wait for the beep.

4Touch [LOAD CASSETTE].

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

29 of 180

5Check the status of the SENSORS.

6Does the status of the SENSORS match?

Yes |

|

No |

Continue with Step 7. |

1. |

Check the error logs. See Checking the Error Logs. |

|

2. |

See the Error Codes to determine the possible cause |

|

|

and action for the problem. |

|

3. |

Continue with Step 7. |

|

|

|

7 Touch [LOAD PLATE TO SCAN Position].

8Check the status of the SENSORS.

9Does the status of the SENSORS match?

Yes |

No |

Continue with Step 10. 1. Check the error logs. See Checking the Error Logs.

2.See the Error Codes to determine the possible cause and action for the problem.

3.Continue with Step 10.

10 Touch [SCAN (without laser)].

DIAGNOSTICS |

Using the Diagnostics |

|

|

10DEC05 DG4825-1 Page

30 of 180

11 Wait for the test to complete.

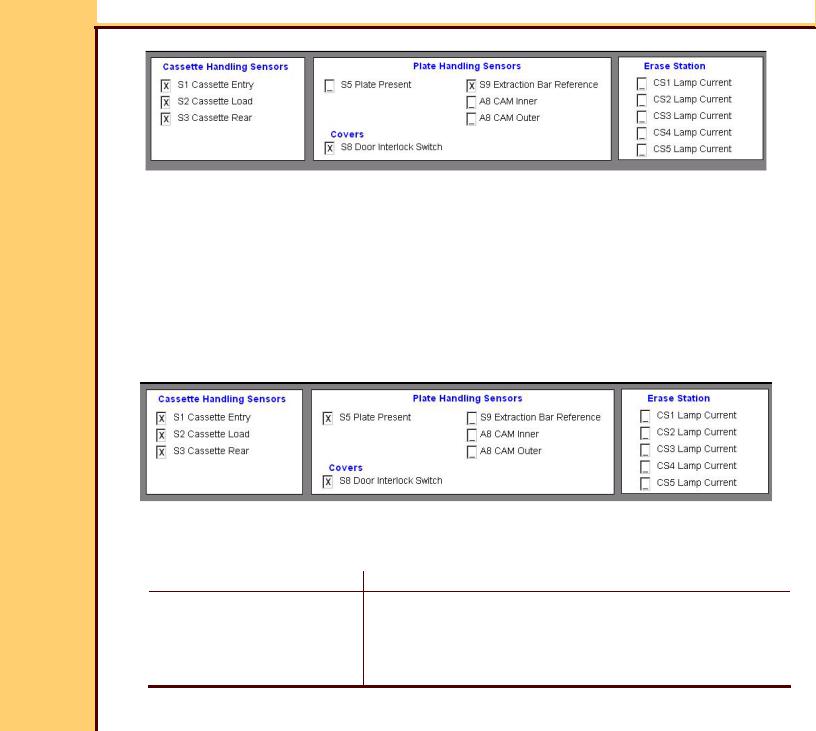

Important

Important

The ERASE LAMPS energize for approximately 2 - 10 seconds. The marks display in the

“Erase Station” check boxes while the ERASE LAMPS are energized.

12 Select [LOAD PLATE TO ERASE Position].

13 Check the status of the SENSORS.

Loading...

Loading...