Kodak DirectView CR-825, DirectView CR-850 Preventive maintenance instructions

© EASTMAN KODAK COMPANY, 2005 |

HEALTH GROUP |

|

Publication No. PM4825-1 |

|

10DEC05 |

|

Supersedes PM4825-1 |

|

09JAN04 |

PREVENTIVE MAINTENANCE

for the

Kodak DirectView CR 825/850 SYSTEMS

Service Codes: 5634, 4825

Important

Important

Qualified service personnel must do these procedures.

H177_0500AC

PREVENTIVE MAINTENANCE

10DEC05 PM4825-1 Page

2 of 30

PLEASE NOTE The information contained herein is based on the experience and knowledge relating to the subject matter gained by Eastman Kodak Company prior to publication.

No patent license is granted by this information.

Eastman Kodak Company reserves the right to change this information without notice, and makes no warranty, express or implied, with respect to this information. Kodak shall not be liable for any loss or damage, including consequential or special damages, resulting from any use of this information, even if loss or damage is caused by Kodak’s negligence or other fault.

This equipment includes parts and assemblies sensitive to damage from electrostatic |

|

discharge. Use caution to prevent damage during all service procedures. |

|

Table of Contents |

|

Description |

Page |

Necessary Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

Maintenance Plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

Checking the Error Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

Checking the Scan Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

Cleaning the FILTER - 2.4 GHz PC only . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

Cleaning the PMT/DAS BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

Cleaning the PMTs and COLLECTOR AY . . . . . . . . . . . . . . . . . . . . . . . . . . |

8 |

Cleaning and Applying Lubricant to the CASSETTE HANDLING AY . . . . |

9 |

Cleaning the BAR CODE READER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

11 |

Cleaning the EXTRACTION BAR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

12 |

Cleaning and Applying Lubricant to the SLOW SCAN SLIDES . . . . . . . . |

13 |

Cleaning the ERASE LAMP AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

14 |

Cleaning the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

15 |

Installing the New LIGHT SEALS on the TOP COVER . . . . . . . . . . . . . . . |

16 |

Installing the New CLAMP BAR PLUSH . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

Installing the New RIGHT and LEFT LIGHT BAFFLES . . . . . . . . . . . . . . . . |

19 |

Installing the New REAR CLIP AY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

Installing the New LIGHT SEAL PLUSH . . . . . . . . . . . . . . . . . . . . . . . . . . . |

21 |

Installing the New LEAF SPRINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

23 |

Installing the New FIXED LIGHT SEAL PADDLE. . . . . . . . . . . . . . . . . . . . . |

24 |

Installing the New LIGHT SEAL PADDLE. . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

Installing the New CASSETTE DRIVE ROLLERS . . . . . . . . . . . . . . . . . . . . |

26 |

Checking the CAM and MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

27 |

Checking the Adjustments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

28 |

Checking the Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

29 |

PREVENTIVE MAINTENANCE

10DEC05 |

|

|

|

|

|

|

PM4825-1 |

|

|

|

|

|

|

Page |

|

|

|

|

|

|

3 of 30 |

|

Necessary Materials |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Part No. |

Description |

Quantity |

Notes |

|

|

|

|

|

|

|

|

|

--- |

soap - solution |

--- |

Purchase locally |

||

|

|

|

|

|

|

|

|

|

3E0899 |

soft LINT-FREE CLOTH |

--- |

Package of 300 |

|

|

|

|

|

|

|

|

|

|

1C8026 |

LUBRICANT |

--- |

|

|

|

|

|

|

|

|

|

|

|

TL-4071 |

VACUUM CLEANER |

--- |

|

|

|

|

|

|

|

|

|

|

|

1C8000 |

LENS CLEANER |

--- |

|

|

|

|

|

|

|

|

|

|

952807 |

LENS PAPER |

--- |

Package of 50 |

||

|

|

|

|

|

|

|

|

|

5E6777 |

SPINDLE OIL |

--- |

4-oz BOTTLE |

|

|

|

|

|

|

|

|

|

|

1C8067 |

CANNED AIR |

--- |

Package of 2 |

|

|

|

|

|

|

|

|

|

|

7E7978 |

PM KIT |

1 |

|

|

|

|

|

|

|

|

|

|

|

6E5266 |

LIGHT SEAL - left |

1 |

Included in PM KIT. |

|

|

|

|

|

|

|

|

|

|

6E5267 |

LIGHT SEAL - right |

1 |

|

|

|

|

|

|

|

|

|

|

|

1F2215 |

PLUSH - clamp bar |

2 |

|

|

|

|

|

|

|

|

|

|

|

1F5142 |

LIGHT BAFFLE - right |

1 |

|

|

|

|

|

|

|

|

|

|

|

1F6140 |

LIGHT BAFFLE - left |

1 |

|

|

|

|

|

|

|

|

|

|

|

1F7859 |

LIGHT SEAL AY - front |

1 |

|

|

|

|

|

|

|

|

|

|

|

1F2941 |

CLIP AY |

1 |

|

|

|

|

|

|

|

|

|

|

|

1F5817 |

PLUSH - light seal |

2 |

|

|

|

|

|

|

|

|

|

|

|

1F6723 |

SPRING - leaf |

3 |

|

|

|

|

|

|

|

|

|

|

|

9F6823 |

PADDLE - light seal, fixed |

1 |

|

|

|

|

|

|

|

|

|

|

|

1F5967 |

PADDLE - light seal, plush |

3 |

|

|

|

|

|

|

|

|

|

|

|

1F5661 |

ROLLER - cassette drive |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PREVENTIVE MAINTENANCE

10DEC05 PM4825-1 Page

4 of 30

Maintenance Plan

Procedure |

Do: |

Checking the Error Logs |

Every service call |

|

|

Checking the Scan Operation |

Every service call |

|

|

Cleaning the FILTER - 2.4 GHz PC only |

Every 6 months |

|

|

Cleaning the PMT/DAS BOARD |

Every 6 months |

|

|

Cleaning the PMTs and COLLECTOR AY |

Every 6 months |

|

|

Cleaning and Applying Lubricant to the CASSETTE HANDLING AY |

Every 6 months |

|

|

Cleaning the BAR CODE READER |

Every 6 months |

|

|

Cleaning the EXTRACTION BAR |

Every 6 months |

|

|

Cleaning and Applying Lubricant to the SLOW SCAN SLIDES |

Every 6 months |

|

|

Cleaning the ERASE LAMP AY |

Every 6 months |

|

|

Cleaning the System |

Every 6 months |

|

|

Installing the New LIGHT SEALS on the TOP COVER |

Every 6 months |

|

|

Installing the New CLAMP BAR PLUSH |

Every 6 months |

|

|

Installing the New RIGHT and LEFT LIGHT BAFFLES |

Every 6 months |

|

|

Installing the New REAR CLIP AY |

Every 6 months |

|

|

Installing the New LIGHT SEAL PLUSH |

Every 6 months |

|

|

Installing the New LEAF SPRINGS |

Every 6 months |

|

|

Installing the New FIXED LIGHT SEAL PADDLE |

Every 6 months |

|

|

Installing the New LIGHT SEAL PADDLE |

Every 6 months |

|

|

Installing the New CASSETTE DRIVE ROLLERS |

Every 6 months |

|

|

Checking the CAM and MOTOR |

Every 6 months |

|

|

Checking the Adjustments |

Every 6 months |

|

|

Checking the Operation |

Every service call |

|

|

PREVENTIVE MAINTENANCE

10DEC05 PM4825-1 Page

5 of 30

Checking the Error Logs

1 Check the Error Logs. See Checking the Error Logs.

Important

Important

If you see more than one error code of the same component or assembly, you might have to install new parts or do adjustments during this procedure.

2Do an evaluation of the error logs.

3Continue with Checking the Scan Operation.

Checking the Scan Operation

Important

Important

You must check the scan operation before de-energizing the system.

1Observe the scan operation or all CASSETTE sizes and make repairs before doing preventive maintenance procedures.

2Is this service call a 6 - month call?

Yes |

No |

Continue with Cleaning the FILTER |

Advance to Checking the Operation. |

- 2.4 GHz PC only. |

|

|

|

PREVENTIVE MAINTENANCE

10DEC05 PM4825-1 Page

6 of 30

Cleaning the FILTER - 2.4 GHz PC only

2.4 GHz |

Caution |

|

Dangerous Voltage |

||

|

computer

1 De-energize the system. See

Energizing the System.

2 Remove the REAR PANEL.

3 Use the VACUUM CLEANER to remove dust from the FILTER in the computer.

4 Install the REAR PANEL.

5 Continue with Cleaning the PMT/DAS BOARD.

FILTER

H194_0029GCA

H194_0029GC

PREVENTIVE MAINTENANCE

10DEC05

PM4825-1 Cleaning the PMT/DAS BOARD

Page 7 of 30

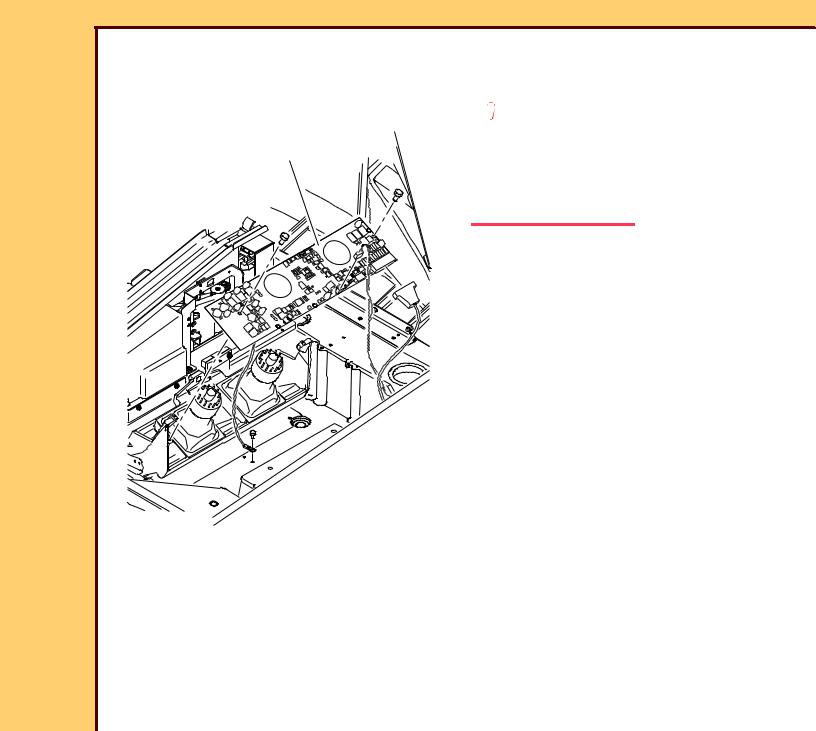

PMT/DAS BOARD

H194_1076GCA

H194_1076GC

1 Remove the PMT/DAS BOARD.

Caution

Caution

•Use the VACUUM CLEANER to remove dust before using the CANNED AIR.

•Use the CANNED AIR to move debris away from the OPTICAL CAVITY.

2Use the VACUUM CLEANER to remove dust from the PMT/DAS BOARD.

3If necessary, use the CANNED AIR

1C8067 to remove dust from the PMT/

DAS BOARD.

4Continue with Cleaning the PMTs and COLLECTOR AY.

PREVENTIVE MAINTENANCE

10DEC05 PM4825-1 Page

8 of 30

Cleaning the PMTs and COLLECTOR AY

1If necessary remove the PMT/DAS BOARD.

2Remove the PMTs and COLLECTOR AY.

2 PMTs

COLLECTOR AY

H194_1077GCA |

OPTICAL |

|

CAVITY |

||

H194_1077GC |

Caution

Caution

•Use the VACUUM CLEANER to remove dust before using the CANNED AIR.

•Use the CANNED AIR to move debris away from the OPTICAL CAVITY.

3Use the VACUUM CLEANER to remove dust from:

•2 PMTs

•COLLECTOR AY

•OPTICAL CAVITY

4If necessary, use the CANNED AIR to remove dust from:

•2 PMTs

•COLLECTOR AY

•OPTICAL CAVITY

5Install:

•PMTs and COLLECTOR AY

•PMT/DAS BOARD

6Continue with Cleaning and Applying

Lubricant to the CASSETTE HANDLING AY.

PREVENTIVE MAINTENANCE

10DEC05 PM4825-1 Page

9 of 30

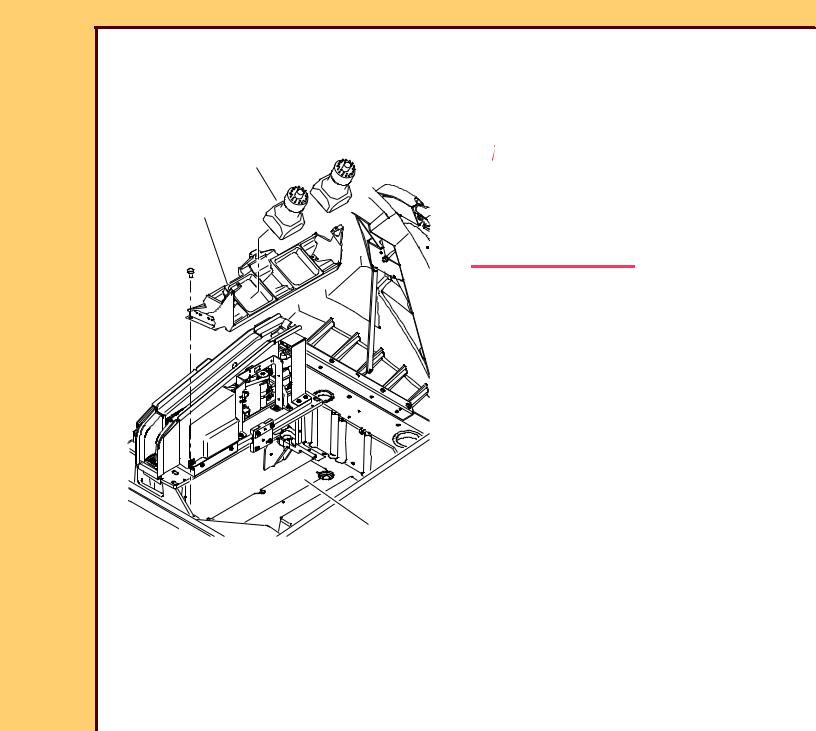

Cleaning and Applying Lubricant to the CASSETTE HANDLING AY

CASSETTE HANDLING AY

1Remove the CASSETTE HANDLING AY.

Caution

Caution

Use the VACUUM CLEANER to remove dust before using the CANNED AIR.

2Use the VACUUM CLEANER to remove dust from the CASSETTE HANDLING

AY.

3If necessary, use the CANNED AIR to remove dust from the CASSETTE

HANDLING AY.

H194_1078ACA

H194_1078AC

Loading...

Loading...