ABB ACS880-0500-3, ACS880-1510-3, ACS880-1000-3, ACS880-0750-3, ACS880-3770-3 Hardware Manual

...

—

ABB INDUSTRIAL DRIVES

ACS880-607 3-phase brake units

Hardware manual

ACS880-607 3-phase brake units

Hardware manual

Table of contents

3. Mechanical installation

5. Electrical installation

8. Start-up

© 2019 ABB Oy. All Rights Reserved. 3AXD50000022034 Rev D

EN

EFFECTIVE: 2019-04-29

Table of contents

1 Introduction to the manual

2 Operation principle and hardware description

Table of contents 5

9Contents of this chapter . ... ... ... ... ... ... ... ............. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ..

9Applicability . . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... .

9Safety instructions ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ..

9Target audience .... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ...

10Related manuals ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... .

10Categorization by frame size and option code . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ...

11Use of component designations . ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ..

11Terms and abbreviations . . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... .

13Contents of this chapter . ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

13Product overview ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... .

13Operation principle ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ..

13Simplified main circuit diagram of the drive system .. ... . ... . .. . ... . ... ... . ... ... . ... . .. . ...

15Layout drawings ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .

18Frame R8i layout .... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . ..

19Brake chopper module connectors . ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ...

19Connectors X50…X53 ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . .

20Fibre optic connectors .... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ...

20Overview of power and control connections .... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ...

21Brake unit control devices . ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ..

22Overview of the control connections of the BCU control unit . ... ... . ... ... . ... . .. . ... . .

22The control panel .... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ..

23Control by PC tools . ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . ..

23Fieldbus control ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ..

23DC switch and charging switch .. . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ..

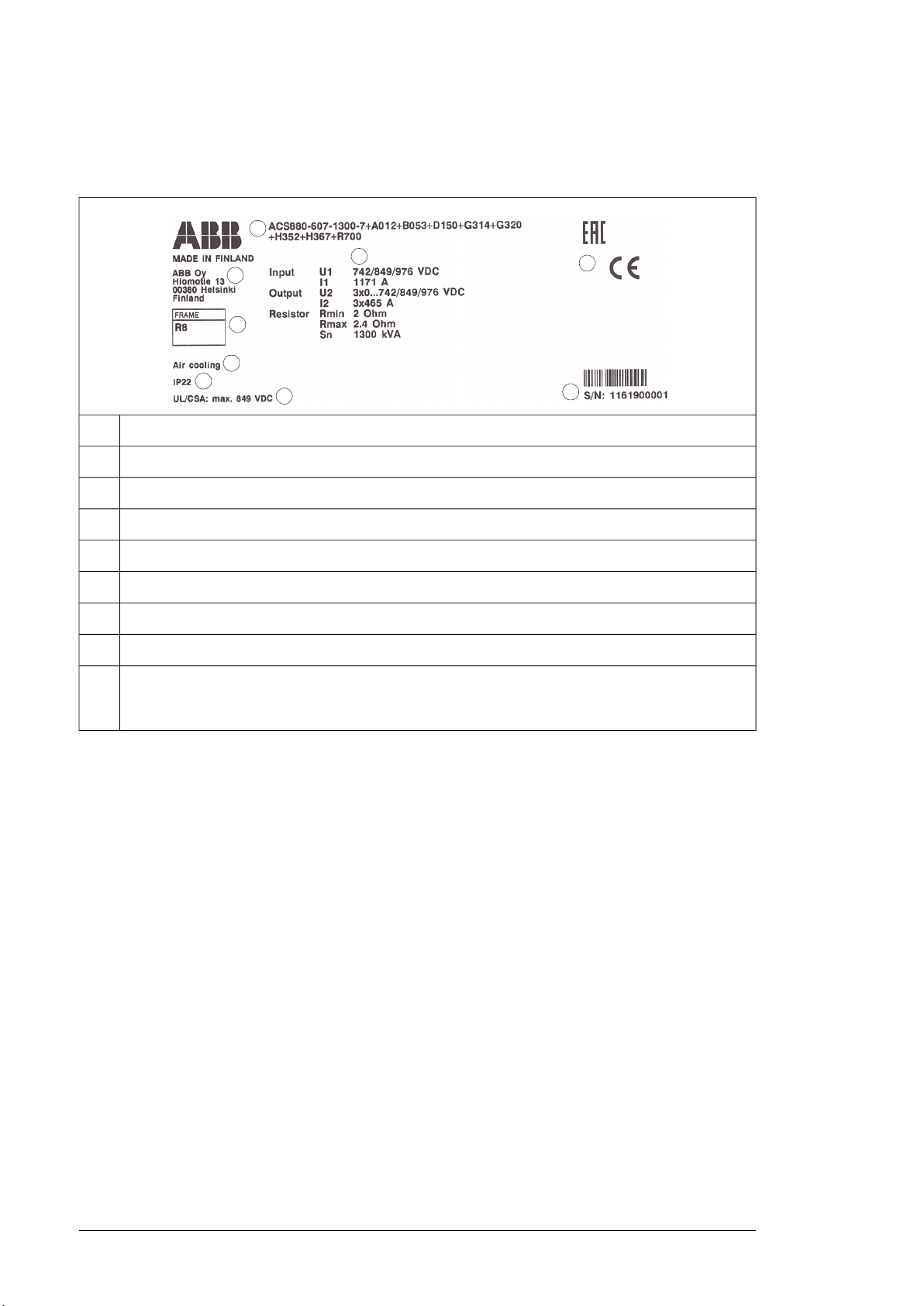

23Type designation labels .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ...

24Brake unit type designation label .. . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ...

24Brake chopper module type designation label .... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... .

25Brake unit type designation key .. . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... .

28Brake chopper module type designation key .... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ..

3 Mechanical installation

4 Guidelines for planning the electrical installation

31Contents of this chapter . ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

31Brake units ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... .

31User-defined brake resistors .... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ...

33Contents of this chapter . ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

33Limitation of liability .... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ...

33Generic guidelines ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ..

33Selecting the brake resistors . ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . ..

34Selecting and routing the brake resistor cables . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ..

34Typical resistor cable sizes .... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . .

6 Table of contents

5 Electrical installation

34Minimizing electromagnetic interference .... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ...

34Maximum cable length .... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ...

34Placing the brake resistors . ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . .

35Selecting the resistor thermal switch cable .... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... .

35Protecting the system against thermal overload .... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

35Operation principle ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .

35Protecting the system against short-circuits .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... .

37Contents of this chapter . ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

38Electrical safety precautions .... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ...

39General notes ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ...

39Static electricity ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ..

39Optical components ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... .

39Checking the insulation of brake resistor and resistor cable ... . ... ... . ... . .. . ... . ... ... . ..

40Connecting the brake resistor cables and thermal switch .. ... . ... . .. . ... . ... ... . ... ... . ...

40Connection diagram ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ...

41Connection procedure of the resistor cables .... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . ..

41Connection procedure of the thermal switch cable . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ..

43Connecting a PC .... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . ..

6 Control units of the drive

7 Installation checklist of the drive

8 Start-up

45Contents of this chapter . ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

45General . . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ..

46BCU-x2 control unit layout and connections .... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ...

48Default I/O diagram of the brake control unit .. . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... .

49External power supply for the control unit (XPOW) .. . ... ... . ... ... . ... ... . ... . .. . ... . ... ... .

49The XD2D connector .... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . .

50Safe torque off (XSTO, XSTO OUT) .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . ..

50FSO-xx safety functions module connection (X12) .... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ..

50SDHC memory card slot . ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... .

51Connector data ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ..

53BCU-x2 ground isolation diagram . ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... .

55Contents of this chapter . ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

55Checklist . . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... .

57Contents of this chapter . ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

57Start-up procedure ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ..

57Start-up procedure ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .

9 Fault tracing

59Contents of this chapter . ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

59Fault indications ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

60LEDs . . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ..

60Control panel and panel platform/holder LEDs .... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ...

60Control unit LEDs .... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ..

61R8i module LEDs .... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ..

10 Maintenance

11 Technical data

Table of contents 7

61Warning and fault messages ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... .

617-segment display of the brake control unit . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... .

63Contents of this chapter . ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

63Reference to maintenance instructions . . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . .

64Replacing brake chopper and brake resistor fuses – bottom exit ..... ... . ... ... . ... . .. . ..

65Replacing brake chopper and brake resistor fuses – top exit ..... ... . ... ... . ... . .. . ... . ...

67Contents of this chapter . ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

67Ratings . . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ..

69Definitions . . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ..

70Derating . . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ..

70Input and output voltages . . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ...

71Type equivalence table .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ...

72Typical resistor cable sizes .... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .

73Maximum cable length .... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ...

73Fuses . . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... .

74Dimensions, weights and free space requirements .... ... . ... . .. . ... . ... ... . ... ... . ... ... . ..

75Losses, cooling data and noise .. . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ..

76Resistor connection ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. .

76Efficiency .. . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ...

76Protection classes ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ..

76Ambient conditions ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . .

78Materials . . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... .

78Standards . . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ...

78Markings . . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... .

79Tightening torques . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . .

79Electrical connections ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . .

79Mechanical connections ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ...

79Insulation supports ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .

79Cable lugs ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . .

79Disclaimers . . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... .

79Generic disclaimer ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ..

80Cybersecurity disclaimer ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ..

12 Dimension drawings

Further information

81Contents of this chapter . ... . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . .

82Dimension drawing – bottom exit .. . ... ... . ... . .. . ... . ... ... . ... ... . ... ... . ... . .. . ... . ... ... . ...

84Dimension drawing – top exit .. . ... ... . ... . .. . ... . .. . ... . ... ... . ... ... . ... . .. . ... . ... ... . ... ... .

8

Introduction to the manual

Introduction to the manual 9

1

Contents of this chapter

This chapter gives basic information on the manual.

Applicability

The manual is applicable to ACS880-607 3-phase brake units that form a part of an ACS880

multidrive system.

Safety instructions

Follow all safety instructions delivered with the drive.

• Read the complete safety instructions before you install, commission, use or service

the drive. The complete safety instructions are given in ACS880 multidrive cabinets and

modules safety instructions (3AUA0000102301 [English]).

• Read the software-function-specific warnings and notes before changing the default

settings of a function. For each function, the warnings and notes are given in the section

describing the related user-adjustable parameters.

• Read the task-specific safety instructions before starting the task. See the section

describing the task.

Target audience

This manual is intended for people who plan the installation, install, start up and service the

drive, or create instructions for the end user of the drive concerning the installation and

maintenance of the drive.

Read the manual before working on the drive. You are expected to know the fundamentals

of electricity, wiring, electrical components and electrical schematic symbols.

10 Introduction to the manual

The manual is written for readers worldwide. Both SI and imperial units are shown.

Related manuals

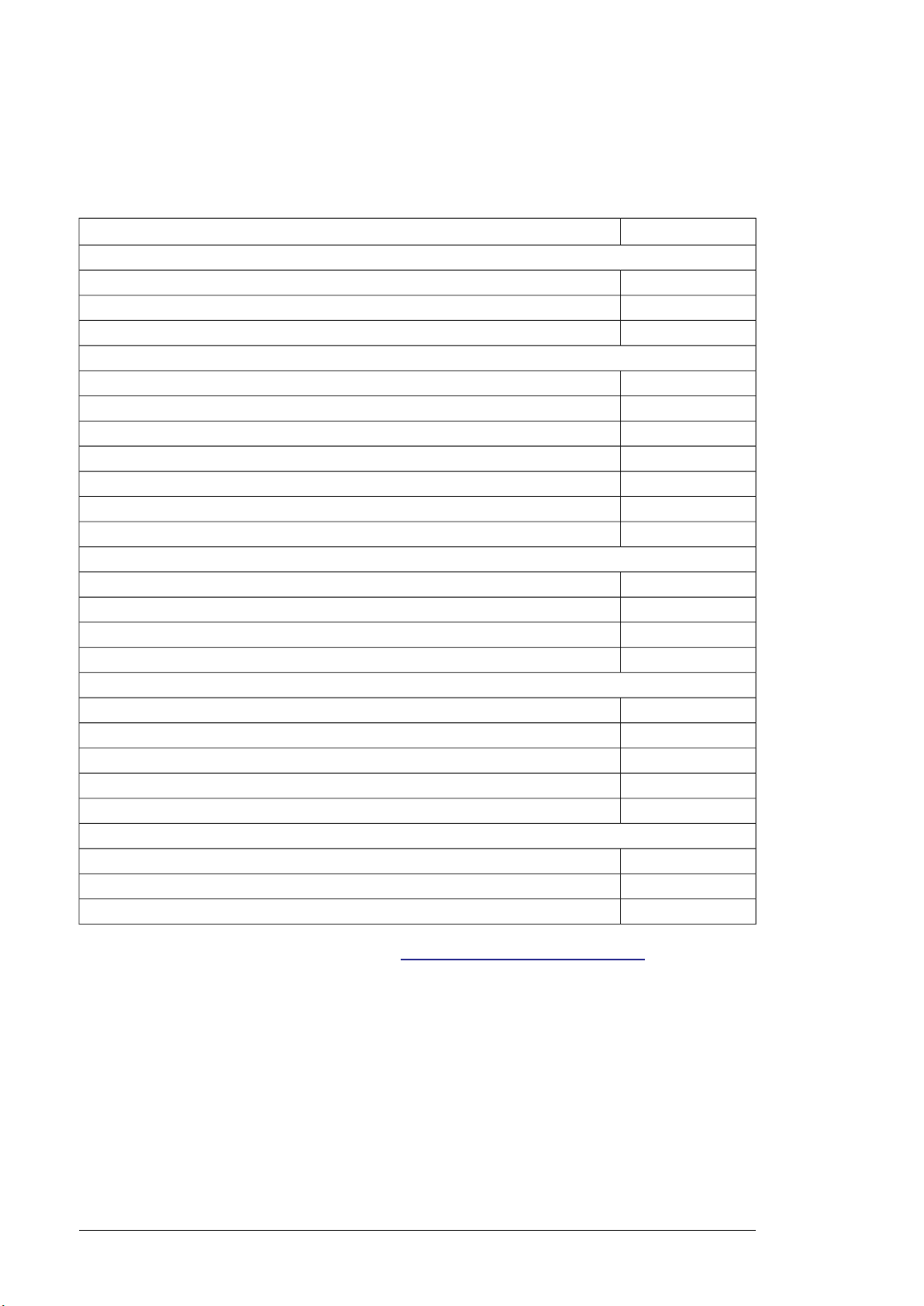

CodeManual

General manuals

3AUA0000102301ACS880 multidrive cabinets and modules safety instructions

3AUA0000102324ACS880 multidrive cabinets and modules electrical planning instructions

3AUA0000101764ACS880 multidrive cabinets mechanical installation instructions

Supply unit manuals

3AUA0000130644ACS880-207 IGBT supply units hardware manual

3AUA0000131562ACS880 IGBT supply control program firmware manual

3AUA0000102453ACS880-307 +A003 diode supply units hardware manual

3AXD50000011408ACS880-307 +A018 diode supply units hardware manual

3AUA0000103295ACS880 diode supply control program firmware manual

3AXD50000020546ACS880-907 regenerative rectifier units hardware manual

3AXD50000020827ACS880 regenerative rectifier control program firmware manual

Inverter unit manuals

3AUA0000102519ACS880-107 inverter units hardware manual

3AUA0000085967ACS880 primary control program firmware manual

3AUA0000098062ACS880 primary control program quick start-up guide

Manuals for application programs (Crane, Winder, etc.)

Brake unit and DC/DC converter unit manuals

3AUA0000102559ACS880-607 1-phase brake units hardware manual

3AXD50000022034ACS880-607 3-phase brake units hardware manual

3AXD50000020967ACS880 (3-phase) brake control program firmware manual

3AXD50000023644ACS880-1607 DC/DC converter units hardware manual

3AXD50000024671ACS880 DC/DC converter control program firmware manual

Option manuals

3AUA0000085685ACS-AP-x assistant control panels user’s manual

3AUA0000094606Drive composer start-up and maintenance PC tool user’s manual

Manuals for I/O extension modules, fieldbus adapters, safety options etc.

You can find manuals on the Internet. See www.abb.com/drives/documents. For manuals

not available in the document library, contact your local ABB representative.

Categorization by frame size and option code

Some descriptions, instructions, technical data and dimensional drawings which concern

only certain brake units are marked with the symbol of the frame size such as 4×R8i. The

marking derives from the quantity and basic construction of the brake chopper modules that

form the brake unit. For example, frame size 2×R8i indicates that the brake unit consists of

two frame size R8i brake chopper modules connected in parallel.

The frame size is marked on the type designation labels. The frame size of each brake

chopper module is also shown in the technical data.

Introduction to the manual 11

The instructions and technical data which concern only certain optional selections are marked

with option codes (such as +E210). The options included in the drive can be identified from

the option codes visible on the type designation label.

Use of component designations

Some device names in the manual include the item designation in brackets, for example

[Q20], to make it possible to identify the components in the circuit diagrams of the drive.

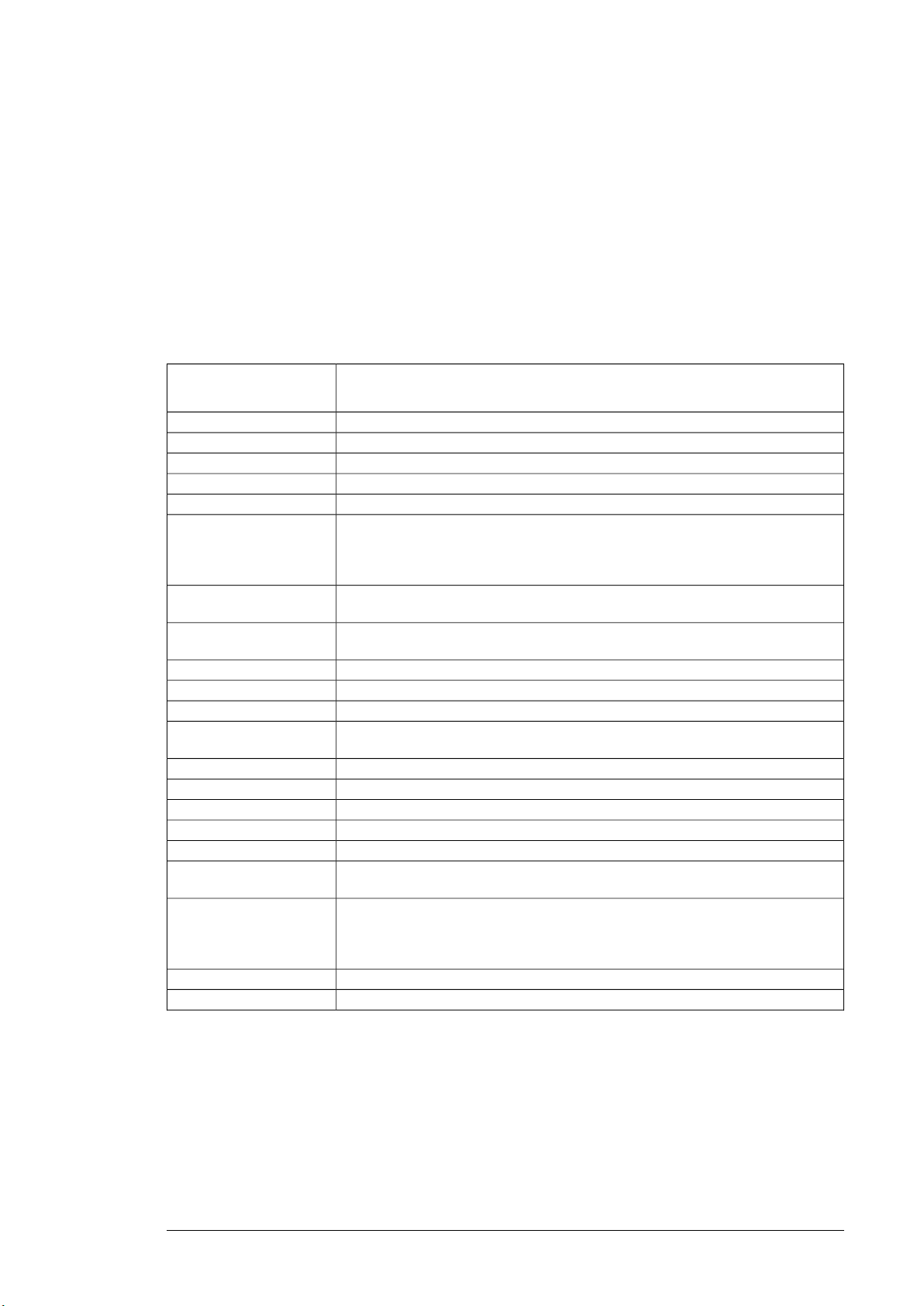

Terms and abbreviations

DescriptionTerm/

Abbreviation

Type of control boardBCON

Type of control unitBCU

Control board for direct-on-line cooling fanBDFC

Internal power supply board in frame R8i modulesBDPS

Control and power supply board for speed-controlled cooling fanBFPS

Brake chopper

Brake chopper module

Brake resistor

Cubicle

Multidrive

Parameter

Conducts the surplus energy from the intermediate circuit of the drive to the brake

resistor when necessary. The chopper operates when the DC link voltage exceeds

a certain maximum limit. The voltage rise is typically caused by deceleration

(braking) of a high inertia motor.

Brake chopper enclosed in a metal frame or housing. Intended for cabinet installation.

Dissipates the drive surplus braking energy conducted by the brake chopper to

heat

Brake chopper modules under control of one control board, and related accessoriesBrake unit

Circuit board in which the control program runsControl board

Control board built in a housing (often rail-mountable)Control unit

One section of a cabinet-installed drive. A cubicle is typically behind a door of its

own.

DC circuit between rectifier and inverterDC link

Frequency converter for controlling AC motorsDrive

Electromagnetic compatibilityEMC

Physical size of the drive or power moduleFrame, frame size

DC circuit between rectifier and inverterIntermediate circuit

Drive for controlling several motors which are typically coupled to the same machinery. Includes one supply unit, and one or several inverter units.

In the drive control program, user-adjustable operation instruction to the drive, or

signal measured or calculated by the drive.

In some (for example fieldbus) contexts, a value that can be accessed as an object,

eg, variable, constant, or signal.

Drive for controlling one motorSingle drive

Type of memory unit, attached to the control unitZMU

12

Operation principle and hardware description 13

2

Operation principle and hardware description

Contents of this chapter

This chapter describes the operation principle and construction of the brake unit.

Product overview

ACS880-607 is an air-cooled cabinet-installed brake unit, which forms a part of an ACS880

multidrive system. As standard, it includes brake chopper(s). Brake resistors are external.

Operation principle

The brake chopper handles the energy generated by a decelerating motor. The extra energy

increase the DC link voltage. The chopper connects the brake resistor to the DC link of the

drive whenever the voltage exceeds an activation limit. The energy consumption by the

resistor losses lowers the voltage until the resistor can again be disconnected.

Typically, a drive system is equipped with a brake chopper or brake choppers if

• high capacity braking is needed and the drive cannot be equipped with a regenerative

supply unit

• a backup for the regenerative supply unit is needed.

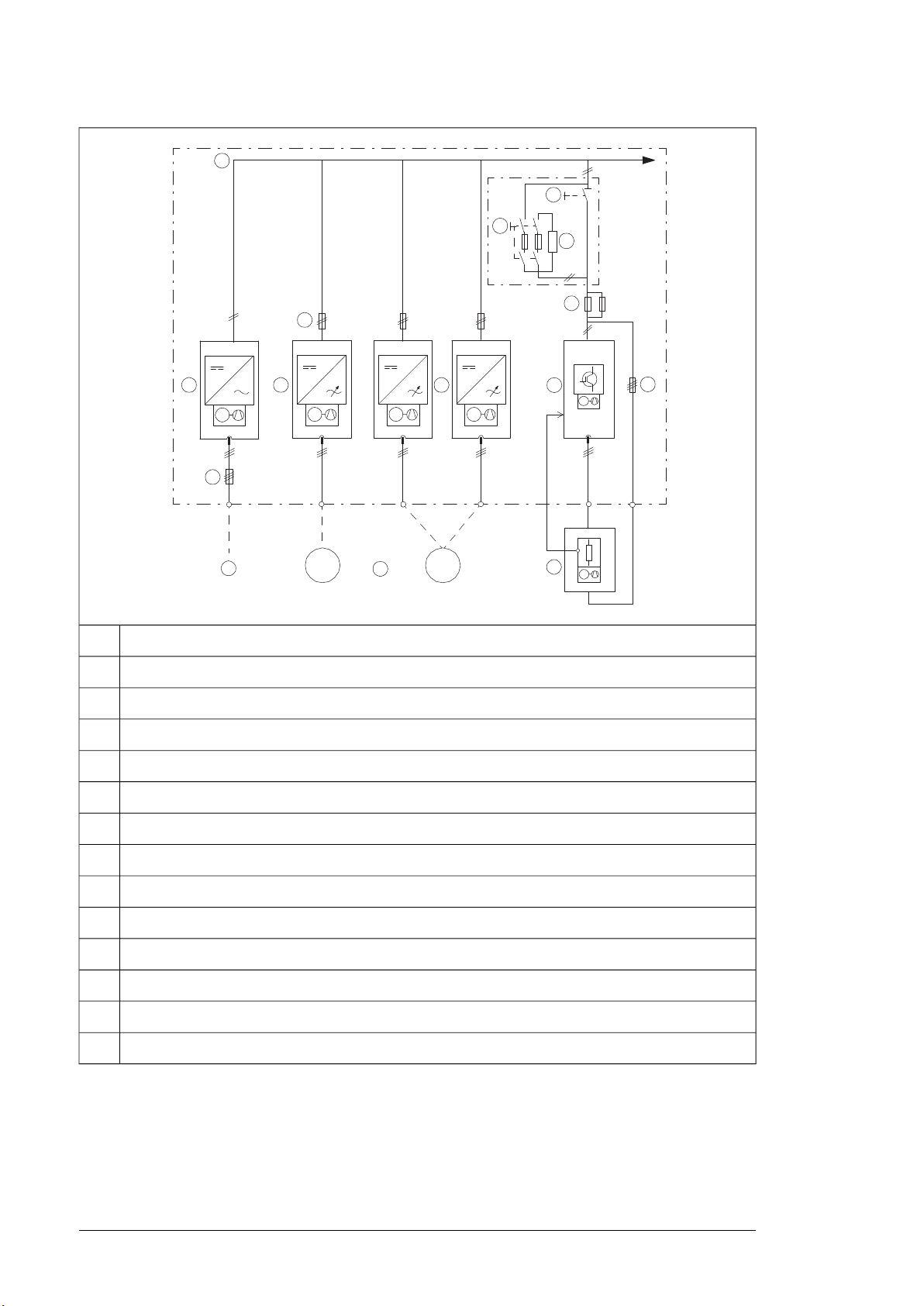

Simplified main circuit diagram of the drive system

This diagram shows a typical common DC bus drive system.

0

000

0

a

0

a

0

0

t°

14 Operation principle and hardware description

AC supply1

Input (AC) fuses2

Supply unit3

DC bus4

Inverter DC fuses (with or without a DC switch/disconnector)5

Inverter units (in this example, one of the two units consists of two inverter modules connected in parallel)6

Brake chopper fuses7

Brake unit8

Brake resistors (user-defined or option +D151)9

Brake resistor fuses10

Motor(s)11

DC switch/disconnector (part of option +F286)12

Charging circuit switch with fuses (part of option +F286)13

Charging resistors (part of option +F286)14

The supply unit connects to the AC supply network. The supply unit converts the AC voltage

into DC. The DC voltage is distributed through the DC bus to all inverter and brake units.

The inverter unit, consisting of one or more inverter modules, converts the DC back to AC

that rotates the motor. The brake unit, consisting of one or more brake chopper modules,

conveys energy to brake resistors whenever needed.

Operation principle and hardware description 15

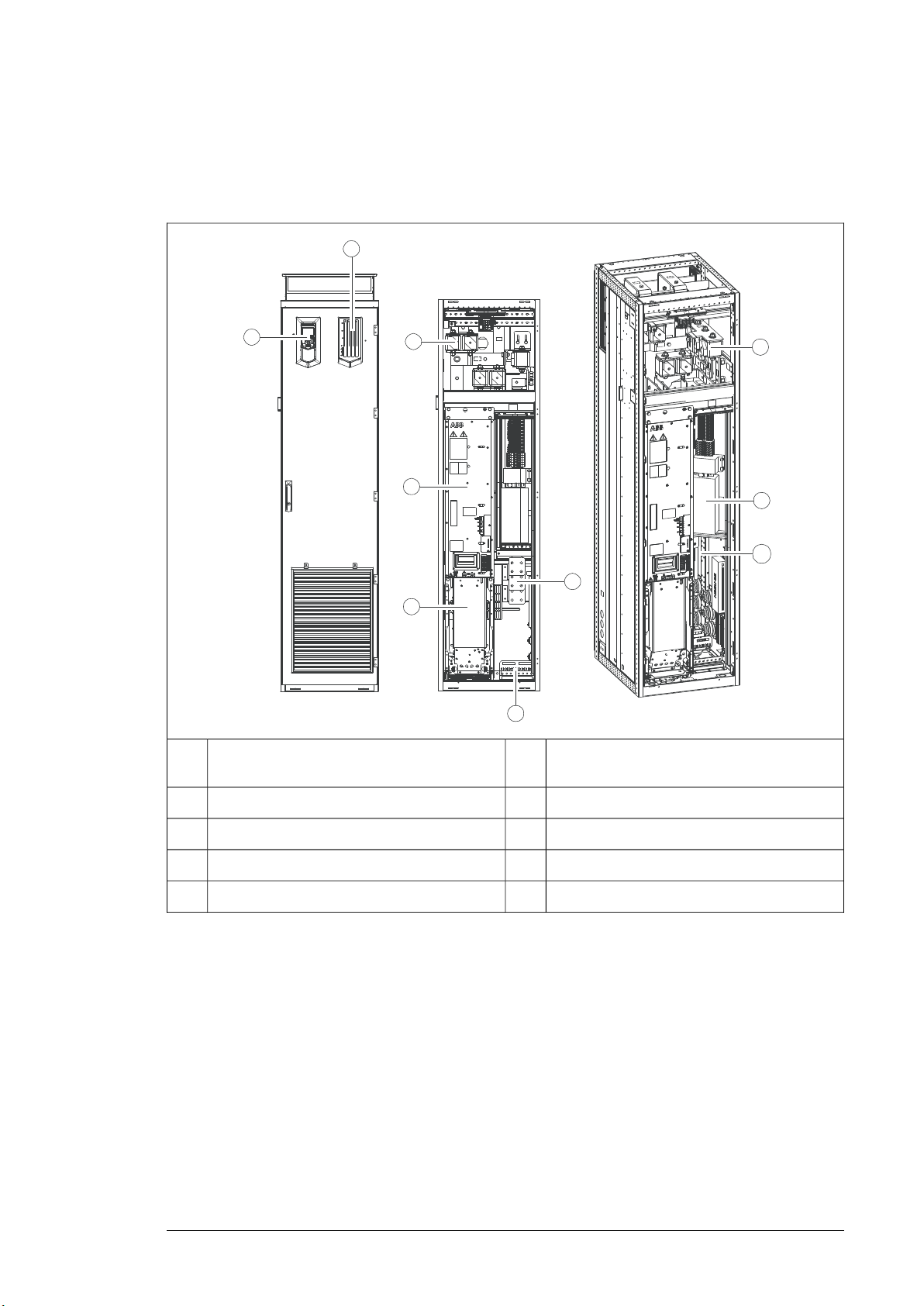

Layout drawings

The figure below shows the components of the brake chopper cubicle with bottom entry

and exit of cables and shrouds removed.

Cable entries for brake resistor and control

6Control panel (option +J400)1

cables

Terminals for brake resistor cable connection7Drive monitoring display (option +J401)2

Brake resistor fuses8Brake chopper fuses3

BCU-x2 control unit9Brake chopper module4

Cabinet heater (option +G300)10Brake chopper cooling fan5

1

2

3

4

5

6

7

9

10

11

12

8

13

16 Operation principle and hardware description

The figure below shows the components of the brake chopper cubicle with bottom entry

and exit of cables and shrouds removed – option +F286 included.

Brake resistor fuses8Control panel (option +J400)1

2

BCU-x2 control unit9DC switch/disconnector handle (part of option

+F286)

3

Terminals for brake resistor cable connection10Charging circuit switch fuse handle (part of op-

tion +F286)

Cable entries for brake resistor and control

11Drive monitoring display (option +J401)4

cables.

Brake chopper fuses12Charging circuit fuses5

Cabinet heater (option +G300)13Brake chopper module6

Brake chopper cooling fan7

Operation principle and hardware description 17

The figure below shows the components of the brake chopper cubicles with top entry and

exit of cables and shrouds removed.

Cable entries for brake resistor and control

6

cables

Terminals for brake resistor cable connection7Control panel (option +J400)1

Brake resistor fuses8Drive monitoring display (option +J401)2

Cabinet fans9Brake chopper fuses3

BCU-x2 control unit10Brake chopper module4

Cabinet heater (option +G300)11Brake chopper cooling fan5

A

B

1

8

10

5

7

12

3

2

9

4

6

5

11

18 Operation principle and hardware description

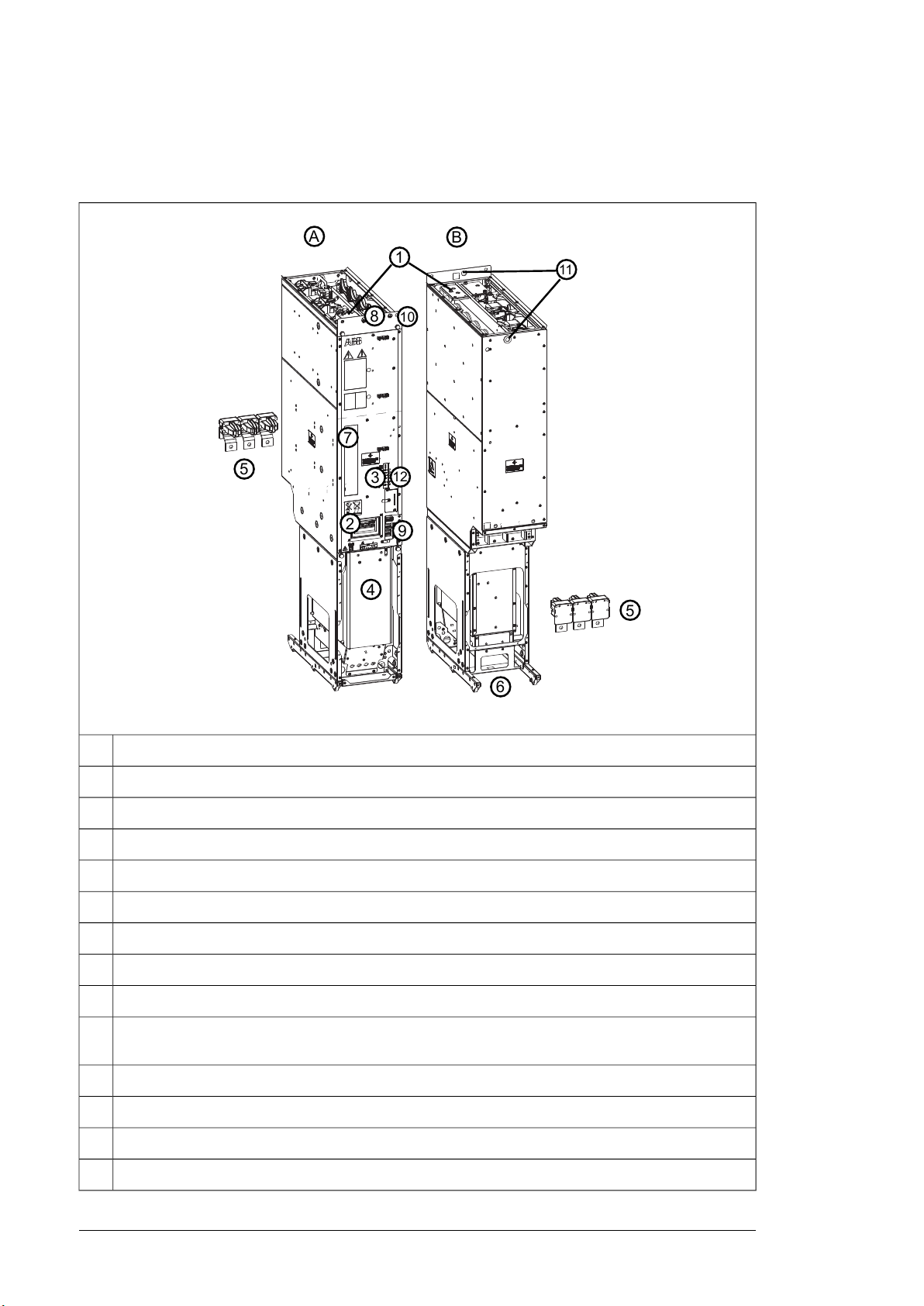

Frame R8i layout

This figure shows the layout of the R8i module.

R8i module, frontA

R8i module, backB

DC busbars1

Handle2

LEDs and fiber optic connectors3

Fan (standard speed-controlled fan shown; a direct-on-line fan is available as option +C188)4

Quick connector (three phases). The counterpart is fastened to the cabinet behind the module.5

Wheels6

Type designation label7

Terminal block [X50] (power supply for internal boards and module heating element, option +C183; DOL

8

fan supply, option +C188)

Connectors [X51], [X52], [X53]9

The unpainted grounding point (PE) between module frame and cabinet frame.10

Lifting eyes11

Circuit board compartment fan12

STO OUT

X51

FE

GND

24V

GND

24V

STO IN

X52

FE

GND

24V

GND

24V

24V OUT

X53

FE

24V

GND

24V

GND

Operation principle and hardware description 19

Brake chopper module connectors

■ Connectors X50…X53

Connector X50

Not in use.9

N8

L7

Not in use.6

N5

L4

W3

V2

U1

115/230 V AC (50/60 Hz) input for optional heating element

(+C183).

Not in use in brake chopper modules.

115/230 V AC 50 Hz input for internal power supply (BDPS)

(115 V AC 60 Hz with option +G304).

400 V AC (50/60 Hz) supply for optional DOL (direct-online)

cooling fan (option +C188).

Note:

In modules without +C188, the DOL wiring is present but not

in use.

Connectors X51, X52, X53

X51

OUT

STO INX52

24V OUTX53

Note:

The Safe torque off (STO) safety function is only

implemented in inverter units. Therefore, the STO

function cannot be used in supply, rectifier, DC/DC

converter and brake units. In these units, de-energizing any connection of STO IN (X52) connector

stops the unit. Note that this stop is not safety related and must not be used for safety function

purposes.

Not in use.STO

STO connectors of the module. Must be connected to

24 V DC for the module to

start.

24 V DC for BCU and for

STO IN to enable the module operation.

BSFC

V50

V60

BFPS

V30

V40

BCU

V10

V20

9 :8

'&'&

3(

'&

'&

t

t

t

5 5 5

9

',

97

95

9

9

5 5 5

20 Operation principle and hardware description

■ Fibre optic connectors

DescriptionName

Charging controller connection (option +F286).BSFC

Fan control connection (to fan control box).BFPS

Control unit connection.BCU

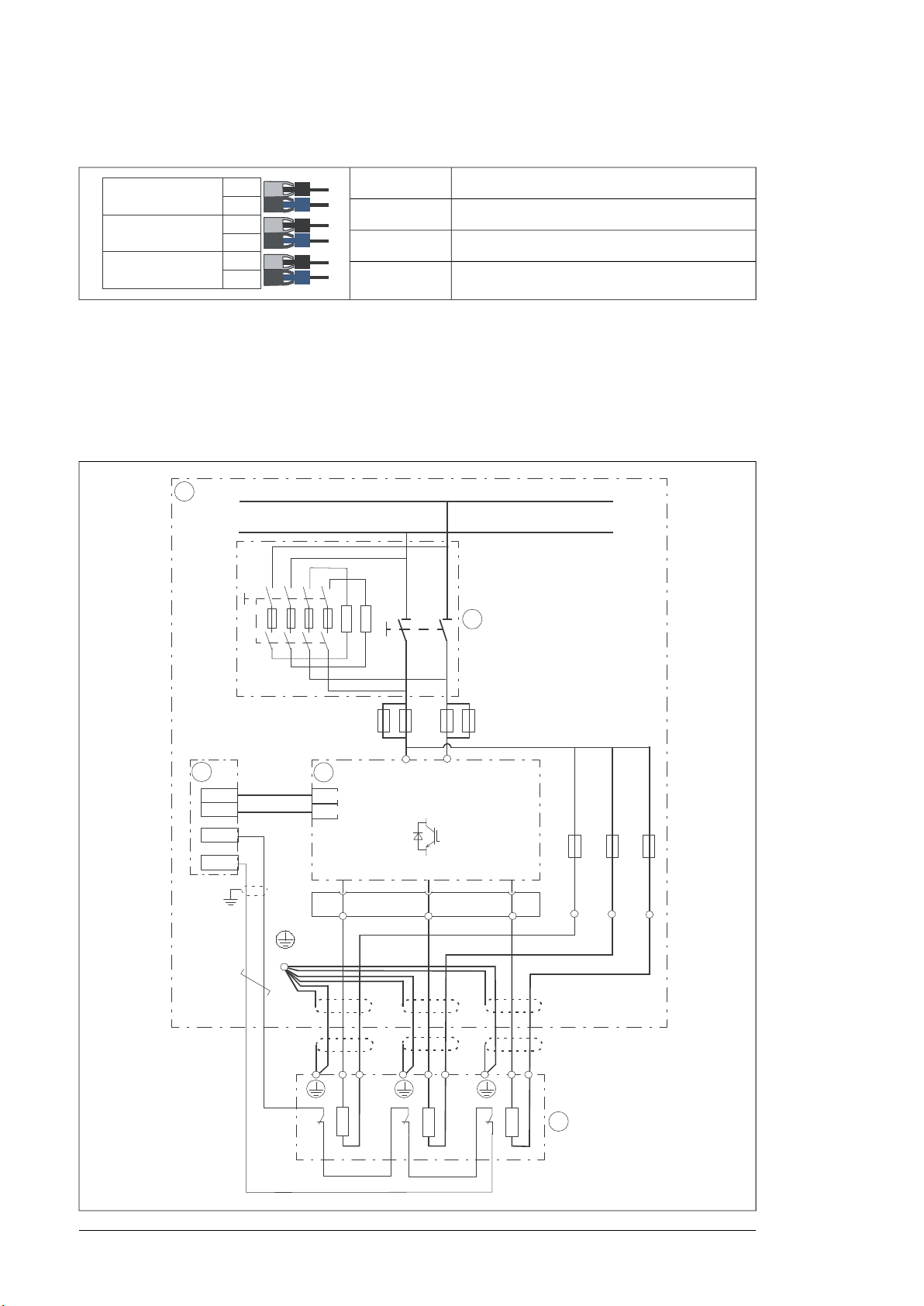

Overview of power and control connections

The diagram below shows the power and control connections of the brake unit consisting

of one 3-phase brake chopper module. For parallel-connected brake chopper modules, the

brake resistors are connected to each brake chopper module also as shown below. Each

parallel-connected brake chopper module has a dedicated control unit.

Operation principle and hardware description 21

Brake chopper cubicle1

DC switch/disconnector with charging circuit (option +F286)2

Control unit3

Brake chopper module4

Brake resistors (user-defined or option +D151)5

Brake unit control devices

Each brake chopper module employs a dedicated control unit (BCU) that contains the BCON

board with basic I/Os and slots for optional modules. A fiber optic link connects the BCU to

the brake chopper module.

1

2

3

4

5

6

7

F

X

X

F

X

X

F

X

X

X

8

CLOSE

9

10

22 Operation principle and hardware description

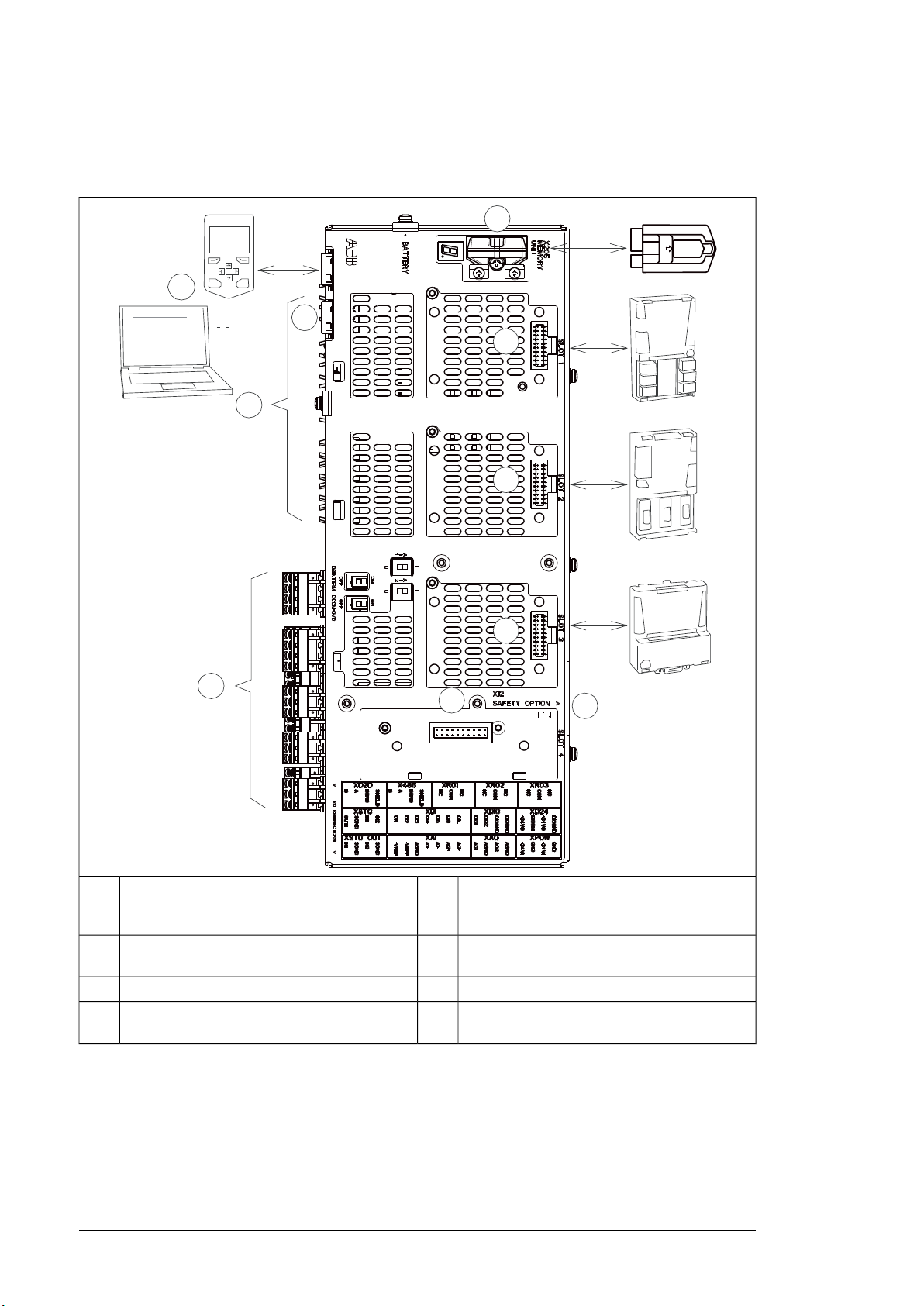

■ Overview of the control connections of the BCU control unit

The diagram shows the control connections and interfaces of the BCU control unit.

1

fieldbus communication modules can be inserted

2

into slots 1, 2 and 3.

3

■ The control panel

Control panel.7Analog and digital I/O extension modules and

Fiber optic links to power modules (inverter,

8Memory unit4

supply, brake or converter)

Ethernet port. Not in use.9Slot 4 for RDCO-0x5

Safety option interface. Only in use for the invert-

10Terminal blocks.6

er units.

The control panel (option +J400) is the user interface of the brake unit, providing the essential

controls such as reset, and the parameter settings for the control program.

The control panel is mounted on a platform on the brake chopper cubicle door.

For details on the control panel, see ACS-AP-x Assistant control panels user’s manual

(3AUA0000085685 [English]).

Operation principle and hardware description 23

■ Control by PC tools

There is a USB connector on the front of the panel that can be used to connect a PC to the

drive.

■ Fieldbus control

The unit can be controlled through a fieldbus interface if it is equipped with an optional

fieldbus adapter, and when the control program has been configured for fieldbus control by

parameters. For information on the parameters, see the firmware manual.

■ DC switch and charging switch

DC switch/disconnector (option +F286)

The brake unit can optionally be equipped with DC switch/disconnectors which allow the

isolation of the brake chopper modules from the DC bus. When a brake chopper module is

reconnected to the DC bus, its DC capacitors are automatically charged through a charging

circuit.

The status of the DC switch/disconnector is connected to the DIIL input on the brake control

unit. By default, the run enable signal is removed when the DC switch/disconnector is open.

WARNING!

Do not open the DC switch/disconnector under load.

Charging switch

The brake chopper modules equipped with a DC switch/disconnector have a DC link

precharging circuit including an xSFC-02 charging control unit and a charging switch on the

cubicle door.

Type designation labels

Each brake unit and brake chopper module is equipped with type designation labels.

L

24 Operation principle and hardware description

■ Brake unit type designation label

An example label of the brake unit is shown below.

Type designation.1

Manufacturer’s address.2

Frame size.3

Cooling method.4

Degree of protection.5

Maximum input voltage (UL/CSA).6

Ratings.7

Valid markings.8

Serial number. The first digit refers to the manufacturing plant. The next four digits indicate manufacturing

9

year and week respectively (yyww). The remaining digits complete the serial number so that there are

no two units with the same number.

■ Brake chopper module type designation label

Each module has a type designation label attached to it. The type designation stated on

the label contains information on the specifications and configuration of the module. The

first digits express the basic construction, for example “ACS880-104-0100A-3”. Any optional

selections are given thereafter, separated by plus signs.

Examples of the label are shown below.

Operation principle and hardware description 25

Type designation.1

Frame size.2

Degree of protection; additional UL/CSA specifications.3

Ratings. The labels show ratings for inverter module (INVERTER), IGBT supply module (LINE CONVERT-

4

ER), brake chopper module (BRAKE CHOPPER), regenerative rectifier module (REGENERATIVE

RECTIFIER) and DC/DC converter module (DC/DC CONVERTER).

Valid markings.5

Serial number. The first digit refers to the manufacturing plant. The next four digits indicate manufacturing

6

year and week respectively (yyww). The remaining digits complete the serial number so that there are

no two units with the same number.

Brake unit type designation key

Type designation describes the composition of the unit in short. The complete designation

code is divided in subcodes:

• The first digits form the basic code. It describes the basic construction of the unit. The

fields in the basic code are separated by hyphens.

• The plus codes follow the basic code. Each plus code starts with an identifying letter

(common for the whole product series), followed by descriptive digits. The plus codes

are separated by plus signs.

The subcodes are described below.

DESCRIPTIONCODE

Basic codes

Product seriesACS880

607

Ratings / size

Brake unit: Supply frequency 50 Hz, control (auxiliary) voltage 230 V AC, IEC industrial cabinet

construction, degree of protection IP22 (UL Type 1), cabling through bottom of cabinet, speedcontrolled module cooling fans, European-style cable entries, aluminum DC busbars (up to

3200 A), tin-plated copper DC busbars (from 3200 A up), DC fuses, ACS880 brake control

program, coated circuit boards, USB memory stick containing complete documentation in

English.

Sizexxxxx

26 Operation principle and hardware description

DESCRIPTIONCODE

Voltage range

3

513…566 V DC. This is indicated in the type designation label as typical input voltage level

566 V DC.

5

513…707 V DC. This is indicated in the type designation label as typical input voltage levels

566 / 679 / 707 V DC.

7

709…976 V DC. This is indicated in the type designation label as typical input voltage levels

742 / 849 / 976 (849 UL, CSA) V DC.

Option codes (plus codes)

Supply frequency

50 HzA012

60 HzA013

Degree of protection

IP22 (UL type 1)B053

IP42 (UL Type 1)B054

IP54 (UL Type 12)B055

Construction

Marine constructionC121

Cooling air through bottomC128

C129

UL approved

Channeled air outletC130

CSA approvedC134

Plinth height 100 mmC164

Plinth height 200 mmC179

Seismic designC180

Direct-on-line cooling fanC188

Resistor braking

Brake chopperD150

Brake resistorsD151

Filters

E210

EMC filter for second environment TN and IT (grounded and ungrounded) systems, category

C3.

Switchgear

DC switch/disconnectorF286

Heaters lights and auxiliary control voltage

Cabinet heater (external supply)G300

Cabinet lightingG301

Materials

Cabling

Operation principle and hardware description 27

DESCRIPTIONCODE

115 V control voltage for relaysG304

DC busbar material aluminumG314

DC busbar material tin plated copperG315

230 V AC control transformerG320

Halogen-free wiring and materialsG330

Brake resistor cables through the bottom of the cabinetH352

Brake resistor cables through the roof of the cabinetH353

Blind 3 mm steel cable gland platesH358

Blind 3 mm aluminum cable gland platesH364

Blind 6 mm brass cable gland platesH365

Control cables through the bottom of the cabinetH367

Control cables through the roof of the cabinetH368

Control panel and PC options

Control panel (max. 4 per door)J400

Drive monitoring displayJ401

Control panel mounting platform (max. 4 per door)J410

Common control panelJ412

I/O extension and feedback interface modules

FIO-11 analog I/O extension moduleL500

FIO-01 digital I/O extension moduleL501

RDCO-04 DDCS communication moduleL509

FAIO-01 analog I/O extension moduleL525

FDIO-01 digital I/O extension moduleL526

Ring topology for fiber optic link without NDCU-95 DDCS branching unitZ2016

Fieldbus adapter modules

Panel bus selectedK450

FDNA-01 DeviceNet™ adapter moduleK451

FPBA-01 PROFIBUS DP adapter moduleK454

FCAN-01 CANopen adapter moduleK457

FSCA-01 Modbus/RTU adapter moduleK458

FCNA-01 ControlNet™ adapter moduleK462

FECA-01 EtherCAT adapter moduleK469

Loading...

Loading...