ABB ACQ550-x1-046A-2, ACQ550-x1-04A6-2, ACQ550-x1-059A-2, ACQ550-x1-031A-2, ACQ550-x1-088A-2 User Manual

...

ACQ550

User’s Manual

ACQ550-U1 Drives (1

…200 hp)

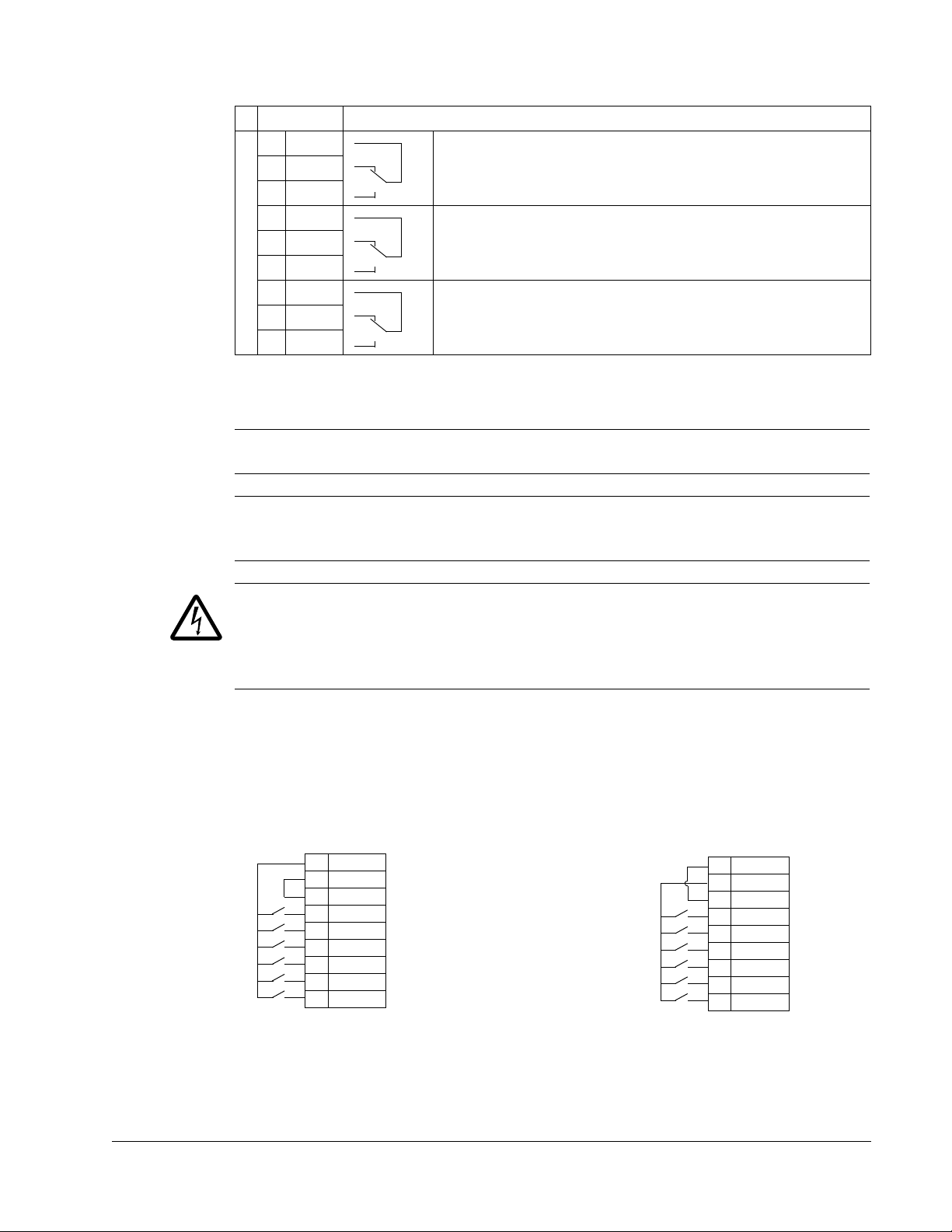

Kit, IP21 / UL type 1 Frame size Code (English)

FMK-A-R1 R1 100000982

FMK-A-R2 R2 100000984

FMK-A-R3 R3 100000986

FMK-A-R4 R4 100000988

AC8-FLNGMT-R5 R5

ACS800PNTG01U-EN

AC8-FLNGMT-R6 R6

Kit, IP54 / UL type 12 Frame size Code (English)

FMK-B-R1 R1 100000990

FMK-B-R2 R2 100000992

FMK-B-R3 R3 100000994

FMK-B-R4 R4 100000996

BACNet is a registered trademark of ASHRAE.

CANopen is a registered trademark of CAN in Automation

e.V.

CC-Link is a trademark of CC-Link Partner Association.

ControlNet™ is a trademark of ODVA™.

DeviceNet™ is a trademark of ODVA™.

DRIVECOM is a registered trademark of DRIVECOM User

Group e.V.

EtherCAT is a registered trademark of Beckhoff.

EtherNet/IP™ is a trademark of ODVA™.

Modbus and Modbus/TCP are registered trademarks of

Schneider Automation Inc.

PROFIBUS, PROFIBUS DP and PROFINET IO are

registered trademarks of Profibus International.

List of related manuals

GENERAL MANUALS

ACQ550-U1 User’s Manual (1…200 hp)

• Safety

•Installation

• Start-up, control with I/O and ID Run

• Control panels

• Application macros

• Parameters

• Embedded fieldbus

• Fieldbus adapter

• Diagnostics

• Maintenance

• Technical data

Flange Mounting Instructions

REPL-01 Ethernet POWERLINK Adapter Module

User’s Manual

3AUA0000052289 (English)

RETA-01 Ethernet Adapter Module User’s Manual

3AFE64539736 (English)

RETA-02 Ethernet Adapter Module User’s Manual

3AFE68895383 (English)

RPBA-01 PROFIBUS DP Adapter User’s Manual

3AFE64504215 (English)

SREA-01 Ethernet Adapter User’s Manual

3AUA0000042896 (English)

Typical contents

• Safety

• Installation

• Programming/Start-up

• Diagnostics

• Technical data

MAINTENANCE MANUALS

Guide for Capacitor Reforming in ACS50, ACS55,

ACS150, ACS310, ACS320, ACS350, ACS550, ACH550

and ACQ550

3AFE68735190 (English)

OPTION MANUALS

(delivered with optional equipment)

OHDI-01 115/230 V Digital Input Module User ’s Manual

3AUA0000003101 (English)

OREL-01 Relay Output Extension Module User’s

Manual

3AUA0000001935 (English)

RCAN-01 CANopen Adapter User’s Manual

3AFE64504231 (English)

RCCL-01 CC-Link Adapter Module User’s Manual

3AUA0000061340 (English)

RCNA-01 ControlNet Adapter User’s Manual

3AFE64506005 (English)

RDNA-01 DeviceNet Adapter User’s Manual

3AFE64504223 (English)

RECA-01 EtherCAT Adapter Module User’s Manual

3AUA0000043520 (English)

ACQ550-U1 Drives

1…200 hp

User’s Manual

2017 ABB Oy. All Rights Reserved.

3AUA0000145616 Rev C

EN

EFFECTIVE 3-15-2017

ACQ550-U1 User’s Manual 5

Safety

Use of warnings and notes

There are two types of safety instructions throughout this manual:

• Notes draw attention to a particular condition or fact, or give information on a

subject.

• Warnings caution you about conditions which can result in serious injury or death

and/or damage to the equipment. They also tell you how to avoid the danger . The

warning symbols are used as follows:

Electricity warning warns of hazards from electricity which can cause physical

injury and/or damage to the equipment.

General warning warns about conditions, other than those caused by electricity,

which can result in physical injury and/or damage to the equipment.

WARNING! The ACQ550 adjustable speed AC drive should ONLY be installed by a

qualified electrician.

WARNING! Even when the motor is stopped, dangerous voltage is present at the

power circuit terminals U1, V1, W1 and U2, V2, W2 and, depending on the frame

size, UDC+ and UDC-, or BRK+ and BRK-.

WARNING! Dangerous voltage is present when input power is connected. After

disconnecting the supply, wait at least 5 minutes (to let the intermediate circuit

capacitors discharge) before removing the cover.

WARNING! Even when power is switched off from the input terminals of the

ACQ550, there may be dangerous voltage (from external sources) on the terminals

of the relay outputs RO1…RO3.

WARNING! When the control terminals of two or more drives are connected in

parallel, the auxiliary voltage for these control connections must be taken from a

single source which can either be one of the drives or an external supply.

Safety

6 ACQ550-U1 User’s Manual

WARNING! Disconnect the internal EMC filter when installing the drive on an IT

system (an ungrounded power system or a high-resistance-grounded [over 30 ohm]

power system), otherwise the system will be connected to ground potential through

the EMC filter capacitors. This may cause danger, or damage the drive.

Disconnect the internal EMC filter when installing the drive on a corner grounded TN

system, otherwise the drive will be damaged.

Note: When the internal EMC filter is disconnected, the drive is not EMC comp atible.

See section Disconnecting the internal EMC filter on page 23. Also see sections IT

systems on page 276 and Corner grounded TN systems on page 275.

WARNING! Do not attempt to install or remove EM1, EM3, F1 or F2 screws while

power is applied to the drive’s input terminals.

WARNING! Do not control the motor with the disconnecting device (disconnecting

means); instead, use the control panel start and stop keys and , or

commands via the I/O board of the drive. The maximum allowed number of charging

cycles of the DC capacitors (i.e. power-ups by applying power) is five in ten minutes.

WARNING! The ACQ550-U1 is not field repairable. Never attempt to repair a

malfunctioning drive; contact the factory or your local Authorized Service Center for

replacement.

WARNING! The ACQ550 will start up automatically after an input voltage

interruption if the external run command is on.

WARNING! The heat sink may reach a high temperature. See chapter Technical

data on page 267.

Note: For more technical information, contact the factory or your local ABB

representative.

Safety

ACS550-U1 User’s Manual 7

Table of contents

List of related manuals

Safety

Use of warnings and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table of contents

Installation

Installation flow chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Preparing for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Installing the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Start-up, control with I/O and ID Run

How to start up the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

How to control the drive through the I/O interface . . . . . . . . . . . . . . . . . . . . . . 39

How to perform the ID Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Control panel

W/WW control panel features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

W/WW control panel modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Application macros

ABB 2-wire macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3-wire macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Alternate macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Motor Potentiometer macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Hand-Auto macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

PID Control macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

PFC macro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Connection examples of two-wire and three-wire sensors . . . . . . . . . . . . . . . . 65

User parameter sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Macro default values for parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Parameters

Complete parameter list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Complete parameter descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Embedded fieldbus

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Mechanical and electrical installation – EFB . . . . . . . . . . . . . . . . . . . . . . . . . 179

Communication setup – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Activate drive control functions – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Feedback from the drive – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Table of contents

8 ACS550-U1 User’s Manual

Diagnostics – EFB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Modbus protocol technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

ABB control profiles technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

BACnet protocol technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Fieldbus adapter

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Mechanical and electrical installation – FBA . . . . . . . . . . . . . . . . . . . . . . . . . 232

Communication set-up – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Activate drive control functions – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

Feedback from the drive – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Diagnostics – FBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

ABB Drives profile technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Generic profile technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Diagnostics

Diagnostic displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Correcting faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Correcting alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

Maintenance

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

Main fan replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Internal enclosure fan replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Technical data

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Input power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Motor connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Brake components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 285

Control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291

Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

Degrees of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 297

Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

C-Tick marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

UL/CSA markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 300

IEC/EN 61800-3 (2004) Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

Compliance with the IEC/EN 61800-3 (2004) . . . . . . . . . . . . . . . . . . . . . . . . . 301

Table of contents

ACS550-U1 User’s Manual 9

Index

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . 315

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

Table of contents

10 ACS550-U1 User’s Manual

Table of contents

ACQ550-U1 User’s Manual 11

Installation

Study these inst allation instructio ns carefully before proceeding. Failure to observe

the warnings and instructions may cause a malfunction or personal hazard.

WARNING! Before you begin read chapter Safety on page 5.

Note: The installation must always be designed and made according to applicable

local laws and regulations. ABB does not assume any liability whatsoever for any

installation which breaches the local laws and/or other regulations. Furthermore, if

the recommendations given by ABB are not followed, the drive may experience

problems that the warranty does not cover.

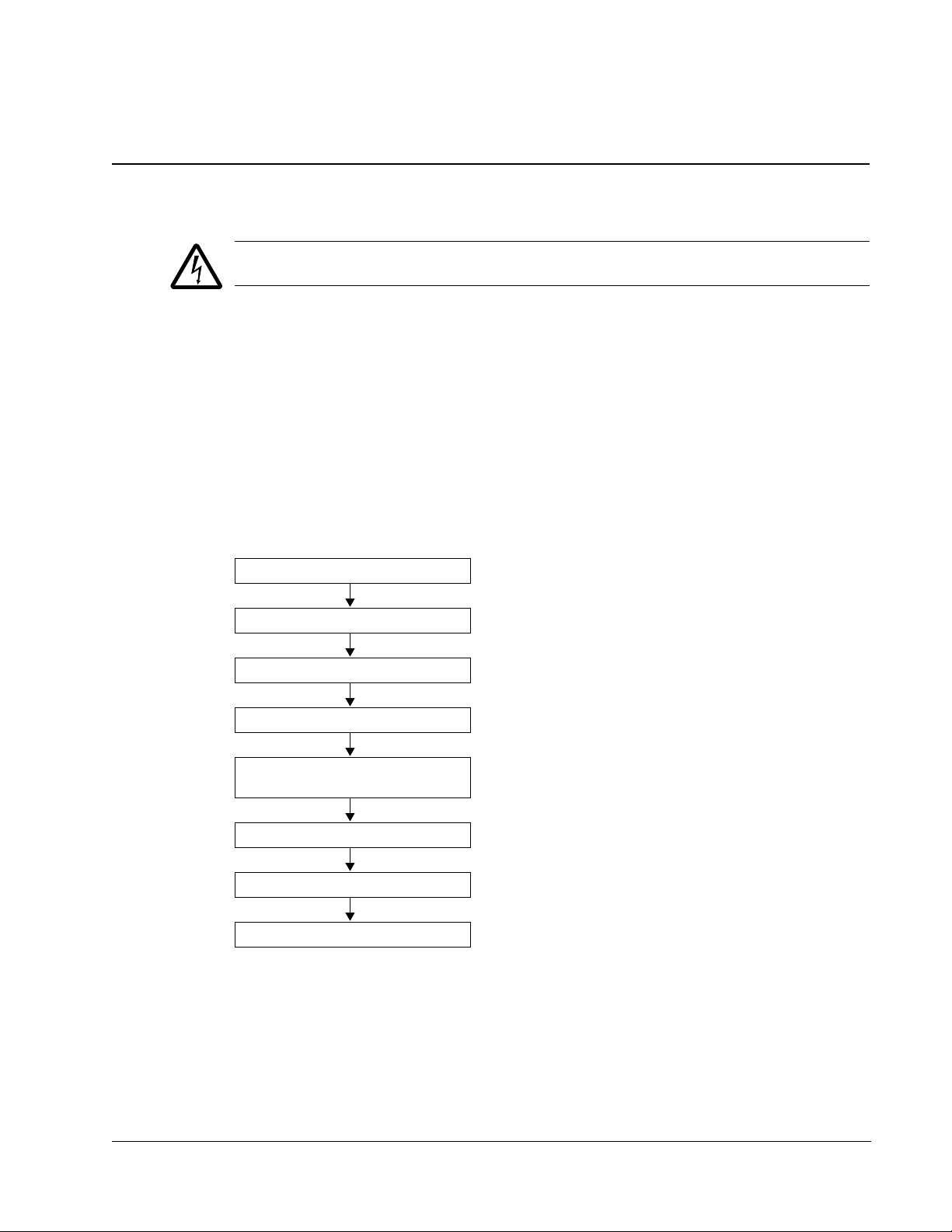

Installation flow chart

The installation of the ACQ550 adjustable speed AC drive follows the outline below.

The steps must be carried out in the order shown. At the right of each step are

references to the detailed information needed for the correct installation of the drive.

Task See

PREPARE for installation Preparing for installation on page 12

PREPARE the mounting location Prepare the mounting location on page 16

REMOVE the front cover Remove the front cover on page 17

MOUNT the drive Mount the drive on page 18

INSTALL wi ri n g Wiring overview on page 19 and

Install the wiring on page 26

CHECK installation Check installation on page 31

REINSTALL the cover Reinstall the cover on page 32

START-UP How to start up the drive on page 33

Installation

12 ACQ550-U1 User’s Manual

IP2040

Serial number

Type designation

Serial number

Type designation

Type designation

Serial number

Preparing for installation

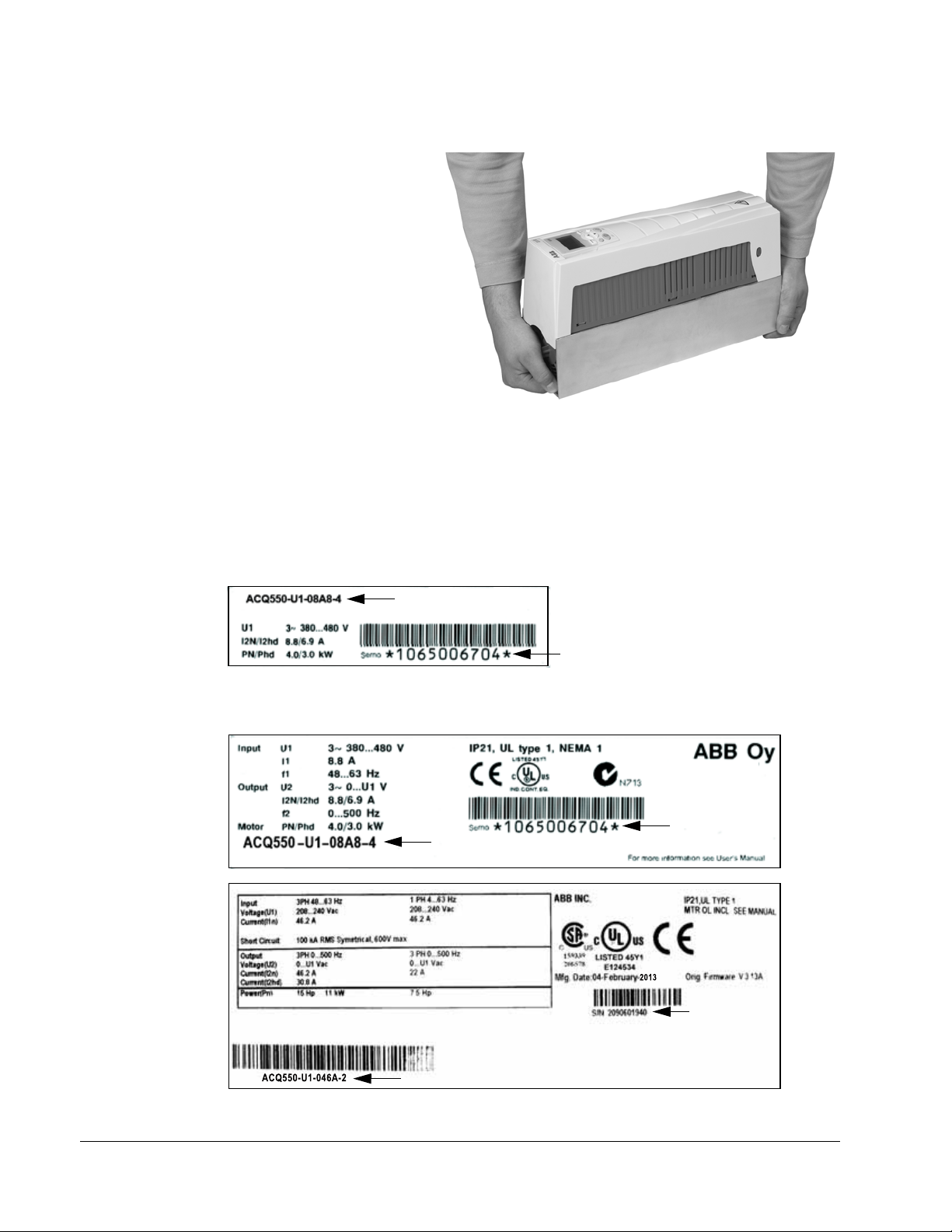

Lifting the drive

Lift the drive only by the metal

chassis.

Unpacking the drive

1. Unpack the drive.

2. Check for any damage and

notify the shipper immediately

if damaged components are

found.

3. Check the contents against

the order and the shipping label to verify that all parts have been received.

Drive identification

Drive labels

To determine the type of drive you are installing, refer to either:

• serial number label attached on upper part of the chokeplate between the

mounting holes, or

• type designation label attached on the heat sink – on the right side of the drive

cover. Two examples of the type designation label are given below.

Installation

ACQ550-U1 User’s Manual 13

AC, Standard Drive – 550 product series

Construction (region specific)

Output current rating

Voltage rating

Options

Examples of options:

B055 = IP54 / UL type 12 (no specification = IP21 / UL type 1).

0J400 = No control panel

L511 = OREL-01 Relay output extension

K451 = RDNA-01 DeviceNet

ACQ550-U1-08A8-4+J404+…

e.g. 08A8 = 8.8 A, see section Ratings on page 267 for details

2 = 208…240 V AC

4 = 380…480 V AC

6 = 500…600 VAC

U1= Setup and parts specific to US installation and NEMA compliance

Type designation

Use the following chart to interpret the type designation found on both the type

designation and the serial number label.

Ratings and frame size

The chart in section Ratings

the drive’s frame size – significant, since some instructions in this document vary,

depending on the drive’s frame size. To read the ratings tab le, you need the “Output

current rating” entry from the type designation. Also, when using the ratings table,

note that the table is broken into sections based on the drive’s “Voltage rating”.

Serial number

The format of the drive serial number shown on the labels is described below.

Serial number is of format CYYWWXXXXX, where

C: Country of manufacture

YY: Year of manufacture

WW: Week of manufacture; 01, 02, 03, … for week 1, week 2, week 3, …

XXXXX: Integer starting every week from 00001.

on page 267 lists technical specifications and identifies

Installation

14 ACQ550-U1 User’s Manual

Motor compatibility

The motor, drive and supply power must be compatible:

Motor

specification

Motor type 3-phase induction motor –

Nominal current Motor valu e is within this

Nominal frequency 10…500 Hz –

Voltage range Motor is compatible with

Insulation 500…600 V drives: Either

range: 0.2…2.0 · I

(I

2hd

current)

the ACQ550 voltage range.

the motor complies with

NEMA MG1 Part 31, or a

du/dt filter is used between

the motor and drive.

Verify Reference

• Type designation label on drive, entry for

= drive heavy duty

2hd

Output I

• Type designation on drive and rating table in

chapter Technical data on page 267.

208…240 V (for ACQ550-U1-XXXX-2) or

380…480 V (for ACQ550-U1-XXXX-4) or

500…600 V (for ACQ550-U1-XXXX-6)

For ACQ550-U1-XXXX-6

2hd

Tools required

To install the ACQ550 you need the following:

• screwdrivers (as appropriate for the mounting hardware used)

• wire stripper

• tape measure

, or

•drill

• for installations involving ACQ550-U1, frame sizes R5 or R6 and IP54 / UL type

12 enclosures: punch for creating conduit mounting holes

• for installations involving ACQ550-U1, frame size R6: appropriate crimping tool

for power cable lugs. See section Power terminal considerations – R6 frame size

on page 277.

• mounting hardware: screws or nuts and bolts, four each. The type of hardware

depends on the mounting surface and the frame size:

Frame size Mounting hardware

R1…R4 M5

R5 M6 1/4 in

R6 M8

#10

5/16 in

Suitable environment and enclosure

Confirm that the site meets the environmental requirements. To prevent damage

prior to installation, store and transport the drive according to the environmental

requirements specified for storage and transportation. See section Ambient

conditions

on page 296.

Installation

ACQ550-U1 User’s Manual 15

Confirm that the enclosure is appropriate, based on the site contamination level:

• IP21 / UL type 1 enclosure: The site must be free of airborne dust, corrosive

gases or liquids, and conductive contaminants such as dripping water,

condensation, carbon dust and metallic particles.

• IP54 / UL type 12 enclosure: This enclosure provides protection from airborne

dust and light sprays or splashing water from all directions.

• If, for some reason, an IP21 drive needs to be installed without the conduit box or

cover, or an IP54 drive without the conduit plate or hood, see the note in chapter

Technical data, page 300.

Suitable mounting location

Confirm that the mounting location meets the following constraints:

• The drive must be mounted vertically on a smooth, solid surface, and in a suitable

environment as defined above. For horizontal installation, contact your local ABB

representative for more information.

• The minimum space requirements for the drive are the outside dimensions (see

section Outside dimensions on page

(see section Cooling

on page 291).

294), plus air flow space around the drive

• The distance between the motor and the drive is limited by the maximum motor

cable length. See section Motor connection specifications

on page 279.

• The mounting site must support the drive’s modest weight. See section Weight on

page 295.

Installation

16 ACQ550-U1 User’s Manual

X0002

1

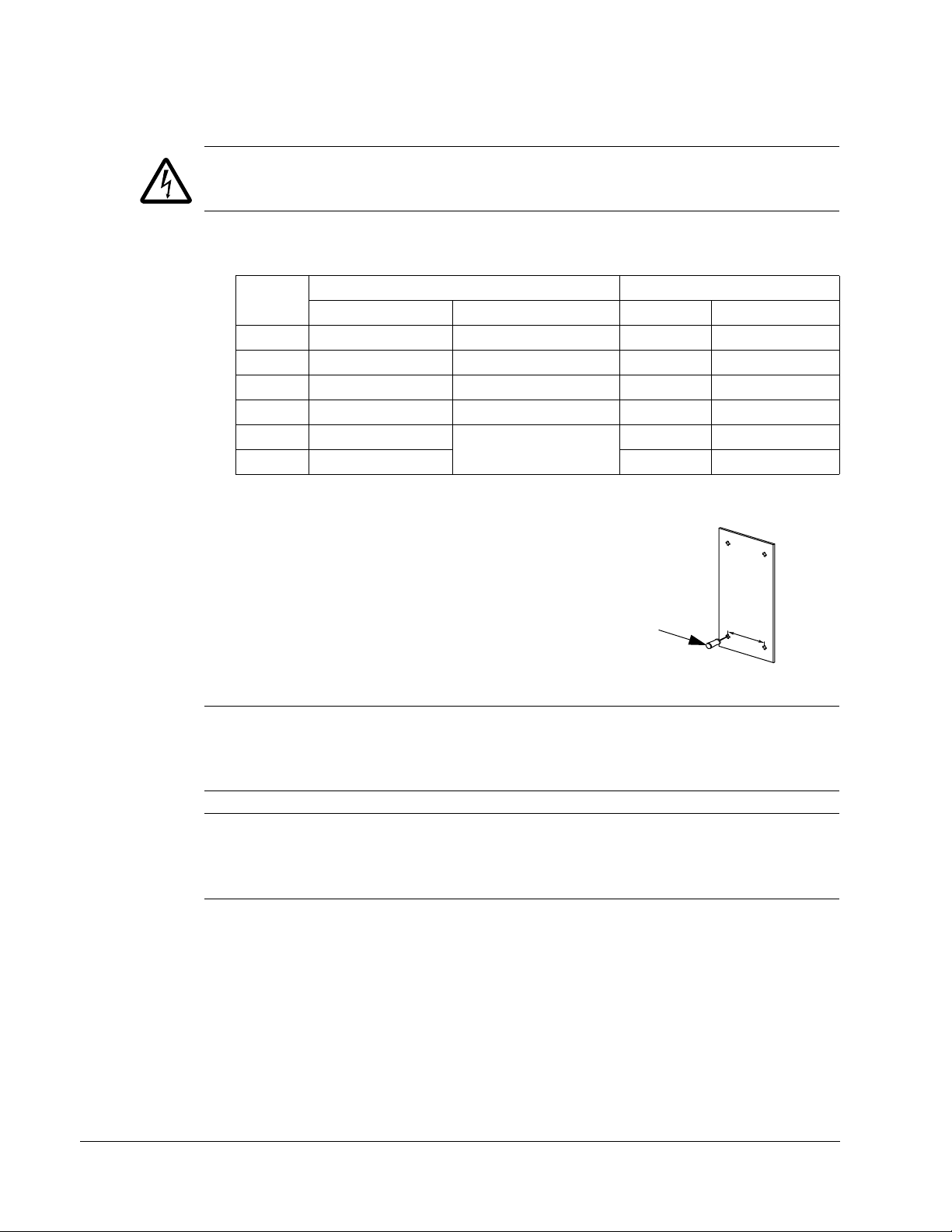

Installing the drive

WARNING! Before installing the ACQ550, ensure the input powe r supply to the drive

is off.

For flange mounting (mounting the drive in a cooling air duct), see the appropriate

Flange Mounting Instructions:

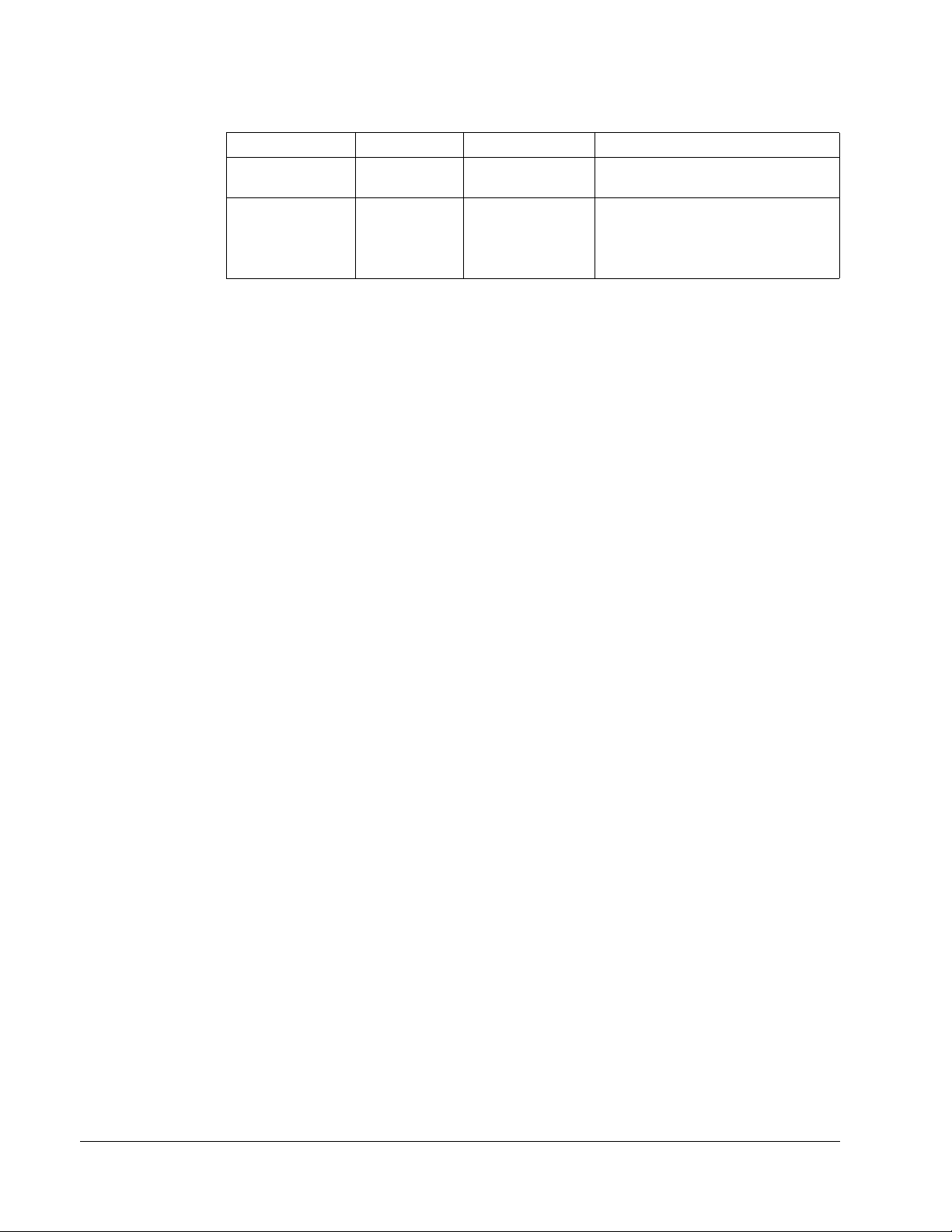

Frame

size

R1 FMK-A-R1 100000982 FMK-B-R1 100000990

R2 FMK-A-R2 100000984 FMK-B-R2 100000992

R3 FMK-A-R3 100000986 FMK-B-R3 100000994

R4 FMK-A-R4 100000988 FMK-B-R4 100000996

1

R5

1

R6

1

Not available in ACQ550-U1 IP54/UL type 12

AC8-FLNGMT-R5 ACS800-PNTG01U-EN - AC8-FLNGMT-R6 - -

IP21 / UL type 1 IP54 / UL type 12

Kit Code (English) Kit Code (English)

Prepare the mounting location

The ACQ550 should only be mounted where all of the

requirements defined in section Prepa ring for installation

on page 12 are met.

1. Mark the position of the mounting holes with the help of

the mounting template provided with the drive.

2. Drill the holes.

Note: Frame sizes R3 and R4 have four holes along the top. Use only two. If

possible, use the two outside holes (to allow room to remove the fan for

maintenance).

Note: ACS400 drives can be replaced using the original mounting holes. For R1 and

R2 frame sizes, the mounting holes are identical. For R3 and R4 frame sizes, the

inside mounting holes on the top of ACQ550 drives match ACS400 mounts.

Installation

ACQ550-U1 User’s Manual 17

3

IP2000

1

2

3

4

1

2

FM

R6

1

R1…R5

Remove the front cover

IP21 / UL type 1

1. Remove the control panel, if attached.

2. Loosen the captive screw at the top.

3. Pull near the top to remove the cover.

IP54 / UL type 12

1. If hood is present: Remove screws

(2) holding hood in place.

2. If hood is present: Slide hood up and

off of the cover.

3. Loosen the captive screws around

the edge of the cover.

4. Remove the cover.

Installation

18 ACQ550-U1 User’s Manual

IP2002

1

2

3

1, 4

FM

5

Mount the drive

IP21 / UL type 1

1. Position the ACQ550 onto the mounting screws or

bolts and securely tighten in all four corners.

Note: Lift the ACQ550 by its metal chassis (frame

size R6 by the lifting holes on both sides at the top).

2. Non-English speaking locations: Add a warning

sticker in the appropriate language over the existing

warning on the top of the module.

IP54 / UL type 12

For the IP54 / UL type 12 enclosures, rubber plugs are required in the holes

provided for access to the drive mounting slots.

1. As required for access, remove the rubber plugs.

Push plugs out from the back of the drive.

2. R5 & R6: Align the sheet metal hood (not shown) in

front of the drive’s top mounting holes. (Attach as

part of next step.)

3. Position the ACQ550 onto the mounting screws or

bolts and securely tighten in all four corners.

Note: Lift the ACQ550 by its metal chassis (frame

size R6 by the lifting holes on both sides at the top).

4. Reinstall the rubber plugs.

5. Non-English speaking locations: Add a warning sticker in the appropriate language

over the existing warning on the top of the module.

Installation

ACQ550-U1 User’s Manual 19

Wiring overview

Conduit/Gland kit

Wiring drives with the IP21 / UL type 1 enclosure requires a cond uit/gland kit with the

following items:

• conduit/gland box

• screws

• cover.

The kit is included with IP21 / UL type 1 enclosures.

Wiring requirements

WARNING! Ensure the motor is compatible for use with the ACQ550. The drive

must be installed by a competent person in accordance with the considerations

defined in section Preparing for installation on p age 12. If in doubt, contact you r local

ABB sales or service office.

As you install the wiring, observe the following:

• There are four sets of wiring instructions – one set for each combination of drive

enclosure type (IP21 / UL type and IP54 / UL type 12) and wiring type (conduit or

cable). Be sure to select the appropriate procedure.

• Determine electro-magnetic compliance (EMC) requirements per local codes.

See section Motor cable requirements for CE & C-Tick compliance on page 283.

In general:

– Follow local codes for cable size.

– Keep these four classes of wiring separated: input power wiring, motor wiring,

control/communications wiring and braking unit wiring.

• When installing input power and motor wiring, refer to the following, as

appropriate:

Terminal Description Specifications and notes

1

U1, V1, W1

PE Protective Ground Ground connections on page 275

U2, V2, W2 Power output to motor Motor connections on page 279

1

The ACQ550 -x1-xxxx-2 (208…240 V series) can be used with a single phase supply, if output

current is derated by 50%. For single phase supply voltage, connect power at U1 and W1.

3-phase power supply input Input power connections on page 271

• To locate input power and motor connection terminals, see section Power

connection diagrams on page 21. For specifications on power terminals, see

section Drive’s power connection terminals on page 276.

• For corner grounded TN systems, see section Corner grounded TN systems on

page 275.

• For IT systems, see section IT systems on page 276.

• For frame size R6, see section Power terminal considerations – R6 frame size on

page 277 to install the appropriate cable lugs.

Installation

20 ACQ550-U1 User’s Manual

• For drives using braking (optional), refer to the following, as appropriate:

Frame size Terminal Description Braking accessory

R1, R2 BRK+, BRK- Braking resistor Braking resistor. See section Brake

components on page 285.

R3, R4, R5, R6 UDC+, UDC- DC bus Contact your ABB representative to

order either:

• braking unit or

• chopper and resistor

• When installing control wiring, refer to the following chapters or sections, as

appropriate:

– Control terminals table on page 24

– Control connections

on page 289

– Application macros on page 57

– Complete parameter descriptions on page 83

– Embedded fieldbus on page 177

– Fieldbus adapter on page 229.

Installation

ACQ550-U1 User’s Manual 21

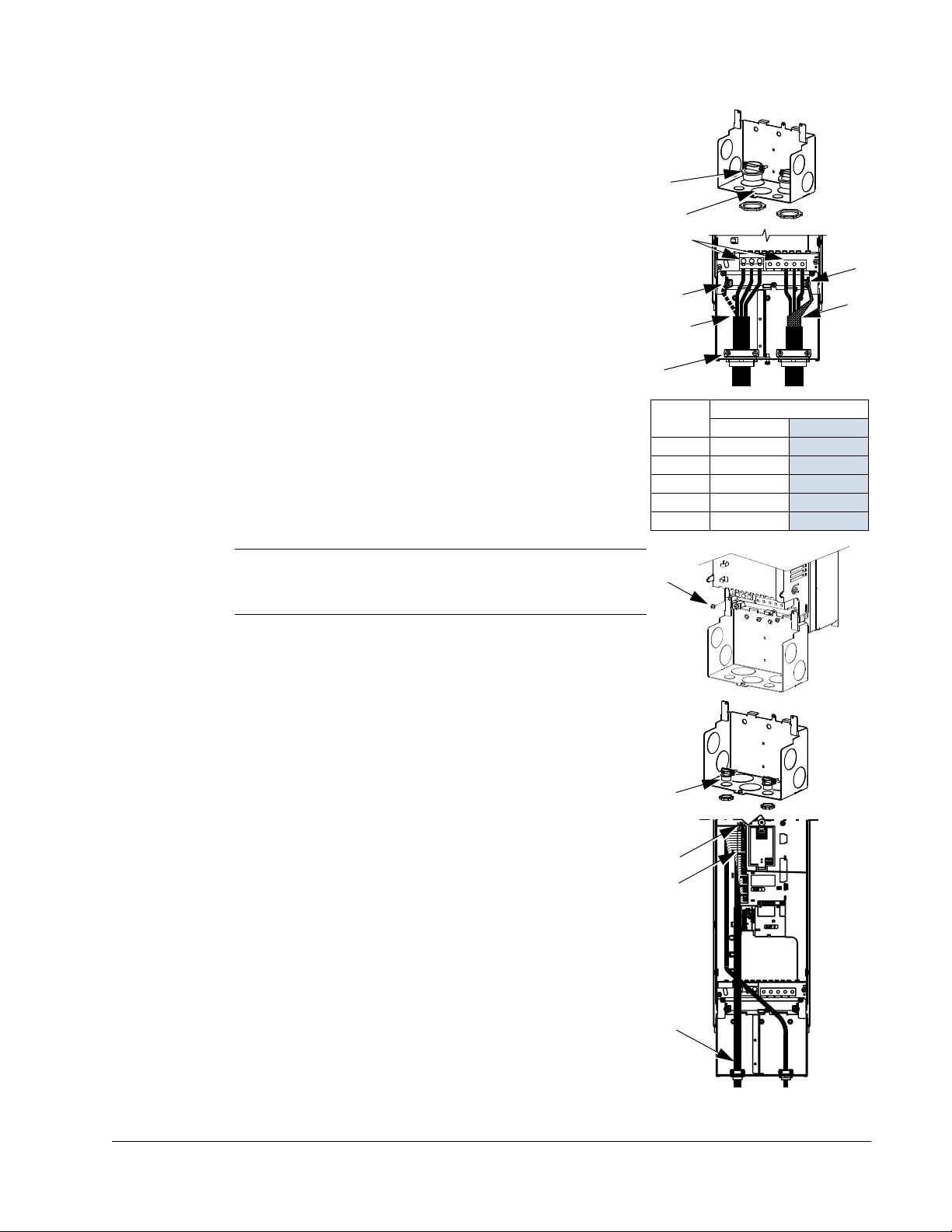

Panel connector

Fault LED (red)

Optional module 1

J2 – DIP switch

X1 – Communications

Optional module 2

GND

Power output to motor

Power input

EM1

X1 – Analog inputs and outputs

X1 – Digital inputs

X1 – Relay outputs

J2

ON

off position on position

for RS485 termination

(and 10 V ref. voltage output)

(and 24 V aux. voltage output)

PE

(U1, V1, W1)

(U2, V2, W2)

Optional braking

Frame

size

Terminal

labels

Brake options

R1, R2 BRK+, BRK- Brake resistor

R3, R4 UDC+, UDC- • Braking unit

• Chopper and resistor

(RS485)

R5/R6 differ.

See

Frame sizes

next page.

Diagram shows the R3 frame.

J2

ON

Other frames have similar layouts.

J1

AI1: (in voltage position)

AI2: (in current position)

ON

ON

J1 – DIP switches for analog inputs (two types can be used)

ON

12

J1

Power LED (green)

3AUA0000001571

EM3

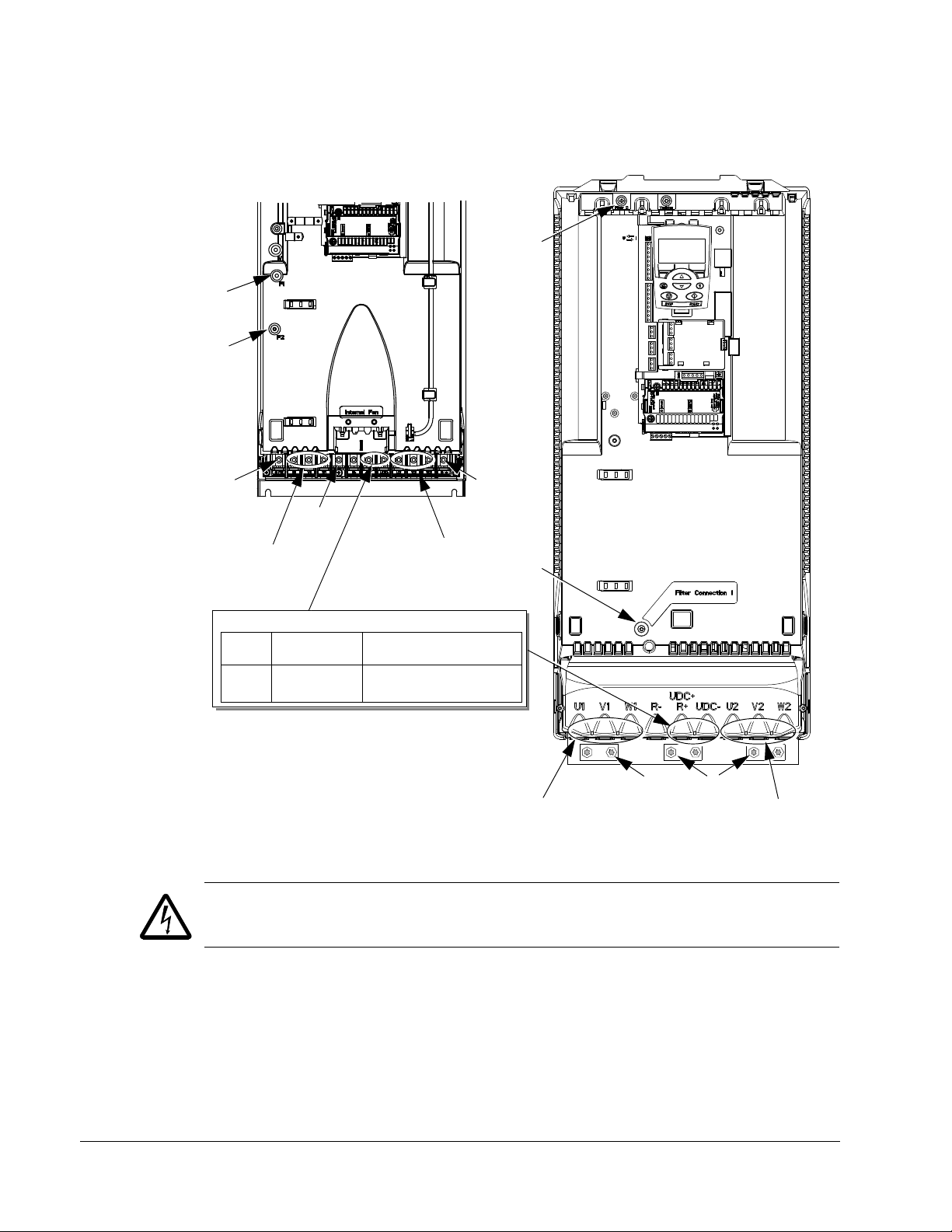

Power connection diagrams

The following diagram shows the terminal layout for frame size R3, which, in

general, applies to frame sizes R1

terminals.

…R6, except for the R5/R6 power and ground

WARNING! To avoid danger, or damage to the drive, on IT systems and corner

grounded TN systems, see section Disconnecting the internal EMC filte r on page 23.

Installation

22 ACQ550-U1 User’s Manual

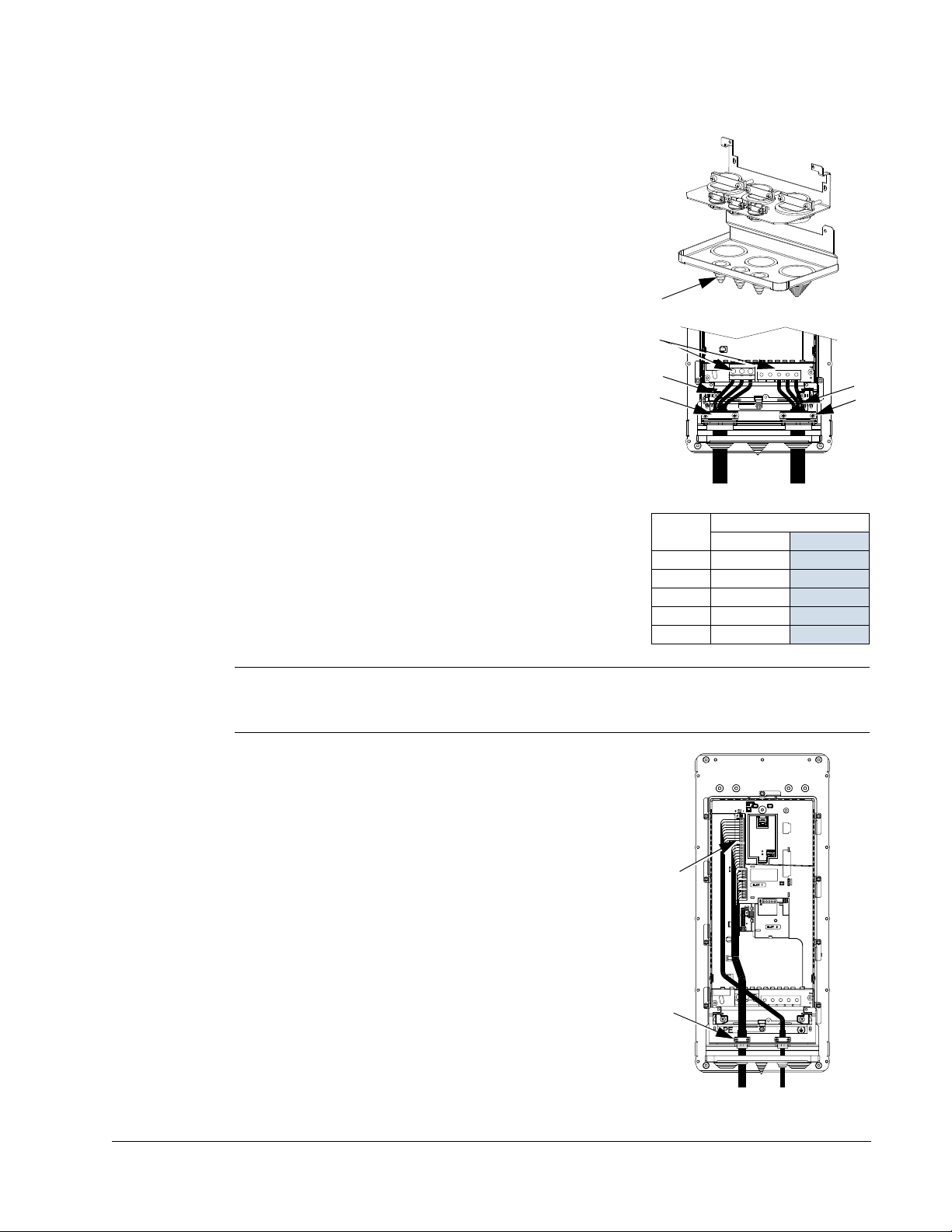

GND

Power input

PE

(U1, V1, W1)

Optional braking

Frame

size

Terminal

labels

Brake options

R5, R6 UDC+, UDC- • Braking unit

• Chopper and resistor

X0011

F2

Power input

PE

(U1, V1, W1)

F1

F2

X0013

Power output to motor

(U2, V2, W2)

R5 R6

GND

GND

Power output to motor

(U2, V2, W2)

F1

The following diagram shows the power and ground terminal layout for frame sizes

R5 and R6.

WARNING! To avoid danger, or damage to the drive, on IT systems and corner

grounded TN systems, see section Disconnecting the internal EMC filter on p ag e 23.

Installation

ACQ550-U1 User’s Manual 23

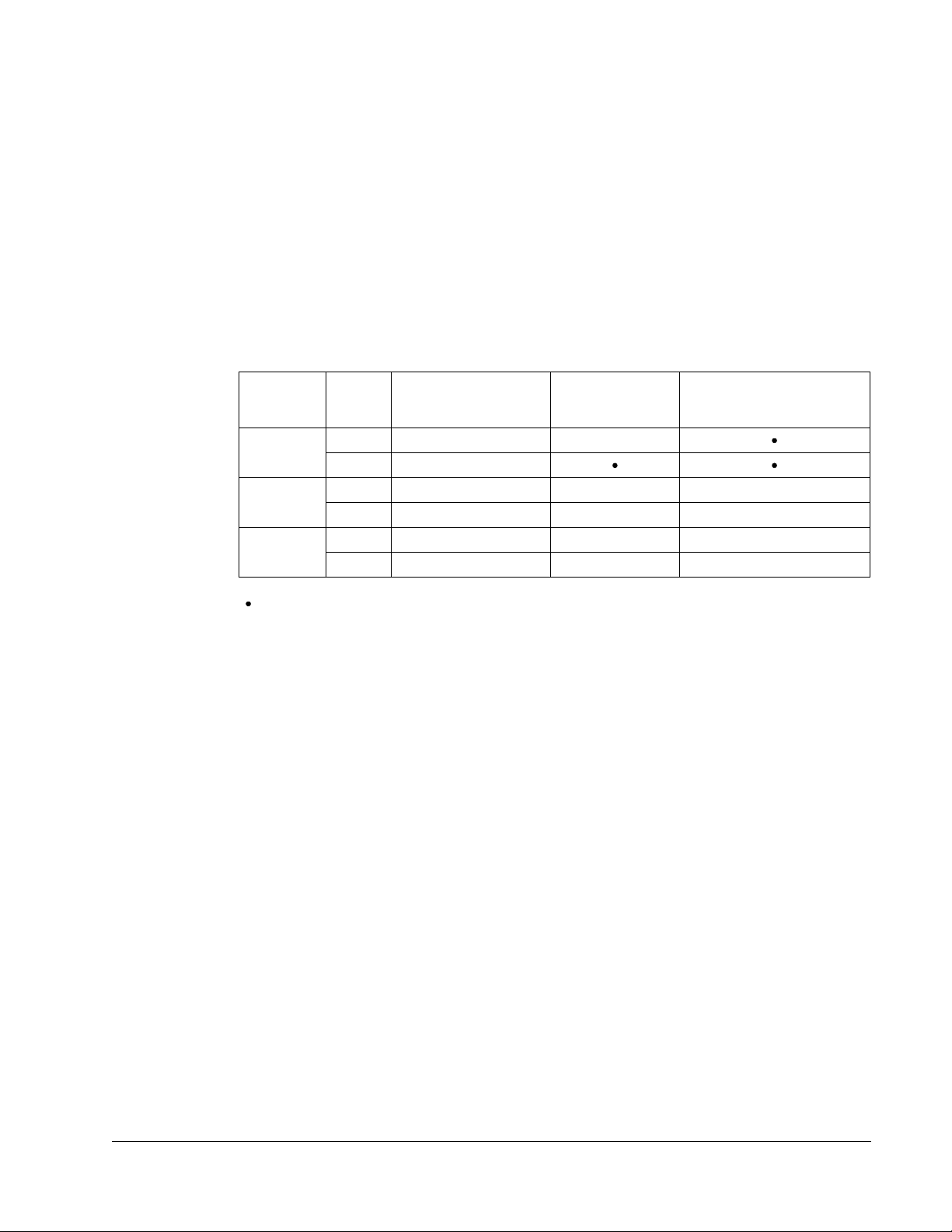

Disconnecting the internal EMC filter

On certain types of systems, you must disconnect the internal EMC filter, otherwise

the system will be connected to ground potential through the EMC filter capacitors,

which might cause danger, or damage the drive.

Note: When the internal EMC filter is disconnected, the drive is not EMC compa tible.

The following table shows the installation rules for the EMC filter screws in order to

connect or disconnect the filter, depending on the system type and the frame size.

For more information on the different system types, see IT sy stems on page 276 and

Corner grounded TN systems on page 275.

The locations of screws EM1 and EM3 are shown in the diagram on page 21. The

locations of screws F1 and F2 are shown in the diagram on page 22.

Frame

sizes

R1…R3

R4

R5…R6

x = Install the screw. (EMC filter will be connected.)

= Replace the screw with the provided polyamide screw. (EMC filter will be disconnected.)

–

= Remove the screw. (EMC filter will be disconnected.)

1

ACQ550-U1 drives are shipped with screw EM3 already removed.

Screw

EM1 x x

1

EM3

EM1 x x –

1

EM3

F1 x x –

F2 x x –

Symmetrically

grounded TN systems

(TN-S systems)

x

x ––

Corner grounded

TN systems

IT systems (ungrounded

or high-resistance-

grounded [> 30 ohm])

Installation

24 ACQ550-U1 User’s Manual

Analog I/O

ON

1

ON

ON

1

ON

ON

1

ON

ON

1

ON

Digital inputs

1

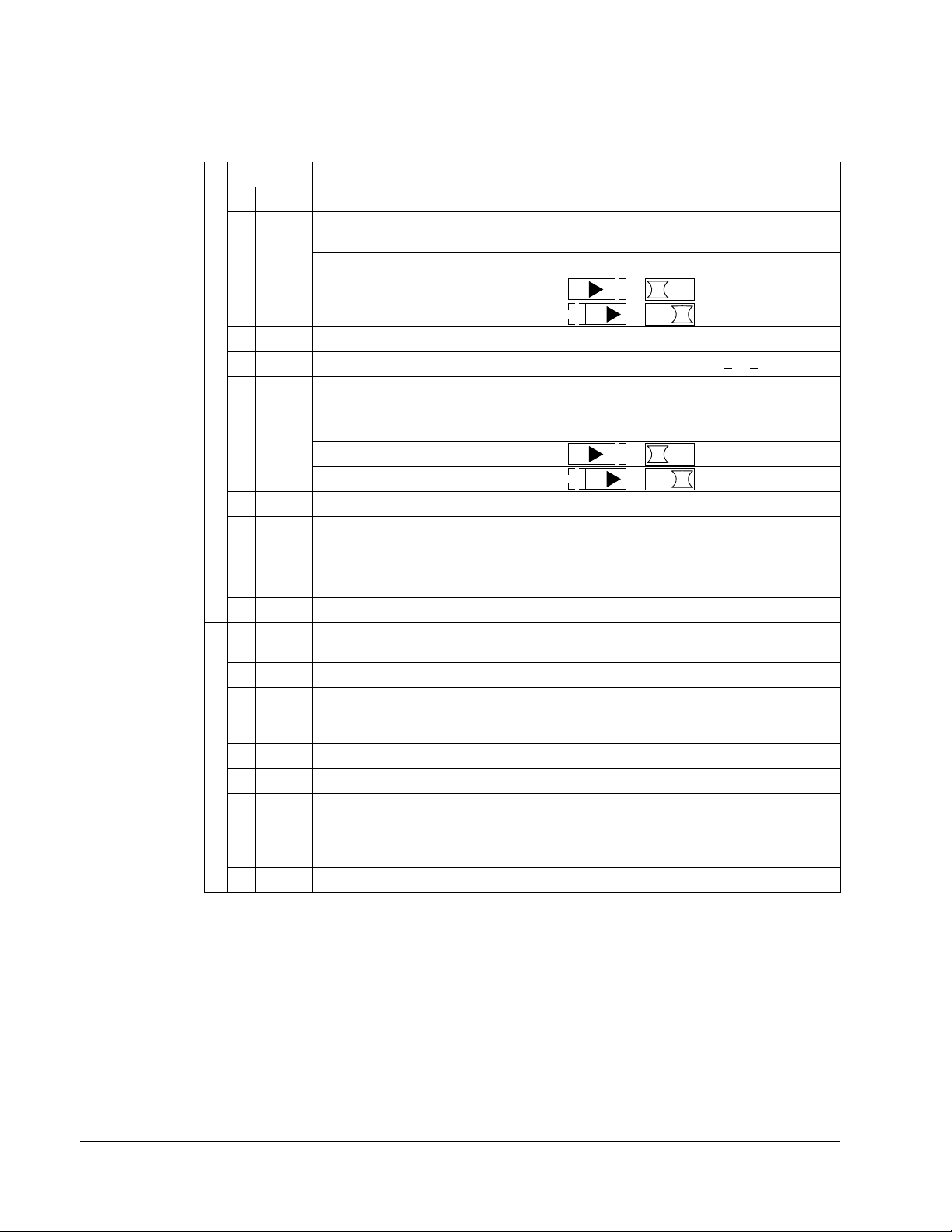

Control terminals table

The following provides information for connecting control wiring at X1 on the drive.

X1 Hardware description

1 SCR Terminal for signal cable shield (screen). (Connected internally to chassis ground.)

2 AI1 Analog input channel 1, programmable. Default2= frequency reference. Resolution

0.1%, accuracy ±1%.

Two different DIP switch types can be used.

J1: AI1 OFF: 0…10 V (R

J1: AI1 ON: 0…20 mA (Ri= 100 ohm)

3 AGND Analog input circuit common (connected internally to chassis gnd. through 1 Mohm).

4 +10 V Potentiometer reference source: 10 V ±2%, max. 10 mA (1 kohm <

5 AI2 Analog input channel 2, programmable. Default2= not used. Resolution 0.1%,

accuracy ±1%.

Two different DIP switch types can be used.

J1: AI2 OFF: 0…10 V (R

J1: AI2 ON: 0…20 mA (R

6 AGND Analog input circuit common (connected internally to chassis gnd. through 1 Mohm).

7 AO1 Analog output, programmable. Default2= frequency. 0…20 mA (load < 500 ohm).

Accuracy ±3%.

8 AO2 Analog output, programmable. Default

Accuracy ±3%.

9 AGND Analog output circuit common (connected internally to chassis gnd. through 1 Mohm).

10 +24V Auxiliary voltage output 24 V DC / 250 mA (reference to GND), short circuit

protected.

11 GND Auxiliary voltage output common (connected interna lly as floating).

12 DCOM Digital input common. To activate a digital input, there must be 10 V

(or -10 V) betwee n that input and DCOM. The 24 V may be provided by the

ACQ550 (X1-10) or by an external 12…24 V source of either polarity.

13 DI1 Digital input 1, programmable. Default

14 DI2 Digital input 2, programmable. Default2=fwd/rev.

15 DI3 Digital input 3, programmable. Default

16 DI4 Digital input 4, programmable. Default2= constant speed sel (code).

17 DI5 Digital input 5, programmable. Default

18 DI6 Digital input 6, programmable. Default

= 312 kohm)

i

= 312 kohm)

i

= 100 ohm)

i

R < 10 kohm).

2

= current. 0…20 mA (load < 500 ohm).

2

= start/stop.

2

= constant speed sel (code).

2

= ramp pair selection (code).

2

= not used.

Installation

ACQ550-U1 User’s Manual 25

Relay outputs

NPN connection (sink)PNP connection (source)

10 +24V

11 GND

12 DCOM

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

10 +24V

11 GND

12 DCOM

13 DI1

14 DI2

15 DI3

16 DI4

17 DI5

18 DI6

X1

X1

X1 Hardware description

19 RO1C Relay output 1, programmable. Default2= Ready

20 RO1A

21 RO1B

22 RO2C Relay output 2, programmable. Default

23 RO2A

24 RO2B

25 RO3C Relay output 3, programmable. Default

26 RO3A

27 RO3B

1

Digital input impedance 1.5 kohm. Maximum voltage for digital inputs is 30 V .

2

Default values depend on the macro used. Values specified are for the default macro. See chapter

Application macros on page 57.

Maximum: 250 VAC / 30 V DC, 2 A

Minimum: 500 mW (12 V, 10 mA)

Maximum: 250 VAC / 30 V DC, 2 A

Minimum: 500 mW (12 V, 10 mA)

Maximum: 250 VAC / 30 V DC, 2 A

Minimum: 500 mW (12 V, 10 mA)

2

= Running

2

= Fault (-1)

Note: Terminals 3, 6 and 9 are at the same potential.

Note: For safety reasons the fault relay signals a “fault” when the ACQ550 is

powered down.

WARNING! All ELV (Extra Low V oltage) circuits connected to the drive must be used

within a zone of equipotential bonding, i.e. within a zone where all simultaneously

accessible conductive parts are electrically connected to prevent hazardous voltages

appearing between them. This is accomplished by a proper factory grounding.

The terminals on the control board as well as on the optional modules attachable to

the board fulfil the Protective Extra Low Voltage (PELV) requirements stated in

EN 50178, provided that the external circuits connected to the terminals also fulfil

the requirements and the installation site is below 2000 m (6562 ft).

You can wire the digital input terminals in either a PNP or NPN configuration.

Installation

26 ACQ550-U1 User’s Manual

ohm

M

3~

U1

V1

W1

PE

Install the wiring

Checking motor and motor cable insulation

WARNING! Check the motor and motor cable insulation before connecting the drive

to input power. For this test, make sure that motor cables are NOT connected to the

drive.

1. Complete motor cable connections to the motor, but NOT to the drive output

terminals (U2, V2, W2).

2. Measure the insulation resistance between each

phase conductor and the Protective Earth conductor

using a measuring voltage of 500 V DC. The

insulation resistance of an ABB motor must exceed

10 Mohm (reference value at 25 °C or 77 °F). For the

insulation resistance of other motors, please consult

the manufacturer’s instructions. Note: Moisture inside the motor casing will reduce

the insulation resistance. If moisture is suspected, dry the motor and repeat the

measurement.

Installation

ACQ550-U1 User’s Manual 27

1

2

X0004

6

3

IP2001

6

7

4

8

8

X0005

Frame

size

Tightening torque

N·m

lb·ft

R1, R2 1.4

1

R3 2.5

1.8

R4 5.6; PE: 2

4; PE 1.5

R5 15

11

R6 40; PE: 8

30; PE: 6

9

X0006

12

IP2003

11

13

Wiring IP21 / UL type 1 enclosure with cables

1. Open the appropriate knockouts in the conduit/gland

box. (See section Conduit/Gland kit on page 19.)

2. Install the cable clamps for the power/motor cables.

3. On the input power cable, strip the sheathing back far

enough to route individual wires.

4. On the motor cable, strip the sheathing back far

enough to expose the copper wire shield so that the

shield can be twisted into a bundle (pig-tail). Keep the

bundle not longer than five times its width to minimize

noise radiation.

360° grounding under the clamp is recommended for

the motor cable to minimize noise radiation. In this

case, remove the sheathing at the cable clamp.

5. Route both cables through the clamps.

6. Strip and connect the power/motor wires and the

power ground wire to the drive terminals. See the

table on the right for tightening torques.

Note: For R6 frame size, refer to section Power

terminal considerations – R6 frame size on page 277.

7. Connect the bundle (pig-tail) created from the motor

cable shield to the GND terminal.

8. Install conduit/gland box and tighten the cable clamps.

9. Install the cable clamp(s) for the control cable(s).

(Power/motor cables and clamps not shown in the

figure.)

10. Strip control cable sheathing and twist the copper

shield into a bundle (pig-tail).

11. Route control cable(s) through clamp(s) and tighten

clamp(s).

12. Connect the ground shield bundle (pig-tail) for digital and

analog I/O cables at X1-1. (Ground only at the drive end.)

13. Strip and connect the individual control wires to the

drive terminals. See section Control terminals table

on page 24. Use a tightening torque of 0.4 N·m

(0.3 lb·ft).

14. Install the conduit/gland box cover (1 screw).

Installation

28 ACQ550-U1 User’s Manual

2

X0007

3

X0005

4

IP2004

7

7

5

Frame

size

Tightening torque

N·m lb·ft

R1, R2 1.4

1

R3 2.5

1.8

R4 5.6; PE: 2

4; PE 1.5

R5 15

11

R6 40; PE: 8

30; PE: 6

10

8

IP2005

11

Wiring IP21 / UL type 1 enclosure with conduit

1. Open the appropriate knockouts in the conduit/gland

box. (See section Conduit/Gland kit on page 19.)

2. Install thin-wall conduit clamps (not supplied).

3. Install conduit/gland box.

4. Connect conduit runs to box.

5. Route input power and motor wiring through

conduits (must be separate conduit runs).

6. Strip wires.

7. Connect power, mot or and ground wires to the drive

terminals. See the table on the right for tightening

torques.

Note: For R6 frame size, refer to section Power

terminal considerations – R6 frame size on page

277.

8. Route the control cable through the conduit (must be

separate from input power and motor conduit runs).

9. Strip the control cable sh eathing and twist the copper

shield into a bundle (pig-tail).

10. Connect the ground shield bundle (pig-tail) for digital

and analog I/O cables at X1-1. (Ground only at the

drive end.)

11. Strip and connect the individual control wires to the

drive terminals. See section Control terminals table

on page 24. Use a tightening torque of 0.4 N·m

(0.3 lb·ft).

Installation

12. Install the conduit/gland box cover (1 screw).

ACQ550-U1 User’s Manual 29

1

IP5003

4

5

2

IP5004

3

4

Frame

size

Tightening torque

N·m

lb·ft

R1, R2 1.4

1

R3 2.5

1.8

R4 5.6; PE: 2

4; PE 1.5

R5 15

11

R6 40; PE: 8

30; PE: 6

8

IP5005

9, 10

Wiring IP54 / UL type 12 enclosure with cables

1. Cut the cable seals as needed for the power, motor

and control cables. The cable seals are coneshaped, rubber seals on the bottom of the drive.

The conical part of the seals must face downwards

when the seals are inserted in the lead-through

plate holes.

2. On the input power cable, strip the sheathing back

far enough to route individual wires.

3. On the motor cable, strip the sheathing back far

enough to expose the copper wire shield so that

the shield can be twisted into a bundle (pig-tail).

Keep the bundle not longer than five times its width

to minimize noise radiation.

360° grounding under the clamp is recommended

for the motor cable to minimize noise radiation. In

this case, remove the sheathing at the cable

clamp.

4. Route both cables through the clamps and tighten

the clamps.

5. Strip and connect the power/motor wires and the

power ground wire to the drive terminals. See the

table on the right for tightening torques.

Note: For R6 frame size, refer to section Power terminal considerations – R6 frame

size on page 277.

6. Connect the bundle (pig-tail) created from the

motor cable shield to the GND terminal.

7. Strip control cable sheathing and twist the copper

shield into a bundle (pig-tail).

8. Route control cable(s) through clamp(s) and

tighten clamp(s).

9. Connect the ground shield bundle (pig-tail) for

digital and analog I/O cables at X1-1. (Ground only

at the drive end.)

10. Strip and connect the individual control wires to the

drive terminals. See section Control terminals table

on page 24. Use a tightening torque of 0.4 N·m

(0.3 lb·ft).

Installation

30 ACQ550-U1 User’s Manual

IP5013

1

2

IP5016

3

IP5007

6

4

Frame

size

Tightening torque

N·m

lb·ft

R1, R2 1.4

1

R3 2.5

1.8

R4 5.6; PE: 2

4; PE 1.5

R5 15

11

R6 40; PE: 8

30; PE: 6

Wiring IP54 / UL type 12 enclosure with conduit

1. Remove and discard the cable seals where conduit

will be installed. (The cable seals are cone-shaped,

rubber seals on the bottom of the drive.)

2. For each conduit run, install water tight conduit

connectors (not supplied).

3. Route the power wiring through the conduit.

4. Route the motor wiring through the conduit.

5. Strip the wires.

6. Connect the power, motor and ground wires to the

drive terminals. See the table on the right for

tightening torques.

Note: For R6 frame size, refer to section Power

terminal considerations – R6 frame size on page

277.

7. Route the control cable through the conduit.

8. Strip the control cable sheathing and twist the

copper shield into a bundle (pig-tail).

9. Connect the ground shield bundle (pig-tail) for digital and analog I/O ca bles at X1-1.

(Ground only at the drive end.)

10. Strip and connect the individual control wires to the drive terminals. See section

Control terminals table on page 24. Use a tightening torque of 0.4 N·m (0.3 lb·ft).

Installation

Loading...

Loading...