ABB ACS880-07 Hardware Manual

ABB industrial drives

Hardware manual

ACS880-07 drives

(45 to 710 kW, 50 to 700 hp)

List of related manuals

ACS880-07 manuals

Drive hardware manuals and guides Code (English)

ACS880-07 hardware manual 3AUA0000105718

ACS-AP-X assistant control panels user’s manual 3AUA0000085685

ACS880-07 lifting device user’s manual 3AUA0000131337

Drive firmware manuals and guides

ACS880 primary control program firmware manual 3AUA0000085967

Quick start-up guide for ACS880 drives with primary

control program

Option manuals and guides

Drive composer start-up and maintenance PC tool user’s

manual

FSO-12 safety functions module user’s manual 3AXD50000015612

User’s manual for Prevention of unexpected start-up

(+Q950) for ACS880-07/17/37 drives

User’s manual for Emergency stop, stop category 0

(+Q951) for ACS880-07/17/37 drives

User’s manual for Emergency stop, stop category 1

(+Q952) for ACS880-07/17/37 drives

User’s manual for Prevention of unexpected start-up

(+Q957) for ACS880-07/17/37 drives

User’s manual for Emergency stop, stop category 0

(+Q963) for ACS880-07/17/37 drives

User’s manual for Emergency stop, stop category 1

(+Q964) for ACS880-07/17/37 drives

User’s manual for Emergency stop, configurable stop

category 0 or 1 (+Q978) for ACS880-07/17/37 drives

User’s manual for Emergency stop, configurable stop

category 0 or 1 (+Q979) for ACS880-07/17/37 drives

3AUA0000098062

3AUA0000094606

3AUA0000145922

3AUA0000119895

3AUA0000119896

3AUA0000119910

3AUA0000119908

3AUA0000119909

3AUA0000145920

3AUA0000145921

You can find manuals and other product documents in PDF format on the Internet. See section

Document library on the Internet on the inside of the back cover. For manuals not available in the

Document library, contact your local ABB representative.

The code below opens an online listing of the manuals applicable to this product.

Hardware manual

ACS880-07 drives

(45 to 710 kW, 50 to 700 hp)

Table of contents

1. Safety instructions

4. Mechanical installation

6. Electrical installation

10. Start-up

2015 ABB Oy. All Rights Reserved.

3AUA0000105718 Rev E

EN

EFFECTIVE: 2015-06-25

5

Table of contents

1. Safety instructions

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Use of warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

General safety in installation, start-up and maintenance . . . . . . . . . . . . . . . . . . . . . . . . 14

Electrical safety in installation, start-up and maintenance . . . . . . . . . . . . . . . . . . . . . . . 16

Precautions before electrical work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Additional instructions and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Additional instructions for permanent magnet motor drives . . . . . . . . . . . . . . . . . . . . . . 19

Safety in installation, start-up and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2. Introduction to the manual

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Contents of the manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Categorization by frame size and option code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Quick installation, start-up and operating flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3. Operation principle and hardware description

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Single-line circuit diagram of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Block diagram of the brake and DC options (+D150, +D151 and +H356) . . . . . . . . . 27

General information on the cabinet layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cabinet layout of frames R6 to R8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cabinet layout of frames R6 to R8 with option +C129 . . . . . . . . . . . . . . . . . . . . . . . . 30

Cabinet layout of frames R6 to R8 with options +C129 and +F289 . . . . . . . . . . . . . . 31

Cabinet layout of frame R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Cabinet layout of frame R9 with options +C129 and +F289 . . . . . . . . . . . . . . . . . . . . 35

Cabinet layout of frames R10 and R11 – bottom entry and exit of cables . . . . . . . . . 37

Cabinet layout of frames R10 and R11 – top entry and exit of cables

(option +C129) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Overview of power and control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Door switches and lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Main switch-disconnector Q1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Control by PC tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Descriptions of cabinet options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Degree of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

IP22 and UL Type 1 (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

IP42 and UL Type 1 Filtered (option +B054) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

IP54 and UL Type 12 (option +B055) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Channeled air inlet through bottom (option +C128) . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6

Channeled air outlet (option +C130) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Marine construction (option +C121) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

UL listed (option +C129) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

CSA approved (option +C134) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Plinth height (options +C164 and +C179) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Seismic design (option +C180) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Resistor braking (options +D150 and +D151) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

EMC filters (options + E200, +E201, +E202, +E210) . . . . . . . . . . . . . . . . . . . . . . . . 45

du/dt filter (option +E205) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Sine filter (option +E206) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Common mode filter (option +E208) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Cabinet heater with external supply (option +G300) . . . . . . . . . . . . . . . . . . . . . . . . . 46

Terminals for external uninterruptible control voltage (option +G307) . . . . . . . . . . . 46

Output for motor space heater (option +G313) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Additional wire markings (options +G340 and +G342) . . . . . . . . . . . . . . . . . . . . . . . 47

US/UK gland/conduit plate (option +H358) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Additional terminal block X504 (option +L504) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Thermistor relays (options +L505, +2L505) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Pt100 relays (options +3L506, +5L506, +8L506) . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

What the option contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Type designation label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Type designation key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4. Mechanical installation

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Examining the installation site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Necessary tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Moving and unpacking the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Unpacking the transport package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Checking the delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Moving the drive cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Installing the IP54 roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Frames R6 to R8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Frame R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Frames R10 and R11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Lifting the drive cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Moving the cabinet on rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Final placement of the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Fastening the cabinet to the floor and wall or roof (non-marine units) . . . . . . . . . . . . . . 64

General rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Fastening methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Alternative 1 – Clamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Alternative 2 – Using the holes inside the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Fastening the cabinet to the floor and roof/wall (marine units) . . . . . . . . . . . . . . . . . . . 66

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Cable duct in the floor below the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Air inlet through the bottom (option +C128+B055) . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Air outlet duct on the cabinet roof (option +C130) . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Calculating the required static pressure difference . . . . . . . . . . . . . . . . . . . . . . . 68

Arc welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7

5. Guidelines for planning the electrical installation

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Limitation of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Selecting the supply disconnecting device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Selecting the main contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Examining the compatibility of the motor and drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Protecting the motor insulation and bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Requirements table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Additional requirements for explosion-safe (EX) motors . . . . . . . . . . . . . . . . . . . . 74

Additional requirements for ABB motors of types other than M2_, M3_, M4_, HX_

and AM_ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Additional requirements for the braking applications . . . . . . . . . . . . . . . . . . . . . . . 75

Additional requirements for ABB high-output and IP23 motors . . . . . . . . . . . . . . . 75

Additional requirements for non-ABB high-output and IP23 motors . . . . . . . . . . . 76

Additional data for calculating the rise time and the peak line-to-line voltage . . . . 77

Additional note for sine filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Selecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

General rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Typical power cable sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Alternative power cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Recommended power cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Power cable types for limited use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Not allowed power cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Motor cable shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Additional US requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Armored cable / shielded power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Planning the braking system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Selecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Signals in separate cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Signals allowed to be run in the same cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Relay cable type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Control panel cable length and type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Routing the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Separate control cable ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Continuous motor cable shield or enclosure for equipment on the motor cable . . . . . 83

Implementing thermal overload and short-circuit protection . . . . . . . . . . . . . . . . . . . . . . 84

Protecting the drive and input power cable in short-circuits . . . . . . . . . . . . . . . . . . . . 84

Protecting the motor and motor cable in short-circuits . . . . . . . . . . . . . . . . . . . . . . . . 84

Protecting the drive and the input power and motor cables against thermal

overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Protecting the motor against thermal overload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Protecting the drive against ground faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Residual current device compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Implementing the emergency stop function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Implementing the Safe torque off function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Implementing Prevention of unexpected start-up function . . . . . . . . . . . . . . . . . . . . . . . 86

Implementing the functions provided by the FSO-xx safety functions module (option

+Q972 or +Q973) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Implementing the Power-loss ride-through function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Units with main contactor (option +F250) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8

Supplying power for the auxiliary circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Using power factor compensation capacitors with the drive . . . . . . . . . . . . . . . . . . . . . 87

Implementing a safety switch between the drive and the motor . . . . . . . . . . . . . . . . . . 88

Using a contactor between the drive and the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Implementing a bypass connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Example bypass connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Switching the motor power supply from drive to direct-on-line . . . . . . . . . . . . . . . 90

Switching the motor power supply from direct-on-line to drive . . . . . . . . . . . . . . . 90

Protecting the contacts of relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Connecting a motor temperature sensor to the drive I/O . . . . . . . . . . . . . . . . . . . . . . . . 91

6. Electrical installation

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Input cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Motor and motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Brake resistor assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Checking the compatibility with IT (ungrounded) systems . . . . . . . . . . . . . . . . . . . . . . . 94

Attaching the device stickers on the cabinet door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Connecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Layout of the power cable connection terminals and lead-throughs (frames R6

to R8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Layout of the power cable connection terminals and lead-throughs (frames R6

to R8 with option +C129) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Layout of the power cable connection terminals and lead-throughs (frames R6

to R8 with options +C129+F277+F289) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Layout of the input and motor cable connection terminals (frame R9) . . . . . . . . . . 100

Layout of the power cable connection terminals and lead-throughs (frame R9 with

option +C129) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Layout of the input and motor cable connection terminals (frames R10 and R11) . 102

Layout of the input and motor cable connection terminals (frames R10 and R11

with option +C129) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Lead-through of external resistor and DC cables . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Connection procedure (IEC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Connection procedure (US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Grounding the motor cable shield at the motor end . . . . . . . . . . . . . . . . . . . . . . . . 107

DC connection (option +H356) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Connecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Control cable connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Grounding the outer shields of the control cables at the cabinet lead-through . 108

Routing the control cables inside the cabinet (frames R6 to R8) . . . . . . . . . . . . 110

Routing the control cables inside the cabinet (frame R9) . . . . . . . . . . . . . . . . . . 111

Routing the control cables inside the cabinet (frames R10 and R11) . . . . . . . . 112

Connecting the control unit cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Connecting the external 230 V or 115 V uninterruptible control voltage (UPS,

option +G307) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Connecting the emergency stop push buttons (options +Q951, +Q952, +Q963,

+Q964) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Wiring the starter for auxiliary motor fan (options +M600…+M605) . . . . . . . . . . 114

Wiring the thermistor relay(s) (options +L505 and +2L505) . . . . . . . . . . . . . . . . 115

9

Wiring the Pt100 relays (options +2L506, +3L506, +5L506 and +8L506) . . . . . . 116

Connecting the external power supply cables for the cabinet heater and lighting

and motor heater (options +G300, +G301 and +G313) . . . . . . . . . . . . . . . . . . . . 117

Wiring ground fault monitoring for IT ungrounded systems (option +Q954) . . . . 118

Setting the voltage range of the auxiliary control voltage transformer (T21) . . . . . . . . . 118

Connecting a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Installing option modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Mechanical installation of I/O extension, fieldbus adapter and pulse encoder

interface modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Wiring I/O extension, fieldbus adapter and pulse encoder interface modules . . . . . 120

Installation of safety functions modules (frames R6 to R9) . . . . . . . . . . . . . . . . . . . 121

installation of safety functions modules (frames R10 and R11) . . . . . . . . . . . . . . . . 122

Case 1: FSO-xx safety functions module on Slot 2 . . . . . . . . . . . . . . . . . . . . . . . 122

Case 2: FSO-xx safety functions module above the control unit . . . . . . . . . . . . . 124

7. Control unit of frames R6 to R9

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Default I/O connection diagram of frames R6 to R9 . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Notes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Jumpers and switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

External power supply for the control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

AI1 and AI2 as Pt100, Pt1000, PTC and KTY84 sensor inputs (XAI, XAO) . . . . . . . 129

DI6 (XDI:6) as PTC sensor input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

DIIL input (XD24:1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Drive-to-drive link (XD2D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Safe torque off (XSTO) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Safety functions module connection (X12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

8. Control unit of frames R10 and R11

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Default I/O connection diagram of frames R10 and R11 . . . . . . . . . . . . . . . . . . . . . . . 137

Notes: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Drive-to-drive link (XD2D) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Ground isolation diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

9. Installation checklist

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

10. Start-up

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Start-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Checks/Settings with no voltage connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Powering up the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Setting up the drive parameters, and performing the first start . . . . . . . . . . . . . . 144

On-load checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

10

11. Fault tracing

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Warning and fault messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

12. Maintenance

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Descriptions of symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Recommended annual maintenance actions by the user . . . . . . . . . . . . . . . . . . . . 149

Recommended maintenance intervals after start-up . . . . . . . . . . . . . . . . . . . . . . . 150

Cleaning the interior of the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Cleaning the air inlet (door) meshes (IP22 / UL Type 1, IP42 / UL Type 1 Filtered) . . 151

Replacing the air filters (IP54 / UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Inlet (door) filters (IP54 / UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Outlet (roof) filters (IP54 / UL Type 12) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Heatsink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Replacing the cabinet “door” fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Replacing the cabinet fans (frames R6 to R9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Replacing the drive module main fans (frames R6 to R8) . . . . . . . . . . . . . . . . . . . 156

Replacing the auxiliary cooling fan of the drive module (frames R6 to R9) . . . . . . 157

Replacing the drive module main fans (frame R9) . . . . . . . . . . . . . . . . . . . . . . . . . 158

Replacing the drive module main fans (frames R10 and R11) . . . . . . . . . . . . . . . . 159

Replacing the circuit board compartment cooling fan (frames R10 and R11) . . . . . 160

Replacing the IP54 (UL type 12) roof fan of frames R6 to R8 . . . . . . . . . . . . . . . . . 161

Replacing the IP54 (UL type 12) roof fan of frame R9 . . . . . . . . . . . . . . . . . . . . . . 162

Replacing the IP54 (UL type 12) roof fan of frames R10 and R11 . . . . . . . . . . . . . 163

Replacing the drive module (frames R6 to R8) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Replacing the drive module (frame R9) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Replacing the drive module (frames R10 and R11) . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Reforming the capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Replacing the control panel battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Replacing the control unit battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Memory unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Transferring the memory unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

13. Technical data

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Ambient temperature derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Altitude derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Deratings for special settings in the drive control program . . . . . . . . . . . . . . . . . . . 187

Ex motor, sine filter, low noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

High speed mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Fuses (UL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Dimensions and weights of sine filter cabinet (option +E206) . . . . . . . . . . . . . . . . 195

11

Free space requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Losses, cooling data and noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Cooling data and noise for drives with sine filter (option +E206) . . . . . . . . . . . . . . . . . 197

Terminal and lead-through data for the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . 198

IEC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

US . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Terminal data for the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Electrical power network specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Motor connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Control unit connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Protection classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Auxiliary circuit power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Compliance with the European Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . 209

Compliance with the European EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Compliance with the European Machinery Directive . . . . . . . . . . . . . . . . . . . . . . . . 209

Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Declaration of Conformity (Safe torque off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Compliance with the EN 61800-3:2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Category C2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Category C3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Category C4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

UL marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

UL checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

CSA marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

“C-tick” marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

EAC marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Cyber security disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

14. Dimension drawings

Frames R6 to R8 (IP22, IP42 [+B054], UL Type 1) – standard and options +C129,

+H350, +H352 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Frames R6 to R8 (IP54 / UL Type 12 [+B055]) – standard and options +C129,

+H350, +H352 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Frames R10 and R11 (options +C129+F277+F289) . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

15. Safe torque off function

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Compliance with the European Machinery Directive . . . . . . . . . . . . . . . . . . . . . . . . 230

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Activation switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Cable types and lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Grounding of protective shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Single drive (internal power supply) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Multiple drives (internal power supply) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Multiple drives (external power supply) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

12

Operation principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Start-up including acceptance test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Competence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Acceptance test reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Acceptance test procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Competence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Fault tracing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

Safety data (SIL, PL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

16. Resistor braking

Contents of this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Operation principle and hardware description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Planning the braking system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Selecting the brake circuit components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Selecting a custom resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Selecting and routing the external brake resistor cables . . . . . . . . . . . . . . . . . . . . 240

Minimizing electromagnetic interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Maximum cable length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

EMC compliance of the complete installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Placing the brake resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Protecting the system against thermal overload . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

Protecting the resistor cable against short-circuits . . . . . . . . . . . . . . . . . . . . . . . . . 241

Mechanical installation of external brake resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Electrical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Degree of protection of SAFUR resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Terminals and cable lead-through data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Further information

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Document library on the Internet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

1

Safety instructions

Safety instructions 13

Contents of this chapter

This chapter contains the safety instructions which you must obey when you install and

operate the drive and do maintenance on the drive. If you ignore the safety instructions,

injury, death or damage can occur.

Use of warnings

Warnings tell you about conditions which can cause injury or death, or damage to the

equipment. They also tell you how to prevent the danger. The manual uses these warning

symbols:

Electricity warning tells about hazards from electricity which can cause injury

or death, or damage to the equipment.

General warning tells about conditions, other than those caused by electricity,

which can cause injury or death, or damage to the equipment.

Electrostatic sensitive devices warning tells you about the risk of

electrostatic discharge which can cause damage to the equipment.

14 Safety instructions

1

2

3

A

General safety in installation, start-up and maintenance

These instructions are for all personnel that install the drive and do maintenance work on

it.

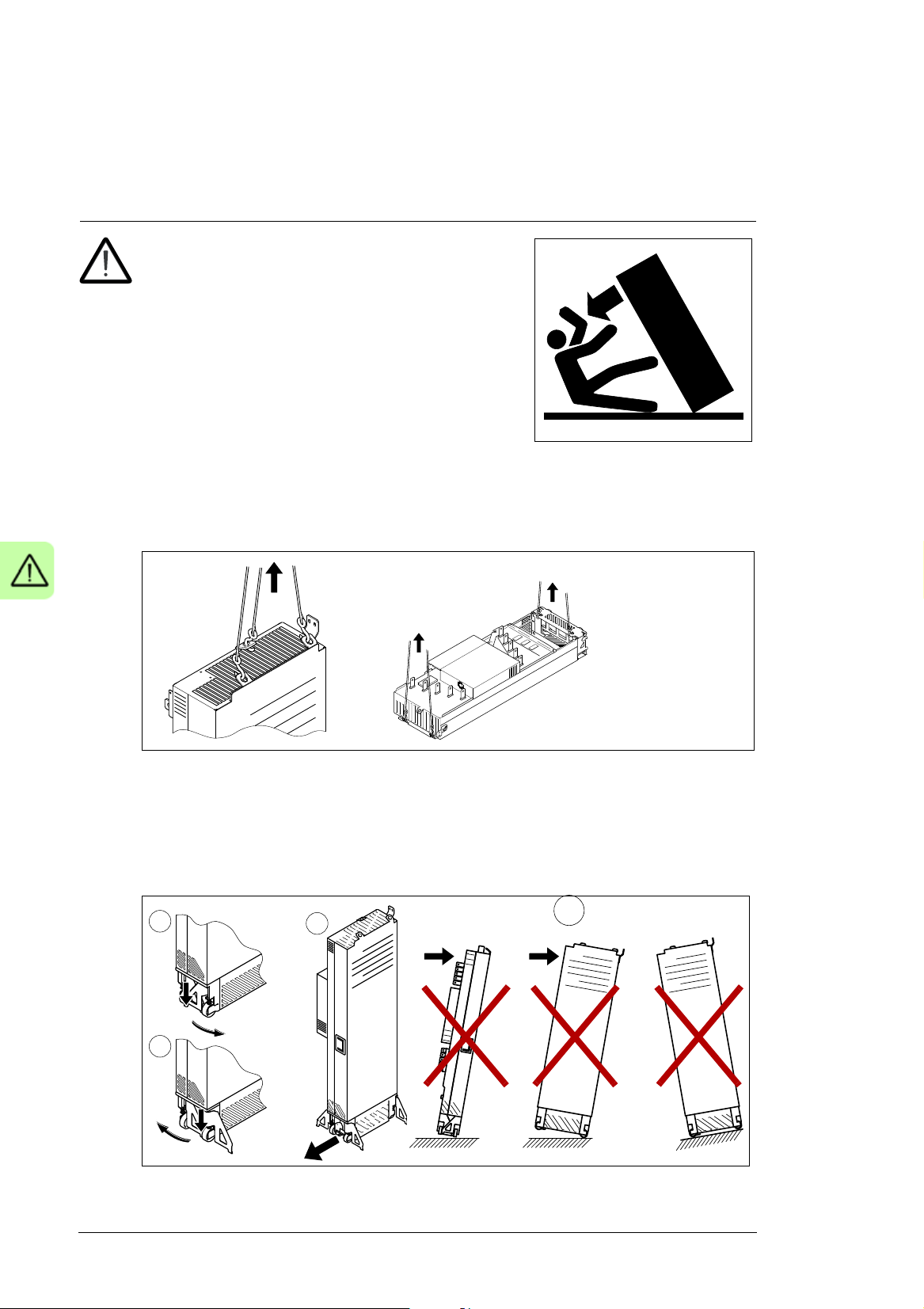

WARNING! Obey these instructions. If you ignore

them, injury or death, or damage to the equipment

can occur.

• Secure the cabinet to the floor (see chapter

Mechanical installation) to prevent it from toppling over

when you pull out the module. The drive module is

heavy and has a high center of gravity.

• Wear protective gloves and long sleeves. Some parts

have sharp edges.

• Handle the drive module carefully:

• Use safety shoes with a metal toe cap to avoid foot injury.

• For frames R10 and R11:

• Lift the module with a lifting device only. Use the designated lifting points.

• Make sure that the module does not topple over when you move it on the floor:

Extend the support legs by pressing each leg a little down (1, 2) and turning it

aside. Whenever possible secure the module also with chains.

• Do not tilt the drive module (A). It is heavy and its center of gravity is high. The

module overturns from a sideways tilt of 5 degrees. Do not leave the module

unattended on a sloping floor.

Safety instructions 15

• Do not use the module installation ramp with plinth heights which exceed the

maximum height (50 mm [1.97 in]) marked on the ramp.

• Secure the module installation ramp carefully.

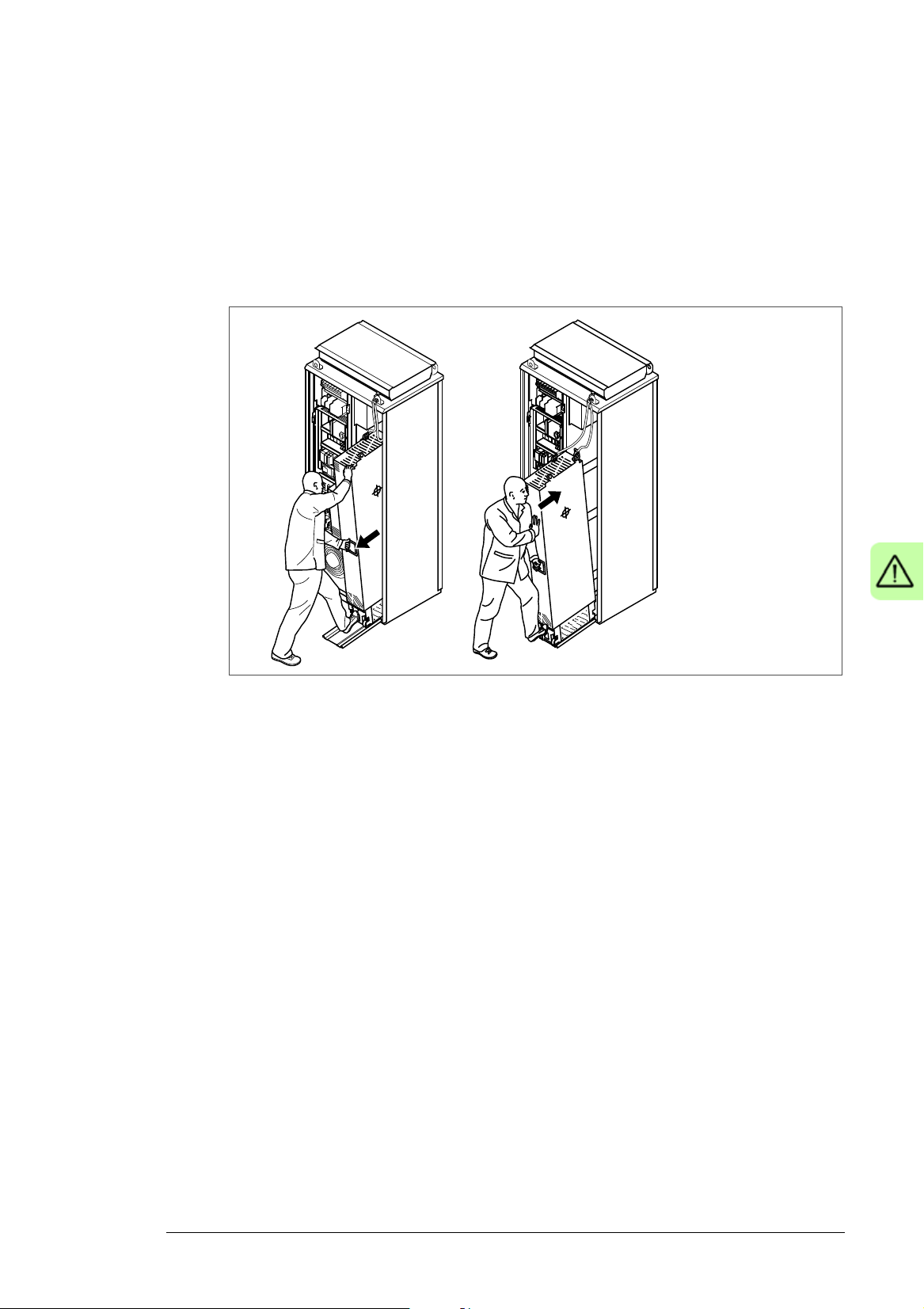

• To prevent the drive module from falling, attach its top lifting lugs with chains to the

cabinet lifting lug before you push the module into the cabinet and pull it from the

cabinet. Work carefully preferably with help from another person as shown below.

Keep a constant pressure with one foot on the base of the module to prevent the

module from falling on its back.

• Beware of hot surfaces. Some parts, such as heatsinks of power semiconductors,

remain hot for a while after disconnection of the electrical supply.

• Keep the drive in its package or protect it otherwise from dust and burr from drilling

and grinding until you install it. Protect also the installed drive against dust and burr.

Electrically conductive debris inside the drive can cause damage or malfunction.

• Vacuum clean the area below the drive before the start-up to prevent the drive cooling

fan from drawing the dust inside the drive.

• Make sure that there is sufficient cooling. See section Examining the installation site

on page 55.

• Before you connect voltage to the drive, make sure that the cabinet doors are closed.

Keep the doors closed during the operation.

• Before you adjust the drive operation limits, make sure that the motor and all driven

equipment can operate throughout the set operation limits.

• Before you activate the automatic fault reset or automatic restart functions of the drive

control program, make sure that no dangerous situations can occur. These functions

reset the drive automatically and continue operation after a fault or supply break.

• The maximum number of drive power-ups is five in ten minutes. Too frequent power-

ups can damage the charging circuit of the DC capacitors.

• Make sure that any safety circuits (for example, emergency stop and Safe torque off)

are validated in start-up. For the Safe torque off, see chapter Safe torque off function

on page 229. For other safety functions, see their separate instructions.

16 Safety instructions

Note:

• If you select an external source for start command and it is on, the drive will start

immediately after fault reset unless you configure the drive for pulse start. See the

firmware manual.

• When the control location is not set to Local, the stop key on the control panel will not

stop the drive.

• Only authorized persons are allowed to repair a malfunctioning drive.

Electrical safety in installation, start-up and maintenance

Precautions before electrical work

These warnings are for all personnel who do work on the drive, motor cable or motor.

WARNING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur. If you are not a qualified electrician, do not

do installation or maintenance work. Go through these steps before you begin any

installation or maintenance work.

1. Clearly identify the work location.

2. Disconnect all possible voltage sources.

• Open the main switch-disconnector (Q1) of the drive.

• Open the disconnector of the supply transformer as the main switch-disconnector

(Q1) of the drive does not remove the voltage from the input busbars of the drive.

• Make sure that reconnection is not possible. Lock the disconnectors to open

position and attach a warning notice to them.

• Disconnect any external power sources from the control circuits before you do

work on the control cables.

• After you disconnect the drive, always wait 5 minutes to let the intermediate circuit

capacitors discharge before you continue.

3. Protect any other energized parts in the work location against contact.

4. Take special precautions when close to bare conductors.

5. Measure that the installation is de-energized.

• Use a multimeter with an impedance of at least 1 Mohm.

• Make sure that the voltage between the drive input power terminals (L1, L2, L3)

and the grounding (PE) busbar is close to 0 V.

• Make sure that the voltage between the drive module UDC+ and UDC- terminals

and the grounding (PE) busbar is close to 0 V.

6. Install temporary grounding as required by the local regulations.

7. Ask for a permit to work from the person in control of the electrical installation work.

Safety instructions 17

Additional instructions and notes

WARNING! Obey these instructions. If you ignore them, injury or death, or

damage to the equipment can occur.

• If you are not a qualified electrician, do not do installation or maintenance work.

• Do not install a drive with EMC filter option +E200 or +E202 on an ungrounded power

system or a high resistance-grounded (over 30 ohms) power system.

• Do not connect the drive to a voltage higher than what is on the type designation label.

If you do, the brake chopper starts to operate which causes the overheating of the

brake resistor (if present). Overvoltage can also cause the motor to rush to its

maximum speed.

• We do not recommend that you secure the cabinet by arc welding. If you have to, obey

the instructions in section Arc welding on page 69.

• Do not do insulation or voltage withstand tests on the drive or drive modules.

Note:

• The motor cable terminals of the drive are at a dangerous voltage when the input

power is on, regardless of whether the motor is running or not.

• The DC bus and brake resistor terminals (UDC+, UDC-, R+ and R-) are at a

dangerous voltage.

• External wiring can supply dangerous voltages to the terminals of relay outputs

(XRO1, XRO2 and XRO3).

• The Safe torque off function does not remove the voltage from the main and auxiliary

circuits. The function is not effective against deliberate sabotage or misuse.

WARNING! Use a grounding wrist band when you handle the printed circuit

boards. Do not touch the boards unnecessarily. The boards contain components

sensitive to electrostatic discharge.

WARNING! Obey these instructions. If you ignore them, equipment malfunction

and damage to the fiber optic cables can occur.

• Handle the fiber optic cables with care.

• When you unplug the cables, always hold the connector, not the cable itself.

• Do not touch the ends of the fibers with bare hands as the ends are extremely

sensitive to dirt.

• Do not bend the fiber optic cables too tightly. The minimum allowed bend radius is

35 mm (1.4 in).

18 Safety instructions

Grounding

These instructions are for all personnel who are responsible for the grounding of the drive.

WARNING! Obey these instructions. If you ignore them, injury or death and

equipment malfunction can occur, and electromagnetic interference can increase.

• If you are not a qualified electrician, do not do grounding work.

• Always ground the drive, the motor and adjoining equipment. This is necessary for the

personnel safety. Proper grounding also reduces electromagnetic emission and

interference.

• Make sure that the conductivity of the grounding conductors is sufficient. See section

Selecting the power cables on page 78. Obey the local regulations.

• Connect the power cable shields to protective earth (PE) of the drive to make sure of

personnel safety.

• Make a 360° grounding of the power and control cable shields at the cable entries to

suppress electromagnetic disturbances.

• In a multiple-drive installation, connect each drive separately to the protective earth

(PE) busbar of the switch board or the transformer.

Note:

• You can use power cable shields as grounding conductors only when their conductivity

is sufficient.

• As the normal touch current of the drive is higher than 3.5 mA AC or 10 mA DC, you

must use a fixed protective earth connection. See standard EN 61800-5-1, 4.3.5.5.2.

Safety instructions 19

Additional instructions for permanent magnet motor drives

Safety in installation, start-up and maintenance

These are additional warnings concerning permanent magnet motor drives. The other

safety instructions in this chapter are also valid.

WARNING! Obey these instructions. If you ignore them, injury or death and

equipment malfunction can occur.

• Do not do work on the drive when the permanent magnet motor is rotating. A rotating

permanent magnet motor energizes the drive including its input power terminals.

Before installation, start-up and maintenance work on the drive:

• Stop the motor.

• Disconnect the motor from the drive with a safety switch or by other means.

• If you cannot disconnect the motor, make sure that the motor cannot rotate during

work. Make sure that no other system, like hydraulic crawling drives, can rotate the

motor directly or through any mechanical connection like felt, nip, rope, etc.

• Measure that the installation is de-energized.

• Use a multimeter with an impedance of at least 1 Mohm.

• Make sure that the voltage between the drive output terminals (U2, V2, W2) and

the grounding (PE) busbar is close to 0 V.

• Make sure that the voltage between the drive input power terminals (L1, L2, L3)

and the grounding (PE) busbar is close to 0 V.

• Make sure that the voltage between the drive module UDC+ and UDC- terminals

and the grounding (PE) busbar is close to 0 V.

• Install temporary grounding to the drive output terminals (U2, V2, W2). Connect the

output terminals together as well as to the PE.

• Make sure that the operator cannot run the motor over the rated speed. Motor

overspeed causes overvoltage can damage or explode the capacitors in the

intermediate circuit of the drive.

20 Safety instructions

Introduction to the manual 21

2

Introduction to the manual

Contents of this chapter

This chapter describes the manual. It contains a flowchart of steps in checking the

delivery, installing and starting up the drive. The flowchart refers to chapters/sections in

this manual and to other manuals.

Target audience

This manual is intended for people who plan the installation, install, start up, use and

service the drive. Read the manual before you work on the drive. You are expected to

know the fundamentals of electricity, wiring, electrical components and electrical

schematic symbols.

The manual is written for readers worldwide. Both SI and imperial units are shown.

Contents of the manual

This manual contains the instructions and information for the basic drive configuration. The

chapters of the manual are briefly described below.

Safety instructions gives safety instructions for the installation, start-up, operation and

maintenance of the drive.

Introduction to the manual gives an introduction to this manual.

Operation principle and hardware description describes the operation principle and

constructions of the drive.

Mechanical installation describes how to install the drive mechanically.

Guidelines for planning the electrical installation contains instructions for the motor and

cable selection, protections and cable routing.

22 Introduction to the manual

Electrical installation gives instructions on wiring the drive.

Control unit of frames R6 to R9 contains the default I/O connection diagram, descriptions

of the terminals and technical data for the control unit.

Control unit of frames R10 and R11 contains the default I/O connection diagram and

references for the descriptions of the terminals and technical data of the control unit.

Installation checklist contains a list for checking the mechanical and electrical installation

of the drive.

Start-up describes the start-up procedure of the drive.

Fault tracing describes the fault tracing possibilities of the drive.

Maintenance contains preventive maintenance instructions.

Technical data contains the technical specifications of the drive, eg, the ratings, sizes and

technical requirements, provisions for fulfilling the requirements for CE and other

markings.

Dimension drawings contains example dimension drawings of the drive.

Safe torque off function describes the Safe torque off function of the drive and gives

instructions on its implementing.

Resistor braking describes selection, protection and wiring of optional brake choppers and

resistors. The chapter also contains technical data.

Related manuals

See List of related manuals on the inside of the front cover.

Categorization by frame size and option code

Some instructions, technical data and dimension drawings which concern only certain

frame sizes are marked with the symbol of the frame size (R6, R7, R8, R9, R10 or R11)

The frame size is marked on the type designation label, see page 49.

The instructions, technical data and dimension drawings which concern only certain

optional selections are marked with option codes (such as +E205). The options included in

the drive can be identified from the option codes visible on the type designation label. The

option selections are listed in section Type designation key on page 49.

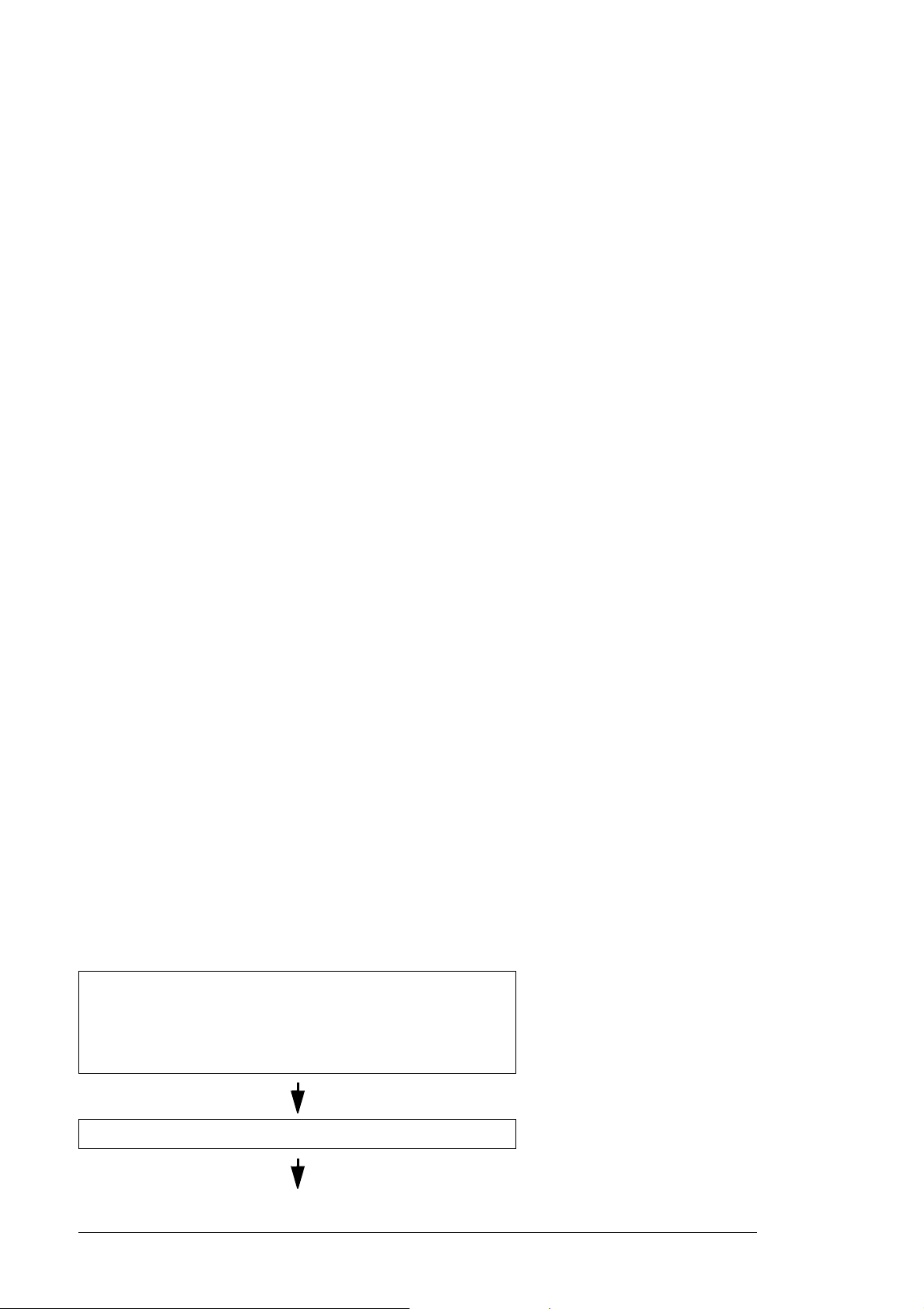

Quick installation, start-up and operating flowchart

Tas k Se e

Plan the electrical installation and acquire the accessories needed

(cables, fuses, etc.).

Check the ratings, required cooling air flow, input power connection,

compatibility of the motor, motor connection, and other technical

data.

Guidelines for planning the

electrical installation (page 71)

Technical data (page 183)

Check the installation site. Ambient conditions (page 207)

Tas k Se e

Introduction to the manual 23

Unpack and check the units (only intact units may be started up).

Examine that all necessary option modules and equipment are

present and correct.

Mount the drive.

Route the cables. Routing the cables (page 83)

Check the insulation of the supply cable, the motor and the motor

cable.

If the drive is about to be connected to an IT (ungrounded) system,

check that the drive is not equipped with EMC filter +E200 or +E202.

Connect the power cables.

Connect the control cables.

Mechanical installation (page 55)

If the drive has been nonoperational for more than one year,

the converter DC link capacitors

need to be reformed (page 180)

Checking the insulation of the

assembly (page 93)

Checking the compatibility with IT

(ungrounded) systems (page 94)

Connecting the power cables (page

96), Connecting the control cables

(page 107),

Check the installation. Installation checklist (page 141)

Start the drive up. Start-up (page 143)

Operate the drive: start, stop, speed control etc. ACS880 quick start-up guide,

firmware manual

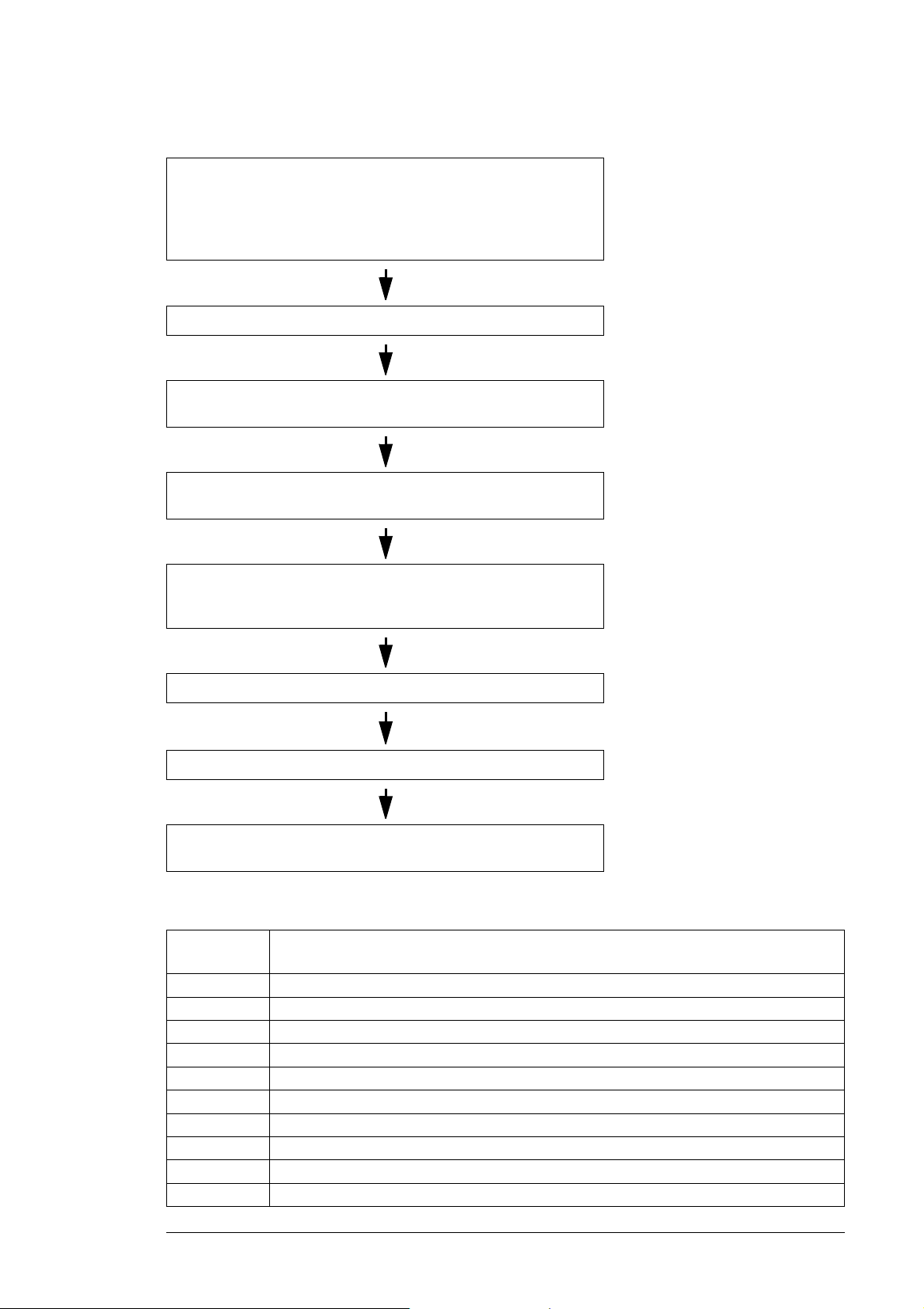

Terms and abbreviations

Term/

Abbreviation

EMC Electromagnetic compatibility

EMI Electromagnetic interference

EMT Electrical metallic tubing

FIO-01 Optional digital I/O extension module

FIO-11 Optional analog I/O extension module

FCAN-01 Optional FCAN-01 CANopen adapter module

FCNA-01 Optional ControlNet™ adapter module

FDCO-01 Optional DDCS communication module with two pairs of 10 Mbit/s DDCS channels

FDNA-01 Optional DeviceNet™ adapter module

FECA-01 Optional EtherCAT adapter module

Explanation

24 Introduction to the manual

Term/

Abbreviation

FEPL-01 Optional Ethernet POWERLINK adapter module

FENA-11 Optional Ethernet adapter module for EtherNet/IP™, Modbus TCP and PROFINET IO

FENA-21 Optional Ethernet adapter module for EtherNet/IP™, Modbus TCP and PROFINET IO

FLON-01 Optional LonWorks® adapter module

FPBA-01 Optional PROFIBUS DP adapter module

FEN-01 Optional TTL incremental encoder interface module

FEN-11 Optional TTL absolute encoder interface module

FEN-21 Optional resolver interface module

FEN-31 Optional HTL incremental encoder interface module

FSO-12,

FSO-21

Frame (size) Physical size of the drive

IGBT Insulated gate bipolar transistor; a voltage-controlled semiconductor type widely used in

I/O Input/Output

MCCB Molded case circuit breaker

ZCU Drive control unit. As standard, the external I/O control signals are connected to the control

ZGAB Brake chopper adapter board

ZGAD, BGAD Gate driver adapter board

ZINT Main circuit board

ZMU The memory unit attached to the control unit of the drive

RFI Radio-frequency interference

R6…R11 Frame size designation of the drive

SAR Safe acceleration range

SBC Safe brake control

SLS Safely-limited speed without encoder

SS1 Safe stop 1

SSE Safe stop emergency

SSM Safe speed monitor without encoder

STO Safe torque off

Explanation

protocols

protocols, 2-port

Optional functional safety module

drives due to their easy controllability and high switching frequency.

unit, or optional I/O extensions mounted on it.

Operation principle and hardware description 25

3

Operation principle and hardware description

Contents of this chapter

This chapter briefly describes the operation principle and construction of the drive.

Product overview

The ACS880-07 is an air-cooled cabinet-installed drive for controlling asynchronous AC

induction motors, permanent magnet synchronous motors, AC induction servomotors and

ABB synchronous reluctance motors (SynRM motors) with option N7502.

26 Operation principle and hardware description

L1

L2

L3

Q1

Q2

T21

R12R1 R11T1

>

T

T

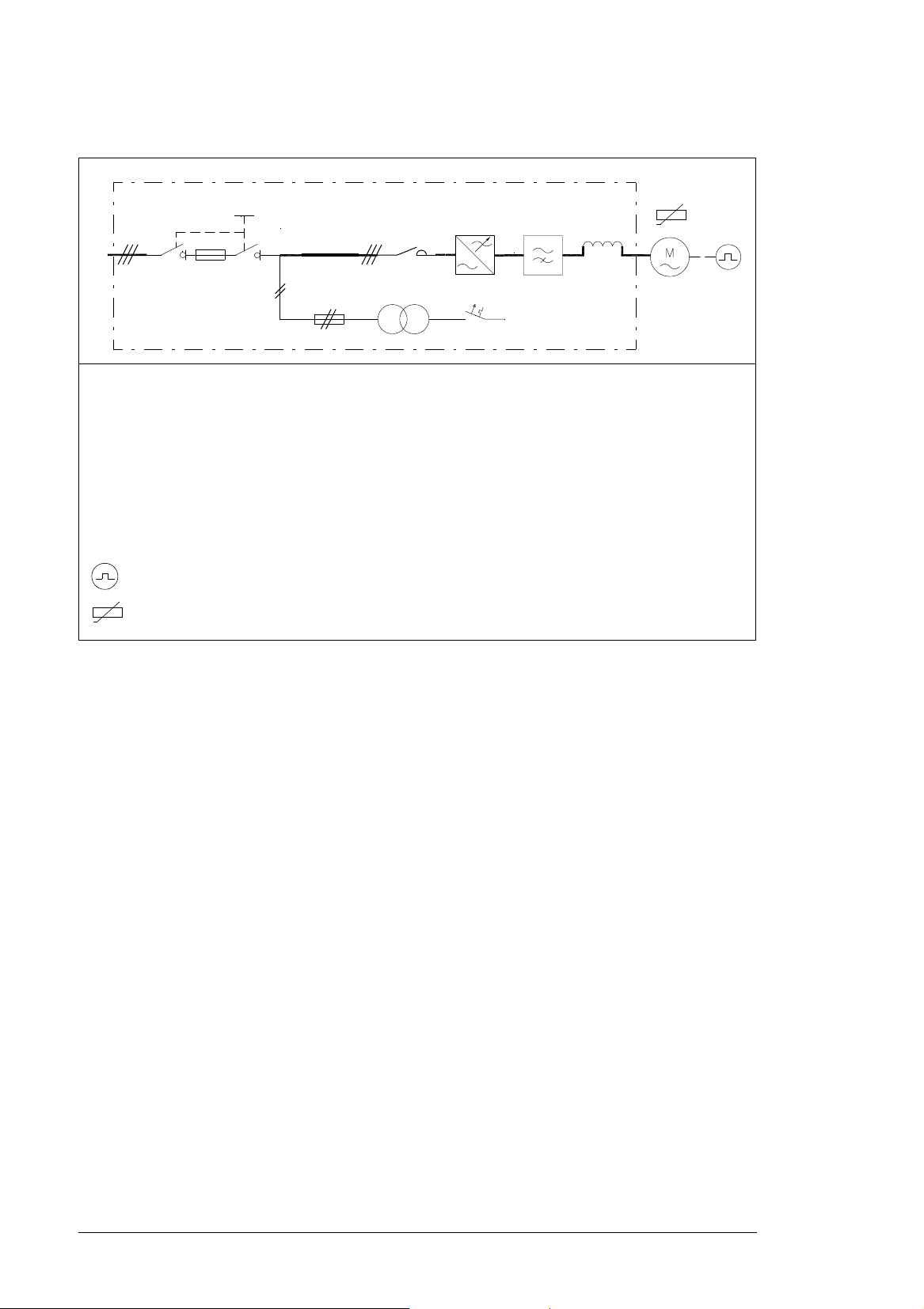

Single-line circuit diagram of the drive

Q1 Main switch-disconnector (switch fuse in frames R6 to R8, switch-disconnector and separate fuses

in frames R9 to R11, or molded case circuit breaker and separate fuses [option +F289 for US

market only])

Q2 Optional line contactor (+F250)

T21 Auxiliary voltage transformer supplying 24 V and 230/115 V control voltage for, eg, cabinet fan(s),

control devices and I/O extension adapter module.

T1 Drive module

R11 Optional common mode filter (+E208)

R12 Optional du/dt filter (+E205) or sine filter (+E206)

HTL pulse encoder for optional FEN-31 HTL incremental encoder interface module (+L205)

PTC sensors for optional thermistor relay(s) (+L205, +2L205) or Pt100 sensors for optional Pt100

relays (+xL206)

Operation principle and hardware description 27

1 2 3

4

5

T1

B

A

6

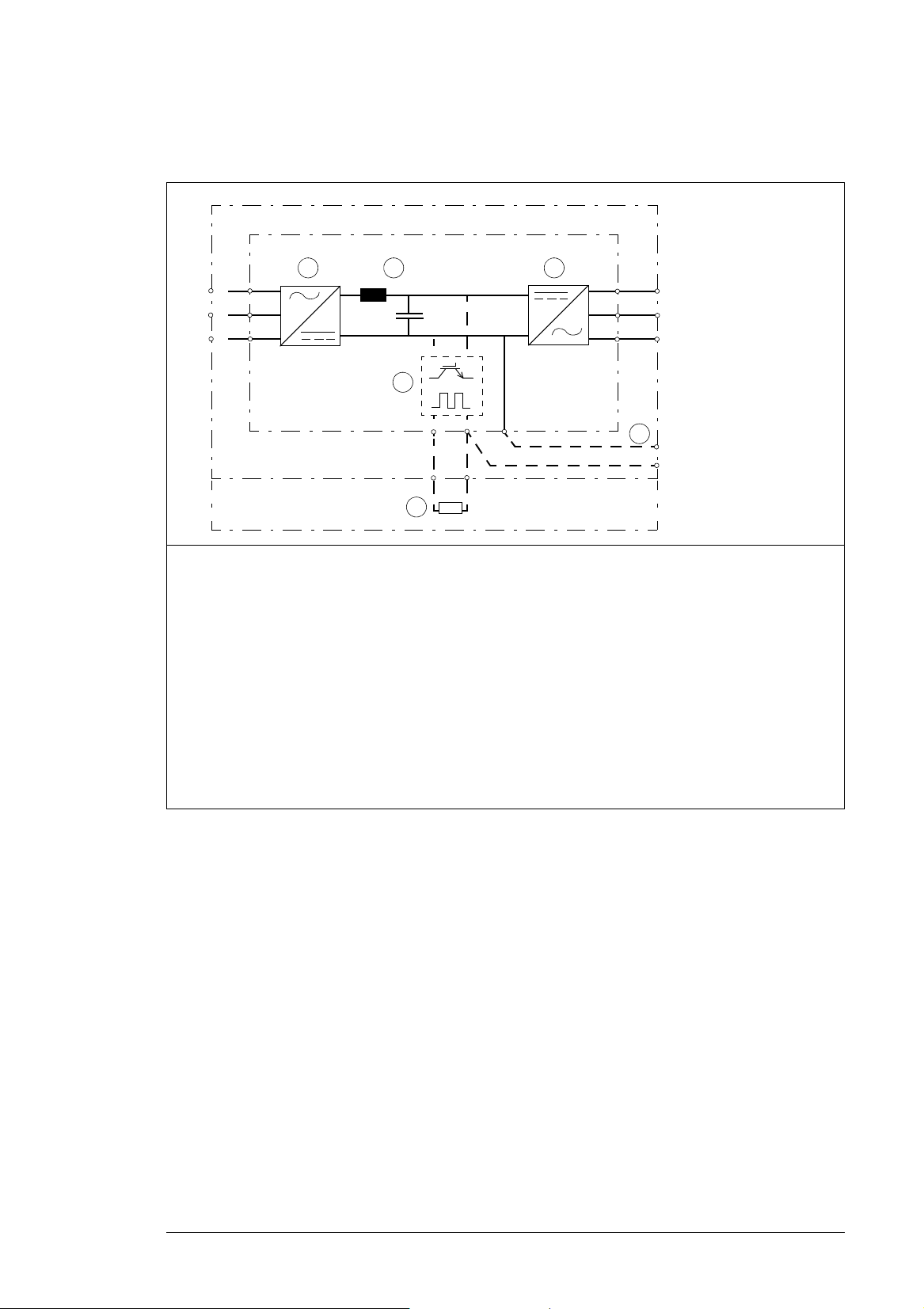

Block diagram of the brake and DC options (+D150, +D151 and

+H356)

A Drive module cubicle

T1 Drive module

B Brake resistor cubicle

1 Rectifier. Converts alternating current and voltage to direct current and voltage.

2 DC link. DC circuit between rectifier and inverter. DC choke is included in frames R6 to R9. An AC

input choke is included in frames R10 and R11.

3 Inverter. Converts direct current and voltage to alternating current and voltage.

4 Brake chopper (option +D150). Conducts the surplus energy from the intermediate DC circuit of the

drive to the brake resistor when necessary. The chopper operates when the DC link voltage exceeds a

certain maximum limit. The voltage rise is typically caused by deceleration (braking) of a high inertia

motor. User obtains and installs the brake resistor when needed.

5 Brake resistor (option +D151)

6 Optional DC cable connection busbars (+H356). Not available with option +D150.

28 Operation principle and hardware description

IP22/IP42 IP54

UL Type 1 with molded case circuit

breaker (option +F289 for US market

only)

UL Type 1 /

UL Type 1 Filtered

UL Type 12

12

General information on the cabinet layout

Example cabinet line-up

1 Frames R6 to R8:

Frame

s R9 to R11: two cubicles with one door (main

switch and power cabling cubicle and drive module

cubicle)

2 Brake resistor cubicle with option +D151

drive module cubicle.

Operation principle and hardware description 29

4

7

12

13

14

1

2

3

7

16

20

10

15

17

8

6

18

9

19

11

5

7

6

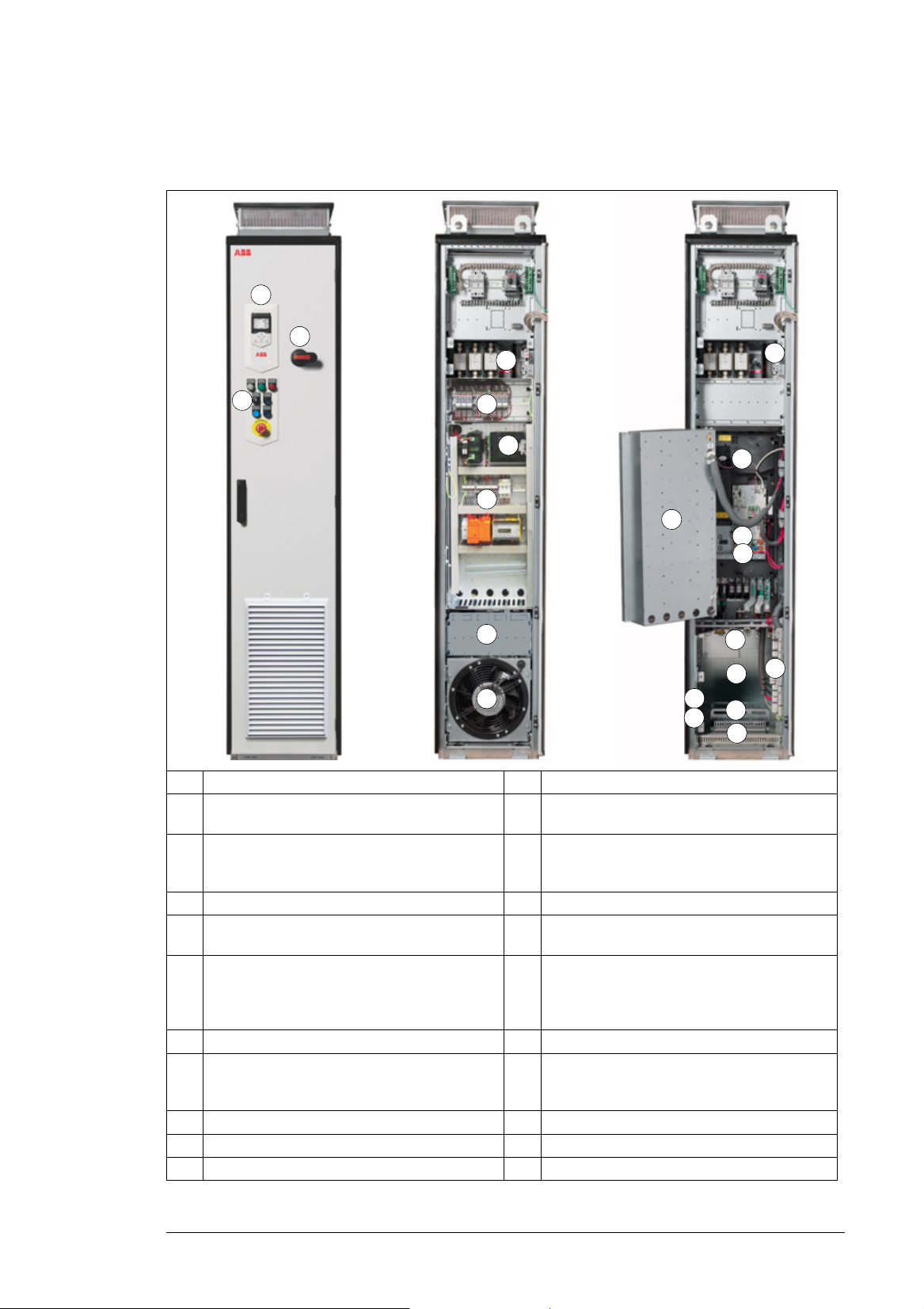

Cabinet layout of frames R6 to R8

The cabinet layout without shrouds is shown below.

1 Drive control panel 12 Control unit, see page 125.

2 Door switches and lights, see page 42. 13 Optional terminal block for external control unit

3 Main switch handle 14 Power cable connection terminals and du/dt

4 Main switch-disconnector with fuses

5 Thermistor and Pt100 relays (options +L505

and +L506)

6 Buffering module C22 16 Connection terminals for options +F250,

7 Swing-out frame 17 Cabinet heater (option +G300)

8 Mounting plate with connection terminals for

options +G300, +G307, +G313 at the back side

of the plate

9 “Door” fan 19 Power cable lead-throughs

10 Auxiliary voltage transformer (T21) 20 Control cable lead-through

11 Drive module - -

connections (X504, option +L504)

filter (option +E205) and common mode filter

(option +E208) behind

15 Common mode filter (option +E208)

+Q951, +Q952, +Q963, +Q964+Q968,

+Q954, +M600…+M605,+ L505, +L506. See

page 41.

18 PE busbar

30 Operation principle and hardware description

9

12

16

17

1

2

3

18

8

19

13

10

14

15

11

4

6 7

5

12

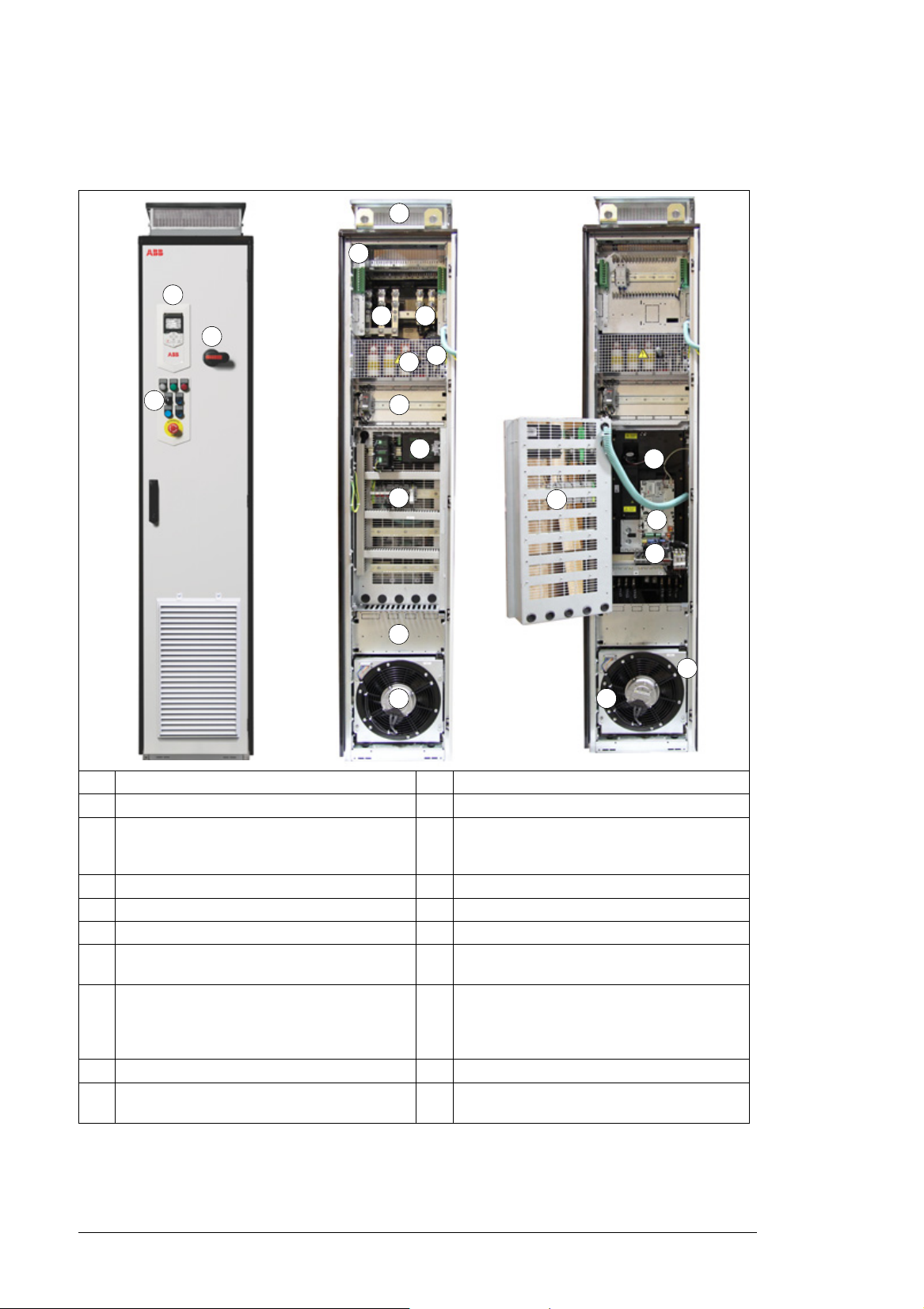

Cabinet layout of frames R6 to R8 with option +C129

The cabinet layout without shrouds is shown below.

1 Drive control panel 11 Buffering module C22

2 Door switches and lights, see page 42. 12 Swing-out frame

3 Main switch handle 13 Mounting plate with connection terminals for

4 Power and control cable lead-throughs 14 “Door” fan

5 Ground bar 15 Drive module

6 Input cable connection terminals 16 Control unit, see page 125.

7 Motor cable connection terminals 17 Optional terminal block for external control unit

8 Auxiliary voltage transformer (T21) 16 Connection terminals for options +F250,

9 Main switch-disconnector with fuses 19 Cabinet heater (option +G300)

10 Thermistor and Pt100 relays (options +L505

and +L506)

options +G300, +G307, +G313 at the back

side of the plate

connections (X504, option +L504)

+Q951, +Q952, +Q963, +Q964+Q968,

+Q954, +M600…+M605,+ L505, +L506. See

page 41.

--

Loading...

Loading...