ABB ACS800-07-1850-3, ACS800-07-0870-3, ACS800-07-1230-3, ACS800-07-1030-3, ACS800-07-0760-5 Hardware Manual

...

ACS800

Hardware Manual

ACS800-07 Drives (500 to 2800 kW)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

ACS800 Single Drive Manuals

HARDWARE MANUALS (appropriate manual is included in the

delivery)

ACS800-01/U1 Hardware Manual 0.55 to 160 kW (0.75 to 200 HP)

3AFE64382101 (English)

ACS800-01/U1/04 Marine Supplement 0.55 to 160 kW (0.75 to

200 HP) 3AFE64291275 (English)

ACS800-11/U11 Hardware Manual 5.5 to 110 kW (7.5 to 125 HP)

3AFE68367883 (English)

ACS800-31/U31 Hardware Manual 5.5 to110 kW (7.5 to 125 HP)

3AFE68599954 (English)

ACS800-02/U2 Hardware Manual 90 to 500 kW (125 to 600 HP)

3AFE64567373 (English)

ACS800-04/U4 Hardware Manual 0.55 to 160 kW (0.75 to 200 HP)

3AFE68372984 (English)

ACS800-04/04M/U4 Hardware Manual 45 to 560 kW (60 to

600 HP) 3AFE64671006 (English)

ACS800-04/04M/U4 Cabinet Installation 45 to 560 kW (60 to

600 HP) 3AFE68360323 (English)

ACS800-07/U7 Hardware Manual 45 to 560 kW (50 to 600 HP)

3AFE64702165 (English)

ACS800-07/U7 Dimensional Drawings 45 to 560 kW (50 to

600 HP) 3AFE64775421

ACS800-07 Hardware Manual 500 to 2800 kW

3AFE64731165 (English)

ACS800-17 Hardware Manual 55 to 2500 kW (75 to 2800 HP)

3AFE68397260 (English)

ACS800-37 Hardware Manual 55 to 2700 kW (75 to 3000 HP)

3AFE68557925 (English)

• Safety instructions

• Electrical installation planning

• Mechanical and electrical installation

• Motor control and I/O board (RMIO)

• Maintenance

• Technical data

• Dimensional drawings

• Resistor braking

FIRMWARE MANUALS, SUPPLEMENTS AND GUIDES

(appropriate documents are included in the delivery)

Standard Control Program Firmware Manual

3AFE64527592 (English)

System Application Program Firmware Manual

3AFE64670646 (English)

Application Program Template Firmware Manual

3AFE64616340 (English)

Master/Follower 3AFE64590430 (English)

Pump Control Application Program Firmware Manual

3AFE68478952 (English)

Extruder Control Program Supplement 3AFE64648543 (English)

Centrifuge Control Program Supplement 3AFE64667246 (English)

Traverse Control Program Supplement 3AFE64618334 (English)

Crane Control Program Firmware Manual 3BSE11179 (English)

Adaptive Programming Application Guide

3AFE64527274 (English)

OPTION MANUALS (delivered with optional equipment)

Fieldbus Adapters, I/O Extension Modules etc.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

ACS800-07 Drives

500 to 2800 kW

Hardware Manual

3AFE64731165 REV E EN

EFFECTIVE: 15.2.2008

© 2008 ABB Oy. All Rights Reserved.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Update Notice

1

Update Notice

NEW (page 6): Safety / Installation and maintenance work

• After maintaining or modifying a drive safety circuit or changing circuit boards

inside the module, retest the functioning of the safety circuit according to the

start-up instructions.

• Do not change the electrical installations of the drive except for the essential

control and power connections. Changes may affect the safety performance or

operation of the drive unexpectedly. All customer-made changes are on the

customer's responsibility.

[...]

Note:

• The Safe torque off function (option +Q968) does not remove the voltage from the

main and auxiliary circuits.

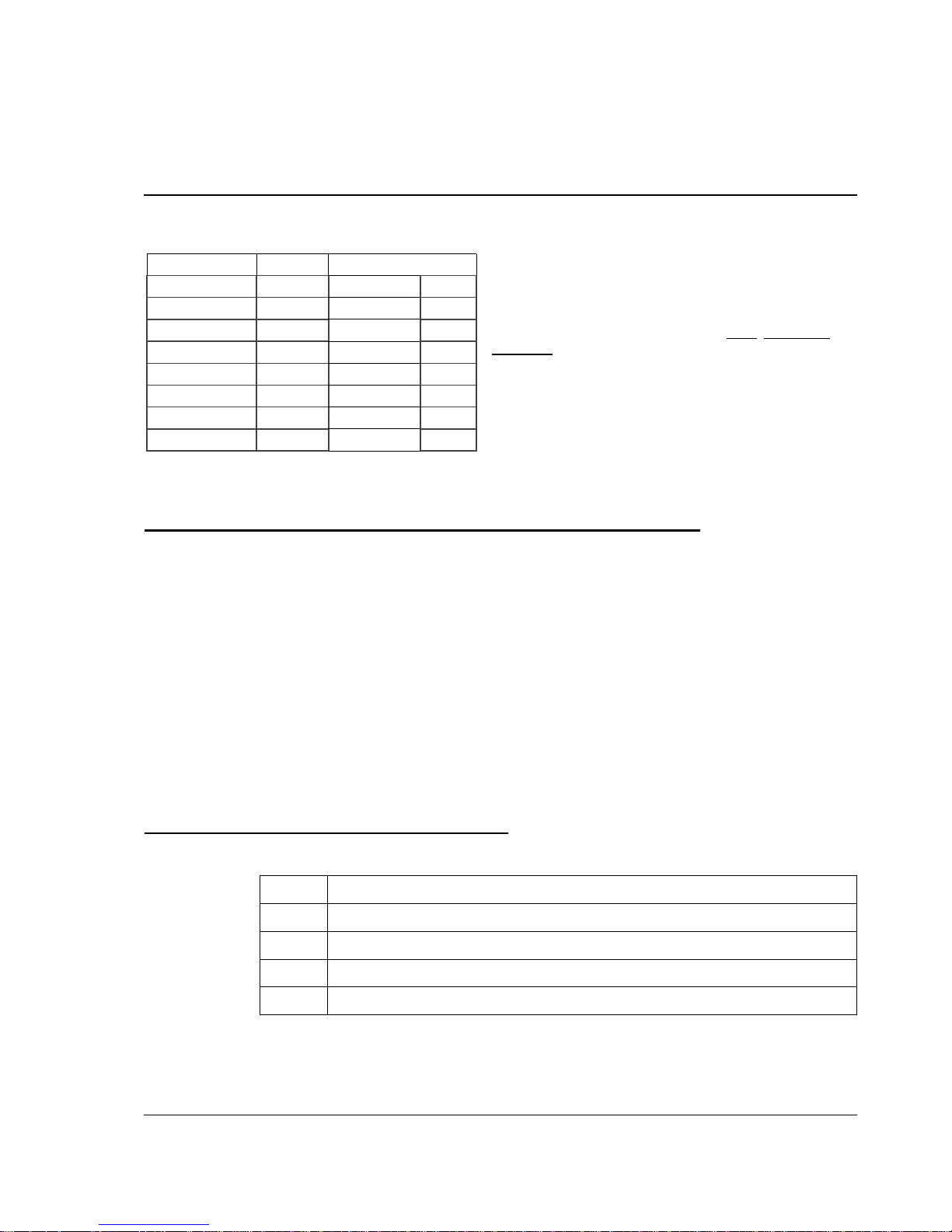

NEW/CHANGED (page 37): Type code

The table below contains the valid option code definitions for the emergency stop.

The notice concerns the following ACS800-07 Drives (500

to 2800 kW) Hardware Manuals:

Code: 3AUA0000059446 Rev A

Valid: from 01.02.2010 until the release of the next revision of

the manual

Contents:

The headings in this update notice refer to the modified

subsections in the original English manual. Each heading also

includes a page number and a classifier NEW

, CHANGED, or

DELETED

. The page number refers to the page number in the

original English manual. The classifier describes the type of

the modification.

Code Description

+Q951 Emergency stop, stop category 0 with opening the main contactor/breaker

+Q952 Emergency stop, stop category 1 with opening the main contactor/breaker

+Q963 Emergency stop, stop category 0 without opening the main contactor/breaker

+Q964 Emergency stop, stop category 1 without opening the main contactor/breaker SS1

Code Revision Language

3AFE64731165 E English EN

3AFE64772911 E German DE

3AFE64772929 E Span ish ES

3AFE64772937 E Finnish FI

3AFE64774239 E French FR

3AFE64772945 E Italian IT

3AFE68588235 E Russian RU

3AFE64772953 E Swedish SV

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Update Notice

2

NEW (page 37): Type code

The table below contains the new option code definition for the Safe torque off

function.

NEW (page 61): Emergency stop

Note: If you add or modify the wiring in the drive safety circuits, ensure that the

appropriate standards (e.g. IEC 61800-5-1, EN 62061, EN/ISO 13849-1 and -2) and

the ABB guidelines are met. After making the changes, verify the operation of the

safety function by testing it.

NEW (page 61): Safe torque off

The drive supports the Safe torque off (STO) function according to standards

EN 61800-5-2:2007; EN/ISO 13849-1:2008, IEC 61508, and EN 62061:2005. The

function also corresponds to an uncontrolled stop in accordance with category 0 of

EN 60204-1 and prevention of unexpected start-up of EN 1037.

The STO may be used where power removal is required to prevent an unexpected

start. The function disables the control voltage of the power semiconductors of the

drive output stage, thus preventing the inverter from generating the voltage required

to rotate the motor (see the diagram below). By using this function, short-time

operations (like cleaning) and/or maintenance work on non-electrical parts of the

machinery can be performed without switching off the power supply to the drive.

Code Description

+Q968 Safe torque off (STO) with a safety relay

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Update Notice

3

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Update Notice

4

WARNING! The Safe torque off function does not disconnect the voltage of the main

and auxiliary circuits from the drive. Therefore maintenance work on electrical parts

of the drive or the motor can only be carried out after isolating the drive system from

the main supply.

Note: The Safe torque off function can be used for stopping the drive in emergency

stop situations. In the normal operating mode, use the Stop command instead. If a

running drive is stopped by using the function, the drive will trip and stop by coasting.

If this is not acceptable, e.g. causes danger, the drive and machinery must be

stopped using the appropriate stopping mode before using this function.

Note concerning permanent magnet motor drives in case of a multiple IGBT

power semiconductor failure: In spite of the activation of the Safe torque off

function, the drive system can produce an alignment torque which maximally rotates

the motor shaft by 180/p degrees. p denotes the pole pair number.

Note: If you add or modify the wiring in the drive safety circuits, ensure that the

appropriate standards (e.g. IEC 61800-5-1, EN 62061, EN/ISO 13849-1 and -2) and

the ABB guidelines are met.

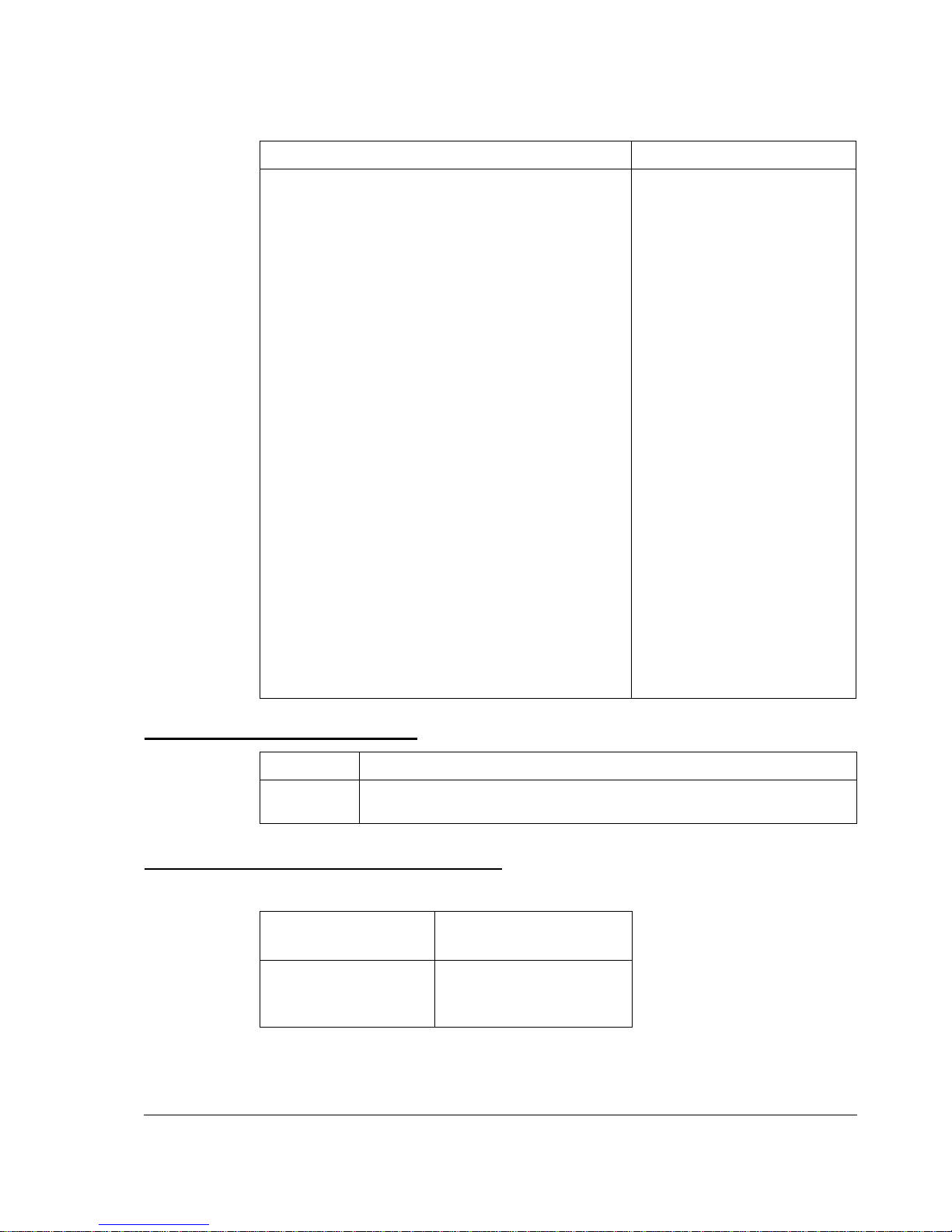

NEW (page 101): On-load checks

The following information has been added to the procedure:

NEW (page 101): On-load checks

The following information has been added to the procedure:

Action Additional information

Check the correct operation of the emergency stop

circuits from each operating location.

If the drive is equipped with the category 1

emergency stop function (option +Q952 or +Q964),

adjust the delay time of the emergency stop relay

and the deceleration time of the drive emergency

stop function. The factory default settings do not

necessarily meet the application needs.

Action Additional information

Check that the Safe torque off function (option

+Q968, if installed) works:

Optional function. See delivery

specific circuit diagrams.

• Ensure that the drive can be run and stopped

freely during the commissioning.

• Stop the drive (if running), switch the input power

off and isolate the drive from the power line by a

disconnector.

• Check the STO circuit connections against the

circuit diagram.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Update Notice

5

CHANGED (page 115): LEDs

NEW (page 126): Ambient conditions

Cabinets with option +Q968: the installation site altitude in operation is 0 to 2000 m.

• Close the disconnector and switch the power on.

• Test the operation of the STO function when the

motor is stopped:

- Give a stop command for the drive (if running)

and wait until the motor shaft is at standstill.

- Activate the STO circuit and give a start

command for the drive.

- Ensure that the motor stays at standstill.

- Deactivate the STO circuit.

• Restart the drive and check that the motor runs

normally.

• Test the operation of the STO function when the

motor is running:

- Start the drive and ensure that the motor is

running.

- Activate the STO circuit.

- Ensure that the motor stops and the drive trips.

- Reset the fault and try to start the drive.

- Ensure that the motor stays at standstill.

- Deactivate the STO circuit.

• Restart the drive and check that the motor runs

normally.

LED Indication

V309 (red) Prevention of unexpected start (option +Q950) or Safe torque off (option +Q968) is

ON.

Operation

installed for stationary use

Installation site altitude

[...]

Cabinets with option +Q968:

0 to 2000 m

Action Additional information

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Update Notice

6

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety instructions

5

Safety instructions

What this chapter contains

This chapter contains safety instructions you must follow when installing, operating

and servicing the drive. If ignored, physical injury or death may follow, or damage

may occur to the drive, the motor or driven equipment. Read the safety instructions

before you work on the unit.

Usage of warnings and notes

There are two types of safety instructions throughout this manual: warnings and

notes. Warnings caution you about conditions which can result in serious injury or

death and/or damage to the equipment, and advise on how to avoid the danger.

Notes draw attention to a particular condition or fact, or give information on a

subject. The warning symbols are used as follows:

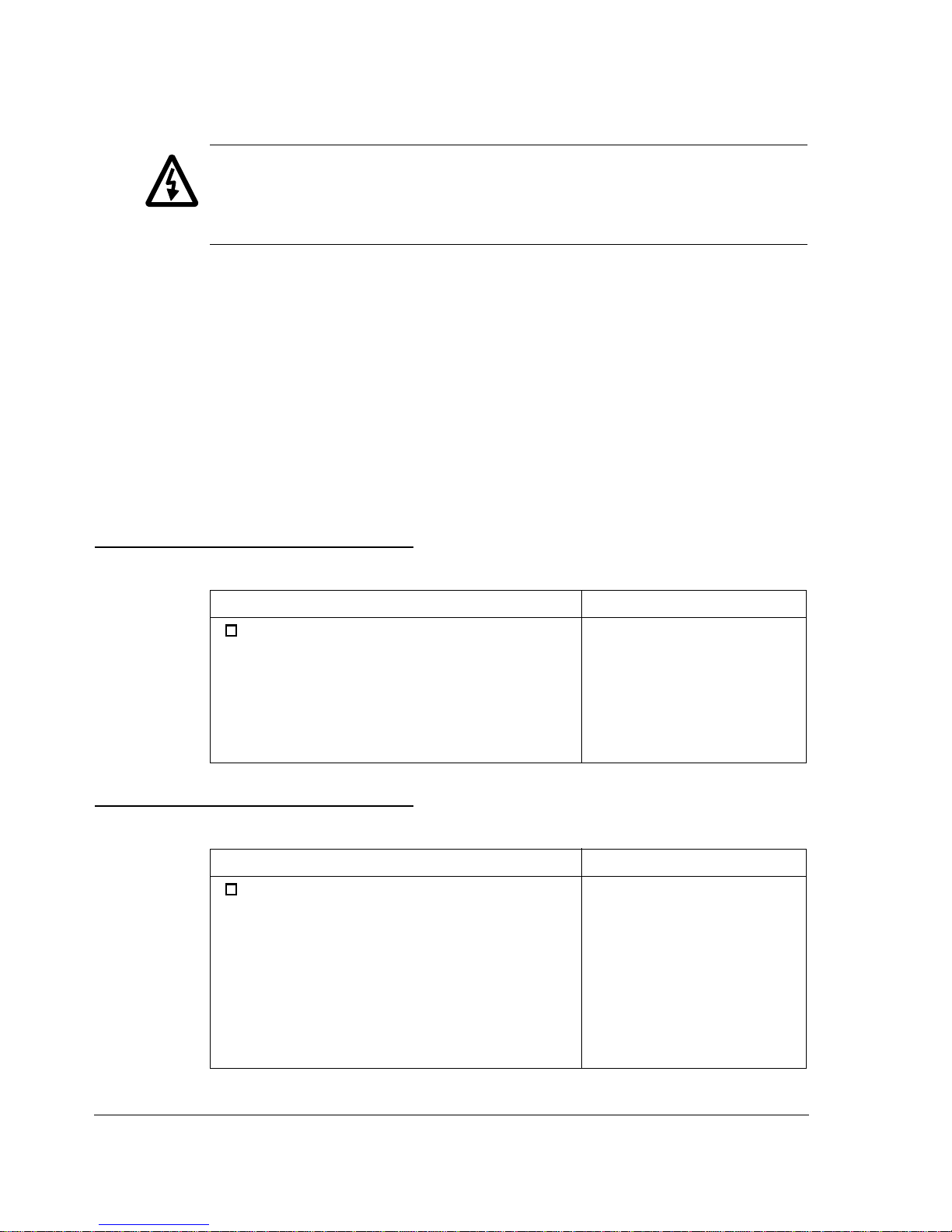

Dangerous voltage warning warns of high voltages which can cause

physical injury and/or damage to the equipment.

General warning warns about conditions, other than those caused by

electricity, which can result in physical injury and/or damage to the

equipment.

Electrostatic discharge warning warns of electrostatic discharge which

can damage the equipment.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety instructions

6

Installation and maintenance work

These warnings are intended for all who work on the drive, motor cable or motor.

Ignoring the instructions can cause physical injury or death, or damage the

equipment.

WARNING!

•

Only qualified electricians are allowed to install and maintain the drive.

•

The main switch on the cabinet door does not remove the voltage from the input

busbars of the drive. Before working on the drive, isolate the whole drive from

the supply.

•

Never work on the drive, the motor cable or the motor when main power is

applied. After switching off the input power, always wait for 5 min to let the

intermediate circuit capacitors discharge before you start working on the drive,

the motor or the motor cable. Measure the voltage between terminals UDC+

and UDC- (L+ and L–) with a multimeter (impedance at least 1 Mohm) to

ensure that the drive is discharged before beginning work.

•

Apply temporary grounding before working on the unit.

•

Do not work on the control cables when power is applied to the drive or to the

external control circuits. Externally supplied control circuits may cause

dangerous voltages to exist inside the drive even when the main power of the

drive is switched off.

•

Do not make any insulation or voltage withstand tests on the drive or drive

modules.

•

When reconnecting the motor cable, always check that the phase order is

correct.

•

When joining shipping splits (if any), check the cable connections at the joints

before switching on the supply voltage.

•

Live parts on the inside of the doors are protected against direct contact.

Special attention shall be paid when handling metallic shrouds.

Note:

•

The motor cable terminals on the drive are at a dangerously high voltage when

the input power is on, regardless of whether the motor is running or not.

•

The brake control terminals (UDC+, UDC-, R+ and R- terminals) carry a

dangerous DC voltage (over 500 V).

•

Depending on the external wiring, dangerous voltages (115 V, 220 V or 230 V)

may be present on the relay outputs of the drive system.

•

The Prevention of Unexpected Start function does not remove the voltage from

the main and auxiliary circuits.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety instructions

7

WARNING!

•

During the installation procedure, the inverter modules may have to be

temporarily extracted from the cabinet. The modules have a high centre of

gravity. In order to minimise the danger of toppling over, keep the support legs

of the modules extended whenever manoeuvring the modules outside the

cabinet.

•

Electrically conductive dust inside the unit may cause damage or lead to

malfunction. Make sure that dust from drilling does not enter the drive when

installing.

•

Fastening the cabinet by riveting or welding is not recommended. However, if

welding is necessary, ensure the return wire is properly connected in order not

to damage the electronic equipment in the cabinet. Also ensure that welding

fumes are not inhaled.

•

Ensure sufficient cooling of the unit.

•

Cooling fans may continue to rotate for a while after the disconnection of the

electrical supply.

•

Some parts inside the drive cabinet, such as heatsinks of power

semiconductors, remain hot for a while after the disconnection of the electrical

supply.

WARNING!

•

The printed circuit boards contain components sensitive to electrostatic

discharge. Wear a grounding wrist band when handling the boards. Do not

touch the boards unnecessarily.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety instructions

8

Grounding

These instructions are intended for all who are responsible for the grounding of the

drive. Incorrect grounding can cause physical injury, death or equipment malfunction

and increase electromagnetic interference.

Fibre optic cables

WARNING!

•

Ground the drive, the motor and adjoining equipment to ensure personnel

safety in all circumstances, and to reduce electromagnetic emission and pickup.

•

Make sure that grounding conductors are adequately sized as required by

safety regulations.

•

In a multiple-drive installation, connect each drive separately to protective

earth (PE).

•

Do not install a drive equipped with an EMC (line) filter to an ungrounded

power system or a high resistance-grounded (over 30 ohms) power system.

Note:

•

Power cable shields are suitable for equipment grounding conductors only

when adequately sized to meet safety regulations.

•

As the normal leakage current of the drive is higher than 3.5 mA AC or 10 mA

DC (stated by EN 50178, 5.2.11.1), a fixed protective earth connection is

required.

WARNING!

•

Handle the fibre optic cables with care. When unplugging optic cables, always

grab the connector, not the cable itself. Do not touch the ends of the fibres with

bare hands as the fibre is extremely sensitive to dirt. The minimum allowed

bend radius is 35 mm (1.4”).

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety instructions

9

Operation

These warnings are intended for all who plan the operation of the drive or operate

the drive. Ignoring the instructions can cause physical injury or death or damage the

equipment.

WARNING!

•

If the drive is equipped with an optional brake unit, make sure there are

inverters connected to the intermediate circuit before start. As a rule of thumb,

the sum capacitance of the inverters connected must be at least 30% of the

sum capacitance of all inverters.

•

Close the switch fuses of all parallel-connected inverters before start.

•

Do not open the DC switch fuse of an inverter when the inverter is running.

WARNING!

•

Before adjusting the drive and putting it into service, make sure that the motor

and all driven equipment are suitable for operation throughout the speed range

provided by the drive. The drive can be adjusted to operate the motor at

speeds above and below the speed provided by connecting the motor directly

to the power line.

•

Do not activate automatic fault reset functions of the Standard Application

Program if dangerous situations can occur. When activated, these functions

will reset the drive and resume operation after a fault.

•

Do not control the motor with the disconnecting device (means); instead, use

the control panel keys and , or commands via the I/O board of the drive.

The maximum allowed number of charging cycles of the DC capacitors (i.e.

power-ups by applying power) is five in ten minutes.

Note:

•

If an external source for start command is selected and it is ON, the drive (with

Standard Application Program) will start immediately after fault reset unless the

drive is configured for 3-wire (a pulse) start/stop.

•

When the control location is not set to Local (L not shown in the status row of

the display), the stop key on the control panel will not stop the drive. To stop

the drive using the control panel, press the LOC/REM key and then the stop

key .

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Safety instructions

10

Permanent magnet motor drives

These are additional warnings concerning permanent magnet motor drives.

WARNING! Do not work on the drive when the permanent magnet motor is rotating.

Also when the supply power is switched off, a rotating permanent magnet motor

feeds power to the intermediate circuit of the drive and also the supply connections

become live (even when the inverter is stopped!).

Installation and maintenance work

• Disconnect the motor from the drive with a safety switch

and additionally, if possible,

• lock the motor shaft and ground the motor connection terminals temporarily by

connecting them together as well as to the PE.

Operation

Do not run the motor above the rated speed. Motor overspeed leads to overvoltage

which may result in explosion of the capacitors in the intermediate circuit of the drive.

Application program

Controlling a permanent magnet motor is only allowed using the ACS800 Permanent

Magnet Synchronous Motor Drive Application Program, or using other application

programs in scalar control mode only.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table of contents

11

Table of contents

ACS800 Single Drive Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety instructions

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Usage of warnings and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation and maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Fibre optic cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Permanent magnet motor drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Installation and maintenance work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Application program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table of contents

About this manual

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Target audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Common chapters for multiple products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Categorization according to the frame size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation and commissioning flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Product and service inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Product training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Providing feedback on ABB Drives manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Terms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Hardware description

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

The ACS800-07 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cabinet line-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Swing-out frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cabling direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Single-line circuit diagram of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Door switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Load switch-disconnector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Auxiliary voltage switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Earthing/Grounding switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Other door controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Supply unit control electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table of contents

12

Reading and setting of values (page 1 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Reading and setting of values (page 2 of 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Terminal blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Digital input and relay output terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Emergency stop input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Earth (ground) current function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Power loss ride-through function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Inverter unit control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Motor control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Reduced run capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Type code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Mechanical installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Required tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Moving the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

…by crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

…by fork-lift or pallet truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

…on rollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Laying the unit on its back . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Final placement of the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Delivery check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Installation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Fastening the cabinet to the floor (Non-marine units) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Clamping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Holes inside the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Fastening the unit to the floor and wall (Marine units) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Joining the shipping splits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Connecting the DC busbars and the PE busbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

DC busbars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

PE busbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Cable duct in the floor below the cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Cooling air intake through bottom of cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Electric welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Planning the electrical installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Motor selection and compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Protecting the motor insulation and bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Requirements table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Permanent magnet synchronous motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Thermal overload and short-circuit protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Thermal overload protection of the drive and the input and motor cables . . . . . . . . . . . . . . .59

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table of contents

13

Thermal overload protection of the motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Protection against short-circuit in the motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Protection against short-circuit inside the drive or in the supply cable . . . . . . . . . . . . . . . . . 60

Earth fault (Ground fault) protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Emergency stop devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Restarting after an emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Prevention of unexpected start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Selecting the power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

General rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Alternative power cable types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Motor cable shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Additional US requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Conduit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Armored cable / shielded power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Power factor compensation capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Equipment connected to the motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Installation of safety switches, contactors, connection boxes, etc. . . . . . . . . . . . . . . . . . . . . 65

Bypass connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Before opening an output contactor (in DTC motor control mode) . . . . . . . . . . . . . . . . . . . . 65

Relay output contacts and inductive loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Selecting the control cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Relay cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Control panel cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Coaxial cable (for use with Advant Controllers AC 80/AC 800) . . . . . . . . . . . . . . . . . . . . . . . 67

Connection of a motor temperature sensor to the drive I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Installation sites above 2000 metres (6562 feet) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Routing the cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Control cable ducts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Electrical installation

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Before installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Checking the insulation of the assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Motor and motor cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

IT (ungrounded) systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Setting the earth fault (ground fault) trip level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Grounded systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

IT (ungrounded) systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Input power connection – Units without load switch-disconnector or air circuit breaker . . . . . . . . . 73

Connection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

6-pulse connection, two supply modules in parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

12-pulse connection, two supply modules in parallel . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Use of the dual-cable screw lug connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Removal of the dual-cable screw lug connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Input power connection – Units with load switch-disconnector or air circuit breaker . . . . . . . . . . . 77

Connection diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

6-pulse connection, two supply modules in parallel . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

12-pulse connection, two supply modules in parallel . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table of contents

14

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Motor connection – Units without common motor terminal cubicle . . . . . . . . . . . . . . . . . . . . . . . . .80

Output busbars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Motor connection – Units with common motor terminal cubicle . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Connection diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Drive control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Supply unit control connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Connection procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Installation of optional modules and PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Cabling of I/O and fieldbus modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Cabling of pulse encoder interface module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Fibre optic link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Connections and tap settings of the auxiliary voltage transformer . . . . . . . . . . . . . . . . . . . . . . . . .89

Installation of brake resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Motor control and I/O board (RMIO)

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

To which products this chapter applies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Note on cabinet-installed ACS800 drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Note on terminal labelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Note on external power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

External control connections (non-US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

External control connections (US) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

RMIO board specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Analogue inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Constant voltage output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Auxiliary power output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Analogue outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Relay outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

DDCS fibre optic link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

24 VDC power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Installation checklist and start-up

Installation checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

Start-up procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Basic checks with no voltage connected . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Connecting voltage to input terminals and auxiliary circuit . . . . . . . . . . . . . . . . . . . . . . . . . .100

Starting the supply unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Checks with the supply unit running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Application program set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

On-load checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table of contents

15

Maintenance

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Maintenance intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Replacing the PPCS branching unit (APBU-xx) memory backup battery . . . . . . . . . . . . . . . . . . . 105

Checking and replacing the air filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Cooling fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Power module cooling fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Supply module fan replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Inverter module fan replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Control and I/O cubicle cooling fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Air circuit breaker cubicle fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

IP54 (UL type 12) fan replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Heatsinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Capacitors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Reforming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Capacitor replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Other maintenance actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Power module replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Fault tracing

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Supply unit status, fault and warning LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Other LEDs of the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Technical data

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Temperature derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Altitude derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

ACS800-07 frame sizes and power module types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Internal AC fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

DC fuses at inverter module input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Fuses for main circuit voltage measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

DC fuses for the DSU module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Input power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Motor connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Degrees of protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Ambient conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Tightening torques for power connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Applicable standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Table of contents

16

CE marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Compliance with the EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Compliance with the EN 61800-3 + Amendment A11 (2000) . . . . . . . . . . . . . . . . . . . . . . . .128

First environment (restricted distribution) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

Second environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Machinery Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

“C-tick” marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Compliance with IEC 61800-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

First environment (restricted distribution) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

Second environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Dimensions

Cabinet line-ups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

Frame size 1×D4 + 2×R8i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Frame size 1×D4 + 2×R8i (with load switch-disconnector) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .141

Frame size 1×D4 + 2×R8i (with top entry/exit) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Frame size 2×D4 + 2×R8i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Frame size 2×D4 + 2×R8i (with load switch-disconnector) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

Frame size 2×D4 + 3×R8i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

Frame size 2×D4 + 3×R8i (with load switch-disconnector) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Frame size 2×D4 + 3×R8i (with air circuit breaker) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .163

Frame size 3×D4 + 4×R8i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .167

Frame size 3×D4 + 4×R8i (with load switch-disconnector) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .170

Frame size 3×D4 + 4×R8i (with air circuit breaker) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .174

Common motor terminal cubicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

300 mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

400 mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .179

600 mm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

Resistor braking

What this chapter contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Resistor braking options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .181

Chopper/Resistor combinations – Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

Brake resistors – Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .182

Verifying the capacity of the braking equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Custom resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .183

Calculating the maximum braking power (P

br

) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Example 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Example 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .184

Example 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .185

Custom resistor installation and wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .186

Brake circuit commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

About this manual

17

About this manual

What this chapter contains

This chapter describes the intended audience and contents of the manual. It

contains a flowchart of steps in checking the delivery, installing and commissioning

the drive. The flowchart refers to chapters/sections in this manual and other

manuals.

Target audience

This manual is intended for people who plan the installation, install, commission, use

and service the drive. Read the manual before working on the drive. The reader is

expected to know the fundamentals of electricity, wiring, electrical components and

electrical schematic symbols.

The manual is written for readers worldwide. Both SI and imperial units are shown.

Special US instructions for installations within the United States that must be

installed per the National Electrical Code and local codes are marked with (US).

Common chapters for multiple products

Some chapters in this manual apply to several products including the ACS800-07.

Other product types may be mentioned in these chapters.

Categorization according to the frame size

Some instructions, technical data and dimensional drawings which concern only

certain drive frame sizes are marked with the symbol of the frame size (such as

“1×D4 + 2×R8i”, etc.). The frame size is not marked on the drive designation label.

To identify the frame size of your drive, see the rating tables in chapter Technical

data.

Contents

The chapters of this manual are briefly described below.

Safety instructions gives safety instructions for the installation, commissioning,

operation and maintenance of the drive.

About this manual introduces this manual.

Hardware description describes the drive.

Mechanical installation instructs how to move, place and mount the drive.

Planning the electrical installation provides advice on motor and cable selection, the

protective functions of the drive, and cable routing.

Electrical installation describes the cabling and wiring of the drive.

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

About this manual

18

Motor control and I/O board (RMIO) shows external control connections to the motor

control and I/O board and its specifications.

Installation checklist and start-up helps in checking the mechanical and electrical

installation of the drive.

Maintenance contains preventive maintenance instructions.

Fault tracing contains troubleshooting instructions.

Technical data contains the technical specifications of the drive, e.g. ratings, frame

sizes and technical requirements, provisions for fulfilling the requirements for CE

and other markings and warranty policy.

Dimensions contains information on the dimensions of the drive.

Resistor braking describes how to select, protect and wire optional brake choppers

and resistors.

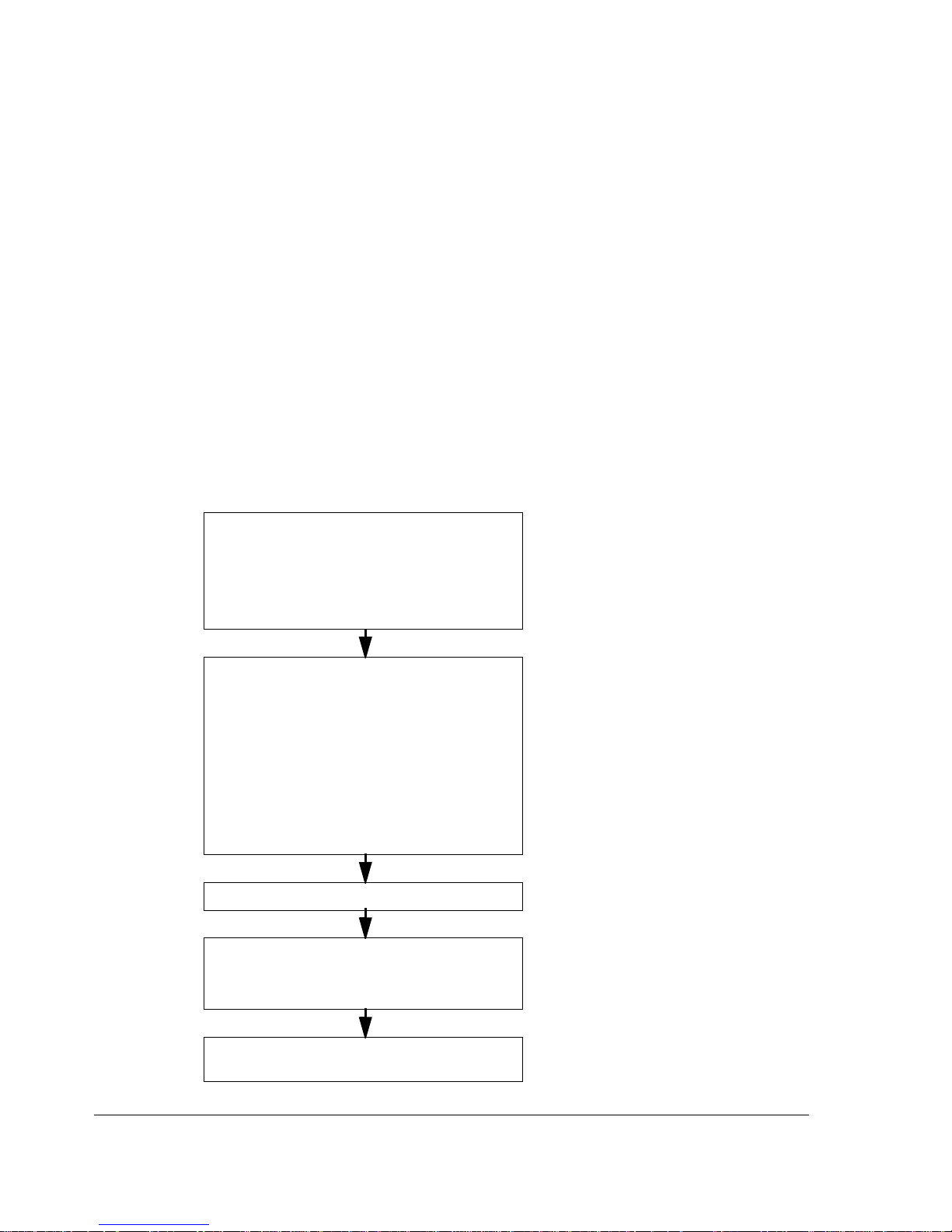

Installation and commissioning flowchart

Task See

Plan the installation.

Check the ambient conditions, ratings, required

cooling air flow, input power connection, compatibility

of the motor, motor connection, and other technical

data.

Select the cables.

Technical data

Planning the electrical installation

Option manuals (if optional equipment is

included)

Unpack and check the units.

Check the type code indicated by the type

designation label with the original order. If the drive is

about to be connected to an IT (ungrounded) system,

check that the drive is not equipped with EMC/RFI

filtering +E202. Check that all necessary optional

modules and equipment are present and correct.

Mechanical installation

Hardware description

For instructions on how to disconnect the EMC/

RFI filtering, contact your local ABB

representative.

If the converter has been non-operational for

more than one year, the converter DC link

capacitors need to be reformed. Contact your

local ABB representative for more information.

Only intact units may be started up.

Check the installation site. Mechanical installation, Technical data

Route the cables. Planning the electrical installation: Routing the

cables

Mount the cabinet line-up. Mechanical installation

Check the insulation of the motor and the motor

cable.

Electrical installation: Checking the insulation of

the assembly

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

About this manual

19

Product and service inquiries

Address any inquiries about the product to your local ABB representative, quoting

the type code and serial number of the unit in question. A listing of ABB sales,

support and service contacts can be found by navigating to ABB website and

selecting Drives – Sales, Support and Service network.

Product training

For information on ABB product training, navigate to ABB website and select

Drives – Training courses.

Providing feedback on ABB Drives manuals

Your comments on our manuals are welcome. Go to ABB website and select

Document Library – Manuals feedback form (LV AC drives).

Connect the power cables. Connect the control and

the auxiliary control cables.

Mechanical installation, Planning the electrical

installation, Electrical installation, Resistor

braking (optional)

Check the installation. Installation checklist and start-up

Commission the drive. Installation checklist and start-up and

appropriate firmware manual

Commission the optional brake chopper (if present). Resistor braking

Task See

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

About this manual

20

Terms and abbreviations

Term/Abbreviation Explanation

APBU Type of optical branching unit used for connecting parallel-

connected converter modules to the RDCU.

DSSB Diode Supply System Board

DSU Diode Supply Unit

Frame (size) Relates to the construction type of the component in question. For

example, several drive types with different power ratings may have

the same basic construction, and this term is used in reference to all

those drive types.

With the ACS800-07 (> 500 kW), the frame size of the drive

indicates the quantity and frame size of the supply modules, plus the

quantity and frame size of the inverter modules, e.g. “2×D4 + 4×R8i”.

To determine the frame size of a drive type, see the rating tables in

the chapter Technical data.

RDCU Drive control unit.

THD Total Harmonic Distortion

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Hardware description

21

Hardware description

What this chapter contains

This chapter describes the construction of the drive in short.

The ACS800-07

The ACS800-07 is a cabinet-mounted drive for controlling AC motors.

Cabinet line-up

The drive consists of several cubicles that contain the supply and motor terminals,

1 to 4 diode supply module(s), 2 to 6 inverter modules, and optional equipment. The

actual arrangement of the cubicles vary from type to type and the selected options.

See the chapter Dimensions for the different line-up variations.

The picture below shows the main components of a frame 1×D4 + 2×R8i drive.

1

3

4

No. Description

1 Supply (input) cable lead-throughs. Top entry optional.

2 Supply module.

3 Input terminals (behind module). Input cables connect here

if a load switch-disconnector cubicle is not present.

4 Chassis socket for quick supply module connection (behind

module).

5 Supply module switch-disconnector. Not present if the drive

is equipped with an optional load switch-disconnector

cubicle.

6 Supply unit control board (DSSB; mounted sideways).

Contains an actual value display and status LEDs.

7 Inverter DC fuses.

8 Inverter modules.

9 Chassis socket for inverter module output connection

(behind each module).

10 Output terminals (behind each module). Motor cables

connect here if a common motor terminal cubicle is not

present.

11 Motor (output) cable lead-throughs. Not used if optional

common motor terminal cubicle is present.

12 Swing-out frame. Contains the drive control unit with I/O

terminals, and provides space for standard and optional

electrical equipment.

13 Auxiliary voltage transformer (accessible by opening the

swing-out frame).

14 Auxiliary voltage switch with fuses.

8

7

9

10

11

12

13

6

11

10

9

2

5

14

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Hardware description

22

The following drawing represents a 2×D4 + 2×R8i drive with optional load switchdisconnector.

No. Description No. Description

1 Supply (input) cable lead-throughs. Top entry optional. 10 Inverter DC fuses.

2 Input busbars. 11 Inverter modules.

3 Load switch-disconnector. 12 Chassis socket for inverter module output connection

(behind each module).

4 Earthing/Grounding switch (optional). 13 Output terminals (behind each module). Motor cables

connect here if a common motor terminal cubicle is not

present.

5 AC fuses. Only present if the drive is equipped with a

load switch-disconnector or air circuit breaker.

14 Motor (output) cable lead-throughs. Not used if optional

common motor terminal cubicle is present.

6 Supply modules. 15 Swing-out frame. Contains the drive control unit with I/O

terminals, and provides space for standard and optional

electrical equipment.

7 Chassis socket for quick supply module connection

(behind each module).

16 Auxiliary voltage transformer (accessible by opening the

swing-out frame).

8 Supply module switch-disconnectors (coupled to an

operating handle on the cabinet door). Not present if the

drive is equipped with a load switch-disconnector or air

circuit breaker.

17 Auxiliary voltage switch.

9 Supply unit control board (DSSB; mounted sideways).

Contains an actual value display and status LEDs.

1

5

10

9

12

15

16

11

3

4

2

6

77

88

12

13 13

14 14

17

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Hardware description

23

Swing-out frame

The swing-out frame inside the control and I/O cubicle provides space for the control

electronics of the drive, I/O terminal blocks, and optional electrical equipment. The

lead-throughs for I/O cables, the auxiliary voltage transformer, and further space for

additional equipment are available behind the frame. The frame can be opened by

removing the two locking screws (arrowed in the picture below) and moving the

swing-out frame aside. (Depending on selected options, actual equipment of the

drive may differ from what is depicted below.)

Mounting rails for

additional equipment

Remove screws (arrowed) to

release swing-out frame

Drive control unit

(RDCU) with I/O

terminal blocks

Space for optional

terminal block X2

Terminal block X1

Auxiliary voltage

transformer

I/O cable entry (into

swing-out frame)

I/O cable entry (into

cabinet)

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Hardware description

24

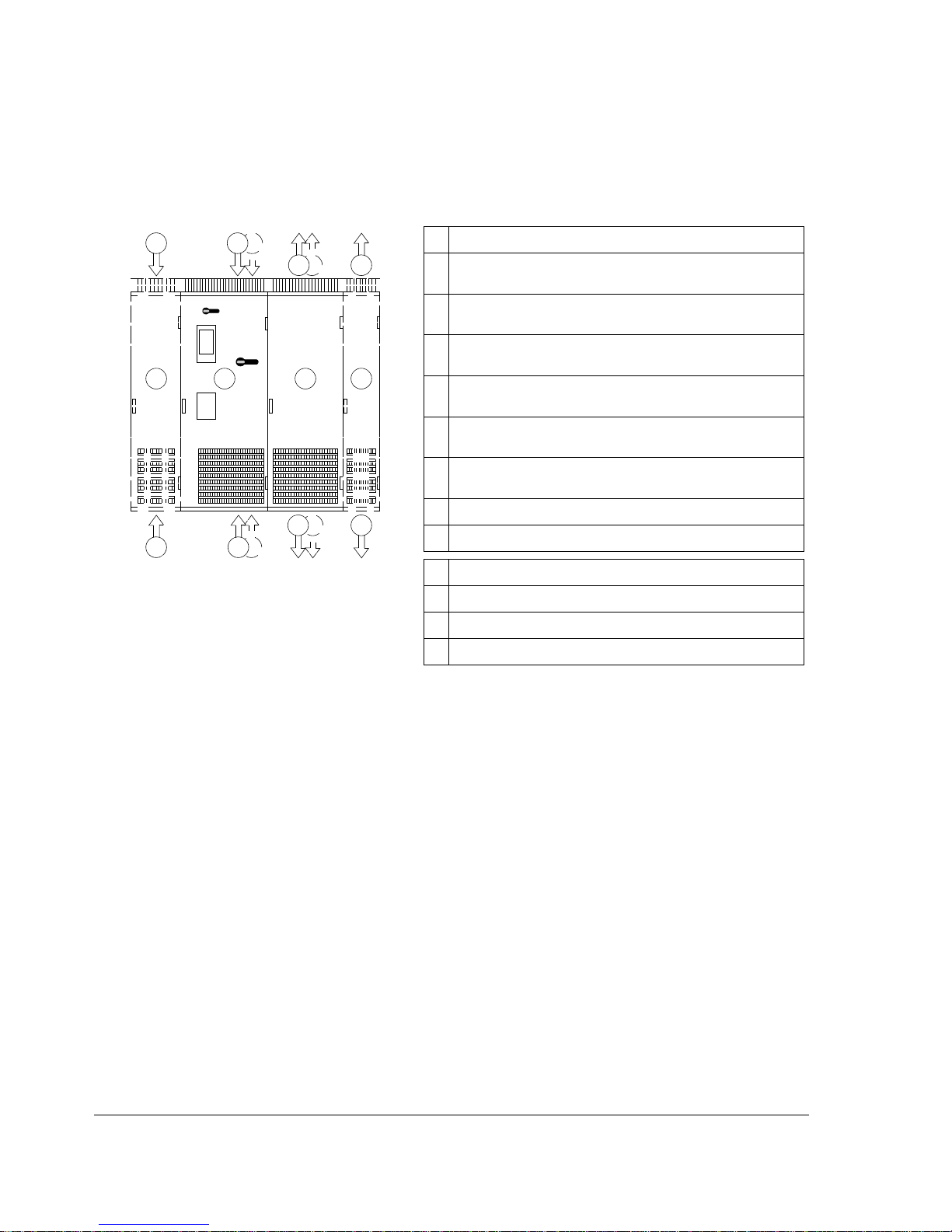

Cabling direction

The drawing below shows the available power cabling directions of the drive. Note

that the desired cabling direction must be specified on ordering.

3

2

A B C D

Description

1 Main supply – Bottom entry at each supply module (without load

switch-disconnector or air breaker)

2 Main supply – Bottom entry with load switch-disconnector or air

circuit breaker

3 Main supply – Top entry at each supply module (without load

switch-disconnector or air circuit breaker) (not for IP54)

4 Main supply – Top entry with load switch-disconnector or air

circuit breaker

5 Motor output – Bottom exit at each inverter module (without

common motor terminal cubicle)

6 Motor output – Top exit at each inverter module (without common

motor terminal cubicle). Added depth: 130 mm

7 Motor output – Bottom exit with common motor terminal cubicle

8 Motor output – Top exit with common motor terminal cubicle

A Load switch-disconnector or air circuit breaker cubicle (optional)

B Control, I/O and supply cubicle

C Inverter unit cubicle

D Common motor terminal cubicle (optional)

11

4 3

55

66

7

8

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: info@clrwtr.com

Loading...

Loading...