ABB ACS880-01 Installation Manual

ABB AC Drives

ACS880-01…+C212 Extension Box,

1 – 60 HP at 230V

1 – 150 HP at 480V

7.5 – 125 HP at 575V

Document No. 3AXD50000043508 Rev. 0

ACS880-01…+C212 Extension Box Installation Quick Guide

The ACS880-01…+C212 Extension Box is an ACS880-01 wall-mounted variable frequency AC drive on a back panel with an electrical box for additional devices. Standard devices include line fuses to protect the drive and a power distribution block. Optional devices includes a line disconnect switch, control power transformer, switches and pilot lights as well as

ACS880-01 options for fieldbus, input/output adapters, special software, etc.

1. Safety in installation and maintenance

Electrical safety

These warnings are intended for all who work on the drive, motor cable or motor.

WARNING! Ignoring the following instructions can cause physical injury or death, or damage to the equipment:

–Only qualified electricians are allowed to install and maintain the drive.

–Never work on the drive, motor cable or motor when main power is applied. After disconnecting the input power, always wait for 5

minutes to let the intermediate circuit capacitors discharge before you start working on the drive, motor or motor cable.

–Always ensure by measuring with a multimeter (impedance at least 1 Mohm) that:

–Voltage between drive input phases L1, L2 and L3 and the frame is close to 0 V

–Voltage between terminals UDC+ and UDCand the frame is close to 0 V.

–Do not work on the control cables when power is applied to the drive or to the external control circuits. Externally supplied control circuits may cause dangerous voltages inside the drive even when the main power on the drive is switched off.

–Do not make any insulation or voltage withstand tests on the drive.

–Do not connect the drive to a voltage higher than what is marked on the type designation label. Higher voltage can activate the brake chopper and lead to brake resistor overload, or activate the overvolt-

age controller what can lead to motor rushing to maximum speed.

Note:

–The motor cable terminals on the drive are at a dangerously high voltage when the input power is on, regardless of whether the motor is running or not.

–The DC terminals (UDC+, UDC-) carry a dangerous DC voltage (over 500 V) when internally connected to the intermediate DC circuit.

–Depending on the external wiring, dangerous voltages (115 V, 220 V or 230 V) may be present on the terminals of relay outputs (XRO1, XRO2 and XRO3).

–The Safe torque off function does not remove the voltage from the main and auxiliary circuits. The function is ineffective against deliberate sabotage or misuse.

IMPORTANT: Other Safety Information

Before handling the equipment or connecting voltage to the drive, see ACS880 Hardware Manual (3AUA0000078093) Chapter 1 Safety instructions for additional information on grounding, lifting, starting up and operating the equipment.

This guide instructs briefly how to install the drive. For more detailed instructions, engineering guide lines, technical data and complete safety instructions, see the ACS880 Hardware Manual in the accompanying CD or available here: www.abb.com/drives: Select Document Library and search for document number 3AUA0000078093 [English].

2. List of related manuals

Drive hardware manuals and guides |

Code (English) |

ACS880-01 hardware manual |

3AUA0000078093 |

ACS880-01 quick installation guide for frames R1 to R3 |

3AUA0000085966 |

ACS880-01 quick installation guide for frames R4 and R5 |

3AUA0000099663 |

ACS880-01 quick installation guide for frames R6 to R9 |

3AUA0000099689 |

ACS880-01 drives for cabinet installation (option +P940, |

|

+P944) supplement |

3AUA0000145446 |

ACS880-01 assembly drawings for cable entry boxes of |

|

P21 frames R5 to R9 |

3AUA0000119627 |

ACS-AP-x assistant control panels user’s manual |

3AUA0000085685 |

Vibration dampers for ACS880-01 drives (frames R4, R5, |

|

option +C131) installation |

3AXD50000010497 |

Vibration dampers for ACS880-01 drives (frames R6, R9, |

|

option +C131) installation |

3AXD50000013389 |

ACS880-01 marine type-approved drives (option +C132) |

|

supplement |

3AXD50000010521 |

Drive firmware manuals and guides |

|

ACS880 standard control program firmware manual |

3AUA0000085967 |

Quick start-up guide for ACS880 drives with primary |

|

control program |

3AUA0000098062 |

Option manuals and guides |

|

FDIO-01 digital I/O extension module user’s manual EN |

3AUA0000124966 |

Other manuals and quick guides for I/O extension modules, |

|

fieldbus adapters, etc. |

Multiple |

You can find manuals and other product documents in PDF format on the Internet. See section manuals not available in the Document library, contact your local ABB representative

The QR code below opens an online listing of the manuals applicable to this product.

ACS880-01 manuals

3. Packing List

The following items are included in the box:

1.ACS880 Extension Box drive unit (See ratings chart for size and variants)

2.ACS880 Extension Box Quick Guide (this document)

3.ACS880 Quick Start Guide

4.ACS880 Manuals on CD

5.ACS880 Extension Box schematic diagram and layout drawing

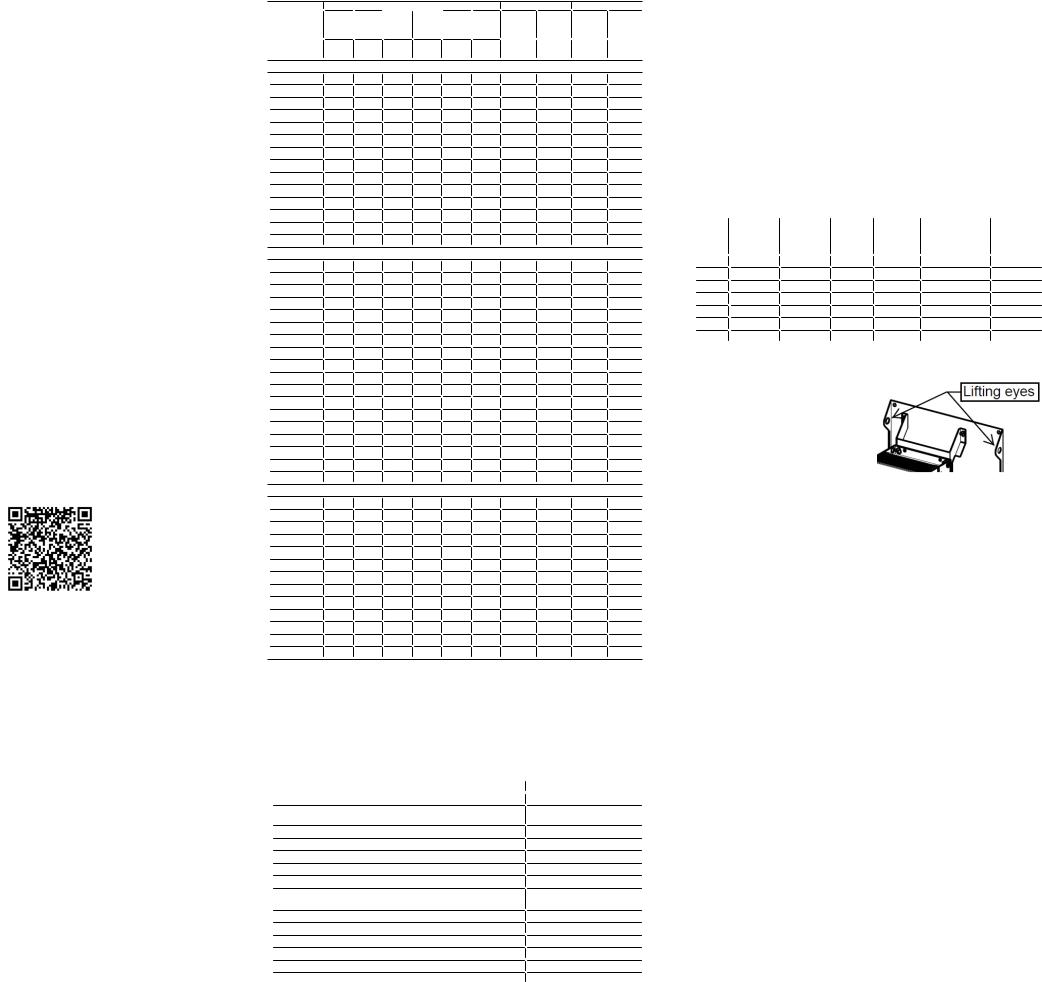

4. Drive Ratings Table and Plus Code Variants

Type code |

|

|

Nominal ratings |

|

UL Type 1 |

UL Type 12 |

||||

|

|

Light duty |

|

Heavy duty |

|

Frame |

Weight |

Frame |

Weight |

|

|

(110% overload for |

(150% overload for |

||||||||

|

size |

(lb) |

size |

(lb) |

||||||

|

|

1 min) |

|

|

1 min) |

|

||||

|

|

|

|

|

|

|

|

|

||

ACS880-01- |

ILd |

PLd |

PLd |

I2Hd |

PHd |

PHd |

|

|

+B055 |

+B005 |

|

A |

HP |

kW |

A |

HP |

kW |

|

|

|

|

240 VAC (range 208 to 240 VAC); Power ratings are valid at nominal voltage 230 VAC, 60 Hz |

|

|||||||||

04A6-2+C212 |

4.4 |

1 |

0.75 |

3.7 |

0.75 |

0.55 |

F2-R1 |

57 |

F12-R1 |

88 |

06A6-2+C212 |

6.3 |

1.5 |

1.1 |

4.6 |

1 |

0.75 |

F2-R1 |

57 |

F12-R1 |

88 |

07A5-2+C212 |

7.1 |

2 |

1.5 |

6.6 |

1.5 |

1.1 |

F2-R1 |

57 |

F12-R1 |

88 |

10A6-2+C212 |

10.1 |

3 |

2.2 |

7.5 |

2 |

1.5 |

F2-R1 |

57 |

F12-R1 |

88 |

16A8-2+C212 |

16 |

5 |

4 |

10.6 |

3 |

3 |

F2-R2 |

62 |

F12-R2 |

93 |

24A3-2+C212 |

23.1 |

7.5 |

5.5 |

16.8 |

5 |

4 |

F3-R2 |

54 |

F12-R2 |

93 |

031A-2+C212 |

29.3 |

10 |

7.5 |

24.3 |

7.5 |

5.5 |

F3-R3 |

58 |

F12-R3 |

97 |

046A-2+C212 |

44 |

15 |

11 |

38 |

10 |

7.5 |

F4-R4 |

82 |

F12-R4 |

116 |

061A-2+C212 |

58 |

20 |

15 |

45 |

15 |

11 |

F4-R4 |

84 |

F12-R4 |

116 |

075A-2+C212 |

71 |

25 |

18.5 |

61 |

20 |

15 |

F5-R5 |

118 |

--- |

--- |

087A-2+C212 |

83 |

30 |

22 |

72 |

25 |

18.5 |

F5-R5 |

118 |

--- |

--- |

115A-2+C212 |

109 |

40 |

30 |

87 |

30 |

22 |

F5-R6 |

166 |

--- |

--- |

145A-2+C212 |

138 |

50 |

37 |

105 |

40 |

30 |

F5-R6 |

166 |

--- |

--- |

170A-2+C212 |

162 |

60 |

45 |

145 |

50 |

37 |

F6-R7 |

210 |

--- |

--- |

500 VAC (range 380 to 500 VAC); Power ratings are valid at nominal voltage 460 VAC, 60 Hz |

|

|||||||||

02A1-5+C212 |

2.1 |

1 |

0.75 |

1.7 |

0.75 |

0.55 |

F2-R1 |

57 |

F12-R1 |

88 |

03A0-5+C212 |

3 |

1.5 |

1.1 |

2.1 |

1 |

0.75 |

F2-R1 |

57 |

F12-R1 |

88 |

03A4-5+C212 |

3.4 |

2 |

1.5 |

3 |

1.5 |

1.1 |

F2-R1 |

57 |

F12-R1 |

88 |

04A8-5+C212 |

4.8 |

3 |

2.2 |

3.4 |

2 |

1.5 |

F2-R1 |

57 |

F12-R1 |

88 |

07A6-5+C212 |

7.6 |

5 |

4 |

5.2 |

3 |

3 |

F2-R1 |

57 |

F12-R1 |

88 |

11A0-5+C212 |

11 |

7.5 |

5.5 |

7.6 |

5 |

4 |

F2-R1 |

57 |

F12-R1 |

88 |

014A-5+C212 |

14 |

10 |

7.5 |

11 |

7.5 |

5.5 |

F2-R2 |

62 |

F12-R2 |

93 |

021A-5+C212 |

21 |

15 |

11 |

14 |

10 |

7.5 |

F3-R2 |

54 |

F12-R2 |

93 |

027A-5+C212 |

27 |

20 |

15 |

21 |

15 |

11 |

F3-R3 |

58 |

F12-R3 |

97 |

034A-5+C212 |

34 |

25 |

18.5 |

27 |

20 |

15 |

F3-R3 |

58 |

F12-R3 |

97 |

040A-5+C212 |

40 |

30 |

22 |

34 |

25 |

18.5 |

F4-R4 |

84 |

F12-R4 |

116 |

052A-5+C212 |

52 |

40 |

30 |

40 |

30 |

22 |

F4-R4 |

84 |

F12-R4 |

116 |

065A-5+C212 |

65 |

50 |

37 |

52 |

40 |

30 |

F5-R5 |

118 |

--- |

--- |

077A-5+C212 |

77 |

60 |

45 |

65 |

50 |

37 |

F5-R5 |

118 |

--- |

--- |

096A-5+C212 |

96 |

75 |

55 |

77 |

60 |

45 |

F5-R6 |

166 |

--- |

--- |

124A-5+C212 |

124 |

100 |

75 |

96 |

75 |

55 |

F6-R6 |

188 |

--- |

--- |

156A-5+C212 |

156 |

125 |

90 |

124 |

100 |

75 |

F6-R7 |

210 |

--- |

--- |

180A-5+C212 |

180 |

150 |

110 |

156 |

125 |

90 |

F6-R7 |

210 |

--- |

--- |

600 VAC (range 525 to 690 VAC); Power ratings are valid at nominal voltage 575 VAC, 60 Hz |

|

|||||||||

07A3-7+C212 |

9 |

7.5 |

5.5 |

6.1 |

5 |

4 |

F5-R5 |

118 |

--- |

--- |

09A8-7+C212 |

11 |

10 |

7.5 |

9 |

7.5 |

5.5 |

F5-R5 |

118 |

--- |

--- |

14A2-7+C212 |

17 |

15 |

11 |

11 |

10 |

7.5 |

F5-R5 |

118 |

--- |

--- |

018A-7+C212 |

22 |

20 |

15 |

17 |

15 |

11 |

F5-R5 |

118 |

--- |

--- |

022A-7+C212 |

27 |

25 |

18.5 |

22 |

20 |

15 |

F5-R5 |

118 |

--- |

--- |

026A-7+C212 |

32 |

30 |

22 |

27 |

25 |

18.5 |

F5-R5 |

118 |

--- |

--- |

035A-7+C212 |

41 |

40 |

30 |

32 |

30 |

22 |

F5-R5 |

118 |

--- |

--- |

042A-7+C212 |

52 |

50 |

37 |

41 |

40 |

30 |

F5-R5 |

118 |

--- |

--- |

049A-7+C212 |

52 |

50 |

37 |

41 |

40 |

30 |

F5-R5 |

118 |

--- |

--- |

061A-7+C212 |

62 |

60 |

45 |

52 |

50 |

37 |

F5-R6 |

166 |

--- |

--- |

084A-7+C212 |

77 |

75 |

55 |

62 |

60 |

45 |

F5-R6 |

166 |

--- |

--- |

098A-7+C212 |

99 |

100 |

75 |

77 |

75 |

55 |

F6-R7 |

210 |

--- |

--- |

119A-7+C212 |

125 |

125 |

90 |

99 |

100 |

75 |

F6-R7 |

210 |

--- |

--- |

Notes:

Ratings apply at an ambient temperature of 40°C (104°F) unless otherwise noted.

To achieve the rated motor power given in the table, the rated current of the drive must be higher than or equal to the rated motor current.

Definitions: |

|

||

ILD |

Continuous rms output current allowing 110% overload for 1 minute every 5 minutes. |

||

PLD |

Typical motor power in light-overload use. |

|

|

IHD |

Continuous rms output current allowing 150% overload for 1 minute every 5 minutes. |

||

PHD |

Typical motor power in heavy-duty use. |

|

|

|

|

|

|

|

Variant |

Plus Code |

|

UL Type 12 (IP54) |

B055 |

||

Back panel and electrical box below the drive with line fuses and power |

C212 |

||

distribution block |

|||

|

|||

Drive output (dV/dt) filter (10 hp max) |

E205 |

||

Input disconnect switch and handle (replaces power distribution block) |

F253 |

||

Hand-off-auto (HOA) switch |

G302 |

||

Speed potentiometer |

G303 |

||

Control power transformer (CPT) |

G304 |

||

CPT and digital I/O extension; provides 115 VAC digital inputs and |

G304+L526 |

||

outputs. Field wiring required. |

|||

|

|||

Ready pilot light, white |

G327 |

||

Run pilot light, green |

G328 |

||

Fault pilot light, red |

G329 |

||

Emergency stop push button |

G331 |

||

Start/ Stop push buttons |

G401 |

||

Fault reset push button |

G404 |

||

|

|

|

|

5.Installation

1.Unpacking the unit

Detach the protective wrapping from the shipping pallet. Remove the unit by unscrewing the four bolts.

2.Mounting:

a.See Technical Specifications section for environmental conditions.

b.The unit must be installed in an upright position with the back panel against a wall.

c.The mounting wall must be vertical, non-flammable and strong enough to hold the weight of the unit. The material below and above the unit should be non-flammable.

d.Unit has four (4) mounting holes. (Frame F3 has five (5).) The recommended method is to mount the units on horizontal strut channel. The table below shows mounting dimensions.

Frame |

Horizontal |

Vertical |

Overall |

Overall |

Depth without |

Depth with |

|

Distance |

Distance |

Width |

Height |

Disconnect |

Disconnect |

|

between |

between |

|

|

Switch |

Switch |

|

Holes |

Holes** |

|

|

|

|

|

(in) |

(in) |

(in) |

(in) |

(in) |

(in) |

F2 |

11-1/4 |

29-3/8 |

12-3/4 |

30-1/4 |

10-1/8 |

12 |

F3* |

12-1/2 |

29-1/8 |

14 |

30 |

10-1/8 |

12 |

F4 |

12-1/2 |

32-1/8 |

14 |

33 |

12-3/8 |

13 |

F5 |

18-1/2 |

43-1/8 |

20 |

44 |

14-1/4 |

15-3/8 |

F6 |

18-1/2 |

47-3/8 |

20 |

48-1/4 |

17-3/8 |

18-1/2 |

F12 |

14-1/2 |

50 |

16 |

51 |

12-1/2 to 13-1/2 |

14-5/8 |

Recommended hardware: Four (4) bolts, 3/8 in. (10mm) diameter * F3 has 3rd hole at top center

**Slots at bottom

3.Lifting

Lift the unit into place. See ratings table for weight. Lifting equipment may be required. Use the back panel lifting eyes which are on units F5 and above. Do NOT use the base drive lifting eyes which are not rated

for the additional weight of the back panel.

4.Minimum Clearance

a. Above unit: |

8 inches (area becomes hot!) |

b. Below unit: |

12 inches |

c. Left side: |

0 inches |

d. Right side: |

2 inches to allow for door swing |

e.Between units: 2 inches to allow for door swing

5.Additional Clearance

a.Air flows from bottom to top. Allow enough free space above and below the drive for cooling air flow, service and maintenance.

b.Allow enough free space in front of the drive for operation, service and maintenance.

6.Cable entry and exit connections

a.The unit is designed for connection to the top and/or the bottom of the box for both the motor and the line connections. Conduit knockouts are provided for this purpose. There are four (4) knocks on the top and four (4) on the bottom.

b.Knockout Dimensions:

F2 – F5: Suitable for (QTY 2) ½” conduit and (QTY 2) ¾” conduit F6: Suitable for (QTY 2) ½” conduit and (QTY 2) 1” conduit F12: Suitable for (QTY 2) ½” conduit and (QTY 2) ¾” conduit

Loading...

Loading...