ABB DCS800 Firmware Manual

DCS800

Firmware manual

DCS800 Drives (20 to 5200 A)

DCS800 Drive Manuals

All the documents available for the drive system DCS800 are listed below:

|

|

|

Language |

|

|

|

|

|

|

|

|

|

Public. number |

E |

D |

I |

ES |

F |

CN |

RU |

PL |

DCS800 Quick Guide |

|

3ADW000191 |

x |

x |

x |

x |

x |

|

|

|

DCS800 Tools & Documentation CD |

3ADW000211 |

x |

|

|

|

|

|

|

|

|

DCS800 Converter module |

|

|

|

|

|

|

|

|

|

|

Flyer DCS800 |

|

3ADW000190 |

x |

x |

|

x |

x |

|

|

|

Technical Catalogue DCS800 |

3ADW000192 |

x |

x |

x |

x |

x |

x |

x |

|

|

Hardware Manual DCS800 |

3ADW000194 |

x |

x |

x |

x |

x |

x |

x |

x |

|

Hardware Manual DCS800 update DCF503B/DCF504B |

3ADW000194Z0301 |

x |

|

|

|

|

|

|

|

|

Firmware Manual DCS800 |

3ADW000193 |

x |

x |

p |

x |

x |

x |

x |

x |

|

Installation according to EMC |

3ADW000032 |

x |

|

|

|

|

|

|

|

|

Technical Guide |

|

3ADW000163 |

x |

|

|

|

|

|

|

|

Service Manual DCS800 |

3ADW000195 |

x |

x |

|

|

|

|

|

|

|

12-Pulse Manual |

|

3ADW000196 |

x |

|

|

|

|

|

|

|

CMA-2 Board |

|

3ADW000136 |

p |

|

|

|

|

|

|

|

Flyer Hard - Parallel |

|

3ADW000213 |

x |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Drive Tools |

|

|

|

|

|

|

|

|

|

|

DriveWindow 2.x - User's Manual |

3BFE64560981 |

x |

|

|

|

|

|

|

|

|

DriveOPC 2.x - User's Manual |

3BFE00073846 |

x |

|

|

|

|

|

|

|

|

Optical DDCS Communication Link |

3AFE63988235 |

x |

|

|

|

|

|

|

|

|

DDCS Branching Units - User’s Manual |

3BFE64285513 |

x |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DCS800 Applications |

|

|

|

|

|

|

|

|

|

|

PLC Programming with CoDeSys |

CoDeSys_V23 |

x |

x |

|

|

x |

|

|

|

|

61131 DCS800 target +tool description - Application Program |

3ADW000199 |

x |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DCS800 Crane Drive |

|

|

|

|

|

|

|

|

|

|

DCS800 Crane Drive Manual suppl. |

3AST004143 |

x |

|

|

|

|

|

|

|

|

DCS800 Crane Drive Product note |

PDC5 EN REVA |

p |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DCS800 Winder ITC |

|

|

|

|

|

|

|

|

|

|

DCS800 Winder Product note |

PDC2 EN |

x |

|

|

|

|

|

|

|

|

DCS800 Winder description ITC |

3ADW000308 |

x |

|

|

|

|

|

|

|

|

Winder Questionnaire |

|

3ADW000253z |

x |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DCS800-E Panel Solution |

|

|

|

|

|

|

|

|

|

|

Flyer DCS800-E Panel solution |

3ADW000210 |

x |

|

|

|

|

|

|

|

|

Hardware Manual DCS800-E |

3ADW000224 |

x |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DCS800-A Enclosed Converters |

|

|

|

|

|

|

|

|

|

|

Flyer DCS800-A |

|

3ADW000213 |

x |

|

|

|

|

|

|

|

Technical Catalogue DCS800-A |

3ADW000198 |

x |

|

|

|

|

|

|

|

|

Installation of DCS800-A |

3ADW000091 |

x |

x |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DCS800-R Rebuild System |

|

|

|

|

|

|

|

|

|

|

Flyer DCS800-R |

|

3ADW000007 |

x |

x |

|

|

|

|

|

|

DCS800-R Manual |

|

3ADW000197 |

x |

|

|

|

|

|

|

|

DCS500/DCS600 Size A5...A7, C2b, C3 and C4 Upgrade Kits |

3ADW000256 |

x |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Extension Modules |

|

|

|

|

|

|

|

|

|

|

RAIO-01 Analog IO Extension |

3AFE64484567 |

x |

|

|

|

|

|

|

|

|

RDIO-01 Digital IO Extension |

3AFE64485733 |

x |

|

|

|

|

|

|

|

|

RRIA-01 Resolver Interface Module |

3AFE68570760 |

x |

|

|

|

|

|

|

|

|

RTAC-01 Pulse Encoder Interface |

3AFE64486853 |

x |

|

|

|

|

|

|

|

|

RTAC-03 TTL Pulse Encoder Interface |

3AFE68650500 |

x |

|

|

|

|

|

|

|

|

AIMA R-slot extension |

|

3AFE64661442 |

x |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Serial Communication |

|

|

|

|

|

|

|

|

|

|

Drive specific serial communication |

|

|

|

|

|

|

|

|

|

|

NETA Remote diagnostic interface |

3AFE64605062 |

x |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fieldbus Adapter with DC Drives RPBA- (PROFIBUS) |

3AFE64504215 |

x |

|

|

|

|

|

|

|

|

Fieldbus Adapter with DC Drives RCAN-02 (CANopen) |

|

|

|

|

|

|

|

|

|

|

Fieldbus Adapter with DC Drives RCNA-01 (ControlNet) |

3AFE64506005 |

x |

|

|

|

|

|

|

|

|

Fieldbus Adapter with DC Drives RDNA- (DeviceNet) |

3AFE64504223 |

x |

|

|

|

|

|

|

|

|

Fieldbus Adapter with DC Drives RMBA (MODBUS) |

3AFE64498851 |

x |

|

|

|

|

|

|

|

|

Fieldbus Adapter with DC Drives RETA (Ethernet) |

3AFE64539736 |

x |

|

|

|

|

|

|

|

|

x -> existing |

p -> planned |

|

|

|

|

|

|

|

|

|

Status 04.2010 |

|

|

|

|

|

|

|

|

|

|

DCS800 Drive Manuals-List_j.doc

3

Safety instructions

What this chapter contains

This chapter contains the safety instructions you must follow when installing, operating and servicing the drive. If ignored, physical injury or death may follow, or damage may occur to the drive, the motor or driven equipment. Read the safety instructions before you work on the unit.

To which products this chapter applies

The information is valid for the whole range of the product DCS800, the converter modules DCS800-S0x size D1 to D7, field exciter units DCF80x, etc. like the Rebuild Kit DCS800-R00-9xxx.

Usage of warnings and notes

There are two types of safety instructions throughout this manual: warnings and notes. Warnings caution you about conditions which can result in serious injury or death and/or damage to the equipment, and advise on how to avoid the danger. Notes draw attention to a particular condition or fact, or give information on a subject. The warning symbols are used as follows:

Dangerous voltage warning warns of high voltage which can cause physical injury or death and/or damage to the equipment.

General danger warning warns about conditions, other than those caused by electricity, which can result in physical injury or death and/or damage to the equipment.

Electrostatic sensitive devices warning warns of electrostatic discharge which can damage the equipment.

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

4

Installation and maintenance work

These warnings are intended for all who work on the drive, motor cable or motor. Ignoring the instructions can cause physical injury or death and/or damage to the equipment.

WARNING!

•Only qualified electricians are allowed to install and maintain the drive!

•Never work on the drive, motor cable or motor when main power is applied.

Always ensure by measuring with a multimeter (impedance at least 1 Mohm) that:

1.Voltage between drive input phases U1, V1 and W1 and the frame is close to 0 V.

2.Voltage between terminals C+ and D- and the frame is close to 0 V.

•Do not work on the control cables when power is applied to the drive or to the external control circuits. Externally supplied control circuits may cause dangerous voltages inside the drive even when the main power on the drive is switched off.

•Do not make any insulation resistance or voltage withstand tests on the drive or drive modules.

•Isolate the motor cables from the drive when testing the insulation resistance or voltage withstand of the cables or the motor.

•When reconnecting the motor cable, always check that the C+ and D- cables are connected with the proper terminal.

Note:

•The motor cable terminals on the drive are at a dangerously high voltage when the main power is on, regardless of whether the motor is running or not.

•Depending on the external wiring, dangerous voltages (115 V, 220 V or 230 V) may be present on the relay outputs of the drive system (e.g. SDCS-IOB-2 and RDIO).

•DCS800 with enclosure extension: Before working on the drive, isolate the whole drive system from the supply.

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

5

Grounding

These instructions are intended for all who are responsible for the grounding of the drive. Incorrect grounding can cause physical injury, death and/or equipment malfunction and increase electromagnetic interference.

WARNING!

•Ground the drive, motor and adjoining equipment to ensure personnel safety in all circumstances, and to reduce electromagnetic emission and pick-up.

•Make sure that grounding conductors are adequately sized and marked as required by safety regulations.

•In a multiple-drive installation, connect each drive separately to protective earth (PE

).

).

•Minimize EMC emission and make a 360° high frequency grounding (e.g. conductive sleeves) of screened cable entries at the cabinet lead-through plate.

•Do not install a drive equipped with an EMC filter to an ungrounded power system or a high resistance-grounded (over 30 ohms) power system.

Note:

•Power cable shields are suitable as equipment grounding conductors only when adequately sized to meet safety regulations.

•As the normal leakage current of the drive is higher than 3.5 mA AC or 10 mA DC (stated by EN 50178, 5.2.11.1), a fixed protective earth connection is required.

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

6

Printed circuit boards and fiber optic cables

These instructions are intended for all who handle the circuit boards and fiber optic cables. Ignoring the following instructions can cause damage to the equipment.

WARNING! The printed circuit boards contain components sensitive to electrostatic discharge. Wear a grounding wrist band when handling the boards. Do not touch the boards unnecessarily.

Use grounding strip:

ABB order no.: 3ADV050035P0001

WARNING! Handle the fiber optic cables with care. When unplugging optic cables, always grab the connector, not the cable itself. Do not touch the ends of the fibers with bare hands as the fiber is extremely sensitive to dirt. The minimum allowed bend radius is 35 mm (1.38 in.).

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

7

Mechanical installation

These notes are intended for all who install the drive. Handle the unit carefully to avoid damage and injury.

WARNING!

•DCS800 sizes D4 ... D7: The drive is heavy. Do not lift it alone. Do not lift the unit by the front cover. Place units D4 and D5 only on its back.

DCS800 sizes D5 ... D7: The drive is heavy. Lift the drive by the lifting lugs only. Do not tilt the unit. The unit will overturn from a tilt of about 6 degrees.

•Make sure that dust from drilling does not enter the drive when installing. Electrically conductive dust inside the unit may cause damage or lead to malfunction.

•Ensure sufficient cooling.

•Do not fasten the drive by riveting or welding.

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

8

Operation

These warnings are intended for all who plan the operation of the drive or operate the drive. Ignoring the instructions can cause physical injury or death and/or damage to the equipment.

WARNING!

•Before adjusting the drive and putting it into service, make sure that the motor and all driven equipment are suitable for operation throughout the speed range provided by the drive. The drive can be adjusted to operate the motor at speeds above and below the base speed.

•Do not control the motor with the disconnecting device

(disconnecting mains); instead, use the control panel keys  and

and  , or commands via the I/O board of the drive.

, or commands via the I/O board of the drive.

•Mains connection

You can use a disconnect switch (with fuses) to disconnect the electrical components of the drive from the mains for installation and maintenance work. The type of disconnect switch used must be as per EN 60947-3, Class B, so as to comply with EU regulations, or a circuit-breaker type which switches off the load circuit by means of an auxiliary contact causing the breaker's main contacts to open. The mains disconnect must be locked in its "OPEN" position during any installation and maintenance work.

•EMERGENCY STOP buttons must be installed at each control desk and at all other control panels requiring an emergency stop function. Pressing the STOP button on the control panel of the drive will neither cause an emergency stop of the motor, nor will the drive be disconnected from any dangerous potential.

To avoid unintentional operating states, or to shut the unit down in case of any imminent danger according to the standards in the safety instructions it is not sufficient to merely shut down the drive via signals "RUN", "drive OFF" or "Emergency Stop" respectively "control panel" or "PC tool".

•Intended use

The operating instructions cannot take into consideration every possible case of configuration, operation or maintenance. Thus, they mainly give such advice only, which is required by qualified personnel for normal operation of the machines and devices in industrial installations.

If in special cases the electrical machines and devices are intended for use in non-industrial installations - which may require stricter safety regulations (e.g. protection against contact by children or similar) - these additional safety measures for the installation must be provided by the customer during assembly.

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

9

Note:

•When the control location is not set to Local (L not shown in the status row of the display), the stop key on the control panel will not

stop the drive. To stop the drive using the control panel, press the LOC/REM key and then the stop key  .

.

Safety instructions

3ADW000193R0701 DCS800 Firmware Manual e g

10

Table of contents

Safety instructions |

3 |

What this chapter contains ......................................................................................................... |

3 |

To which products this chapter applies ...................................................................................... |

3 |

Usage of warnings and notes..................................................................................................... |

3 |

Installation and maintenance work ............................................................................................. |

4 |

Grounding ....................................................................................................................... |

5 |

Mechanical installation ............................................................................................................... |

7 |

Operation ................................................................................................................................... |

8 |

Table of contents |

10 |

Introduction |

23 |

Chapter overview.......................................................................................................... |

23 |

Before You Start ........................................................................................................... |

23 |

What this manual contains ........................................................................................... |

23 |

Start-up |

24 |

Chapter overview.......................................................................................................... |

24 |

General ......................................................................................................................... |

24 |

Start-up procedure ................................................................................................................... |

25 |

Tools ............................................................................................................................. |

25 |

Checking with the power switched off .......................................................................... |

25 |

Checking with the power switched on .......................................................................... |

27 |

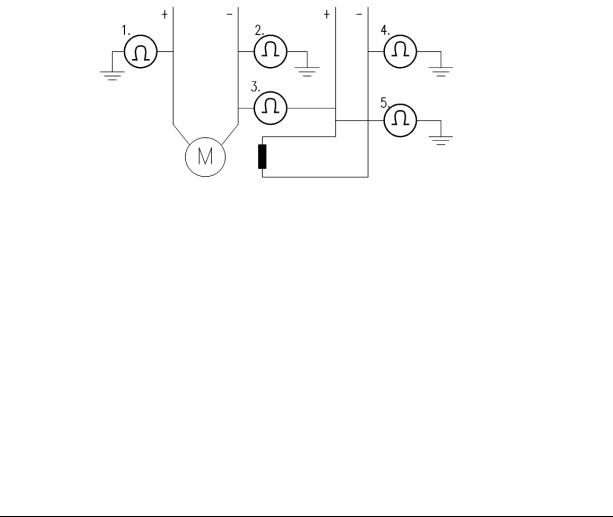

Commissioning a DCS800 ....................................................................................................... |

28 |

Connect DCS800 to PC with DriveWindow Light ..................................................................... |

28 |

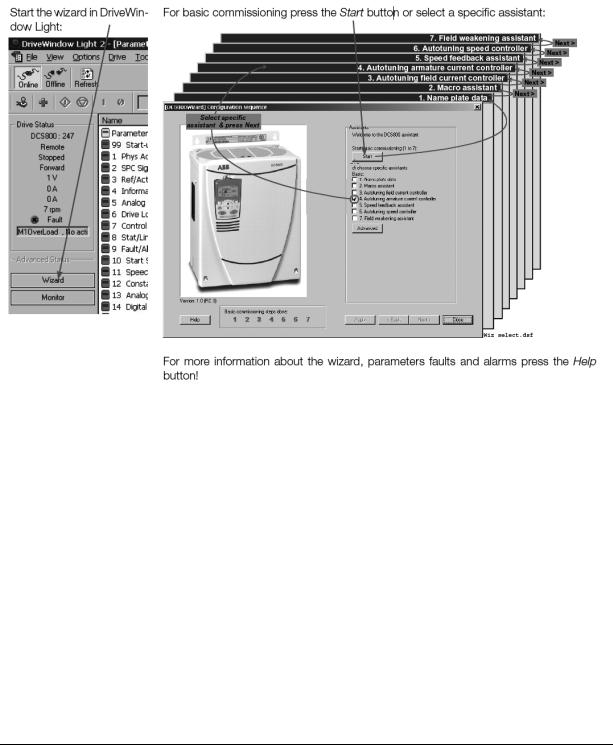

Commissioning a DCS800 with the wizard .............................................................................. |

29 |

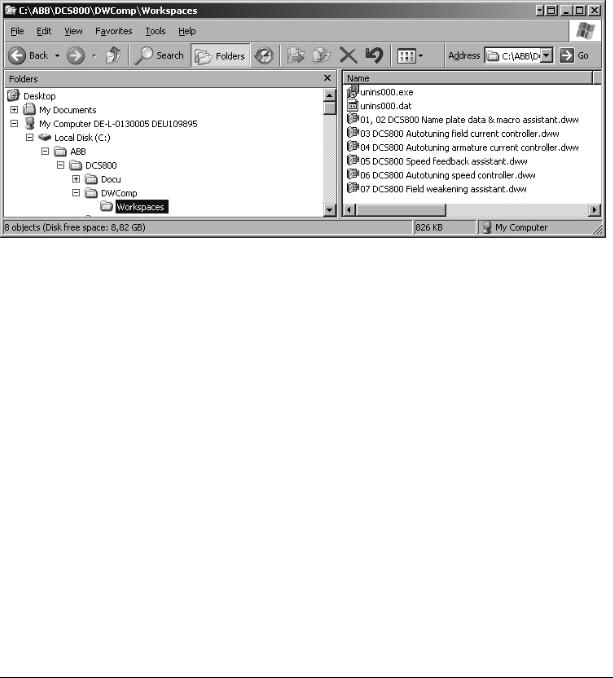

Commissioning a DCS800 with DriveWindow.......................................................................... |

30 |

Requirements ............................................................................................................... |

30 |

01, 02 Macro assistant / Name plate data .................................................................... |

30 |

03 Autotuning field current controller ............................................................................ |

31 |

04 Autotuning armature current controller .................................................................... |

31 |

05 Speed feedback assistant ....................................................................................... |

32 |

Analog tacho fine tune procedure ................................................................ |

32 |

06 Autotuning speed controller ..................................................................................... |

32 |

07 Field weakening assistant ....................................................................................... |

33 |

Manual tuning........................................................................................................................... |

34 |

I/O configuration ........................................................................................................... |

34 |

Field current controller .................................................................................................. |

34 |

Armature current controller ........................................................................................... |

35 |

Control principle ........................................................................................... |

35 |

Manual tuning ............................................................................................... |

36 |

Analog tacho................................................................................................................. |

41 |

Manual tuning ............................................................................................... |

42 |

Speed controller ........................................................................................................... |

42 |

Basics........................................................................................................... |

42 |

Manual tuning ............................................................................................... |

43 |

EMF controller .............................................................................................................. |

45 |

|

|

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

|

11 |

Basics............................................................................................................ |

45 |

Manual tuning................................................................................................ |

45 |

Flux linearization............................................................................................................ |

47 |

Basics............................................................................................................ |

47 |

Manual tuning................................................................................................ |

48 |

Thyristor diagnosis ........................................................................................................ |

50 |

Basics............................................................................................................ |

50 |

Check all thyristors ........................................................................................ |

50 |

Check individual firing pulses ........................................................................ |

50 |

Firmware description |

52 |

Chapter overview........................................................................................................... |

52 |

Identification of the firmware versions ........................................................................... |

52 |

Start / stop sequences .............................................................................................................. |

53 |

General.......................................................................................................................... |

53 |

Switch on sequence ...................................................................................................... |

53 |

Start the drive ................................................................................................................ |

54 |

Stop the drive ................................................................................................................ |

55 |

Field excitation .......................................................................................................................... |

58 |

General.......................................................................................................................... |

58 |

Field Reversal................................................................................................................ |

58 |

Field control................................................................................................... |

58 |

Field reference hysteresis ............................................................................. |

59 |

Force field current direction........................................................................... |

59 |

Reversal time ................................................................................................ |

59 |

Bumpless transition ....................................................................................... |

59 |

Optitorque...................................................................................................................... |

59 |

Field current reference gain .......................................................................... |

59 |

Field current monitoring................................................................................................. |

60 |

Field minimum trip ......................................................................................... |

60 |

Flux reversal.................................................................................................. |

60 |

Field reversal hysteresis................................................................................ |

60 |

Field reversal active ...................................................................................... |

60 |

Field Heating ................................................................................................................. |

60 |

Overview ....................................................................................................... |

60 |

Modes of operation........................................................................................ |

61 |

E-stop ............................................................................................................ |

62 |

Field exciter mode..................................................................................................................... |

63 |

General.......................................................................................................................... |

63 |

Large field exciter controlled by a DCS800 armature converter.................................... |

63 |

Parameters to be set in the DCS800 armature converter: ............................ |

64 |

Parameters to be set in large field exciters: .................................................. |

64 |

Field current autotuning for large field exciters: ............................................ |

65 |

Stand alone field exciter ................................................................................................ |

66 |

Parameters to be set in the stand alone field exciter: ................................... |

66 |

Field current autotuning for stand alone field exciter:.................................... |

67 |

DC-breaker, DC-contactor ........................................................................................................ |

68 |

General.......................................................................................................................... |

68 |

HVCB controlled externally, DC-breaker controlled by the drive................................... |

68 |

DC-contactor US version .......................................................................................................... |

69 |

|

Table of contents |

3ADW000193R0701 DCS800 Firmware Manual e g

12 |

|

ACand DC-breaker controlled by the drive................................................................. |

71 |

No AC-breaker, DC-breaker controlled by the drive ..................................................... |

72 |

AC-breaker controlled by the drive, DC-breaker controlled externally.......................... |

73 |

No AC-breaker, DC-breaker controlled externally ........................................................ |

74 |

Command Trip DC-breaker .......................................................................................... |

74 |

Dynamic braking ...................................................................................................................... |

75 |

General ......................................................................................................................... |

75 |

Operation ...................................................................................................................... |

75 |

Activation...................................................................................................... |

75 |

Function........................................................................................................ |

75 |

Deactivation.................................................................................................. |

76 |

Position counter ....................................................................................................................... |

78 |

General ......................................................................................................................... |

78 |

Counting procedure ...................................................................................................... |

78 |

Synchronization ............................................................................................................ |

78 |

I/O configuration |

81 |

Chapter overview.......................................................................................................... |

81 |

Digital inputs (DI’s) ................................................................................................................... |

81 |

SDCS-CON-4 / SDCS-IOB-2........................................................................................ |

81 |

1st and 2nd RDIO-01 ....................................................................................................... |

81 |

Configuration ................................................................................................................ |

82 |

Digital outputs (DO’s) ............................................................................................................... |

84 |

SDCS-CON-4 / SDCS-IOB-2........................................................................................ |

84 |

1st and 2nd RDIO-01 ....................................................................................................... |

84 |

Configuration ................................................................................................................ |

85 |

Analog inputs (AI’s) .................................................................................................................. |

87 |

SDCS-CON-4 ............................................................................................................... |

87 |

SDCS-IOB-3 ................................................................................................................. |

87 |

1st RAIO-01 ................................................................................................................... |

88 |

2nd RAIO-01................................................................................................................... |

88 |

Configuration ................................................................................................................ |

89 |

Scaling .......................................................................................................................... |

89 |

Analog outputs (AO’s) .............................................................................................................. |

91 |

SDCS-CON-4 / SDCS-IOB-3........................................................................................ |

91 |

1st RAIO-01 ................................................................................................................... |

91 |

2nd RAIO-01................................................................................................................... |

92 |

Configuration ................................................................................................................ |

92 |

Scaling .......................................................................................................................... |

93 |

Communication |

94 |

Chapter overview.......................................................................................................... |

94 |

DCSLink with SDCS-DSL-4 ..................................................................................................... |

94 |

General ......................................................................................................................... |

94 |

Excitation, commissioning a FEX-4.......................................................................................... |

94 |

Layout FEX-4................................................................................................................ |

94 |

Layout SDCS-DSL-4 .................................................................................................... |

94 |

Set the FEX-4 type ....................................................................................................... |

95 |

Set the node numbers, transmission speed and the communication supervision ........ |

95 |

Set the DCSLink ........................................................................................................... |

96 |

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

|

13 |

Set the supply of the FEX-4........................................................................................... |

97 |

Checking the FEX-4 ...................................................................................................... |

97 |

Master-follower, commissioning................................................................................................ |

98 |

Set the DCSLink hardware ............................................................................................ |

98 |

Set the node ID numbers and transmission speed........................................................ |

99 |

Activate the mailboxes................................................................................................... |

99 |

Activate the communication supervision ....................................................................... |

99 |

Send and receive values ............................................................................................. |

100 |

Firmware structure....................................................................................................... |

101 |

Additional settings ....................................................................................................... |

102 |

Drive-to-drive communication ................................................................................................. |

103 |

Set the DCSLink hardware .......................................................................................... |

103 |

Set the node ID numbers and transmission speed...................................................... |

104 |

Activate the mailboxes................................................................................................. |

104 |

Activate the communication supervision ..................................................................... |

104 |

Send and receive values ............................................................................................. |

105 |

12-pulse .................................................................................................................................. |

106 |

Set the DCSLink hardware .......................................................................................... |

106 |

Set the node numbers, transmission speed and the communication supervision....... |

107 |

DDCS channels with SDCS-COM-8 ....................................................................................... |

108 |

General........................................................................................................................ |

108 |

Integer scaling on the DDCS link................................................................................. |

108 |

Ch0 communication to overriding control................................................................................ |

109 |

ABB overriding control................................................................................................. |

109 |

Parameter setting example.......................................................................................... |

109 |

Received data set table ............................................................................................... |

110 |

Transmitted data set table ........................................................................................... |

111 |

Fieldbus communication (N-type)................................................................................ |

111 |

Ch1 I/O devices ...................................................................................................................... |

112 |

Ch2 Master-follower link.......................................................................................................... |

112 |

General........................................................................................................................ |

112 |

Link configuration ........................................................................................................ |

112 |

Master.......................................................................................................................... |

112 |

Followers ..................................................................................................................... |

113 |

Firmware structure....................................................................................................... |

113 |

Toggle between speedand torque control ................................................................. |

115 |

Follower diagnostics .................................................................................................... |

115 |

Master-follower link specification................................................................................. |

115 |

Ch3 commissioning and maintenance tools............................................................................ |

116 |

DriveWindow ............................................................................................................... |

116 |

Ethernet communication for monitoring with Ethernet adapter NETA-01 ............................... |

117 |

General........................................................................................................................ |

117 |

NETA-01 - DCS800 ..................................................................................................... |

117 |

Related documentation................................................................................................ |

117 |

NETA-01 configuration ................................................................................................ |

117 |

Mechanical and electrical installation .......................................................................... |

118 |

Drive configuration....................................................................................................... |

118 |

CANopen communication with fieldbus adapter RCAN-01 ..................................................... |

119 |

General........................................................................................................................ |

119 |

RCAN-01 - DCS800 .................................................................................................... |

119 |

Table of contents |

|

3ADW000193R0701 DCS800 Firmware Manual e g

14 |

|

Related documentation............................................................................................... |

119 |

Overriding control configuration.................................................................................. |

119 |

EDS file....................................................................................................................... |

119 |

Mechanical and electrical installation ......................................................................... |

119 |

Drive configuration...................................................................................................... |

119 |

Parameter setting example 1 using group 51 ............................................................. |

119 |

Further information ..................................................................................................... |

121 |

Parameter setting example 2 using groups 90 and 92 ............................................... |

122 |

Switch on sequence ................................................................................................... |

124 |

ControlNet communication with fieldbus adapter RCNA-01................................................... |

125 |

General ....................................................................................................................... |

125 |

RCNA-01 - DCS800 ................................................................................................... |

125 |

Related documentation............................................................................................... |

125 |

Overriding control configuration.................................................................................. |

125 |

EDS file....................................................................................................................... |

125 |

Mechanical and electrical installation ......................................................................... |

125 |

Drive configuration...................................................................................................... |

125 |

Parameter setting example 1 using ABB Drives assembly......................................... |

125 |

Parameter setting example 2 using Vendor specific assembly .................................. |

127 |

Setting of parameter groups 51, 90 and 92 ................................................................ |

128 |

Further information ..................................................................................................... |

128 |

Switch on sequence ................................................................................................... |

128 |

DeviceNet communication with fieldbus adapter RDNA-01 ................................................... |

129 |

General ....................................................................................................................... |

129 |

RDNA-01 - DCS800 ................................................................................................... |

129 |

Related documentation............................................................................................... |

129 |

Overriding control configuration.................................................................................. |

129 |

EDS file....................................................................................................................... |

129 |

Mechanical and electrical installation ......................................................................... |

129 |

Drive configuration...................................................................................................... |

129 |

Parameter setting example 1 using ABB Drives assembly......................................... |

129 |

Parameter setting example 2 using User specific assembly ...................................... |

131 |

Setting of parameter groups 51, 90 and 92 ................................................................ |

132 |

Further information ..................................................................................................... |

132 |

Switch on sequence ................................................................................................... |

132 |

Ethernet/IP communication with fieldbus adapter RETA-01 .................................................. |

133 |

General ....................................................................................................................... |

133 |

RETA-01 - DCS800 .................................................................................................... |

133 |

Related documentation............................................................................................... |

133 |

EDS file....................................................................................................................... |

133 |

Mechanical and electrical installation ......................................................................... |

133 |

Drive configuration...................................................................................................... |

133 |

Parameter setting example using Ethernet/IP ABB Drives communication profile..... |

133 |

Up to 4 data words ..................................................................................................... |

135 |

Up to 12 data words ................................................................................................... |

135 |

Switch on sequence ................................................................................................... |

138 |

Modbus (RTU) communication with fieldbus adapter RMBA-01 ............................................ |

139 |

General ....................................................................................................................... |

139 |

RMBA-01 - DCS800 ................................................................................................... |

139 |

Related documentation............................................................................................... |

139 |

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

|

15 |

Mechanical and electrical installation .......................................................................... |

139 |

Drive configuration....................................................................................................... |

139 |

Parameter setting example … ..................................................................................... |

139 |

… when controlling a drive .......................................................................................... |

139 |

… when used for monitoring only ................................................................................ |

141 |

Setting of PLC, parameter groups 90 and 92 .............................................................. |

143 |

Switch on sequence .................................................................................................... |

143 |

Modbus/TCP communication with fieldbus adapter RETA-01 ................................................ |

144 |

General........................................................................................................................ |

144 |

RETA-01 - DCS800 ..................................................................................................... |

144 |

Related documentation................................................................................................ |

144 |

Mechanical and electrical installation .......................................................................... |

144 |

Drive configuration....................................................................................................... |

144 |

Parameter setting example using Modbus/TCP .......................................................... |

144 |

Switch on sequence .................................................................................................... |

146 |

Profibus communication with fieldbus adapter RPBA-01........................................................ |

147 |

General........................................................................................................................ |

147 |

RPBA-01 - DCS800..................................................................................................... |

147 |

Related documentation................................................................................................ |

147 |

Overriding control configuration................................................................................... |

147 |

Mechanical and electrical installation .......................................................................... |

147 |

Drive configuration....................................................................................................... |

147 |

Parameter setting example 1 using PPO Type 1 ........................................................ |

147 |

Parameter setting example 2 using PPO types 2, 4 and 5.......................................... |

148 |

Communication via group 51....................................................................................... |

149 |

Communication via group 90 and group 92................................................................. |

150 |

Switch on sequence .................................................................................................... |

151 |

Data set table .......................................................................................................................... |

152 |

Adaptive Program (AP) |

153 |

Chapter overview......................................................................................................... |

153 |

What is the Adaptive Program..................................................................................... |

153 |

Features ...................................................................................................................... |

153 |

How to build the program ............................................................................................ |

154 |

How to connect the Application Program with the firmware ........................................ |

154 |

Block Parameter Set for block 1 .................................................................................. |

155 |

How to control the execution of the program............................................................... |

156 |

DWL AP .................................................................................................................................. |

157 |

General........................................................................................................................ |

157 |

Important keys and buttons ......................................................................................... |

157 |

Program modes ........................................................................................................... |

157 |

Change to Edit mode................................................................................................... |

157 |

Insert function blocks................................................................................................... |

158 |

Connect function blocks .............................................................................................. |

159 |

Set the Time level........................................................................................................ |

161 |

Saving AP applications................................................................................................ |

161 |

Function blocks ....................................................................................................................... |

162 |

General rules ............................................................................................................... |

162 |

Block inputs ................................................................................................................. |

162 |

Block input attributes ................................................................................... |

163 |

|

Table of contents |

3ADW000193R0701 DCS800 Firmware Manual e g

16 |

|

Parameter value as an integer input .......................................................... |

164 |

How the block handles the input ................................................................ |

164 |

How to select the input ............................................................................... |

164 |

Constant as an integer input ...................................................................... |

165 |

How to set and connect the input ............................................................... |

165 |

Parameter value as a boolean input........................................................... |

166 |

How the block handles the input ................................................................ |

166 |

Constant as a boolean input....................................................................... |

167 |

How to set and connect the input ............................................................... |

167 |

String input ................................................................................................. |

167 |

How to select the input ............................................................................... |

167 |

Function blocks ...................................................................................................................... |

168 |

ABS ............................................................................................................................ |

168 |

ADD ............................................................................................................................ |

169 |

AND ............................................................................................................................ |

169 |

Bitwise ........................................................................................................................ |

170 |

Bset ............................................................................................................................ |

171 |

Compare ..................................................................................................................... |

171 |

Count .......................................................................................................................... |

172 |

D-Pot .......................................................................................................................... |

172 |

Event .......................................................................................................................... |

173 |

Filter............................................................................................................................ |

173 |

Limit ............................................................................................................................ |

174 |

MaskSet...................................................................................................................... |

174 |

Max ............................................................................................................................. |

175 |

Min .............................................................................................................................. |

175 |

MulDiv......................................................................................................................... |

175 |

NotUsed...................................................................................................................... |

176 |

OR .............................................................................................................................. |

176 |

ParRead ..................................................................................................................... |

176 |

ParWrite...................................................................................................................... |

177 |

PI ................................................................................................................................ |

177 |

PI-Bal .......................................................................................................................... |

178 |

Ramp .......................................................................................................................... |

178 |

Sqrt ............................................................................................................................. |

179 |

SqWav ........................................................................................................................ |

179 |

SR............................................................................................................................... |

180 |

Switch-B ..................................................................................................................... |

180 |

Switch-I ....................................................................................................................... |

181 |

TOFF .......................................................................................................................... |

181 |

TON ............................................................................................................................ |

182 |

Trigg ........................................................................................................................... |

182 |

XOR ............................................................................................................................ |

183 |

Diagram.................................................................................................................................. |

184 |

Signal and parameter list |

185 |

Signals and parameters ......................................................................................................... |

185 |

Signal groups list.................................................................................................................... |

185 |

Parameter groups list ............................................................................................................. |

187 |

Signal and parameter list ....................................................................................................... |

190 |

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

|

17 |

Group 1........................................................................................................................ |

190 |

Physical actual values ................................................................................. |

190 |

Group 2........................................................................................................................ |

194 |

Speed controller signals .............................................................................. |

194 |

Group 3........................................................................................................................ |

198 |

Reference actual values.............................................................................. |

198 |

Group 4........................................................................................................................ |

201 |

Information .................................................................................................. |

201 |

Group 5........................................................................................................................ |

209 |

Analog I/O ................................................................................................... |

209 |

Group 6........................................................................................................................ |

210 |

Drive logic signals ....................................................................................... |

210 |

Group 7........................................................................................................................ |

216 |

Control words .............................................................................................. |

216 |

Group 8........................................................................................................................ |

222 |

Status / limit words ...................................................................................... |

222 |

Group 9........................................................................................................................ |

228 |

Fault / alarm words...................................................................................... |

228 |

Group 10...................................................................................................................... |

244 |

Start / stop select ........................................................................................ |

244 |

Group 11...................................................................................................................... |

257 |

Speed reference inputs ............................................................................... |

257 |

Group 12...................................................................................................................... |

264 |

Constant speeds ......................................................................................... |

264 |

Group 13...................................................................................................................... |

265 |

Analog inputs .............................................................................................. |

265 |

Group 14...................................................................................................................... |

269 |

Digital outputs ............................................................................................. |

269 |

Group 15...................................................................................................................... |

271 |

Analog outputs ............................................................................................ |

271 |

Group 16...................................................................................................................... |

273 |

System control inputs .................................................................................. |

273 |

Group 19...................................................................................................................... |

276 |

Data storage................................................................................................ |

276 |

Group 20...................................................................................................................... |

278 |

Limits ........................................................................................................... |

278 |

Group 21...................................................................................................................... |

282 |

Start / stop ................................................................................................... |

282 |

Group 22...................................................................................................................... |

286 |

Speed ramp................................................................................................. |

286 |

Group 23...................................................................................................................... |

289 |

Speed reference.......................................................................................... |

289 |

Group 24...................................................................................................................... |

294 |

Speed control .............................................................................................. |

294 |

Group 25...................................................................................................................... |

299 |

Torque reference......................................................................................... |

299 |

Group 26...................................................................................................................... |

300 |

Torque reference handling .......................................................................... |

300 |

Group 30...................................................................................................................... |

304 |

Fault functions ............................................................................................. |

304 |

|

Table of contents |

3ADW000193R0701 DCS800 Firmware Manual e g

18

Group 31..................................................................................................................... |

315 |

Motor 1 temperature ................................................................................... |

315 |

Group 34..................................................................................................................... |

317 |

DCS800 Control Panel display ................................................................... |

317 |

Group 40..................................................................................................................... |

318 |

PID control.................................................................................................. |

318 |

Group 42..................................................................................................................... |

321 |

Brake control .............................................................................................. |

321 |

Group 43..................................................................................................................... |

327 |

Current control............................................................................................ |

327 |

Group 44..................................................................................................................... |

333 |

Field excitation ........................................................................................... |

333 |

Group 45..................................................................................................................... |

340 |

Field converter settings .............................................................................. |

340 |

Group 47..................................................................................................................... |

347 |

12-pulse operation...................................................................................... |

347 |

Group 49..................................................................................................................... |

348 |

Shared motion ............................................................................................ |

348 |

Group 50..................................................................................................................... |

360 |

Speed measurement .................................................................................. |

360 |

Group 51..................................................................................................................... |

367 |

Fieldbus...................................................................................................... |

367 |

Group 52..................................................................................................................... |

368 |

Modbus....................................................................................................... |

368 |

Group 60, …, 69 ......................................................................................................... |

369 |

Application program parameters ................................................................ |

369 |

Group 70..................................................................................................................... |

370 |

DDCS control ............................................................................................. |

370 |

Group 71..................................................................................................................... |

375 |

Drivebus ..................................................................................................... |

375 |

Group 83..................................................................................................................... |

375 |

Adaptive Program control ........................................................................... |

375 |

Group 84..................................................................................................................... |

377 |

Adaptive Program....................................................................................... |

377 |

Group 85..................................................................................................................... |

380 |

User constants ........................................................................................... |

380 |

Group 86..................................................................................................................... |

382 |

Adaptive Program outputs .......................................................................... |

382 |

Group 88..................................................................................................................... |

383 |

Internal ....................................................................................................... |

383 |

Group 90..................................................................................................................... |

385 |

Receiving data sets addresses 1 ............................................................... |

385 |

Group 91..................................................................................................................... |

387 |

Receiving data sets addresses 2 ............................................................... |

387 |

Group 92..................................................................................................................... |

388 |

Transmit data sets addresses 1 ................................................................. |

388 |

Group 93..................................................................................................................... |

390 |

Transmit data sets addresses 2 ................................................................. |

390 |

Group 94..................................................................................................................... |

391 |

DCSLink control ......................................................................................... |

391 |

Table of contents

3ADW000193R0701 DCS800 Firmware Manual e g

|

19 |

Group 97...................................................................................................................... |

399 |

Measurement .............................................................................................. |

399 |

Group 98...................................................................................................................... |

407 |

Option modules ........................................................................................... |

407 |

Group 99...................................................................................................................... |

415 |