CL-60E CL-60A

Conext™ CL-60 PV Inverter

Owner’s Guide

975-0768-01-01 Revision B

03-2017

http://solar.schneider-electric.com

Conext™ CL-60 PV Inverter

Owner’s Guide

http://solar.schneider-electric.com

Copyright © 2017 Schneider Electric. All Rights Reserved. All trademarks are owned by Schneider Electric Industries SAS

or its affiliated companies. Other 3rd party trademarks are owned by their respective companies.

Exclusion for Documentation

U

NLESS SPECIFICALLY AGREED TO IN WRITING, SELLER

(A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER INFORMATION PROVIDED

IN ITS MANUALS OR OTHER DOCUMENTATION;

(

B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION

WILL BE ENTIRELY AT THE USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH STEPS HAVE BEEN TAKEN TO

MAINTAIN THE ACCURACY OF THE TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED CONTENT IS CONTAINED WITH

THE ENGLISH LANGUAGE VERSION WHICH IS POSTED AT SOLAR.SCHNEIDER-ELECTRIC.COM.

Document Number: 975-0768-01-01 Revision: Revision B Date: 03-2017

Product Part Numbers: PVSCL60A (CL-60A—North American version)

PVSCL60E (CL-60E—IEC version)

Contact Information: http://solar.schneider-electric.com

Please contact your local Schneider Electric Sales Representative or visit our website at:

http://solar.schneider-electric.com/tech-support/

About This Guide

Purpose

The purpose of this Owner’s Guide is to explain the procedures for operating,

configuring, maintaining, and troubleshooting the Conext CL-60 PV Inverter.

Scope

The Guide provides safety guidelines and general information for installing and

operating the Conext CL-60, as well as information about configuring,

monitoring, and troubleshooting the unit. It does not include information on how

to use other Schneider Electric and third-party products.

Audience

The Guide is intended for use by anyone who plans to design, construct, install,

or operate a system involving the CL-60. The installation information in this guide

is intended for qualified personnel. Qualified personnel have training,

knowledge, and experience in:

• Installing electrical equipment and PV power systems (up to 1000 volts)

• Applying all applicable installation codes

• Analyzing and reducing the hazards involved in performing electrical work

• Selecting and using Personal Protective Equipment (PPE)

975-0768-01-01 Revision B v

About This Guide

Organization

This Guide is organized into:

Chapter 1, “Introduction”

Chapter 2, “Installation”

Chapter 3, “Electrical Connections”

Chapter 4, “Commissioning”

Chapter 5, “LCD Display Operation”

Chapter 6, “Troubleshooting”

Chapter 7, “Disconnecting, Dismantling, and Disposing the CL-60”

Chapter 8, “Specifications”

Abbreviations and Acronyms

Related Information

AFD

EMI

G

GND

HMI

IGBT

LAN / WAN

LCD

LED

NFPA

PE

PPE

PV

SPD

You can find more information about Schneider Electric, as well as its products

and services at http://solar.schneider-electric.com.

Arc Fault Detection device

Electromagnetic Interference

Ground (also referred as Protective Earth)

Human-Machine Interface

Insulated Gate Bipolar Transistor

Local Area Network / Wide Area Network

Liquid Crystal Display (used for HMI displays)

Light Emitting Diode (used for indicator lights)

National Fire Protection Association

Protective Earth (also referred as Ground)

Personal Protective Equipment

Photovoltaic (or Solar)

Surge Protection Device

vi 975-0768-01-01 Revision B

Important Safety Instructions

DANGER

WARNING

CAUTION

NOTICE

READ AND SAVE THESE INSTRUCTIONS - DO NOT DISCARD

This document contains important safety instructions that must be followed

during installation procedures (if applicable). Read and keep this Owner’s Guide

for future reference.

Read these instructions carefully and look at the equipment (if applicable) to

become familiar with the device before trying to install, operate, service or

maintain it. The following special messages may appear throughout this bulletin

or on the equipment to warn of potential hazards or to call attention to information

that clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety

label indicates that an electrical hazard exists which will result

in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous situation, which, if not avoided,

will result in death or serious injury.

WARNING indicates a potentially hazardous situation, which, if not avoided,

can result in death or serious injury.

CAUTION indicates a potentially hazardous situation, which, if not avoided,

can result in moderate or minor injury.

NOTICE indicates important information that you need to read carefully.

975-0768-01-01 Revision B vii

Safety

Please Note

Electrical equipment must be installed, operated, serviced, and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for

any consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the

construction, installation, and operation of electrical equipment and has received

safety training to recognize and avoid the hazards involved.

Safety Information

1. Before using this product, read all instructions and cautionary markings on

the unit and all appropriate sections of this manual.

2. Use of accessories not recommended or sold by the manufacturer may result

in a risk of fire, electric shock, or injury to persons.

3. The manufacturer recommends that all wiring be done by a certified

technician or electrician to ensure adherence to the local and national

electrical codes applicable in your jurisdiction.

4. To avoid a risk of fire and electric shock, make sure that existing wiring is in

good condition and that wire is not undersized. Do not operate the

equipment with damaged or substandard wiring.

5. Do not operate the equipment if it has been damaged in any way.

6. Do not disassemble the Conext CL-60 except where noted for connecting

wiring and cabling. See your warranty for instructions on obtaining service.

Attempting to service the unit yourself may result in a risk of electrical shock

or fire.

7. To reduce the risk of electrical shock, disconnect the power supply from the

equipment before attempting installation, and any maintenance (including

cleaning or working on any components connected to the equipment).

Internal capacitors remain charged for ten minutes after all power is

disconnected.

8. The equipment must be grounded. Use the protective grounding conductor

provided with the AC input conductors.

9. This product is designed for outdoor use and is rated IP65 and Type 4X.

10. To reduce the chance of short-circuits, always use insulated tools when

installing or working with this equipment. Do not leave tools inside.

11. Remove personal metal items such as rings, bracelets, necklaces, and

watches when working with electrical equipment.

12. Do not open nor disassemble the top half of the unit. There are no userserviceable parts inside.

13. To disconnect the unit from DC power, turn the DC switch to OFF and then

remove all PV string connectors from the DC terminals.

viii 975-0768-01-01 Revision B

Safety

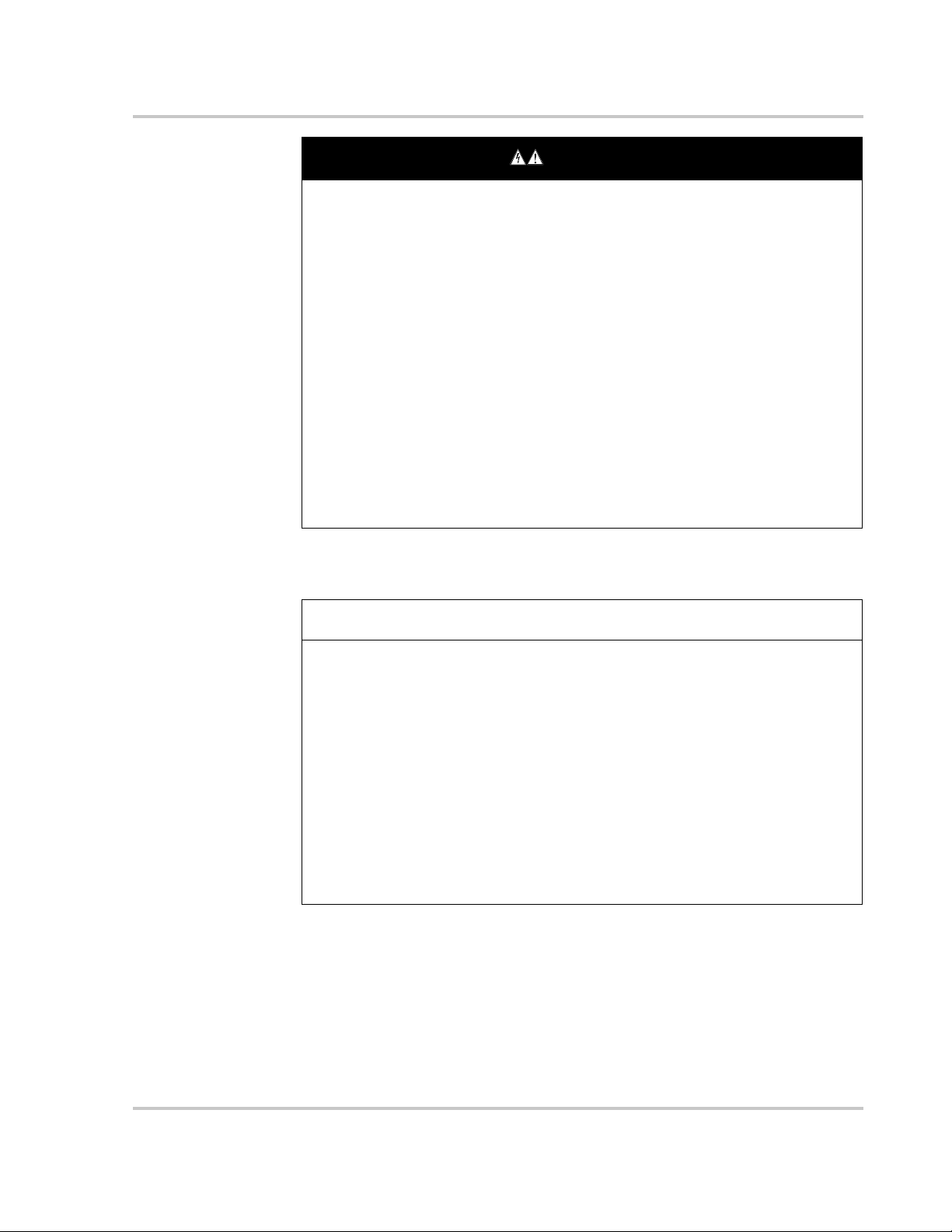

DANGER

NOTICE

ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH HAZARDS

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must only be installed and serviced by qualified electrical

personnel.

• Never energize the inverter with the covers removed.

• Do not open fuse holders under load. The fuse must be de-energized from

all sources before servicing.

• The inverter is energized from multiple sources. Before removing covers

identify all source, de-energize, lock-out, and tag-out and wait 10 minutes.

• Always use a properly rated voltage sensing device to confirm all circuits

are de-energized.

• Replace all devices and covers before turning on power to this equipment.

• The DC conductors of this photovoltaic system are ungrounded and may

be energized.

Failure to follow these instructions will result in death or serious injury.

Access to live parts shall be limited to suitably qualified electrical personnel. See

installation instructions before connecting to the supply.

EQUIPMENT DAMAGE

• All cables connected to the CL-60 must run through the cable glands on

the unit.

• This unit is susceptible to damage from EMI and nearby lightning strikes

unless a surge protection device (a lightning arrestor) is installed.

• Turn Off all devices before connecting cables.

• Use the CL-60’s DC switch as its On/Off switch.

• To isolate the CL-60, follow “Lock-Out Tag-Out (LOTO) Procedure” on

page xi.

Failure to follow these instructions can damage equipment or affect

network performance.

975-0768-01-01 Revision B ix

Safety

Storage Information

Store the inverter properly when the inverter is not to be installed immediately.

1. Inverter must be packed inside its original carton with the desiccant bags

inside.

2. Store the inverter with its front panel facing up. The carton should lay flat and

parallel to the ground.

3. Seal the carton with standard packaging tape.

4. Store the inverter in a dry and clean place to protect it against dust and

moisture.

5. Temperature: -30 to 85 °C (-22 to 185 ºF)

Relative humidity: 0 to 100%.

6. Do not stack more than two inverters on top of another.

7. Keep the inverter away from chemically corrosive materials.

8. Periodically check for any visible damages to the carton and inspect the

inverter right away if the carton shows signs of penetration during the storage

period. Replace the carton, if necessary.

NOTE: A thorough and professional inspection may be required before

installing the inverter after more than six months in storage. Contact a local

Schneider Electric sales representative for information on how to arrange the

inspection.

IMPORTANT: Storage beyond two years voids the warranty.

x 975-0768-01-01 Revision B

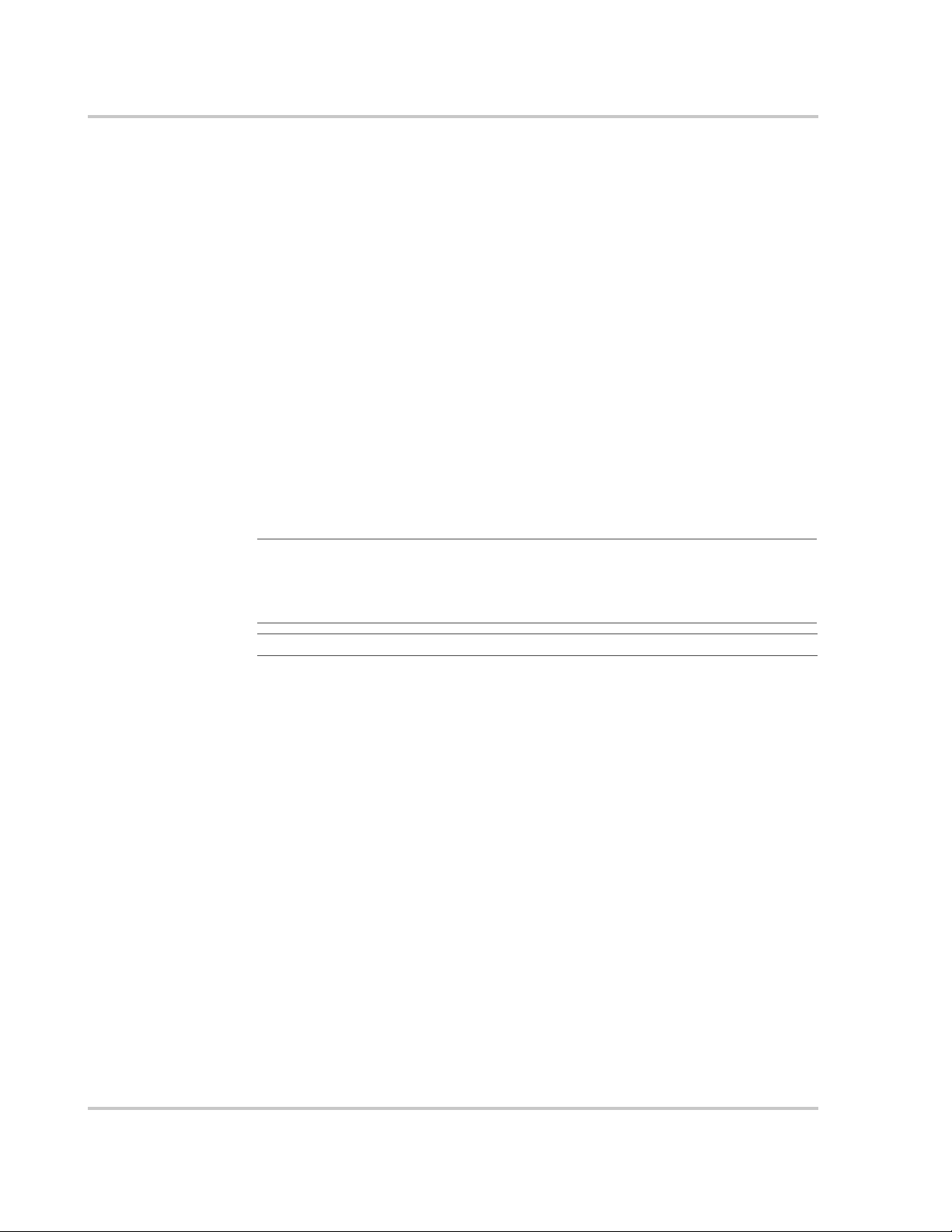

Lock-Out Tag-Out (LOTO) Procedure

DANGER

CL-60

Mains

AC Panel

Breaker

DC Disconnect Device

LOTO

LOTO

DC Switch

PV string

Lock-out refers to the practice of preventing de-energized circuits from being reenergized by putting locks on the disconnecting devices, holding them open.

Tag-out refers to the practice of attaching a tag to the disconnect-device locks

warning others not to operate the disconnect device and containing information

relating to the lock-out, such as the person responsible, the reason, and the date

and time. Combined these two practices are called the lock-out and tag-out

(LOTO) procedure.

ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH HAZARDS

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must only be installed and serviced by qualified electrical

personnel.

• Never energize the inverter with the covers removed.

• Always use a properly rated voltage sensing device to confirm all circuits

are de-energized.

• Replace all devices and covers before turning on power to this equipment.

• The inverter is energized from multiple sources. Before opening the cover

identify the power source (see A), de-energize (see B), lock-out and tagout (see C), and wait ten minutes for circuits to discharge (see D).

Failure to follow these instructions will result in death or serious injury.

Safety

Figure 1-1 Single Line Diagram for CL-60

A 1. Identify any disconnect device upstream from the CL-60 unit.

B 2. Open the disconnect device that connects to the CL-60 to cut off DC power.

C 3. Turn the CL-60’s DC Switch to OFF position.

4. Lock-out and tag out the external DC disconnect device.

5. Remove all PV string connectors from the DC terminals.

975-0768-01-01 Revision B xi

Safety

A 6. Identify the AC Panel Breaker downstream from the CL-60 unit.

B 7. Open the AC Panel door.

8. Turn Off the AC Panel Breaker (open the switch) that connects to the CL-60

to cut off AC power.

9. Close the AC Panel door.

C 10. Lock-out and tag out the AC Panel.

D 11. Wait ten minutes for the circuits in the CL-60 to discharge.

12. Check that the inverter is in zero energy state before performing work.

13. Open the CL-60 enclosure and commence service and maintenance

activities.

xii 975-0768-01-01 Revision B

Contents

Important Safety Instructions

Safety Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

Storage Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - x

Lock-Out Tag-Out (LOTO) Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -xi

1 Introduction

Conext CL-60 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Physical Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Inverter Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Packaging Box Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Product Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

LCD Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

DC Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Technical Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

CL-60 Circuit Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Standard Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Derating Feature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

2 Installation

Pre-Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Planning the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

What’s In The Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Material and Tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Location Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Install and Mount the CL-60 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Torque Values - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

3 Electrical Connections

Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Planning the Electrical Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Cabling and Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Material and Tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Terminal and Cable Entry Points (for CL-60E) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Terminal and Cable Entry Points (for CL-60A) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

AC Side Cable Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

AC Side Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

AC Circuit Breaker - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

Residual Current Device - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

975-0768-01-01 Revision B xiii

Contents

Multiple Inverters in Parallel Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Grid Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

PV Array Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

PV Input Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

PV Input Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–16

Grounding the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–21

Grounding System Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–21

Second Protective Earth Terminal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–22

Communication Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–23

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–23

RS-485 Communication System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–24

Ethernet Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–28

4 Commissioning

Inspection Before Commissioning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Commissioning Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

5 LCD Display Operation

Description of the Selection Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Menu Tree - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Main Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Contrast Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6

Checking Running Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6

Checking History Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8

Checking Running Records - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8

Checking Fault (Event) Records - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8

Checking History Event Records - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9

Checking Energy Records - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9

Starting/Stopping - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–10

Password Entry - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–11

System Parameter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–12

Language Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–12

Time Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–12

Total Energy Deviation Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–13

Load Default (Factory Reset) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–14

Checking Firmware Version - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–14

Running Parameter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–15

Main Screen of Run-param - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–15

Active/Reactive Power Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–18

Reactive Power Regulation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–18

Pf Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–18

Qt Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–19

Off Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–19

Q(P) Mode (when the country selection is not “IT”) - - - - - - - - - - - - - - - - - - - - - - - - - - 5–19

xiv 975-0768-01-01 Revision B

Q(U) Mode (when the country selection is not “IT”) - - - - - - - - - - - - - - - - - - - - - - - - - - 5–20

Reactive Power Setting for Italy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–22

Italy Q(P) Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–22

Italy Q(U) Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–23

Save P/Q-set - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–25

Time Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–25

LVRT Parameter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–26

Derating Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–26

ISO Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–27

Protection Parameter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–27

Country Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–28

Single-stage Protection Parameter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–30

Multi-stage Protection Parameter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–30

Protection Recovery Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–32

Protection Parameter Confirmation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–32

Communication Parameter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–33

6 Troubleshooting

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–2

LED Indicator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–3

LCD Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–4

Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–10

Routine Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–10

Maintenance Instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–11

Fan Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–11

Replacing the Fuse - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–13

Replacing an Expended DC SPD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–14

Cleaning the Air Inlet and Outlet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–15

Contents

7 Disconnecting, Dismantling, and Disposing the CL-60

Disconnecting the CL-60 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–2

Dismantling the CL-60- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–4

Disposing the CL-60 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–5

8 Specifications

Product Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–2

975-0768-01-01 Revision B xv

xvi

1 Introduction

Chapter 1 contains general information about:

• Conext CL-60

• Physical Features

• Technical Features

975-0768-01-01 Revision B 1–1

Introduction

WARNING

PV Array CL-60 Transformer Utility Grid

TT, TN-C, TN-S,

TN-C-S, IT

without grounding

Conext CL-60

The Conext CL-60 (also referred to as CL-60 PV Inverter) is a transformerless

three-phase PV string inverter that is designed to be an integral part of any utility

grid-connected PV Power System.

The Conext CL-60 is designed to convert DC power generated from the PV array

into AC power that is compatible with utility grade AC power. The following

diagram illustrates its fundamental application.

ELECTRICAL SHOCK HAZARD

• Do not connect the inverter to a PV string where the positive and negative

terminals of the PV strings need to be grounded.

• Do not connect any local load between the inverter and the AC circuit

breaker.

• Use the inverter ONLY in a grid-connected PV system.

Failure to follow these instructions can result in death or serious injury.

Figure 1-1 Fundamental Application

1–2 975-0768-01-01 Revision B

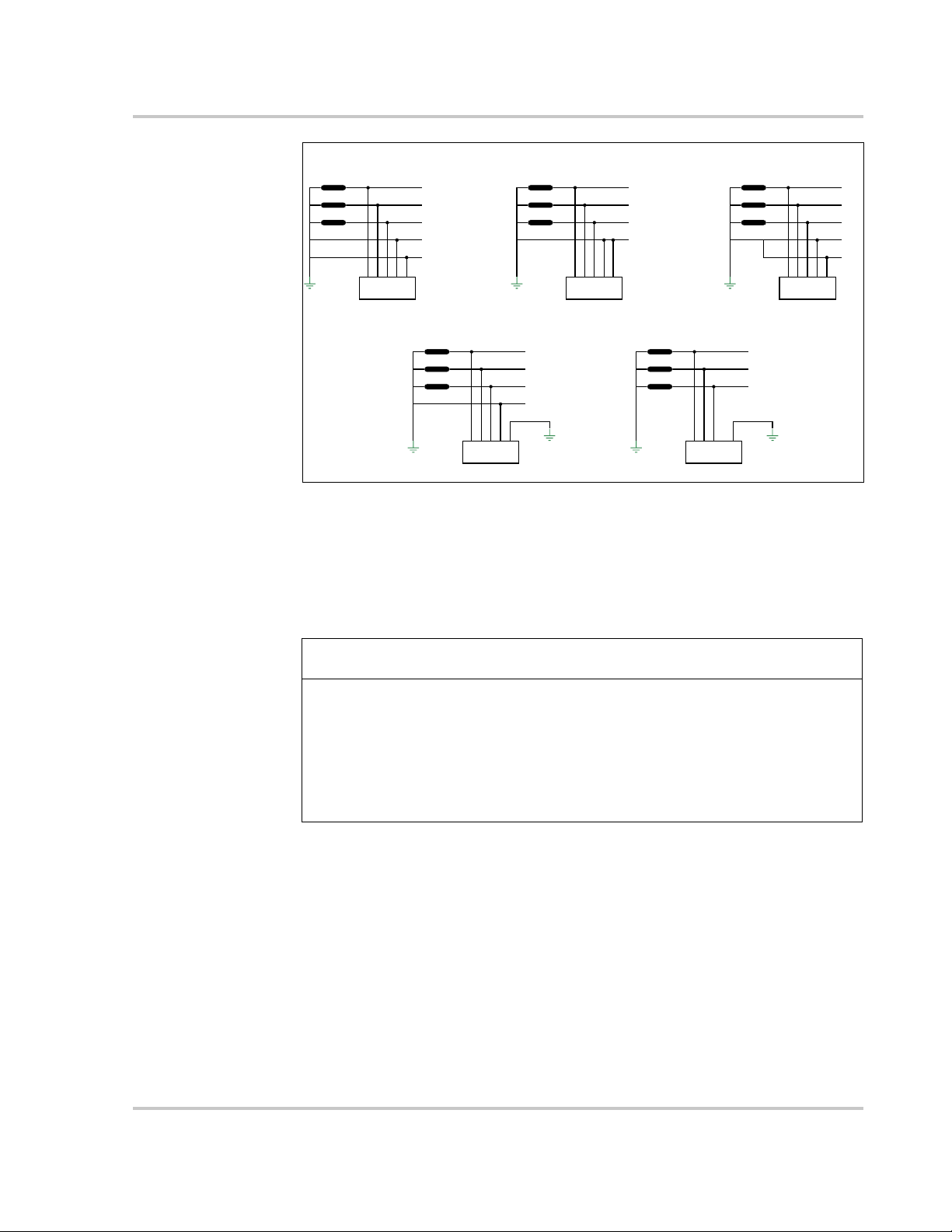

Figure 1-2 Type of Grid Connections

L1

L2

L3

N

PE

CL 60

transformer

TT

L1

L2

L3

N

PE

PE

CL 60

transformer

TN-S

L1

L2

L3

N

PE

PE

CL 60

transformer

TN-C-S

L1

L2

L3

PEN

PE

CL 60

transformer

TN-C

L1

L2

L3

PE

CL 60

transformer

IT

NOTICE

Conext CL-60

Grid Connection

Conditions

More than one CL-60 PV Inverter can be connected to the PV system if the total

capacity of the PV system (PV array) exceeds the capacity of a single inverter.

Each inverter in the multiple setup connects individually to a PV string at the

inverter’s DC input side. Then the inverter’s AC output side connects to the AC

mains (the grid).

EQUIPMENT DAMAGE

Follow local regulations when installing a connection to a either a TT or TN

system. An additional external Type B RCD (residual current detection) device

rated 300 mA continuous may be required and combined with additional

automatic disconnect devices.

Failure to follow these instructions can result in equipment damage.

975-0768-01-01 Revision B 1–3

Introduction

1

2

4

3

3

6

8

7

3

3

5

9

10

11

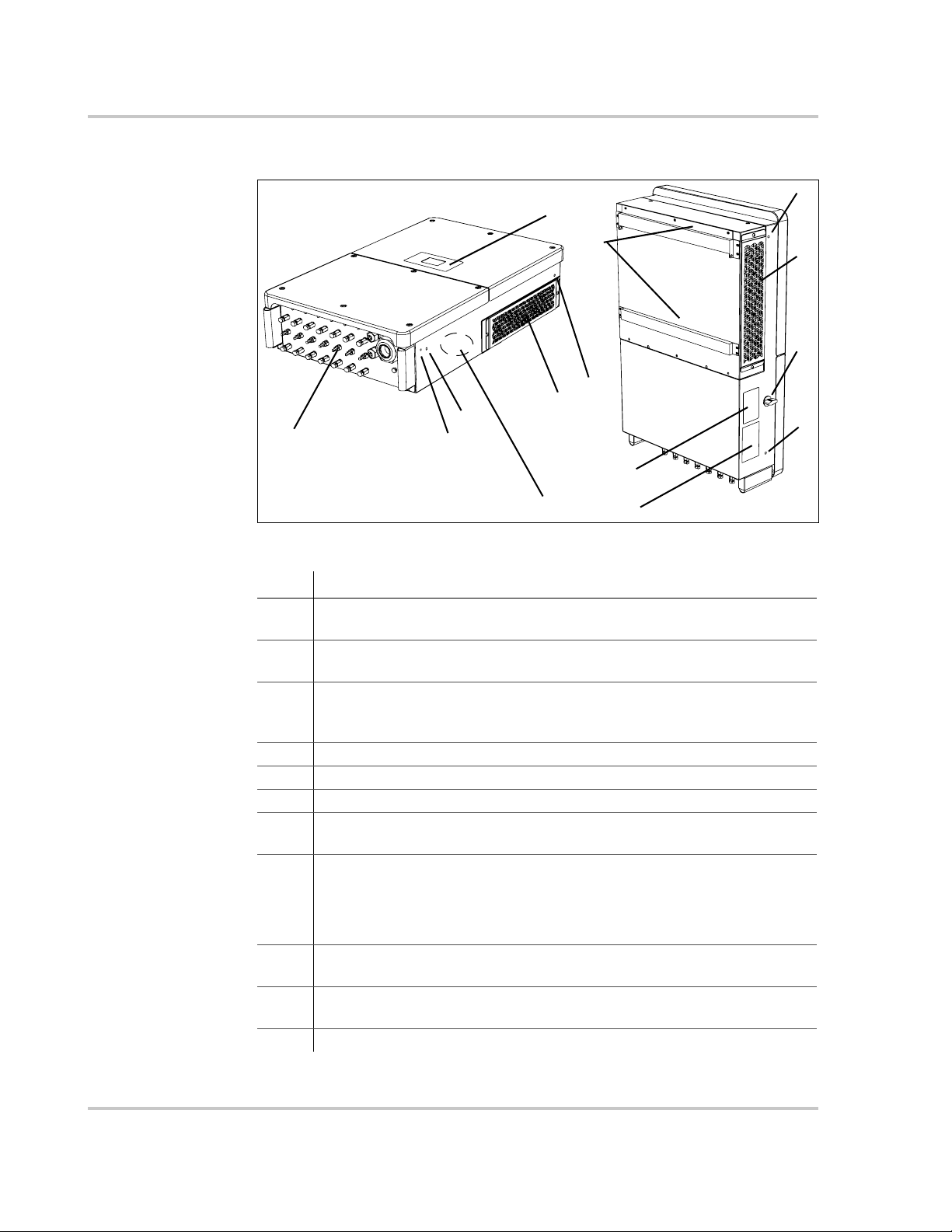

Physical Features

Figure 1-3 CL-60 Components (CL-60E shown)

Item Description

1 LCD Display is the main HMI for viewing operational information and

changing parameter values for settings.

2 Electrical connection area includes the DC terminals, AC terminals,

and RS-485 communication terminals.

3 Hole Inserts for Screw-in Handles are used for seating the screw-in

handles. The handles are used for moving, handling, and mounting the

PV Inverter.

4 PE second terminal

5 Air ventilation is equipped with fans to draw hot air out.

6Backplate is used to hang the PV Inverter onto the wall.

7 Fans (3x) with protective grate are used for forced-air cooling inside

the inverter enclosure.

8 DC switch is a protective component for safely disconnecting DC

power from the PV Array but only up to the terminals.

For full disconnection, disconnect power from the PV disconnect

device. See “Single Line Diagram for CL-60” on page xi.

9 Warning Label Read before installing, maintaining, and servicing the

10 Rating Label contains the unit’s electrical specifications and regulatory

11 CL-60A has an AC Switch in the area shown.

unit.

markings.

1–4 975-0768-01-01 Revision B

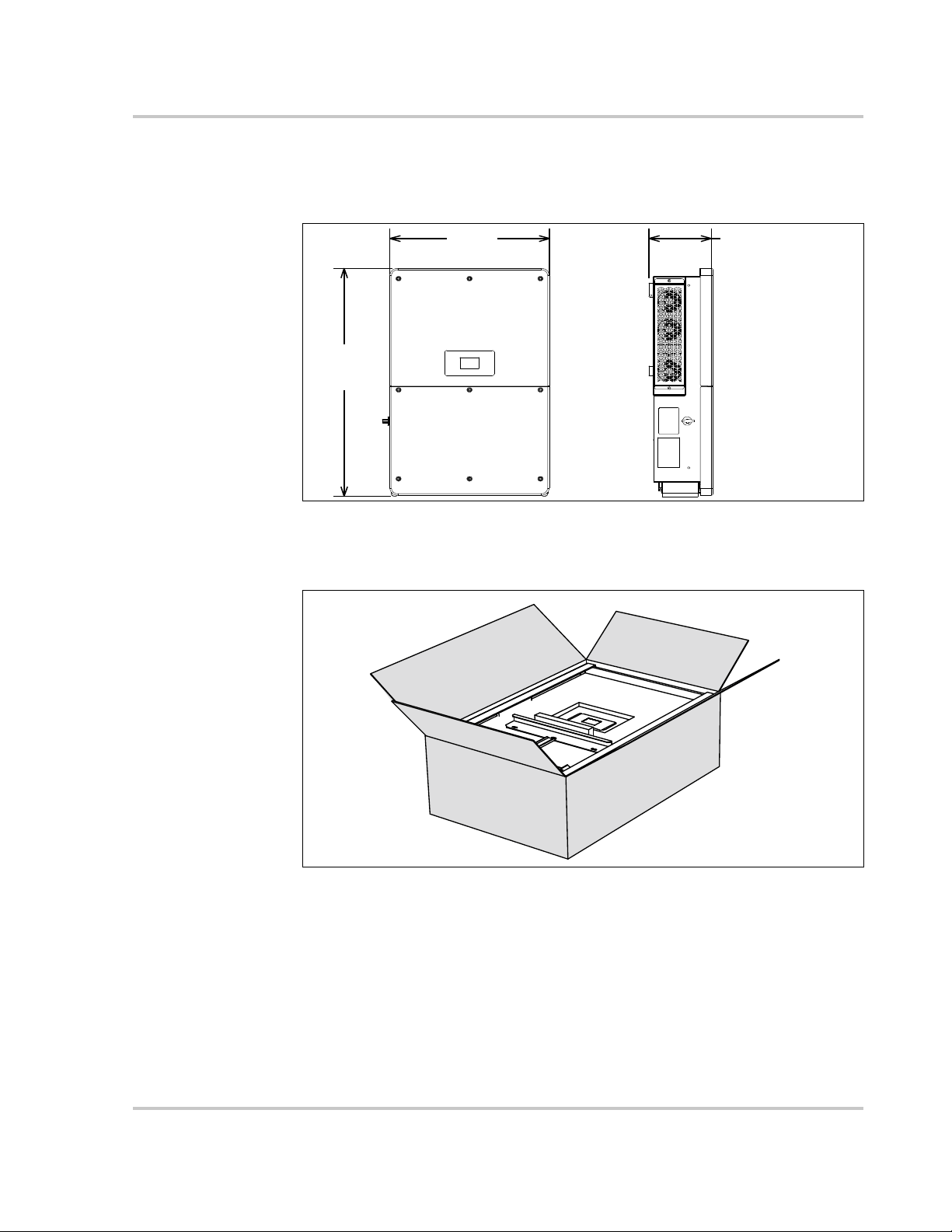

Dimensions

625 mm

24.6 in

250 mm

9.8 in

991 mm

39 in

Unit weight:

66.0 kg (CL-60E)

147 lbs (CL-60A)

Length:

1160 mm / 45.7 inWidth:

770 mm / 30.3 in

Height:

375 mm / 14.8 in

Gross weight:

76.0 kg (CL-60E)

168 lbs (CL-60A)

Inverter Dimensions

Physical Features

Figure 1-4 Conext CL-60 Dimensions (CL-60E shown)

Packaging Box Dimensions

Figure 1-5 Conext CL-60 Packaging Box Dimensions

975-0768-01-01 Revision B 1–5

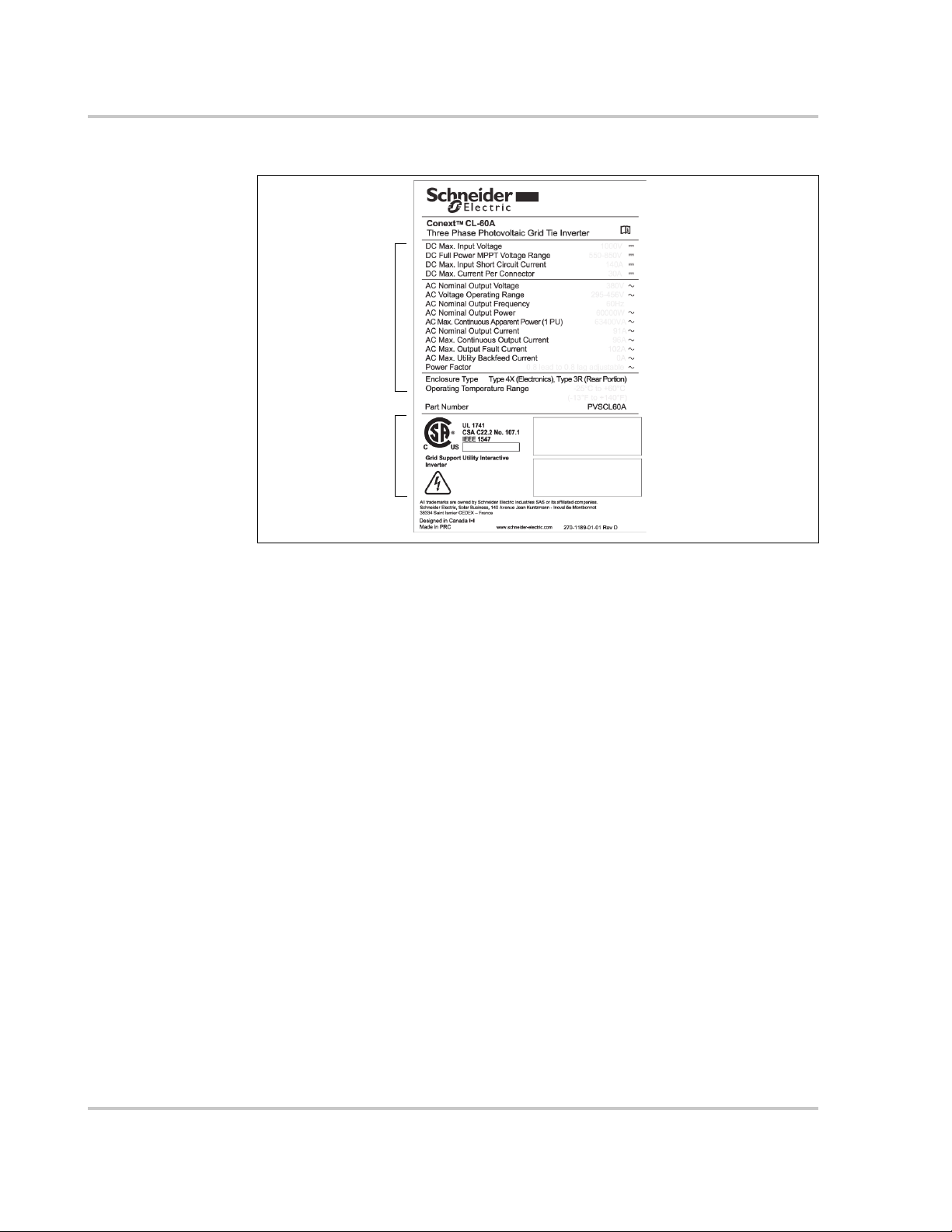

Introduction

product name

product ratings

product part number

certification and

regulatory

markings

serial number

manufacturing

date

Product Label

Figure 1-6 Example of a Conext CL-60 Product Label

1–6 975-0768-01-01 Revision B

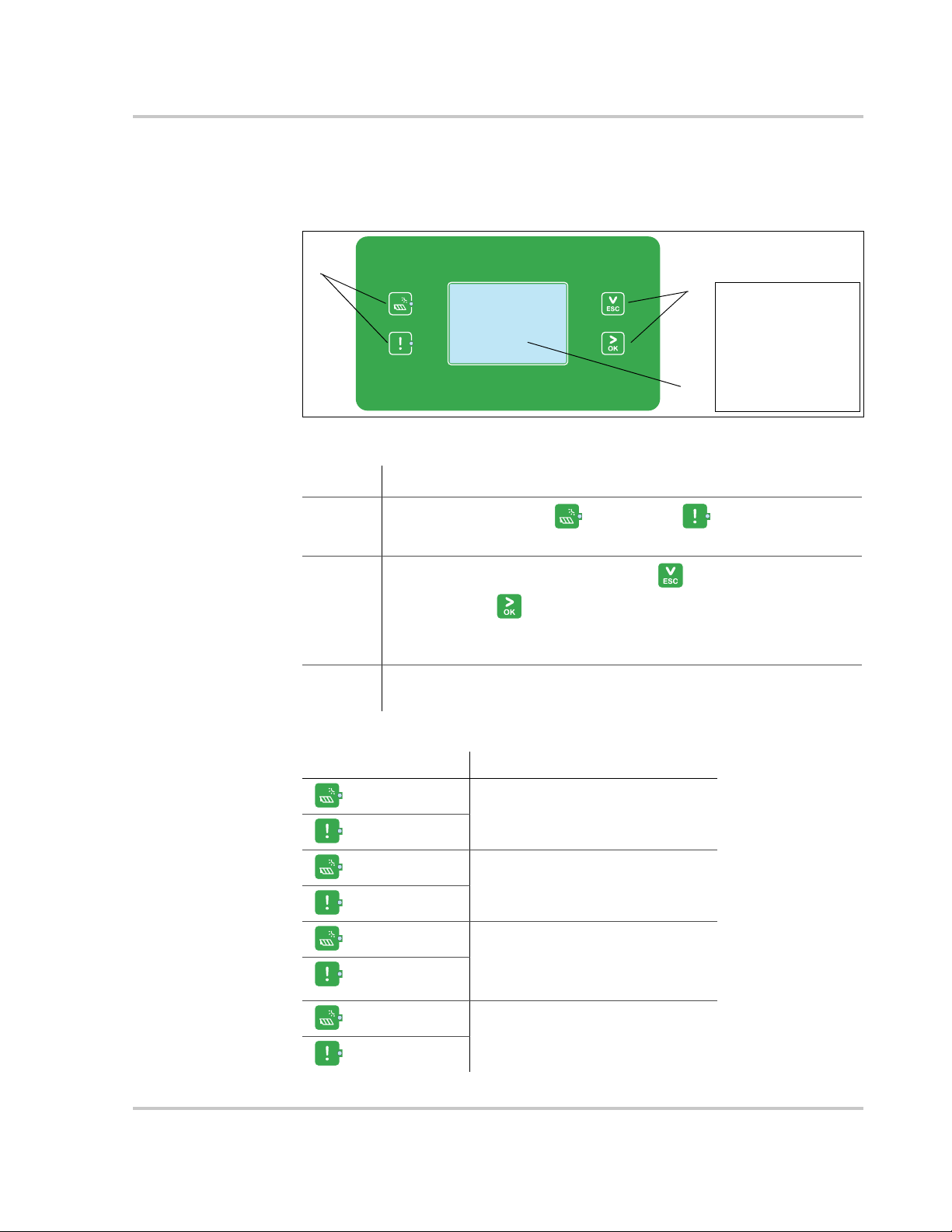

LCD Display

1

2

3

NOTE: Condensation may

appear behind the LCD

display. This occurrence is

normal in cold climate

conditions. The

condensation dissipates

soon after the unit starts

producing power or when

ambient temperature settles

above the dew point.

Physical Features

The LCD Display is the main interface of the CL-60 PV Inverter. It is made up of

two LED indicators, two buttons, and the screen itself.

Figure 1-7 LCD Display

Item Description

1

LED Indicators – RUN and ALERT .

Indicates the present operational state of the PV Inverter.

2

Selection Buttons – ESC (and down) and

OK (and next) .

Use for navigating the LCD interface, selecting settings, and

changing parameters of settings.

3 LCD Screen. Displays the present state of the PV Inverter,

operational and alarm information, and present settings.

Tab l e 1 -1 Description of LED Indicators

LED Indicators Description

RUN - On

The PV Inverter is in operation.

ALERT - Off

RUN - Off

A ground fault (or any event) is

detected or a protection feature is

ALERT - On

RUN - Off

ALERT - Off

enabled.

The PV Inverter is not in operation

or a communication fault is

detected between the DSP and

the LCD Display.

RUN - flashing

ALERT - Off

975-0768-01-01 Revision B 1–7

The PV Inverter is communicating

a warning.

Introduction

WARNING

DC Switch

The DC Switch is both the main power switch and a protective component which

is used to safely disconnect DC power between the PV array and the PV Inverter

whenever necessary to do so.

The PV Inverter operates automatically (without the need of switching On or Off)

when DC input and AC output requirements are continuously met. Turn the DC

switch to the Off position only to stop PV Inverter operation when a ground fault

condition is detected or when there is a non-ground fault condition to stop

inverter operation such as maintenance and servicing.

ELECTRIC SHOCK HAZARD

• Do not perform maintenance and servicing without totally disconnecting

the DC source from the inverter. The DC switch does not de-energize the

DC fuse circuits. The fuse circuits remain live even if the DC switch is

turned to the Off position.

• To remove power to the inverter, disconnect power from the PV disconnect

device. See “Single Line Diagram for CL-60” on page xi.

• Alternatively, to remove power to the inverter, open all MC4 type connectors

using a special tool for disconnection.

Failure to follow these instructions can result in death or serious injury.

NOTE: For CL-60A, the DC switch is provided with a lockable twisting knob to

meet the NFPA 70E standard.

1–8 975-0768-01-01 Revision B

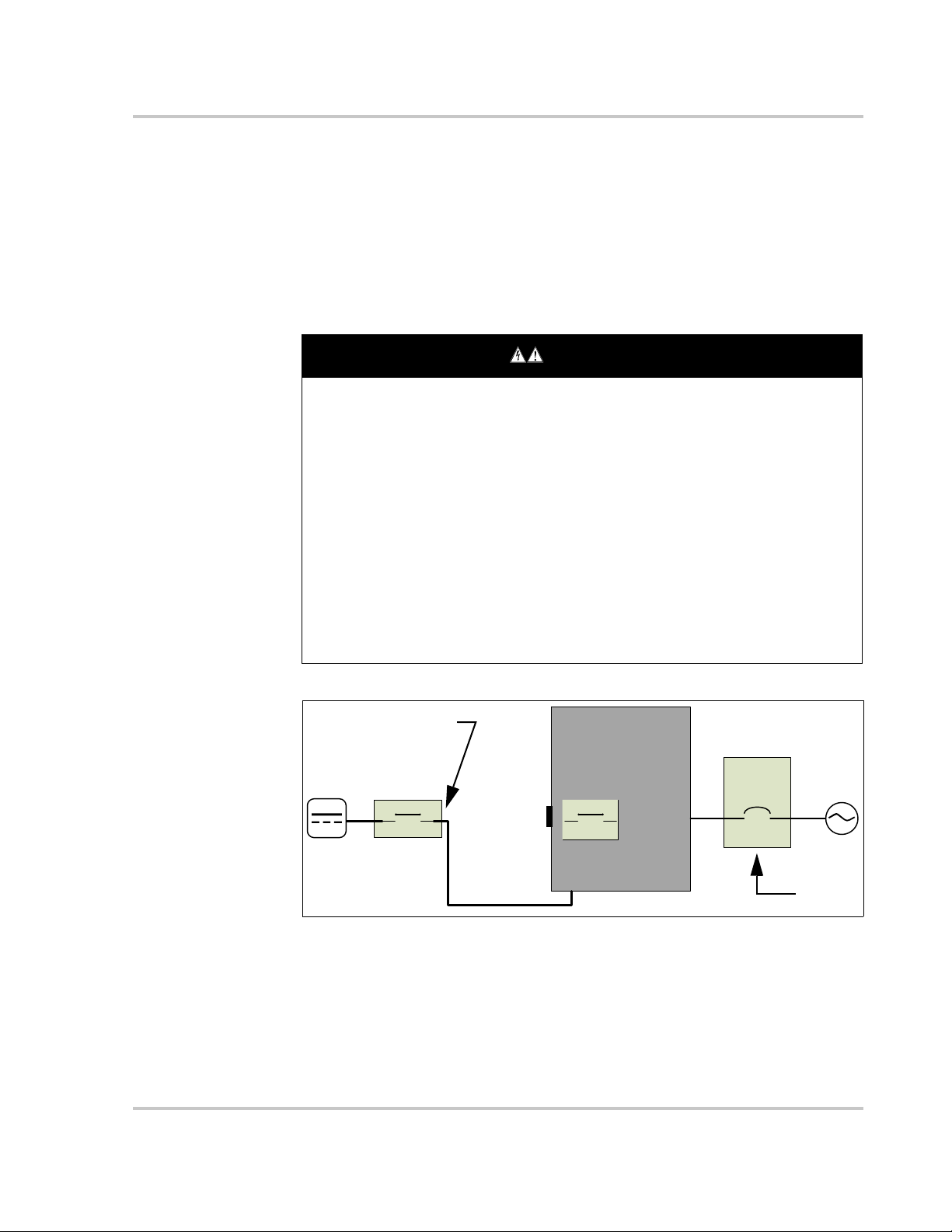

Technical Features

LCD/RS485

DSP+CPLD

DC

L1

L2

L3

N

PE

NL3L2L1

PE

DC

DC In

+-

+-

NL3L2

L1

PE

DC

DC In

+-

+-

L1 L2 L3

N

L1 L2 L3

N

DC EMI

Filter

DC bus

Inversion

circuit

AC

EMI

Filter

AC

Reactor

Relay

Fan

AC SPD

DC

switch

AC

switch

DC SPD

Current detection

DC SPD

DC

switch

DC fuse

DC fuse

Auxilia ry

power circuit

Current detection

CL-60E Wiring Box contents CL-60A Wiring Box contents

- DC switch

- 14 strings

- 15A fuses in positive polarity

- monitoring in negative polarity

- type 2 DC SPD

- type 3 AC SPD

- DC switch

- 8 inputs (1@ for 2 combined strings)

- 30A fuses in both polarities

- type 2 DC SPD

- type 3 AC SPD

- AC switch

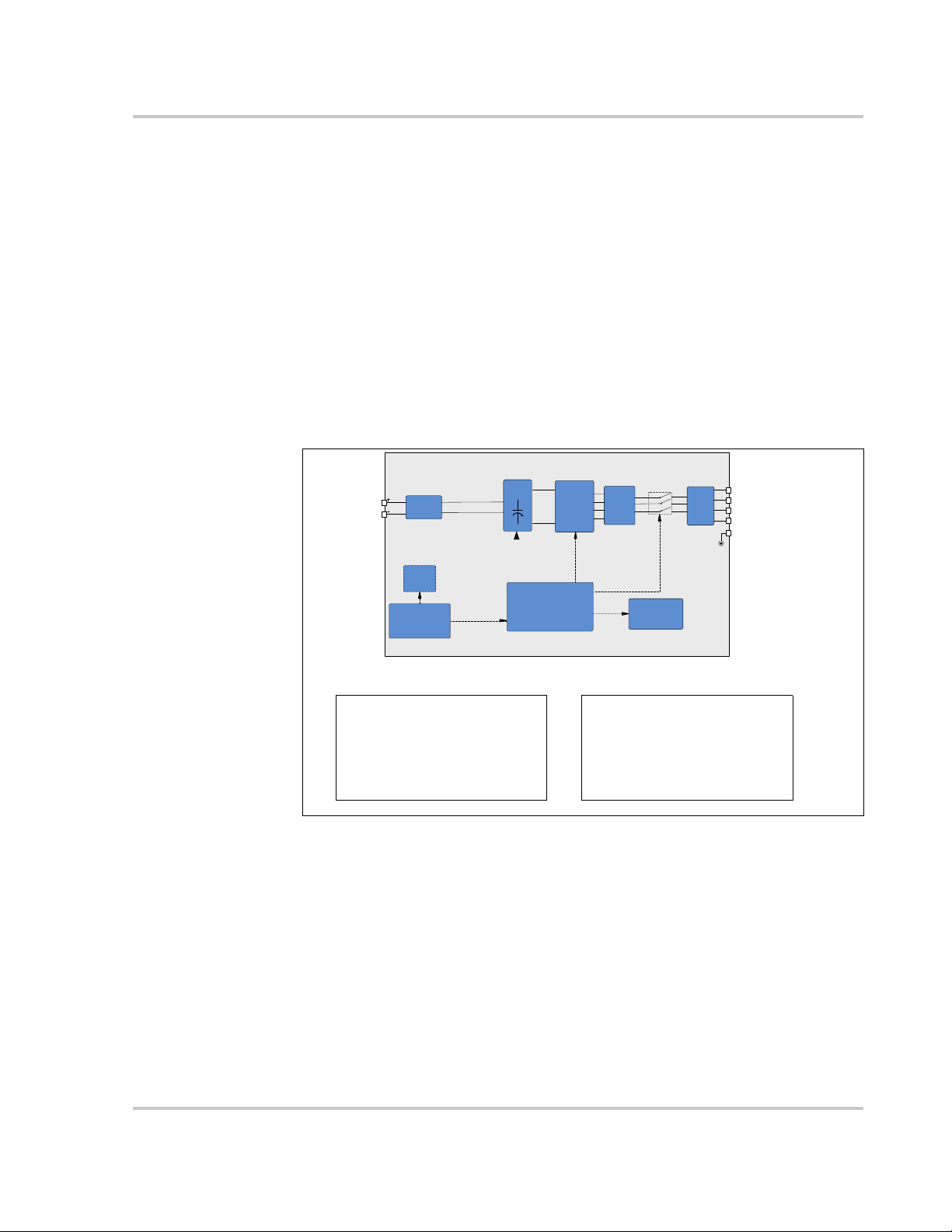

CL-60 Circuit Diagram

Figure 1-8 shows the main circuit of the PV Inverter.

Maximum Power Point Tracking (MPPT) is utilized to optimize harvesting DC

power from the PV array with different PV input conditions.

The PV Inverter circuit converts DC power into AC power and feeds it to the utility

grid through the inverter’s AC terminal. The protection circuit is equipped to

ensure the device’s safe operation and personal safety.

The DC switch is used to disconnect DC power from the PV Array safely.

The inverter provides standard RS-485 ports for communication.

Technical Features

Figure 1-8 Conext CL-60 Circuit Diagram

Standard Features

Inverter Function The device’s main function is to convert DC current into grid-

compatible AC current then feed this current into the grid.

Data Storage and LCD Display The onboard memory stores information such

as fault detection and displays them on the screen of the integrated LCD Display.

Device Configuration The LCD Display provides the main interface for

accessing device settings and changing them for optimal operation of the

inverter.

975-0768-01-01 Revision B 1–9

Introduction

Communication Interface Features a standard RS-485 port which can be

connected with a monitoring device such as a power meter,

Protection Features The unit is equipped with the following features for

preventing inverter damage, other equipment damage, and personal injury

hazards.

• Short-circuit protection

• Ground insulation resistance detection

• Inverter output voltage monitoring

• Inverter output frequency detection

• Residual current protection

• DC injection of AC output current surveillance

• Anti-islanding protection

• Ambient temperature monitoring

• DC over-voltage protection

• Over-current protection

• Power module over-temperature protection

• Fan failure protection

• Arc fault detection and protection (for CL-60A)

Derating Feature

Output derating is a way to protect the inverter from overload or potential fault

detections. These situations prompt the PV Inverter to initiate power derating:

• Altitude higher than 3000 meters

• Internal temperature is too high (including ambient temperature and

internal components temperature)

NOTE: For example, installing the inverter in an enclosed

space may hasten derating.

• Grid voltage is too low

• External power class adjustment

• Grid frequency is too high (see NOTE)

NOTE: Valid only when the country selected is DE or IT.

• High grid voltage with a simultaneous low PV voltage.

Power Limit Setting Inverter output power can be adjusted via the LCD

Display or a remote grid dispatch from the utility company. The corresponding

operating state will be displayed on the LCD screen.

1–10 975-0768-01-01 Revision B

Technical Features

Vmpp=600V

Vmpp=710V

Vmpp=850V

40 45

50 55 60

40

45

50

55

60

Ambient Temp (°C)

Apparent Power˄KVA˅

CL-60E Temperature Derating Curve

˄Vac=400V˅

35

66

Vmpp=600V

Vmpp=710V

Vmpp=850V

40 45

50 55 60

40

45

50

55

60

Ambient Temp (°C)

Apparent power˄KVA˅

CL-60A Temperature derating curve

˄Vac=380V˅

35

63.36

NOTE: The lower limit of the over-temperature derating is 75% of nominal power.

If both the module and internal temperatures reach power derating conditions, the

inverter will derate the power output based on the lower temperature between the two.

not to scale

V

min

V

max

P

n

215V

Working area

P[Vmin…266V] = Pn × (Vgrid / 230V)

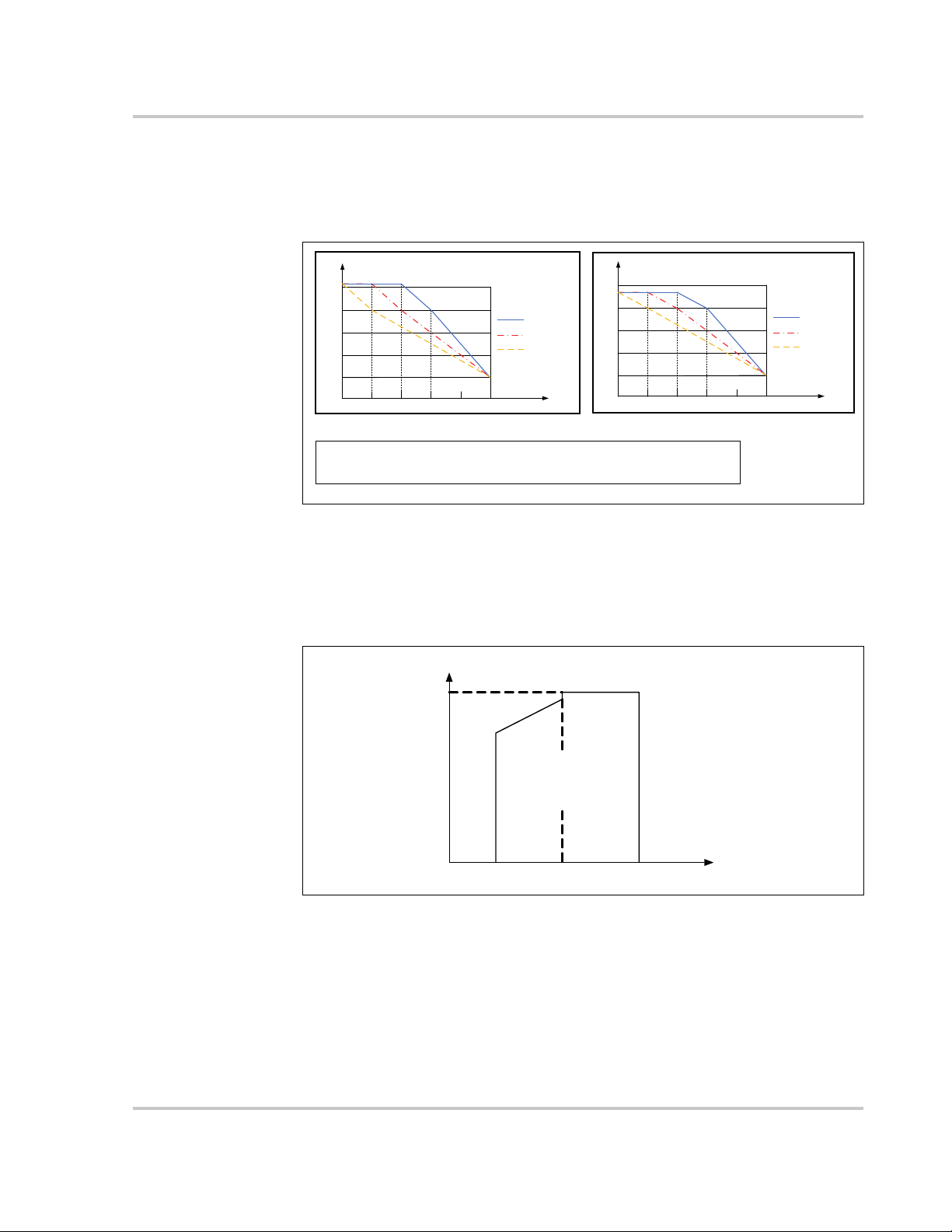

Over-temperature Derating High ambient temperature, a blocked fan, or poor

ventilation will initiate inverter power derating.

When the temperature inside the unit exceeds the upper limit, the inverter will derate

its power output until the internal temperature drops within the allowable range.

Figure 1-9 Over-Temperature Derating

Grid Under-voltage Derating When grid voltage is low, the inverter will derate

the output power to make sure the output current is within the allowable range.

Once the grid voltage is within Vmin (215V), the inverter will derate its output

power.

Figure 1-10 Grid Under-Voltage Derating

975-0768-01-01 Revision B 1–11

Introduction

Output voltage max when PV voltage < 860

Output voltage max when PV voltage < 890

Output voltage max when PV voltage < 950

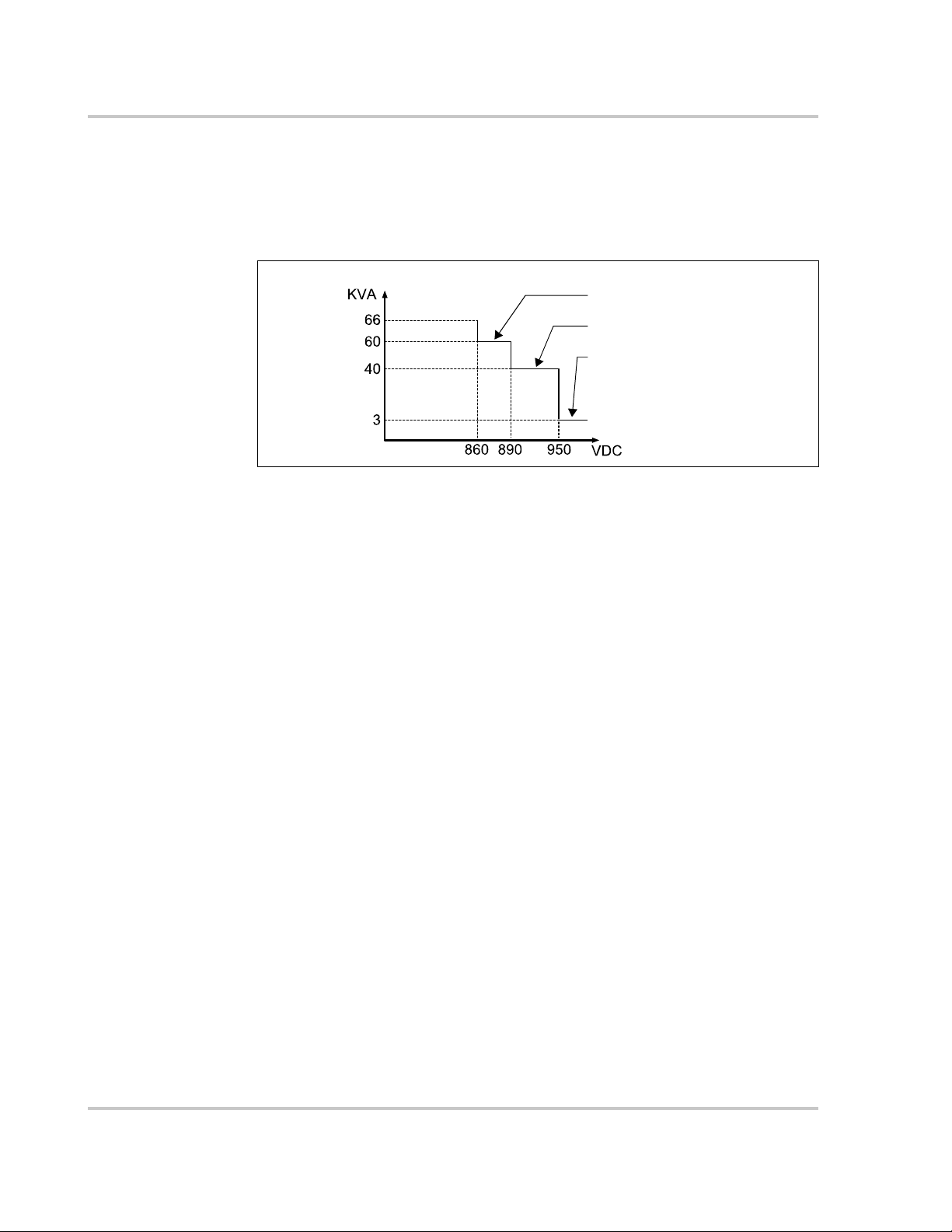

PV Over-voltage Derating The inverter regularly scans the PV voltage every 25

minutes and forces the PV to derate to test whether the maximum power point is

less than 860 volts.

At 66 KVA, if the maximum power point is higher than 860 volts, then the inverter

will return to the higher voltage limit before it starts derating.

Figure 1-11 PV Over-Voltage Derating

1–12 975-0768-01-01 Revision B

2 Installation

Chapter 2 contains information about:

• Pre-Installation

• Installation

975-0768-01-01 Revision B 2–1

Installation

Pre-Installation

Before installing the Conext CL-60, read all instructions and cautionary markings

in this Guide.

NOTE: Obtain all necessary permits prior to starting the installation.

Installations must meet all local codes and standards. Installation of this

equipment should only be performed by skilled personnel such as qualified

electricians and Certified Renewable Energy (RE) System installers.

Planning the Installation

• Read this entire chapter before beginning the installation. It is important to

plan the installation from beginning to end.

• Assemble all tools and materials needed for the installation.

2–2 975-0768-01-01 Revision B

Installation

DANGER

ABCD

EF G H I

NOTE: Use only these

fasteners when mounting

the inverter.

ELECTRIC SHOCK AND FIRE HAZARD

• Do not connect the PV Inverter to a live power source prior to cabling and

wiring found in Chapter 3, “Electrical Connections”. The inverter can be

energized from two sources namely, DC from the PV array and AC from the

grid.

• Do not connect any powered device to the PV Inverter during installation.

Failure to follow these instructions will result in death or serious injury.

What’s In The Box

The following materials are supplied in the Conext CL-60 package:

First Row • A CL-60 unit

• B Wall-mounting backplate

• C CL-60 USB drive contains the CL-60 Owner’s Guide

• D CL-60 Quick Install Guide including extra multi-lingual product labels

Second Row • E Metal frame M10x45 fasteners (6x)

• F M4x16 backplate screws (2x)

• G Screw-in handles (4x)

• H MC4 DC cable connectors (14x pairs) for the CL-60E

Amphenol

• I AC cable gland

®

H4 DC cable connectors (8x pairs) for the CL-60A

Installation

Figure 2-1 What’s In the Box

975-0768-01-01 Revision B 2–3

Installation

DANGER

Material and Tools

The following materials and tools are not supplied but are required to complete

the installation:

• Personal protective equipment (PPE)

• Screwdriver and drill set (powered and/or manual)

• Six (M10x65) screws (for fastening wall-mounting backplate to the wall)

• Calibrated professional digital multimeter

• Crimping tool from Multi-Contact (http://www.multi-contact-usa.com/ for CL-

Location Information

ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH HAZARDS

• Apply appropriate personal protective equipment (PPE) and follow safe

• This equipment must only be installed and serviced by qualified electrical

• Never energize the inverter with the covers removed.

• Do not open fuse holders under load. The fuse must be de-energized from

• The inverter is energized from multiple sources. Before removing covers

• Always use a properly rated voltage sensing device to confirm all circuits

• Replace all devices and covers before turning on power to this equipment.

• The DC conductors of this photovoltaic system are ungrounded and may

Failure to follow these instructions will result in death or serious injury.

60E) and Amphenol (https://www.amphenol.com/ for CL-60A)

electrical work practices.

personnel.

all sources before servicing.

identify all source, de-energize, lock-out, and tag-out and wait 10 minutes.

See “Lock-Out Tag-Out (LOTO) Procedure” on page xi.

are de-energized.

be energized.

Environment The CL-60 is IP65 rated (CL-60E) and Type 4X rated (CL-60A). It is suitable for

outside installation.

The ambient temperature should be within the range of –25 to 60 °C (–13 to

140 °F) to prevent automatic power derating in over-temperature conditions.

Relative humidity at the installation site can be from 0 to 100%.

Allow for at least 600 mm (~24 inches) clearance on all sides of the inverter.

When installing another inverter next to it (or several inverters around it), increase

the clearance between inverters from all sides to 800 mm (~32 inches).

See Figure 2-2, “Clearances and Ambient Temperature” on page 2–5.

2–4 975-0768-01-01 Revision B

Fire Safety

600mm

~24”

800mm

~32”

600mm

~24”

600mm

~24”

-13 +140 °F

-25 +60 °C

between

CL-60s

between other

objects

WARNING

Installation

Figure 2-2 Clearances and Ambient Temperature

IGNITION AND FIRE HAZARD

• This equipment is not ignition protected. To prevent fire or explosion, do

not install this product in locations that require ignition-protected

equipment. This includes any confined space containing lead acid

batteries, or flammable chemicals such as, natural gas (NG), liquid

petroleum gas (LPG) or gasoline (Benzine/Petrol).

• Do not install in a confined space with machinery powered by flammable

chemicals, or storage tanks, fittings, or other connections between

components of fuel or flammable chemical systems.

• Do not install the CL-60 on a wooden/plastic/plaster wall.

• Do not install the CL-60 near readily flammable materials such as cloth,

paper, straw, or plastic sheeting. Keep flammable materials from all sides

including the front of the CL-60.

Failure to follow these instructions can result in death or serious injury.

Flammable or combustible materials are defined as “any material containing

wood, compressed paper, cellulose, plant fibers, plastics, liquids, or other

material that will ignite and burn, whether flame-proofed or not” according to

NFPA 70E. Flammable liquids are defined as “any liquid whose flash point does

not exceed 100 °F (38 °C).” Examples of flammable liquids are gasoline,

methanol, and ether.

When choosing a wall or flat surface to install the CL-60, choose a wall or flat

surface that is not considered a flammable material such as concrete, brick, or

metal.

975-0768-01-01 Revision B 2–5

Installation

CAUTION

WARNING

Handling

Precautions

HEAVY LOAD HAZARD

• Do not handle and lift the unit by yourself. Use two people to move, lift,

and mount the unit.

• Always use proper lifting techniques during installation including using the

provided screw-in handles.

• When handling the inverter, install all four screw-in handles to both sides of

the inverter first and make sure they are seated correctly in their slots.

• Do not substitute the screw-in handles with something else. Use only the

provided screw-in handles.

• Use mechanical or motorized hand trucks and/or lifts whenever possible

to aid in proper handling.

Failure to follow these instructions can result in moderate or minor injury.

Storage

Considerations

Location Hazards In order to avoid other potential hazards follow the instructions in the WARNING

If the inverter cannot be installed immediately after delivery at the installation site,

consider storing the inverter inside its original carton and setting it aside away

from potential damage. For more guidelines, see “Storage Information” on

page x.

below.

ELECTRICAL SHOCK, FIRE, AND PHYSICAL INJURY HAZARD

• Install the CL-60 on a concrete wall or metal frame which can support the weight

(66 kg (CL-60E) /147 lbs(CL-60A)) of the unit over time. When installing multiple

units, make sure the wall or metal frame can support the total weight of the units

over time.

• Install the unit upright at 90° vertical angle in relation to the floor. The unit

can also be installed horizontally flat and parallel to the floor. When

installing on a slope, the top of the unit must be higher than its bottom.

• Install the unit at the recommended height of 1.2 m (4 ft.) for easy access

to the terminals and ports.

• Avoid installing the CL-60 in completely uncovered locations where

persistent rain and moisture spray can eventually penetrate the enclosure.

Install under a covered structure.

• Install a separate and external surge protection device to protect the CL60’s power module and communication ports.

Failure to follow these instructions can result in death or serious injury.

2–6 975-0768-01-01 Revision B

Installation

NOTICE

90°

<90°

0°

Not allowed

Allowed

EQUIPMENT DAMAGE

• Avoid installing the CL-60 in direct sunlight or near other heat sources like

the exhausts of inverters and generators, steam exhausts from boilers and

dryers, and engine compartments. Install in shaded locations.

• Choose a location and an installation layout that minimizes potentially

induced voltage spikes that might damage the electronics.

Failure to follow these instructions can result in equipment damage.

Figure 2-3 Mounting Orientations

975-0768-01-01 Revision B 2–7

Installation

NOTE: To install the inverter onto a

concrete wall, use the recommended

M10x65 screws (not supplied).

6x M10

NOTE: Whenever possible, use only

the supplied fasteners when mounting

the inverter.

26 mm

~1 in

425 mm

~16.7 in

524 mm

~20.6 in

544 mm

~21.4 in

32 mm

~1.2 in

2x M4x7

74 mm

~2.9 in

90 mm

~3.5 in

512 mm

~20.2 in

DANGER

Install and Mount the CL-60

Figure 2-4 Wall-mounting Backplate Dimensions

To install on a concrete or brick wall in an upright position:

1. Remove the wall-mounting backplate and the two M4x12 backplate screws

from the CL-60 packaging.

2. Follow all preceding precautions and warnings starting on page 2–3.

3. Unpack the backplate from the box and use the backplate to mark the

location of the holes on the wall. See Figure 2-5, “Mark and Pre-drill Wall” on

page 2–9.

EXPLOSION HAZARD

Check that there are no plumbing or gas pipes or electrical conduits behind

the wall when marking for holes and before drilling.

Failure to follow these instructions will result in death or serious injury.

2–8 975-0768-01-01 Revision B

Installation

4. Pre-drill the mounting surface, if necessary. See Figure 2-5, “Mark and Predrill Wall” on page 2–9.

Figure 2-5 Mark and Pre-drill Wall

5. Unpack the screw-in handles and install them as shown. Screw in the

handles until they are fully seated in the inserts. See Figure 2-6, “Install

Screw-in Handles” on page 2–9.

Figure 2-6 Install Screw-in Handles

6. Fasten the wall-mounting backplate to the wall with six M10x65 screws (not

supplied). Use a torque of 35 Nm (25.8 lbf-ft) to fasten the screws and the

backplate.

975-0768-01-01 Revision B 2–9

Installation

use the handles to

mount the inverter

to the backplate

after hanging the inverter to the

backplate, lock it with the two M4 screws

(supplied)

for illustration

purposes only

7. Mount (hang) the inverter manually onto the backplate.

Figure 2-7 Mounting the CL-60

8. Lock the inverter to the backplate by fastening the two screws (M4x16) as

shown. See Figure 2-7.

9. Remove the screw-in handles from the sides of the inverter and store them

away from the top of the inverter or inside the inverter enclosure.

2–10 975-0768-01-01 Revision B

Installation

backplate

bolt (M10x45)

metal frame

hex nut (M10)

spring washer

flat washer

NOTE: Whenever possible, use only

the supplied fasteners when mounting

the inverter.

To install on a metal frame in an upright position:

1. Remove the backplate, its corresponding metal frame fasteners, and the two

M4x12 backplate screws from the CL-60 packaging. Use only the provided

metal frame fasteners for attaching to a metal frame structure.

2. Follow all preceding precautions and warnings starting on page 2–3.

3. Use the backplate to mark the metal frame with the location of the holes to be

drilled. See Figure 2-8.

4. Pre-drill the mounting surface, if necessary. See Figure 2-8.

Use a drill bit appropriate for a bolt of size M10.

Figure 2-8 Mark and Pre-drill Metal Frame

5. Unpack the screw-in handles and install them as shown. Screw in the

handles until they are fully seated in the inserts. See Figure 2-6, “Install

Screw-in Handles” on page 2–9 for an illustration.

6. Fasten the backplate to the metal frame using the metal frame fasteners that

came with the CL-60 packaging. Use a torque of 35 Nm (25.8 lbf-ft) to fasten

the nut and the backplate.

Figure 2-9 Securing the Backplate to the Metal Frame

7. Mount (hang) the inverter manually onto the backplate. See Figure 2-7,

“Mounting the CL-60” on page 2–10 for a similar illustration.

8. Lock the inverter to the backplate by fastening the two screws (M4x16). See

Figure 2-7, “Mounting the CL-60” on page 2–10 for a similar illustration.

9. Remove the screw-in handles from the sides of the inverter. See Figure 2-7,

“Mounting the CL-60” on page 2–10 for a similar illustration.

975-0768-01-01 Revision B 2–11

Installation

WARNING

450mm

~18”

ground (floor)

for illustration

purposes only

To install on a horizontally flat metal or concrete surface:

ELECTRICAL SHOCK AND FIRE HAZARD

• Do not install the unit within 800 mm (31.5 inches) of vegetation (weeds,

grass) and other flammable materials. See the definition of flammable

materials in “Fire Safety” on page 2–5.

• Provide a minimum distance of 450 mm (~18 inches) between the PV

Inverter’s back and the ground (the floor).

• Install the backplate even though the inverter is not going to hang on it.

The backplate provides stability for the inverter.

• Be careful to check that there are no plumbing or gas pipes or electrical

conduits underneath the flat surface you are marking for holes.

Failure to follow these instructions can result in death or serious injury.

1. Remove the wall-mounting backplate and its corresponding fasteners from

the CL-60 packaging.

2. Follow all preceding precautions and warnings starting on page 2–3.

3. Unpack the backplate from the box and use the backplate to mark the flat

surface with the location of the holes to be drilled. See Figure 2-5, “Mark and

Pre-drill Wall” on page 2–9.

4. Pre-drill the mounting surface, if necessary. Use a drill bit appropriate for a

bolt of size M10.

Figure 2-10 Ground Clearance and Fastening the Backplate

5. Unpack the screw-in handles and install them as shown. Screw in the

handles until they are fully seated in the inserts. See Figure 2-6, “Install

Screw-in Handles” on page 2–9.

2–12 975-0768-01-01 Revision B

Installation

for illustration

purposes only

450 mm

~18 in.

6. Fasten the backplate to the flat metal surface (using the metal frame

fasteners that came with the CL-60 packaging, if necessary) or concrete

surface (using M10x65 screws which are not provided). Use a torque of 35

Nm (25.8 lbf-ft) to fasten the nut and the backplate.

7. Lay the inverter manually onto the backplate to lock its position. Handle the

inverter by the screw-in handles.

Figure 2-11 Mounting to a Flat Surface

8. Lock the inverter to the backplate by fastening the two screws (M4x16). See

Figure 2-7, “Mounting the CL-60” on page 2–10 for a similar illustration.

9. Remove the screw-in handles from the sides of the inverter. See Figure 2-7,

“Mounting the CL-60” on page 2–10 for a similar illustration.

975-0768-01-01 Revision B 2–13

Installation

WARNING

within 90º angle

for illustration

purposes only

top

bottom

bottom

top

To install on a sloped metal or concrete surface:

Examples of sloped surfaces are rooftops and uneven terrain.

ELECTRICAL SHOCK AND FIRE HAZARD

• Do not install the unit on a slope in which the top part of the inverter is

lower than its bottom. See Figure 2-12 below.

• Be careful to check that there are no plumbing or gas pipes or electrical

conduits underneath the surface you are marking for holes.

Failure to follow these instructions can result in death or serious injury.

◆ Follow the same procedures in the previous section “To install on a

horizontally flat metal or concrete surface:” on page 2–12.

Figure 2-12 Installing on Sloped Surfaces

2–14 975-0768-01-01 Revision B

Torq u e Va l u e s

CAUTION

NOTICE

Installation

FIRE HAZARD

Tighten fasteners such as screws, nuts, bolts, and cable glands (used for

routing field wiring and current carrying cable) according to the

recommendations in the table below. Incorrect torque may cause a fire.

Failure to follow these instructions can result in moderate or minor injury.

EQUIPMENT DAMAGE

Tighten fasteners such as wall screws, metal frame nuts, and panel screws

according to the recommendations in the table below. Over torquing may

damage the head of the fastener. Under torquing may loosen the installation

over time.

Failure to follow these instructions can result in equipment damage.

Tab l e 2 -1 Summary of Torque Values

Type Description Nm (IEC) lbf-ft (NA)

cable gland for communication cables

such as RS-485 Ethernet

cable

cable gland for smaller AC cable 12–13 8.8–9.6

cable gland for larger AC cable 16–17 11.8–12.5

connector screw RS-485 wire connector 0.2 0.15

fastener transparent protection

panel

fastener lower enclosure panel 4.3 ±0.2 3.2 ±0.15

fastener to lock the CL-60 unit to

the mounting backplate

fastener (metal) metal frame-mounting

backplate nut

fastener (wall) wall-mounting backplate

expansion

terminal gland MC4 DC terminal 2.5–3 1.8–2.2

terminal screw AC terminal block 4.3 ±0.2 3.2 ±0.15

terminal screw PE (ground) terminal

block

3.75 2.8

0.8 ±0.1 0.6 ±0.1

2.7–4.8 2–3.5

35 25.8

35 25.8

4.3 ±0.2 3.2 ±0.15

975-0768-01-01 Revision B 2–15

Installation

•THIS PAGE INTENTIONALLY BLANK•

2–16 975-0768-01-01 Revision B

3 Electrical

Connections

Chapter 3 contains information about:

• Precautions

• Cabling and Wiring

• Communication Connection

975-0768-01-01 Revision B 3–1

Electrical Connections

Precautions

Before connecting the Conext CL-60 to electrical cables, wires, and

communication cables, read all instructions and cautionary markings in this

Guide.

NOTE: Obtain all necessary permits prior to starting the installation.

Installations must meet all local codes and standards. Installation of this

equipment should only be performed by skilled personnel such as qualified

electricians and Certified Renewable Energy (RE) System installers.

Planning the Electrical Connections

• Read this entire chapter before making electrical connections to and from the

unit. It is important to plan the installation from beginning to end.

• Assemble all tools and materials needed for the installation.

3–2 975-0768-01-01 Revision B

Cabling and Wiring

DANGER

ELECTRIC SHOCK AND FIRE HAZARD

• All wiring must be done by qualified personnel to ensure compliance with

all applicable installation codes and regulations.

• Do not connect the PV Inverter to a live power source prior to finishing all

cabling and wiring. The inverter can be energized from two sources

namely, DC from the PV array and AC from the grid.

• Do not connect any powered device to the PV Inverter during cabling and

wiring.

Failure to follow these instructions will result in death or serious injury.

Material and Tools

The following materials and tools are not supplied but are required to complete

the installation:

• AC power cable (4-wire/5-wire)

• Crimping tool from Multi-Contact (http://www.multi-contact-usa.com/ for CL60E) and Amphenol (https://www.amphenol.com/ for CL-60A)

• DC power cable (color-coded - red for (+), black for (-))

• RS-485 cable(s) for Modbus/RS-485 device connections

• Wire stripper, RJ45 crimper, connector tool spanner

• Screwdriver set, pliers

• CAT6/5/e network cable(s) for Modbus/RS-485 PV Inverter and Ethernet TCP/

IP connections

• Laptop computer (PC or Mac)

• Network router for LAN and internet connectivity

Cabling and Wiring

Once the Conext CL-60 is installed at the site, it is now ready to be connected to

the PV array and the utility grid.

975-0768-01-01 Revision B 3–3

Electrical Connections

DANGER

ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH HAZARDS

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must only be installed and serviced by qualified electrical

personnel.

• Never energize the inverter with the covers removed.

• Do not open fuse holders under load. The fuse must be de-energized from

all sources before servicing.

• The inverter is energized from multiple sources. Before removing covers

identify all source, de-energize, lock-out, and tag-out and wait 10 minutes.

See “Lock-Out Tag-Out (LOTO) Procedure” on page xi.

• Always use a properly rated voltage sensing device to confirm all circuits

are de-energized.

• Replace all devices and covers before turning on power to this equipment.

• The DC conductors of this photovoltaic system are ungrounded and may

be energized.

Failure to follow these instructions will result in death or serious injury.

3–4 975-0768-01-01 Revision B

Terminal and Cable Entry Points (for CL-60E)

1

2

4

3

5

678

910

Front

View

Bottom

View

The CL-60E’s electrical connection terminals are located inside the inverter

wiring box and the cable entry points are at the bottom of the unit.

Cabling and Wiring

Figure 3-1 Terminals and Cable Entry Points

Tab l e 3 -1 Description of Terminals and Cable Entry Points

No. Description No. Description

1 DC switch 6 DC input MC4 terminals

2 DC SPD 7 Communication cable glands

3 AC crimping terminal 8 AC cable gland (large)

4 DC fuse board 9 Second PE (ground) location

5 Communication circuit board 10 Waterproof air valve

975-0768-01-01 Revision B 3–5

Electrical Connections

1

23

4

6

8910

1112

Front

View

Bottom

View

5

7

Terminal and Cable Entry Points (for CL-60A)

The CL-60A’s electrical connection terminals are located inside the inverter

wiring box and the cable entry points are at the bottom of the unit.

Figure 3-2 Terminals and Cable Entry Points

Tab l e 3 -2 Description of Terminals and Cable Entry Points

No. Description No. Description

1 DC switch 7 Communication circuit board

2 DC SPD 8 DC input Amphenol H4

3 Arc fault circuit interrupter 9 Communication cable glands

4 AC crimping terminal 10 AC cable gland (large)

5 AC switch 11 Second PE (ground) location

6 DC fuse board 12 Waterproof air valve

terminals

3–6 975-0768-01-01 Revision B

AC Side Cable Connection

NOTICE

AC Side Requirements

NOTE: Connection to the utility grid must be done only after receiving approval

from the local company.

Before connecting to the grid, verify that both the grid voltage and frequency

meet the requirements of the CL-60’s voltage and frequency settings. Contact the

local utility company for a solution if the grid does not meet the specifications. For

information on the settings, see “Product Specifications” on page 8–2.

AC Circuit Breaker

An independent three- or four-pole circuit breaker must be installed downstream

from the inverter before the grid connection. This is to ensure that the inverter can

be disconnected safely from the grid.

Inverter Recommended

CL-60E

CL-60A

Cabling and Wiring

AC circuit breaker

120A

EQUIPMENT DAMAGE

• Do not connect multiple PV Inverters to a single circuit breaker.

• Do not connect loads between the PV Inverter and the circuit breaker.

Failure to follow these instructions can result in damage to the inverter

and other connected equipment.

Residual Current Device

With an integrated comprehensive residual current monitoring component, the

inverter is capable of distinguishing a ground fault current from normal

capacitive leakage current. This allows the inverter to disconnect from the grid as

soon as the ground fault is detected.

975-0768-01-01 Revision B 3–7

Electrical Connections

L1

L2

L3

N

PE

inverter 1 inverter 2 inverter n

...

U2

V2

W2

U1

V1

W1

N

inverter 1 inverter 2 inverter n

...

low voltage high voltage

MV Transformer

Multiple Inverters in Parallel Connection

Follow either of the two scenarios when attempting to connect several inverters in

parallel to the grid.

Scenario 1 Several inverters are in parallel connection to the 3-phase low voltage grid.

Requirements If the number of the grid-connected PV Inverters exceed 40,

contact a local Schneider Electric Sales Application Engineer (SAE).

Scenario 2 Several inverters are in parallel connection to the low voltage side of the MV

transformer. The high voltage side is connected to the MV grid.

3–8 975-0768-01-01 Revision B

Requirements If the number of the grid-connected PV Inverters exceed 40,

contact a local Schneider Electric Sales Application Engineer (SAE).

The nominal power of the MV transformer’s low voltage side matches the

inverter’s output power.

NOTE: It is recommended to use a transformer with a short circuit impedance

of less than 6%.

Grid Connection

230 235 240 245 250 255 260

0

0.5

1

1.5

2

Max. grid impedance [Ohm]

AC voltage without loads [V]

265

Cabling and Wiring

The AC terminal block on the bottom of the CL-60E inverter accommodates an

AC connection for a 3-phase-5-wire grid connection (L1, L2, L3, N and PE).

The AC terminal block on the bottom of the CL-60A inverter accommodates an

AC connection for a 3-phase-4-wire grid connection (L1, L2, L3, and GND).

AC Cable Requirements

Select AC cables according to the following factors:

• Grid impedance should correspond to the specifications below to avoid

accidental short-circuit or output power derating.

• When calculating voltage drop, a cable with a higher cross section area

could be selected to ensure power loss within a 1% limit. Check that the

AC cable outer diameter is suitable for the AC terminals of the inverter.

• Ambient temperature

• Cable layout (that is, inside wall, underground, free air, etc.)

• UV resistance

• Cable resistance / length

975-0768-01-01 Revision B 3–9

Electrical Connections

DANGER

AC Cable

Connection

To connect the PV Inverter to the grid:

ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH HAZARD

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must only be installed and serviced by qualified electrical

personnel.

• Never energize the inverter with the covers removed.

• Do not open fuse holders under load. The fuse must be de-energized from

all sources before servicing.

• The inverter is energized from multiple sources. Before removing covers

identify all source, de-energize, lock-out, and tag-out and wait 10 minutes.

• Always use a properly rated voltage sensing device to confirm all circuits

are de-energized.

• Replace all devices and covers before turning on power to this equipment.

• The DC conductors of this photovoltaic system are ungrounded and may

be energized.

• Do not connect to the AC circuit breaker until all inverter electrical

connections are completed.

Failure to follow these instructions will result in death or serious injury.

1. Open the AC circuit breaker (turn it OFF) and perform the “Lock-Out Tag-Out

(LOTO) Procedure” on page xi.

2. Remove the six screws on the front cover of the wiring box to access the

terminals.

3–10 975-0768-01-01 Revision B

Cabling and Wiring

1

2

34

PE

L1

L2

L3

N

For illustration

purposes only.

3. Strip the cables as shown below. Example below is for a five-wire cable.

NOTE:

For AC cables with stranded wires, use cold-press terminal lugs for

termination. Always use lugs that grip the shape of the wires on AC cables. Always

use the proper lugs according to the type of metal of the wires on AC cables.

The cross-section diameter of the AC cable must be selected carefully in order to

prevent accidental disconnections of the inverter from the grid due to high

impedance of the cable.

No. Description Remark

1 Protective layer External diameter of the cable:

Proper range 25 to 40 mm (~1 to 1.5 in)

2 Length of insulation to

24 mm (~1 in)

be stripped off

3 Insulation layer -

4 Cross section of AC

cable

Range: 25 to 95 mm

Recommended value: 50 mm

2

2

5 Type Aluminum or copper

• Use a smaller AC cable gland (supplied), if the selected AC cable has an

external diameter of between 25 to 30.5 mm (~1 to 1.25 in).

For replacement instructions, see “To replace the larger AC cable gland with

the smaller AC cable gland:” on page 3–13.

• Use a larger AC cable gland (pre-installed), if the selected AC cable has an

external diameter of between 30.5 to 40 mm (~1.25 to 1.5 in).

There is no need to replace this AC cable gland.

975-0768-01-01 Revision B 3–11

Electrical Connections

For illustration

purposes only.

PE | N | L3 | L2 | L1

L3 | L2 | L1

GND

CL-60E

CL-60A

The following table lists the recommended maximum length of the AC cable

based on its cross-section diameter.

Cross-section of the

AC cable (mm

2

)

Max. length of the AC

cables (m) Cu

25 0-50

35 50-100

50 >100

4. Select the corresponding AC cable gland based on the actual AC cable

diameter.

Remove or install the two selected AC cable glands at the bottom of the

wiring box using the torque guidelines below.

• Smaller AC cable gland (supplied): Torque of 12-13 Nm (~9.2 lbf-ft)

• Larger AC cable gland (pre-installed): Torque of 16-17 Nm (~12.2 lbf-ft)

5. Connect the AC cable’s wires to their corresponding terminals.

6. Pull the cable away from the terminals gently to make sure the wires do not

disconnect from their terminals.

3–12 975-0768-01-01 Revision B

Cabling and Wiring

NOTICE

remove the sealing nut

with a torque of 16-17

Nm (~12.2 lbf-ft)

sealing nut

lock nut

pre-installed

AC cable gland

(large)

sealing nut

lock nut

supplied AC cable

gland (small)

replace the sealing nut

with a torque of 12-13 Nm

(~9.2 lbf-ft)

EQUIPMENT DAMAGE

• Observe and strictly follow the AC terminal layout. The PV Inverter will not

work normally if the phase wire is connected to the PE terminal.

• Do not insert wires without stripping the insulation layer. Damaged wires

may affect the normal operation of the inverter.

Failure to follow these instructions may cause inverter damage.

AC Cable Gland

Replacement

Instructions

To replace the larger AC cable gland with the smaller AC cable gland:

1. Remove the pre-installed larger AC cable gland.

2. Set the sealing and lock nuts aside for reuse.

3. Store the pre-installed AC cable gland (large).

4. Install the supplied AC cable gland (small) onto the unit.

5. Proceed with “AC Cable Connection” steps.

975-0768-01-01 Revision B 3–13

Electrical Connections

DANGER

DANGER

NOTICE

PV Array Connection

ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH HAZARDS

• Apply appropriate personal protective equipment (PPE) and follow safe

• This equipment must only be installed and serviced by qualified electrical

• Never energize the inverter with the covers removed.

• Do not open fuse holders under load. The fuse must be de-energized from

• The inverter is energized from multiple sources. Before removing covers

• Always use a properly rated voltage sensing device to confirm all circuits

• Replace all devices and covers before turning on power to this equipment.

• The DC conductors of this photovoltaic system are ungrounded and may

Failure to follow these instructions will result in death or serious injury.

electrical work practices.

personnel.

all sources before servicing.

identify all source, de-energize, lock-out, and tag-out and wait 10 minutes.

are de-energized.

be energized.

ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH HAZARDS

• Be careful when handling cables from PV arrays. PV arrays produce

• Check that the PV impedance to ground is within specifications before

Failure to follow these instructions will result in death or serious injury.

PV Input Configuration

The CL-60 PV Inverter has a PV input area and is equipped with a built-in

Maximum Power Point Tracker (MPPT).

EQUIPMENT DAMAGE

• Check and make sure that the voltage capacity rating of each PV array is

• Check that the maximum short circuit current on the DC side is within

Failure to follow these instructions may cause inverter damage.

electrical energy when exposed to light.

connecting the PV array to the inverter.

less than 1000 V.

specifications.

3–14 975-0768-01-01 Revision B

Cabling and Wiring

To make full use of the DC input power, PV modules should be homogenous. This

means that each module in the PV string must be of the same type and the same

number of PV cells. All the PV strings should have identical tilt and orientation.

Before connecting a PV string to the inverter, the following electrical parameters

must be met.

Max. open-circuit

Total DC power limit

voltage limit for each

input

Short-circuit current

limit

67500 W

a

a.Multiply by a factor of 1.35 for over-panelling.

1000 V 140 A

Considering the negative voltage temperature coefficient of PV cells, more

attention should be paid to the open-circuit voltage of PV strings when the

ambient temperature is the lowest. For example, consider the YL250P-29bPV

module.

Item Parameter

PV module model YL250P-29b

Power 250W

Open-circuit voltage (STC) 37.6V

Short-circuit current (STC) 8.92A

Open-circuit voltage temperature

coefficient (

)

-0.32%/°C

No. of PV modules in a PV string 23