Schneider Electric CL-60E, CL-60A User Manual

CL-60E CL-60A

Conext™ CL-60 PV Inverter

Owner’s Guide

975-0768-01-01 Revision B

03-2017

http://solar.schneider-electric.com

Conext™ CL-60 PV Inverter

Owner’s Guide

http://solar.schneider-electric.com

Copyright © 2017 Schneider Electric. All Rights Reserved. All trademarks are owned by Schneider Electric Industries SAS

or its affiliated companies. Other 3rd party trademarks are owned by their respective companies.

Exclusion for Documentation

U

NLESS SPECIFICALLY AGREED TO IN WRITING, SELLER

(A) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR OTHER INFORMATION PROVIDED

IN ITS MANUALS OR OTHER DOCUMENTATION;

(

B) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSSES, DAMAGES, COSTS OR EXPENSES, WHETHER SPECIAL, DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION

WILL BE ENTIRELY AT THE USER’S RISK; AND

(C) REMINDS YOU THAT IF THIS MANUAL IS IN ANY LANGUAGE OTHER THAN ENGLISH, ALTHOUGH STEPS HAVE BEEN TAKEN TO

MAINTAIN THE ACCURACY OF THE TRANSLATION, THE ACCURACY CANNOT BE GUARANTEED. APPROVED CONTENT IS CONTAINED WITH

THE ENGLISH LANGUAGE VERSION WHICH IS POSTED AT SOLAR.SCHNEIDER-ELECTRIC.COM.

Document Number: 975-0768-01-01 Revision: Revision B Date: 03-2017

Product Part Numbers: PVSCL60A (CL-60A—North American version)

PVSCL60E (CL-60E—IEC version)

Contact Information: http://solar.schneider-electric.com

Please contact your local Schneider Electric Sales Representative or visit our website at:

http://solar.schneider-electric.com/tech-support/

About This Guide

Purpose

The purpose of this Owner’s Guide is to explain the procedures for operating,

configuring, maintaining, and troubleshooting the Conext CL-60 PV Inverter.

Scope

The Guide provides safety guidelines and general information for installing and

operating the Conext CL-60, as well as information about configuring,

monitoring, and troubleshooting the unit. It does not include information on how

to use other Schneider Electric and third-party products.

Audience

The Guide is intended for use by anyone who plans to design, construct, install,

or operate a system involving the CL-60. The installation information in this guide

is intended for qualified personnel. Qualified personnel have training,

knowledge, and experience in:

• Installing electrical equipment and PV power systems (up to 1000 volts)

• Applying all applicable installation codes

• Analyzing and reducing the hazards involved in performing electrical work

• Selecting and using Personal Protective Equipment (PPE)

975-0768-01-01 Revision B v

About This Guide

Organization

This Guide is organized into:

Chapter 1, “Introduction”

Chapter 2, “Installation”

Chapter 3, “Electrical Connections”

Chapter 4, “Commissioning”

Chapter 5, “LCD Display Operation”

Chapter 6, “Troubleshooting”

Chapter 7, “Disconnecting, Dismantling, and Disposing the CL-60”

Chapter 8, “Specifications”

Abbreviations and Acronyms

Related Information

AFD

EMI

G

GND

HMI

IGBT

LAN / WAN

LCD

LED

NFPA

PE

PPE

PV

SPD

You can find more information about Schneider Electric, as well as its products

and services at http://solar.schneider-electric.com.

Arc Fault Detection device

Electromagnetic Interference

Ground (also referred as Protective Earth)

Human-Machine Interface

Insulated Gate Bipolar Transistor

Local Area Network / Wide Area Network

Liquid Crystal Display (used for HMI displays)

Light Emitting Diode (used for indicator lights)

National Fire Protection Association

Protective Earth (also referred as Ground)

Personal Protective Equipment

Photovoltaic (or Solar)

Surge Protection Device

vi 975-0768-01-01 Revision B

Important Safety Instructions

DANGER

WARNING

CAUTION

NOTICE

READ AND SAVE THESE INSTRUCTIONS - DO NOT DISCARD

This document contains important safety instructions that must be followed

during installation procedures (if applicable). Read and keep this Owner’s Guide

for future reference.

Read these instructions carefully and look at the equipment (if applicable) to

become familiar with the device before trying to install, operate, service or

maintain it. The following special messages may appear throughout this bulletin

or on the equipment to warn of potential hazards or to call attention to information

that clarifies or simplifies a procedure.

The addition of either symbol to a “Danger” or “Warning” safety

label indicates that an electrical hazard exists which will result

in personal injury if the instructions are not followed.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow

this symbol to avoid possible injury or death.

DANGER indicates an imminently hazardous situation, which, if not avoided,

will result in death or serious injury.

WARNING indicates a potentially hazardous situation, which, if not avoided,

can result in death or serious injury.

CAUTION indicates a potentially hazardous situation, which, if not avoided,

can result in moderate or minor injury.

NOTICE indicates important information that you need to read carefully.

975-0768-01-01 Revision B vii

Safety

Please Note

Electrical equipment must be installed, operated, serviced, and maintained only

by qualified personnel. No responsibility is assumed by Schneider Electric for

any consequences arising out of the use of this material.

A qualified person is one who has skills and knowledge related to the

construction, installation, and operation of electrical equipment and has received

safety training to recognize and avoid the hazards involved.

Safety Information

1. Before using this product, read all instructions and cautionary markings on

the unit and all appropriate sections of this manual.

2. Use of accessories not recommended or sold by the manufacturer may result

in a risk of fire, electric shock, or injury to persons.

3. The manufacturer recommends that all wiring be done by a certified

technician or electrician to ensure adherence to the local and national

electrical codes applicable in your jurisdiction.

4. To avoid a risk of fire and electric shock, make sure that existing wiring is in

good condition and that wire is not undersized. Do not operate the

equipment with damaged or substandard wiring.

5. Do not operate the equipment if it has been damaged in any way.

6. Do not disassemble the Conext CL-60 except where noted for connecting

wiring and cabling. See your warranty for instructions on obtaining service.

Attempting to service the unit yourself may result in a risk of electrical shock

or fire.

7. To reduce the risk of electrical shock, disconnect the power supply from the

equipment before attempting installation, and any maintenance (including

cleaning or working on any components connected to the equipment).

Internal capacitors remain charged for ten minutes after all power is

disconnected.

8. The equipment must be grounded. Use the protective grounding conductor

provided with the AC input conductors.

9. This product is designed for outdoor use and is rated IP65 and Type 4X.

10. To reduce the chance of short-circuits, always use insulated tools when

installing or working with this equipment. Do not leave tools inside.

11. Remove personal metal items such as rings, bracelets, necklaces, and

watches when working with electrical equipment.

12. Do not open nor disassemble the top half of the unit. There are no userserviceable parts inside.

13. To disconnect the unit from DC power, turn the DC switch to OFF and then

remove all PV string connectors from the DC terminals.

viii 975-0768-01-01 Revision B

Safety

DANGER

NOTICE

ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH HAZARDS

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must only be installed and serviced by qualified electrical

personnel.

• Never energize the inverter with the covers removed.

• Do not open fuse holders under load. The fuse must be de-energized from

all sources before servicing.

• The inverter is energized from multiple sources. Before removing covers

identify all source, de-energize, lock-out, and tag-out and wait 10 minutes.

• Always use a properly rated voltage sensing device to confirm all circuits

are de-energized.

• Replace all devices and covers before turning on power to this equipment.

• The DC conductors of this photovoltaic system are ungrounded and may

be energized.

Failure to follow these instructions will result in death or serious injury.

Access to live parts shall be limited to suitably qualified electrical personnel. See

installation instructions before connecting to the supply.

EQUIPMENT DAMAGE

• All cables connected to the CL-60 must run through the cable glands on

the unit.

• This unit is susceptible to damage from EMI and nearby lightning strikes

unless a surge protection device (a lightning arrestor) is installed.

• Turn Off all devices before connecting cables.

• Use the CL-60’s DC switch as its On/Off switch.

• To isolate the CL-60, follow “Lock-Out Tag-Out (LOTO) Procedure” on

page xi.

Failure to follow these instructions can damage equipment or affect

network performance.

975-0768-01-01 Revision B ix

Safety

Storage Information

Store the inverter properly when the inverter is not to be installed immediately.

1. Inverter must be packed inside its original carton with the desiccant bags

inside.

2. Store the inverter with its front panel facing up. The carton should lay flat and

parallel to the ground.

3. Seal the carton with standard packaging tape.

4. Store the inverter in a dry and clean place to protect it against dust and

moisture.

5. Temperature: -30 to 85 °C (-22 to 185 ºF)

Relative humidity: 0 to 100%.

6. Do not stack more than two inverters on top of another.

7. Keep the inverter away from chemically corrosive materials.

8. Periodically check for any visible damages to the carton and inspect the

inverter right away if the carton shows signs of penetration during the storage

period. Replace the carton, if necessary.

NOTE: A thorough and professional inspection may be required before

installing the inverter after more than six months in storage. Contact a local

Schneider Electric sales representative for information on how to arrange the

inspection.

IMPORTANT: Storage beyond two years voids the warranty.

x 975-0768-01-01 Revision B

Lock-Out Tag-Out (LOTO) Procedure

DANGER

CL-60

Mains

AC Panel

Breaker

DC Disconnect Device

LOTO

LOTO

DC Switch

PV string

Lock-out refers to the practice of preventing de-energized circuits from being reenergized by putting locks on the disconnecting devices, holding them open.

Tag-out refers to the practice of attaching a tag to the disconnect-device locks

warning others not to operate the disconnect device and containing information

relating to the lock-out, such as the person responsible, the reason, and the date

and time. Combined these two practices are called the lock-out and tag-out

(LOTO) procedure.

ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH HAZARDS

• Apply appropriate personal protective equipment (PPE) and follow safe

electrical work practices.

• This equipment must only be installed and serviced by qualified electrical

personnel.

• Never energize the inverter with the covers removed.

• Always use a properly rated voltage sensing device to confirm all circuits

are de-energized.

• Replace all devices and covers before turning on power to this equipment.

• The inverter is energized from multiple sources. Before opening the cover

identify the power source (see A), de-energize (see B), lock-out and tagout (see C), and wait ten minutes for circuits to discharge (see D).

Failure to follow these instructions will result in death or serious injury.

Safety

Figure 1-1 Single Line Diagram for CL-60

A 1. Identify any disconnect device upstream from the CL-60 unit.

B 2. Open the disconnect device that connects to the CL-60 to cut off DC power.

C 3. Turn the CL-60’s DC Switch to OFF position.

4. Lock-out and tag out the external DC disconnect device.

5. Remove all PV string connectors from the DC terminals.

975-0768-01-01 Revision B xi

Safety

A 6. Identify the AC Panel Breaker downstream from the CL-60 unit.

B 7. Open the AC Panel door.

8. Turn Off the AC Panel Breaker (open the switch) that connects to the CL-60

to cut off AC power.

9. Close the AC Panel door.

C 10. Lock-out and tag out the AC Panel.

D 11. Wait ten minutes for the circuits in the CL-60 to discharge.

12. Check that the inverter is in zero energy state before performing work.

13. Open the CL-60 enclosure and commence service and maintenance

activities.

xii 975-0768-01-01 Revision B

Contents

Important Safety Instructions

Safety Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

Storage Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - x

Lock-Out Tag-Out (LOTO) Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -xi

1 Introduction

Conext CL-60 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Physical Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Inverter Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Packaging Box Dimensions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Product Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

LCD Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

DC Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Technical Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

CL-60 Circuit Diagram - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Standard Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–9

Derating Feature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–10

2 Installation

Pre-Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Planning the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

What’s In The Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Material and Tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Location Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Install and Mount the CL-60 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Torque Values - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

3 Electrical Connections

Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Planning the Electrical Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Cabling and Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Material and Tools - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Terminal and Cable Entry Points (for CL-60E) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Terminal and Cable Entry Points (for CL-60A) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

AC Side Cable Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

AC Side Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

AC Circuit Breaker - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

Residual Current Device - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

975-0768-01-01 Revision B xiii

Contents

Multiple Inverters in Parallel Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Grid Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

PV Array Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

PV Input Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

PV Input Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–16

Grounding the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–21

Grounding System Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–21

Second Protective Earth Terminal - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–22

Communication Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–23

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–23

RS-485 Communication System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–24

Ethernet Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–28

4 Commissioning

Inspection Before Commissioning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Commissioning Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

5 LCD Display Operation

Description of the Selection Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Menu Tree - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Main Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Contrast Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6

Checking Running Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6

Checking History Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8

Checking Running Records - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8

Checking Fault (Event) Records - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8

Checking History Event Records - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9

Checking Energy Records - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9

Starting/Stopping - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–10

Password Entry - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–11

System Parameter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–12

Language Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–12

Time Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–12

Total Energy Deviation Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–13

Load Default (Factory Reset) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–14

Checking Firmware Version - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–14

Running Parameter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–15

Main Screen of Run-param - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–15

Active/Reactive Power Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–18

Reactive Power Regulation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–18

Pf Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–18

Qt Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–19

Off Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–19

Q(P) Mode (when the country selection is not “IT”) - - - - - - - - - - - - - - - - - - - - - - - - - - 5–19

xiv 975-0768-01-01 Revision B

Q(U) Mode (when the country selection is not “IT”) - - - - - - - - - - - - - - - - - - - - - - - - - - 5–20

Reactive Power Setting for Italy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–22

Italy Q(P) Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–22

Italy Q(U) Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–23

Save P/Q-set - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–25

Time Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–25

LVRT Parameter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–26

Derating Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–26

ISO Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–27

Protection Parameter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–27

Country Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–28

Single-stage Protection Parameter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–30

Multi-stage Protection Parameter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–30

Protection Recovery Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–32

Protection Parameter Confirmation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–32

Communication Parameter Setting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–33

6 Troubleshooting

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–2

LED Indicator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–3

LCD Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–4

Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–10

Routine Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–10

Maintenance Instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–11

Fan Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–11

Replacing the Fuse - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–13

Replacing an Expended DC SPD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–14

Cleaning the Air Inlet and Outlet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–15

Contents

7 Disconnecting, Dismantling, and Disposing the CL-60

Disconnecting the CL-60 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–2

Dismantling the CL-60- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–4

Disposing the CL-60 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–5

8 Specifications

Product Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–2

975-0768-01-01 Revision B xv

xvi

1 Introduction

Chapter 1 contains general information about:

• Conext CL-60

• Physical Features

• Technical Features

975-0768-01-01 Revision B 1–1

Introduction

WARNING

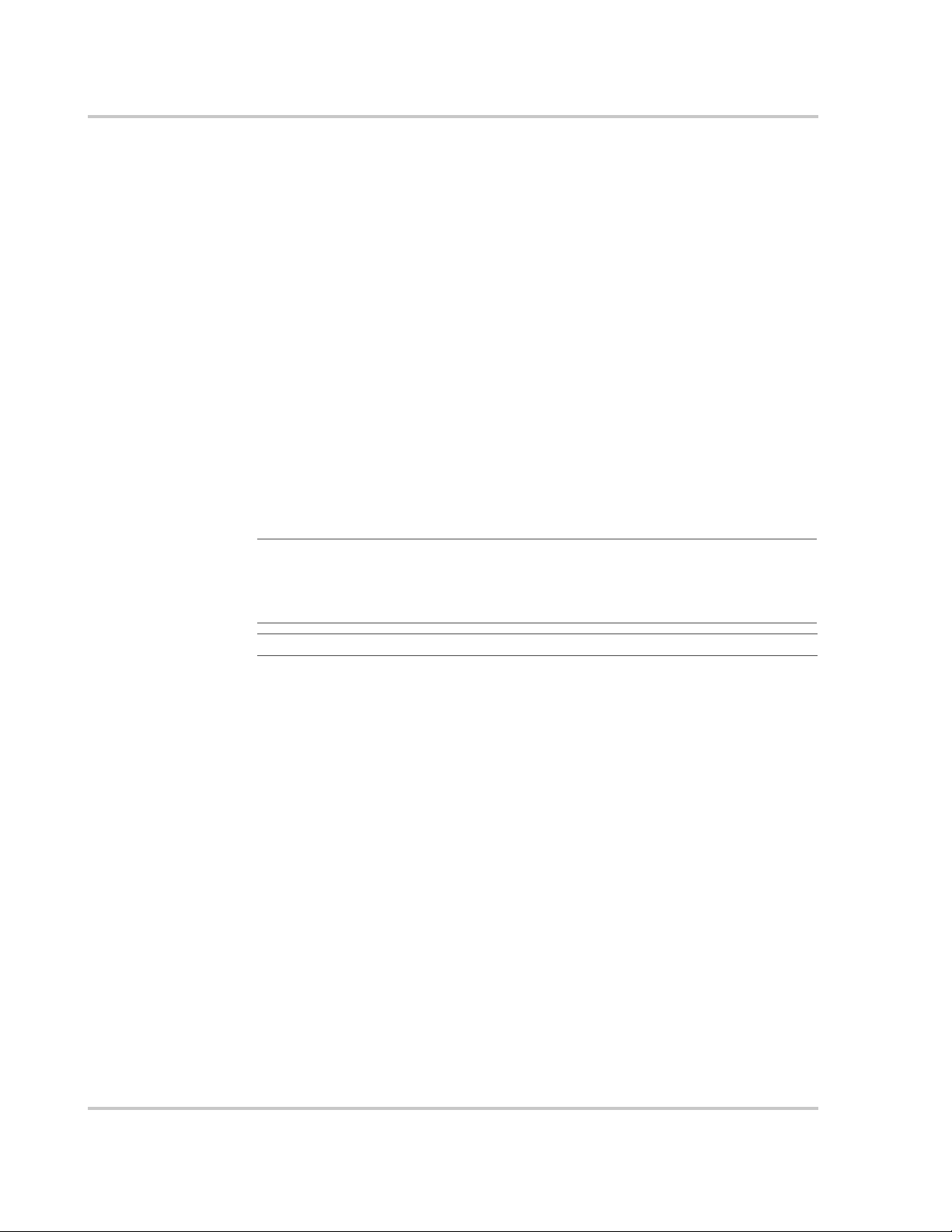

PV Array CL-60 Transformer Utility Grid

TT, TN-C, TN-S,

TN-C-S, IT

without grounding

Conext CL-60

The Conext CL-60 (also referred to as CL-60 PV Inverter) is a transformerless

three-phase PV string inverter that is designed to be an integral part of any utility

grid-connected PV Power System.

The Conext CL-60 is designed to convert DC power generated from the PV array

into AC power that is compatible with utility grade AC power. The following

diagram illustrates its fundamental application.

ELECTRICAL SHOCK HAZARD

• Do not connect the inverter to a PV string where the positive and negative

terminals of the PV strings need to be grounded.

• Do not connect any local load between the inverter and the AC circuit

breaker.

• Use the inverter ONLY in a grid-connected PV system.

Failure to follow these instructions can result in death or serious injury.

Figure 1-1 Fundamental Application

1–2 975-0768-01-01 Revision B

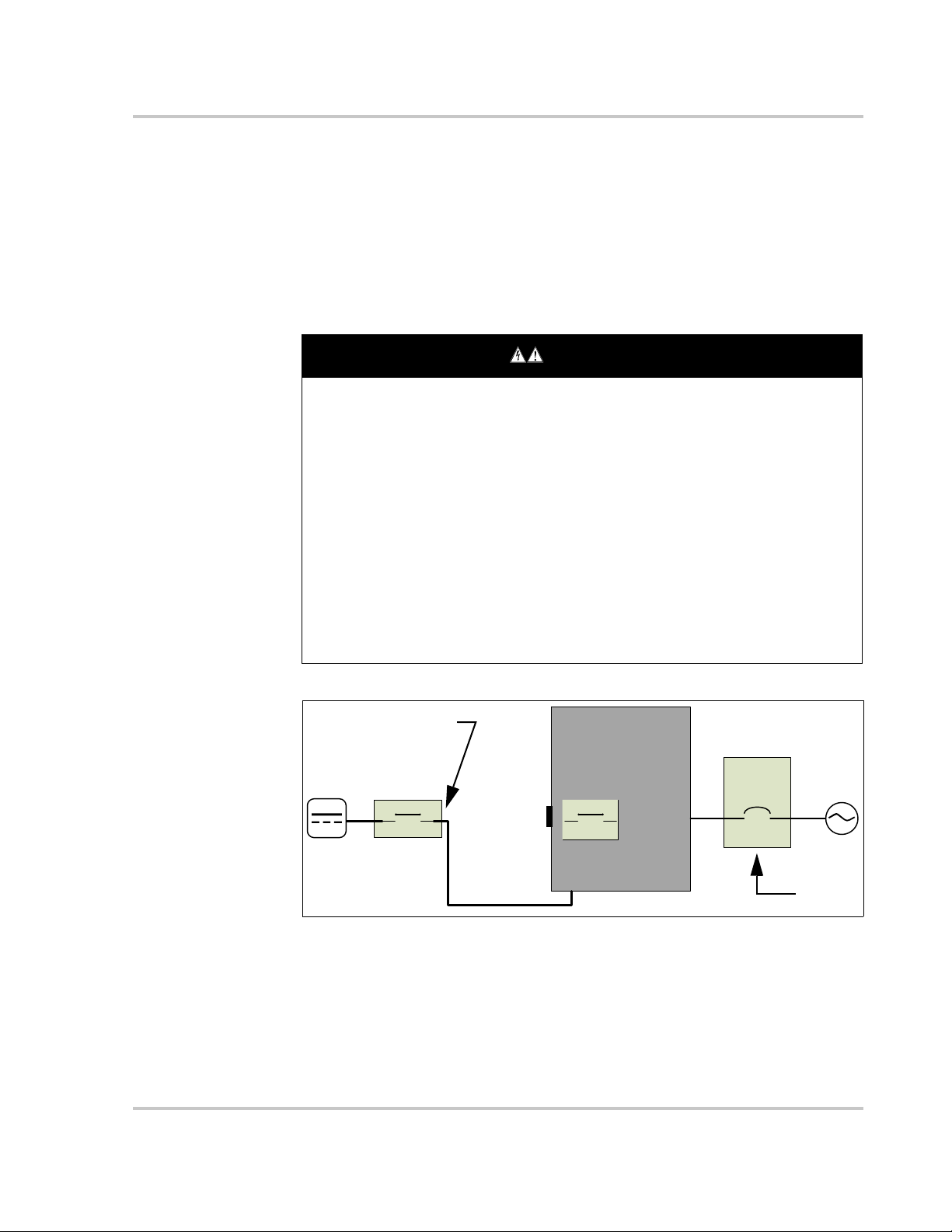

Figure 1-2 Type of Grid Connections

L1

L2

L3

N

PE

CL 60

transformer

TT

L1

L2

L3

N

PE

PE

CL 60

transformer

TN-S

L1

L2

L3

N

PE

PE

CL 60

transformer

TN-C-S

L1

L2

L3

PEN

PE

CL 60

transformer

TN-C

L1

L2

L3

PE

CL 60

transformer

IT

NOTICE

Conext CL-60

Grid Connection

Conditions

More than one CL-60 PV Inverter can be connected to the PV system if the total

capacity of the PV system (PV array) exceeds the capacity of a single inverter.

Each inverter in the multiple setup connects individually to a PV string at the

inverter’s DC input side. Then the inverter’s AC output side connects to the AC

mains (the grid).

EQUIPMENT DAMAGE

Follow local regulations when installing a connection to a either a TT or TN

system. An additional external Type B RCD (residual current detection) device

rated 300 mA continuous may be required and combined with additional

automatic disconnect devices.

Failure to follow these instructions can result in equipment damage.

975-0768-01-01 Revision B 1–3

Introduction

1

2

4

3

3

6

8

7

3

3

5

9

10

11

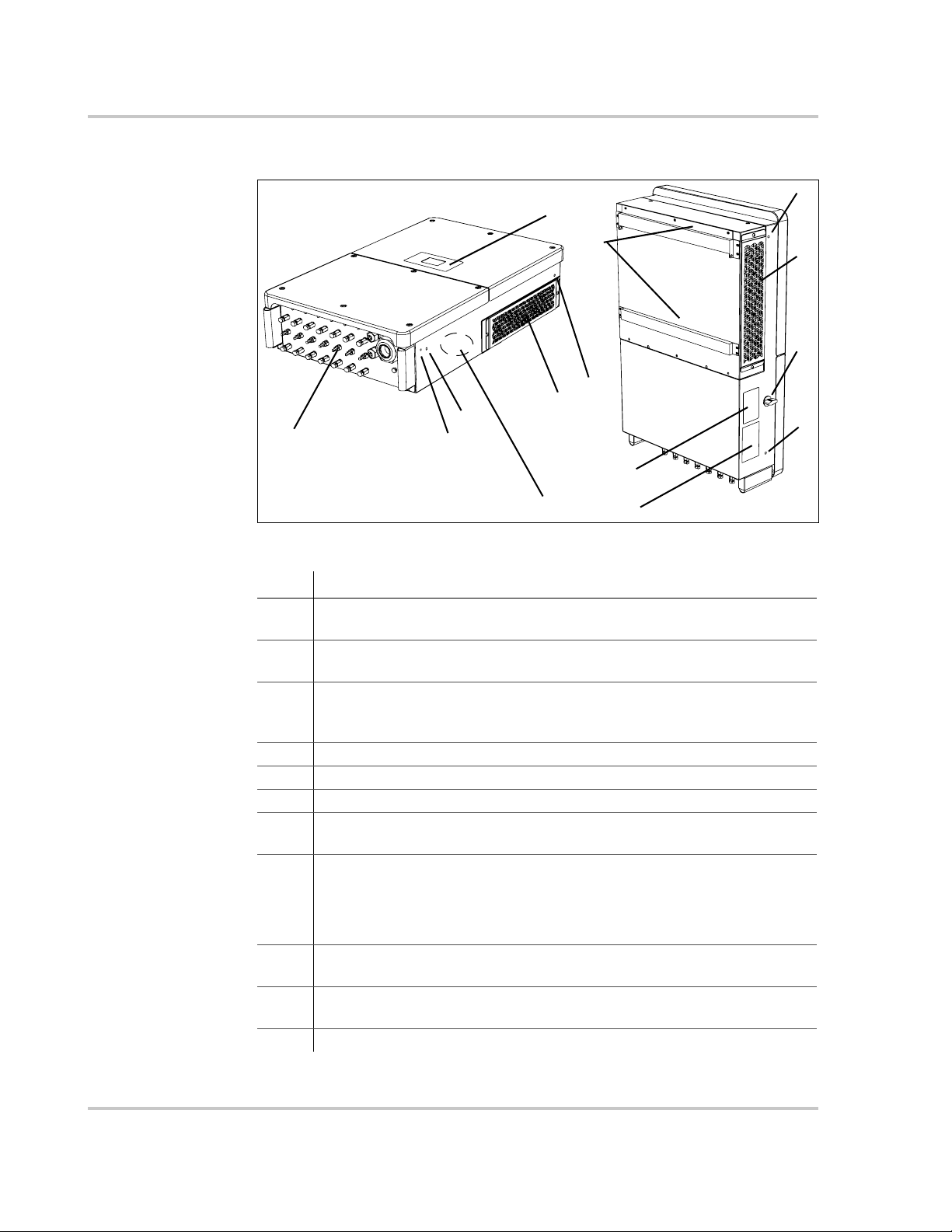

Physical Features

Figure 1-3 CL-60 Components (CL-60E shown)

Item Description

1 LCD Display is the main HMI for viewing operational information and

changing parameter values for settings.

2 Electrical connection area includes the DC terminals, AC terminals,

and RS-485 communication terminals.

3 Hole Inserts for Screw-in Handles are used for seating the screw-in

handles. The handles are used for moving, handling, and mounting the

PV Inverter.

4 PE second terminal

5 Air ventilation is equipped with fans to draw hot air out.

6Backplate is used to hang the PV Inverter onto the wall.

7 Fans (3x) with protective grate are used for forced-air cooling inside

the inverter enclosure.

8 DC switch is a protective component for safely disconnecting DC

power from the PV Array but only up to the terminals.

For full disconnection, disconnect power from the PV disconnect

device. See “Single Line Diagram for CL-60” on page xi.

9 Warning Label Read before installing, maintaining, and servicing the

10 Rating Label contains the unit’s electrical specifications and regulatory

11 CL-60A has an AC Switch in the area shown.

unit.

markings.

1–4 975-0768-01-01 Revision B

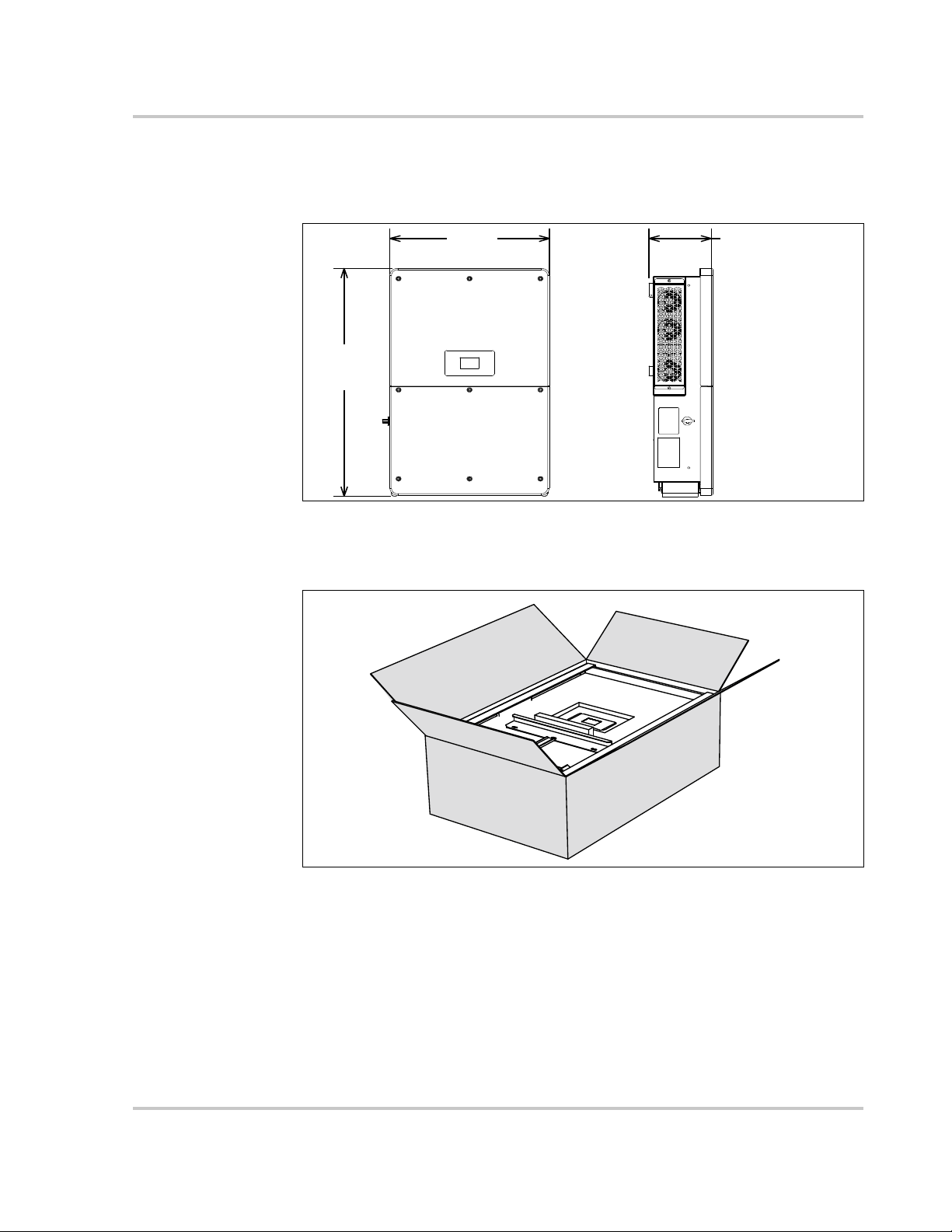

Dimensions

625 mm

24.6 in

250 mm

9.8 in

991 mm

39 in

Unit weight:

66.0 kg (CL-60E)

147 lbs (CL-60A)

Length:

1160 mm / 45.7 inWidth:

770 mm / 30.3 in

Height:

375 mm / 14.8 in

Gross weight:

76.0 kg (CL-60E)

168 lbs (CL-60A)

Inverter Dimensions

Physical Features

Figure 1-4 Conext CL-60 Dimensions (CL-60E shown)

Packaging Box Dimensions

Figure 1-5 Conext CL-60 Packaging Box Dimensions

975-0768-01-01 Revision B 1–5

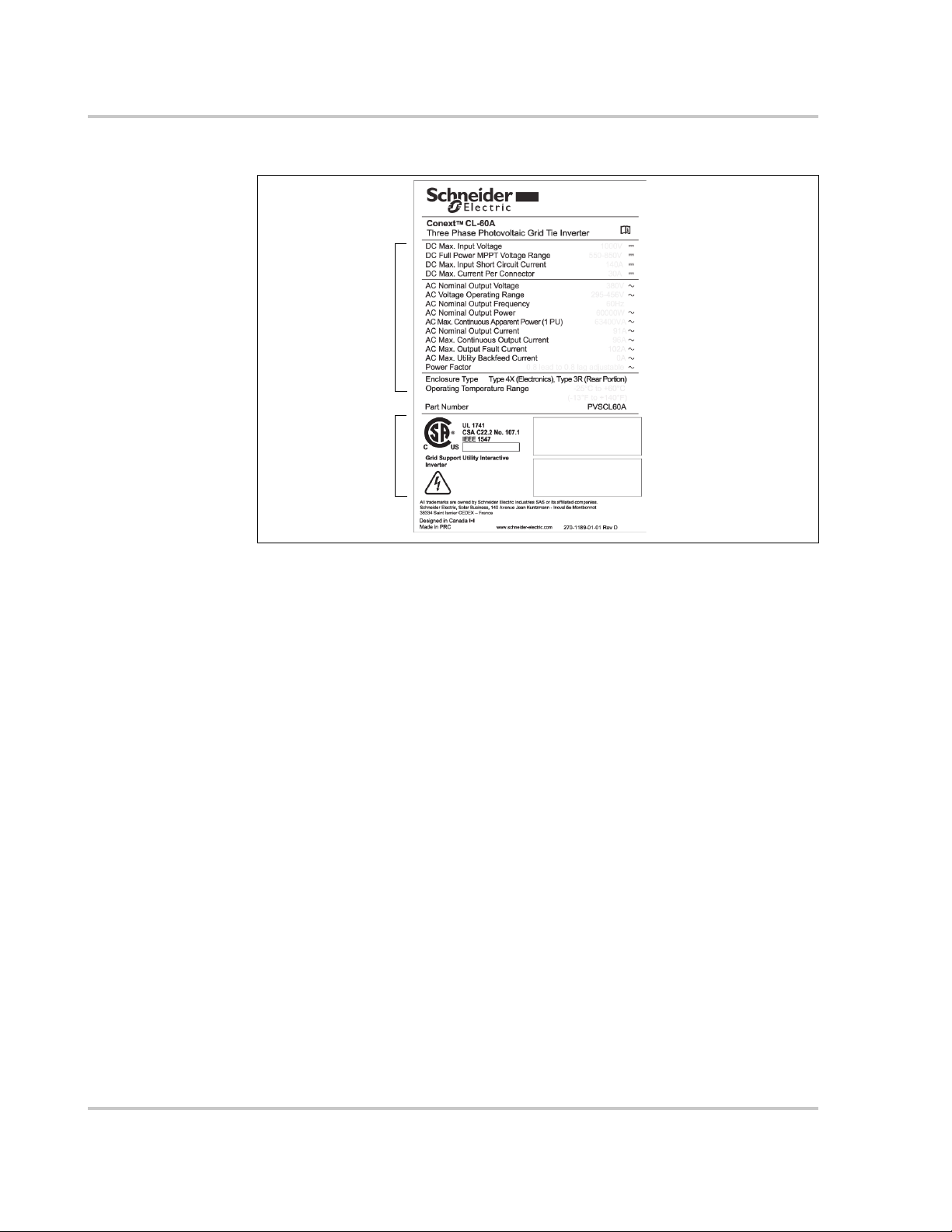

Introduction

product name

product ratings

product part number

certification and

regulatory

markings

serial number

manufacturing

date

Product Label

Figure 1-6 Example of a Conext CL-60 Product Label

1–6 975-0768-01-01 Revision B

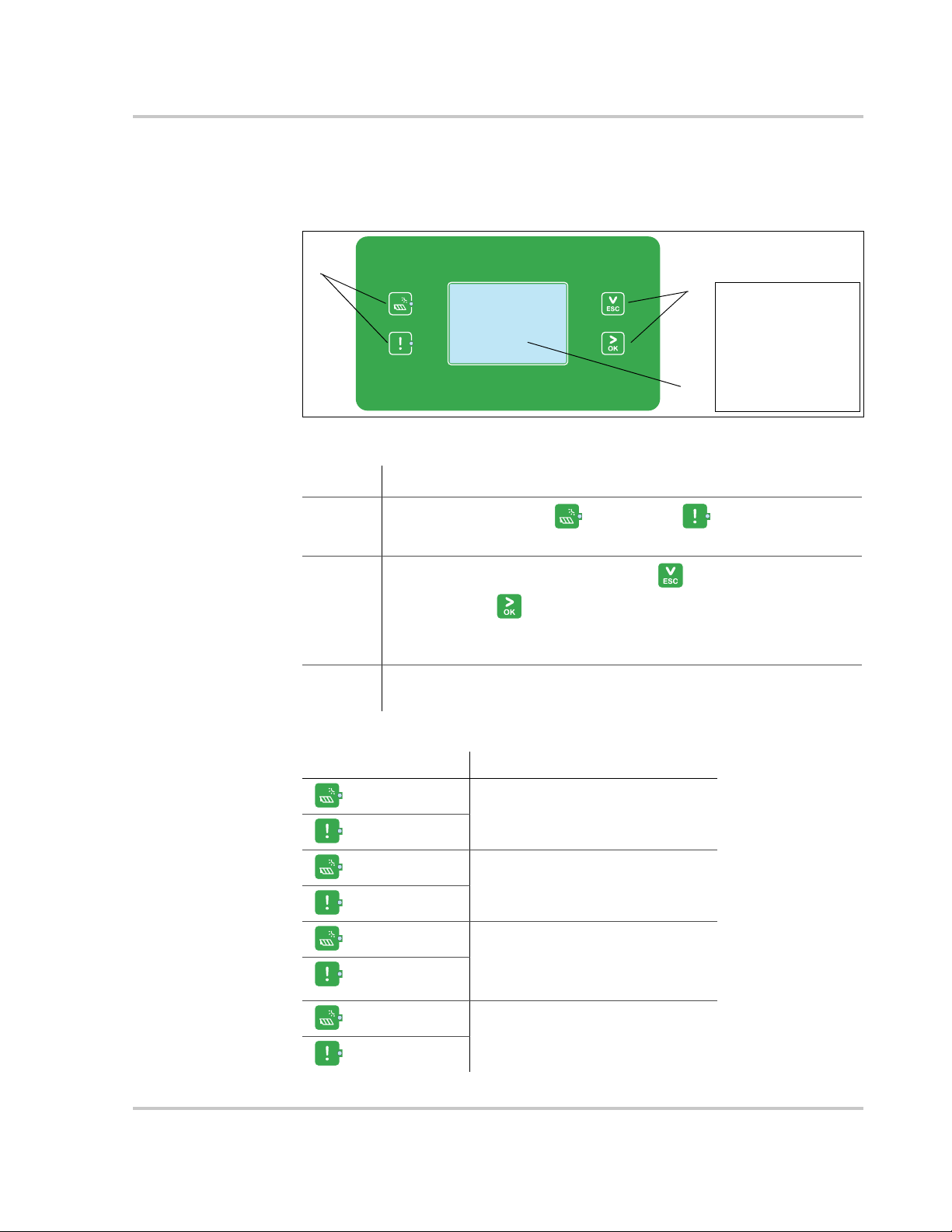

LCD Display

1

2

3

NOTE: Condensation may

appear behind the LCD

display. This occurrence is

normal in cold climate

conditions. The

condensation dissipates

soon after the unit starts

producing power or when

ambient temperature settles

above the dew point.

Physical Features

The LCD Display is the main interface of the CL-60 PV Inverter. It is made up of

two LED indicators, two buttons, and the screen itself.

Figure 1-7 LCD Display

Item Description

1

LED Indicators – RUN and ALERT .

Indicates the present operational state of the PV Inverter.

2

Selection Buttons – ESC (and down) and

OK (and next) .

Use for navigating the LCD interface, selecting settings, and

changing parameters of settings.

3 LCD Screen. Displays the present state of the PV Inverter,

operational and alarm information, and present settings.

Tab l e 1 -1 Description of LED Indicators

LED Indicators Description

RUN - On

The PV Inverter is in operation.

ALERT - Off

RUN - Off

A ground fault (or any event) is

detected or a protection feature is

ALERT - On

RUN - Off

ALERT - Off

enabled.

The PV Inverter is not in operation

or a communication fault is

detected between the DSP and

the LCD Display.

RUN - flashing

ALERT - Off

975-0768-01-01 Revision B 1–7

The PV Inverter is communicating

a warning.

Introduction

WARNING

DC Switch

The DC Switch is both the main power switch and a protective component which

is used to safely disconnect DC power between the PV array and the PV Inverter

whenever necessary to do so.

The PV Inverter operates automatically (without the need of switching On or Off)

when DC input and AC output requirements are continuously met. Turn the DC

switch to the Off position only to stop PV Inverter operation when a ground fault

condition is detected or when there is a non-ground fault condition to stop

inverter operation such as maintenance and servicing.

ELECTRIC SHOCK HAZARD

• Do not perform maintenance and servicing without totally disconnecting

the DC source from the inverter. The DC switch does not de-energize the

DC fuse circuits. The fuse circuits remain live even if the DC switch is

turned to the Off position.

• To remove power to the inverter, disconnect power from the PV disconnect

device. See “Single Line Diagram for CL-60” on page xi.

• Alternatively, to remove power to the inverter, open all MC4 type connectors

using a special tool for disconnection.

Failure to follow these instructions can result in death or serious injury.

NOTE: For CL-60A, the DC switch is provided with a lockable twisting knob to

meet the NFPA 70E standard.

1–8 975-0768-01-01 Revision B

Technical Features

LCD/RS485

DSP+CPLD

DC

L1

L2

L3

N

PE

NL3L2L1

PE

DC

DC In

+-

+-

NL3L2

L1

PE

DC

DC In

+-

+-

L1 L2 L3

N

L1 L2 L3

N

DC EMI

Filter

DC bus

Inversion

circuit

AC

EMI

Filter

AC

Reactor

Relay

Fan

AC SPD

DC

switch

AC

switch

DC SPD

Current detection

DC SPD

DC

switch

DC fuse

DC fuse

Auxilia ry

power circuit

Current detection

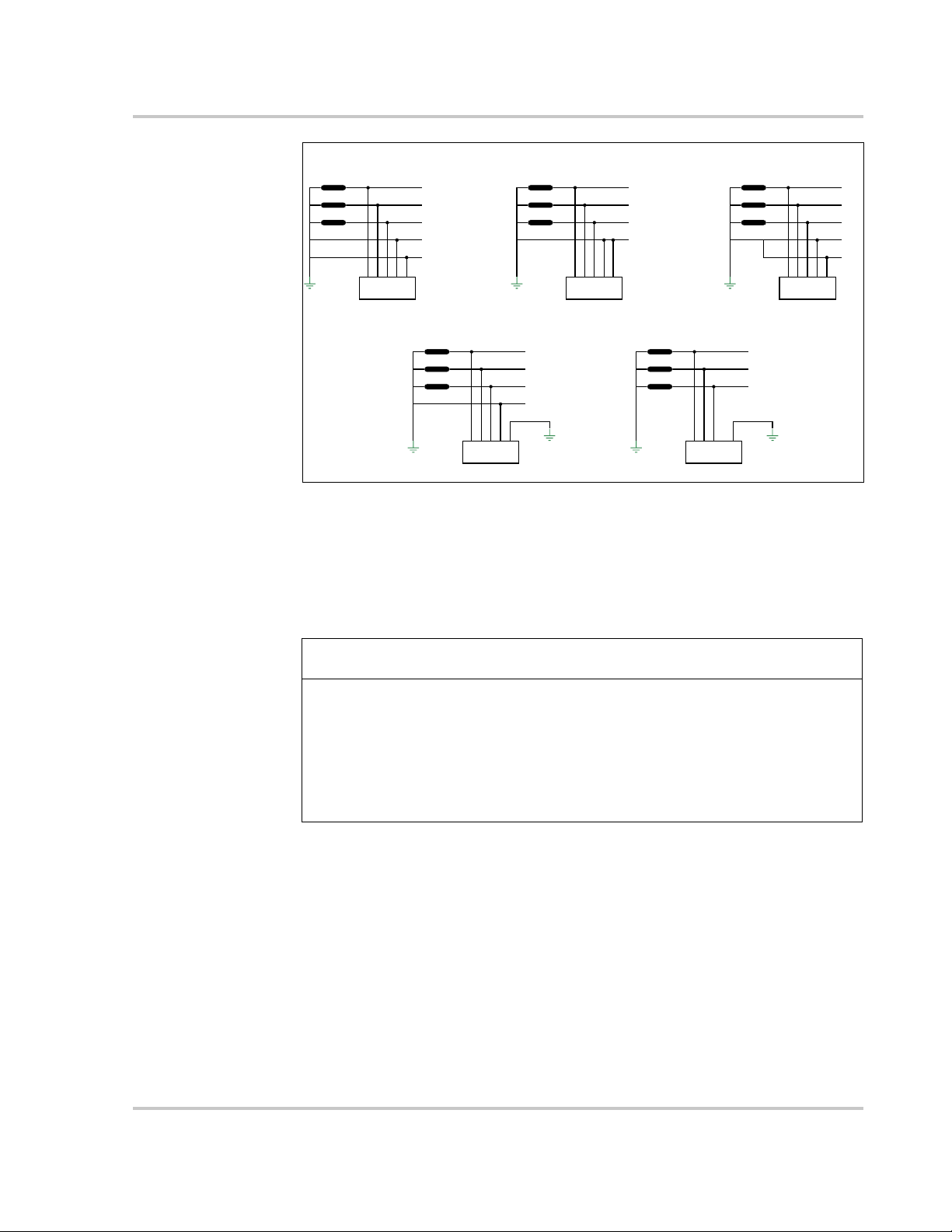

CL-60E Wiring Box contents CL-60A Wiring Box contents

- DC switch

- 14 strings

- 15A fuses in positive polarity

- monitoring in negative polarity

- type 2 DC SPD

- type 3 AC SPD

- DC switch

- 8 inputs (1@ for 2 combined strings)

- 30A fuses in both polarities

- type 2 DC SPD

- type 3 AC SPD

- AC switch

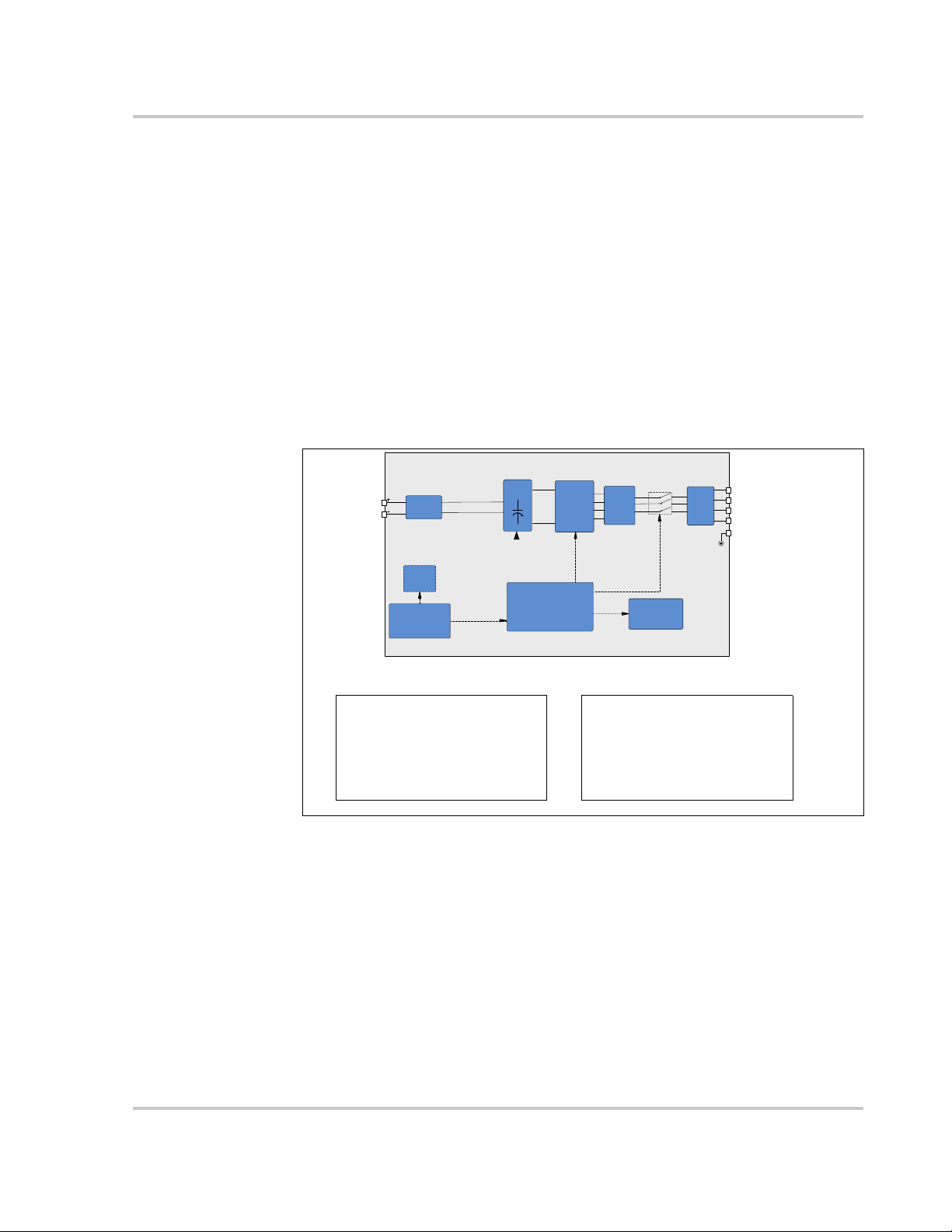

CL-60 Circuit Diagram

Figure 1-8 shows the main circuit of the PV Inverter.

Maximum Power Point Tracking (MPPT) is utilized to optimize harvesting DC

power from the PV array with different PV input conditions.

The PV Inverter circuit converts DC power into AC power and feeds it to the utility

grid through the inverter’s AC terminal. The protection circuit is equipped to

ensure the device’s safe operation and personal safety.

The DC switch is used to disconnect DC power from the PV Array safely.

The inverter provides standard RS-485 ports for communication.

Technical Features

Figure 1-8 Conext CL-60 Circuit Diagram

Standard Features

Inverter Function The device’s main function is to convert DC current into grid-

compatible AC current then feed this current into the grid.

Data Storage and LCD Display The onboard memory stores information such

as fault detection and displays them on the screen of the integrated LCD Display.

Device Configuration The LCD Display provides the main interface for

accessing device settings and changing them for optimal operation of the

inverter.

975-0768-01-01 Revision B 1–9

Introduction

Communication Interface Features a standard RS-485 port which can be

connected with a monitoring device such as a power meter,

Protection Features The unit is equipped with the following features for

preventing inverter damage, other equipment damage, and personal injury

hazards.

• Short-circuit protection

• Ground insulation resistance detection

• Inverter output voltage monitoring

• Inverter output frequency detection

• Residual current protection

• DC injection of AC output current surveillance

• Anti-islanding protection

• Ambient temperature monitoring

• DC over-voltage protection

• Over-current protection

• Power module over-temperature protection

• Fan failure protection

• Arc fault detection and protection (for CL-60A)

Derating Feature

Output derating is a way to protect the inverter from overload or potential fault

detections. These situations prompt the PV Inverter to initiate power derating:

• Altitude higher than 3000 meters

• Internal temperature is too high (including ambient temperature and

internal components temperature)

NOTE: For example, installing the inverter in an enclosed

space may hasten derating.

• Grid voltage is too low

• External power class adjustment

• Grid frequency is too high (see NOTE)

NOTE: Valid only when the country selected is DE or IT.

• High grid voltage with a simultaneous low PV voltage.

Power Limit Setting Inverter output power can be adjusted via the LCD

Display or a remote grid dispatch from the utility company. The corresponding

operating state will be displayed on the LCD screen.

1–10 975-0768-01-01 Revision B

Technical Features

Vmpp=600V

Vmpp=710V

Vmpp=850V

40 45

50 55 60

40

45

50

55

60

Ambient Temp (°C)

Apparent Power˄KVA˅

CL-60E Temperature Derating Curve

˄Vac=400V˅

35

66

Vmpp=600V

Vmpp=710V

Vmpp=850V

40 45

50 55 60

40

45

50

55

60

Ambient Temp (°C)

Apparent power˄KVA˅

CL-60A Temperature derating curve

˄Vac=380V˅

35

63.36

NOTE: The lower limit of the over-temperature derating is 75% of nominal power.

If both the module and internal temperatures reach power derating conditions, the

inverter will derate the power output based on the lower temperature between the two.

not to scale

V

min

V

max

P

n

215V

Working area

P[Vmin…266V] = Pn × (Vgrid / 230V)

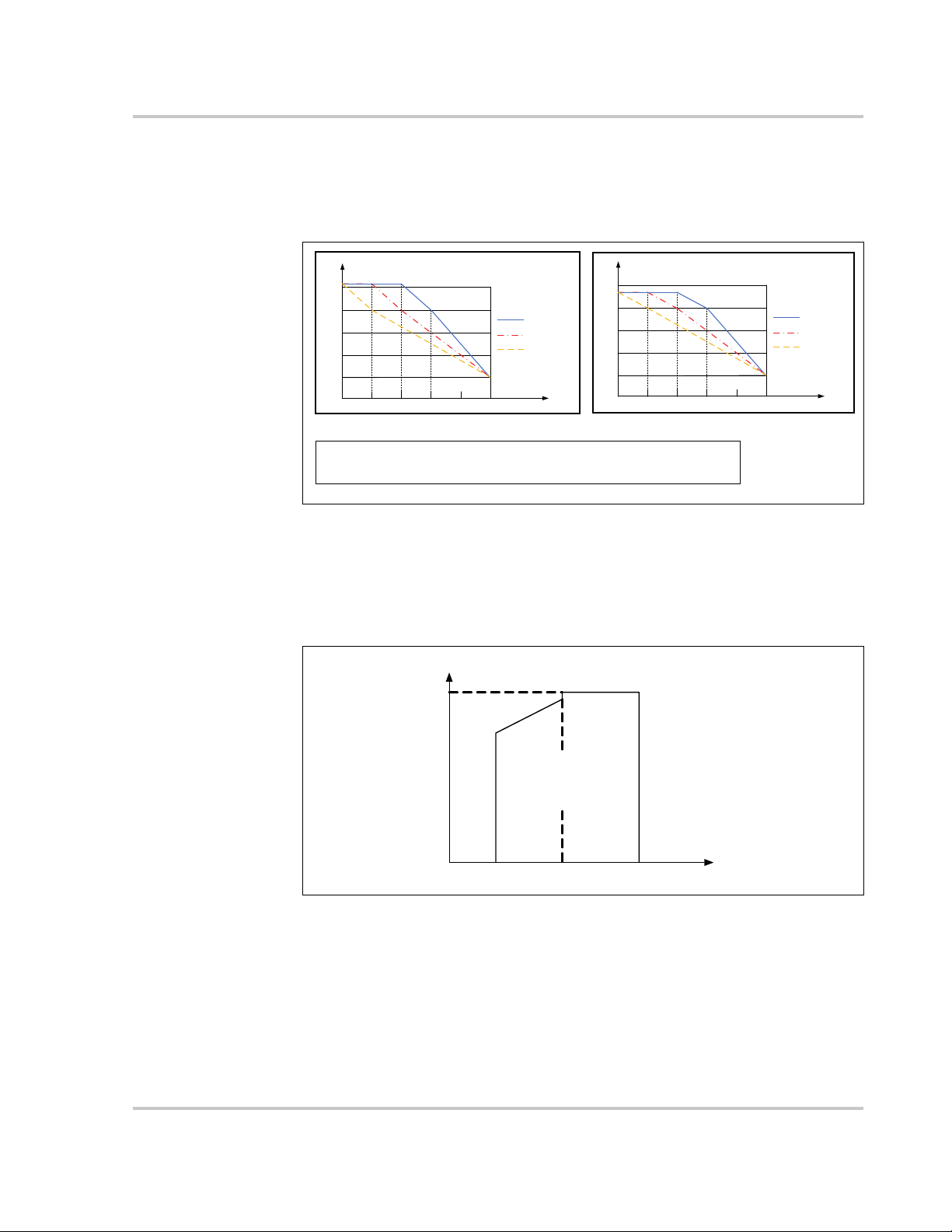

Over-temperature Derating High ambient temperature, a blocked fan, or poor

ventilation will initiate inverter power derating.

When the temperature inside the unit exceeds the upper limit, the inverter will derate

its power output until the internal temperature drops within the allowable range.

Figure 1-9 Over-Temperature Derating

Grid Under-voltage Derating When grid voltage is low, the inverter will derate

the output power to make sure the output current is within the allowable range.

Once the grid voltage is within Vmin (215V), the inverter will derate its output

power.

Figure 1-10 Grid Under-Voltage Derating

975-0768-01-01 Revision B 1–11

Introduction

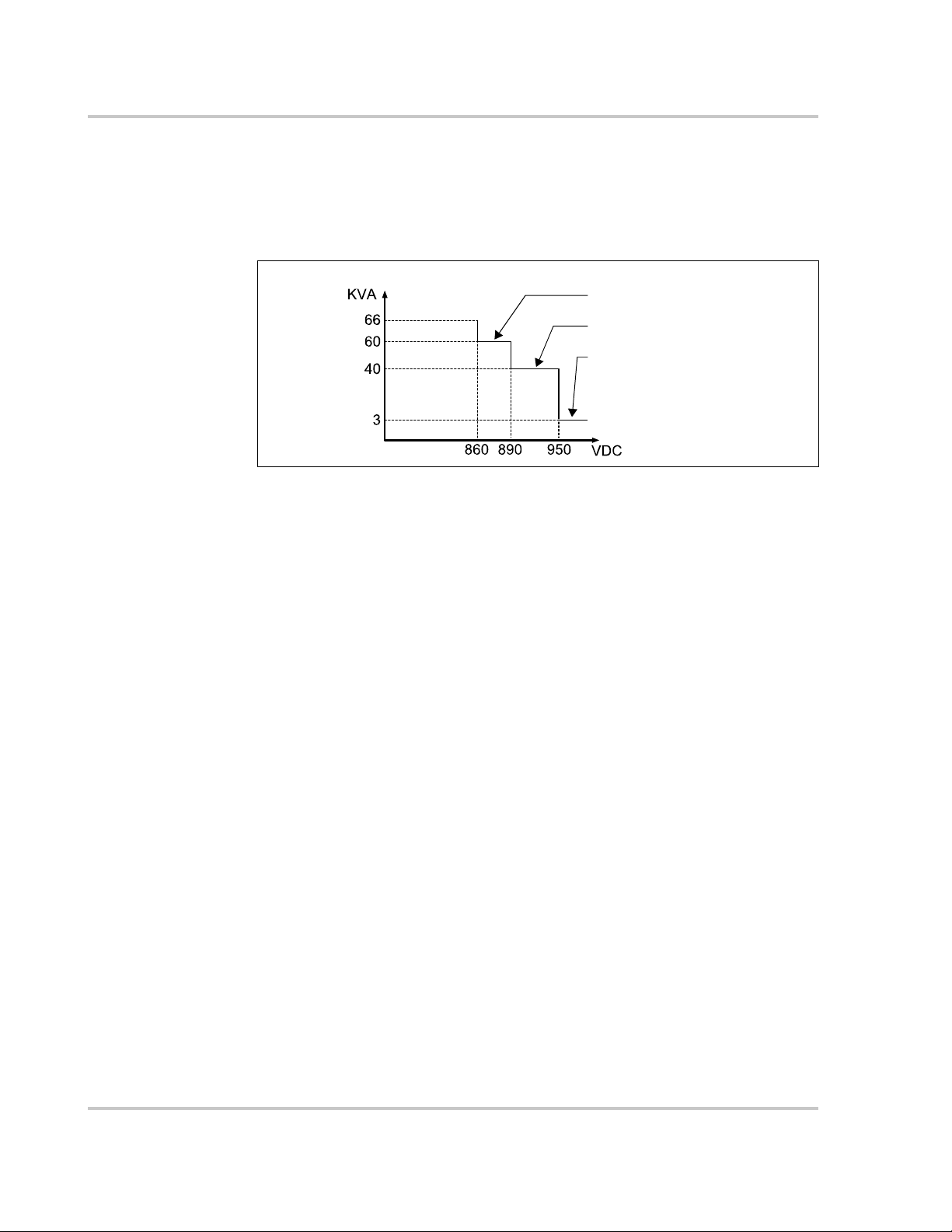

Output voltage max when PV voltage < 860

Output voltage max when PV voltage < 890

Output voltage max when PV voltage < 950

PV Over-voltage Derating The inverter regularly scans the PV voltage every 25

minutes and forces the PV to derate to test whether the maximum power point is

less than 860 volts.

At 66 KVA, if the maximum power point is higher than 860 volts, then the inverter

will return to the higher voltage limit before it starts derating.

Figure 1-11 PV Over-Voltage Derating

1–12 975-0768-01-01 Revision B

2 Installation

Chapter 2 contains information about:

• Pre-Installation

• Installation

975-0768-01-01 Revision B 2–1

Installation

Pre-Installation

Before installing the Conext CL-60, read all instructions and cautionary markings

in this Guide.

NOTE: Obtain all necessary permits prior to starting the installation.

Installations must meet all local codes and standards. Installation of this

equipment should only be performed by skilled personnel such as qualified

electricians and Certified Renewable Energy (RE) System installers.

Planning the Installation

• Read this entire chapter before beginning the installation. It is important to

plan the installation from beginning to end.

• Assemble all tools and materials needed for the installation.

2–2 975-0768-01-01 Revision B

Loading...

Loading...