Hilti PR 20 User Manual

en

zh

ja

ko

PR 20

Operating instructions

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X+ |

||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

+ |

|

|

|

Y- |

Y+ |

|

x |

+ |

|

|

||

|

y |

|

||||

- |

|

|

|

|

|

|

y |

x- |

|

|

|

||

|

|

|

|

|

|

X- |

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

x |

+ |

|

|

|

|

|

+ |

|

|

|

|

|

|

|

y |

|

|

|

- |

|

|

|

|

|

|

y |

|

x |

- |

|

|

|

|

|

|

|

2 |

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

3 |

|

|

|

|

|

|

|

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00 |

|

|

|

|

|

|

x+ y+

y- x-

5

4

3

2

214

214  213

213

211

211  210

210  209

209  208

208  207

207  206

206  205

205  204

204  203

203  202

202  201

201  200

200  199

199  198

198  197

197  196

196  195

195

194

194  193

193  192

192  191

191  190

190  189

189  188

188  187

187  186

186  185

185  184

184  183

183  182

182  113

113  112

112  111

111  110

110  109

109  108

108  107

107  106

106

180˚ |

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

PR 20 rotating laser |

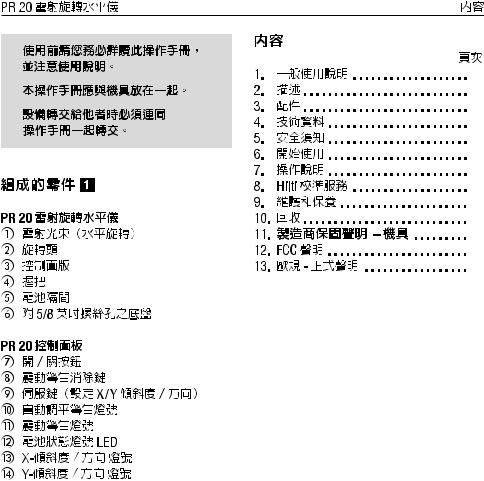

Contents |

It is essential that the operating instructions are read before the tool is used the first time.

Always keep these operating instructions together with the tool.

Ensure that the operating instructions are with the tool when it is given to other persons.

Component parts

PR 20 rotating laser

Laser beam (plane of rotation)

Rotating head

Control panel

Grip

Battery compartment

Base plate with 5/8" thread

PR 20 control panel

On / off button

Shock warning deactivation key

Servo key (sets X/Y inclination / direction)

Auto leveling LED

Shock warning deactivation LED

Battery LED

X-inclination / direction LED

Y-inclination / direction LED

Contents |

|

|

|

|

Page |

1. |

General information . . . . . . . . |

. . . . . .2 |

2. |

Description . . . . . . . . . . . . . . . |

. . . . . .2 |

3. |

Accessories . . . . . . . . . . . . . . |

. . . . . .3 |

4. |

Technical data . . . . . . . . . . . . . . |

. . . . .4 |

5. |

Safety precautions . . . . . . . . . . |

. . . . .5 |

6. |

Getting started . . . . . . . . . . . . . |

. . . . .7 |

7. |

Operation . . . . . . . . . . . . . . . . . |

. . . . .8 |

8. |

Hilti calibration service . . . . . . . |

. . . . .9 |

9. |

Care and maintenance . . . . . . . |

. . . .10 |

10. Disposal . . . . . . . . . . . . . . . . . |

. . . .10 |

|

11. Manufacturer's warranty – tools . . .11 |

||

12. FCC statement . . . . . . . . . . . . |

. . . .12 |

|

13. EC declaration of conformity |

. . . . .12 |

|

1

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

1. General information / 2. Description

1. General information

1.1 Safety notices and their meaning

- CAUTION -

This word indicates a possibly hazardous situation which could result in slight bodily injuries or damage to property.

- NOTE -

This word indicates information to help the user employ the product efficiently, and other useful notes.

1.2 Pictograms

Warning signs

General warning

Laser class 2

(Do not stare into the beam.)

Symbole

Read the operating instructions before use.

Return waste material for recycling

These numbers refer to the corresponding illustrations. The illustrations can be found on the fold-out cover pages. Keep these pages open when studying the operating instructions. In these operating instructions, the PR 20 rotating laser is referred to as "the tool".

2

1.3 Location of identification data on the tool

The type designation and serial number can be found on the rating plate on the tool. Make a note of this data in your operating instructions and always refer to it when making an enquiry to your Hilti representative or service department.

Type : |

PR 20 |

Serial-no.: ____________

2. Description

2.1 PR 20 rotating laser

The PR 20 is a rotating laser with one rotating laser beam.

2.2 Features

_The tool allows a single person to level or align in any plane quickly and with great accuracy (always in conjunction

with the PRA 20 laser detector).

_The laser’s speed of rotation is 300 r.p.m. (revolutions per minute) once the tool has leveled itself.

_Automatic leveling (within ±5° inclination).

_ LEDs for indication of operating status

_Built-in shock warning: The tool switches to warning mode (all LEDs blink, laser stops rotating) when brought out of level

as a result of vibration or an impact during operation.

_Automatic cut-out: The laser remains switched off and all LEDs blink if the tool is outside its self-leveling range or if movement of the mechanism is physically impeded.

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

2. Description / 3. Tools and accessories

_The tool can be set up on a tripod with a 5/8" thread or stood directly on some other steady surface.

_The tool is easy to operate, robustly built and comparatively light in weight.

2.3 Description of functions

2.3.1Horizontal plane (automatic leveling)

When switched on, the tool levels itself automatically by way of the 2 built-in servo motors for the X- and Y-directions.

2.3.2Inclined plane (manual adjustment to any desired slope)

Inclination can be set up in alignment with given marks or contours by pressing the X- and Y-keys.

2.3.3Automatic cut-out

During automatic leveling in one or both directions, the servo system monitors compliance with the specified accuracy. The tool switches itself off in the following situations:

–Leveling is not accomplished (tool set up outside leveling range or mechanism physically impeded)

–The tool is brought out of level (due to vibration or impact)

After automatic cut-out, rotation of the laser beam stops and all LEDs blink.

Items supplied

1 PR 20 rotating laser

1 PRA 20 laser detector

1 PRA 75 laser detector holder

1 PR 20 operating instructions

1 PRA 20 operating instructions

3 batteries (size D cells)

2 batteries (size AA cells)

1 PRA 52 slope calculator

1 manufacturer’s certificate

1 desiccant sachet

1 Hilti toolbox

3. Tools and accessories

Accessories |

|

Various tripods |

PA 910, PA 911, PA |

|

921 and PA 931/2 |

Laser detector |

PRA 20 |

Laser detector- |

|

holder |

PRA 75 |

Leveling staffs |

PA 950/960 and |

|

PA 951/961 |

Battery charger |

PUA 80 |

Battery pack |

PRA 801 |

Slope calculator |

PRA 52 |

3

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

4. Technical data for the PR 20

4. Technical data for the PR 20

Range (diameter)

2 to 400m [6 to 1300’] with PRA

20 laser detector

Accuracy (at 24°C/+75°F)

± 0.5mm @ 10m [0.2” @ 32.8’]

Laser product class

Class 2, visible, 650nm, < 1mW (IEC825-1/EN60825;

FDA 21 CFR 1040)

Speed of rotation [r.p.m.]

300 (operating speed)

Self-leveling range

± 5°, LED indicator

Automatic cut-out

When the laser is brought out of level (after 1 minute), unless both axes set to inclined mode:

-rotation stops

-all LEDs blink

Status indicators

-Auto leveling LED

-Battery condition LED

-Shock warning LED

-X inclination/direction LED

-Y inclination/direction LED

Power supply

3 x size D alkaline batteries

Battery life at 20°C [+68°]

Alkaline batteries: > 80 hours NiMh batteries: > 60 hours

4

Operating temperature

-20 to +50°C

[-4° to +122°F]

Storage temperature

-30 to +60°C dry

[-22° to +140°F]

Protection class

IP 56 (as per IEC 529)

Tripod thread

5/8" x 18

Weight

Approx. 2.4 kg (5.3 lbs.) including 3 batteries

Dimensions

186(L) x 186(W) x 213(H) mm [7.3"(L) x 7.3"(W) x 10.9"(H) inches]

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

5. Safety precautions

5. Safety precautions

5.1Basic information concerning safety

In addition to the information relevant to safety given in each of the sections of these operating instructions, the following points must be strictly observed at all times.

5.2Intended use

The tool is designed to be used for determining, transferring or checking alignment in the horizontal and inclined planes, e.g.:

–Transferring datum and height marks

–Setting out inclines

Hilti offers various accessories that allow optimum use to be made of the tool.

5.3 Misuse

–The tool and its accessories may present hazards when used incorrectly by untrained personnel or when used not as directed.

–To avoid the risk of injury, use only original Hilti accessories and additional equipment.

–Modification of the tool is not permissible.

–Observe the information printed in the operating instructions concerning operation, care and maintenance.

–Do not render safety devices ineffective and do not remove information and warning notices.

–Keep laser tools out of reach of children.

–Have the tool repaired only at a

Hilti service centre. Failure to follow the correct procedures when opening the tool may cause emission of laser radiation in excess of class 2.

–Take the surrounding conditions into account. Do not use the tool where there is a risk of fire or explosion.

5.4 Proper organization of the workplace

–Secure the area in which you are working. When setting up the tool, take care to avoid directing the beam towards yourself or other people.

–Avoid unfavorable body positions when working on ladders. Make sure you have a stable stance and stay in balance at all times.

–Measurements taken through panes of glass or other objects may be inaccurate.

–Ensure that the tool is set up on a steady surface (not subject to vibration).

–Use the tool only within its specified limits.

5.4.1 Electromagnetic compatibility

Although the tool complies with the strict requirements of the relevant guidelines, Hilti cannot entirely rule out the following possibilities:

–The tool may cause interference to other equipment, e.g. aircraft navigational equipment.

–The tool may be subject to interference caused by powerful radiation, which can then lead to incorrect operation.

Check the readings for plausibility when measuring in these conditions or if you are unsure of the results.

5

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

5. Safety precautions

5.4.2 Laser classification

The tool conforms to laser class 2 based on the IEC825-1 / EN60825-01 standard and class II based on CFR 21 § 1040

(FDA). These tools may be used without need for further protective measures. The eyelid closure reflex protects the eyes if a person looks into the beam unintentionally for a brief moment. The eyelid closure reflex can, however, be negatively influenced by medication, alcohol or drugs. Nevertheless, as with the sun, a person should not look directly into sources of bright light. The laser beam should not be directed towards persons.

Laser information plates based on IEC825 / EN6082-1

Laser information plates for the US based on CFR 21 § 1040 (FDA)

This laser product complies with 21 CFR 1040, as applicable.

5.5 General safety precautions

–Check the tool before use. If the tool is found to be damaged, have it repaired at a Hilti service center.

–The accuracy of the tool must be checked after it has been dropped or subjected to other mechanical stressing.

–When the tool is brought into a warm environment from very cold conditions, or vice versa, allow it to become acclimatized before use.

–If mounting on an adaptor, ensure that

the tool is screwed on securely.

–Keep the laser exit aperture clean to avoid measurement errors.

–Although the tool is designed for the tough conditions of jobsite use, as with other optical instruments (binoculars, spectacles, cameras) it should be treated with care.

–Although the tool is protected to prevent entry of dampness, it should be wiped dry each time before being put away in its transport container.

–Check the tool before using it for important leveling work.

5.5.1 Electrical

–Do not allow the batteries to fall into the hands of children.

–Do not overheat or incinerate the batteries. They may explode or release toxic substances.

–Do not attempt to recharge the batteries.

–Do not solder the batteries into the tool.

–Do not discharge the batteries by short circuiting. This may cause overheating and swelling of the batteries.

–Do not attempt to open the batteries and do not subject them to excessive mechanical stress.

6

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

6. Getting started

6. Getting started

-NOTE-

The tool may be powered only by the PRA 801 battery pack or by batteries manufactured according to the

IEC standard.

PR 801 battery pack

–The performance of the battery pack drops at low temperatures.

–Store the battery pack at room temperature.

–Never store the battery pack where it is exposed to direct sunlight, on a radiator or heater, or behind glass (windows, motor vehicle windscreens, etc).

Batteries

–Do not use damaged batteries.

–Do not mix old and new batteries. Do not mix batteries of different types or batteries from various manufacturers.

6.1Switching on the tool

Press the ON / OFF key.

-NOTE-

After switching on, the tool begins to level itself automatically.

6.2 LED indicators

Auto leveling LED

The LED blinks rapidly.

The tool is leveling itself automatically.

The LED lights constantly.

The tool has leveled itself / is operating normally.

Shock warning LED

All LED’s blink.

The tool has been bumped or brought out of level temporarily.

The shock warning LED lights red.

The shock warning LED lights red after deactivation of the shock warning.

Battery voltage LED

The LED lights.

The batteries are almost exhausted.

Inclination LED

The X and Y LEDs do not light. Operation in the horizontal plane.

The X LED does not light and The Y LED lights red

Manual operation: Y-direction can be aligned manually by way of the servo keys.

X–direction is still under automatic control.

The X LED lights red and The Y LED does not light

Manual operation: X direction can be aligned manually by way of the servo keys.

Y axis is still under automatic control.

The X LED lights red and The Y LED lights red

Manual operation: X and Y directions can be aligned manually by way of the servo keys.

The shock warning system is deactivated.

6.3 Inserting new batteries

1.Open the battery compartment by turning the locking button.

2.Insert the batteries in the battery compartment. Take care to ensure correct polarity.

3.Close the battery compartment by turning the locking button.

7

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

7. Operation

7. Operation

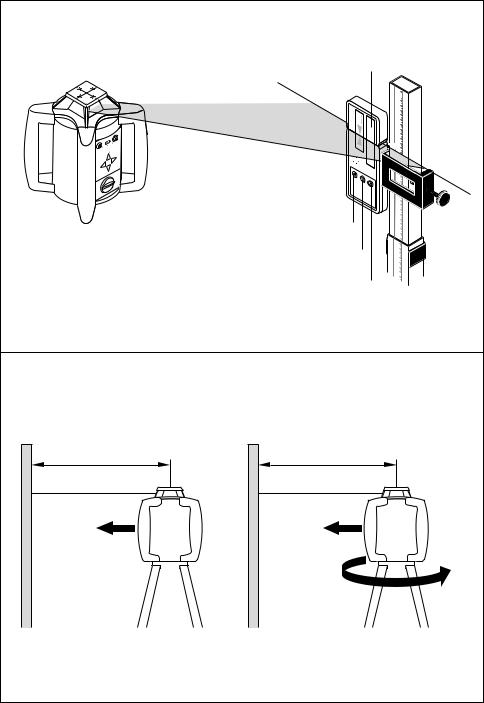

7.1 Switching the tool on and using the laser detector

1.The PRA 20 laser detector can be used within an area up to 400m (1300ft) in diameter.The laser beam is indicated by visible and audible signals.

2.Mount the PRA 20 detector securely on the telescopic staff or leveling staff and switch it on by pressing the on / off key.

3.Set the desired sensitivity by pressing the laser plane detection tolerance selection key.

4.Optional settings:

Use the audible signal setting key to select the desired volume level. Switching on sets the detector to the standard signal volume. Adjust the signal volume by pressing this key repeatedly until the desired volume is set (normal / loud / off).

5.Hold the PRA 20 within the plane of the rotating laser beam.The laser beam is indicated by visible and audible signals.

7.2 Working in the horizontal plane

1.Set up the tool in a suitable way for the application to be carried out, e.g. on a tripod.

2.Press the on / off button.

3.The auto leveling LED blinks green. Shortly before the tool achieves the correct level, the laser beam switches

on and begins to rotate. The auto leveling LED lights constantly.

8

7.3 Working in manual mode

1.Set up the tool in a suitable way for the application to be carried out, e.g. on a tripod.

2.The horizontal plane is no longer monitored when manual mode is selected for the X- and Y-directions.

3.Inclination in the X-direction: Press the X-servo key twice within 2 seconds. The X-direction can then be adjusted manually by way of the X-key. The LED lights red.

4.Inclination in the Y-direction: Press the Y-servo key twice within 2 seconds. The Y-direction can then be adjusted manually by way of the Y-key. The LED lights red.

5.To return to the original mode, switch the tool off and then on again.

-NOTE-

If the tool has been used immediately beforehand in manual mode (manual adjustment of the X- and/or Y-direction) the settings last used can be retained by pressing one of the inclination / direction keys within 3 seconds after switching the tool on. This must then be confirmed by pressing the inclination / direction key, otherwise the tool returns to the standard operating mode..

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

7. Operation / 8. Hilti calibration service

7.4 Deactivating the inclined plane function

The inclined plane function can be deactivated by pressing a special key combination. The inclination adjustment keys are then no longer active.

The deactivation procedure is started with the tool switched off.

Procede by pressing the following key combination:

–Press and hold down the Y- and the shock warning keys simultaneously and then press the on /off button. Subsequently press the Y+ button within 10 seconds (release the other keys before pressing the Y+ key).

The inclined plane function can be reactivated when required. This is done by pressing the same key combination once again.

8. Hilti calibration service

We recommend that the tool is checked by the Hilti calibration service at regular intervals in order to verify its reliability in accordance with standards and legal requirements.

Use can be made of the Hilti calibration service at any time, but checking at least once a year is recommended.

The calibration service provides confirmation that the tool is in conformance, on the day it is tested, with the specifications given in the operating instructions.

If deviations from the manufacturer's specification are found, the tool is then re-adjusted. After checking and adjustment, a calibration sticker applied to the tool and a calibration certificate provide written verification that the tool operates in accordance with the manufacturer's specification.

Calibration certificates are always required by companies certified according to ISO 900x.

Your local Hilti center or representative will be pleased to provide further information.

8.1 Checking horizontal rotation

Horizontal alignment of the tool in the X- or Y-directions can be checked as follows:

8.1.1 Checking

1.Set up the tool in the horizontal plane at a distance of about 20m (65 ft) from a wall (can also be carried out with the tool set up on a tripod).

2.With the aid of the laser detector, make a mark on the wall.

3.Pivot the tool through 180° about its own axis (check the same laser axis).

4.With the aid of the laser detector, make a second mark on the wall.

If the check has been carried out carefully, the distance between the marks A and B should be less than 2 mm / 0,15 inch (at 20 m / 65 ft from the wall).

In the event of a deviation in excess of this, please return the tool to a Hilti Service Center for inspection.

9

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

9. Care and maintenance / 10. Disposal

9. Care and maintenance

9.1 Cleaning and drying

–Blow dust off the lenses.

–Do not touch the glass with your fingers.

–Use only a clean, soft cloth for cleaning. If necessary, slightly moisten the cloths with pure alcohol or a little water.

- NOTE -

–Do not use any other liquids as these may damage the plastic parts.

–Observe the temperature limits when storing your equipment. This is particularly important in winter or summer, especially if the equipment is kept inside a vehicle (storage temperatures: -30°C to +60°C / -22°F to +140°F).

9.2 Storage

–Remove the tool from its case if it has become wet. Clean and dry the tool, its carrying case and accessories (at max. temperature of 40°C / 108° F). Re-pack the equipment only when it is completely dry.

–Check the accuracy of the equipment before it is used after a long period of storage or transportation.

–Remove the batteries if the tool is to be stored for a long period.

9.3 Transportation

Use either the original Hilti cardboard box or packaging of equivalent quality for transporting or shipping your equipment.

- NOTE -

Always remove the batteries before shipping the tool.

10

10. Disposal

-CAUTION-

Improper disposal of the equipment may have serious consequences:

–The burning of plastic components generates toxic fumes which may present a health hazard.

–Batteries may explode if damaged or exposed to very high temperatures and thus cause poisoning, burns, acid burns or environmental pollution.

–Careless disposal may permit unauthorized and improper use of the equipment, possibly leading to serious personal injury, injury to third parties

and pollution of the environment.

Most of the materials from which Hilti tools or appliances are manufactured can be recycled. The materials must be properly separated before they can be recycled.

In many countries, Hilti has already made arrangements for taking back old tools and appliances for recycling. Ask Hilti customer service or your Hilti representative for further information.

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

10. Disposal / 11. Manufacturer's warranty – tools

* |

|

|

|

Dispose of batteries in |

|

||||

|

||||

|

|

|

|

accordance with national |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

regulations. |

|

|

|

|

Please help to protect our |

|

|

|

|

environment. |

Only for EU countries Disposal of electric tools together with household waste is not permissible! In observance of European Directive 2002/ 96 / EC on waste electrical and electronic equipment and its implementation in accordance with national law, electric tools that have reached the end of their life must be collected separately and returned to an environmentally compatible recycling facility.

11. Manufacturer's warranty – tools

Hilti warrants that the tool supplied is free of defects in material and workmanship.

This warranty is valid so long as the tool is operated and handled correctly, cleaned and serviced properly and in accordance with the Hilti Operating Instructions, and the technical system is maintained. This means that only original Hilti consumables, components and spare parts may be used in the tool.

This warranty provides the free-of-charge repair or replacement of defective parts only over the entire lifespan of the tool. Parts requiring repair or replacement as a result of normal wear and tear are not covered by this warranty.

Additional claims are excluded, unless stringent national rules prohibit such exclusion. In particular, Hilti is not obligated for direct, indirect, incidental or consequential damages, losses or expenses in connection with, or by reason of, the use of, or inability to use the tool for any purpose. Implied warranties of merchantability or fitness for a particular purpose are specifically excluded.

For repair or replacement, send tool or related parts immediately upon discovery of the defect to the address of the local Hilti marketing organization provided.

This constitutes Hilti's entire obligation with regard to warranty and supersedes all prior or contemporaneous comments and oral or written agreements concerning warranties.

11

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

12. FCC statement (applicable in US)

- WARNING -

This equipment has been tested and has been found to comply with the limits for a class B digital device, pursuant to part 15 of the FCC rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment on and off, the user is encouraged to try to correct the interference by one or more of the following measures:

–Re-orient or re-locate the receiving antenna.

–Increase the separation between the equipment and receiver.

–Consult the dealer or an experienced TV / radio technician for assistance.

Changes or modifications not expressly approved by Hilti could limit the user’s right to operate the equipment.

12

12. FCC statement / 13. EC conformity

Product information plate

PR 20

Made in Germany

Hilti= registered trademark of the Hilti Corporation, Schaan, Liechtenstein

|

1/4 s |

|

|

LASER RADIATION - DO NOT |

2 |

|

|

|

|

||

STARE INTO BEAM |

EN 60825-1:2003 |

195873 |

|

620-690nm/0.95mW max. |

This Laser Product |

||

complies with 21CFR |

|||

CLASS II LASER PRODUCT |

1040 as applicable |

||

Power: 4,5V=nom./120 mA |

|||

|

|

13. EC conformity

Designation: Rotating laser

Type: PR 20

Year of design: 2003

In conformance with

We declare, on our own responsibility, that this product complies with the following standards or standardization documents: EN 50081-1 and EN 50082-1 according to the stipulations of the directive 89/336/EEC.

Hilti Corporation

|

Dr. Heinz-Joachim Schneider |

Matthias Gillner |

Executive Vice President |

Head BU |

BA Electric |

Measuring Systems |

Tools & Accessories |

12/2004 |

12/2004 |

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

14

14

15

16

17

19

20

21

22

22

23

24

24

13

Printed: 07.07.2013 | Doc-Nr: PUB / 5070169 / 000 / 00

Loading...

Loading...