Hilti DX 351 User Manual

DX 351

Bedienungsanleitung |

de |

Operating instructions |

en |

Mode d’emploi |

fr |

Istruzioni d’uso |

it |

Manual de instruções |

pt |

Manual de instrucciones |

es |

Οδηγιες χρησεως |

el |

Printed: 12.08.2013 | Doc-Nr: PUB / 5126242 / 000 / 01

1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Printed: 12.08.2013 | Doc-Nr: PUB / 5126242 / 000 / 01 |

|

|

|

||

2

1 |

2 |

3 |

4 |

|

|

5 |

|

|

|

|

|

|

3 |

2 |

1 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

X |

5 |

|

|

|

|

|

|

3 |

|

|

|

|

|

|

|

D |

|

|

|

|

|

6 |

7 |

8 |

|

|

|

|

Printed: 12.08.2013 | Doc-Nr: PUB / 5126242 / 000 / 01 |

|

|

|

|

|

|

|

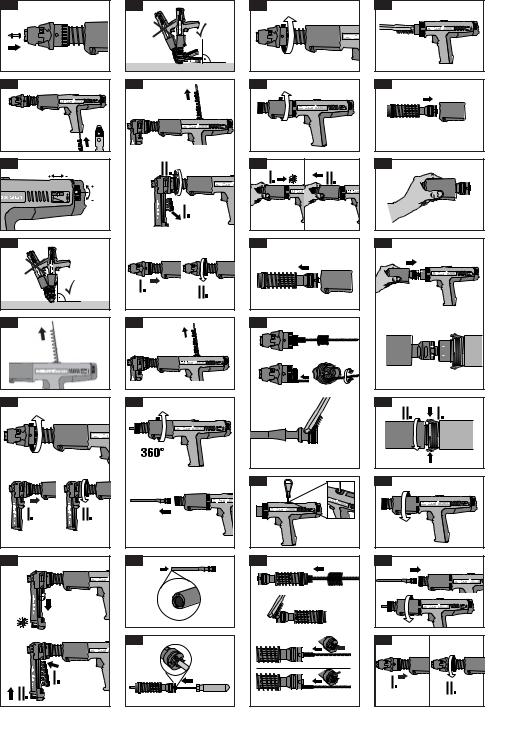

6.1 |

6.2 |

6.3 |

6.4 |

6.5 |

6.6 |

6.7 |

6.8 |

6.9 |

7.2 |

7.3 |

7.4 |

7.5 |

8.1 |

8.8 |

8.2 |

9.1 |

8.3 |

9.2 |

8.4 |

9.3 |

8.5 |

|

|

9.4 |

8.6 |

9.5 |

8.7 |

9.6 |

|

9.6 |

Printed: 12.08.2013 | Doc-Nr: PUB / 5126242 / 000 / 01

ORIGINAL OPERATING INSTRUCTIONS

DX351 powder-actuated tool

It is essential that the operating instructions are read before the tool is operated for the first time.

Always keep these operating instructions together with the tool.

Ensure that the operating instructions are with the tool when it is given to other persons.

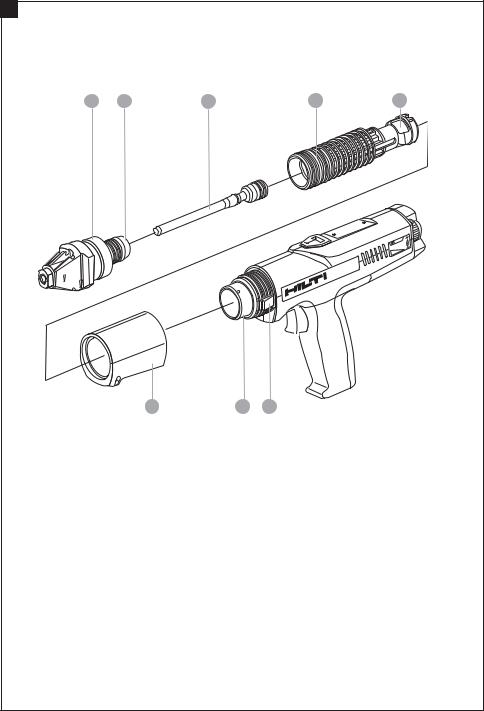

Description of main parts

Magazine housingNail pusher

Fastener feed delay device

Piston brake (part of fastener guide)Threaded sleeve

Fastener guide

Piston return springBlack housing

Trigger

Handle

Cartridge feedingCartridge ejectionGrip

Aeration slots

Power regulation indicatorPower regulation wheelNail detector assy

Contents |

Page |

|

1. Safety precautions |

17 |

|

2. General information |

19 |

|

3. Technical description |

19 |

|

4. Accessories, cartridges and fasteners |

20 |

|

5. Technical data |

21 |

|

6. Operation |

22 |

|

7. Service (changing the piston and piston brake) 23

8. Care and maintenance |

23 |

|

9. Assembly |

24 |

|

10. Troubleshooting |

25 |

|

11. Disposal |

30 |

|

12. Manufacturer’s warranty – DX tools |

30 |

|

13. EC declaration of conformity (original) |

30 |

|

14. CIP approval mark |

31 |

|

15. Health and safety of the user |

31 |

|

Tool components |

Item no. |

|

Fastener guide* |

|

|

Piston brake (part of fastener guide) |

|

en |

Piston* |

|

|

|

|

|

Piston return spring |

331010 |

|

Piston guide |

331203 |

|

Black housing |

331027 |

|

Piston stopper right |

331158 |

|

Piston stopper left |

331045 |

|

* These parts may be replaced by the user/operator

1. Safety precautions

1.1 Basic safety instructions

In addition to the safety precautions listed in the individual sections of these operating instructions, the following points must be strictly observed at all times.

1.2Only use Hilti cartridges or cartridges of equivalent quality

The use of cartridges of inferior quality in Hilti tools may lead to build-up of unburned powder, which may explode and cause severe injuries to operators and bystanders. At a minimum, cartridges must either:

a)Be confirmed by their supplier to have been successfully tested in accordance with EU standard EN 16264

NOTE:

●All Hilti cartridges for powder-actuated tools have been tested successfully in accordance with EN 16264.

●The tests defined in the EN 16264 standard are system tests carried out by the certification authority using specific combinations of cartridges and tools.

The tool designation, the name of the certification authority and the system test number are printed on the cartridge packaging.

or

b)Carry the CE conformity mark (mandatory in the EU as of July 2013).

See packaging sample at: www.hilti.com/dx-cartridges

1.3 Use as intended

The tool is designed for professional use in fastening applications in construction where specially-designed nails, threaded studs and composite fasteners are driven into concrete, steel and sand-lime block masonry.

17

Printed: 12.08.2013 | Doc-Nr: PUB / 5126242 / 000 / 01

1.4 Improper use

●Manipulation or modification of the tool is not permissible.

●Do not operate the tool in an explosive or flammable

en atmosphere, unless the tool is specially approved for such use.

●Use only original Hilti fasteners, cartridges, accessories and spare parts or those of equivalent quality.

●Observe the information printed in the operating instructions concerning operation, care and maintenance.

●Never point the tool at yourself or any bystander.

●Never press the muzzle of the tool against your hand or other part of your body.

●Do not drive nails into excessively hard or brittle materials such as glass, marble, plastic, bronze, brass, copper, natural rock, insulation material, hollow brick, glazed tile, thin-gauge sheet metal (< 4 mm), grey cast iron, spheroidal cast iron and gas concrete.

1.5 Technology

●This tool is designed with the latest available technology.

●The tool and its ancillary equipment may present hazards when used incorrectly by untrained personnel or not as directed.

1.6 Making the workplace safe

●Ensure that the workplace is well lit.

●Operate the tool only in well-ventilated working areas.

●The tool is for hand-held use only.

●Avoid unfavorable body positions. Work from a secure stance and stay in balance at all times

●Keep other persons, children in particular, outside the working area.

●Before using the tool, make sure that no one is standing behind or below the point where fasteners are to be driven.

●Keep the grip dry, clean and free from oil and grease.

1.7 General safety precautions

●Operate the tool only as directed and only when it is in faultless condition.

●If a cartridge misfires or fails to ignite, proceed as follows:

1. Keep the tool pressed against the working surface for 30 seconds.

2. If the cartridge still fails to fire, withdraw the tool from the working surface, taking care that it is not pointed towards your body or bystanders.

18

3.Manually advance the cartridge strip one cartridge. Use up the remaining cartridges on the strip. Remove the used cartridge strip and dispose of it in such a

way that it can be neither reused nor misused.

●Never attempt to pry a cartridge from the magazine strip or the tool.

●Keep the arms flexed when the tool is fired (do not straighten the arms).

●Never leave the loaded tool unattended.

●Always unload the tool before beginning cleaning, servicing or changing parts and before storage.

●Unused cartridges and tools not presently in use must be stored in a place where they are not exposed to humidity or excessive heat. The tool should be transported and stored in a toolbox that can be locked or secured to prevent use by unauthorized persons.

1.8 Temperature

●Do not disassemble the tool while it is hot.

●Never exceed the recommended maximum fastener driving rate (number of fastenings per hour). The tool may otherwise overheat.

●Should the plastic cartridge strip begin to melt, stop using the tool immediately and allow it to cool down.

1.9 Requirements to be met by users

●The tool is intended for professional use.

●The tool may be operated, serviced and repaired only by authorised, trained personnel. This personnel must be informed of any special hazards that may be encountered.

●Proceed carefully and do not use the tool if your full attention is not on the job.

●Stop working with the tool if you feel any pain or discomfort.

1.10 Personal protective equipment

● The operator and other persons in the immediate vicinity must always wear approved eye protection, a hard hat and suitable ear protection.

Printed: 12.08.2013 | Doc-Nr: PUB / 5126242 / 000 / 01

2. General information

2.1 Signal words and their meaning

WARNING: The word WARNING is used to draw attention to a potentially dangerous situation which could lead to severe personal injury or death.

CAUTION: The word CAUTION is used to draw attention to a potentially dangerous situation which could lead to minor personal injury or damage to the equipment or other property.

2.2 Pictograms |

|

|

Warning signs |

|

Symbols |

General |

Warning: |

Read the opera- |

warning |

hot surface |

tion instructions |

Obligation signs |

|

before use |

|

|

|

Wear eye |

Wear a |

Wear ear |

protection |

safety helmet |

protection |

The numbers refer to the illustrations. The illustrations can be found on the fold-out cover pages. Keep these pages open while you read the operating instructions.

In these operating instructions, the designation “the tool” always refers to the DX 351 powder-actuated tool.

Location of identification data on the tool

The type designation and the serial number are printed on the type plate on the tool. Make a note of this information in your operating instructions and always refer to it when making an enquiry to your Hilti representative or service department.

Type: DX351 |

Serial no.: |

3. Technical description

The tool is designed for professional use in fastening applications where specially-designed nails, threaded studs and composite fasteners are driven into concrete, steel and sand-lime block masonry.

The tool works on the well-proven piston principle and is therefore not related to high-velocity tools. The piston principle provides an optimum of working and fastening safety. The tool works with cartridges of 6.8/11 caliber.

Piston return and cartridge transport is fully automatic. This permits fastenings to be made very quickly and economically with nails and threaded studs. The use of a nail magazine (MX27 or MX32) greatly increases the speed and convenience of fastening with the tool, above all when making large numbers of identical fastenings of all kinds.

As with all powder-actuated tools, the tool, magazine, en fastener program and cartridge program form a “tech-

nical unit”. This means that optimal fastening with this system can only be achieved if the fasteners and cartridges are specially manufactured for it, or products of equivalent quality, are used. The fastening and application recommendations given by Hilti are only applicable if these conditions are observed.

The tool features 5-way safety – for the safety of the operator and bystanders.

The piston principle

1

The energy from the propellant charge is transferred to a piston, the accelerated mass of which drives the fastener into the base material. As approximately 95 % of the kinetic energy is absorbed by the piston, the fastener is driven into the base material at much reduced velocity (less than 100 m/sec.) in a controlled manner. The driving process ends when the piston reaches the end of its travel. This makes dangerous through-shots virtually impossible when the tool is used correctly.

The drop-firing safety device 2 is the result of coupling the firing mechanism with the cocking movement. This is designed to prevent the Hilti DX tool from firing when it is dropped onto a hard surface, no matter at which angle the impact occurs.

The trigger safety device 3 ensures that the cartridge cannot be fired simply by pulling the trigger only. The tool can be fired only when fully depressed.

The contact pressure safety device 4 requires the tool to be fully depressed with a significant force. The tool can be fired only when pressed fully in this way.

In addition, all Hilti DX tools are equipped with an unintentional firing safety device 5 . This prevents the tool from firing if the trigger is pulled and the tool then pressed against the work surface. The tool can be fired only when it is first pressed correctly and the trigger then pulled.

19

Printed: 12.08.2013 | Doc-Nr: PUB / 5126242 / 000 / 01

Loading...

Loading...