Hilti DD 160E Manual

*236036*

236036

DD-160 E

Diamond Core Coring System

Operating Instructions

Système de carottage au diamant

Mode d’emploi

Sistema de taladro con diamante

Manual de instrucciones

Sistema de perfuração com coroa diamantada Manual de Instruções

2 – 8

9 – 15

16 – 22

23 – 29

Safety precautions for grounded tools

Read all instructions

Warning!

The following fundamental safety precautions must always be observed when using electric tools/machines as protection against an electric shock, the risk of injury and a fire hazard. Please read and take note of these precautions before you use the tool/machine. Please read and keep these safety precautions in a safe place!

1.Keep Work Area Clean. Cluttered areas and benches invite injuries.

2.Consider Work Area Environment. Don’t expose power tools to rain. Don’t use power tools in damp or wet locations. Keep work area well lit. Do not use tool in presence of flammable liquids or gases.

3.Guard Against Electric Shock. Prevent body contact with grounded surfaces. For example; pipes, radiators, ranges, refrigerator enclosures.

4.Keep Children Away. Do not let visitors contact tool or extension cord. All visitors should be kept away from work area.

5.Store Idle Tools. When not in use, tools should be stored in dry, and high or locked-up place – out of reach of children.

6.Don’t Force Tool. It will do the job better and safer at the rate for which it was intended.

7.Use Right Tool. Don’t force small tool or attachment to do the job of a heavy-duty tool. Don’t use tool for purpose not intended – for example – don’t use circular saw for cutting tree limbs or logs.

8.Dress Properly. Do not wear loose clothing or jewelry. They can be caught in moving parts. Rubber gloves and non-skid footwear are recommended when working outdoors. Wear protective hair covering to contain long hair.

9.Use Safety Glasses. Also use face or dust mask if cutting operation is dusty.

10.Don’t Abuse Cord. Never carry tool by cord or yank it to disconnect from receptacle. Keep cord from heat, oil, and sharp edges.

11.Secure Work. Use clamps or a vise to hold work. It’s safer than using your hand and it frees both hands to operate tool.

12.Don’t Overreach / Maintain Control. Keep proper footing and balance at all times.

13.Maintain Tools With Care. Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and if damaged, have repaired by authorized service facility. Inspect extension cords periodically and replace if damaged. Keep handles dry, clean, and free from oil and grease.

14.Disconnect Tools. When not in use, before servicing and when changing accessories, such as blades, bits, cutters.

15.Remove Adjusting Keys and Wrenches. Form habit of checking to see that keys and adjusting wrenches are removed from tool before turning it on.

16.Avoid Unintentional Starting. Don’t carry tool with finger on switch. Be sure switch is off when plugging in.

16A. Extension Cords. Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. The following table shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gage. The smaller the gage number, the heavler the cord.

Extension Cord Table

Volts |

Total Length of Cord in Feet |

|

|

|

120 V |

0–25 |

26– 50 |

51–100 |

101–150 |

240 V |

0–50 |

51–100 |

101–200 |

201–300 |

Ampere Rating |

AWG |

|

|

|

|

More Than |

Not More Than |

|

|

|

|

0 |

6 |

18 |

16 |

16 |

14 |

6 |

10 |

18 |

16 |

14 |

12 |

10 |

12 |

16 |

16 |

14 |

12 |

12 |

16 |

14 |

12 |

Not recommended |

|

17.Outdoor Use Extension Cords. When tool is used outdoors, use only extension cords intended for use outdoors and so marked.

18.Stay Alert. Watch what you are doing. Use common sense. Do not operate tool when you are tired.

19.Check Damaged Parts. Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced by an authorized service center unless otherwise indicated elsewhere in this instruction manual. Have defective switches replaced by authorized service center. Do not use tool if switch does not turn it on and off.

20.Only use accessories and attachments which are given in the operating instructions or in the respective catalogue. The use of accessories or insert tools or attachments other than those speci-

fied in the operating instructions can result in personal injury to you.

21.Only have repairs carried out by recognized electrical specialists. This electric tool/machine complies with respective safety regulations. Repairs may only be carried out by an electrical specialist otherwise an accident hazard for the operator can exist.

22.Wear ear protectors when using for extended periods.

23.Always use any supplied side handle, and keep it tightly secured; use both hands during operation. Firm control of the tool is necessary should the tool bind.

24.Hold Tool by Handle(s) Provided. Do not touch uninsulated parts of tool when drilling. Exposed metal surfaces may be made live if the tool drills into electrical wiring.

25.Grounding instructions. This tool should be grounded while in use to protect the operator from electric shock. The tool is equipped with a 3-conductor cord and 3-prong grounding type plug to fit the proper grounding type receptacle. The green (or green and yellow) conductor in the cord is the grounding wire. Never connect the green (or green and yellow) wire to a live terminal. If your unit is for use on less than 150 V, it has a plug that looks like that shown in sketch (A) in Figure «Grounding Methods». An adapter, see sketch (B), is available for connecting sketch

(A) type plugs to 2-prong receptacles. The green-colored rigid ear, lug, or the like, extending from the adapter must be connected in a permanent ground, such as a properly grounded outlet box.

GROUNDING METHODS

|

|

metal screw |

|

|

cover of grounded |

|

|

outlet box |

grounding pin |

(A) |

(B) |

|

26.Extension Cords. Use only 3-wire extension cords that have 3- prong grounding-type plugs and 3-pole receptacles that accept the tool’s plug. Replace or repair damaged cords.

27.Replacement parts. When servicing use only identical replacement parts.

Save these instructions.

Contents |

Page |

|

1. |

DD-160 E |

|

|

diamond coring system |

2 |

2. |

DD-160 E |

|

|

diamond coring rig |

3 |

3. |

Safety |

3 |

4. |

Technical data |

4 |

5. |

Assembling the system |

|

|

components |

4 |

6. |

Selecting the method of |

|

|

fastening the coring rig |

5 |

7. |

Preparing the coring system |

|

|

for use |

5 |

8. |

Operating the system |

8 |

9. |

Maintenance |

8 |

10. Warranty |

8 |

|

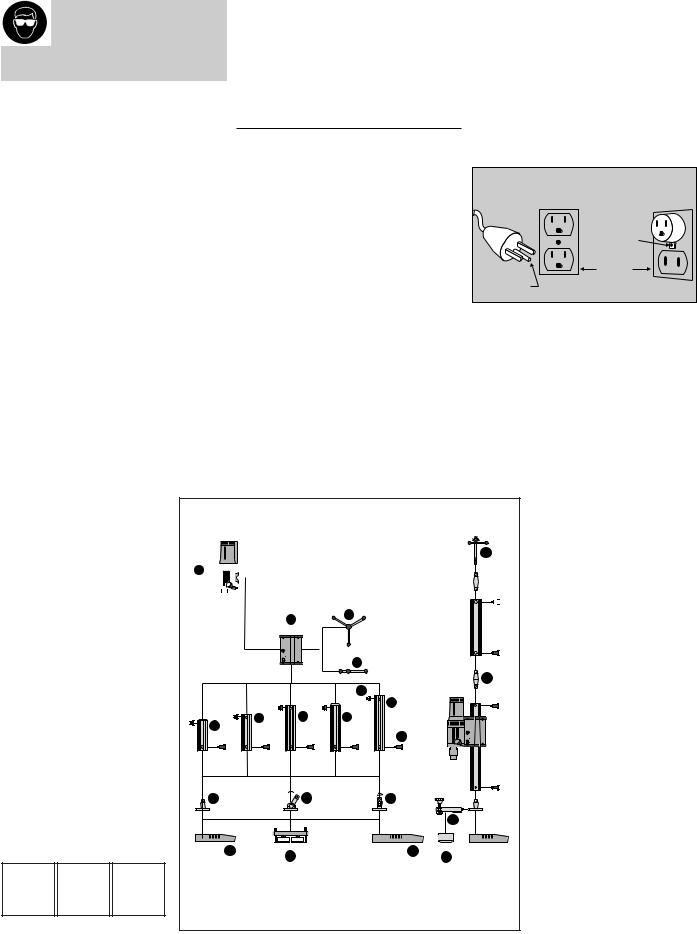

1. The DD-160 E diamond coring system

12

1 |

-160-E |

|

|

|

|

||||

|

|

|

|

|

|

|

|||

|

DD |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

3 |

|

|

DD-CA-S |

|

|

|

|

|

4 |

-CO-S |

|

|

|

|

|

|

10 |

|

|

|

|

|

13 |

DD |

|

|

|

|

|

|

|

|

|

|

|

|

DD-CP-S |

7 |

|

R-DD65F-S |

R-DD80-S |

5 |

6 |

9 |

|

DD-CA-S |

R-DD100-S |

R-DD100FS- |

R-DD120-S |

|

|||

|

8 |

|

|

|

11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

DD-EP-S |

|

17 |

18 |

19 |

DD-HSM-S |

|

DD-BCQ-S |

DD-BCS-S |

DD-BCR-S |

DD-BCQ-S |

|

|

|

21 |

|

|

|

|

|

|

|

|

|

|

|

|

|

DD-BA-3 14 |

DD-BV-P |

DD-BAV-4 15 |

DD-WC-SM |

DD-BA-3 |

||||||||

|

|

|

16 |

|

|

|

20 |

|

|

|||

1.DD-160 E motor unit

2.DD-CA-S carriage

3.Handwheel DD-FH 1/2’’

4.Ratchet 1/2’’

5.DD-R 80-S rail

6.DD-R 100-S rail

7.DD-R 120-S rail

8.DD-R 65 F-S rail

9.DD-R 100 F-S rail

10.DD-CO-S taper

11.DD-EP-S eccentric pin

12.DD-SL-SML spindle

13.DD-CP-S stop

14.DD-BA-3 baseplate

15.DD-BAV-4 baseplate

16.DD-BV-P baseplate

17.DD-BCQ-S baseplate taper

18.DD-BCS-S baseplate taper

19.DD-BCR-S baseplate taper

20.DD-WC-SM water collector

21.DD-HSM-S holder

Do not use this product in any

way other than as directed by these operating instructions.

Always wear ear |

Always wear |

Always wear safety |

protectors. |

protective gloves. |

glasses. |

2

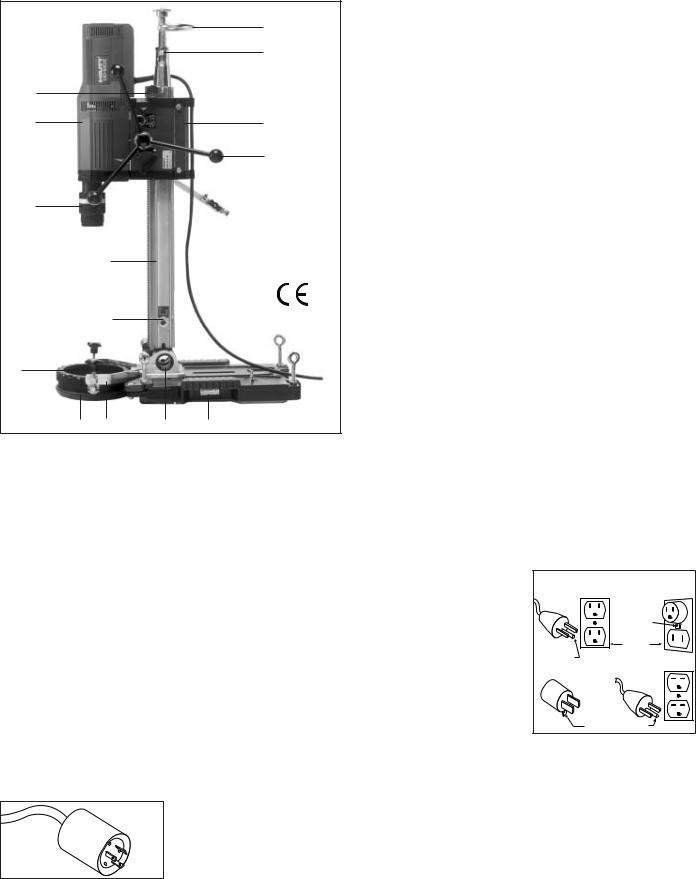

2. DD-160 E diamond coring rig

|

|

|

|

■The coring system must only be operated with the built-in GFCI ground fault circuit interruptor.

■In order to ensure safe, trouble-free operation, the drilling system must be kept clean.

(Do not clean using a jet of water.)

■Drilling work should only be carried out by trained personnel.

■When working with the vacuum baseplate on walls an additional means of securing the rig must be employed (see section 7.2).

■If leakage occurs in the water supply system, the equipment must be serviced.

■Do not touch rotating parts.

3.2 Electrical safety

The GFCI ground fault circuit interruptor protects the operator in case of faults in the insulation of the motor unit or supply cord (between the GFCI and the motor unit). This device also prevents the machine from restarting on its own accord when power returns after an interruption in the power supply. The earth/ground connection protects the operator from dangerously high voltages in case of coring into live cables. The protective function of the ground fault interrupter must be checked at regular intervals in accordance with regulations issued by national authorities (see section 7.17).

1.DD-160 E motor unit

2.DD-C-BU chuck

3.DD-CA-S carriage

4.DD-FH 1/2” handwheel

5.DD-R 100-S rail

6.DD-CO-S taper

7.DD-SL-SML spindle

8.DD-CP-S stop

9.DD-EP-S eccentric pin

10.DD-BCS-S baseplate taper

11.DD-BAV-4 baseplate

12.DD-HSM-S holder

13.DD-WC-SM water collector

14.DD-SW-SM sealing disc

3. Safety

3.1 Safety precautions on the jobsite

Before beginning work with the coring system, read the operating instructions carefully and ensure that the safety precautions listed below are observed.

Please also note that permission to begin coring work must be obtained from the site engineer or other authorised person.

■Ensure that no electric cables, gas or water pipes etc. are situated where holes are to be drilled.

■Cables, pipes or other supply lines situated in close proximity to where holes are to be drilled must be switched off.

3.2a Grounding instructions

This tool should be grounded while in use to help protect the operator from electric shock. The tool is equipped with a 3-conductor cord and 3-prong grounding type plug to fit the

proper grounding type receptacle. The green (or green and yellow) conductor in the cord is the grounding wire. Never connect the green (or green and yellow) wire to a live terminal.

If your unit is for use on less than 150 V, it has a plug that looks like that shown in sketch (A) in Figure 1. If it is for use on 150 to 250 V, it has a plug that looks like that shown in sketch

(D). An adapter, see sketches (B) and (C), is available for connecting sketch

(A) type plugs to 2-prong receptacles. The greencolored rigid ear, lug, or the like, extending from the adapter must be connected to a permanent ground,

■The coring work must not have a negative effect on the structural design of the building (coring through steel reinforcement!).

■Cordon off areas where coring work is taking place, particularly behind/ below walls or ceilings which are being drilled through.

■Wear a helmet, safety shoes, gloves and ear protectors.

■Tidiness and good organisation on the jobsite help to prevent accidents.

■Use only original Hilti parts.

■Protect the motor unit from water spray and rain.

■For overhead coring, the water collector and water removal system must be in good order and function correctly.

such as a properly grounded outlet box. No adapter is available for a plug as shown in sketch (D).

|

GROUNDING METHODS |

|

||

|

|

|

metal screw |

|

|

|

|

cover of grounded |

|

|

|

|

outlet box |

|

grounding pin |

(A) |

|

(B) |

|

|

|

|||

|

|

grounding |

|

|

(C) |

|

means |

grounding pin |

(D) |

Figure 1

For the DD-160 E a 20 A plug is demanded that looks like that shown in Figure 2.

Figure 2

3.2b Extension Cords

Use only 3-wire extension cords that have 3-prong grounding-type plugs and 3-pole receptacles that accept the tool’s plug. Replace or repair damaged cords.

3.3 Overload protection

Hilti diamond coring systems are equipped with mechanical, electronic and thermal overload protection devices.

Mechanical clutch:

Protects the operator, motor and core bit in case the core bit suddenly sticks.

Electronic protection:

In case of overloading caused by excessive coring feed pressure, motor current is reduced automatically so that the core bit then only rotates slowly. Motor current returns to normal when coring feed pressure is reduced, and the motor then continues to run at full power.

Protection against overheating:

The motor is protected against overheating by a sensor which auto-mati- cally reduces current input in case of sustained overloading and at high ambient temperatures. The machine can be operated normally after the temperature of the motor windings has dropped to a satisfactory level. The motor windings can be cooled more quickly by allowing the motor to run without load.

3

Loading...

Loading...