Hilti DCH 300 User Manual

DCH 300

Operating instructions |

en |

Mode d’emploi |

fr |

Manual de instrucciones |

es |

Manual de instruções |

pt |

1

This Product is Certified

Ce produit est homologué

Producto homologado por

Este produto está registrado

C  US

US

2 |

3 |

4

1

"# 2 "“ "[

"Ç "]

3

5

DCH 300 Diamond cutter

It is essential that the operating instructions are read before the machine is operated for the first time.

Always keep these operating instructions together with the machine.

Ensure that the operating instructions are with the machine when it is given to other persons.

|

Contents |

Page |

|||

|

1. |

General information |

1 |

|

|

|

2. |

Description |

2 |

|

|

|

3. |

Accessories, consumables |

5 |

|

|

|

4. |

Technical data |

5 |

|

|

|

5. |

Safety instructions |

6 |

|

|

|

6. |

Before use |

11 |

|

|

|

7. |

Operation |

13 |

|

|

|

8. |

Care and maintenance |

15 |

|

|

|

9. |

Troubleshooting |

15 |

|

|

|

10. |

Disposal |

16 |

|

|

|

11. |

Manufacturer’s warranty |

17 |

|

|

1These numbers refer to the corresponding illustrations. The illustrations can be found on the fold out cover pages. Keep these pages open while studying the operating instructions.

In these operating instructions, the designation “the power tool” always refers to the DCH 300 diamond cutter.

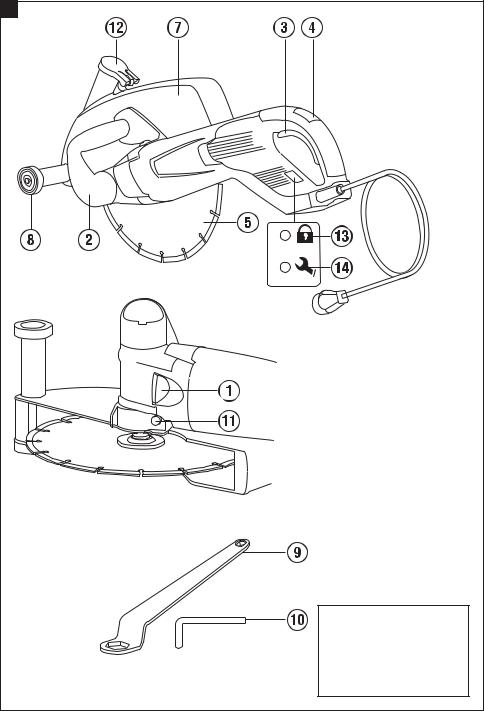

Operating controls and indicators 1

@ Spindle lockbutton

; Front grip en = On / off switch

% Switch on interlock release button & Diamond cutting disc

( Spindle

) Guard (hood) + Guide wheels

§ Clamping nut wrench, 24 mm AF / 10 mm AF / Hex. socket wrench, 6 mm AF

: Guard (hood) clamping screw · Dust removal connector cap $ Service indicator

£ Theft protection indicator (option)

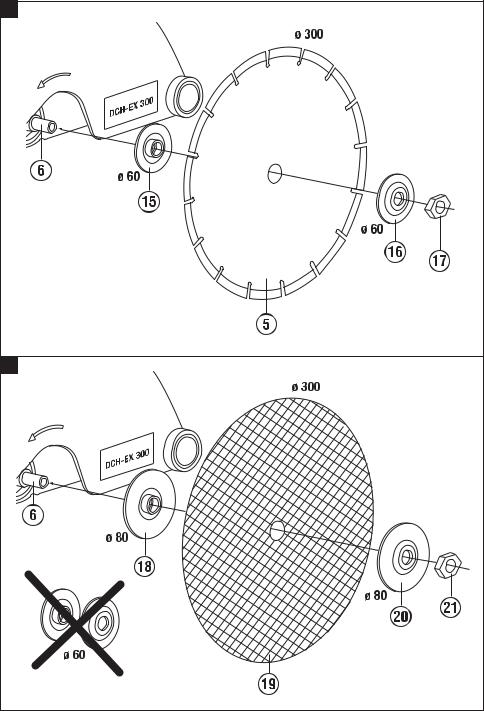

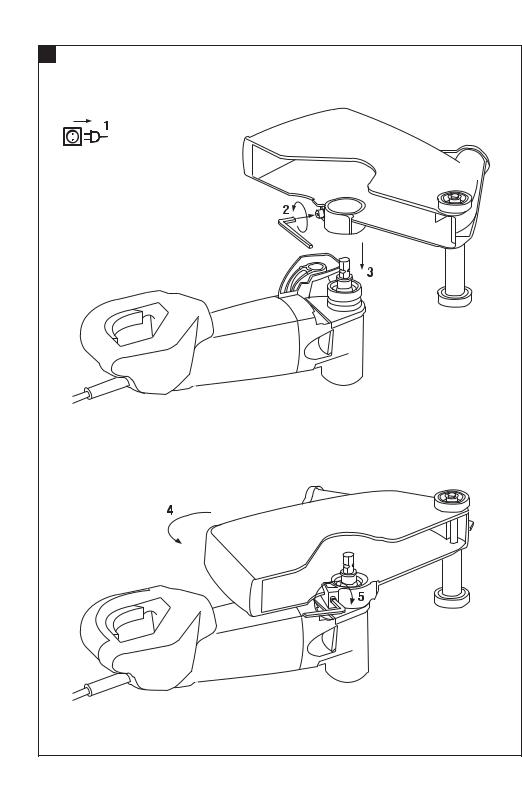

DCH 300 mounting system for diamond cutting discs 2

| Reversible flange 60 mm dia. ¡ Clamping flange, 60 mm dia. Q Clamping nut, M16 x 1.5

DCH 300 mounting system for synthetic resin bonded fiber reinforced abrasive cutting discs (optional) 3

W Reversible flange 80 mm dia.

E Synthetic resin bonded fiber reinforced cutting discs with a diameter of 300 mm (12")

R Clamping flange, 80 mm dia. T Clamping nut, M16 x 1.5

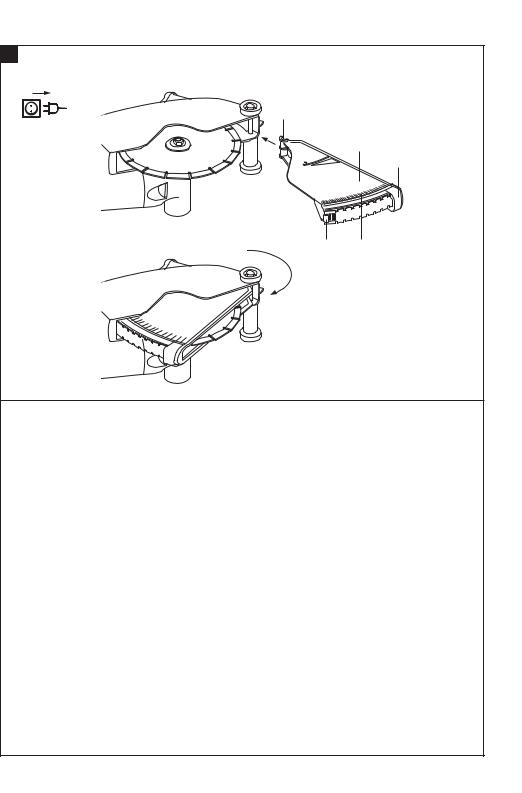

Hood extension with depth gauge (optional) 4

Z Hood extension U Hook

I Stop

O Cutting depth sliding indicator P Cutting depth scale

1. General information

1.1 Safety notices and their meaning

DANGER

Draws attention to imminent danger that could lead to serious bodily injury or fatality.

WARNING

Draws attention to a potentially dangerous situation that could lead to serious personal injury or fatality.

1

CAUTION

Draws attention to a potentially dangerous situation that could lead to slight personal injury or damage to the equipment or other property.

en NOTE

Draws attention to an instruction or other useful information.

1.2Explanation of the pictograms and other information

Warning signs

General |

Warning: |

warning |

electricity |

Obligation signs

Wear a hard |

Wear eye |

Wear ear |

Wear |

hat. |

protection. |

protection. |

protective |

|

|

|

gloves. |

Wear safety |

Wear |

shoes. |

breathing |

|

protection. |

Symbols

Read the |

Return waste |

Amps |

Volts |

operating |

material for |

|

|

instructions |

recycling. |

|

|

before use. |

|

|

|

Alternating |

Revolutions |

Diameter |

Nominal speed |

||||

current |

per minute |

|

under no load |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Double insulated

Location of identification data on the machine

The type designation and serial number can be found on the type identification plate on the machine. Make a note of this data in your operating instructions and always refer to it when making an enquiry to your Hilti representative or service department.

Type:

Serial no.:

2. Description

2.1 Use of the product as directed

The DCH 300 is an electrically powered diamond cutter for professional use in the construction industry. It is designed for cutting mineral materials with diamond discs without use of water.

A vacuum cleaner with the appropriate filter, e.g. Hilti VCD 50 vacuum cleaner, must be used when cutting mineral materials.

In order to avoid electrostatic effects, a vacuum cleaner equipped with an antistatic hose should be used. Use only diamond cutting discs with a maximum permissible peripheral speed of at least 80 m/sec (16000 ft/min).

The power tool is to be used exclusively in pushing mode (counter rotation). The use of liquids, e.g. to cool the disc or suppress dust, is not permissible.

Do not use the power tool for cutting with cutting tools of a type not specified in these operating instructions (e.g. circular saw blades) or for grinding.

When equipped with synthetic resin bonded fiber reinforced abrasive cutting discs, the power tool can also be used for cutting metals. When doing so, use only synthetic resin bonded fiber reinforced abrasive cutting discs with a maximum permissible peripheral speed of at least 80 m/sec (16000 ft/min).

2

The working environment may be as follows: construction site, workshop, renovation, conversion or new construction.

To avoid the risk of injury, use only genuine Hilti accessories and cutting tools. Observe the safety rules and operating instructions for the accessories used.

Observe the information printed in the operating instructions concerning operation, care and maintenance.

The machine is designed for professional use and may be operated, serviced and maintained only by trained, en authorized personnel. This personnel must be informed of any special hazards that may be encountered. The machine and its ancillary equipment may present hazards when used incorrectly by untrained personnel or when used not as directed.

The machine may be used only in a dry environment.

The machine may be operated only when connected to a power supply providing a voltage and frequency in compliance with the information given on its type identification plate.

Do not use the machine where there is a risk of fire or explosion.

Working on materials hazardous to the health (e.g. asbestos) is not permissible. Modification of the machine or tampering with its parts is not permissible.

2.2 Switches

On/off switch with switch on interlock

2.3 Starting current limitation

The starting current drawn by the power tool is several times higher than its rated current. The electronic starting current limiter reduces the starting current drawn by the power tool and thus prevents the mains fuse blowing. It also allows the power tool to start smoothly, without a jolt.

2.4 Restart interlock

The power tool does not restart by itself after an interruption in the electric supply. The switch must first be released and then pressed again after approx. 1 second.

2.5 TPS theft protection system (optional)

The power tool may be optionally equipped with the TPS theft protection system. If equipped with this feature, the power tool can be unlocked and made ready for operation only through use of the corresponding TPS key.

2.6 LED indicators

Service indicator LED (see section “Care and maintenance”)

Theft protection system indicator (optional) (see section “Operation”)

2.7 Guard (hood) with guide wheels

Cutting and slitting work on stone may be carried out only when the power tool is equipped with a dust hood with wheels.

2.8 Electronic overload protection

The electronic overload protection system monitors current input and thus protects the power tool from overload.

If the motor is overloaded through application of excessive working pressure, the power tool’s performance drops noticeably or it may come to a complete standstill. A standstill should be avoided.

Permissible overload cannot be given as a specific value as it depends on the temperature of the motor.

If the power tool has been overloaded, release the pressure applied and then allow it to run under no load for approx. 30 seconds.

3

Loading...

Loading...