Hilti DX 36 User Manual

DX 36

Operating instructions |

en |

Mode d’emploi |

fr |

Manual de instrucciones |

es |

Manual de instruções |

pt |

Printed: 12.08.2013 | Doc-Nr: PUB / 5125370 / 000 / 01

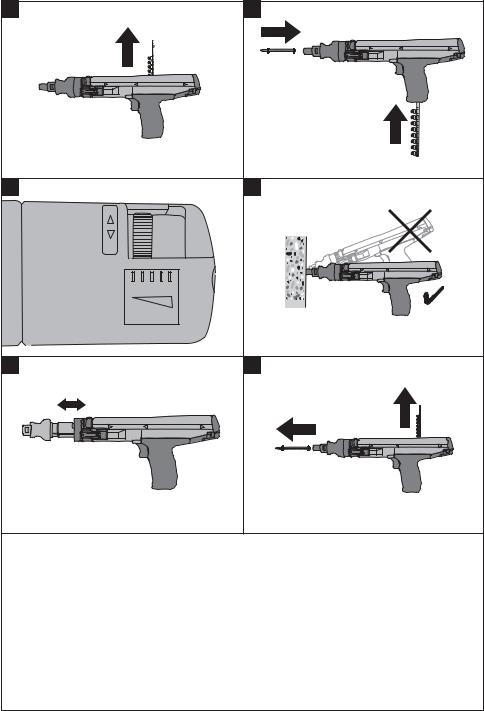

1 |

Printed: 12.08.2013 | Doc-Nr: PUB / 5125370 / 000 / 01 |

2 |

|

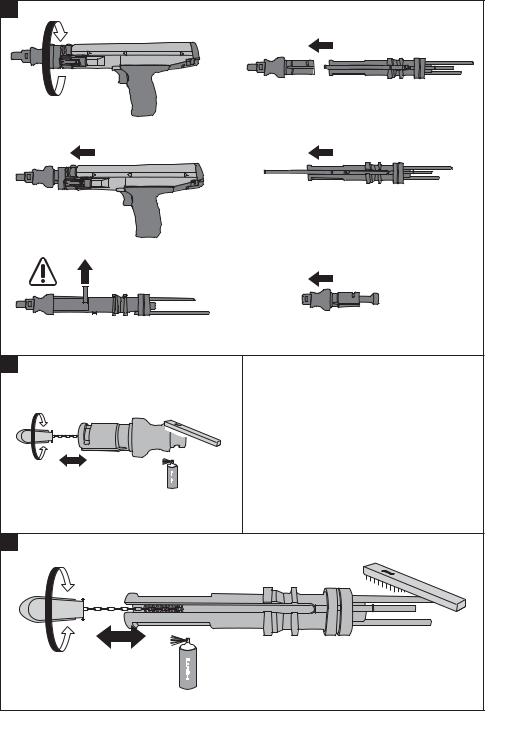

3 |

|

|

|

|

|

|

|

|

|

4 |

|

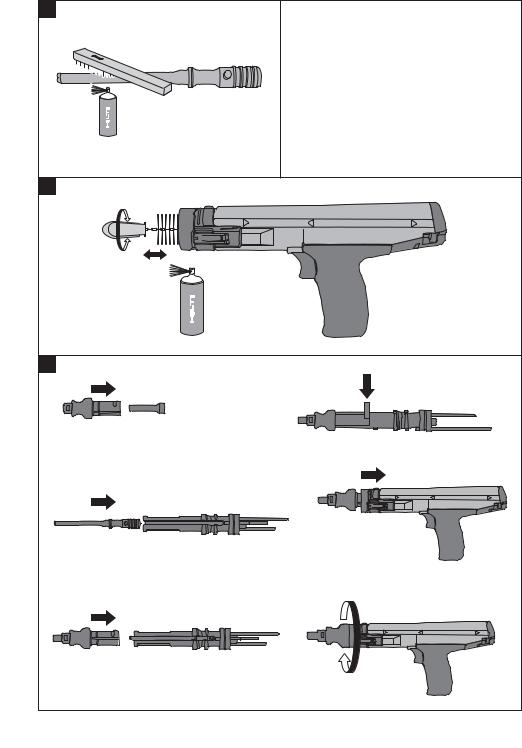

5 |

² |

|

|

|

|

|

|

|

|

² |

|

|

6 |

|

7 |

|

|

|

|

|

|

Printed: 12.08.2013 | Doc-Nr: PUB / 5125370 / 000 / 01

8 |

|

|

|

|

|

|

|

|

|

|

|

9 |

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

|

Printed: 12.08.2013 | Doc-Nr: PUB / 5125370 / 000 / 01 |

|

11 |

|

|

12 |

|

|

13 |

|

|

|

|

|

|

Printed: 12.08.2013 | Doc-Nr: PUB / 5125370 / 000 / 01 |

ORIGINAL OPERATING INSTRUCTIONS

DX 36 powder-actuated fastening tool

It is essential that the operating instructions are read before the tool is operated for the first time.

Always keep these operating instructions together with the tool.

Ensure that the operating instructions are with the tool when it is given to other persons.

Contents |

Page |

|

1 |

Safety instructions |

1 |

2 |

General information |

3 |

3 |

Description |

4 |

4 |

Accessories, consumables |

5 |

5 |

Technical data |

6 |

6 |

Before use |

6 |

7 |

Guidelines |

6 |

8 |

Operation |

7 |

9 |

Care and maintenance |

8 |

10 |

Troubleshooting |

10 |

11 |

Disposal |

14 |

12 |

Manufacturer’s warranty - tools |

15 |

13 |

EC declaration of conformity (original) |

15 |

14 |

Confirmation of CIP testing |

15 |

15 |

Health and safety of the operator |

16 |

1 These numbers refer to the corresponding illustra- |

en |

|

tions. The illustrations can be found on the fold-out cover |

||

|

||

pages. Keep these pages open while studying the oper- |

|

|

ating instructions. |

|

|

In these operating instructions, the designation “the tool” |

|

|

always refers to the DX 36 powder-actuated fastening |

|

|

tool. |

|

|

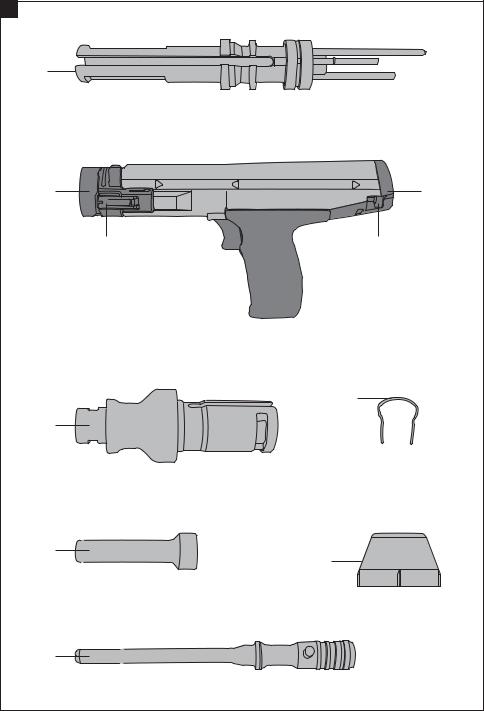

Parts and operating controls 1 |

|

|

@ Casing |

|

|

; Piston guide |

|

|

= Base plate |

|

|

% Fastener guide |

|

|

& Piston |

|

|

( Spring clip |

|

|

) Power regulation wheel |

|

|

+ Catch |

|

|

§ Swivel ring |

|

|

/ Stabilizer (fragmentation guard, only USA) |

|

1 Safety instructions

1.1 Basic information concerning safety

In addition to the information relevant to safety given ineachofthesectionsoftheseoperatinginstructions, the following points must be strictly observed at all times.

1.1.1 Using cartridges

Use only Hilti cartridges or cartridges of equivalent quality.

Use of cartridges of inferior quality in Hilti tools may lead to a build-up of unburned powder, which may explode and cause sever injuries to operators and bystanders. Cartridges must fulfill one of the following minimum requirements:

a)The applicable manufacturer must be able to verify successful testing in accordance with the EU standard EN 16264 or

b)The cartridges must bear the CE conformity mark (mandatory in the EU as of July 2013).

NOTE

All Hilti cartridges for powder-actuated tools have been tested successfully in accordance with EN 16264. The tests defined in the EN 16264 standard are system tests

carried out by the certification authority using specific combinations of cartridges and tools. The tool designation,thenameofthecertificationauthorityandthesystem test number are printed on the cartridge packaging.

Please refer to the packaging example at: www.hilti.com/dx-cartridges

1.1.2Requirements to be met by users

a)The tool is intended for professional use.

b)The tool may be operated, serviced and repaired only by authorized, trained personnel. This personnel must be informed of any special hazards that may be encountered.

1.1.3Personal safety

a)Stay alert, watch what you are doing and use common sense when operating a direct fastening tool.Don’tusethetoolwhenyouaretiredorunder theinfluenceofdrugs,alcoholormedication.Stop using the tool if you experience pain or do not feel well. A moment of inattention while operating the tool may result in serious personal injury.

1

|

b) |

Avoid unfavorable body positions. Make sure you |

|

|

work from a safe stance and stay in balance at all |

|

c) |

times. |

|

Wear non-skid shoes. |

|

|

d) |

Never point the tool toward yourself or other per- |

|

|

sons. |

en |

e) |

Neverpressthenosepieceofthetoolagainstyour |

|

|

hand or against any other part of your body (or |

|

|

|

|

|

other person’s hand or part of their body). |

f)Keep other persons, especially children, away from the area in which the work is being carried out.

g)Keep the arms slightly bent while operating the tool (do not straighten the arms).

h)Observe the information printed in the operating instructions concerning operation, care and maintenance.

1.1.4Use and care of powder-actuated fastening tools

a)Use the right tool for the job. Do not use the tool for purposes for which it was not intended. Use it only as directed and when in faultless condition.

b)Never leave a loaded tool unattended.

c)Store unused cartridges and tools currently not in use in a dry place where they are not exposed to high temperatures.

d)Transport and store the tool in a toolbox that can be secured to prevent unauthorized use.

e)Always unload the tool (remove cartridges and fasteners) before cleaning, before maintenance, before work breaks and before storing the tool.

f)When not in use, tools must be unloaded and stored in a dry place, locked up or out of reach of children.

g)Check the tool and its accessories for any damage. Guards, safety devices and any slightly worn parts must be checked carefully to ensure that they function faultlessly and as intended. Check thatmovingpartsfunctioncorrectlywithoutsticking and that no parts are damaged. All parts must be fitted correctly and fulfill all conditions necessary for correct operation of the tool. Damaged guards, safety devices and other parts must be repaired or replaced properly at a Hilti service center unless otherwise indicated in the operating instructions.

h)Pull the trigger only when the tool is fully pressed against the working surface at right angles.

i)Always hold the tool securely and at right angles to the working surface when driving in fasteners. This will help to prevent fasteners being deflected by the working surface.

j)Never redrive a fastener. This may cause the fastener to break and the tool may jam.

k)Never drive fasteners into existing holes unless this is recommended by Hilti (e.g. DX Kwik).

l)Always observe the application guidelines.

m)Usethefragmentationguardwhentheapplication permits.

n)Never pull the fastener guide back by hand as this could make the tool ready to fire. This could

cause a fastener or the piston to be driven into a part of the body.

1.1.5Work area safety

a)Ensure that the workplace is well lit.

b)Operate the tool only in well-ventilated working areas.

c)Do not attempt to drive fasteners into unsuitable materials: Materials that are too hard, e.g. welded steel and cast iron. Materials that are too soft, e.g. wood and drywall panel (gypsum board). Materials that are too brittle, e.g. glass and ceramic tiles. Driving a fastener into these materials may cause the fastener to break, shatter or to be driven right through.

d)Never attempt to drive fasteners into materials such as glass, marble, plastic, bronze, brass, copper, rock, insulation material, hollow brick, ceramic brick, thin sheet metal (< 4 mm), cast iron or cellular concrete.

e)Before driving fasteners, check that no one is present immediately behind or below the working surface.

f)Keep the workplace tidy. Objects which could cause injury should be removed from the working area. Untidiness at the workplace can lead to accidents.

g)Keep the grips dry, clean and free from oil and grease.

h)Do not use the tool where there is a risk of fire or explosion unless it has been specially approved for use under these conditions.

1.1.6Mechanical safety precautions

a)Select the correct combination of fastener guide, piston and fastener. Failure to use the correct combination of these items may result in injury or cause damage to the tool and/or lead to unsatisfactory fastening quality.

b)Useonlyfastenersofa typeapprovedforusewith the tool.

c)Do not tamper with or modify the tool or parts of it, especially the piston.

1.1.7Thermal safety precautions

a)Do not exceed the recommended fastener driving rate (number of fasteners driven per hour).

b)If the tool has overheated, allow it to cool down.

c)Do not dismantle the tool while it is hot. Allow the tool to cool down.

2

Loading...

Loading...