Flowserve SuperNova User Manual

SuperNova Series

S050 - S200

Rack & Pinion AUTOMAX Actuators

Page 1/4

B00043e4-rev3.doc

Installation, Operating & Maintenance Instructions

All actuators are factory lubricated for life, but still should be protected from the elements and stored indoors until ready for use. The ports of the actuator are plugged as supplied from the factory. In case the actuators are stored a long period before installation, it would be a good practice to stroke the actuators before mounting. Prior to assembly, check the mounting surfaces, the stem adaptor and the bracket to assure proper fit.

Manually open and close the valve to insure freeness of operation. Be sure the valve and actuator rotate in the same direction and are in the same position. Secure the valve with the stem vertical. Bolt the bracket to the valve and place the stem adaptor on the valve stem. Position the actuator over the valve and lower to engage the stem adaptor to the actuator shaft.

Continue to lower until the actuator seats on the bracket mounting surface. In order to align the bolt holes, it may be necessary to turn or stroke the actuator a few degrees and/or adjust the actuator travel stops. Bolt the actuator to the bracket.

After consulting the valve manufacturer’s recommendations, adjust the travel stop bolts of the actuator for the proper open and closed valve positions. Pneumatically stroke the actuator several times to assure proper operation with no binding of the stem adaptor. If the actuator is equipped with limit switches or other accessories, adjust them at this time.

To prolong actuator life use only clean, dry plant air. Lubricated air is not required, however it is recommended particularly for high cycle applications. Do not use lubricated air with positioners.

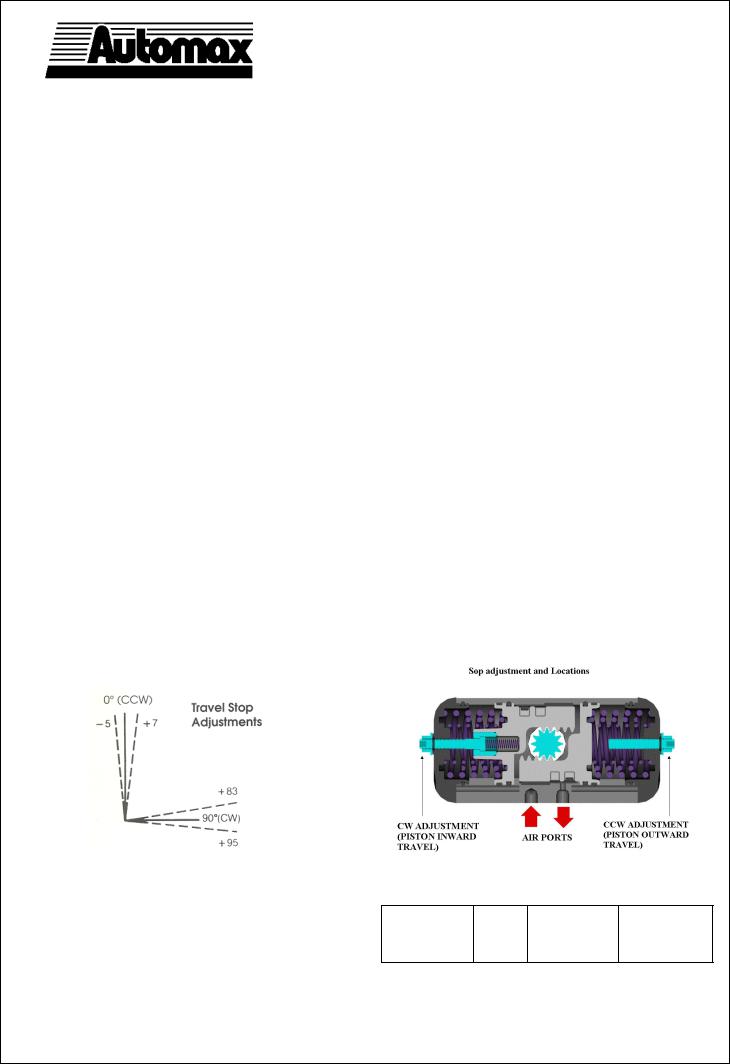

Travel Stop Adjustment Both Directions 5° Overtravel 12°Adjustment Each End

The SuperNova Series actuators have unique travel stop adjustments in both clockwise and counterclockwise directions. The 10° total overtravel provides adjustments from –5° to +7° at the “0°” Counterclockwise position and from +83° to + 95° at the “90°” Clockwise position.

All actuated valves require accurate travel-stop adjustments at both ends of the stroke to obtain optimum performance and valve seat life. The accumulation of tolerances in the adaption of the actuators to valves is such that there must be a range of adjustment for both ends of the stroke to achieve the expected performance.

Ball and Plug Valves require precise adjustment at the open (CCW) position to protect the seat from the flow media and the closed (CW) position to assure absolute shut-off

Butterfly Valves require precise adjustment at the closed position to assure full shut-off, to prevent disc overtravel and damage to the seat at the closed position.

Tandem Valves, where two valves are operated in tandem through a single solenoid valve (eg. A 3-Way configuration), absolutely require precise adjustment at both ends of the stroke to assure the seating of both valves.

Actuator |

Endcap Screw |

Adjustment Bolt |

Spring Color |

|

Socket Size |

Socket Size |

Code |

S050 |

4 mm |

3 mm |

White |

S063 |

5 mm |

4 mm |

Light green |

S085 |

6 mm |

5 mm |

Blue |

S100 |

6 mm |

6 mm |

Red |

S115 |

6 mm |

6 mm |

Yellow |

S125 |

8 mm |

6 mm |

Grey |

S150 |

8 mm |

8 mm |

Dark green |

S175 |

10 mm |

8 mm |

Purple |

S200 |

12 mm |

8 mm |

Orange |

Adjustment Bolt Location

Actuator Type |

Fail |

Clockwise (CW) |

Counterclockwise |

|

position |

closed |

(CCW) open |

Double Acting |

|

Left End Cap |

Right End Cap |

Spring Return |

CW |

Left End Cap |

Right End Cap |

Spring Return* |

CCW* |

Right End Cap |

Left End Cap |

*The pistons are rotated 180° for CCW fail position

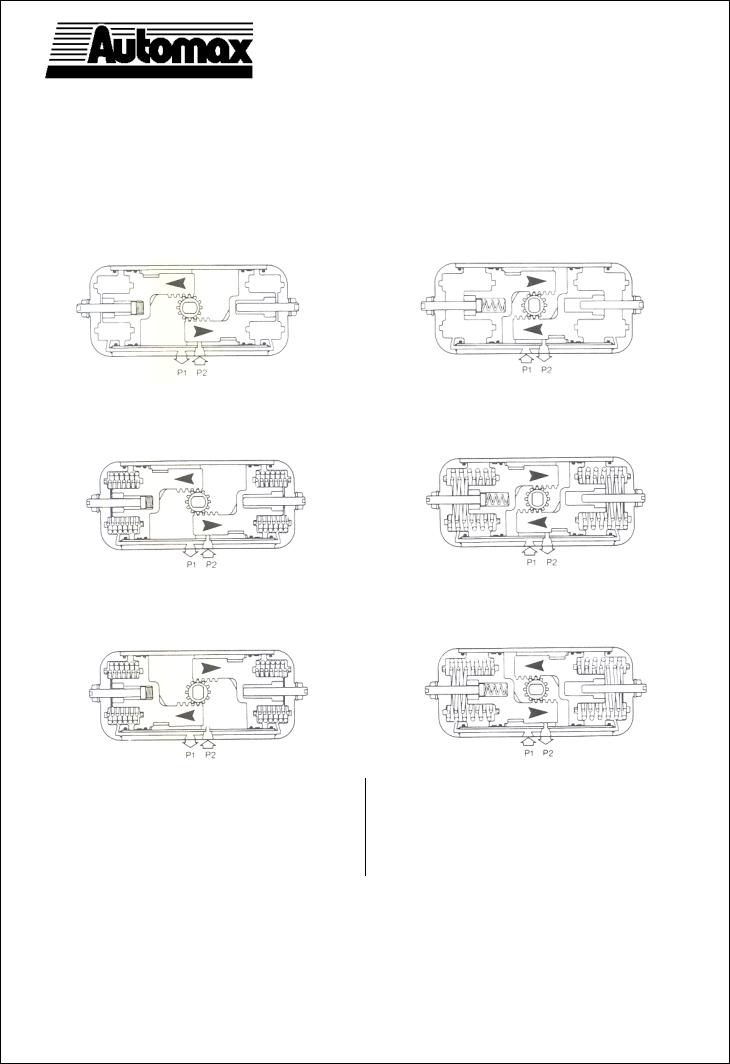

OPERATION

(As viewed from top of the actuator)

Double Acting

Applying air pressure to Port 2 drives the pistons outward, which turns the pinion counterclockwise as the air volume on the outside of the pistons exhausts through Port 1.

Spring return (Fail CW)

Applying air pressure to Port 2 drives the pistons outward, which compresses the springs and turns the pinion counterclockwise as the air volume on the outside of the pistons exhausts through Port 1.

Spring Return (Fail CCW)

Applying air pressure to Port 2 drives the pistons outward, which compresses the springs and turns the pinion clockwise as the air volume on the outside of the pistons exhausts through Port 1.

Changing direction of pinion rotation (CW to CCW)

The SuperNova series actuators are normally assembled as Double Acting or Spring Return Fail CW (spring action turns pinion clockwise).

To assembly the actuator on Spring Return Fail CCW (spring action turns pinion counterclockwise):

1.Follow disassembly procedures (next page) from point #1 through #8.

SuperNova Series

S050 - S200

Rack & Pinion AUTOMAX Actuators

Page 2/4

B00043e4-rev3.doc

Applying air pressure to Port 1 drives the pistons inward, which turns the pinion clockwise as the air volume on the inside of the pistons exhausts through Port 2.

Exhausting the air pressure from Port 2 allows stored energy of the springs to drive pistons inward, turning the pinion clockwise. Air volume on outside of pistons vents through Port 1.

Exhausting the air pressure from port P2 allows stored energy of the spring to drive pistons inward, turning the pinion counterclockwise. Air volume on outside of pistons vents through Port 1.

2.Rotate both pistons 180° around their axis: left piston rack must be on air supply ports side, right pinion on the opposite side (see Spring Return CCW drawing).

3.Follow reassembly procedures.

Loading...

Loading...