USER INSTRUCTIONS

Worcester Controls

Pulsair III Digital

Electronic Positioner

FCD WCAIM2056-00 – 08/04 (Replaces IOM-19990)

Installation

Operation

Maintenance

Experience In Motion

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Contents

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

1 Introduction 4

Safety Instruction 4

2 Storage 5

General 5

Storage Indoors 5

Storage Outdoors or for a Longer Period 6

Storage in a Warm Place 6

3 Design 7

4 Variants 8

Pulsair III 270° (W) 8

Pulsair III Explosion-Proof (Z) 8

Pulsair III Intrinsically Safe 8

Pulsair III Remote Mounted 8

5 Function 9

Double-Action Function 9

Single-Action Function 9

6 Installation 10

Tubing 10

Air Supply Requirements 10

Mounting 11

Connections 12

Air 12

Electrical Connection 12

Dimensions 12

Single-Action Positioner (Direct Function) 13

Double-Action Positioner (Direct Function) 14

Electrical Connections 14

7 Control 16

Menu and Pushbuttons 16

Other Functions 16

Menu Indicator 17

Menus 17

Changing Parameter Values 18

Basic Menu: Calibrate 19

First Start 19

Calibration Error Messages 19

Basic Menu: Read 22

Basic Menu: Man/Aut 23

Basic Menu: Shift Menu 23

Full Menu: Protection 24

Full Menu: Status 25

Full Menu: Setup 26

Full Menu: Tuning 32

Full Menu: Alarms 34

Full Menu: Fact Set 38

8 Maintenance/Service 40

Disassembling Pulsair III W 40

Silencer 44

Spindle Adapter 44

Potentiometer 45

Transmitter Boards 46

Disassembling the Worcester Pulsair III Z 51

Filter Change, Pulsair III W and Z 52

Converting for Remote Control 52

9 Troubleshooting 54

10 Technical Data 55

11 Spare Parts 58

2

fl owserve.com

3

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

1 Introduction

The PULSAIR III is a digital positioner designed primarily for controlling modulation

valves.

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Warning:

a

• The valve package moves when in operation and can cause personal injury or damage

if handled incorrectly.

The positioner can be used with single- or double-action actuators with either rotary or

linear movement.

The PULSAIR III can be equipped with modules for feedback, limit switches, and a

pressure gauge block.

The modules can be factory-assembled before delivery or fi tted later.

The modules for feedback and limit switches can contain 4-20 mA feedback and one of

the following functions:

• Two mechanical switches

• Two reed switches

• Two inductive sensors

Safety notices are presented in this manual in three forms:

Warning: Refers to personal safety. Alerts the user to potential danger. Failure to

a

follow warning notices could result in personal injury or death.

Caution: Directs the user’s attention to general precautions that, if not followed,

c

could result in personal injury and/or equipment damage.

NOTE: Highlights information critical to the user’s understanding of the actuator’s installation and operation.

• If the input signal fails or is turned off, the valve moves quickly to its end position.

• If the compressed air supply fails or is turned off, fast movements can occur.

• The valve is not controlled by the input signals when in the “Out of service” mode. It

will open/close in the event of a leak.

• If a high value is set for Cut off, fast movements can occur.

• If the valve is controlled in the Manual mode, the valve can move quickly.

• Incorrect settings can cause self-oscillation, which can lead to damage.

Important:

• Always turn off the compressed air supply before removing or disconnecting the air

supply or the integral fi lter. Remove or disconnect with care because C- is still under

pressure even after the air supply is turned off.

• Always work in an ESD protected area when servicing the PCBs. Make sure the input

signal is switched off.

• The air supply must be free from moisture, water, oil and particles.

2 Storage

Safety Instruction

Read the safety instructions in this manual carefully before using the product. The

installation, operation, and maintenance of the product must be done by staff with the

necessary training and experience. If any questions arise during installation, contact the

supplier/sales offi ce before continuing work.

4

General

The PULSAIR III positioner is a precision instrument. Therefore, it is essential that it is

handled and stored in the correct way. Always follow the instructions below!

NOTE: As soon as the positioner is connected and started, an internal air leakage will

provide protection against corrosion and prevent the ingress of moisture. For this

reason, the air supply pressure should always be kept on.

5

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Storage Indoors

Store the positioner in its original packaging. The storage environment must be clean,

dry, and cool 60-80°F (15-26°C).

Storage Outdoors or for a Longer Period

If the positioner must be stored outdoors, it is important that all cover screws are

tightened and that all connections are properly sealed. The unit should be packed with a

desiccant (silica gel) in a plastic bag or similar, covered with plastic, and not exposed to

sunlight, rain, or snow.

This is also applicable for long-term storage (more than 1 month) and for long transport

by sea.

Storage in a Warm Place

When the positioner is stored in a warm place with a high relative humidity and is subjected to daily temperature variations, the air inside the unit will expand and contract.

This means that air from outside the unit may be drawn into the positioner. Depending

on the temperature variations, relative humidity, and other factors, condensation and

corrosion can occur inside the unit, which in turn can give rise to functional disorders or

a failure.

3 Design

The PULSAIR III positioner contains:

• electronic board with microprocessor, HART modem, display etc.

• pneumatic valve block

• positional feedback with potentiometer

• sealed compartment for electrical connections.

The pushbuttons and display are accessible underneath the aluminum cover, which is

sealed with an O-ring.

The fi gure shows the PULSAIR III with the cover removed.

Display, control

Filter

Adjusting screws,

damping

pushbuttons

Terminal block

Valve

block

6

Potentiometer

Processor and

motherboard

7

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

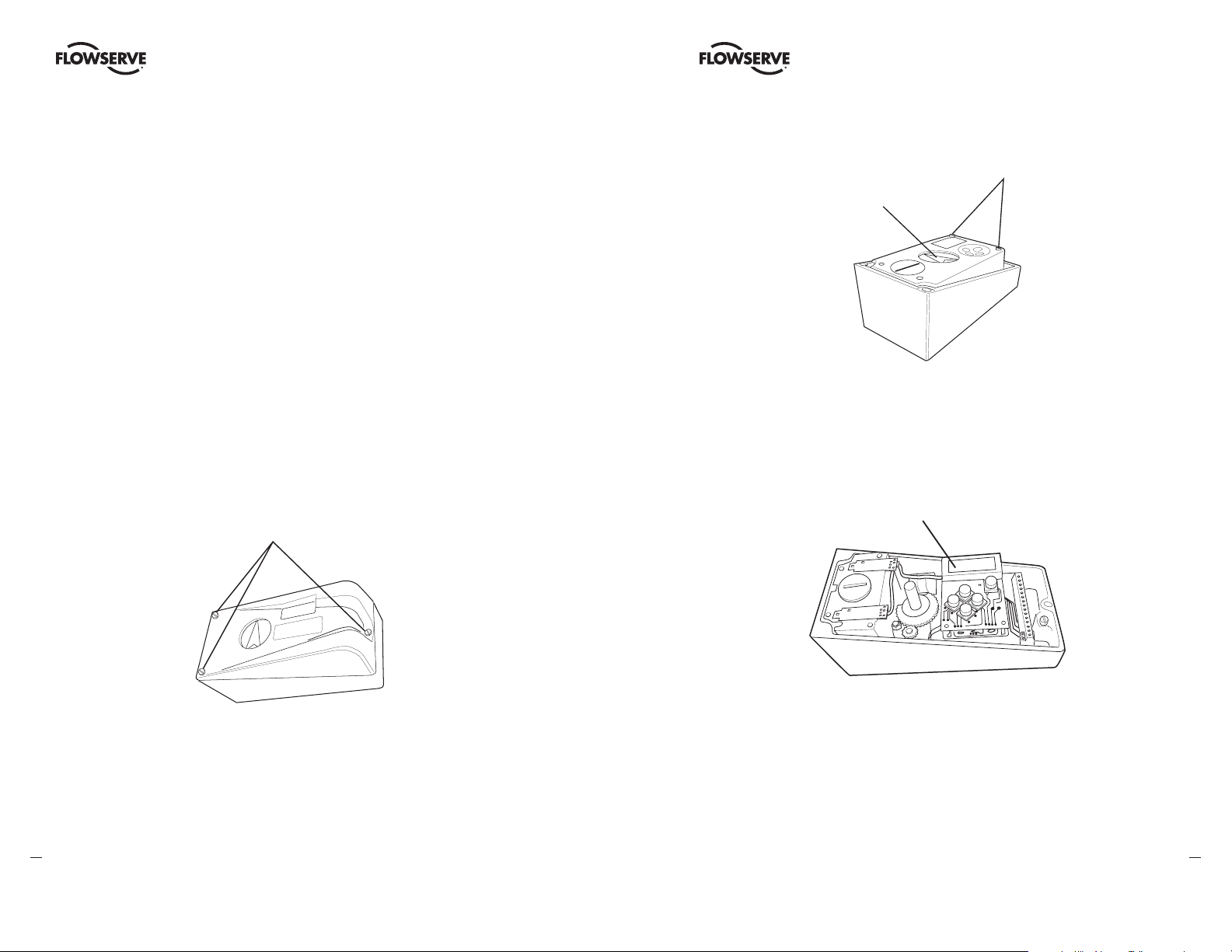

4 Variants

Pulsair III 270° (W)

A Pulsair III for up to 270° extended travel

range is available. It features all benefi ts and

options similar to the standard Pulsair III.

Communication with HART is possible.

Pulsair III Intrinsically Safe

The Pulsair III is available in an intrinsically

safe version for installation in hazardous

areas. It features the same easy-to-use user

interface for local confi guration as the Pulsair

III. Communication with HART is possible. It

features all benefi ts and options similar to the

Standard Pulsair III positioner: gauge block,

local graphic LCD display, feedback option, etc.

Pulsair III Explosion-Proof (Z)

The Pulsair III digital positioner is available

in an explosion-proof enclosure. It features

the same easy-to-use user interface for local

confi guration as the Pulsiar III. Communication

with HART is possible.

Further features are gauge ports and local

graphic LCD display.

Pulsair III Remote Mounted

The Pulsair III with remote mount is now

available. This version is suitable for

installations in severe applications, e.g.

vibration, high or low temperature, corrosive

environment, diffi cult to access installations,

etc. A fl at or dome-style indicator can be fi tted

on the feedback box installed on the actuator.

8

The maximum recommended distance between

the Pulsair III and remote unit is 16 ft. (5m).

Standard Housing

Weatherproof (W) and

Intrinsically Safe

“Z” Housing

Remote Mount

Control signal 4-20 mA

Potentiometer

Piezo–valve 2

D

Actuator

C

E

➾

Venting

C– C+

F

V enting

B

G

H

Signal converter

and microprocessor

Piezo–valve 1

Diaphragm

17.4 psig (1.2 bar)

Pressure

regulator

Replaceable

Filter

Air supply

30-105 psig

(2-7 bar)

A

5 Function

Double-Action Function

The control signal and the feedback potentiometer position are converted to digital

signals that are processed with a PID algorithm in the microprocessor. This provides

control signals to the two piezo-valves.

The two piezo-valves are closed in the schematic diagram above and have no effect on

the valves A and D. Air from the pressure regulator is lead through the open valve A

to the valve B, which opens. The supply pressure can now pass through valve B to the

actuator via H. The actuator then moves in the direction of the arrow. At the same time,

air from valve A keeps valve C open and allows venting of the actuator.

When both the piezo-valves open, valve A closes but valve D opens and controls valves

E and F to that the actuator moves in a direction opposite to the arrow. When only piezovalve 1 is open, the actuator is stationary.

Single-Action Function

Valve B is used for the supply air and valve F for venting.

9

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

6 Installation

Tubing

Use tubes with an inner diameter of ¼ " (6 mm) minimum.

Air Supply Requirements

For the maximum air supply pressure, see section 10, Technical Data.

The air supply must be free from moisture, water, oil, and particles.

The air must come from a refrigeration-dried supply or be treated in such a way that its

dew point is at least 18°F (10°C) below the lowest expected ambient temperature. If air

is now used, the supply medium must be a noncorrosive and non-fl ammable gas.

To ensure a stable and problem-free air supply, we recommend the installation of a

fi lter/pressure regulator <30 microns as close to the positioner as possible.

Before the air supply is connected to the positioner, open the hose freely for 2 to 3

minutes to allow any contamination to be blown out.

Direct the air jet into a large paper bag to trap any water, oil, or other foreign materials. If

contamination is detected, the air supply should be thoroughly cleaned before connecting to the positioner.

Warning: Do not direct the open air jet towards people or objects because it

a

may cause personal injury or damage.

Poor air supplies are the main source of problems in pneumatic and

electro-pneumatic systems.

Mounting

NOTE: If the positioner is installed in a hazardous environment, it must be of a type

approved for this purpose.

The PULSAIR III W positioner has an ISO F05 footprint, A. The holes are used to attach it

to the mounting bracket B, which is suitable for most types of linear actuator.

The spindle adapter C can be changed to suit the actuator in question.

C

Remove the existing adapter using two screwdrivers. Check that the spring ring on the

new spindle is undamaged and fi ts the new adapter before installing.

It is important that the positioner’s spindle and the arms that transfer the actuator

movements are correctly mounted. Any tension between these parts can cause incorrect

operation and abnormal wear.

Assembly Examples

A

B

Linear Movement

Rotary Movement

B

10

C

11

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

The PULSAIR III Z positioner has an ISO F05 footprint, A. The holes are used to attach it

to the mounting bracket B, which is suitable for most types of linear actuators.

The spindle adapter C can be changed to suit the actuator in question, as previously

explained in this section.

For data for air and electrical connections, see Technical Data section.

A

B

C

Connections

Air

Port S Supply air

Port C+ Connection to actuator

Port C- Connection to actuator (only for

double-action)

Must be plugged

when converting

to single-action

function.

Electrical Connection

See Electrical Connections section.

Dimensions

Air connections: ¼ " NPT or G ¼ "

Electrical connection: ½ " NPT or M20 x 1.5

Loctite 577 or equivalent is recommended

as a sealant.

Single-Action Positioner (Direct Function)

Actuator with Fail/Close Spring

When the control signal increases, the pressure C+ to the actuator is increased. The

valve stem moves upward and rotates the positioner spindle counterclockwise. When

the control signal drops to zero, C+ is vented and the valve closes.

C

–

S

C+

C

–

S

C+

Actuator with Fail/Open Spring

When the control signal increases, the pressure C+ to the actuator is decreased. The

springs press the valve stem upward and the positioner spindle rotates counterclockwise. When the control signal drops to zero, C+ is vented and the valve opens.

For data for air and electrical connections,

C– S C+

12

see Technical Data section.

13

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Double-Action Positioner (Direct Function)

Double-Action Actuator

When the control signal increases, the pressure C+ to the actuator is increased. The

valve stem is pressed upward and rotates the positioner spindle counterclockwise.

When the control signal is reduced, the pressure C- to the actuator increases and the

valve stem is pressed downward. If the control signal disappears, the pressure goes to

C-, C+ vents, and the valve closes.

C

–

S

C+

Electrical Connections

The diagrams on the next page show the terminal blocks in the Pulsair III W and Z.

Remote Unit

The remote unit shall be connected between terminals 3, 4 and 5 in the Pulsair III and 3,

4 and 5 in the remote unit. Use a shielded cable and ground it in the Pulsair III only. The

maximum recommended distance between the Pulsair III and the remote unit is 16 ft.,

5 in. (5 m).

Pulsair III W

1 4-20 mA + input signal

2 4-20 mA – input signal

3 Switch 1 NO

4 Switch 1 NC

5 Switch 1 COM

6 Switch 2 NO

7 Switch 2 NC

8 Switch 2 COM

9 AUX input 4-20 mA +

10 AUX input 4-20 mA –

11 4-20 mA + Feedback

12 4-20 mA – Feedback

13 Alarm output +

14 Alarm output –

Pulsair III Z

HART –

connection

1 2 3 4 5 6 7 8 9 10 11 12 13 14

+ – + – + – + –

Option

Shielded cables,

grounded in the

Pulsair III unit

HART

Connection

Connecting a

remote unit

123456

+ –

345

Remote

unit

Shielded cables,

grounded on the

Pulsair III unit

3

4

5

Remote

Unit

Note: When converting a Pulsair III W or Z for use with a remote unit, some changes

have to be done inside the positioner, see section 8.

Warning: In a hazardous environment where there is a risk of explosion,

a

electrical connections must comply with the relevant regulations.

Terminal Blocks

The terminal blocks in the illustrations at right are accessible when the terminal cover is

removed, see Section 8 for disassembly instructions.

14

Warning: In a hazardous environment where there is a risk of explosion,

a

electrical connections must comply with the relevant regulations.

1 4-20 mA + input signal

2 4-20 mA – input signal

3 Switch 1 NO (Remote unit)

4 Switch 1 NC (Remote unit)

5 Switch 1 COM (Remote unit)

9 AUX input 4-20 mA +

10 AUX input 4-20 mA –

11 4-20 mA +

12 4-20 mA –

13 Alarm output +

14 Alarm output –

Optional

15

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

7 Control

Menu and Pushbuttons

The positioner is controlled using the fi ve pushbuttons and the display, which are accessible when the aluminium cover is removed.

For normal functioning, the display shows the current value. Press the ESC button for

two seconds to display the main menu.

Use the up and down pushbuttons to browse through the main menu and the submenus.

The main menu is divided up into a basic menu and a full menu, see the fl owchart in the

section, “The Menu System.”

OUT OF

SERVICE

MANUAL

BASIC MENU

MAN/AUTO

UNPROTECTED

ESC FUNC

OK

MANUAL: The positioner can be adjusted manually using the pushbuttons. See Man/

Auto section.

UNPROTECTED: Most of the parameters can be changed when the positioner is in the

“Unprotected” position. However, critical parameters are locked when the positioner is in

the “In service” position.

Menu Indicator

There are indicators at both sides of the display window and they indicate as follows:

• Flashing in position Out of service

• Flashing in position Manual

• Displayed in position Unprotected

The indicators on the right-hand side show the position in the current menu.

Flashing in position Out of Service

FULL MENU

MAN/AUTO

Flashing in position Manual

FULL MENU

CALIBRATE

Other Functions

ESC: Exit the menu without making any changes (as long as any changes have not been

confi rmed with OK).

FUNC: To select functions and change parameters.

OK: To confi rm selection or change of parameters.

MENU INDICATOR: Displays the position of the current menu row in the menu.

IN SERVICE: The positioner is following the input signal. This is the normal status when

the positioner is working.

16

OUT OF SERVICE: The positioner is not following the input signal. Critical parameters

can be changed.

Displayed in position Unprotected

FULL MENU

SHIFT MENU

Menus

To display the menu you can select:

• Basic menu, which means you can browse through four different steps

• Full menu, which comprises ten steps. Use the Shift Menu to browse through the

steps.

Full Menu can be locked out using a passcode.

The main menus and submenus are shown on the subsequent pages.

fl owserve.com

17

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Changing Parameter Values

Change by pressing the left and right arrows until the desired fi gure is fl ashing.

Press the up and down arrows to step to

the desired fi gure. Confi rm by pressing OK.

A change can be undone by pressing the

ESC button, which returns you to the previous menu.

BASIC MENU

READ

BASIC MENU

MAN/AUTO

BASIC MENU

CALIBRATE

BASIC MENU

SHIFT MENU

FULL MENU

READ

FULL MENU

MAN/AUTO

FULL MENU

CALIBRATE

FULL MENU

SHIFT MENU

FULL MENU

PROTECTION

FULL MENU

STATUS

FULL MENU

SETUP

FULL MENU

TUNING

Basic Menu: Calibrate

BASIC MENU

CALIBRATE

First Start

Calibrate in the basic menu is displayed automatically the fi rst time the positioner is connected, and can be selected from the basic/main menu at any later time.

A complete calibration takes about three minutes and includes end limit calibration,

auto-tuning, leak test, and a check on the speed of movement. Start the automatic calibration by selecting Auto-Cal and then answer the questions on the display by pressing

OK or the respective arrow. The menu is described later in this section.

Calibration Error Messages

If a fault occurs during the calibration, one of the following error messages will be

displayed:

Invalid movement/press ESC to abort

No movement because the air is incorrectly connected, for example. After the fault is

corrected, the calibration sequence must be restarted.

Pot unaligned/press ESC to abort

The potentiometer has been set to an illegal value. The potentiometer is aligned using

the Calibrate - Expert cal - pot Menu. The calibration sequence must be restarted after

the fault is corrected.

FULL MENU

ALARMS

FULL MENU

FACT SET

18

An air leak has been detected. The calibration sequence should be restarted after the

fault is corrected.

Increase C- damper/ESC = abort OK to retry

Increase C+ damper/ESC = abort OK to retry

Clockwise Increased damping/Less flow

CCW Decreased damping/More flow

3 revs CCW Maximum flow

C+

(C–)

NOTE: Too much increased damping (low flow)

might cause irregular actuator function.

fl owserve.com

19

Air leak detected/ESC = abort OK = go on

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Speed of movement is too fast. Adjust with the damper screws. Press OK. Repeat the

adjustment and press OK until the speed is correct. If there is an abort, the calibration

sequence must be restarted.

The contents of the menu are shown on subsequent pages. The various menu texts are

described below.

Auto-Cal Auto-tuning and calibration of end positions

Start tune Starts the tuning. Questions/commands are displayed during calibra-

tion. Select the type of movement, function, etc. with the down arrow and confi rm

the OK as shown in the chart on the next page.

Lose prev value? OK? A warning that the value set previously will be lost (not

during the fi rst auto-tuning).

Actuator? Rotating Select for rotating actuator.

Actuator? Linear Select for linear actuator.

Actuator single act Select for single-acting.

Actuator double act Select for double-acting.

Direction? direct Select for direct function.

Direction? reverse Select for reverse function.

In service? Press OK Calibration fi nished. Press OK to start positioner function-

ing. (If ESC is pressed, the positioner assumes the “Out of service” position but the

calibration is retained).

TravelCal Calibration of end position

Start cal Start end position calibration

Lose prev value? OK? A warning that the previously set value will be lost. Confi rm

with OK. The calibration sequence starts.

In service? Press OK Calibration fi nished, Press OK to start positioner functioning. (If ESC is pressed, the positioner assumes the “Out of service” position but the

calibration is retained).

Perform Setting gain

Normal 100% gain

Perform 50%, 25%, 12%, L, M, S Possibility to select a lower gain in steps

L, M, S Preset values for L, M, S actuators

20

Factory set Resets all set values and enters Factory Mode. Should only be used by

authorized staff.

Note: Original P.I.D. will always be shown in display.

CALIBRATE

AutoCal

CALIBRATE

TravelCal

CALIBRATE

Perform

CALIBRATE

ExpertCal

AutoCal

Start tune

TravelCal

Start cal

OK

LOSE PREV

VALUE? OK?

OK

Calibration

in progress

IN SERVICE?

Press OK

OK

Set point LO: Use the calibrator set to 4 mA (or set another

value on the display). Press OK.

Set point HI: Use a calibrator of 20 mA (or set another value

on the display). Pess OK. Pressure read out only possible on

Pulsair III with built-in pressure sensor.

Pressure LO: Use a supply of 30 psi (2 bar) (or set another

value on the display). Press OK.

Pressure HI: Use a supply of 105 psi (7 bar) (or set another

value on the display). Press OK.

Temp: Calibrate using a known temperature.

Aux input LO: Use the calibrator and a power supply of 4 mA

(or set another value on the display). Press OK.

Aux input HI: Use a supply of 20 mA (or set another value on

the display). Press OK.

Pot: Potentiometer setting, if its position relative to the gear

segment has been changed. See Section 8.

Full reset: Resets all the set values.

All of these values are set at the factory before delivery and

should not normally be changed.

OK

LOSE PREV

VALUE? OK?

Actuator?

rotating

Actuator?

linear

OK

OK

OK

Actuator

single act

Actuator

single act

Direction?

direct

Direction?

reverse

OK

Calibration

in progress

IN SERVICE?

Press OK

OK

Perform

normal

Perform

50%

25%

12%

L

M

S

Perform

Factory set

OK

OK

OK

OK

OK

OK

21

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Basic Menu: Read

The menu contents are shown in the

fi gures on the right and the steps are

described below:

BASIC MENU

READ

Current values can be read using the Read

Menu and some values can be reset.

Pos Shows current position

Set&pos Set point and position

Set&dev Set point and deviation

Temp Shows current temperature

Aux Shows aux input signal value.

External pot or similar.

Statistics

n cycles Shows number of

movements (turns)

Acc travel Shows accumulated

movement

READ

pos

READ

set&pos

READ

set&dev

READ

temp

READ

aux

READ

Statistics

READ

Alarms

Statistics

n cycles

Statistics

acc travel

Statistics

mean dev

Statistics

runtime

Statistics

extr. temp

Statistics

histogram

Statistics

Reset stat

Reset stat

yes

Reset stat

no

Basic Menu: Man/Aut

The Man/Auto menu is used to change between manual and automatic modes.

BASIC MENU

MAN/AUTO

The menu contents are shown in the fi gures below and the various texts are described

below:

AUT, OK = MAN Positioner in automatic mode

MAN, OK = AUT Positioner in manual mode

In the MAN mode, the value of POS can be changed using the up and down arrows. The

pushbuttons increase/decrease the value in steps. The value can also be changed in the

same way as for the other parameter values, as previously described.

Other Functions

C+ can be fully opened by fi rst pressing the up arrow and then immediately OK simultaneously.

C- can be fully opened by pressing the down arrow and OK simultaneously.

C+ and C- can be fully opened for blowing clean by pressing the up and down arrows

and OK simultaneously.

When changing between MAN and AUT mode, the OK button must be depressed for

three seconds.

mean dev Shows accumulated

deviation in %

runtime Shows accumulated

runtime since last reset

extr temp Shows extreme min and

max temperature

Histogram Shows position and time

22

for PV

Alarms Displays tripped alarms

AUT, OK=MAN

SET=12.3%

OK

MAN, OK=AUT

POS=12.3%

Basic Menu: Shift Menu

The Shift Menu is used to choose between the basic menu and the full menu.

BASIC MENU

SHIFT MENU

23

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

The menu contents are shown in the fi gures below and the various steps are described

below:

No Full menu selected.

Yes Basic menu selected.

Full menu

no

Full menu

yes

OK

OK

Full Menu can be locked with a passcode, see the SETUP Menu section.

Full Menu: Protection

The Protection menu is used to protect all essential settings.

FULL MENU

PROTECTION

Full Menu: Status

The Status Menu is used to select whether or not the positioner is in service.

FULL MENU

STATUS

The menu contents are shown in the fi gures below and the various texts are described

below:

o o service Not in service. Flashing indicator in upper left-hand corner of display.

in service Positioner in service. Critical parameters cannot be changed.

STATUS

o o service

STATUS

in service

OK

OK

The menu contents are shown in the fi gures below and the various steps are described

below:

No Entered values are not write-protected. “Unprotected” is displayed in the

lower left-hand corner.

Yes Entered values are write protected. Passcode needed for change to No (Ap-

plicable when a passcode has been set up in SETUP menu).

PROTECTION

no

PROTECTION

yes

24

OK

OK

When changing between Yes and No mode, the OK button must be depressed for three

seconds.

When changing between In service and Out of service, the OK button must be depressed

for three seconds.

25

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Full Menu: Setup

The Setup Menu is used for various settings.

FULL MENU

SETUP

The menu contents are shown in the chart on subsequent pages and the various texts

are described below:

Actuator Type of Actuator

Rotating Rotating actuator

Linear Linear actuator

Size of Actuator Time Out

Small 10 s

Medium 25 s

Large 60 s

Texas 180 s

Character

Curves that show position as a function of input signal.

Linear See diagram

Equal % See diagram

Quick open See diagram

Sqr root See diagram

Custom Create own curve.

Cust chr

# of point Specify number of points (3, 5, 9, 17, or 33)

Cust curve Enter values on X and Y axes.

y

Qo

Sqr

Lin

Eq%

Movement

Lever Only for linear actuator.

Lever stroke Stroke length to achieve correct display

Level cal Calibration of positions to achieve correct display

Direction

Direct Direct function (signal increase opens). Indicator/spindle rotates

counterclockwise.

Reverse Reverse function

26

x

Signal

Curr range

0% = 4.0 mA

100% = 20.0 mA Possibility of selecting which input signal values will correspond

to 0% and 100% movement respectively. Examples of settings:

• 4 mA = 0%

• 12 mA = 100%

• 12 mA = 0%

• 20 mA = 100%

fl owserve.com

27

SETUP

Actuator

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Actuator

type

Typ e

linear

OK

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

TRVL range Setting end positions

0% = 0.0% Select Out of Service. Set percentage value for desired end position

(e.g. 3%).

Displayed

only when

actuator

linear is

selected

SETUP

Lever

SETUP

Direction

SETUP

Character

SETUP

Cust chr

SETUP

curr range

Actuator

function

Actuator

size

Lever

Stroke

Lever

Lever Cal

Direction

direct

Direction

reverse

Cust chr

# of point

Cust chr

Cust curve

Curr range

0%=4.0 mA

OK

OK

See text See text

OK

Function

single act

Function

Double act

Stroke

LEN=XX,Xmm

Character

linear

Character

equal %

Character

quick open

Character

custom

OK

OK

OK

OK

OK

OK

OK

Typ e

rotating

Size

Medium

Size

Small

Size

Large

Size

Texas size

Set lever

at max ...

Set lever

at center ...

Set lever

at min ...

Set lever

at center ...

Lever cal

Done

OK

Set 0% Select In Service. Connect calibrator. Move forward to desired end posi-

tion (0%) and press OK.

100% = 100.0% Select Out of Service. Set percentage value for desired end

position (e.g. 100%).

Set 100% Select In Service. Connect calibrator. Move forward to desired end posi-

OK

tion (100%) and press OK.

TRVL ctrl Behavior at set end position

OK

Set low Choose between Free (go to mechanical stop), Limit (stop at set end posi-

tion), and Cut off (go directly to mechanical stop at set end position).

OK

Set high Similar to Set low.

Values Select position for Cut off and Limit at the respective end positions.

OK

Passcodes Setting passcodes for various functions

Full menu Passcode for access to full menu.

Write prot Passcode for removing write protect.

OK

Expert Passcode for access to Expert menu (TUNING).

Fact set Passcode to return to default values applicable when positioner was

OK

delivered.

Numbers between 0000 and 9999 can be used as passcodes. 0 = no passcode

required.

OK

OK

OK

28

See page

Curr range

100%=20 mA

Character

OK

sqr root

OK

29

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Appearance On display

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Language Select menu language.

Units Select units.

Def. Display Select value(s) to be displayed during service. The display reverts to

this value 10 minutes after any change is made.

Start menu Start in Basic menu or Full menu.

Contrast Adjust display contrast.

Orient Orientation of text on display.

Par mode Display of control parameters such as P, I, D or K, Ti, Td.

Devicedata

HW rew General Parameters

SW rew General Parameters

Capability General Parameters

HART Menu with HART parameters. Only amendable with HART communicator. It

is possible to read from display.

SETUP

TRVL range

SETUP

Trvl ctrl

SETUP

Passcodes

SETUP

Appearance

SETUP

Devicedata

Trvl Ctrl

Set low

Trvl Ctrl

Set high

Trvl Ctrl

Values

Devicedata

HW rew

See text

Appearance

Language

Appearance

Units

Trvl range

0% = 0.0%

Trvl range

Set 0%

Trvl range

100% = 100.0%

Trvl range

Set 100%

Passcodes

full menu

Passcodes

protection

Passcodes

expert

Passcodes

fact set

OK

OK

OK

OK

See text

Devicedata

SW rew

Devicedata

Capability

Devicedata

HART

Appearance

Def. Displ

See text

Appearance

Start menu

Appearance

Contrast

Appearance

Orient.

30

Appearance

Par mode

See textSee text

31

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Full Menu: Tuning

FULL MENU

TUNING

The Tuning Menu is used to further tune the operation and set parameters. The menu

contents are shown in the chart and the various steps are described below:

Close time Minimum time from fully open to closed.

Open time Minimum time from closed to fully open.

Deadband Setting deadband. Minimum 0.2%

Expert Advanced settings.

Toggletester Test tool for checking functions. Overlays a square wave on the

set value.

K, Ti, Td Setting K, Ti, and Td parameters.

Self test Test of processor, potentiometer, etc.

Leakage Air leakage detected can be either connections, positioner tubing

or actuator.

Undo Read last 20 changes.

TUNING

Close time

TUNING

Open time

TUNING

Deadband

TUNING

Expert

Close time

Min = 0.05

Open time

Min = 0.05

Deadband

D = 0.2%

Expert

Toggletester

Expert

K,Ti,Td

Expert

Self test

Expert

Leakage

Expert

Undo

OK

OK

OK

Toggletester

Runtimetime

Toggletester

Cycletime

Toggletester

size

Toggletester

start

Toggletester

Abort step

32

33

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Full Menu: Alarms

FULL MENU

ALARMS

The menu contents are shown in the chart and the various steps are described below:

Deviation Alarm generated when deviation occurs.

On/Off Alarm on/off.

Distance Allowed distance before alarm is generated.

Time Total deviation time before alarm is generated.

Alarm Out Select ON/OFF offers output on terminals 13 and 14.

Valve act Behavior of valve when alarm is generated.

Limit 1 Alarm above/below a certain level.

On/Off Alarm on/off. (See diagram below.)

Minipos Setting of desired minimum position. (See diagram below.)

Maxpos Setting of desired maximum position. (See diagram below.)

Hysteresis Desired hysteresis. (See diagram below.)

Pos=aux External potentiometer

On/Off Function on/off.

Max diff Maximum allowed deviation between the internal and external

potentiometers.

Alarm Out Select ON/OFF offers output on terminals 13 and 14.

Valve act Behavior of valve when alarm is generated.

Aux input External input signal 4-20 mA.

On/Off* Alarm on/off

Minipos* Setting of desired minimum position

Maxpos* Setting of desired maximum position

Hysterisis* Desired hysteresis

Alarm Out Select ON/OFF offers output on terminals 13 and 14.

Valve act Behavior of valve when alarm is generated.

* Function similar to Limit 1 and Limit 2. See Limit 1 and Limit 2 sections.

Temp Alarm based on temperature

On/Off Temperature alarm on/off.

Low temp Low temperature setting.

Alarm on Select ON/OFF offers output on terminals 13 and 14.

Valve act Behavior of valve when alarm is generated.

Limit 2 See Limit 1.

34

Alarm Limit 1 on

Alarm Limit 2 on

Control Signal

Alarm Limit 1 off

Alarm Limit 2 off

Alarm Limit 2 on

Alarm Limit 1 on

Alarm Limit 2 off

Alarm Limit 1 off

Set alarm and

hysteresis values

100%

Limit 1, max

Hysteresis

Limit 2, max

Hysteresis

Hysteresis

Limit 2, min

Hysteresis

Limit 1, min

0%

High temp High temperature setting.

Hysteresis Allowed hysteresis.

Alarm Out Select ON/OFF offers output on terminals 13 and 14.

Valve act Behavior of valve when alarm is generated.

No action Alarm generated only. Operation not affected.

Goto open C+ gives full pressure and valve moves to fully open position. Posi-

tioner changes to position Manual.

Goto close C- gives full pressure and valve moves to fully closed position.

Positioner changes to position Manual.

Manual Valve stays in unchanged position. Positioner moves to

position Manual

fl owserve.com

35

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

ALARMS

Deviation

ALARMS

Limit 1

ALARMS

36

Limit 2

Deviation

On/off

Deviation

Distance

Deviation

Time

Deviation

Alarm Out

Deviation

Valve act

Limit 1

On/off

Limit 1

Minipos

Limit 1

Maxpos

Limit 1

Hysteresis

Limit 1

Alarm

Limit 1

Valve act

See

Limit 1

Distance

D = 10.0%

Time

T=0.0 0s

On/off

on

On/off

off

Minipos

P=0.0%

Maxpos

P=0.0%

Hysteresis

H=0.0%

Alarm out

OFF

Alarm out

ON

OK

OK

OK

OK

OK

OK

OK

OK

On/off

on

On/off

off

Alarm Out

on

Alarm Out

on

Valve act

no action

Valve act

goto open

Valve act

goto close

Valve act

manual

Valve act

no action

Valve act

goto open

Valve act

goto close

Valve act

manual

OK

OK

OK

OK

OK

OKOK

OK

OK

OK

OK

OK

OK

ALARMS

Pos=aux

ALARM

Aux input

Aux input

On/off

Aux input

Minpos

Aux input

Maxpos

Aux input

Hysteresis

Aux input

Alarm out

Aux input

Valve act

Pos=aux

On/off

Pos=aux

Max diff

Pos=aux

Alarm out

Pos=aux

Valve act

On/off

on

On/off

off

Minipos

Min=0.0%

Maxpos

Max=0.0%

Hysteresis

H=0.0%

Alarm out

OFF

Alarm out

ON

OK

OK

OK

OK

OK

OK

OK

On/off

on

On/off

off

Max diff

P=0.0%

Alarm out

OFF

Alarm out

ON

Valve act

do nothing

Valve act

goto open

Valve act

goto close

Valve act

manual

Valve act

do noting

Valve act

goto open

Valve act

goto close

Valve act

manual

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

37

See page

See page

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Full Menu: Fact Set

FULL MENU

FACT SET

The menu contents are shown in the chart and the various steps are described below:

The default values that were set on delivery can be reset using the Fact Set menu. Values

from later calibration and from other settings will be lost.

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

ALARMS

temp

Temp

On/off

Temp

Low temp

Temp

High temp

Temp

Hysteresis

Temp

Alarm out

Aux input

Valve act

On/off

on

On/off

off

Low temp

Min=0.0%

High temp

Max=0.0%

Hysteresis

H=

Alarm out

OFF

Alarm out

ON

OK

OK

OK

OK

OK

OK

OK

Valve act

do noting

Valve act

goto open

Valve act

goto close

Valve act

manual

OK

OK

OK

OK

FACT Set

no

FACT Set

yes

38

OK

Discard

OK OK

settings?

Press OK

for 3 sec

Input

OK

accepted

OK

39

FACT SET

Done

OK

OK

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

8 Maintenance/Service

When carrying out service, replace a circuit board, etc., it may be necessary to remove

and refi t various parts of the positioner. This is described on the following pages.

Note: Read the Safety Instructions on page 3 before starting work on the positioner.

Note: Cleanliness is essential when working with the positioner. Contamination in the air

ducts will inevitably lead to operational disturbances. Do not disassemble the unit more

than that described here.

Note: Do not take the valve block apart because its function will be impaired.

Note: When working with the Pulsair III positioner, the work place must be equipped

with ESD protection before the work is started.

Warning: Always turn off the air and electrical supplies before starting any work.

a

Disassembling Pulsair III W

Removing cover and inner cover

1. Unscrew the screws A and remove the cover.

A

3. Unscrew the screws C, pull the inner cover slightly in the direction of the arrow, and

remove the cover.

C

B

➜

Circuit Boards (pcb)

Warning: Disconnect or switch off the power supply before starting any work.

a

1. Lift off the display pcb D.

D

2. Pull off the disc with the arrow B.

40

41

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

2. Unscrew the spacers E, release the cable connections F and G, and lift up the processor pcb.

F

G

E

E

3. Remove the terminal board by unscrewing the spacers H.

H

Valve Block

Warning: Turn off the air and power supply before starting any work.

a

1. Release the connector F from the processor pcb.

2. Remove the four screws I.

F

I

3. Lift out the valve block.

Note: Do not disassemble the valve block.

4. When installing the valve block, torque the four screws to 12.4 in-lb (1.4 Nm) and

seal with Locktite 222.

H

42

fl owserve.com

43

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Silencer

An optional silencer, L can be mounted under the plate M on the Pulsair III. Contact

Flowserve.

M

L

Spindle Adapter

The spindle adapter can be changed to suit the actuator in question, see the Mounting

section.

Potentiometer

90° and 270° spring-loaded potentiometer

The spring-loaded potentiometer K can be removed from the gearwheel for calibration

or replacement.

If the potentiometer is replaced or the setting is changed, it must be calibrated.

1. Select the menu Calibrate - Expert - Cal pot. The display shows Set gear (1).

2. Press the down arrow to rotate the spindle shaft (2) CW to the end position and

press OK.

3. The display will indicate the direction to rotate the potentiometer. Unmesh the

potentiometer (3) and turn it according to display until OK is shown. Press OK.

4. Press the up arrow button to rotate the spindle shaft (2) CCW to the end position

and press OK.

1

2

K

3

44

fl owserve.com

45

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Transmitter Boards

The equipment for transmitter feedback consists of a circuit board A, cam assembly B

and screws.

The circuit board exists in four versions:

• with mechanical switches, SPDT

• with NAMUR sensors, DIN 19234

• with proximity switches

• with feedback transmitter only

A

2. Check that both spacers C are installed.

C

C

3. Carefully mount the circuit board in its position. The pins D should fi t in the connector and the positioners motherboard. Make sure that the feedback PC board is

properly connected.

D

B

Transmitter Board Installation

Caution: Turn off the power and air supply starting the installation.

a

Important for Pulsair III intrinsically safe units: Transmitter boards NOT for onsite

mounting by customer. FM, CSA and ATEX certifi cate only valid when transmitter board

is mounted by manufacturer.

1. Remove the cover, indicator, and inner cover according to the description previously

mentioned in this section.

46

4. Secure the circuit board with the enclosed screws E.

E

47

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

5. Install the cam assembly B on the shaft and push it down to its position. If the board

has microswitches, be careful not to damage the levers.

B

6. Tighten the screws F, on the cam assembly. Do not over tighten the screws. The

cams should be able to move in relation to each other.

F

9. Adjust the position where the switches/sensors should be affected by turning the

cams with a screwdriver.

10. Tighten the cam assembly screws F when the cams are correctly adjusted.

11. Install the indicator and cover. To calibrate the feedback transmitter, see the drawing

on the next page.

F

7. Install the inner cover with the two screws, G.

8. Connect the wiring for the transmitter feedback on the terminal block according to

the drawing on the next page.

G

48

49

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Calibration

Disassembling the Worcester Pulsair III Z

1. Loosen the screws A and B and remove the caps C and D.

2. Remove the inner display cover E by loosening the four screws F.

3. Carefully remove the display board and loosen the connections H and I.

A

F

E

G

C

B

4. Release the wide cable from the connector J on the terminal board.

5. Loosen the three screws K.

D

H

I

6. Remove the circuit board package L, consisting of the terminal and processor board.

7. Remove the four screws M and and lift the block N.

K

L

J

50

M

N

51

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Filter Change, Pulsair III W and Z

Warning: Turn off the compressed air supply before starting any work. Oth-

a

erwise the fi lter can be uncontrollably blown out of the positioner by the air

pressure, which can be dangerous.

• Remove the fi lter cap using a coin of suitable size.

Note: Do not use a screwdriver. The fi lter cap might crack and cause air leakage.

3. Disconnect and secure the potentiometer cable.

4. Install transmitter board D3-AS38T, F.

F

G

5. Install the enclosed wire between G and O.

6. Connect the wiring betwen terminals 3, 4, 5 in the W unit and 3, 4, 5 in the remote

unit.

Use a shielded wire and ground it in the W unit only.

Avoid distances more than 16 ft. (5 m) between W unit and remote unit.

Converting for Remote Control

Warning: Disconnect or switch off the power supply before starting any work.

a

1. Remove cover and inner cover, see instructions earlier in this section.

2. Lift off the display pcb, D.

D

52

5

4

3

O

3 4 5

53

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

9 Troubleshooting

Change in input signal to positioner does not affect actuator position.

• Check air supply pressure, air cleanliness, and connection between positioner and

acuator.

• Check input signal to positioner.

• Check mounting and connections of positioner and acuator.

Change in input signal to positioner makes actuator move to its end positioner.

• Check input signal.

• Check mounting and connections of poistioner and actuator.

Inaccurate regulation.

• Implement auto-tuning. Check for any leaks.

• Uneven air supply pressure.

• Uneven input signal.

• Incorrect actuator size for application.

• High friction in actuator/valve package.

• Excess play in actuator/valve package.

• Excess play in mounting of positioner on actuator.

• Dirty/humid supply air.

10 Technical Data

Rotation angle: min. 30°, max. 100°

Stroke: 0.2" to 5.1" (5-130 mm)

Input signal: 4-20 mA

Air supply: 30-87 psi (2-7 bar) Free from oil, water, and moisture. Filtered to minimum

30 micron

Air delivery: 13.8 scfm (400 nl/min)

Air consumption: 0.01 scfm (<0.3 nl/min)

Air connections: ¼ " G or NPT

Cable entry: 3 x M20 or ½ " NPT

Electrical connections: Screw terminals 2.5 mm

Linearity: <1%

Repeatability: <0.5%

Hysteresis: <0.4%

Deadband: 0.2-10% adjustable

Display: Graphic, view area 0.6" x 1.6"

(15 x 41 mm)

UI: 5 pushbuttons

Processor: 16 bit, M 16C

CE directives: 93/68/EEC, 89/336/EEC, 92/31/EEC

2

/ AWG14

Slow movements, unstable regulation.

• Implement auto-tuing.

• Adjust the presure adjusting screws.

• Increase the deadband (Tuning menu).

• Adjust Performance (Calibrate menu).

54

EMC: EN 50 081-2, EN 50 082-2

Voltage drop: <10.1 V

Vibrations: <1% up to 10 g at frequency 10-500 Hz

Enclosure: IP66/NEMA 4X

Material: Die-cast aluminium, A2/A4 fasteners

Surface treatment: Powder epoxy

Temperature range: -22 to 176°F (-30 to +80°C)

Weight: W, 3 lb. (1.4 kg) Z, 6.6 lb. (3 kg)

Alarm output: Transistor Ri 1k Ω

Alarm Supply Voltage: 8-28 V

55

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Mechanical Switches

Type: SPDT

Size: Sub Sub miniature

Rating: 3 A/125 VAC; 2 A/30 VDC

NAMUR Sensors

Type: Proximity DIN 19234 NAMUR

Load current: ≤1 mA ≤3 mA

Voltage range: 5-25 VDC

Hysteresis: 0.2%

Temp: -4°F to 185°F (-20°C to 85°C)

Proximity Switches

Type: SPDT

Rating: 5 W/250 mA/30 VDC/125 VAC

Operating time: 0.7 ms

Breakdown voltage: 200 VDC

Contact resistance: 0.1 Ω

Mechanical/electrical life: >50 x 10

6

operations

4-20 mA Transmitter

Supply: 9-28 VDC

Dimensions – in. (mm)

4 (101.4)

4.7 (120)

W Enclosure

1.4 (35.4)

2 (50.7)

3 (76)

7.9 (200.6)

10.4 (264)

3.2 (82)

M6 (4x)

1.4 (35.4)

9.4 (240)

Output: 4-20 mA

Resolution: 0.1%

Linearity full span: ±0.5%

Output current limit: 30 mA DC

Load impedance: 800 Ω @ 24 VDC

56

Z Enclosure

M6 (4X)

/8 (17.7)

5

4 (100)

5 (128)

57

fl owserve.com

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

11 Spare Parts

Pulsair III W

4

8a, b

3

5a, b

9; 10a, b; 11a, b

12

7a, b

15

61413

2

20

21 22

Part Description

1 Cover including screws

2 Internal cover including screws

3 Cover plate including screws

4 Spindle adapter

1

5a Block compl including cable, rubber seal, fi lter-plug

5b Block compl including cable, rubber seal, fi lter-plug IS

6 Filter-plug including O-ring, fi lter

7a Potentiometer including spring, holder, cable

7b Potentiometer including spring, holder, cable, 270°

8a Shaft including gearwheel, friction clutch

8b Shaft including gearwheel, friction clutch, 270°

9 Display pcb

10a All pcbs (terminal block, processor, display)

10b All pcbs (terminal block, processor, display) IS

11a All pcbs HART (terminal block, processor, display)

11b All pcbs HART (terminal block, processor, display) IS

12 Arrow pointer

13 Kit, bag with screws

14 Kit, bag with O-rings, seals

15 Cable, pneumatic block including 2xPCB

16a Dump valve G (not shown)

16b Dump valve NPT (not shown)

17 Gauge block G (not shown)

18 Gauge block NPT (not shown)

19 Silencer (not shown)

20 Transmitter board, Mechanical

21 Transmitter board, NAMUR

22 Transmitter board, Proximity

23 Remote cable, potentiometer (not shown)

58

fl owserve.com

59

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Worcester Controls Pulsair III Digital Electronic Positioner FCD WCAIM2056-00 - 08/04

Pulsair III Z

Part Description

1

1 Cover including screws

2 Terminal cover including screws

3 Internal cover including screws

4 Spindle adapter (not shown)

5 Block including cable, rubber seal, fi lter-plug

6 Filter plug including O-ring, fi lter

3

7 Potentiometer including spring, holder, cable

8 Shaft including gearwheel, friction clutch

9

9 Display pcb

10 Mother PCB and processor PCB

11 Mother PCB and processor PCB, HART

10, 11

5

12 Terminal PCB including cable

13 Kit, bag with screws

14 Kit, bag with O-rings

15

15 Cable, pneumatic block

16a Dump valve G (not shown)

2

16b Dump valve NPT (not shown)

17a Connection block G

17b Connection block NPT

18

12 6 14 13

18 Remote cable (potentiometer)

19 Piezokablage (not shown)

17a, b

60

fl owserve.com

61

United States

Flowserve Corporation

Worcester Controls

1978 Foreman Drive

Cookeville, TN 38501 USA

Telephone: 931-432-4021

Fax: 931-432-5518

FCD WCAIM2056-00 Printed in USA. (Replaces IOM-19990)

To find your local Flowserve representative:

For more information about Flowserve Corporation, visit

www.flowserve.com or call USA 1 800 225 6989

Flowserve Corporation has established industry leadership in the design and manufacture of its products. When properly selected,

this Flowserve product is designed to perform its intended function safely during its useful life. However, the purchaser or user of

Flowserve products should be aware that Flowserve products might be used in numerous applications under a wide variety of industrial

service conditions. Although Flowserve can (and often does) provide general guidelines, it cannot provide specifi c data and warnings

for all possible applications. The purchaser/user must therefore assume the ultimate responsibility for the proper sizing and selection,

installation, operation, and maintenance of Flowserve products. The purchaser/user should read and understand the Installation Operation Maintenance (IOM) instructions included with the product, and train its employees and contractors in the safe use of Flowserve

products in connection with the specifi c application.

While the information and specifi cations contained in this literature are believed to be accurate, they are supplied for informative

purposes only and should not be considered certifi ed or as a guarantee of satisfactor y results by reliance thereon. Nothing contained

herein is to be construed as a warranty or guarantee, express or implied, regarding any matter with respect to this product. Because

Flowserve is continually improving and upgrading its product design, the specifi cations, dimensions and information contained herein

are subject to change without notice. Should any question arise concerning these provisions, the purchaser/user should contact

Flowserve Corporation at any one of its worldwide operations or offi ces.

© 2004 Flowserve Corporation, Irving, Texas, USA. Flowserve is a registered trademark of Flowserve Corporation.

fl owserve.com

Loading...

Loading...