fanuc 15iA, 150i- A User Manual

DESCRIPTIONS

B-63322EN/03

B-63322EN/03 |

DEFINITION OF WARNING, CAUTION, AND NOTE |

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine. Precautions are classified into Warning and Caution according to their bearing on safety. Also, supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly before attempting to use the machine.

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and

Caution.

- Read this manual carefully, and store it in a safe place.

s - 1

B-63322EN/03 |

TABLE OF CONTENTS |

TABLE OF CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE................................ |

s-1 |

||

|

|

||

1 |

GENERAL .............................................................................................. |

3 |

|

2 |

LIST OF SPECIFICATIONS ................................................................... |

5 |

|

|

|

||

PREFACE |

.................................................................................................... |

17 |

|

1 |

CONROLLED AXES ............................................................................ |

18 |

|

|

1.1 |

CONTROLLED AXES .................................................................................. |

19 |

|

1.2 |

AXIS NAME ................................................................................................. |

20 |

|

1.3 ................................................................................ |

INCREMENT SYSTEM |

21 |

|

1.4 .................................................................................... |

MAXIMUM STROKE |

23 |

2 PREPARATORY ......................................FUNCTION (G FUNCTION) |

24 |

||

3 |

INTERPOLATION .............................................................FUNCTION |

28 |

|

|

3.1 ................................................................................... |

POSITIONING (G00) |

29 |

|

3.2 ................................................ |

SINGLE DIRECTION POSITIONING (G60) |

30 |

|

3.3 ................................................................ |

LINEAR INTERPOLATION (G01) |

31 |

|

3.4 ................................................... |

CIRCULAR INTERPOLATION (G02,G03) |

32 |

|

3.5 ...................................................... |

HELICAL INTERPOLATION (G02,G03) |

34 |

|

3.6 ................................................... |

HELICAL INTERPOLATION B (G02,G03) |

36 |

|

3.7 .......................... |

POLAR COORDINATE INTERPOLATION (G12.1,G13.1) |

37 |

|

3.8 .................................................. |

CYLINDRICAL INTERPOLATION (G07.1) |

39 |

|

3.9 ... |

CYLINDRICAL INTERPOLATION CUTTING POINT CONTROL (G07.1) |

41 |

|

3.10 ............................................. |

INVOLUTE INTERPOLATION (G02.2,G03.2) |

45 |

|

3.11 ............................. |

HELICAL INVOLUTE INTERPOLATION (G02.2,G03.3) |

47 |

|

....... |

3.11.1 Involute Interpolation with a Linear Axis and Rotation Axis (G02.2,G03.3) |

48 |

|

3.12 ...................................... |

EXPONENTIAL INTERPOLATION (G02.3,G03.3) |

50 |

|

3.13 ............................................................. |

SPLINE INTERPOLATION (G06.1) |

52 |

|

3.14 .......................................................... |

SMOOTH INTERPOLATION (G05.1) |

53 |

|

3.15 ........................................ |

HYPOTHETICAL AXIS INTERPOLATION (G07) |

54 |

|

3.16 ........ |

SPIRAL INTERPOLATION, CONICAL INTERPOLATION (G02,G03) |

55 |

|

3.17 .............................................................. |

NURBS INTERPOLATION(G06.2) |

58 |

c - 1

TABLE OF CONTENTS |

B-63322EN/03 |

||||

|

|

3.17.1 |

NURBS Interpolation Additional Functions ......................................................... |

|

60 |

|

3.18 3-DIMENSIONAL CIRCULAR INTERPOLATION (G02.4 AND G03.4) |

.......62 |

|||

4 |

THREAD CUTTING .............................................................................. |

|

63 |

||

|

4.1 |

THREAD CUTTING (G33) ........................................................................... |

|

64 |

|

|

4.2 |

INCH THREADING (G33)............................................................................ |

|

66 |

|

|

4.3 |

CONTINUOUS THREADING (G33)............................................................. |

|

67 |

|

5 |

FEED FUNCTION................................................................................. |

|

68 |

||

|

5.1 |

RAPID TRAVERSE...................................................................................... |

|

69 |

|

|

5.2 |

CUTTING FEED .......................................................................................... |

|

70 |

|

|

|

5.2.1 |

Tangential Speed Constant Control....................................................................... |

|

70 |

|

|

5.2.2 |

Cutting Feedrate Clamp......................................................................................... |

|

70 |

|

|

5.2.3 |

Feed Per Minute (G94).......................................................................................... |

|

70 |

|

|

5.2.4 |

Feed Per Revolution (G95).................................................................................... |

|

71 |

|

|

5.2.5 |

Inverse Time Feed (G93)....................................................................................... |

|

71 |

|

|

5.2.6 |

One-digit F Code Feed........................................................................................... |

|

71 |

|

|

5.2.7 |

Setting Input of Cutting Feedrate .......................................................................... |

|

72 |

|

|

5.2.8 |

Feedrate Specification on a Virtual Circle for a Rotary Axis ............................... |

|

72 |

|

5.3 |

OVERRIDE .................................................................................................. |

|

73 |

|

|

|

5.3.1 |

Feedrate Override .................................................................................................. |

|

73 |

|

|

5.3.2 |

Second Feed Rate Override ................................................................................... |

|

73 |

|

|

5.3.3 |

Rapid Traverse Override ....................................................................................... |

|

73 |

|

|

5.3.4 |

Override Cancel..................................................................................................... |

|

73 |

|

|

5.3.5 |

Jog Override .......................................................................................................... |

|

73 |

|

5.4 |

ACCELERATION/DECELERATION CONTROL.......................................... |

|

74 |

|

|

|

5.4.1 |

Automatic Acceleration/Deceleration Control After Interpolation....................... |

|

74 |

5.4.2 Acceleration/Deceleration before Interpolation of Linear-Type Rapid Traverse . 76

5.5PMC AXIS CONTROL CONSTANT FEEDRATE COMMAND

|

ACCELERATION/DECELERATION FUNCTION......................................... |

77 |

|

5.6 |

SPEED CNTROL COMMAND AT THE CORNER OF BLOCK.................... |

78 |

|

|

5.6.1 |

Exact Stop (G09) ................................................................................................... |

78 |

|

5.6.2 Exact Stop Mode (G61)......................................................................................... |

78 |

|

|

5.6.3 |

Cutting Mode (G64) .............................................................................................. |

78 |

|

5.6.4 |

Tapping Mode (G63)............................................................................................. |

78 |

|

5.6.5 Automatic Corner Override (G62) ........................................................................ |

79 |

|

5.7 |

DWELL MODE (G94) .................................................................................. |

80 |

|

5.8 |

AUTOMATIC FEEDRATE CONTROL BY AREA......................................... |

81 |

|

c - 2

B-63322EN/03 TABLE OF CONTENTS

6 REFERENCE POSITION...................................................................... |

82 |

|

6.1 |

MANUAL REFERENCE POSITION RETURN............................................. |

83 |

6.2 |

SETTING THE REFERENCE POSITION WITHOUT DOGS ...................... |

84 |

6.3 |

AUTOMATIC REFERENCE POSITION RETURN (G28, G29).................... |

85 |

6.4 |

REFERENCE POSITION RETURN CHECK (G27) ..................................... |

86 |

6.5 |

2ND, 3RD AND 4TH REFERENCE POSITION RETURN (G30) ................. |

86 |

6.6 |

FLOATING REFERENCE POSITION RETURN (G30.1)............................. |

87 |

6.7 |

REFERENCE POSITION SHIFT ................................................................. |

89 |

7 COORDINATE SYSTEM ...................................................................... |

90 |

|

7.1 |

MACHINE COORDINATE SYSTEM (G53).................................................. |

91 |

7.2 |

WORKPIECE COORDINATE SYSTEM ...................................................... |

92 |

|

7.2.1 Setting a Workpiece Coordinate System (G92) .................................................... |

92 |

|

7.2.2 Setting Workpiece Coordinate System (G54 to G59) ........................................... |

94 |

7.3 |

LOCAL COORDINATE SYSTEM ................................................................ |

95 |

|

7.3.1 Workpiece Origin Offset Value Change ............................................................... |

96 |

|

7.3.2 Adding Workpiece Coordinate Systems (G54.1) .................................................. |

96 |

|

7.3.3 Workpiece Coordinate System Preset (G92.1)...................................................... |

97 |

|

7.3.4 Automatically Presetting the Workpiece Coordinate System ............................... |

98 |

7.4 |

PLANE SELECTION.................................................................................... |

99 |

7.5 |

PLANE CONVERSION FUNCTION........................................................... |

100 |

7.6 |

ROTARY TABLE DYNAMIC FIXTURE OFFSET....................................... |

103 |

8 COORDINATE VALUE AND DIMENSION ......................................... |

104 |

|

8.1 |

ABSOLUTE AND INCREMENTAL PROGRAMMING................................ |

105 |

8.2 |

POLAR COORDINATE COMMAND (G15, G16) ....................................... |

106 |

8.3 |

INCH/METRIC CONVERSION (G20,G21) ................................................ |

108 |

8.4DECIMAL POINT INPUT/POCKET CALCULATOR TYPE DECIMAL POINT

|

INPUT ........................................................................................................ |

109 |

8.5 |

DIAMETER AND RADIUS PROGRAMMING ............................................ |

110 |

8.6PROGRAMMABLE SWITCHING OF DIAMETER/RADIUS SPECIFICATION

|

................................................................................................................... |

111 |

8.7 |

LINEAR AXIS AND ROTATION AXIS........................................................ |

112 |

9 SPINDLE SPEED FUNCTION............................................................ |

113 |

|

9.1 |

S CODE OUTPUT ..................................................................................... |

114 |

9.2 |

SPINDLE SPEED BYNARY OUTPUT ....................................................... |

114 |

9.3 |

SPINDLE SPEED ANALOG OUTPUT....................................................... |

114 |

9.4 |

SPINDLE SPEED SERIAL OUTPUT......................................................... |

114 |

c - 3

TABLE OF CONTENTS |

B-63322EN/03 |

||

|

9.5 |

CONSTANT SURFACE SPEED CONTROL (G96, G97) .......................... |

115 |

|

9.6 |

SPINDLE SPEED CLAMP (G92)............................................................... |

116 |

|

9.7 |

ACTUAL SPINDLE SPEED OUTPUT ....................................................... |

116 |

|

9.8 |

SPINDLE POSITIONING ........................................................................... |

117 |

|

9.9 |

SPINDLE ORIENTATION .......................................................................... |

118 |

|

9.10 |

SPINDLE OUTPUT SWITCHING .............................................................. |

118 |

|

9.11 |

SPINDLE SPEED FLUCTUATION DETECTION....................................... |

119 |

10 |

TOOL FUNCTION .............................................................................. |

121 |

|

|

10.1 |

TOOL SELECTION FUNCTION ................................................................ |

122 |

|

10.2 |

TOOL LIFE MANAGEMENT FUNCTION .................................................. |

123 |

|

|

10.2.1 Tool Life Management Function......................................................................... |

123 |

|

|

10.2.2 Addition of Tool Pairs for Tool Life Management 512 Pairs ............................. |

125 |

|

|

10.2.3 Addition of Tool Pairs for Tool Life Management 1024 Pairs ........................... |

125 |

11 |

MISCELLANEOUS FUNCTIONS ....................................................... |

126 |

|

|

11.1 |

AUXILIARY FUNCTION............................................................................. |

127 |

|

11.2 |

MULTIPLE M COMMANDS IN A SINGLE BLOCK.................................... |

128 |

|

11.3 |

THE SECOND AUXILIARY FUNCTIONS.................................................. |

129 |

|

11.4 |

HIGH-SPEED M/S/T/B INTERFACE ......................................................... |

130 |

12 |

PROGRAM CONFIGURATION .......................................................... |

132 |

|

|

12.1 |

PROGRAM NUMBER................................................................................ |

133 |

|

12.2 |

PROGRAM NAME ..................................................................................... |

133 |

|

12.3 |

MAIN PROGRAM ...................................................................................... |

133 |

|

12.4 |

SUB PROGRAM ........................................................................................ |

134 |

|

12.5 |

EXTERNAL DEVICE SUBPROGRAM CALL (M198) ................................ |

136 |

|

12.6 |

SEQUENCE NUMBER .............................................................................. |

137 |

|

12.7 |

PROGRAM CODES................................................................................... |

137 |

|

12.8 |

BASIC ADDRESSES AND COMMAND VALUE RANGE .......................... |

138 |

|

12.9 |

PROGRAM FORMAT ................................................................................ |

140 |

|

12.10 |

LABEL SKIP .............................................................................................. |

140 |

|

12.11 |

CONTROL-IN/CONTROL-OUT ................................................................. |

140 |

|

12.12 |

OPTIONAL BLOCK SKIP .......................................................................... |

141 |

|

12.13 |

ADDITIONAL OPTIONAL BLOCK SKIP.................................................... |

141 |

12.14TAPE HORIZONTAL (TH) PARITY CHECK AND TAPE VERTICAL(TV)

PARITY CHECK ........................................................................................ |

141 |

13 FUNCTIONS TO SIMPLIFY PROGRAMMING................................... |

142 |

13.1 CANNED CYCLE....................................................................................... |

143 |

c - 4

B-63322EN/03 |

|

TABLE OF CONTENTS |

||

|

13.2 |

RIGID TAPPING ........................................................................................ |

151 |

|

|

|

13.2.1 Rigid Tapping Additional Function..................................................................... |

153 |

|

|

13.3 |

EXTERNAL MOTION FUNCTION (G81) ................................................... |

154 |

|

|

13.4 |

OPTIONAL ANGLE CHAMFERING AND CORNER ROUNDING ............. |

155 |

|

|

13.5 |

PROGRAMMABLE MIRROR IMAGE (G50.1, G51.1) ............................... |

156 |

|

|

13.6 |

INDEX TABLE INDEXING FUNCTION...................................................... |

158 |

|

|

13.7 |

FIGURE COPY (G72.1,G72.2) .................................................................. |

159 |

|

|

|

13.7.1 |

Rotation Copy...................................................................................................... |

160 |

|

|

13.7.2 |

Linear Copy ......................................................................................................... |

162 |

|

13.8 |

NORMAL DIRECTION CONTROL (G40.1, G41.1, G42.1)........................ |

164 |

|

14 |

TOOL COMPENSATION FUNCTION ................................................ |

166 |

||

|

14.1 |

TOOL LENGTH OFFSET .......................................................................... |

167 |

|

|

14.2 |

TOOL OFFSET(G45-G48)......................................................................... |

169 |

|

|

14.3 |

CUTTER COMPENSATION ...................................................................... |

171 |

|

|

14.4 |

TOOL COMPENSATION VALUES............................................................ |

174 |

|

|

14.5 |

NUMBER OF TOOL COMPENSATION SETTINGS.................................. |

176 |

|

|

14.6 |

CHANGING THE TOOL COMPENSATION AMOUNT .............................. |

177 |

|

|

14.7 |

THREE-DIMENSIONAL TOOL COMPENSATION (G40, G41) ................. |

178 |

|

|

14.8 |

TOOL OFFSETS BASED ON TOOL NUMBERS ...................................... |

180 |

|

|

14.9 |

TOOL AXIS DIRECTION TOOL LENGTH COMPENSATION................... |

182 |

|

|

14.10 |

DESIGNATION DIRECTION TOOL LENGTH COMPENSATION ............. |

186 |

|

|

14.11 |

THREE-DIMENSIONAL CUTTER COMPENSATION ............................... |

190 |

|

|

|

14.11.1 Three-dimensional Cutter Compensation At Tool Center Point ......................... |

191 |

|

|

14.12 |

TOOL CENTER POINT CONTROL........................................................... |

192 |

|

|

14.13 |

GRINDING WHEEL WEAR COMPENSATION ......................................... |

193 |

|

|

14.14 |

DIAMETER ENTRY FOR TOOL COMPENSATION VALUE ..................... |

194 |

|

|

14.15 |

CUTTER COMPENSATION FOR ROTARY TABLE ................................. |

195 |

|

15 |

ACCURACY COMPENSATION FUNCTION ...................................... |

196 |

||

|

15.1 |

STORED PITCH ERROR COMPENSATION ............................................ |

197 |

|

|

15.2 |

STRAIGHTNESS COMPENSATION......................................................... |

198 |

|

|

15.3 |

INTERPOLATED STRAIGHTNESS COMPENSATION ............................ |

199 |

|

|

15.4 |

128 STRAIGHTNESS COMPENSATION POINTS.................................... |

200 |

|

|

15.5 |

BACKLASH COMPENSATION.................................................................. |

201 |

|

|

15.6 |

INTERPOLATED PITCH ERROR COMPENSATION................................ |

202 |

|

|

15.7 |

CYCLIC SECOND PITCH ERROR COMPENSATION.............................. |

203 |

|

|

15.8 |

GRADIENT COMPENSATION .................................................................. |

204 |

|

c - 5

TABLE OF CONTENTS |

B-63322EN/03 |

||

|

15.9 |

BI-DIRECTIONAL PITCH ERROR COMPENSATION .............................. |

205 |

|

15.10 |

THREE-DIMENSIONAL ERROR COMPENSATION................................. |

206 |

|

15.11 |

PROGRAMMABLE PARAMETER ENTRY (G10)...................................... |

208 |

|

15.12 |

NANO INTERPOLATION TYPE ERROR COMPENSATION .................... |

210 |

|

15.13 |

SMOOTH BACKLASH COMPENSATION................................................. |

211 |

|

15.14 |

ADDITION OF 5000 PITCH ERROR COMPENSATION POINTS............. |

212 |

|

15.15 |

THERMAL GROWTH COMPENSATION ALONG TOOL VECTOR.......... |

213 |

16 COORDINATE SYSTEM CONVERSION FUNCTION........................ |

214 |

||

|

16.1 |

AXIS INTERCHANGE................................................................................ |

215 |

|

16.2 |

COORDINATE SYSTEM ROTATION........................................................ |

216 |

|

16.3 |

SCALING ................................................................................................... |

218 |

|

16.4 |

THREE-DIMENSIONAL COORDINATE CONVERSION........................... |

221 |

17 |

MEASUREMENT FUNCTIOM............................................................ |

224 |

|

|

17.1 |

SKIP FUNCTION (G31) ............................................................................. |

225 |

|

17.2 |

SKIPPING THE COMMANDS FOR SEVERAL AXES............................... |

226 |

|

17.3 |

MULTISTAGE SKIP (G31.1 to G31.4)....................................................... |

226 |

|

17.4 |

HIGH SPEED SKIP SIGNAL (G31) ........................................................... |

226 |

|

17.5 |

TORQUE LIMIT SKIP ................................................................................ |

227 |

|

17.6 |

TOOL LENGTH MANUAL MEASUREMENT............................................. |

228 |

|

17.7 |

WORKPIECE ORIGIN MANUAL SETTING............................................... |

229 |

|

17.8 |

TOOL LENGTH/WORKPIECE ORIGIN MEASUREMENT........................ |

229 |

|

17.9 |

AUTOMATIC TOOL LENGTH MEASUREMENT (G37) ............................ |

230 |

|

17.10 |

CHANGING ACTIVE OFFSET VALUE WITH MANUAL MOVE ................ |

231 |

18 |

CUSTOM MACRO.............................................................................. |

232 |

|

|

18.1 |

CUSTOM MACRO ..................................................................................... |

233 |

|

|

18.1.1 Custom Macro ..................................................................................................... |

233 |

|

|

18.1.2 INCREASED 900 CUSTOM MACRO COMMON VARIABLES .................... |

239 |

|

18.2 |

INTERRUPTION TYPE CUSTOM MACRO............................................... |

240 |

|

18.3 |

MACRO EXECUTOR................................................................................. |

241 |

19 FUNCTIONS FOR HIGH-SPEED CUTTING ...................................... |

242 |

||

19.1DECELERATION BASED ON ACCELERATION DURING CIRCULAR

|

INTERPOLATION...................................................................................... |

243 |

19.2 |

ADVANCED PREVIEW CONTROL........................................................... |

244 |

19.3 |

NANO INTERPOLATION........................................................................... |

244 |

19.4LOOK-AHEAD ACCELERATION/DECELERATION BEFORE

INTERPOLATION...................................................................................... |

245 |

c - 6

B-63322EN/03 |

TABLE OF CONTENTS |

19.5 FINE HPCC |

................................................................................................246 |

19.6MACHINING TYPE IN HPCC SCREEN PROGRAMMING (G05.1 OR G10)

|

................................................................................................................... |

248 |

19.7 |

REMOTE BUFFER .................................................................................... |

249 |

|

19.7.1 Remote Buffer ..................................................................................................... |

249 |

|

19.7.2 Binary Input Operation Function......................................................................... |

251 |

20 AXIS CONTROL FUNCTIONS ........................................................... |

252 |

|

20.1 |

FOLLOW-UP ............................................................................................. |

253 |

20.2 |

MECHANICAL HANDLE FEED ................................................................. |

253 |

20.3 |

SERVO OFF .............................................................................................. |

253 |

20.4 |

MIRROR IMAGE........................................................................................ |

253 |

20.5 |

CONTROLLED AXES DETACH ................................................................ |

254 |

20.6 |

TWIN TABLE CONTROL........................................................................... |

255 |

|

20.6.1 Tool Length Compensation in tool axis direction with Twin Table Control ...... |

256 |

20.7 |

SYNCHRONOUS CONTROL .................................................................... |

257 |

20.8 |

TANDEM CONTROL ................................................................................. |

257 |

20.9 |

PARALLEL AXIS CONTROL ..................................................................... |

258 |

20.10 |

PMC AXIS CONTROL ............................................................................... |

259 |

20.11 |

CHOPPING FUNCTION (G81.1) ............................................................... |

260 |

20.12 |

ELECTRONIC GEAR BOX (G80, G81, G80.5, G81.5).............................. |

262 |

20.13AUTOMATIC PHASE MATCHING FUNCTION WITH ELECTRONIC GEAR

|

BOX ........................................................................................................... |

263 |

20.14 |

SKIP FUNCTION FOR EGB AXIS(G31.8)................................................. |

264 |

20.15 |

ROTARY AXIS ROLL-OVER ..................................................................... |

264 |

20.16 |

MULTIPLE ROTARY CONTROL AXIS FUNCTION .................................. |

265 |

20.17 |

ABSOLUTE POSITION DETECTION........................................................ |

265 |

20.18 |

VERTICAL AXIS DROP PREVENTION FUNCTION ................................. |

266 |

20.19 |

CUTTING/RAPID TRAVERSE IN-POSITION CHECK .............................. |

266 |

20.20 |

DECELERATION STOP UPON A POWER FAILURE............................... |

266 |

20.21 |

HIGH SPEED HRV MODE ........................................................................ |

266 |

21 MANUAL OPERATION ...................................................................... |

267 |

|

21.1 |

JOG FEED................................................................................................. |

268 |

21.2 |

INCREMENTAL FEED............................................................................... |

268 |

21.3 |

MANUAL HANDLE FEED (1ST)................................................................ |

268 |

21.4 |

MANUAL HANDLE FEED (2ND, 3RD) ...................................................... |

268 |

21.5 |

MANUAL FEED IN A SPECIFIED DIRECTION......................................... |

269 |

c - 7

TABLE OF CONTENTS |

B-63322EN/03 |

|

21.6 |

MANUAL ABSOLUTE ON AND OFF......................................................... |

270 |

21.7 |

THREE-DIMENSIONAL HANDLE FEED................................................... |

271 |

|

21.7.1 Handle Feed/Interruption in the Longitudinal Direction of the Tool.................. |

272 |

|

21.7.2 Handle Feed/Interruption in the Transverse Direction of the Tool..................... |

273 |

|

21.7.3 Rotational Handle/Interruption Feed Around the Center of the Tool Tip |

........... 274 |

21.8CHANGING TOOL LENGTH COMPENSATION IN THE LONGITUDINAL

|

DIRECTION OF THE TOOL ...................................................................... |

275 |

21.9 |

TOOL HOLDER OFFSET .......................................................................... |

275 |

21.10 |

DISPLAYING THE COORDINATES OF THE TOOL TIP .......................... |

276 |

21.11DISPLAYING PULSE VALUES AND AMOUNT OF MOVEMENT BY MANUAL

INTERRUPT .............................................................................................. |

277 |

21.12 MANUAL NUMERIC COMMAND .............................................................. |

277 |

21.13MANUAL INTERRUPTION FUNCTION FOR THREE-DIMENSIONAL

COORDINATE CONVERSION.................................................................. |

278 |

22 AUTOMATIC OPERATION ................................................................ |

279 |

||

22.1 |

OPERATION MODE .................................................................................. |

280 |

|

|

22.1.1 |

DNC Operation.................................................................................................... |

280 |

|

22.1.2 |

Memory Operation .............................................................................................. |

280 |

|

22.1.3 |

MDI Operation .................................................................................................... |

280 |

22.2 |

SELECTION OF EXECUTION PROGRAMS............................................. |

280 |

|

|

22.2.1 |

Program Number Search...................................................................................... |

280 |

|

22.2.2 |

Sequence Number Search.................................................................................... |

280 |

|

22.2.3 |

Rewind................................................................................................................. |

280 |

22.3 |

ACTIVATION OF AUTOMATIC OPERATION ........................................... |

280 |

|

|

22.3.1 |

Cycle Start ........................................................................................................... |

280 |

22.4 |

EXECUTION OF AUTOMATIC OPERATION............................................ |

281 |

|

|

22.4.1 |

Buffering.............................................................................................................. |

281 |

22.5 |

STOP/TERMINATION OF AUTOMATIC OPERATION ............................. |

281 |

|

|

22.5.1 |

Program Stop (M00)............................................................................................ |

281 |

|

22.5.2 Program End (M02, M30) ................................................................................... |

281 |

|

|

22.5.3 Sequence Number Comparison and Stop ............................................................ |

281 |

|

|

22.5.4 |

Feed Hold ............................................................................................................ |

281 |

|

22.5.5 |

Reset 281 |

|

22.6 |

AUTOMATIC OPERATION RESART ........................................................ |

282 |

|

|

22.6.1 |

Program Restart ................................................................................................... |

282 |

|

22.6.2 Output of Program Restart M, S, T And B Codes............................................... |

283 |

|

|

22.6.3 |

Block Restart ....................................................................................................... |

284 |

|

|

c - 8 |

|

B-63322EN/03 |

|

TABLE OF CONTENTS |

22.6.4 |

Retrace................................................................................................................. |

286 |

22.6.5 |

Active Block Cancel............................................................................................ |

287 |

22.6.6 Tool Withdrawal and Return............................................................................... |

288 |

|

22.7 MANUAL INTERRUPTION ........................................................................ |

289 |

|

22.7.1 |

Manual Handle Interrupt ..................................................................................... |

289 |

22.7.2 Simultaneous Automatic and Manual Operation ................................................ |

289 |

|

22.8MANUAL INTERVENTION AMOUNT RETURN DURING AUTOMATIC

|

OPERATION.............................................................................................. |

290 |

|

23 TEST FUNCTIONS FOR PROGRAM................................................. |

291 |

||

23.1 |

ALL-AXES MACHINE LOCK ..................................................................... |

292 |

|

23.2 |

MACHINE LOCK ON EACH AXIS ............................................................. |

292 |

|

23.3 |

AUXILIARY FUNCTION LOCK .................................................................. |

292 |

|

23.4 |

DRY RUN................................................................................................... |

292 |

|

23.5 |

SINGLE BLOCK......................................................................................... |

292 |

|

24 SETTING AND DISPLAY UNIT.......................................................... |

293 |

||

24.1 |

SETTING AND DISPLAY UNITS............................................................... |

294 |

|

|

24.1.1 |

9.5"/10.5" LCD Unit............................................................................................ |

295 |

|

24.1.2 |

MDI unit .............................................................................................................. |

296 |

|

24.1.3 |

MDI Unit (Full-keyboard) ................................................................................... |

297 |

24.2 |

EXPLANATION OF THE KEYBOARD....................................................... |

298 |

|

|

24.2.1 |

Function Keys...................................................................................................... |

300 |

|

24.2.2 |

Soft Keys ............................................................................................................. |

301 |

25 DISPLAY AND SETTING ................................................................... |

302 |

||

25.1 |

DISPLAY.................................................................................................... |

303 |

|

25.2 |

LANGUAGE SELECTION.......................................................................... |

306 |

|

25.3 |

CLOCK FUNCTION ................................................................................... |

306 |

|

25.4 |

COMMUNICATION SETTING SCREEN ................................................... |

306 |

|

25.5 |

RUN TIME & PARTS NUMBER DISPLAY................................................. |

307 |

|

25.6 |

MENU SWITCHES .................................................................................... |

308 |

|

25.7DISPLAYING AND SETTING THE SOFTWARE OPERATOR’S PANEL..309

25.8 |

FLOPPY CASSETTE DIRECTRY DISPLAY ............................................. |

311 |

|

25.9 |

GRAPHIC FUNCTION ............................................................................... |

312 |

|

|

25.9.1 |

Tool Path Drawing............................................................................................... |

312 |

|

25.9.2 |

Background Drawing........................................................................................... |

313 |

25.10 |

WAVEFORM DIAGNOSIS FUNCTION ..................................................... |

314 |

|

25.11 |

SERVO SPINDLE SCREEN ...................................................................... |

316 |

|

c - 9

TABLE OF CONTENTS |

B-63322EN/03 |

|

25.11.1 |

Servo Setting Screen............................................................................................ |

316 |

25.11.2 |

Servo Adjustment/Monitor Screen ...................................................................... |

317 |

25.11.3 Servo Function Setting Screen ............................................................................ |

317 |

|

25.11.4 |

Servo Alarm Screen............................................................................................. |

318 |

25.11.5 |

Backlash Adjustment Screen............................................................................... |

319 |

25.11.6 |

Spindle Screen ..................................................................................................... |

320 |

25.12 OPERATING MONITOR SCREEN............................................................ |

321 |

|

25.13DISPLAY OF HARDWARE/SOFTWARE SYSTEM CONFIGURATION

|

SCREEN.................................................................................................... |

322 |

|

25.14 |

OPERATIONS AND ALARM HISTORY SCREENS .................................. |

325 |

|

|

25.14.1 |

Alarm History Screen .......................................................................................... |

325 |

|

25.14.2 |

Operation History Screen .................................................................................... |

326 |

|

25.14.3 |

DI/DO Selection Screen ...................................................................................... |

327 |

25.15 |

STAMPING THE MACHINING TIME......................................................... |

328 |

|

|

25.15.1 Machining Time Display Screen ......................................................................... |

328 |

|

|

25.15.2 |

Program Directory Screen ................................................................................... |

329 |

|

25.15.3 Tool Path Drawing Screen................................................................................... |

329 |

|

25.16 |

CLEARING THE SCREEN ........................................................................ |

330 |

|

25.17 |

PERIODIC MAINTENANCE SCREEN....................................................... |

330 |

|

25.18 |

MAINTENANCE INFORMATION SCREEN............................................... |

331 |

|

25.19 |

HIGH-SPEED HIGH-PRECISION MACHINING SETTING SCREEN........ |

332 |

|

|

25.19.1 |

Adjustment Screen............................................................................................... |

332 |

|

25.19.2 |

Setting Screen...................................................................................................... |

334 |

25.20 |

SUBSCREENS .......................................................................................... |

335 |

|

25.21 |

DIRECTORY DISPLAY / PUNCH FOR EACH GROUP ............................ |

337 |

|

25.22 |

PROGRAM NAME 48 CHARACTERS ...................................................... |

338 |

|

25.23 |

CALCULATION KEY.................................................................................. |

339 |

|

25.24 |

POWER MATE CNC MANAGER FUNCTION........................................... |

340 |

|

25.25 |

HELP FUNCTION ...................................................................................... |

341 |

|

25.26 |

MEMORY CARD SCREEN........................................................................ |

342 |

|

25.27 |

MODEM CARD SETTING SCREEN.......................................................... |

343 |

|

25.28BRIGHTNESS ADJUSTMENT SCREEN FOR MONOCHROME DISPLAY

|

UNIT WITH GRAPHIC FUNCTION ........................................................... |

344 |

25.29 |

REMOTE DIAGNOSTIC FUNCTION......................................................... |

345 |

25.30 |

FINE TORQUE SENSING ......................................................................... |

347 |

25.31 |

DO SIGNAL OUTPUT BY SOFT KEY ....................................................... |

348 |

25.32 |

2-LCD-UNIT CONNECTION FUNCTION .................................................. |

349 |

c - 10

B-63322EN/03 TABLE OF CONTENTS

26 PROGRAM EDITING ......................................................................... |

350 |

||

26.1 |

PROGRAM EDITING................................................................................. |

351 |

|

|

26.1.1 |

Program Editing................................................................................................... |

351 |

|

26.1.2 |

Background Editing............................................................................................. |

351 |

26.2 |

PROGRAM INPUT/OUTPUT AND COLLATION ....................................... |

352 |

|

|

26.2.1 |

Program Input/Output.......................................................................................... |

352 |

|

26.2.2 |

Part program Collation ........................................................................................ |

352 |

|

26.2.3 Keys and Program Encryption............................................................................. |

352 |

|

|

26.2.4 External I/O Device Control................................................................................ |

352 |

|

26.3 |

ADVANCED PROGRAM EDITING/OPERATION...................................... |

353 |

|

|

26.3.1 Automatically Inserting Sequence Numbers ....................................................... |

353 |

|

|

26.3.2 Editing Two Programs Simultaneously............................................................... |

353 |

|

|

26.3.3 Editing Programs in Operation ............................................................................ |

353 |

|

|

26.3.4 |

Playback............................................................................................................... |

354 |

26.4STORED PROGRAM LENGTHS AND NUMBER OF REGISTERABLE

PROGRAMS .............................................................................................. |

355 |

27 DIAGNOSIS FUNCTIONS.................................................................. |

356 |

|

27.1 SELF-DIAGNOSIS FUNCTION ................................................................. |

357 |

|

27.1.1 |

Self-diagnosis Screen .......................................................................................... |

357 |

27.1.2 |

Group Selection Screen ....................................................................................... |

358 |

28 DATA INPUT/OUTPUT....................................................................... |

359 |

||

28.1 |

READER/PUNCHER INTERFACES.......................................................... |

360 |

|

|

28.1.1 |

Connection Port ................................................................................................... |

360 |

28.2 |

INPUT/OUTPUT DEVICES........................................................................ |

361 |

|

|

28.2.1 |

FANUC FLOPPY CASSETTE ........................................................................... |

361 |

|

28.2.2 FANUC PROGRAM FILE Mate ........................................................................ |

361 |

|

|

28.2.3 |

FANUC Handy File............................................................................................. |

361 |

28.3 |

DATA SERVER.......................................................................................... |

362 |

|

28.4 |

SCREEN HARD COPY FUNCTION .......................................................... |

363 |

|

29 SAFETY FUNCTIONS........................................................................ |

364 |

|

29.1 |

EMERGENCY STOP ................................................................................. |

365 |

29.2 |

OVERTRAVEL FUNCTIONS..................................................................... |

366 |

|

29.2.1 Overtravel ............................................................................................................ |

366 |

|

29.2.2 Stored Stroke Check 1 ......................................................................................... |

366 |

|

29.2.3 Stored Stroke Check 2 ......................................................................................... |

367 |

|

29.2.4 Stroke Limit Check Before Movement................................................................ |

367 |

|

c - 11 |

|

TABLE OF CONTENTS |

B-63322EN/03 |

|||

|

29.3 |

INTERLOCK .............................................................................................. |

368 |

|

|

|

29.3.1 |

Interlock per Axis ................................................................................................ |

368 |

|

|

29.3.2 |

All Axes Interlock ............................................................................................... |

368 |

|

|

29.3.3 |

Automatic-Operation All-Axis Interlock............................................................. |

368 |

|

|

29.3.4 |

Block Start Interlock............................................................................................ |

368 |

|

|

29.3.5 Cutting Block Start Interlock............................................................................... |

368 |

|

|

29.4 |

EXTERNAL DECELERATION ................................................................... |

369 |

|

|

29.5 |

ABNORMAL LOAD DETECTION .............................................................. |

370 |

|

30 |

STATUS OUTPUT.............................................................................. |

371 |

||

|

30.1 |

NC READY SIGNAL .................................................................................. |

372 |

|

|

30.2 |

SERVO READY SIGNAL........................................................................... |

372 |

|

|

30.3 |

REWINDING SIGNAL................................................................................ |

372 |

|

|

30.4 |

ALARM SIGNAL ........................................................................................ |

372 |

|

|

30.5 |

DISTRIBUTION END SIGNAL................................................................... |

372 |

|

|

30.6 |

AUTOMATIC OPERATION SIGNAL ......................................................... |

372 |

|

|

30.7 |

AUTOMATIC OPERATION START SIGNAL............................................. |

372 |

|

|

30.8 |

FEED HOLD SIGNAL ................................................................................ |

373 |

|

|

30.9 |

RESET SIGNAL......................................................................................... |

373 |

|

|

30.10 |

IN-POSITION SIGNAL............................................................................... |

373 |

|

|

30.11 |

MOVE SIGNAL .......................................................................................... |

373 |

|

|

30.12 |

AXIS MOVE DIRECTION SIGNAL ............................................................ |

373 |

|

|

30.13 |

RAPID TRAVERSING SIGNAL ................................................................. |

373 |

|

|

30.14 |

TAPPING SIGNAL..................................................................................... |

373 |

|

|

30.15 |

THREAD CUTTING SIGNAL ..................................................................... |

374 |

|

|

30.16 |

CONSTANT SURFACE SPEED CONTROL SIGNAL ............................... |

374 |

|

|

30.17 |

INCH INPUT SIGNAL ................................................................................ |

374 |

|

|

30.18 |

DI STATUS OUTPUT SIGNAL .................................................................. |

374 |

|

|

30.19 |

POSITION SWITCH FUNCTION............................................................... |

374 |

|

|

30.20 |

OILING SIGNAL (CANNED CYCLE) ......................................................... |

375 |

|

31 |

EXTERNAL DATA INPUT .................................................................. |

376 |

||

32 KEY INPUT FORM PMC .................................................................... |

380 |

|||

|

|

|

||

A |

RANGE OF COMMAND VALUE ........................................................ |

383 |

||

B |

LIST OF FUNCTION AND TAPE FORMAT........................................ |

387 |

||

c - 12

B-63322EN/03 |

TABLE OF CONTENTS |

C TAPE CODE LIST |

..............................................................................392 |

c - 13

I. GENERAL

B-63322EN/03 |

GENERAL |

1.GENERAL |

1 GENERAL

The FANUC Series 15i CNC provides the highest level of performance for very-high-speed and very-high-precision machining. It can control 24 axes simultaneously.

With functions such as precise trace control, called nano-interpolation, and fine HPCC for applying optimum acceleration/deceleration control, the CNC maximizes the performance of machine tools, allowing complicated free surface figures such as aircraft parts and metal molds to be machined with very high precision and at very high speed.

The FANUC Series 15i CNC uses the CNC technology and expertise that FANUC has accumulated over many years. At the same time, it has been made extremely compact by incorporating the latest semiconductor and electronics technology. Moreover, it features improvements such as reduced amounts of wiring in the electrical section to facilitate the engineering design of machine tools, a significantly reduced parts count, and the incorporation of many environmental considerations.

The FANUC Series 150i open CNC is a FANUC Series 15i that has a Windows-capable personal computer function built in, such that Windows-compatible software and development environments to be used.

This manual describes the following models and may use the following abbreviations.

Model name |

|

Abbreviation |

|

FANUC Series 15i-MA |

15i-MA |

|

Series15i |

FANUC Series 150i-MA |

150i-MA |

|

Series150i |

1.GENERAL |

GENERAL |

B-63322EN/03 |

Related manuals

The following table lists the manuals related to the FANUC Series 15i, 150i. This manual is indicated by an asterisk(*).

Table 1 (a) Manuals Related to the Series 15i, 150i

Manual name |

Specification |

|

number |

DESCRIPTIONS

CONNECTION MANUAL (Hardware)

CONNECTION MANUAL (Function)

OPERATOR’S MANUAL (PROGRAMMING) for Machining Center

OPERATOR’S MANUAL (OPERATION) for Machining Center

MAINTENANCE MANUAL

PARAMETER MANUAL

DESCRIPTIONS (Supplement for Remote Buffer)

PROGRAMMING MANUAL

(Macro Compiler/Macro Executor)

B-63322EN * B-63323EN

B-63323EN-1

B-63324EN

B-63324EN-1

B-63325EN

B-63330EN

B-63322EN-1

B-63323EN-1

Related manuals for Servo Motor α/β series

The following table lists the manuals related to the FANUC Servo Motor α/β series.

Table 1 (b) Manuals Related to the Servo Motor α/β series.

Manual name

FANUC AC SERVO MOTOR α series DESCRIPTIONS

FANUC AC SPINDLE MOTOR α series DESCRIPTIONS

FANUC SERVO AMPLIFIER α series DESCRIPTIONS

FANUC SERVO MOTOR α series MAINTENANCE MANUAL

FANUC AC SERVO MOTOR α series PARAMETER MANUAL

FANUC AC SPINDLE MOTOR α series PARAMETER MANUAL

FANUC SERVO MOTOR β series DESCRIPTIONS

FANUC SERVO MOTOR β series MAINTENANCE MANUAL

FANUC SERVO MOTOR β series MAINTENANCE MANUAL

(I/O Link Option)

Specification

number

B-65142E

B-65152E

B-65162E

B-65165E

B-65150E

B-65160E

B-65232EN

B-65235EN

B-65245EN

B-63322EN/03 |

GENERAL |

2.LIST OF SPECIFICATIONS |

2 LIST OF SPECIFICATIONS

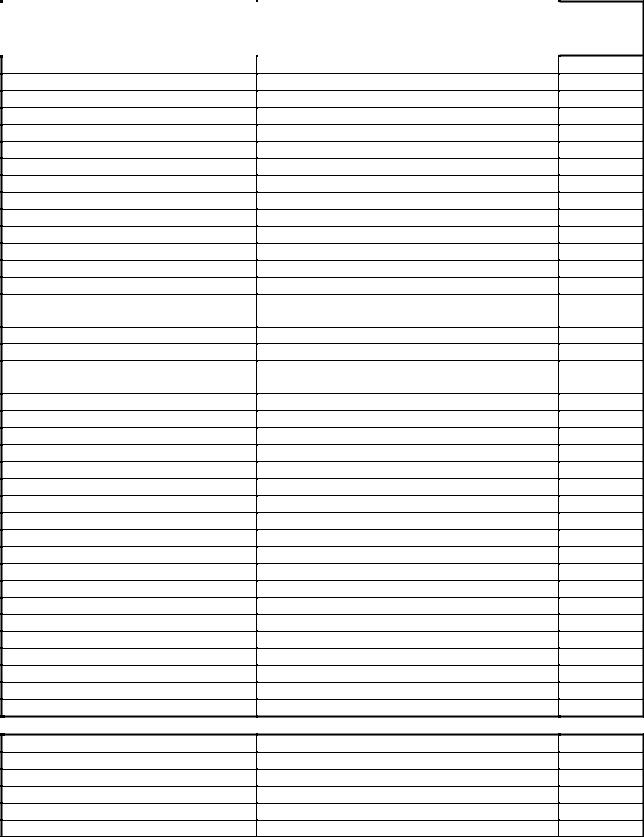

AA: Standard

BB : Standard option

CC : Option

DD : Function included in a nother option

NOTE) The use of some combina tions of options is restricted.

|

|

|

Series 15i |

|

Item |

Specifications |

Series 150i |

|

|

|

MA |

|

Axis control |

|

|

|

Controlled axes |

3 axes (including axis control by PMC) |

AA |

|

Maximum total controlled axes |

Up to 24 axes (multi-axes specification) |

CC |

|

|

Up to 10 axes (standard specification) |

|

|

|

(including two Cs axes) |

|

|

Simultaneously controlled axes |

2 axes |

AA |

|

Simultaneously controlled axis expansion |

Up to maximum total controlled axes |

CC |

|

Axis control by PMC |

Up to 8 axes |

CC |

|

Cs contour control |

Up to 4 axes |

CC |

|

|

Speed control is possible. |

|

|

Axis name |

Optional form X, Y, Z, U, V, W, A , B, C |

AA |

|

Axis name expansion |

Addition of I, J, K, and E |

CC |

|

Controlled axis detach |

|

AA |

|

Flexible feed gear |

Optional DMR |

AA |

|

Optional command multiplier |

Use this function when flexible feed gear is not applied. |

CC |

|

Parallel axes control |

Available on both standard type and Multi-axes type |

CC |

|

Twin table function |

|

CC |

|

Synchronous control |

Synchronous error compensation is possible. |

CC |

|

|

Available on both standard type and Multi-axes type |

|

|

Tandem control |

|

CC |

|

Simple synchronous control |

Synchronous error compensation is possible. |

DD |

|

Synchronous tandem control |

Possible by synchronous control and tandem control |

DD |

|

Dual position feedback |

|

CC |

|

Chopping |

|

CC |

|

Increment system |

IS-A,IS-B,IS-C |

AA |

|

Increment system D |

0.00001mm |

CC |

|

|

0.00001deg |

|

|

|

0.000001inck |

|

|

Increment system E |

0.000001mm |

CC |

|

|

0.000001deg |

|

|

|

0.0000001inch |

|

|

Inch/metric switching |

|

CC |

|

Interlock |

All axes/Each axes/Automatic operation axis/Block |

AA |

|

|

start/Cutting block start |

|

|

Machine lock |

All axes/each axes |

AA |

|

Emergency stop |

|

AA |

2.LIST OF SPECIFICATIONS |

GENERAL |

B-63322EN/03 |

||

|

|

|

|

|

|

|

|

Series 15i |

|

|

Item |

Specifications |

Series 150i |

|

|

|

|

MA |

|

|

Overtravel |

|

AA |

|

|

Stored stroke check 1 |

|

AA |

|

|

Stored stroke check 2 |

|

CC |

|

|

External stroke limit setting |

|

CC |

|

|

Stroke limit check before travel |

|

CC |

|

|

Mirror image |

Each axis |

AA |

|

|

Follow-up |

At emergency stop and at Servo alarm and so on |

AA |

|

|

Servo-off/mechanical handle feed |

|

AA |

|

|

Backlash compensation |

|

AA |

|

|

Separate backlash compensation for rapid |

|

AA |

|

|

traverse and cutting feed |

|

|

|

|

Stored pitch error compensation |

|

CC |

|

|

Interpolated pitch error compensation |

|

CC |

|

|

Periodical secondary pitch error |

|

CC |

|

|

compensation |

|

|

|

|

Gradient compensation |

|

CC |

|

|

Straightness deviation compensation |

|

CC |

|

|

Position switch |

|

CC |

|

|

Absolute position detection |

|

AA |

|

|

Feed forward for rapid traverse |

|

AA |

|

|

Abnormal load detection |

|

CC |

|

|

Straightness compensation at 128 points |

|

CC |

|

|

Interpolation type straightness compensation |

|

CC |

|

|

Bi-directional pitch error compensation |

|

CC |

|

|

Three-dimensional error compensation |

|

CC |

|

|

Linear motor |

|

AA |

|

|

Level-up HRV control |

|

AA |

|

|

Fine acceleration/deceleration |

|

AA |

|

|

Operation |

|

|

|

|

Automatic operation |

DNC operation (Reader/puncher interface is required) |

AA |

|

|

|

Memory operation |

|

|

|

|

MDI operation |

|

|

|

DNC operation with memory card |

|

AA |

|

|

Cycle start/Feed hold |

|

AA |

|

|

Program stop/Program end |

|

AA |

|

|

Reset/Rewind |

|

AA |

|

|

Program number search |

|

AA |

|

|

Sequence number search |

|

AA |

|

|

Sequence number collation stop |

|

AA |

|

|

Program restart |

|

CC |

|

|

Block restart |

|

CC |

|

|

Tool retract & recover |

|

CC |

|

|

Active block cancel |

|

CC |

|

|

Buffer register |

|

AA |

|

|

Multi buffer (5 blocks) |

|

AA |

|

|

Multi buffer (15 blocks) |

|

CC |

|

|

Multi buffer (100 blocks) |

|

CC |

|

|

Dry run |

|

AA |

|

|

Single block |

|

AA |

|

B-63322EN/03 |

GENERAL |

2.LIST OF SPECIFICATIONS |

Item |

Specifications |

|

|

Jog feed

Manual reference position return

Reference position return setting without dog

Reference position shift

Manual handle feed (1 unit)

Manual handle feed (2 or 3 units)

Manual handle feed magnification

Manual handle interrupt

Three-dimensional handle feed

Manual interruption of three-dimensional coordinate system conversion

Incremental feed

Automatic/manual simultaneous operation

Manual arbitrary angle feed

Manual numeric command

Recovery of manual intervention amount

Interpolation functions

Positioning

Single direction positioning

Exact stop mode

Tapping mode

Cutting mode

Exact stop

Linear interpolation

Circular interpolation

Dwell

Helical interpolation

Helical interpolation B

Involute interpolation

Helical involute interpolation

Spline interpolation

Threading/Feed per revolution

Arbitrary spindle gear ratio thread cutting

Polar coordinate interpolation

Cylindrical interpolation

Cutting point interpolation for cylindrical interpolation

Exponential interpolation

Hypothetical axis interpolation

Spiral/conical interpolation

Reference position return

2nd reference position return

Same as “Adjustment for reference return deceleration limit” in 15B

Including manual handle ×1, ×10, ×M, ×N

M, N : Up to 2000

×1, ×10, ×100, ×1000, ×10000, ×100000

Unit of angle : 1/16 deg.

G00 (Linear interpolation type positioning enabled)

G60

G61

G63

G64

G09

Dwell in seconds and dwell in revolution (It is possible with thread cutting option)

(Circular interpolation) +

(Linear interpolation for up to 2 axes)

(Circular interpolation) +

(Linear interpolation for up to 4 axes)

Involute interpolation by linear and rotary axis is possible

Same as “Spline interpolation B” in 15-B

Equal lead thread cutting, inch thread cutting, continuous thread cutting

Included in “Thread cutting, per revolution feed”.

Included in “Cylindrical interpolation”.

G27, G28, G29

Series 15i

Series 150i

MA

AA

AA

AA

AA

CC

CC

DD

CC

CC

CC

AA

CC

CC

CC

AA

AA

CC

AA

DD

AA

AA

AA

AA

AA

CC

CC

CC

CC

CC

CC

DD

CC

CC

DD

CC

CC

CC

AA

CC

2.LIST OF SPECIFICATIONS |

GENERAL |

B-63322EN/03 |

||

|

|

|

|

|

|

|

|

Series 15i |

|

|

Item |

Specifications |

Series 150i |

|

|

|

|

MA |

|

|

3rd/4th reference position return |

|

CC |

|

|

Floating reference position return |

|

CC |

|

|

Normal-direction control |

|

CC |

|

|

Index table indexing |

|

CC |

|

|

Multiple rotary axis control |

|

CC |

|

|

Smooth interpolation |

|

CC |

|

|

NURBS interpolation |

|

CC |

|

|

Feed functions |

|

|

|

|

Rapid traverse 240m/min(1 m) |

|

AA |

|

|

Rapid traverse 100m/min(0.1 m) |

|

AA |

|

|

Rapid traverse 10m/min(0.01 m) |

Included in “Least input increment D” |

DD |

|

|

Rapid traverse 1m/min(0.001 m) |

Included in “Least input increment E” |

DD |

|

|

Rapid traverse override |

F0, Fm, 50%, 100% |

AA |

|

|

Rapid traverse override 1% |

0 to 100% (1%step) |

AA |

|

|

Feed per minute |

m/min |

AA |

|

|

Feed per rotation |

Included in “Thread cutting, per revolution feed”. |

DD |

|

|

Feed per rotation without position coder |

Included in “Thread cutting, per revolution feed”. |

DD |

|

|

Constant tangential speed control |

|

AA |

|

|

Cutting feedrate clamp |

|

AA |

|

|

Automatic acceleration/deceleration |

Rapid traverse : Linear or exponential |

AA |

|

|

|

Cutting feed : Linear or exponential |

|

|

|

Linear acceleration/deceleration after cutting |

|

AA |

|

|

feed interpolation |

|

|

|

|

Bell-shaped acceleration/deceleration after |

|

CC |

|

|

cutting feed interpolation |

|

|

|

|

Bell-shaped acceleration/deceleration after |

|

AA |

|

|

rapid traverse interpolation |

|

|

|

|

Feedrate override |

0 to 254% (1%step) |

AA |

|

|

2nd feedrate override |

0 to 254% (1%step) |

CC |

|

|

|

0 to 655.34% (0.01%step) |

|

|

|

Feed by F with one digit |

|

CC |

|

|

Inverse time feed |

|

CC |

|

|

Jog override |

0 to 655.34% (0.01%step) |

AA |

|

|

Override cancel |

|

AA |

|

|

External deceleration |

|

CC |

|

|

Feed stop |

|

CC |

|

|

Look-ahead acceleration/deceleration before |

|

AA |

|

|

interpolation |

|

|

|

|

Cutting point feedrate control |

Included in “Automatic corner override”. |

DD |

|

|

Advanced preview control |

|

AA |

|

|

Look-ahead Bell-shaped |

|

AA |

|

|

acceleration/deceleration before interpolation |

|

|

|

|

Nano interpolation |

|

AA |

|

|

Fine HPCC |

|

CC |

|

|

Program input |

|

|

|

|

Program code |

Automatic recognition of EIA and ISO |

AA |

|

|

Program format |

Word address format |

AA |

|

|

Label skip |

|

AA |

|

|

Parity check |

Horizontal parity, vertical parity |

AA |

|

B-63322EN/03 |

GENERAL |

2.LIST OF SPECIFICATIONS |

Item

Control in/out

Optional block skip

Additional optional block skip

Maximum value

Program number/Program name

Sequence number

Absolute/incremental programming

Decimal point input, pocket calculator type decimal point input

Input unit (10 times)

Diameter/radius programming

Programmable diameter/radius switching

Plane selection

Plane switching

Rotary axis designation

Rotary axis roll-over

Polar coordinate command

Workpiece coordinate system setting

Workpiece coordinate system preset

Local coordinate system setting

Machine coordinate system

Workpiece coordinate system

Addition of workpiece coordinate systems

Manual absolute on/off

Optional-angle chamfering/corner rounding

Programmable data input

Programmable parameter input

Main program/sub program

External device subprogram call function

Custom macro

Addition to custom macro common variables : total 900

Interrupt-type custom macro

Canned cycle

Arc radius R programming

Automatic corner override

Feedrate clamp by arc radius

Scaling

Coordinate system rotation

Three-dimensional coordinate conversion

Axis switching

Programmable mirror image

Figure copy

Retrace

Macro Executor

Macro Executor / Capacity of User program : 512KB

|

Series 15i |

Specifications |

Series 150i |

|

MA |

|

AA |

1 block |

AA |

9 blocks |

CC |

±9 digit (R, I, J, K ±12 digit) |

AA |

Program number : O with 8 digits |

AA |

Program name : 16 characters |

|

N with 8 digits |

AA |

|

AA |

|

AA |

|

|

|

AA |

|

AA |

|

AA |

G17, G18, G19 |

AA |

|

CC |

|

AA |

|

AA |

|

CC |

G92 |

AA |

G92.1 |

AA |

G52 |

AA |

G53 |

AA |

G54 to G59 |

AA |

48 sets |

CC |

|

AA |

|

CC |

G10, tool offset amount , workpiece zero point offset |

CC |

amount can be changed by programming |

|

|

CC |

Sub program : 10 folds nested |

AA |

|

AA |

Common variable : 600 |

CC |

|

CC |

|

|

|

CC |

|

CC |

|

AA |

|

CC |

|

AA |

|

CC |

|

CC |

|

CC |

|

CC |

|

CC |

|

CC |

|

CC |

Capacity of User program : 256KB |

CC |

|

CC |

|

|

2.LIST OF SPECIFICATIONS |

GENERAL |

B-63322EN/03 |

Item |

Specifications |

|

|

Macro Executor / Capacity of User program : 1MB

Machining type in HPCC screen programming

Miscellaneous/spindle functions

Miscellaneous function

Second auxiliary function

Second auxiliary function with a decimal point

Miscellaneous function lock

High-speed M/S/T/B interface

Multiple miscellaneous-function commands

Spindle function

Spindle serial output

Spindle analog output

Constant surface speed control

Actual spindle speed output

Spindle speed fluctuation detection

Spindle orientation

Spindle output switching

Spindle positioning

Rigid tapping

M with 8 digits, binary output

M with 8 digits Select address from A, B, C, U, V, W so that it does not duplicate with control axis address)

Included in “Second auxiliary function”

S with 8 digits, binary output

Four spindle output is available

Available to use with Spindle serial output

Included in “Spindle serial output” and “Spindle analog output”

Orientation, pecking cycle and return speed override function is also possible

Tool functions, tool compensation functions

Tool function |

T with 8 digits, binary output |

Tool compensation data, 32 items

Tool compensation data, 99 items

Tool compensation data, 200 items

Tool compensation data, 499 items

Tool compensation data, 999 items

Tool offset memory A

Tool offset memory B

Tool offset memory C

Tool length compensation

Tool offset

Cutter compensation