ABB ACS380 Quick Start Guide

—

ABB MACHINERY DRIVES

ACS380 drive

Quick installation and start-up guide

Safety instructions

Read the safety instructions in ACS380 Hardware manual (3AXD50000029274 [EN]).

WARNING! Obey these safety instructions to prevent physical injury or death, or damage to the equipment. If you are not a qualified electrician, do not do electrical installation or maintenance work.

•When you install the drive, make sure that dust does not go into the drive.

•When the drive or connected equipment is energized, do not do work on the drive, motor cable, motor, control cables or control circuits.

•After you disconnect the input power, wait for 5 minutes to let the intermediate circuit capacitors discharge.

•Make sure that the installation is not energized:

•Use a multimeter with an impedance of at least 1 Mohm.

•Make sure that the voltage between the drive output terminals (U, V, W) and the ground (PE) is 0 V.

•Make sure that the voltage between the drive input power terminals (L1, L2, L3) and the ground (PE) is 0 V.

•Make sure that the voltage between the DC and brake resistor terminals (UDC+, UDCand R-) and the ground (PE) is 0 V.

•If you use a permanent magnet synchronous motor, do not do work on the drive when the motor rotates. A permanent magnet motor that rotates energizes the drive and the input power terminals.

WARNING! The installation, start-up and operation of this equipment requires detailed instructions. Refer to this quick guide and the user interface guide in the drive package. Retain the guides with this device at all times. For more information, refer to the hardware manual and firmware manual. You can download these manuals from the ABB website or order hard copies of the manuals with the delivery.

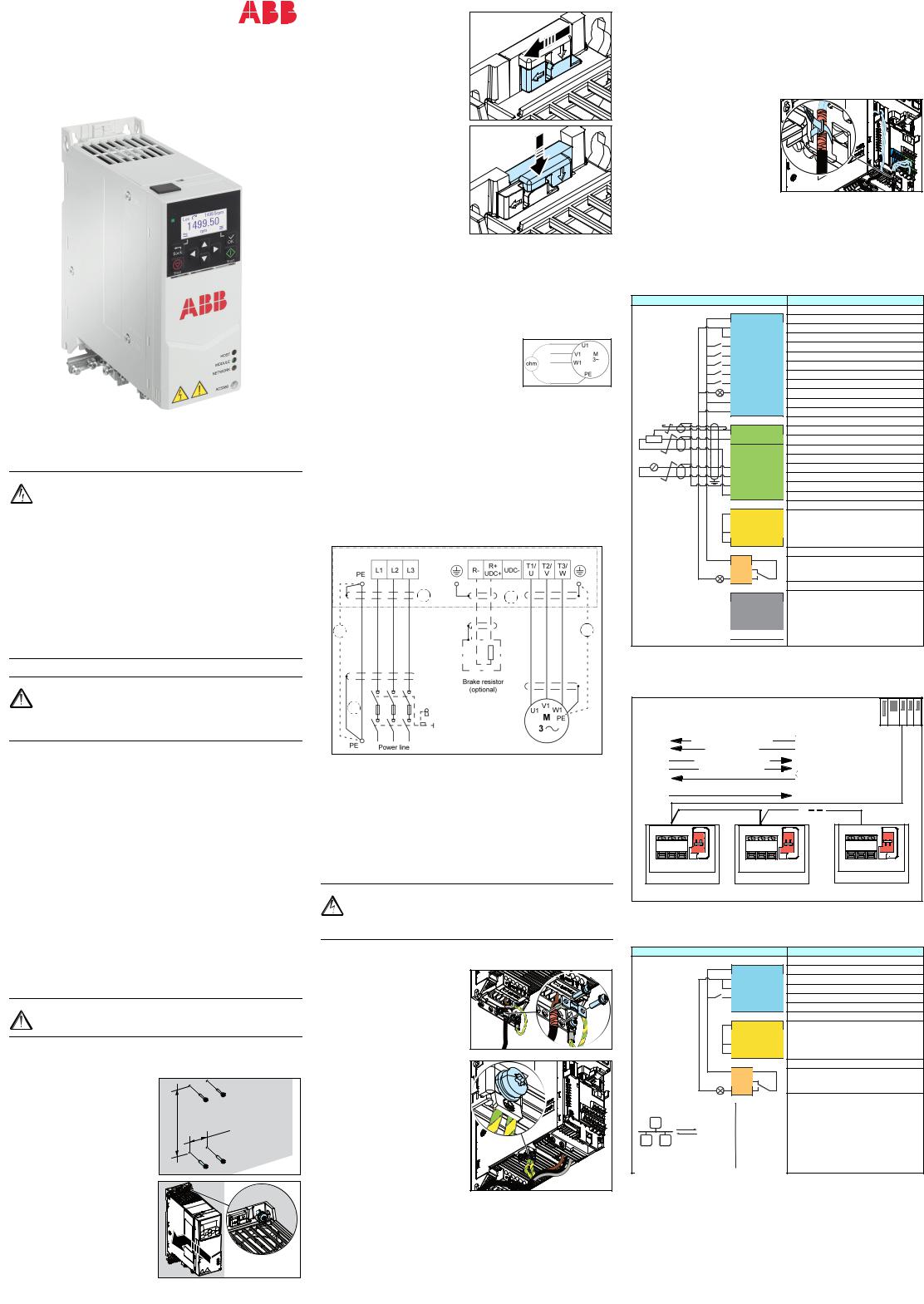

To install the drive to a DIN rail

1. Move the locking part to the left.

2. Push and hold the locking button down.

3. Put the top tabs of the drive onto the top edge of the DIN installation rail.

4. Put the drive against the bottom edge of the DIN installation rail.

5. Release the locking button.

6. Move the locking part to the right.

7. Make sure that the drive is correctly installed.

8. To remove the drive, use a flat-head screwdriver to open the locking part.

3. Measure the insulation resistance

Drive: Do not do voltage tolerance or insulation resistance tests on the drive, because this can cause damage to the drive.

Input power cable: Before you connect the input power cable, measure the insulation of the input power cable. Obey the local regulations.

Motor and motor cable:

1.Make sure that the motor cable is connected to the motor and disconnected from the drive output terminals T1/U, T2/V and T3/W.

2.Use a voltage of 500 V DC to measure the insulation resistance between each phase conductor and the protective earth conductor. The insulation resistance of an ABB motor must be more than 100 Mohm (at 25 °C/77 °F). For the insulation resistance of other motors, refer to the manufacturer’s documentation.

Moisture in the motor decreases the insulation resistance. If you think that there is moisture in the motor, dry the motor and do the measurement again.

4. Select the cables

Input power cable: For the best EMC performance, use a symmetrical shielded cable and two grounding conductors.

Motor cable: Use a symmetrical shielded cable.

Control cable: Use a double-shielded twisted-pair cable for analog signals. Use a single-shielded cable for digital, relay and I/O signals. Use separate cables for analog and relay signals.

5. Connect the power cables

Connection diagram

d |

d |

b |

c |

a

1. Examine the installation area

The drive is intended for cabinet installation and has an ingress protection rating of IP20.

Make sure that in the installation area:

•There is sufficient cooling and hot air does not recirculate.

•The ambient conditions are suitable. Refer to Ambient conditions.

•The mounting surface is non-flammable and can hold the weight of the drive. Refer to Declaration of conformity.

•Materials near the drive are non-flammable.

•There is sufficient space above and below the drive for maintenance work. Refer to Free space requirements.

2. Install the drive

You can install the drive with screws or to a DIN rail.

Installation requirements:

•Make sure that there is a minimum of 75 mm of free space at the top and bottom of the drive for cooling air.

•Install R0 drives upright. R0 drives do not have a fan.

•You can install R1, R2, R3 and R4 drives tilted by up to 90 degrees, from vertical to fully horizontal orientation.

•You can install several drives side by side. Side-mounted options require approximately 20 mm of space on the right side of the drive.

WARNING! Do not install the drive upside down. Make sure that the cooling air exhaust (at the top) is always above the cooling air inlet (at the bottom).

To install the drive with screws

1. Make marks onto the surface for the mounting holes. Refer to

Declaration of conformity. The R3 and R4 drives contain a mounting template.

2. |

Make the holes for the mounting |

<![if ! IE]> <![endif]>H |

W |

|

|||

|

screws and install suitable plugs or |

|

|

|

anchors. |

|

|

3. |

Start to tighten the screws into the |

|

|

|

mounting holes. |

|

|

4. |

Install the drive onto the mounting |

|

|

|

screws. |

|

|

5. |

Tighten the mounting screws. |

|

|

a.Two grounding conductors. Use two conductors if the cross-section of grounding conductor is less than 10 mm2 Cu or 16 mm2 Al (IEC/EN 61800-5-1). For example, use the cable shield in addition to the fourth conductor.

b.Separate grounding cable (line side). Use it if the conductivity of the fourth conductor or shield is not sufficient for the protective grounding.

c.Separate grounding cable (motor side). Use it if the conductivity of the shield is not sufficient for the protective grounding, or there is no symmetrically constructed grounding conductor in the cable.

d.360-degree grounding of the cable shield. Required for the motor cable and brake resistor cable, recommended for the input power cable.

Connection procedure

WARNING! Obey the safety instructions in the ACS380 Hardware manual (3AXD50000029274 [English]). If you ignore them, injury or death, or damage to the equipment can occur.

WARNING! If the drive is connected to an IT (non-grounded) system or to a corner-grounded TN system, disconnect the EMC filter grounding screw.

1.Strip the motor cable.

2. Ground the motor cable shield under the grounding clamp.

3. Twist the motor cable shield into a bundle, mark it accordingly and connect it to the grounding terminal.

4. Connect the phase conductors of the motor cable to the T1/U, T2/V and T3/W motor terminals. Torque the terminals to 0.8 N·m (7 lbf·in).

5. If it is applicable, connect the brake resistor cable to the R- and UDC+ terminals. Torque the terminals to 0.8 N·m (7 lbf·in). Use a shielded cable and ground the shield under the grounding clamp.

6. Strip the input power cable.

7. If the input power cable has a shield, twist it into a bundle, mark it and connect it to the grounding terminal.

8. Connect the PE conductor of the input power cable to the grounding terminal. If it is necessary, use a second PE conductor.

9.Connect the phase conductors of the input power cable to the L1, L2 and L3 input terminals. Torque the terminals to 0.8 N·m (7 lbf·in).

10.Mechanically attach the cables on the outside of the drive.

Make sure that there are no sources of strong magnetic fields such as high-current single-core conductors or contactor coils near the drive. A strong magnetic field can cause interference or inaccuracy in the operation of the drive. If there is interference, move the source of the magnetic field away from the drive.

6. Connect the control cables

Connection procedure

Do the connections according to the default control connections of the application macro that you select. For the connections of the factory default macro (ABB standard macro), refer to Default I/O connections (ABB standard macro), for the connections of fieldbus default macro, refer to Fieldbus connections. For the other macros, refer to the ACS380 Firmware manual (3AXD50000029275 [English]).

Keep the signal wire pairs twisted as near to the terminals as possible to prevent inductive coupling.

1. Strip a part of the outer shield of the control cable for grounding.

2. Use a cable tie to ground the outer shield to the grounding tab.

3. Use metal cable ties for 360-degree grounding.

4. Strip the control cable conductors.

5. Connect the conductors to the correct control terminals. Torque the terminals to 0.5 N·m (4.4 lbf·in).

6.Connect the shields of the twisted pairs and grounding wires to the SCR terminal. Torque the terminals to 0.5 N·m (4.4 lbf·in).

7.Mechanically attach the control cables on the outside of the drive.

Default I/O connections (ABB standard macro)

For the standard variant (I/O & Modbus) (type ACS380-04xS). |

|||

|

Terminals |

Descriptions |

|

|

+24V |

Digital I/O connections |

|

|

Aux. +24 V DC, max. 200 mA |

||

|

DGND |

Aux. voltage output common |

|

|

DCOM |

Digital input common |

|

|

DI1 |

Stop (0) / Start (1) |

|

|

DI2 |

Forward (0) / Reverse (1) |

|

|

DI3 |

Speed selection |

|

|

DI4 |

Speed selection |

|

|

DIO1 |

Ramp 1 (0) / Ramp 2 (1) |

|

|

DIO2 |

Ready (0) / Not ready (1) |

|

|

DIO SRC |

Digital output auxiliary voltage |

|

|

DIO COM |

Digital input/output common |

|

1...10 kohm |

AI1 |

Analog I/O |

|

Freq. ref. / Speed ref. (0...10 V) |

|||

|

|||

|

AGND |

Analog input circuit common |

|

|

AI2 |

Not configured |

|

Max. 500 ohm |

AGND |

Analog input circuit common |

|

|

AO |

Output frequency (0...20 mA) |

|

|

AGND |

Analog output circuit common |

|

|

SCR |

Signal cable shield (screen) |

|

|

+10V |

Reference voltage |

|

|

S+ |

Safe torque off (STO) |

|

|

Safe torque off function. Connected at factory. |

||

|

SGND |

Drive starts only if both circuits are closed. |

|

|

S1 |

|

|

|

S2 |

Relay output |

|

|

RC |

||

|

Relay output 1 |

||

|

RA |

No fault [Fault (-1)] |

|

|

RB |

EIA-485 Modbus RTU |

|

|

|

||

|

B+ |

Embedded Modbus RTU (EIA-485) |

|

|

|

||

|

A- |

|

|

|

BGND |

|

|

|

Shield |

|

|

|

Termination |

|

|

Connecting EIA-485 Modbus RTU terminal to drive

Connect the fieldbus to the EIA-485 Modbus RTU terminal on the BMIO-01 module which is attached on the control unit of the drive. The connection diagram is shown below.

Fieldbus controller |

Termination ON (1

Data flow |

Fieldbus |

|

Control Word (CW) |

|

|

References |

Process I/O (cyclic) |

|

Status Word (SW) |

||

|

||

Actual values |

|

|

Parameter R/W |

Service messages (acyclic) |

|

requests/responses |

||

|

|

|

ON |

|

|

ON |

|

|

|

ON |

|

|

ON |

|

|

ON |

... |

|

|

ON |

| <![if ! IE]> <![endif]>B + |

<![if ! IE]> <![endif]>A - DGND |

1 |

<![if ! IE]> <![endif]>B + |

<![if ! IE]> <![endif]>A - DGND |

1 |

<![if ! IE]> <![endif]>B + |

<![if ! IE]> <![endif]>A - DGND |

1 |

|

|

|

1 |

|

|

1 |

|

|

|

1 |

Termination OFF |

Termination OFF |

|

Termination ON (1 |

||||||

|

Drive |

|

|

Drive |

|

|

|

Drive |

|

1)The device at both ends on the fieldbus must have termination set to ON.

Fieldbus connections

For the configured drives with the preconfigured fieldbus protocol (type ACS380-04xC).

Terminals |

Descriptions |

|

+24V |

Digital I/O connections |

|

Aux. +24 V DC, 200 mA |

||

DGND |

Aux. voltage output common |

|

DCOM |

Digital input common |

|

DI1 |

Fault reset |

|

DI2 |

Not configured |

|

S+ |

Safe torque off (STO) |

|

Safe torque off function. Connected at factory. |

||

SGND |

Drive starts only if both circuits are closed. |

|

S1 |

|

|

S2 |

Relay output |

|

RC |

||

Relay output 1 |

||

RA |

No fault [Fault (-1)] |

|

RB |

Extension module connections |

|

|

DSUB9 |

CANopen |

|

+K457 FCAN-01-M CANopen |

|

DSUB9 |

Profibus DP |

|

+K454 |

FPBA-01-M Profibus DP |

RJ45 X 2 |

EtherCAT |

|

+K469 FECA-01-M EtherCAT |

|

|

+K475 |

FENA-21-M Ethernet/IP, Profinet, |

||

RJ45 X 2 |

Ethernet IP |

|

Modbus TCP |

|

RJ45 X 2 |

Profinet |

|

+K495 |

BCAN-11 CANopen interface |

RJ45 X 2 |

Modbus TCP |

|

+K470 FEPL-02 Ethernet power link (RJ45x2) |

|

Terminal Block |

CANopen |

|

+K451 |

FDNA-01, DeviceNet (Terminal Block) |

|

|

|

||

Loading...

Loading...