VEGA SWING83A User Manual

Level and Pressure

Operating Instructions

VEGASWING 81A, 83A

Safety information

Safety information

The described module must only be installed and operated as described in these operating instructions. Please note that other action can cause damage for which VEGA does not take responsibility.

Note Ex-area

Please note the approval documents attached (yellow binder), and especially the included safety data sheet.

2 |

VEGASWING 81A and 83A |

Contents

Contents

|

Safety information ........................................................................ |

2 |

|

|

Note Ex-area ................................................................................ |

2 |

|

1 |

Product description |

|

|

|

1.1 |

Function and configuration .................................................. |

4 |

|

1.2 |

Approvals ............................................................................. |

5 |

|

1.3 |

Technical data ....................................................................... |

7 |

|

1.4 |

Dimensions ......................................................................... |

11 |

|

1.5 |

Type plate ........................................................................... |

15 |

2 |

Mounting |

|

|

|

2.1 |

VEGASWING ...................................................................... |

16 |

3 |

Electrical connection .............................................................. |

20 |

|

4 |

Set-up |

|

|

|

4.1 |

Functions table ................................................................... |

26 |

5 |

Diagnosis |

|

|

|

5.1 |

Recurring test acc. to WHG .............................................. |

27 |

|

5.2 |

Replacement of electronics ............................................... |

28 |

|

5.3 |

Failure removal ................................................................... |

29 |

VEGASWING 81A and 83A |

3 |

Product description

1 Product description

1.1 Function and configuration |

Function |

VEGASWING series 80 A vibrating level switches detect the levels of liquids with a viscosity between 0,2 mPa s and 10.000 mPa s and densities ³ 0,5 g/cm3.

Their modular design allows them to be used in vessels, tanks and pipelines. T ypical applications involve overfill and dry run protection.

Thanks to its simple and rugged measuring system, VEGASWING can be used in almost any liquid regardless of its chemical and physical properties. It also works well under difficultconditions such as turbulence, air pockets, foam formation, or changes in material, and is insensitive to external vibrations.

VEGASWING with their mechanical connection thread, cone, bolting and flange are also suitable for level detection of liquids in the food processing industr y. The tuning fork and the extension tube are polished for such applications.

For the use in very aggressive products, Hastelloy C4 and coatings ECTFE (Halar) and enamel are used for VEGASWING 81 A and 83 A.

For product temperatures of more than 100°C up to 150°C, VEGASWING 81 A and 83 A can be equipped with a temperature adapter.

The tuning fork is piezoelectrically energised and vibrates at a resonance frequency of approx. 400 Hz. The resonance frequency changes when the tuning fork is covered by the material. This frequency change is detected by the integral oscillator and converted into a switching command.The switching condition (overfill or dry run protection) can be selected using the mode switch.

The oscillator of VEGASWING continuously monitors the instrument for the following faults:

-tuning fork corrosion or damage,

-absence of vibration,

-piezo drive cable malfunction,

-vibrating frequency too low ,

-corrosive medium penetrating the sensor from the vessel.

With a connected signal conditioning instrument (oscillator SWING E82 Z) in addition more functions can be monitored. With oscillator SWING E82 Z and appropriate signal conditioning instrument, the function of the complete measuring chain can be monitored at the touch of a button. This is valid according to the general type approval acc. to WHG as recurring test. More information is provided with the particular signal conditioning instrument.

Should one of the above-mentioned faults occur, or the power supply fails, the electr onics react by switching to a defined switching state, i.e. dependent on the electr onics version

- opening the non-contact switch, - de-energising the r elay, o r

- blocking the output transistor .

With the two-wire output version, the failure is signalled via a defined current to the connected VEGATOR signal conditioning instrument.

4 |

VEGASWING 81A and 83A |

Product description

Recurring test acc. to WHG

According to the type approval WHG (Z-65.11-154) the recurring test acc. to WHG can be carried out by pressing a key on the VEGATOR 536 EX, 537 EX, 636 EX signal conditioning instrument. The sensor must not be removed, nor made to respond by filling the vessel. This is valid for VEGASWING

81 A EX and 83 A EX with two-wire SWING E82 Z EX oscillator .

VEGASWING 81 A EX and 83 A EX meet the fail-safe requirements to class 3 (AK 1 … 3) acc. of DIN 19 251 in mode A (overfill protection).

Configuration

A measuring system consists of:

-a VEGASWING with SWING E82 C, SWING E82 R or SWING E82 T oscillator

-external instruments, switched by VEGASWING

or

-a VEGASWING with SWING E82 Z or SWING E82 Z EX oscillator

-VEGATOR 536 EX, 537 EX or 636 EX signal conditioning instrument or an already mounted instrument, e.g. VEGA TOR

425 EX, 534 EX, 825 EX

-external instruments switched by VEGATOR.

1.2 Approvals

Explosion protection

Only certified VEGASWING 81A EX0, 83A EX0 vibrating level switches should be used in hazardous areas caused by combustible gases, vapours or fog, . VEGASWING

81A EX0, 83A EX0 are suitable for use in hazardous areas zone 1 and zone 0.

The EU-type approval issued by the approval authority is attached to the instruments as proof of explosion protection. Ex-mounting regulations should be noted when VEGASWING 81A EX0, 83A EX0 vibrating level switches are mounted and operated in hazardous areas. The information and conditions of the supplied certificates (EU-type approval, conformity certificate) for VEGASWING 81A EX0, 83A EX0 as well as the appropriate electrical equipment (VEGA TOR signal conditioning instrument, separator , safety barrier) must be taken into account.

•The mounting of Ex-systems must always be carried out by skilled staff.

•VEGASWING 81A EX0, 83A EX0 must be powered by an intrinsically safe circuit; the permissible electrical values are stated in the appropriate Ex-type approval certificate.

•VEGASWING 81A EX0, 83A EX0 with enamelled tuning fork or plastic parts acquiring static electricity have a warning label stating the measures to be taken to avoid dangers due to electrostatic discharges. The contents of the warning label should be noted.

•The explosion protection of the electrical equipment used is only ensured when the limit temperatures stated in the certificate are not exceeded.

•In the case of dangers due to oscillation and vibrations, the appropriate parts of VEGASWING 83A EX0 should be secured effectively against these dangers.

VEGASWING 81A and 83A |

5 |

Product description

Overfill protection

The information and conditions of the supplied general type approvals must be noted when a VEGASWING is used as part of an overfill protection for vessels storing water - endangered liquids. The general type approval should be available at the place of installation place.

VEGASWING should only be used in liquids against which the materials of the wetted parts of VEGASWING are sufficiently chemically resistant.

DruckbehV (pressure vessel regula-

tions)

VEGASWING was tested acc. to TRB 801 no. 45 on its suitability for use in pressurized vessels (DruckbehV).

Overfill protection according to WHG

Level detection with fault monitoring

Instrument |

|

Oscillator |

|

VEGATOR |

|

|

Test certificate no. |

||

|

|

|

|

level switch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VEGASWING |

|

SWING E82Z EX |

|

|

536 EX, |

|

|

Z-65.11-154 |

|

81A EX, 83A EX |

|

|

|

537 EX |

|

|

|

|

|

|

|

|

|

636 EX |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VEGASWING |

|

SWING E82 C |

|

|

Compact instrument |

|

Z-65.11-163 |

||

81A and 83A |

|

SWING E82 R |

|

|

|

|

|

|

|

(C, R, T) |

|

SWING E82 T |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Level measuring instruments for use in hazardous areas |

|

|

|

|

|||||

Level detection with fault monitoring |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

Instrument |

EU-type approval |

|

VEGATOR |

Conformity |

|||||

|

certificate |

|

level |

certificate |

|||||

|

|

|

|

|

switch |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VEGASWING |

TÜV 98 ATEX 1320 X |

|

536 EX |

|

PTB no. Ex 95.D.2065 X |

|

|||

81A EX, 83A EX |

|

|

|

|

537 EX |

PTB no. Ex 95.D.2073 X |

|||

|

|

|

|

|

|

|

|

|

|

with |

|

|

|

|

636 EX |

PTB no. Ex 96.D.2068 |

|||

oscillator |

|

|

|

|

|

|

|

|

|

SWING E82Z EX |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VEGATOR 425 EX, 534 EX and 825 EX signal conditioning instruments meet the r equired connection values and can also be used.

6 |

VEGASWING 81A and 83A |

Product description

1.3 Technical data

VEGASWING 81A and 83A

Housing

Housing material |

plastic PBT (Polyester) or |

|

|

|

aluminium (plastic-coated) |

Protection |

|

|

- |

plastic housing |

IP 66 |

- |

aluminium housing |

IP 66 and IP 67 (meets both categories) |

Cable entry |

1 M20x1,5 unit |

|

|

|

(SWING E82 R: 2 M20x1,5 units) |

Terminals |

max. 1 x 1,5 mm2 cable cross-section |

|

Mechanical connection |

|

|

Thread |

G 1 A or 1“ NPT |

|

- |

material |

1.4571 (stst) or Hastelloy C4 |

Flanges |

DIN and ANSI from DN 32 |

|

- |

material |

1.4571, 1.4571 plated with Hastelloy C4 |

|

|

DN 50 PN 40 enamelled steel |

|

|

or 1.4571 ECTFE-coated |

Hygienic fittings |

|

|

Material |

1.4571 |

|

- |

cone |

DN 25 |

- |

bolting |

DN 40, DN 50 |

- |

Tri-Clamp |

11/ “, 2“ |

- |

Tuchenhagen Varivent |

2 |

DN 50 PN 10 |

||

- |

hyg. connection with compression nut |

F40 PN 25, 14571, 14581 |

- |

hyg. connection with tension flange |

DN 32 PN 25, 1.4571, 1.4581 |

Tuning fork |

|

|

Material |

1.4581, Hastelloy C4, Hastelloy C4 enamelled |

|

|

|

1.4581 with ECTFE coating |

Extension tube (VEGASWING 83 A) |

|

|

Material |

1.4571, Hastelloy C4, Hastelloy C4 enamelled |

|

|

|

1.4571 with ECTFE coating |

Length |

|

|

- |

1.4571, Hastelloy C4 |

140 mm … 4000 mm |

- |

Hastelloy C4 enamelled |

140 mm … 1200 mm |

- |

1.4571, ECTFE (Halar) |

140 mm … 1600 mm |

Weight |

|

|

Plastic housing |

approx. 1,5 kg |

|

Tube extension (VEGASWING 83A) |

approx. 0,11 kg/m |

|

VEGASWING 81A and 83A |

7 |

|

Product description |

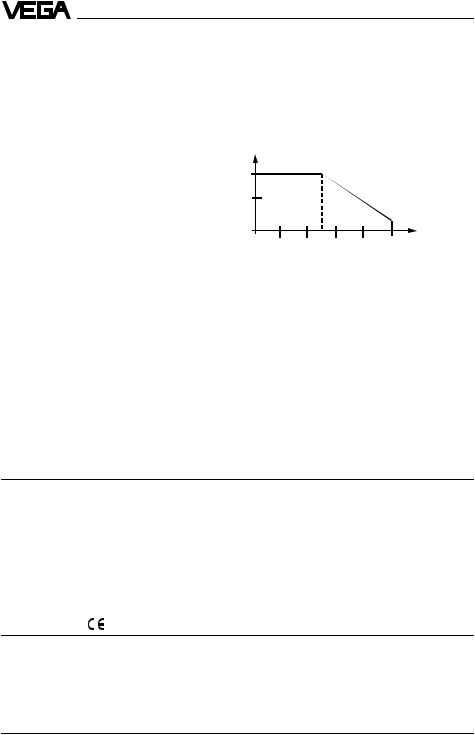

Ambient conditions 1) |

|

Ambient temperature on housing |

-40°C … +70°C |

Storage and transport temperature |

-40°C … +70°C |

Product temperature |

-40°C … +100°C |

|

short-term (30 min.) also over 100°C |

|

(max. 150°C) only valid for instrum ents without |

|

approval. |

Product temperature with 1.4571 |

|

temperature adapter (optional) |

-40°C … +150°C |

Permissible ambient temperature

'

'

Product temperature

with temperature ' adapter

adapter

'

Operating pressure 1) |

|

|

Operating pressure |

-1 bar to 40 bar |

|

|

|

(with locking ARV2EX0.C… |

|

|

up to 25 bar , other lockings un pressurised) |

|

|

With flange versions note nominal pressure |

|

|

of the flange. |

Product |

|

|

Viscosity |

|

|

- |

dynamic |

0,2 … 10.000 mNs/m² (or cSt) |

- |

cineatic |

0,2 … 10.000 mNs/m² (or cP) relating to |

|

|

density 1 |

Density |

0,5 … 2,5 g/cm3 |

|

|

|

0,5 … 0,7 g/cm3 must be readjusted |

|

|

(factory setting 1,0) |

Function |

|

|

Mode |

A/B-modes in oscillator or definition via the |

|

|

|

signal conditioning instrument (SWING E82Z) |

|

|

A: max. detection, overfill protection |

|

|

B: min. dete ction, dry run protection |

Integration time |

approx. 0,5 s |

|

Meas. frequency |

approx. 400 Hz |

|

Hysteresis |

approx. 4 mm with vertical installation |

|

Signal lamp |

|

|

- |

SWING E82 C, R, T |

LED for indication of switching condition |

- |

SWING E82Z, SWING E82Z EX |

LED lights when tuning fork covered |

CE-conformity

VEGASWING 81 A and 83 A vibrating level switches meet the protective regulations of EMC (89/336/EWG) and NSR (73/23/EWG). Conformity has been judged acc. to the following standards:

EMC Emission Susceptibility

NSR

1) Note the information of the conformity certificate or the EU-type approval certificate.

8 |

VEGASWING 81A and 83A |

Product description

Approvals VEGASWING 80 A

WHG

Approval as overfill protection acc. to WHG

Ambient temperature on the housing |

-40°C … +70°C |

|

Product temperature |

-40°C … +100°C |

|

- |

test report Z-65.11-154 |

VEGASWING 81A EX/83A EX with oscillator |

|

|

SWING E82Z EX and suitable signal |

|

|

conditioning instrument |

- |

test report Z-65.11-163 |

VEGASWING 81A EX / 83A EX with oscillator |

|

|

SWING E82 C, R, T |

- |

with temperature adapter |

up to 150°C |

Operating pressure |

max. 40 bar |

|

Recurring test acc. to WHG

According to the type approval to WHG (Z-65.11-154) the recurring test acc. to WHG can be carried out by pr essing the test key on the VEGA TOR 536 EX, 537 EX, 636 EX signal conditioning instrument. The sensor must not be removed, nor can a response be trig-

gered by filling the vessel. This is valid for VEGASWING 81 A EX and 83 A EX with two-wire oscillator SWING E82 Z EX.

Explosion protection VEGASWING 81A EX0, 83A EX0

Certificate |

EU-type approval certificate acc. to ATEX 100 a |

|

TÜV 98 ATEX 1320 X |

Classification mark |

II 1 G EEx ia IIC T6 |

Permissible application range |

Ex Zone 1, Ex Zone 0 |

Ambient temperature dependent on temperature class and Ex-Zone: |

|

see EU-type approval certificate |

|

Electrical safety characteristics: |

|

see EU-type approval certificate |

|

Oscillators

C - Non-contact switch (SWING E82 C)

Supply voltage |

20 … 250 V AC, 50/60 Hz or 20 … 250 V DC |

Output |

non-contact switch |

Current consumption |

approx. 3 mA (via the load circuit) |

Load current |

min. 10 mA |

|

max. 400 mA (at I > 300 mA the ambient |

|

temperature can be max. 60°C) |

|

max. 4 A to 40 ms (not WHG specified) |

Protection class |

I |

Overvoltage category |

III |

Modes |

A: max. level detection, overfill protection |

|

B: min. level detection, dry run protection |

VEGASWING 81A and 83A |

9 |

|

|

|

Product description |

R - Relay output (SWING E82 R) |

|

||

Supply voltage |

20 … 250 V AC, 50/60 Hz or 20 … 72 V DC |

||

|

|

|

(at U > 60 V DC the ambient temperature can |

|

|

|

be max. 50°C) |

Power consumption |

1 … 9 VA AC, max. 1,5 W DC |

||

Output |

relay output (DPDT), 2 floating spdt |

||

Relay data |

|

||

- |

potential separation |

min. 500 V DC |

|

- |

contact material |

AgCdO and Au-plated |

|

- |

turn-on voltage |

min. 10 mV |

|

|

|

|

max. 250 V AC, 250 V DC |

- |

switching current |

min. 10 µA |

|

|

|

|

max. 5 A AC, 1 A DC |

- |

breaking capacity |

max. 750 VA AC, 54 W DC‘ |

|

Protection class |

I |

||

Overvoltage category |

II |

||

Modes |

A: max. level detection, overflow protection, |

||

|

|

|

overfill protection |

|

|

|

B: min. level detection, dry run protection |

T - Transistor output (SWING E82 T) |

|

||

Supply voltage |

10 … 55 V DC |

||

Power consumption |

max. 0,5 W |

||

Output |

floating transistor output |

||

|

|

|

overload and permanently short-circuit proof |

Load current |

max. 400 mA |

||

Voltage loss |

max. 1 V |

||

Turn-on voltage |

max. 55 V DC |

||

Blocking current |

< 10 µA |

||

Protection class |

II |

||

Overvoltage category |

III |

||

Modes |

A: max. detection, overflow protection, |

||

|

|

|

overfill protection |

|

|

|

B: min. detection, dry run protection |

Z - Two-wire output (SWING E82Z) |

|

||

Supply voltage |

12 … 36 V DC (via VEGA-signal conditioning |

||

|

|

|

instrument) |

Output |

two-wire output |

||

Required signal conditioning instrument |

VEGATOR 536 EX, 537 EX, 636 EX, |

||

|

|

|

VEGALOG 571 |

Current consumption |

|

||

- |

tuning fork free |

approx. 8 mA |

|

- |

tuning fork covered |

approx. 16 mA |

|

- |

fault signal |

> 22 mA |

|

Protection class |

II |

||

Overvoltage category |

III |

||

Modes |

definition via signal conditioning instrument |

||

10 |

VEGASWING 81A and 83A |

Loading...

Loading...