VEGA FLEX51K User Manual

Level and Pressure

Operating Instructions

VEGAFLEX 51K

2 VEGAFLEX 51K

Safety information / Note Ex area

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and acci-

dent prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that in-

volved in normal installation and electrical con-

nection, must be carried out only by qualified

VEGA personnel.

Note Ex area

Please note the approval documents (yellow

binder), and especially the included safety

data sheet.

VEGAFLEX 51K 3

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function ................................................................................. 4

1.2 Application features ............................................................. 4

1.3 Types and versions ............................................................. 5

1.4 Type code ............................................................................. 7

1.5 Technical data ....................................................................... 8

1.6 Dimensions ......................................................................... 11

2 Mounting

2.1 Installation instructions ...................................................... 12

3 Electrical connection .............................................................. 15

3.1 Connection and connection cable .................................... 15

3.2 Connection of the sensor .................................................. 17

3.3 Connection of the indicating instrument VEGADIS 50 .... 19

4 Setup

4.1 Adjustment methods .......................................................... 20

4.2 Adjustment with adjustment module MINICOM ............... 20

4.3 Adjustment with the PC ...................................................... 26

4.4 Adjustment with HART

®

handheld ..................................... 29

5 Diagnostics

5.1 Simulation ............................................................................ 30

5.2 Failure rectification ............................................................. 30

Contents

4 VEGAFLEX 51K

Product description

1 Product description

1.1 Function

High frequency microwave impulses are

guided along a steel rope.

The microwave impulses are reflected when

reaching the product surface. The impulse

running time is processed by the integrated

electronics and outputted as level.

The sensors detect levels in all types of sol-

ids. Density, conductivity and dielectric value

of the product do not influence the measure-

ment. Also, varying product properties can-

not influence the measured value.

Lime, cement, cereals, plastic granules, flour,

gravel - VEGAFLEX microwave sensors

solve the most difficult application problems

involving solids. Even in products with vary-

ing moisture or fluctuating dielectric constant,

the level is reliably detected. High, narrow

vessels in which a non-contact measuring

principle often delivers less than optimum

measuring results, can be measured without

problem by VEGAFLEX. VEGAFLEX 51 is

equipped with a cable of 4 mm diameter and

is available up to a length of 10 m.

• Adjustment without filling or emptying of the

vessel.

• 4 … 20 mA two-wire sensors, supply and

measuring signal via one two-wire cable

(loop powered).

• Up to 15 sensors can be connected via

one two-wire cable.

• Measuring range up to 10 m with small min.

distance.

• Unaffected by application conditions such

as:

- dust and noise generation

- moisture changes

- varying products

• Existing cable systems can be still used in

four-wire technology.

• Unaffected by the vessel material, e.g.

metal, concrete, plastic etc.

• As an option, the display with adjustment

can be separated from the sensor.

• Connection to all bus systems: Modbus,

Interbus S, Siemens 3964R, Profibus DP,

Profibus FMS, ASCII.

• Low wiring costs by using bus systems or

two-wire technology.

1.2 Application features

Applications

• Level measurement of solids.

• Measurement also in vacuum.

• All slightly conductive substances and all

substances with a dielectric value e

r

> 1.8

can be measured.

• Measuring range 0 ... 10 m.

Two-wire technology

• Supply, signal transmission and output

signal on one two-wire cable.

• 4 … 20 mA output signal or digital output

signal.

Rugged

• Highly resistant materials: PA, 1.4401.

Precise and reliable

• Resolution 1 mm.

• Unaffected by noise, steam, dusts, gas

compositions and inert gas stratification.

• Unaffected by varying density.

• Measurements under pressure up to

16 bar and with product temperatures up

to 120°C.

Communicative

• Integrated display of measured values.

• As an option, display can be separated

from the sensor.

• Adjustment from the PLC level.

Approvals

• Ex Zone 0

- EExd ia IIC

- EEx ia IIC

• ATEX

• StEx Zone 10

VEGAFLEX 51K 5

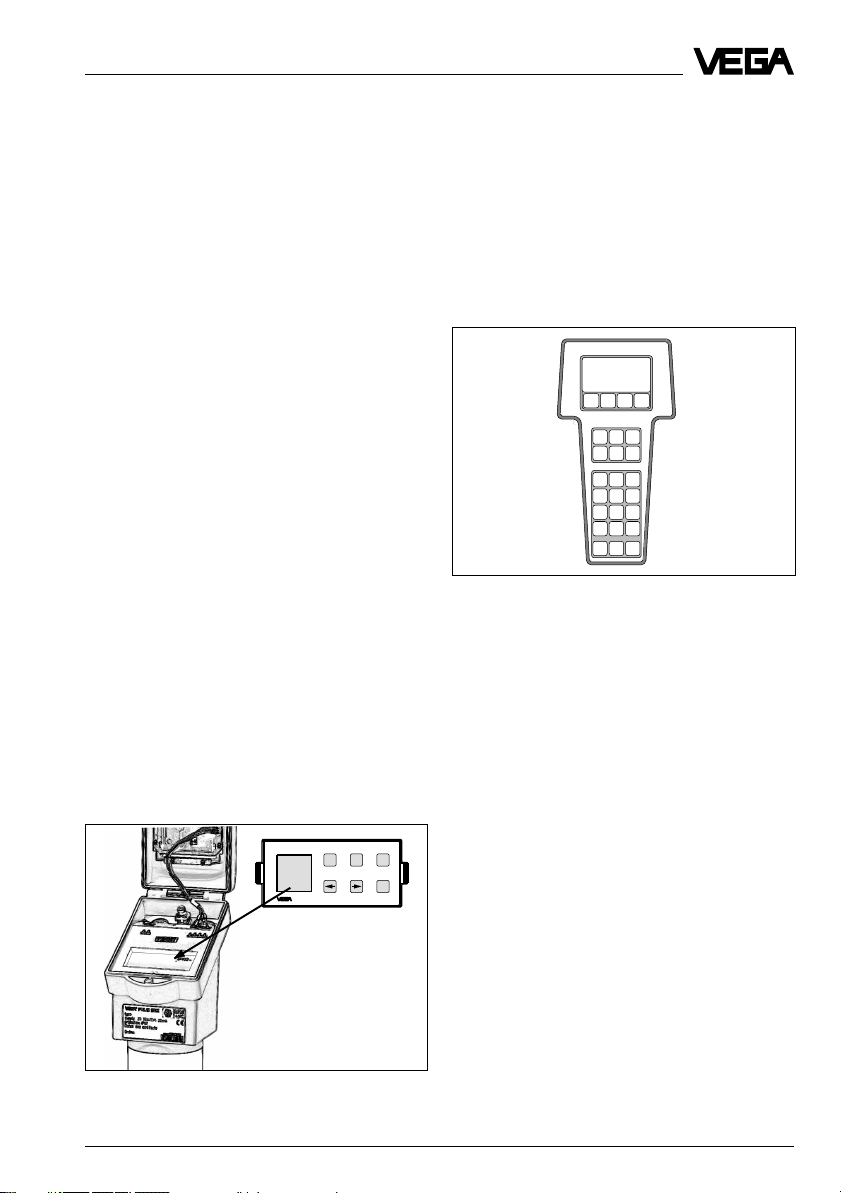

Adjustment with HART

®

handheld

Series 50 with 4 … 20 mA output signal can

also be adjusted with the HART

®

handheld or

via a PC with HART

®

software (e.g. Smart

version). A special DDD (Data Device De-

scription) is not necessary, so that the sen-

sors can be adjusted with the HART

®

standard menus of the handheld.

-

+

ESC

OK

Tank 1

m (d)

12.345

Detachable adjustment module MINICOM

Product description

Adjustment with PC

The setup and adjustment of the VEGAFLEX

sensors is generally made on the PC with the

adjustment program VEGA Visual Operating

(VVO) under Windows

®

.

The program leads

quickly through adjustment and parameter

setting by means of pictures, graphics and

process visualisations.

The PC can be connected to any individual

position of the system or the signal cable.

This is done by connecting the two-wire PC

interface converter VEGACONNECT 2 to the

sensor or the signal cable.

The adjustment and parameter setting data

can be saved with the adjustment software

on the PC and can be protected by pass-

words. On request, the adjustments can be

quickly transferred to other sensors.

Adjustment with adjustment module

MINICOM

With the small (3.2 cm x 6.7 cm) 6 key adjust-

ment module, the adjustment can be carried

out in clear text dialogue.

The adjustment module can be plugged into

VEGAFLEX or the external indicating instru-

ment VEGADIS 50.

Adjustment of VEGAFLEX from the external

indicating instrument VEGADIS 50 is there-

fore possible.

1.3 Types and versions

VEGAFLEX series 50 K

In general, all VEGAFLEX series 50 K sen-

sors can be adjusted with the pluggable

adjustment module MINICOM or with any

standard HART

®

handheld. With the software

VEGA Visual Operating (VVO), it is also pos-

sible to adjust the sensor with a PC.

4 … 20 mA sensors

Two-wire sensors fro connection to a power

supply unit or a PLC.

Compact sensors with mains supply

The sensors deliver a level-proportional

4 … 20 mA signal, which can be processed

in a PLC.

HART Communicator

HART

®

handheld

6 VEGAFLEX 51K

4

+

2

-

+

-

2

2

2 2

VEGADIS 50

VEGAFLEX

4 … 20 mA

VEGADIS 11

PLC

VEGADIS 371 Ex

Relay (4 x)

0/4 … 20 mA

4 … 20 mA

passive

4 … 20 mA

passive

1

2

3

separate power supply with

four-wire technology

Product description

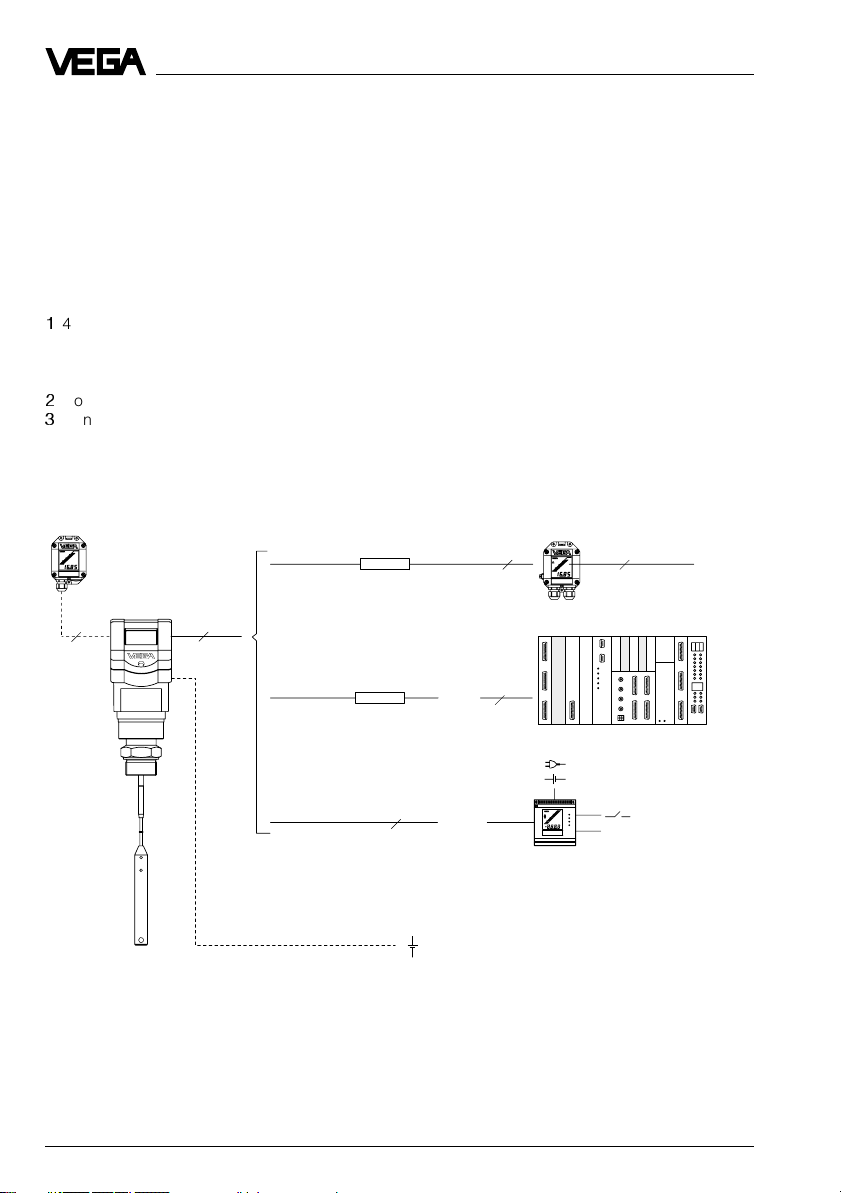

Configuration

A measuring system with a VEGAFLEX can

be realised in different ways (see following

figure).

The external indicating instrument VEGADIS

50 can be separated up to 25 m from the

sensor.

Two-wire technology

1

4 ... 20 mA sensor, supply and measuring

signal via one two-wire cable (loop-pow-

ered), indicating instrument VEGADIS 11

only possible in four-wire technology.

2

Connection to a PLC (active).

3

Connection to an indicating instrument

VEGADIS 371 with up to 4 relay outputs.

Four-wire technology

In addition to a two-wire signal cable, these

measuring systems have a separate supply

cable.

E.g. this is necessary when using a passive

PLC, the inputs of which cannot power the

connected sensors.

This cable is shown in the drawing as a bro-

ken line.

1)

1)

1)

only with HART

®

VEGAFLEX 51K 7

VEGAFLEX 51 K EXS.X X

B - 20…72 V DC, 20…250 V AC / 4 … 20 mA output, HART

®

D - Two-wire loop-powered / 4 … 20 mA output, HART

®

E - Supply via signal conditioning instrument / VBUS output

EXS - StEx Zone 10 approved

EX0 - Ex Zone 0 acc. to PTB and ATEX II 1/2 G

V - Digital output signal (two-wire technology)

K - Analogue 0 … 20 mA output signal (two or

four-wire technology)

Instrument series with 4 mm cable

Measuring technology (FLEX for guided microwave)

1.4 Type code

The second figure of the type name, e.g.

VEGAFLEX 5[1]… distinguishes the instru-

ments according to the stability of the cable.

The letter, e.g. VEGAFLEX 51[K] character-

ises the output signal:

K stands for an analogue 4 … 20 mA output

signal (compact instrument)

V stands for a digital output signal (VBUS).

Product description

8 VEGAFLEX 51K

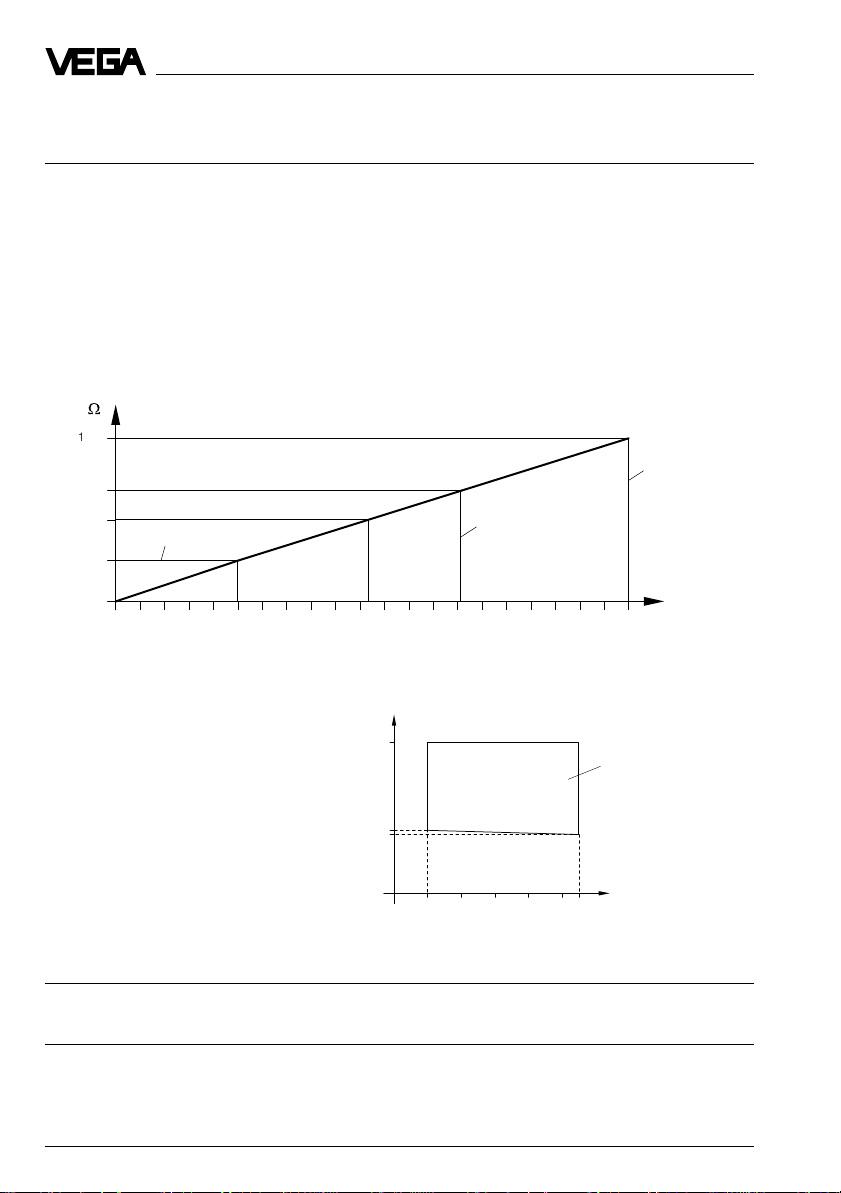

The min. supply voltage depends on the sensor current.

04 22

mA

14

15

36

V

Range of the required

terminal voltage on the

sensor

Sensor current

Product description

1.5 Technical data

Power supply

Supply voltage

- two-wire sensor 24 V DC (15 … 36 V DC)

- four-wire sensor 24 V DC (20 … 72 V)

230 V AC (20 … 250 V), 50/60 Hz

fuse 0.315 A TR

Current consumption

- two-wire sensor max. 22.5 mA

- four-wire sensor max. 60 mA

Power consumption

- two-wire sensor max. 810 mW

- four-wire sensor max. 1.2 W

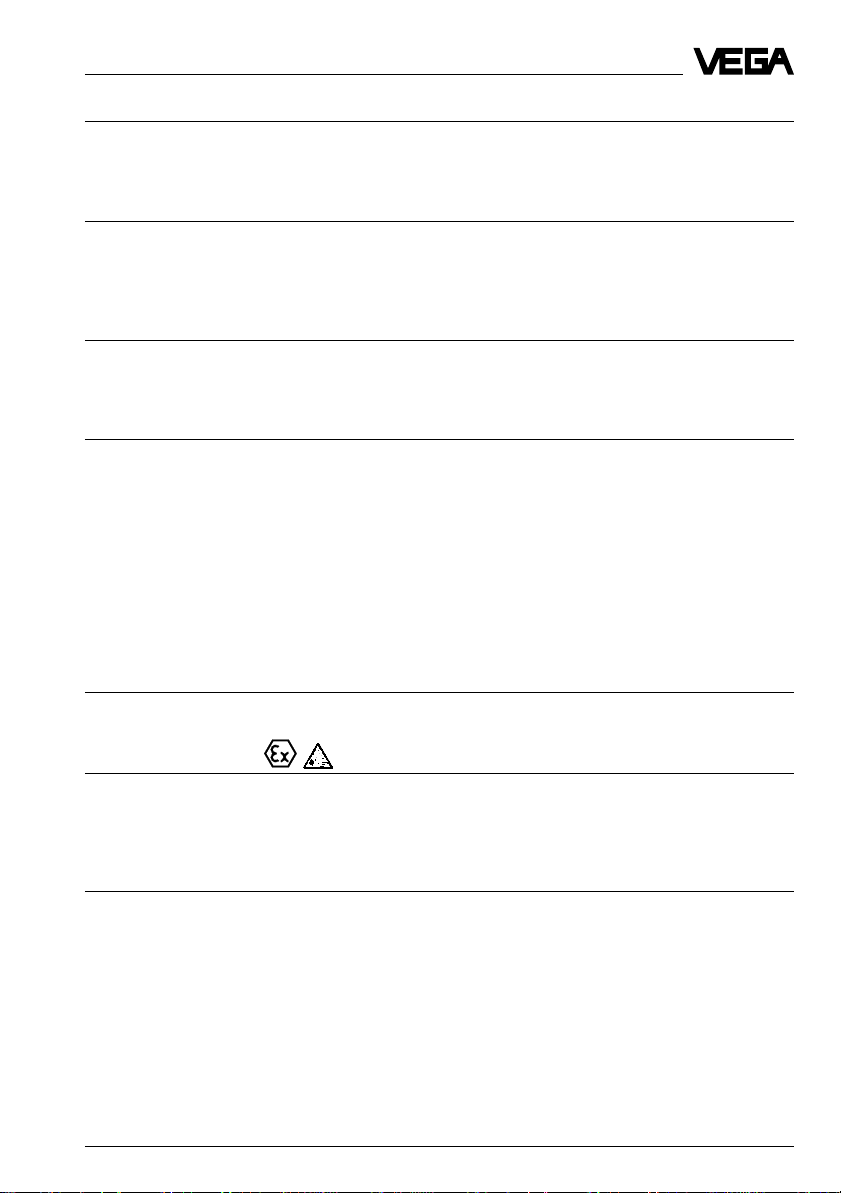

V

W

1000

680

500

250

0

20 22 24 26 28 30 32 34 3615 16 18

Voltage limit

non Ex sensor

Voltage limit

Ex sensor

HART

®

load

Voltage supply

Measuring range

VEGAFLEX 51 0.3 ... 10 m

Output signal

4 … 20 mA current signal, load max. 500 W

VEGAFLEX 51K 9

Product description

Adjustment

- PC and adjustment software VEGA Visual Operating

- adjustment module MINICOM

- HART

®

handheld

Accuracy (under reference conditions acc. to IEC 770 - relating to the max. meas. range)

Linearity error < 0.1 %

Temperature drift 0.015 %/10 K

Resolution of the 4 … 20 mA signal 0.025 % of range (DA converter)

Resolution 1 mm

Characteristics

Min. span between

full and empty adjustment

- analogue output signal 10 mm

Ambient conditions

Vessel pressure -1 … 16 bar

Ambient temperature on the housing -40°C … +60°C

Process temperature -40°C … +120°C

Storage and transport temperature -40°C … +80°C

Protection IP 66/IP 67 (meets both protection standards)

Protection class

- two-wire sensor II

- four-wire sensor I

Overvoltage category III

Max. tensile load cable ø 4 mm: 10 KN (check the max. tensile

load of the silo ceiling)

Process fittings

VEGAFLEX 51 G 1

1

/

2

A, 1

1

/

2

“ NPT

steel chromized or 1.4301 (stainless steel)

Ex technical data

StEx zone 10 (only two-wire sensors)

Ex-Zone 0 acc. to PTB and ATEX II 1/2 G

The permissible operating data of the VEGAFLEX sensors for Ex or StEx areas are listed in

the certificate.

Materials

Housing PBT (Valox) or

aluminium (powder-coated)

Cable 1.4401 (stainless steel; 316) or

galvanized steel - PA-coated

10 VEGAFLEX 51K

Product description

Connection cables

Two-wire sensor

- Supply and signal via one two-wire cable.

The cable resistance depends on the supply voltage (see diagram).

Four-wire sensor

- Supply and signal separate,

cable resistance of the 4 … 20 mA signal cable max. 500 W

Profibus PA sensor

- recommended cable types - SINEC 6XV1 830-5AH10 (Siemens AG)

- SINEC L2 6XV1 830-35H10 (Siemens AG)

- 3079 a (Belden)

- max. cable length 100 m field distributor to sensor

Conductor cross-section generally 2.5 mm

2

Ground connection max. 4 mm

2

Cable entry 2 x M20 x 1.5 (cable diameter 5 … 9 mm)

CE conformity

VEGAFLEX sensors meet the protective regulations of EMC (89/336/EWG) and NSR

(73/23/EWG). Conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010 - 1: 1993

Display

Display scalable, analogue and digital display of

measured values (option).

An external display of measured value, powered by the sensor, can be mounted at a dis-

tance of up to 25 m from the sensor.

Signal output

Signal output

- two-wire technology 4 … 20 mA (see diagram)

- four-wire technology 4 … 20 mA

Resolution of the 20 mA signal 0.025 % of range

Load 0 … 500 W

Two-wire technology:

The analogue 4 … 20 mA output signal (measuring signal) is transmitted together with the

power supply via one two-wire cable.

Four-wire technology:

Separate power supply.

The analogue 4 … 20 mA output signal (measuring signal) is transmitted in a cable sepa-

rated from the power supply.

Loading...

Loading...