VEGA D84 User Manual

p

Operating Instructions

Hydrostatic pressure

transmitters D84

2 Pressure transmitter D84

Contents

Contents

Safety information ........................................................................ 2

Note Ex area ................................................................................ 2

1 Product description

1.1 Function and configuration .................................................. 4

1.2 Electronics version without adjustment .............................. 5

1.3 Electronics version with integrated adjustment

in connection housing .......................................................... 7

1.4 Electronics for connection to VEGADIS 12 ........................ 8

1.5 Technical data ....................................................................... 9

1.6 Approvals and certificates ................................................ 13

1.7 Dimensions ......................................................................... 14

2 Mounting

2.1 Mounting instructions ......................................................... 18

2.2 Compensation of the atmospheric pressure ................... 18

Safety information

Please read this manual carefully, and also take

note of country-specific installation standards

(e.g. the VDE regulations in Germany) as well

as all prevailing safety regulations and acci-

dent prevention rules.

For safety and warranty reasons, any internal

work on the instruments, apart from that in-

volved in normal installation and electrical con-

nection, must be carried out only by qualified

VEGA personnel.

Note Ex area

Please note the attached safety instructions

containing important information on installation

and operation in Ex areas.

These safety instructions are part of the

operating instructions and come with the Ex

approved instruments.

Pressure transmitter D84 3

3 Electrical connection

3.1 Connection instructions ..................................................... 19

3.2 Terminal assignment .......................................................... 20

3.3 Connection to external connection housing

VEGABOX 01 ..................................................................... 21

3.4 Connection examples ........................................................ 22

4 Setup

4.1 Adjustment structure ......................................................... 23

4.2 Sensor without adjustment ................................................ 24

4.3 Sensor with adjustment insert, adjustment

in the sensor ....................................................................... 24

4.4 Setup with HART

®

handheld ............................................. 26

5.5 Adjustment with PC directly on the sensor ...................... 32

6 Diagnostics............................................................................... 40

7 Instrument modification

7.1 Retrofitting the adjustment insert ...................................... 41

7.2 Exchange of hygienic form seal on D84 .......................... 41

Contents

4 Pressure transmitter D84

Product description

1 Product description

1.1 Function and configuration

The pressure transmitter D84 is an efficient

instrument for hydrostatic level measurement.

A dry ceramic-capacitive CERTEC

®

measuring cell is used as pressure sensor

element.

Pressure transmitter D84

Measuring cell: dry, ceramic-capacitive

Diaphragm: flush, ceramic

Series: flanged version

Standard application: All kind of level

measurements, best suited for food

processing and pharmaceutical industries.

The pressure effects a capacitance change

on the measuring cell. This capacitance

change is detected by an ASIC (Application

Specific Integrated Circuit) and converted

into a pressure-proportional signal by the

integrated electronic module with

microcontroller. Precise, high-resolution digi-

tal processing of measurement data ensures

excellent technical data.

To improve reliability, the functionality of im-

portant electronic components is continu-

ously checked, and internal parameters such

as sensor value, temperature and operating

voltage are closely monitored.

Output signal

The output signal is transferred as a digital or

analogue signal from the pressure transmitter

to the signal conditioning instrument:

• analogue output signal

- unstandardised (in conjunction with

VEGA signal conditioning instrument)

- 4 … 20 mA standardised

• digital output signal (VBUS) for connection

to a digital VEGA signal conditioning instru-

ment (VEGAMET 514V, 515V or VEGALOG

571)

Pressure transmitter D84 5

Product description

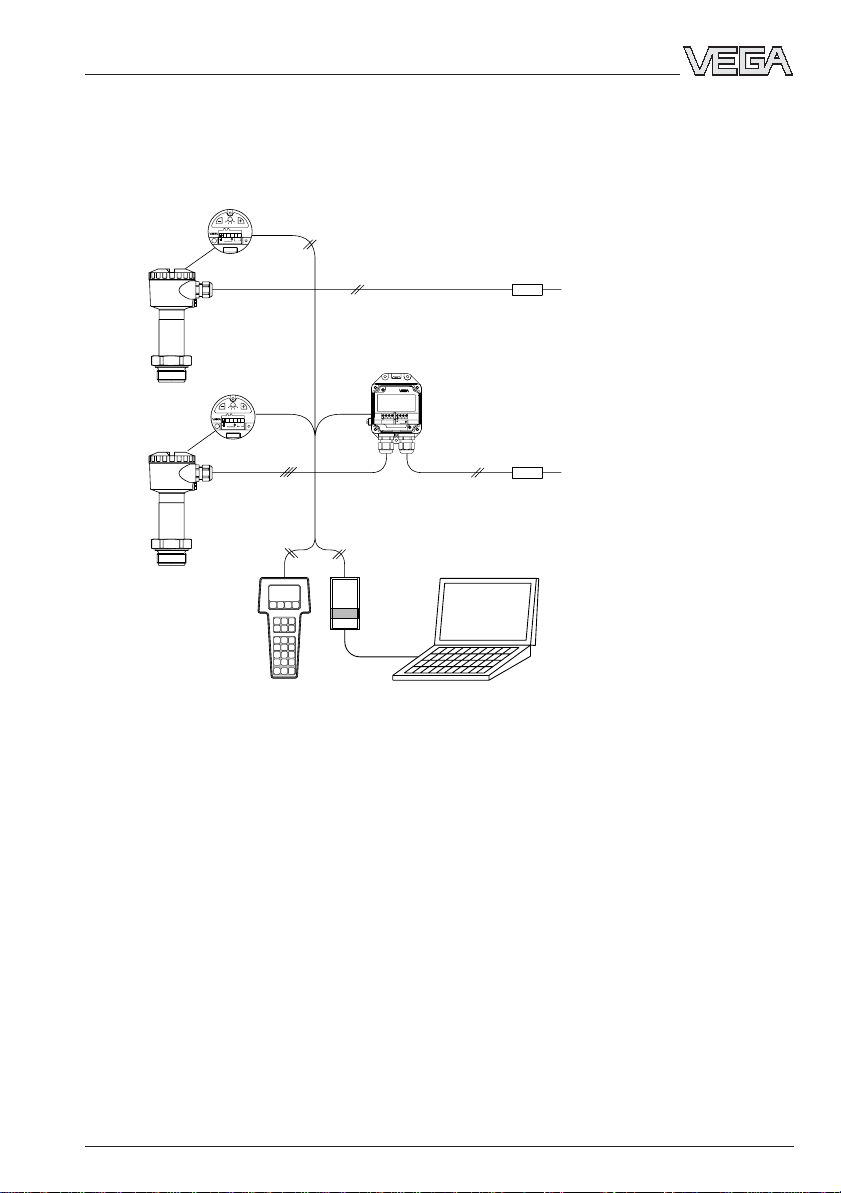

1.2 Electronics version without adjustment

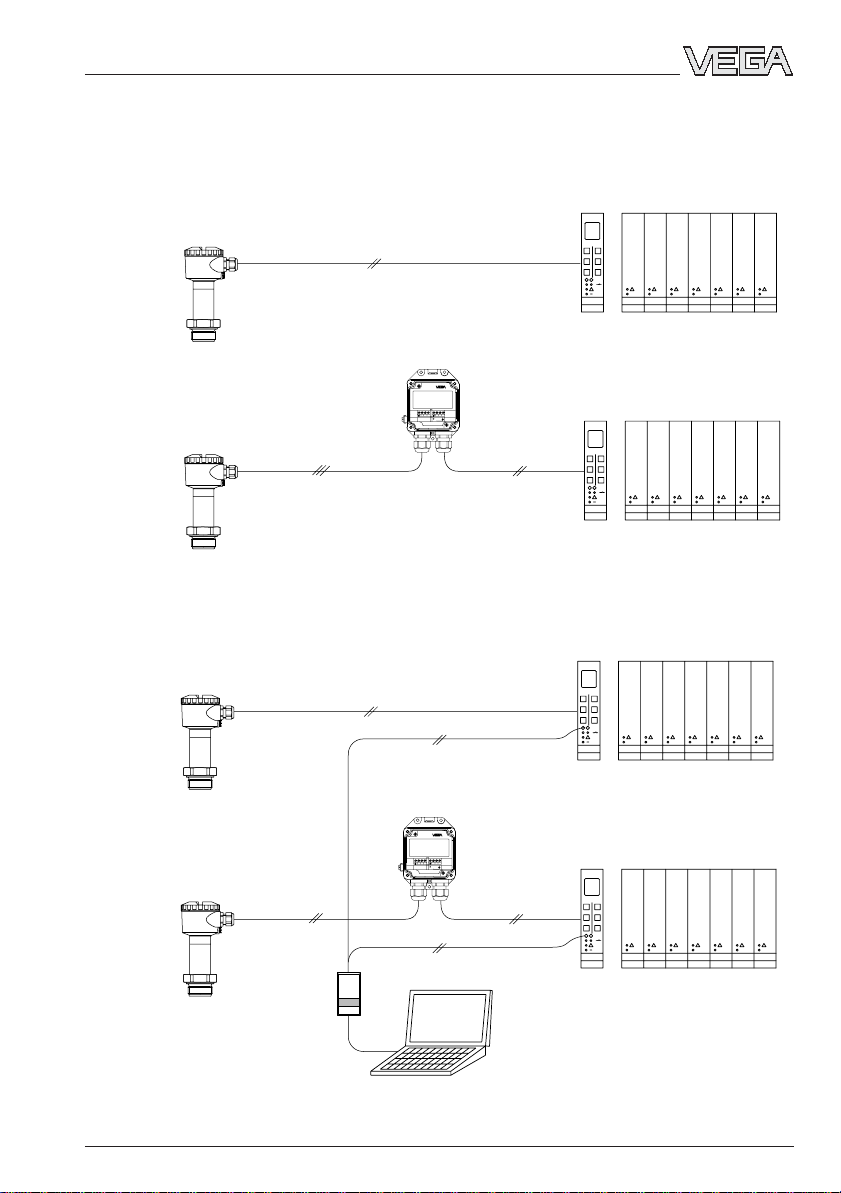

Electronics version B:

Pressure transmitter for connection to VEGA signal conditioning instruments (digital

transmission VBUS)

Electronics version A:

Pressure transmitter for connection to VEGA signal conditioning instruments

Zum Anschluss an

Druckmessumformer mit

analogem Ausgangssignal

VEGABOX 01

TRANSMITTER

-

+

+

-

For connection to

pressure transmitters with

analog output

1

23

10

11 12

Zum Anschluss an

Druckmessumformer mit

analogem Ausgangssignal

VEGABOX 01

TRANSMITTER

-

+

+

-

For connection to

pressure transmitters with

analog output

1

23

10

11 12

e.g. IP 66

e.g. IP 67

VEGABOX 01

VEGALOG

VEGALOG

VEGAMET

VEGAMET

VEGABOX 01

VEGALOG

VEGALOG

VEGAMET

VEGAMET

e.g. IP 66

e.g. IP 67

6 Pressure transmitter D84

Product description

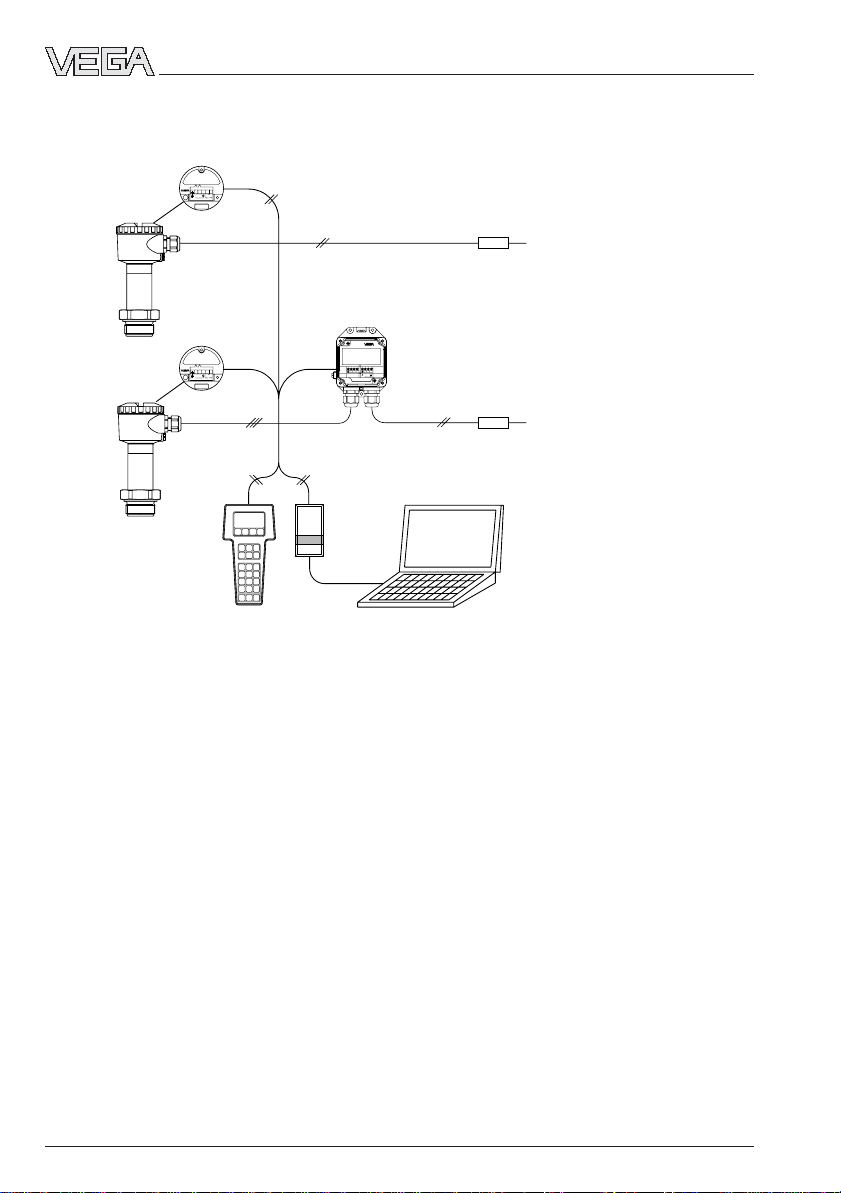

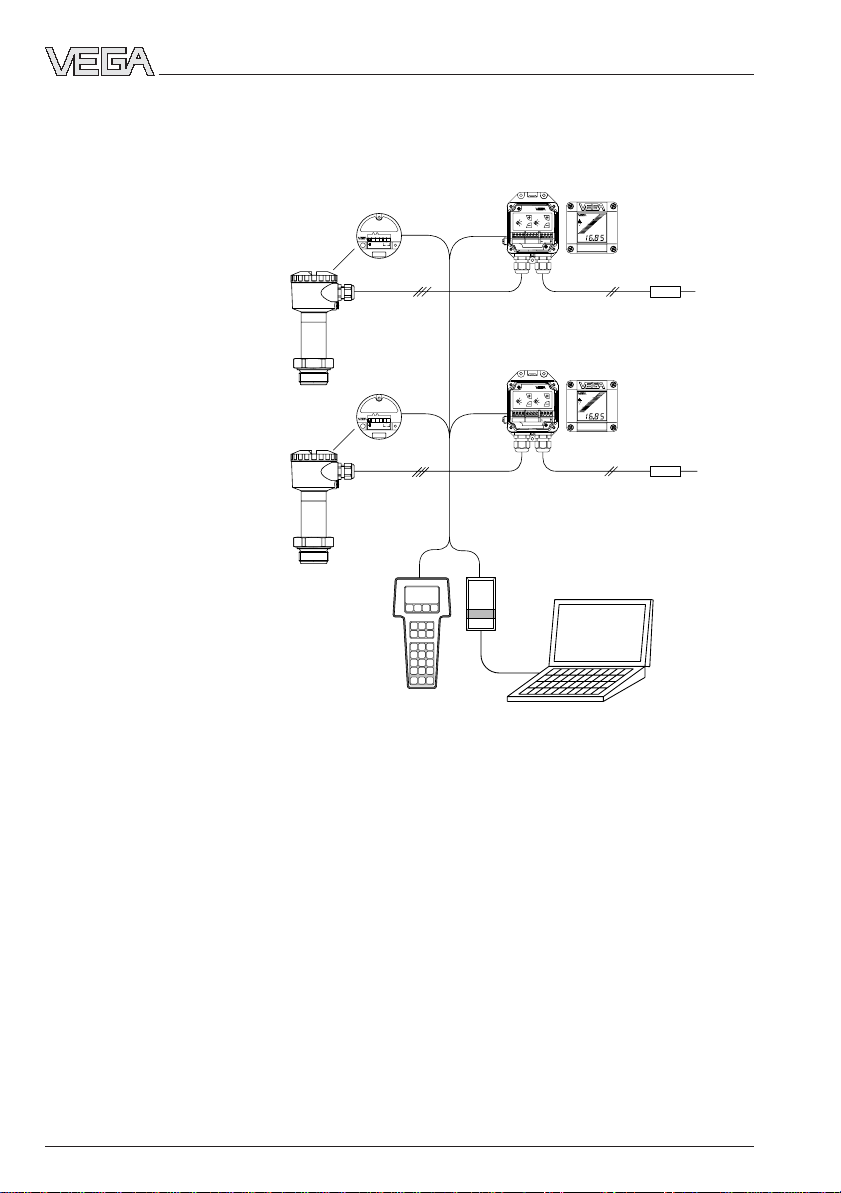

Electronics version I:

Pressure transmitter 4 … 20 mA, HA RT

®

, VVO

VVO

51234

4-20mA

terminal

Klemmeinsatz

+

-

12V...36V DC

4...20mA

51234

4-20mA

terminal

Klemmeinsatz

+

-

12V...36V DC

4...20mA

Zum Anschluss an

Druckmessumformer mit

analogem Ausgangssignal

VEGABOX 01

TRANSMITTER

-

+

+

-

For connection to

pressure transmitters with

analog output

1

23

10

11 12

VEGABOX 01

PLC/DCS

PLC/DCS

e.g. IP 66

e.g. IP 67

HART

®

handheld

250 Ω

250 Ω

Pressure transmitter D84 7

1.3 Electronics version with integrated adjustment in connection housing

Electronics version K:

Pressure transmitter 4 … 20 mA, HART

®

, VVO adjustable

VVO

Zum Anschluss an

Druckmessumformer mit

analogem Ausgangssignal

VEGABOX 01

TRANSMITTER

-

+

+

-

For connection to

pressure transmitters with

analog output

1

23

10

11 12

Bedieneinsatz

operating unit

S

Zt

i

Op

43215

+

-

12V...36V DC

4...20mA

Bedieneinsatz

operating unit

S

Zt

i

Op

43215

+

-

12V...36V DC

4...20mA

VEGABOX 01

PLC/DCS

PLC/DCS

e.g. IP 66

e.g. IP 67

Product description

HART

®

handheld

250 Ω

250 Ω

8 Pressure transmitter D84

1.4 Electronics for connection to VEGADIS 12

VEGADIS 12

DISPLAY

+ -

TRANSMITTER

5876321101112

OPERATE

POINT

DISPLAYTRANSMITTER

END

ZERO

OPERATE

POINT

END

ZERO

VEGADIS 12

DISPLAY

+ -

TRANSMITTER

5876321101112

OPERATE

POINT

DISPLAYTRANSMITTER

END

ZERO

OPERATE

POINT

END

ZERO

51234

VEGADIS 12

Zum Anschluß an

For connection to

+

-

12V...36V DC

terminal

Klemmeinsatz

51234

VEGADIS 12

Zum Anschluß an

For connection to

+

-

12V...36V DC

terminal

Klemmeinsatz

VEGADIS 12

PLC/

DCS

PLC/

DCS

VEGADIS 12

VVO

e.g. IP 66

e.g. IP 67

Product description

HART

®

handheld

250 Ω

250 Ω

Electronics version L:

Pressure transmitter 4 … 20 mA, HA RT

®

, VVO

Pressure transmitter D84 9

Product description

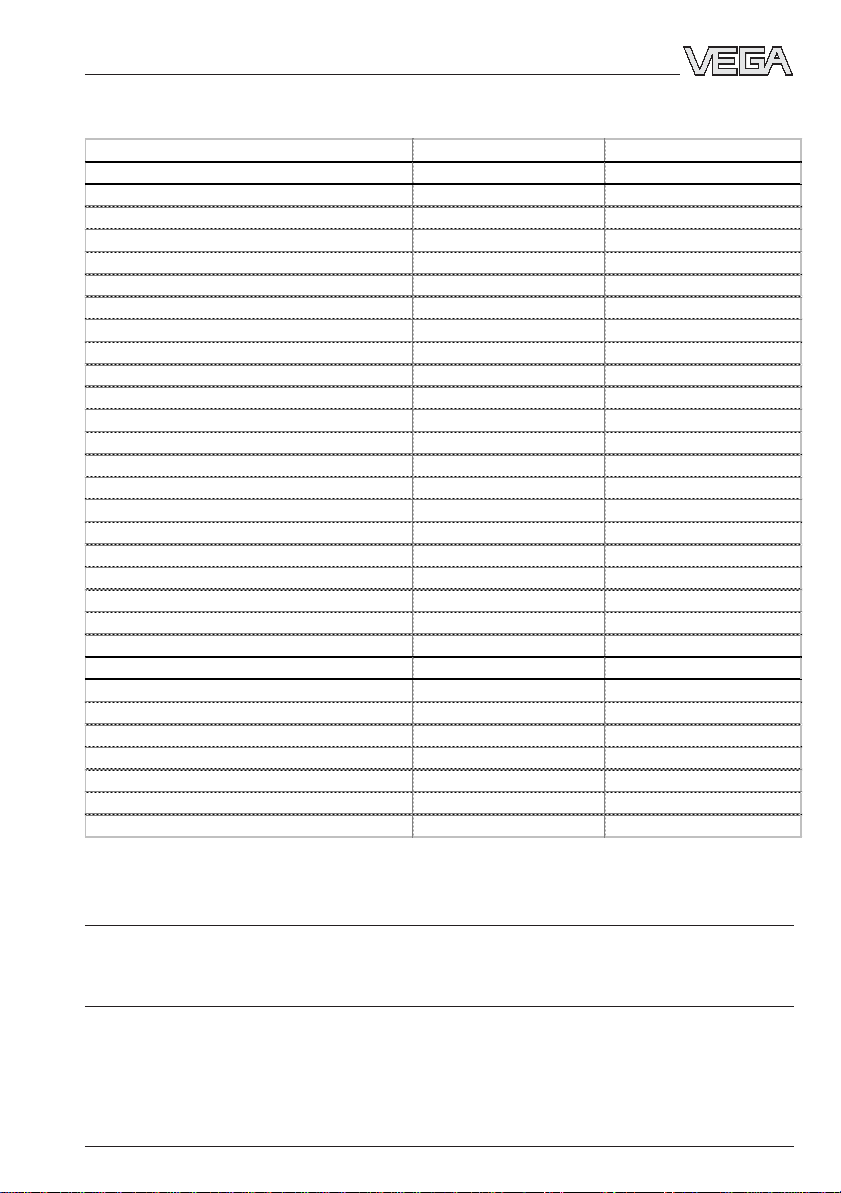

1.5 Technical data

Mechanical data

Materials, wetted parts

Process connection stainless steel 1.4435 or 1.4571

Diaphragm saphire-ceramic

®

Materials, non-wetted parts

Housing Alu (seawater resistant) Pe-powder coated,

stainless steel 1.4571

External connection housing high resistance plastic PBT (Polyester)

Ground terminal stainless steel 1.4305

Window of the display module safety glass

Nominal measuring range Gauge pr. resistance Low pr. re sistance

Gauge pressure

0…0.1 bar / 0…10 kPa 15 bar / 1 500 kPa -0.2 bar / -20 kPa

0…0.2 bar / 0…20 kPa 20 bar / 2 000 kPa -0.4 bar / -40 kPa

0…0.4 bar / 0…40 kPa 30 bar / 3 000 kPa -0.8 bar / -80 kPa

0…1.0 bar / 0…100 kPa 35 bar / 3 500 kPa -1.0 bar / -100 kPa

0…2.5 bar / 0…250 kPa 50 bar / 5 000 kPa -1.0 bar / -100 kPa

0…5.0 bar / 0…500 kPa 65 bar / 6 500 kPa -1.0 bar / -100 kPa

0…10.0 bar / 0…1 000 kPa 90 bar / 9 000 kPa -1.0 bar / -100 kPa

0…20.0 bar / 0…2 000 kPa 130 bar / 13 000 kPa -1.0 bar / -100 kPa

0…40.0 bar / 0…4 000 kPa 200 bar / 20 000 kPa -1.0 bar / -100 kPa

0…60.0 bar / 0…6 000 kPa 300 bar / 30 000 kPa -1.0 bar / -100 kPa

-0.05…+0.05 bar / -5…+5 kPa 15 bar / 1 500 kPa -0.2 bar / -20 kPa

-0.1…+0.1 bar / -10…+10 kPa 20 bar / 2 000 kPa -0.4 bar / -40 kPa

-0.2…+0.2 bar / -20…+20 kPa 30 bar / 3 000 kPa -0.8 bar / -80 kPa

-0.5…+0.5 bar / -50…+50 kPa 35 bar / 3 500 kPa -1.0 bar / -100 kPa

-1.0…0.0 bar / -100…0 kPa 35 bar / 3 500 kPa -1.0 bar / -100 kPa

-1.0…+1.5 bar / -100…+150 kPa 50 bar /5 000 kPa -1.0 bar / -100 kPa

-1.0…+4.0 bar / -100…+400 kPa 65 bar / 6 500 kPa -1.0 bar / -100 kPa

-1.0…+10.0 bar / -100…+1 000 k Pa 90 bar / 9 000 kPa -1.0 b ar / -100 k Pa

-1.0…+20.0 bar / -100…+2 000 kPa 130 bar / 13 000 kPa -1.0 bar / -100 kPa

-1.0 …+40.0 bar / -100…+4 000 kPa 200 bar / 20 000 kPa -1.0 bar / -100 kPa

-1.0…+60.0 bar / -100…+6 000 kPa 300 bar / 30 000 kPa -1.0 bar / -100 kPa

Absolute pressure

0…1.0 bar / 0…100 kPa 35 bar / 3 500 kPa

0…2.5 bar / 0…250 kPa 50 bar / 5 000 kPa

0…5.0 bar / 0 …500 kPa 65 bar / 6 500 kPa

0…10.0 bar / 0…1 000 kPa 90 bar / 9 000 kPa

0…20.0 bar / 0…2 000 kPa 130 bar / 13 000 kPa

0…40.0 bar / 0…4 000 kPa 200 bar / 20 000 kPa

0…60.0 bar / 0…6 000 kPa 300 bar / 30 000 kPa

10 Pressure transmitter D84

Weights

Basic weight without housing approx. 1.6 kg

External housing approx. 400 g

Adjustment and display elements

Pressure transmitter

- terminal insert without adjustment elements

- adjustment insert 2 keys, 1 rotary switch

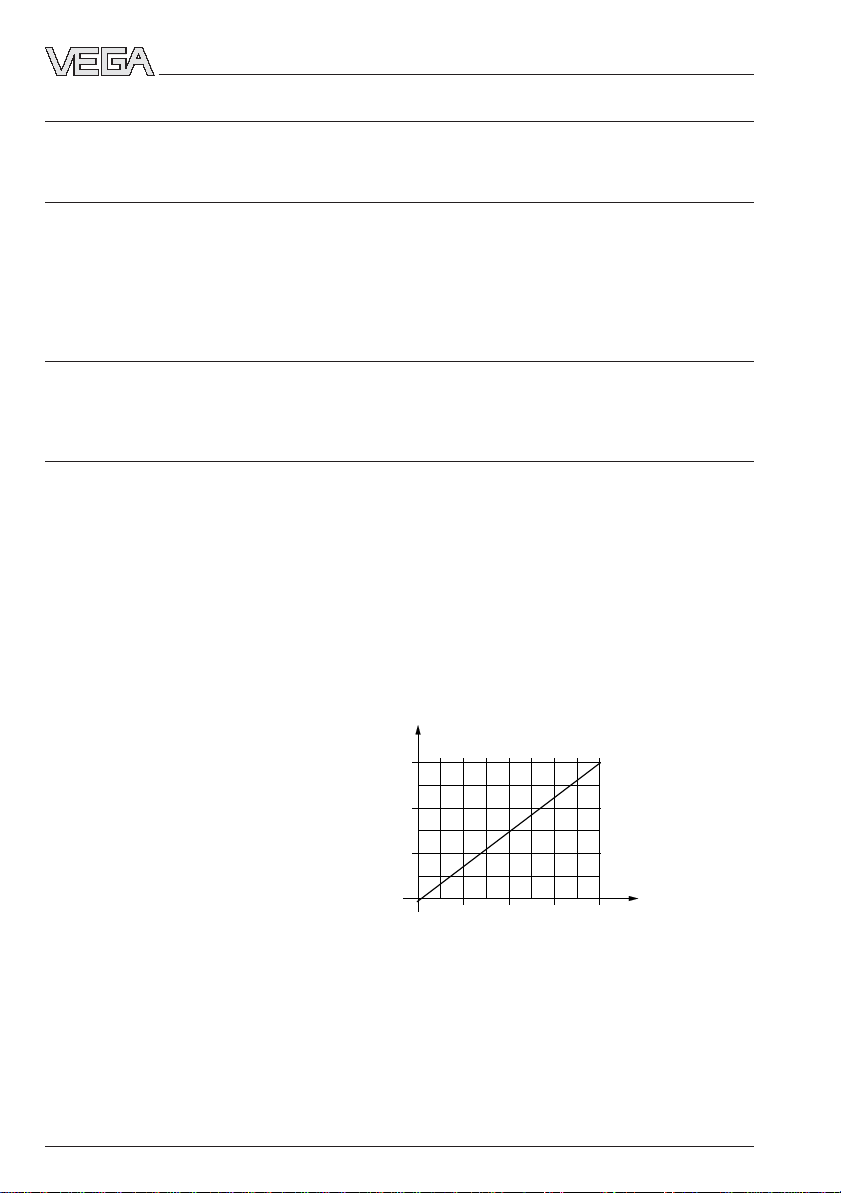

Electrical data

Adjustment ranges

Zero adjustable from -20 … +95 % of nominal range

Span adjustable from 3.3 … 120 % of nominal range

Supply and signal circuit (analogue transmission, 4 … 20 mA),

electronics version A, C, I and K

Supply voltage 12 … 36 V DC

permissible residual ripple U

SS

≤ 1 V

- at 100 Hz … 10 kHz U

SS

≤ 10 mV

Output signal

- terminal insert - analogue transmission (not standardised)

- 4 … 20 mA

- adjustment insert 4 … 20 mA (adjustable)

Current limitation approx. 22 mA

Fault signal 22 mA (3.6 mA)

Integration time 0 … 10 s

Rise time 70 ms (ti = 0 sec; 0 … 63 %)

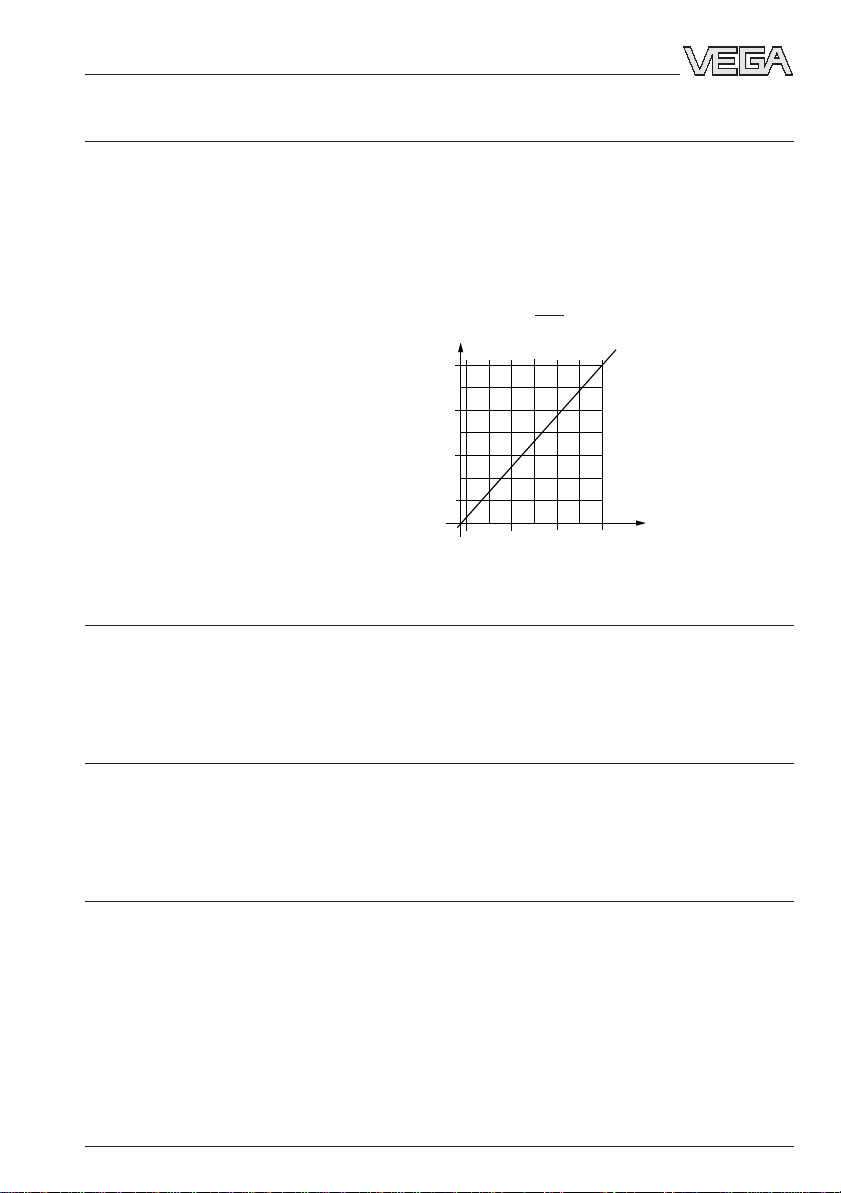

Max. permissible load see load diagram:

Product description

Load in Ω

12

300

600

900

18 24 30 36

Supply voltage

in V

Pressure transmitter D84 11

Product description

Supply and signal circuit (analogue transmission, 4 … 20 mA),

additional data for electronics version L

Supply voltage for pressure transmitters

in conjunction with VEGADIS 12

- without display 12 … 36 V DC

- with display 17 … 36 V DC

Max. input current 150 mA

Current signal range 3.5 … 22 mA

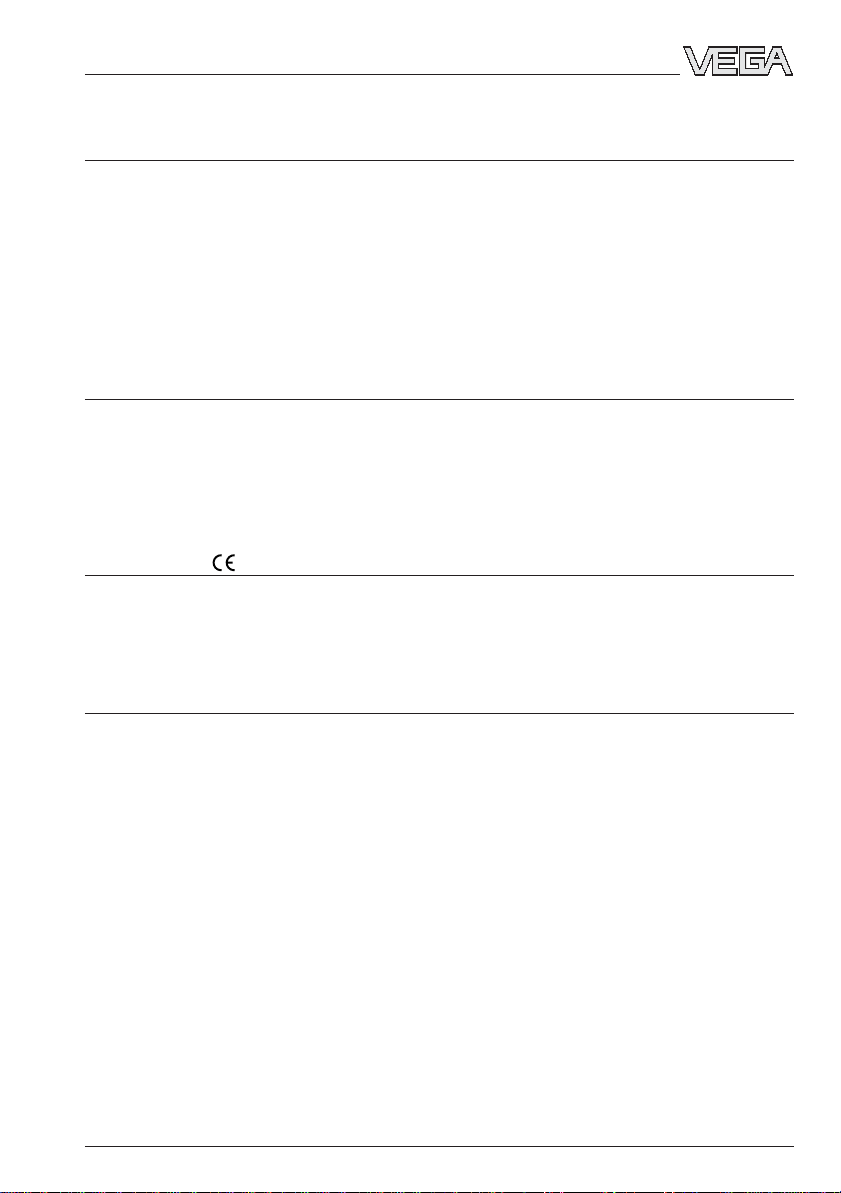

Max. permissible load see load diagram:

Load diagram with display

300

500

700

18

24 30 36

100

Load in Ω

Supply voltage

in V

Supply and signal circuit on VEGA signal conditioning instruments (digital signal

transmission VBUS), additional data for electronics version B

Supply voltage 25 … 36 V DC, from VEGAMET (VBUS) or

from VEGALOG 571 with EV input card

Data transmission digital (VBUS)

Connection cable 2-wire screened

Cable length max. 1000 m

Integrated overvoltage protection (option)

Nominal response DC voltage

- protective diode 40 V

- gas separator 650 V

Nominal leakage current

- gas separator 20 kA

Connection cables

Cable entry

- housing 2 x M20x1.5 (for cable ø 5…9mm or 9…12mm)

- external connection housing 2 x M20x1.5 (for cable ø 5…9mm or 9…12mm)

Screw terminals

- sensor for wire cross-sections of up to 2.5 mm

2

- external connection housing for wire cross-sections of up to 2.5 mm

2

12 Pressure transmitter D84

Protective measures

1)

Protection IP 66, IP 67, IP 68

VEGABOX 01 IP 66 and IP 67

Protection class III

Overvoltage category III

Accuracy (similar to DIN 16 086, DIN V 19 259 - 1 and IEC 770)

Deviation

Reference conditions (acc. to IEC 770)

- temperature 15°C … 30°C

- humidity 45 % … 75 %

- air pressure 86 kPa … 106 kPa

Determination of characteristics limit point adjustment acc. to DIN 16 086

Characteristics linear

Deviation in characteristics incl. hysteresis and repeatability

- Turn Down 1 : 1 < 0.25 % with accuracy class 0.25

< 0.1 % with accuracy class 0.1

- Turn Down up to 1 : 5 typ. < 0.3 % with accuracy class 0.25

typ. < 0.1 % with accuracy class 0.1

- Turn Down up to 1 : 10 typ. < 0.4 % with accuracy class 0.25

typ. < 0.2 % with accuracy class 0.1

Influence of the ambient temperature

Average temperature coefficient

of the zero signal

2)

- Turn Down 1 : 1 < 0.15 %/10 K with accuracy class 0.25

< 0.05 %/10 K with accuracy class 0.1

- Turn Down up to 1 : 5 typ. < 0.225 %/10 K with accuracy class 0.25

typ. < 0.075 %/10 K with accuracy class 0.1

- Turn Down up to 1 : 10 typ. < 0.3 %/10 K with accuracy class 0.25

typ. < 0.1 %/10 K with accuracy class 0.1

Long-term stability

Long-term stability of the zero signal

3)

< 0.1 % per 2 years

Other actuating variables

Calibration position upright, diaphragm points downwards

Influence of the installation position < 0.2 mbar/20 Pa

Vibration resistance mechanical vibrations with 4 g and

5 … 100 Hz, tested acc. to the regulations of

German Lloyd GL-characteristics 2

Product description

1)

Maintaining the housing protection IP 66 or IP 67 requires the use of a seal that correctly fits the cable in

the cable entry. If the supplied seal does not fit, a suitable seal must be provided by the customer.

2)

In compensated temperature range of 0°C … +80°C, reference temperature 20°C.

3)

Acc. to IEC 770, item 6.3.2 relating to the nominal range.

Pressure transmitter D84 13

Product description

Operating conditions

Ambient conditions

Ambient temperature -40°C … +85°C

- with indicating module -10°C … +60°C

Storage and transport temperature -50°C … +100°C

Product temperature

- Viton seal -20°C … +100°C

- EPDM seal -40°C … +100°C

- Kalrez seal 0°C … +100°C

1.6 Approvals and certificates

Approvals

- Ex Zone 2

- CENELEC EEx ia IIC

- ATEX II 1G EEx ia IIC

If the use of approved instruments is required for certain applications, the appropriate

official documents (test reports, test certificates and conformity certificates) must be ob-

served. These are supplied with the respective instrument.

CE conformity

D84 pressure transmitters meet the requirements of EMC (89/336/EWG) and NSR

(73/23/EWG). Conformity has been judged acc. to the following standards:

EMC Emission EN 50 081 - 1: 1992

Susceptibility EN 50 082 - 2: 1995

NSR EN 61 010: 1993

NAMUR regulations

Full compliance with the NAMUR regulations NE21 and NE 43.

14 Pressure transmitter D84

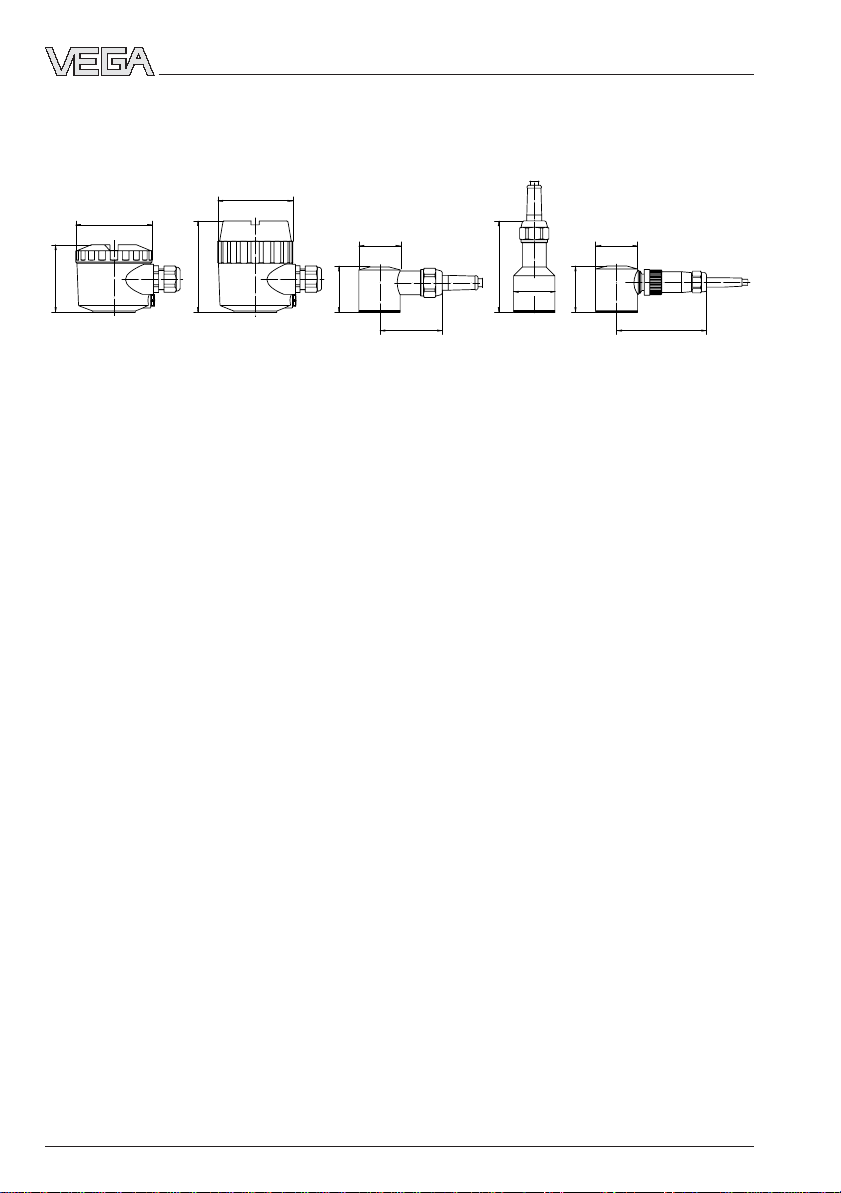

1.7 Dimensions

Housings

Product description

ø 76

67

ø 75

91

ø 41,6

46

63

ø 41,6

93

ø 41,6

46

90

Loading...

Loading...