VEGA BAR86 User Manual

Operating Instructions

Pressure transmitter with ceramic measuring cell

VEGABAR 86

Slave sensor for electronic differential pressure

Document ID: 45052

Contents

Contents

1 About this document |

4 |

|

1.1 |

Function............................................................................................................................ |

|

1.2 |

Target group...................................................................................................................... |

4 |

1.3 |

Symbolism used............................................................................................................... |

4 |

2 For your safety |

5 |

|

2.1 |

Authorised personnel........................................................................................................ |

|

2.2 |

Appropriate use................................................................................................................ |

5 |

2.3 |

Warning about incorrect use............................................................................................. |

5 |

2.4 |

General safety instructions................................................................................................ |

5 |

2.5 |

CE conformity................................................................................................................... |

5 |

2.6 |

Measuring range - permissible process pressure............................................................. |

6 |

2.7 |

Environmental instructions................................................................................................ |

6 |

3 Product description |

7 |

|

3.1 |

Configuration.................................................................................................................... |

|

3.2 |

Principle of operation........................................................................................................ |

8 |

3.3 |

Packaging, transport and storage................................................................................... |

10 |

3.4 |

Accessories and replacement parts................................................................................ |

11 |

4 Mounting |

12 |

|

4.1 |

General instructions to use the instrument...................................................................... |

|

4.2 |

Ventilation and pressure compensation.......................................................................... |

13 |

4.3 |

Combination Master - Slave............................................................................................ |

14 |

4.4 |

Differential pressure measurement................................................................................. |

15 |

4.5 |

Interface measurement................................................................................................... |

15 |

4.6 |

Density measurement..................................................................................................... |

16 |

4.7 |

External housing............................................................................................................. |

18 |

5 Connecting to power supply |

19 |

|

5.1 |

Preparing the connection................................................................................................ |

|

5.2 |

Connecting..................................................................................................................... |

19 |

5.3 |

Single chamber housing................................................................................................. |

20 |

5.4 |

External housing with version IP 68 (25 bar)................................................................... |

21 |

5.5 |

Connection example....................................................................................................... |

23 |

6 |

Set up with the display and adjustment module |

24 |

||

|

6.1 |

Parameter adjustment - Quick setup............................................................................... |

||

|

6.2 |

Parameter adjustment - Extended adjustment................................................................ |

27 |

|

7 |

Diagnosis, asset management and service |

37 |

||

|

7.1 |

Maintenance................................................................................................................... |

||

|

7.2 |

Rectify faults................................................................................................................... |

37 |

|

|

7.3 |

Exchanging the electronics module................................................................................ |

37 |

|

|

7.4 |

Exchange process assembly with version IP 68 (25 bar)................................................ |

37 |

|

|

7.5 |

How to proceed in case of repair..................................................................................... |

39 |

|

8 |

Dismounting |

40 |

||

|

8.1 |

Dismounting steps.......................................................................................................... |

||

|

8.2 |

Disposal.......................................................................................................................... |

40 |

|

9 |

Supplement |

41 |

||

|

9.1 |

Technical data................................................................................................................. |

||

|

|

|

|

|

2 |

|

VEGABAR 86 • Slave sensor for electronic differential pressure |

||

131011-EN-45052

45052-EN-131011

Contents

9.2 Dimensions..................................................................................................................... |

47 |

Safety instructions for Ex areas

Please note the Ex-specific safety information for installation and operation in Ex areas.These safety instructions are part of the operating instructions manual and come with the Ex-approved instruments.

Editing status: 2013-10-09

VEGABAR 86 • Slave sensor for electronic differential pressure |

3 |

1 About this document

1 About this document

1.1Function

This operating instructions manual provides all the information you need for mounting, connection and setup as well as important instructions for maintenance and fault rectification.Please read this information before putting the instrument into operation and keep this manual accessible in the immediate vicinity of the device.

1.2Target group

This operating instructions manual is directed to trained specialist personnel.The contents of this manual should be made available to these personnel and put into practice by them.

1.3Symbolism used

•

→

Information, tip, note

This symbol indicates helpful additional information.

Caution: If this warning is ignored, faults or malfunctions can result.

Warning: If this warning is ignored, injury to persons and/or serious damage to the instrument can result.

Danger: If this warning is ignored, serious injury to persons and/or destruction of the instrument can result.

Ex applications

This symbol indicates special instructions for Ex applications.

List

The dot set in front indicates a list with no implied sequence.

Action

This arrow indicates a single action.

1Sequence of actions

Numbers set in front indicate successive steps in a procedure.

Battery disposal

This symbol indicates special information about the disposal of batteries and accumulators.

131011-EN-45052

4 |

VEGABAR 86 • Slave sensor for electronic differential pressure |

45052-EN-131011

2 For your safety

2 For your safety

2.1Authorised personnel

All operations described in this operating instructions manual must be carried out only by trained specialist personnel authorised by the plant operator.

During work on and with the device the required personal protective equipment must always be worn.

2.2Appropriate use

VEGABAR 86 is a slave sensor for electronic differential pressure measurement.

You can find detailed information on the application range in chapter

"Product description".

Operational reliability is ensured only if the instrument is properly used according to the specifications in the operating instructions manual as well as possible supplementary instructions.

2.3Warning about incorrect use

Inappropriate or incorrect use of the instrument can give rise to application-specific hazards, e.g.vessel overfill or damage to system components through incorrect mounting or adjustment.

2.4General safety instructions

This is a high-tech instrument requiring the strict observance of standard regulations and guidelines. The user must take note of the safety instructions in this operating instructions manual, the country-specific installation standards as well as all prevailing safety regulations and accident prevention rules.

The instrument must only be operated in a technically flawless and reliable condition.The operator is responsible for trouble-free operation of the instrument.

During the entire duration of use, the user is obliged to determine the compliance of the necessary occupational safety measures with the current valid rules and regulations and also take note of new regulations.

2.5CE conformity

The device fulfills the legal requirements of the applicable EC guidelines.By affixing the CE marking, we confirm successful testing of the product.

You can find the CE Certificate of Conformity in the download section of our homepage.

VEGABAR 86 • Slave sensor for electronic differential pressure |

5 |

2 For your safety

2.6Measuring range - permissible process pressure

The permissible process pressure is specified on the type label with "process pressure", see chapter "Configuration". For safety reasons, this range must not be exceeded. This applies also if a measuring cell with higher measuring range (order-related) than the permissible pressure range of the process fitting is installed.

2.7Environmental instructions

Protection of the environment is one of our most important duties.

That is why we have introduced an environment management system with the goal of continuously improving company environmental protection.The environment management system is certified according to DIN EN ISO 14001.

Please help us fulfill this obligation by observing the environmental instructions in this manual:

•

•

Chapter "Packaging, transport and storage"

Chapter "Disposal"

131011-EN-45052

6 |

VEGABAR 86 • Slave sensor for electronic differential pressure |

45052-EN-131011

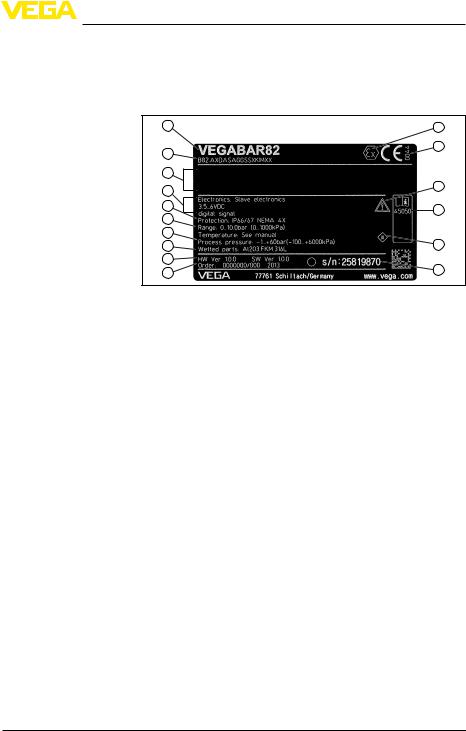

Type plate

Serial number

3 Product description

3 Product description

3.1Configuration

The nameplate contains the most important data for identification and use of the instrument:

1 |

16 |

2 |

15 |

|

3

4 |

14 |

|

5 |

13 |

6 |

|

7 |

12 |

|

8 |

||

9 |

11 |

|

10 |

||

|

Fig.1:Layout of the type label (example)

1 Instrument type

2 Product code

3Field for approvals

4 Power supply and signal output, electronics

5 Protection rating

6Measuring range

7 Permissible process pressure

8Material, wetted parts

9 Hardware and software version

10Order number

11Serial number of the instrument

12Symbol of the device protection class

13ID numbers, instrument documentation

14Reminder to observe the instrument documentation

15Notified authority for CE marking

16Approval directive

The type label contains the serial number of the instrument.With it you can find the following data on our homepage:

•Product code of the instrument (HTML)

•Delivery date (HTML)

•Order-specific instrument features (HTML)

•Operating instructions at the time of shipment (PDF)

•Order-specific sensor data for an electronics exchange (XML)

•Test certificate pressure transmitters (PDF)

Go to www.vega.com, "VEGATools" and "Serial number search".

As an alternative, you can find the data via your Smartphone:

•Download the smartphone app "VEGATools" from the "Apple App Store" or the "Google Play Store"

•Scan the Data Matrix code on the type label of the instrument or

•Enter the serial number manually in the app

VEGABAR 86 • Slave sensor for electronic differential pressure |

7 |

3 Product description

Scope of this operating |

This operating instructions manual applies to the following instrument |

||

instructions manual |

versions: |

||

|

• |

Hardware from 1.0.0 |

|

|

• |

Software version from 1.0.0 |

|

Scope of delivery |

The scope of delivery encompasses: |

||

|

• |

VEGABAR 86 pressure transmitter |

|

|

• |

Connection cable to the master sensor |

|

|

• |

Cable gland for the master sensor |

|

|

• |

Documentation |

|

|

–– |

this operating instructions manual |

|

|

|

–– |

Test certificate measuring accuracy (optional) |

|

|

–– |

Supplementary instructions manual "Plug connector for con- |

|

|

–– |

tinuously measuring sensors" (optional) |

|

|

Ex-specific "Safety instructions" (with Ex versions) |

|

|

|

–– |

if necessary, further certificates |

|

3.2 |

Principle of operation |

|

Electronic differential |

The VEGABAR 86 slave sensor is combined with a sensor from the |

||

pressure measurement |

VEGABAR 80 series for electronic differential pressure measurement. |

||

|

The sensors are connected via a screened four-wire cable. The |

||

|

measured value from the slave sensor is read in and factored into the |

||

|

calculations. Parameter adjustment is carried out through the master |

||

|

sensor. |

||

Measured variables |

The differential pressure measurement is suitable for the measure- |

||

|

ment of the following process variables: |

||

|

• |

Level |

|

|

• |

Flow |

|

|

• |

Differential pressure |

|

|

• |

Density |

|

|

• |

Interface |

|

131011-EN-45052

8 |

VEGABAR 86 • Slave sensor for electronic differential pressure |

3 Product description

45052-EN-131011

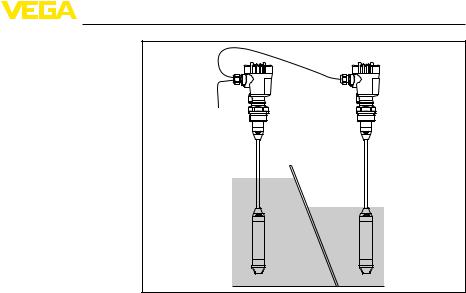

|

Fig.2:Electronic level difference measurement through Master/Slave combina- |

|

|

tion |

|

Electronic differential |

The VEGABAR 86 slave sensor is combined with a sensor from the |

|

pressure measurement |

VEGABAR 80 series for electronic differential pressure measurement. |

|

|

The sensors are connected via a screened four-wire cable. The |

|

|

measured value from the slave sensor is read in and factored into the |

|

|

calculations. Parameter adjustment is carried out through the master |

|

|

sensor. |

|

Application area |

TheVEGABAR 86 is a suspension pressure transmitter for level |

|

|

measurement in wells, basins and open vessels.Its great flexibility |

|

|

through different cable and tube versions allows the instrument to be |

|

|

used in many different applications. |

|

Measured products |

Measured products are liquids. |

|

|

Depending on the instrument version and measurement setup, meas- |

|

|

ured products can be also viscous or contain abrasive substances. |

|

Measuring system |

Sensor element is the CERTEC® measuring cell with robust ceramic |

|

|

diaphragm.The process pressure deflects the ceramic diaphragm |

|

|

and causes a capacitance change in the measuring cell.This capaci- |

|

|

tance change is converted into an electrical signal and outputted as |

|

|

measured value via the output signal. |

|

Pressure types |

The measuring cell design depends on the selected pressure type. |

|

|

Relative pressure:the measuring cell is open to atmosphere.The |

|

|

ambient pressure is detected in the measuring cell and compensated. |

|

|

It thus has no influence on the measured value. |

|

|

|

|

VEGABAR 86 • Slave sensor for electronic differential pressure |

9 |

|

3 Product description

|

Absolute pressure:the measuring cell is evacuated and encapsu- |

|

lated.The ambient pressure is not compensated and does hence |

|

influence the measured value. |

|

Relative pressure, climate-compensated: the measuring cell is |

|

evacuated and encapsulated.The ambient pressure is detected |

|

through a reference sensor in the electronics and compensated.It |

|

thus has no influence on the measured value. |

Seal concept |

The following illustration shows the installation of the CERTEC® |

|

measuring cell in the transmitter as well as the sealing concept. |

|

1 |

|

2 |

|

3 |

|

4 |

|

5 |

|

Fig.3:Front-flush installation of the CERTEC® measuring cell with double seal |

1 Housing, transmitter

2Measuring cell

3Lateral seal for measuring cell

4 Additional, front seal for measuring cell

5Diaphragm

|

3.3 Packaging, transport and storage |

||

Packaging |

Your instrument was protected by packaging during transport.Its |

||

|

capacity to handle normal loads during transport is assured by a test |

||

|

based on ISO 4180. |

||

|

The packaging of standard instruments consists of environment- |

||

|

friendly, recyclable cardboard.For special versions, PE foam or PE |

||

|

foil is also used.Dispose of the packaging material via specialised |

||

|

recycling companies. |

||

Transport |

Transport must be carried out in due consideration of the notes on the |

||

|

transport packaging.Nonobservance of these instructions can cause |

||

|

damage to the device. |

||

Transport inspection |

The delivery must be checked for completeness and possible transit |

||

|

damage immediately at receipt.Ascertained transit damage or con- |

||

|

cealed defects must be appropriately dealt with. |

||

Storage |

Up to the time of installation, the packages must be left closed and |

||

|

stored according to the orientation and storage markings on the |

||

|

outside. |

||

|

Unless otherwise indicated, the packages must be stored only under |

||

|

the following conditions: |

||

|

• |

Not in the open |

|

|

• |

Dry and dust free |

|

10 |

|

VEGABAR 86 • Slave sensor for electronic differential pressure |

|

131011-EN-45052

|

|

|

3 Product description |

|

|

• |

Not exposed to corrosive media |

|

|

• |

Protected against solar radiation |

|

|

• |

Avoiding mechanical shock and vibration |

Storage and transport |

• |

Storage and transport temperature see chapter "Supplement - |

|

temperature |

Technical data - Ambient conditions" |

||

|

|

• |

Relative humidity 20 … 85 % |

|

|

3.4 Accessories and replacement parts |

|

Protective cap |

The protective cover protects the sensor housing against soiling and |

||

|

|

intense heat from solar radiation. |

|

|

|

You will find additional information in the supplementary instructions |

|

|

|

manual "Protective cover" (Document-ID 34296). |

|

Flanges |

Screwed flanges are available in different versions according to the |

||

|

|

following standards: DIN 2501, EN 1092-1, BS 10, ANSI B 16.5, |

|

|

|

JIS B 2210-1984, GOST 12821-80. |

|

|

|

You can find additional information in the supplementary instructions |

|

|

|

manual "Flanges according to DIN-EN-ASME-JIS" (Document-ID |

|

|

|

31088). |

|

Welded socket |

Welded sockets are used to connect the sensors to the process. |

||

|

|

You can find further information in the supplementary instructions |

|

|

|

"Welded socketVEGABAR series 80" (Document-ID 45082). |

|

Electronics module |

The electronics moduleVEGABAR series 80 is a replacement part |

||

|

|

for pressure transmitters ofVEGABAR series 80.There is a different |

|

|

|

version available for each type of signal output. |

|

You can find further information in the operating instructions "Electronics moduleVEGABAR series 80" (Document-ID 45054).

45052-EN-131011

VEGABAR 86 • Slave sensor for electronic differential pressure |

11 |

4 Mounting

4 Mounting

4.1 General instructions to use the instrument

Suitability for the process Make sure that all parts of the instrument exposed to the process are |

|

conditions |

suitable for the existing process conditions. |

These are mainly:

•Active measuring component

•Process fitting

•Process seal

Process conditions are particularly:

•Process pressure

•Process temperature

•Chemical properties of the medium

•Abrasion and mechanical influences

You can find the specifications of the process conditions in chapter "Technical data" as well as on the nameplate.

Protection against mois- |

Protect your instrument further through the following measures |

|

ture |

against moisture penetration: |

|

|

• |

Use the recommended cable (see chapter "Connecting to power |

|

supply") |

|

|

• |

Tighten the cable gland |

|

• |

Loop the connection cable downward in front of the cable gland |

|

This applies particularly to: |

|

|

• |

Outdoor mounting |

|

• |

Installations in areas where high humidity is expected (e.g.through |

|

cleaning processes) |

|

|

• |

Installations on cooled or heated vessels |

Screwing in |

On instruments with process fitting thread, the hexagon must be tight- |

|

|

ened with a suitable screwdriver.Wrench size see chapter "Dimen- |

|

|

sions". |

|

|

Warning: |

|

|

The housing must not be used to screw the instrument in! Applying |

|

|

tightening force can damage internal parts of the housing. |

|

Vibrations |

In case of strong vibrations at the mounting location, the instrument |

|

|

version with external housing should be used.See chapter "External |

|

|

housing". |

|

Temperature limits |

Higher process temperatures often mean also higher ambient |

|

|

temperatures.Make sure that the upper temperature limits stated in |

|

|

chapter "Technical data" for the environment of the electronics hous- |

|

|

ing and connection cable are not exceeded. |

|

12 |

VEGABAR 86 • Slave sensor for electronic differential pressure |

131011-EN-45052

4 Mounting

|

|

|

1 |

|

|

|

2 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

Fig.4:Temperature ranges |

||||||

|

1 |

Process temperature |

|||||

|

2 |

Ambient temperature |

|||||

|

4.2 Ventilation and pressure compensation |

||||||

Filter elements |

Ventilation and pressure compensation are carried out withVE- |

||||||

|

GABAR 86 via a filter element.It is air permeable and moisture- |

||||||

|

blocking. |

||||||

|

Caution: |

||||||

|

The filter element causes a time-delayed pressure compensation. |

||||||

|

When quickly opening/closing the housing cover, the measured value |

||||||

|

can change for approx.5 s by up to 15 mbar. |

||||||

|

For effective ventilation, the filter element must always be free of |

||||||

|

buildup. |

||||||

|

Caution: |

||||||

|

Do not use a high-pressure cleaner.The filter element could be dam- |

||||||

|

aged, which would allow moisture into the housing. |

||||||

|

The following paragraphs describe how the filter element is arranged |

||||||

|

in the different instrument versions. |

||||||

Instruments in non-Ex |

The filter element is mounted into the electronics housing.It has the |

||||||

and Ex-ia version |

following functions: |

||||||

|

• |

Ventilation electronics housing |

|||||

|

• |

Atmospheric pressure compensation (with relative pressure meas- |

|||||

|

|

|

uring ranges) |

||||

45052-EN-131011

VEGABAR 86 • Slave sensor for electronic differential pressure |

13 |

4 Mounting

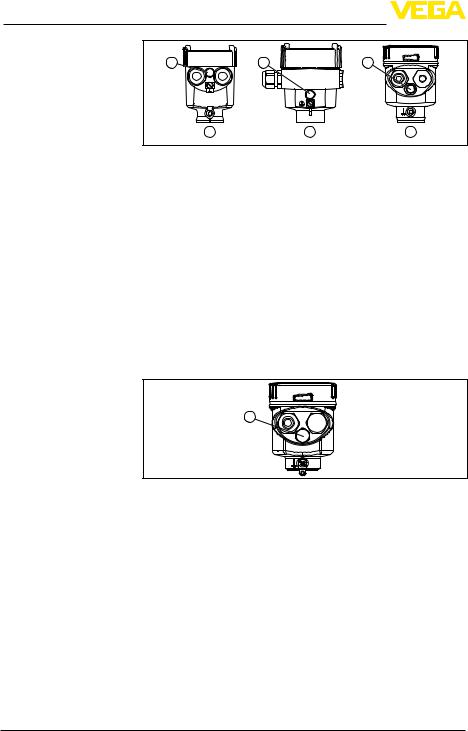

4 |

4 |

4 |

Instruments in IP 69K version

14

1 |

2 |

3 |

Fig.5:Position of the filter element - non-Ex, Ex-ia version 1 Housing plastic, stainless steel precision casting

2Housing aluminium

3 Housing stainless steel, electropolished

4Filter element

With the following instruments a blind plug is installed instead of the filter element:

•Instruments in protection IP 66/IP 68 (1 bar) - ventilation via capillaries in fix connected cable

•Instruments with absolut pressure

The filter element is mounted into the electronics housing.It has the following functions:

• |

Ventilation electronics housing |

• |

Atmospheric pressure compensation (with relative pressure meas- |

|

uring ranges) |

|

1 |

Fig.6:Position of the filter element - IP 69K version

1Filter element

Instruments with absolute pressure have a blind plug mounted instead of the filter element.

4.3Combination Master - Slave

In principle, any sensor combination within theVEGABAR 80 series is allowed.The following requirements must be fulfilled:

• |

pressureConfiguration, Master sensor suitable for electronic differential |

|

• |

Pressure type is identical for both sensors, i.e.relative pressure/ |

-EN-45052 |

relative pressure or absolute pressure/absolute pressure |

||

• |

The master sensor must always measure the higher pressure |

|

• |

Measurement setup as shown in the following chapters |

|

|

|

131011 |

VEGABAR 86 • Slave sensor for electronic differential pressure

|

|

4 Mounting |

|

|

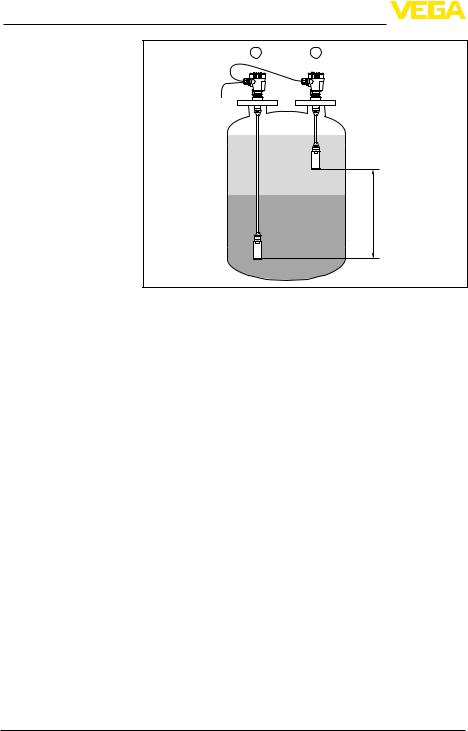

4.4 Differential pressure measurement |

Measurement setup |

With the Master/Slave combination, a gauge different measurement |

|

|

|

can be realized. |

1  2

2

3

|

Fig.7:Measurement setup with a level difference measurement |

|

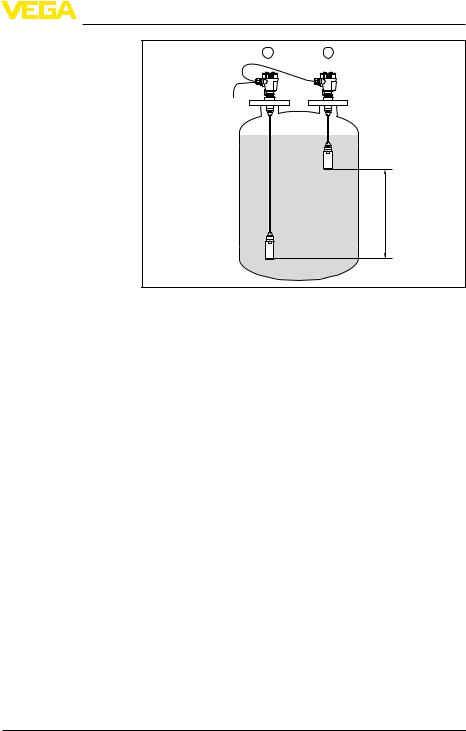

4.5 Interface measurement |

Measurement setup |

With the Master/Slave combination also an interface measurement |

|

can be realised. |

Requirements for a functioning measurement are:

•Vessel with changing level

•Products with steady densities

•Interface always between the measurement points

•Total level always above the upper measurement point

45052-EN-131011

VEGABAR 86 • Slave sensor for electronic differential pressure |

15 |

4 Mounting

1 2

0,8

h

1,0

Fig.8:Measurement setup with interface measurement, h = distance between the two measuring points

1VEGABAR 86

2VEGABAR 86 - Slave sensor

The interface measurement is possible in open as well as in closed vessels.

|

4.6 Density measurement |

Measurement setup |

With the Master/Slave combination also a density measurement can |

|

be realised. |

Requirements for a functioning measurement are:

•Vessel with changing level

•Product with consistent density

•Distance between the measurement points as large as possible

•Level always above the upper measuring point

131011-EN-45052

16 |

VEGABAR 86 • Slave sensor for electronic differential pressure |

4 Mounting

1 2

h

Fig.9:Measurement setup with density measurement, h = distance between the two measuring points

1VEGABAR 86

2VEGABAR 86 - Slave sensor

Density measurement is possible in open as well as in closed vessels. Small changes in the density cause only small changes in the measured differential pressure.So a suitable measuring range has to be selected.

45052-EN-131011

VEGABAR 86 • Slave sensor for electronic differential pressure |

17 |

4 Mounting

4.7External housing

Configuration

1

1

2

3

4

Fig.10:Arrangement measurement loop, external housing 1 Vessel

2Sensor

3 Connection cable sensor - external housing

4 External housing

5Signal cable

Mounting |

1. |

Mark the holes according to the following drilling template |

|

2. |

Fasten wall mounting plate with 4 screws |

90 mm |

|

(3.54") |

|

70 mm |

|

(2.76") |

|

3mm |

8 mm |

(0.12") |

(0.32") |

|

mm |

3,5 ) |

|

R |

.14" |

|

(0 |

110 mm (4.33") 93 mm (3.66")

Fig.11:Drilling template - wall mounting plate

131011-EN-45052

18 |

VEGABAR 86 • Slave sensor for electronic differential pressure |

Loading...

Loading...