VEGA SON71 User Manual

VEGASON 71 - D

TIB • Technical Information • Operating Instructions

1 5.000 m

2

1 2 3 4

VEGASON

Pulse-echo measuring system

Single channel flow measurement

Approvals for hazardous areas, certificate acc. to CENELEC

VEGA Grieshaber KG

Am Hohenstein 113

D-77761 Schiltach

Phone 0 78 36 / 50 - 0

Fax 0 78 36 / 50 201

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Contents |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Contents |

|

|||||||||||||||

1 |

Introduction |

|

||||||||||||||

|

1.1 |

|

Contents of the instruction manual ..................................................................................................................... |

4 |

||||||||||||

|

1.2 |

|

Safety information ............................................................................................................................................... |

4 |

||||||||||||

|

1.3 |

|

Product description ............................................................................................................................................. |

4 |

||||||||||||

|

1.4 |

|

Approvals ............................................................................................................................................................ |

4 |

||||||||||||

2 |

Technical Information |

|

||||||||||||||

|

2.1 |

|

Configuration of a measuring system ................................................................................................................. |

5 |

||||||||||||

|

2.2 |

|

Technical data, VEGASON 71 - D ....................................................................................................................... |

6 |

||||||||||||

|

2.3 |

|

Technical data, transducer .................................................................................................................................. |

7 |

||||||||||||

|

2.3 |

|

Dimensional drawings ......................................................................................................................................... |

8 |

||||||||||||

|

2.4 |

|

Measuring range ................................................................................................................................................. |

8 |

||||||||||||

|

2.5 |

|

General installation instructions .......................................................................................................................... |

9 |

||||||||||||

|

2.6 |

|

Installation fault ................................................................................................................................................. |

10 |

||||||||||||

|

2.7 |

|

Electrical connection ......................................................................................................................................... |

11 |

||||||||||||

3 |

Operating surface |

|

||||||||||||||

|

3.1 |

|

Indicating and operating elements .................................................................................................................... |

12 |

||||||||||||

|

3.2 |

|

Operation .......................................................................................................................................................... |

13 |

||||||||||||

4 |

Set-up |

|

||||||||||||||

|

4.1 |

|

Flow chart for set-up ......................................................................................................................................... |

14 |

||||||||||||

|

4.2 |

|

Mode range, general parameter adjustment, mode 0 - 00 … 0 - 99 ................................................................. |

15 |

||||||||||||

5 |

Adjustment |

|

||||||||||||||

|

5.1 |

|

Empty / full adjustment in metres without flow change ..................................................................................... |

18 |

||||||||||||

|

5.2 |

|

Demonstration and programming example ....................................................................................................... |

18 |

||||||||||||

6 |

Flow measurement |

|

||||||||||||||

|

6.1 |

|

Linearization ...................................................................................................................................................... |

19 |

||||||||||||

|

|

|

|

|

6.1.1 Meter flume / weir .................................................................................................................................. |

19 |

||||||||||

|

|

|

|

|

6.1.2 Enquiry of linearization curves 4 … 6 .................................................................................................... |

20 |

||||||||||

|

6.2 |

|

Linearity protocol ............................................................................................................................................... |

22 |

||||||||||||

2 |

VEGASON 71 - D |

Contents

|

|

|

|

|

|

|

|

|

|

7 Output results |

|

|

|||||||

7.1 |

Display .............................................................................................................................................................. |

23 |

|||||||

|

7.1.1 Allocation of a multiplication factor ......................................................................................................... |

23 |

|||||||

|

7.1.2 |

Measuring unit ....................................................................................................................................... |

23 |

||||||

|

7.1.3 |

Decimal point ......................................................................................................................................... |

23 |

||||||

|

7.1.4 |

Integration time ...................................................................................................................................... |

24 |

||||||

7.2 |

Adjustment max. flow ........................................................................................................................................ |

24 |

|||||||

7.3 |

Impulse value for flow relay ............................................................................................................................... |

24 |

|||||||

7.4 |

Impulse value for sampling relay ....................................................................................................................... |

24 |

|||||||

7.5 |

Definition of the min. flow volume limit .............................................................................................................. |

25 |

|||||||

7.6 |

Calculation examples of the max. flow .............................................................................................................. |

25 |

|||||||

|

7.6.1 |

Khafagi-Venturi flume ............................................................................................................................. |

26 |

||||||

|

7.6.2 |

Trapezoidal weir (Cipolletti) .................................................................................................................... |

27 |

||||||

|

7.6.3 Rectangular weir without throat ............................................................................................................. |

28 |

|||||||

|

7.6.4 Rectangular weir with throat .................................................................................................................. |

29 |

|||||||

|

7.6.5 |

V-Notch .................................................................................................................................................. |

30 |

||||||

|

7.6.6 Palmer-Bowlus-flume ............................................................................................................................. |

31 |

|||||||

7.7 |

Level module ..................................................................................................................................................... |

32 |

|||||||

|

7.7.1 Coordinations and their relations ........................................................................................................... |

32 |

|||||||

|

7.7.2 |

Switching commands ............................................................................................................................. |

32 |

||||||

7.8 |

Current module ................................................................................................................................................. |

33 |

|||||||

8 Supplementary programmings

8.1 |

Failure processing ............................................................................................................................................. |

33 |

8.2 |

Simulation ......................................................................................................................................................... |

34 |

8.3 |

Basic adjustment, mode range general parameter adjustment ......................................................................... |

34 |

8.4 |

Keyword ............................................................................................................................................................ |

34 |

9 Optimization

9.1 |

Enquiry of the optimization ................................................................................................................................ |

35 |

9.2 |

Mode range optimization, mode 1 - 01 … 1 - 27 ............................................................................................... |

36 |

9.3 |

Definition of the operating range ....................................................................................................................... |

37 |

9.4 |

Multiple echo reduction ..................................................................................................................................... |

37 |

9.5 |

Adjustment of the max. gain ............................................................................................................................. |

37 |

9.6 |

Fault signal ........................................................................................................................................................ |

38 |

9.8 |

Protocol of the optimization ............................................................................................................................... |

38 |

9.7 |

Basic adjustment, mode range optimization ..................................................................................................... |

38 |

10 Supplement

10.1 |

Error codes ........................................................................................................................................................ |

39 |

10.2 |

Error schedule ................................................................................................................................................... |

39 |

VEGASON 71 - D |

3 |

1 Introduction

1 Introduction

1.1 Contents of the instruction manual

The Technical Information / Operating Instructions is called TIB. It contains all necessary information for correct

-installation

-connection

-set-up

-linearization

-optimization

of the pulse-echo-measuring system VEGASON 71 - D.

VEGA regularly revises the contents of TIBs as technical improvements are made to the instruments.

A measuring system consists of

-a central electronics and

-a sensor.

The sensor is provided with a temperature sensor for compensation of the temperature influence to the sound running period. Measuring data and temperature information are transmitted along the same coaxial cable.

All adjustment procedures, optimizations etc. can be directly programmed via a keyboard on the central electronics.

1.2 Safety information

The described module must only be installed and operated as described in this TIB. Please note that other action can cause damage for which VEGA does not accept responsiblity.

1.3 Product description

The pulse-echo measuring system VEGASON 71 - D is used for flow and level measurement.

The running periods of periodically emitted sound impulse packets which are reflected by the flow product to be measured are evaluated.

The running period of sound is a measure of the distance between sensor and liquid surface.

The control electronics determines this distance and converts it into flow information.

The measuring results are indicated on the integral LCdisplay and acc. to the version, provided as relay and current outputs.

4

1.4 Approvals

If a measuring system is mounted acc. to the following approval, the respective legal document has to be used and the regulations have to be strictly observed.

Approvals for hazardous areas, certificate acc. to CENELEC.

Consisting of:

-central electronics VEGASON 71 - D

-sensor SW 71 R Ex

defined in the conformity certificate PTB-no. Ex-94.C.4066.

The conformity certificate is included with the product on delivery.

VEGASON 71 - D

2 Technical Information

2 Technical Information

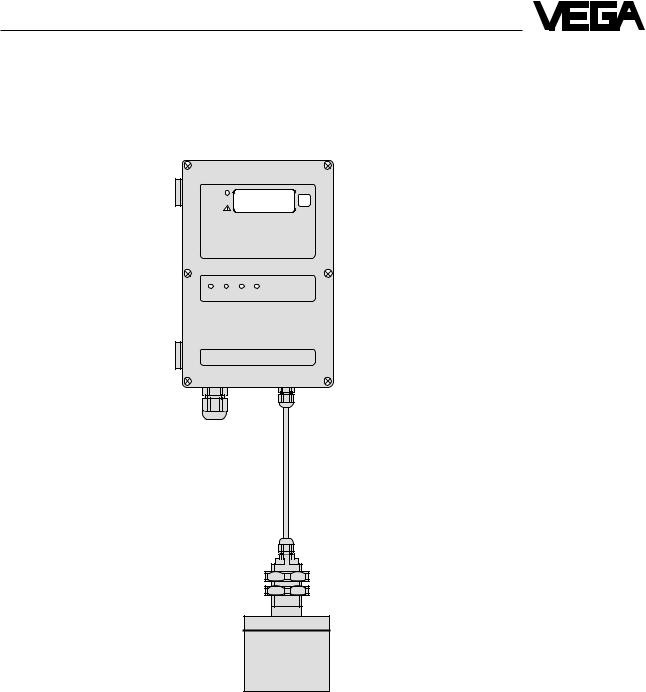

2.1 Configuration of a measuring system

Input |

Central electronics |

Outputs |

Measuring data from the sensor

1 5.000

2

2 LC-display (multi-functional indication)

Flow module

-1 relay output for flow

-1 relay output for sampling

Level module

- 2 relay outputs

1 2 3 4

Current module

- 1 output flow proportional module - 1 output level proportional module

VEGASON

Sensor

Central electronics consisting of: |

Sensor: |

||

- plastic housing with cover |

- in standard version or |

||

- operating elements (5 keys) |

- in Ex-version, certificate acc. to CENELEC |

||

- |

LED-display |

|

|

- two LC-displays (multi-functional displays) |

Accessories: |

||

- |

power supply unit |

- swivelling holder for sensor mounting |

|

- data memory (EEPROM, no buffer battery required) |

|

|

|

- outputs: flow module, level module, current module |

Options: |

||

- terminals for power supply, inputs and outputs |

- |

totalising counter (flow) |

|

|

|

- |

indicator VEGADIS 171 A |

|

|

- |

overvoltage arresters |

VEGASON 71 - D |

5 |

2 Technical Information

2.2 Technical data, VEGASON 71 - D

Power supply

Operating voltage

-Standard

-Option

Power consumption at Unenn and max-load Fuse for version

16 … 42 V AC or 16 … 60 V DC 90 … 250 V AC

Measuring range

Min. distance

Max. distance

Measuring data

Min. span Display in Resolution in Scanning

Measuring frequency Measuring rate

Angle of reflection (at –3 dB)

Linearity error after empty and full adjustment Temperature error of the electronics

Central electronics

Inputs

Outputs

Housing material

Electrical connection

Cable entry

Protection

Ambient temperature

Storage and transport temperature

Weight

Output

Indication

LC-display

Flow module

1 flow relay output

-voltage impulse

-current impulse

-pulse duration

1 sampling relay output

-contact material

-min. turn-on voltage switching current

-max. turn-on voltage switching current

-max. breaking capacity

Unenn = 24 V AC (16 … 42 V), 50/60 Hz Unenn = 24 V DC (16 … 60 V)

Unenn = 230 V AC (90 … 250 V), 50/60 Hz 12 VA, 5 W

2 A

500 mA

0.300 m

4.000 m (5.000 m)

10 cm

m (0.000 … 5.000 distance) mm

3 mm

50 kHz

0,4 sec.

8°

< 0,1 % of measuring range 0,1 % / 10 k of measuring range

1 (1 channel, for 1 sensor) see section "output" Polycarbonate

max. 1,5 mm2

1 x Pg 7, 1 x Pg 13,5 (up to max. 5 x Pg 13,5) IP 65

-20°C … +60°C

-20°C … +80°C approx. 1,9 kg

2, 4-digit each

active, with status indication (LED) 24 V

20 mA

200 ms

floating spdt, with status indication (LED) AgCdO and Au plated

10 mV

10 μA

250 V AC, 60 V DC

2 A AC, 1 A DC

125 VA, 60 W

6 |

VEGASON 71 - D |

2 Technical Information

|

|

|

|

|

|

|

|

|

Level module |

|

|

|

|

|

|

|

|

2 relay outputs |

floating spdts each |

|

||||||

|

|

and 2 status indications (LEDs) |

|

|||||

- contact material |

AgCdO and Au plated |

|

||||||

- min. |

turn-on voltage |

10 mV |

|

|||||

|

switching current |

10 μA |

|

|||||

- max. |

turn-on voltage |

250 V AC, 60 V DC |

|

|||||

|

switching current |

2 A AC, 1 A DC |

|

|||||

- max. |

breaking capacity |

125 VA, 60 W |

|

|||||

Current module |

|

|

|

|

|

|

|

|

2 current outputs |

|

|

|

|

|

|

|

|

- range |

|

0/4 … 20 mA |

|

|||||

- resolution |

0,05 % of range |

|

||||||

- load |

|

max. 500 Ohm |

|

|||||

- load dependent error |

at 0 … 500 Ohm, < 0,2 % related to the range |

|

||||||

or module |

|

|

|

|

|

|

|

|

as described above |

however with 2 floating outputs each |

|

||||||

Fault signal |

|

|

|

|

|

|

|

|

1 fail safe relay |

1 floating spdt |

|

||||||

contact data |

as described under relay outputs |

|

||||||

2 failure-LEDs |

|

|

|

|

|

|

|

|

2.3 Technical data, transducer

Transducer SW 71 |

|

Material of the transducer housing |

PVDF |

Material of the fixing tube |

PVDF, thread G 1 A |

Connection cable to central electronics |

standard coaxial cable type RG 58 |

Cable length |

5 m, as option 300 m |

Diameter of cable |

approx. 5 mm |

Temperature sensor |

integrated in the transducer |

Ambient temperature |

-20°C … +80°C |

Storage and transport pressure |

-20°C … +80°C |

Protection |

IP 68 |

Permissible ambient temperature |

1 bar |

Weight |

approx. 0,8 kg |

Transducer SW 71 R Ex |

|

Ex-approval |

PTB-no. Ex-94.C.4066 |

Flame proofing |

Casting "m" |

Marking |

EEx m II T6 or T5 or T4 |

Material of the transducer housing |

PVDF |

Material of the fixing tube |

PVDF, thread G 1 A |

Connection cable to central electronics |

standard coaxial cable type RG 58 |

Cable length |

5 m, as option up to 300 m |

Diameter of cable |

approx. 5 mm |

Temperature sensor |

integrated in the transducer |

Temperature class |

T6 = 60°C, T5 = 75°C, T4 = 80°C |

Storage and transport temperature |

-20°C … +80°C |

Protection |

IP 68 |

Permissible ambient pressure |

1 bar |

Weight |

approx. 1,0 kg |

VEGASON 71 - D |

7 |

2.3 Dimensional drawings

(Dimensions in mm)

*174

Swivelling flange |

Central electronics |

|

|

|

1 |

28 |

2 |

|

|

|

|

|

|

|

|

|

Min. distance for |

|

|

|

|

adjacent instrument 40 |

|

|

|

|

1 |

2 |

3 |

4 |

|

Flange |

|

|

|

|

DN 150 PN 16 |

|

|

|

|

|

|

|

VEGASON |

2 Technical Information

5 90

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

*229 |

|

Mounting diemsnions |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|||||

|

|

* |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

138 |

2.4 Measuring range

Pg 13,5 |

Pg 7 |

G 1 A |

|

|

45 |

Sensor |

90 |

|

ø95 |

300 mm

Min.-distance

Reference plane |

|

|

|

|

|

|

|

|

|

|

0.000 m |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Min.-distance |

|

|

|

|

|

|

|

|

|

|

0.300 m |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Measuring range

max.

4.000 m (5.000 m)

8 |

VEGASON 71 - D |

2 Technical Information

2.5 General installation instructions

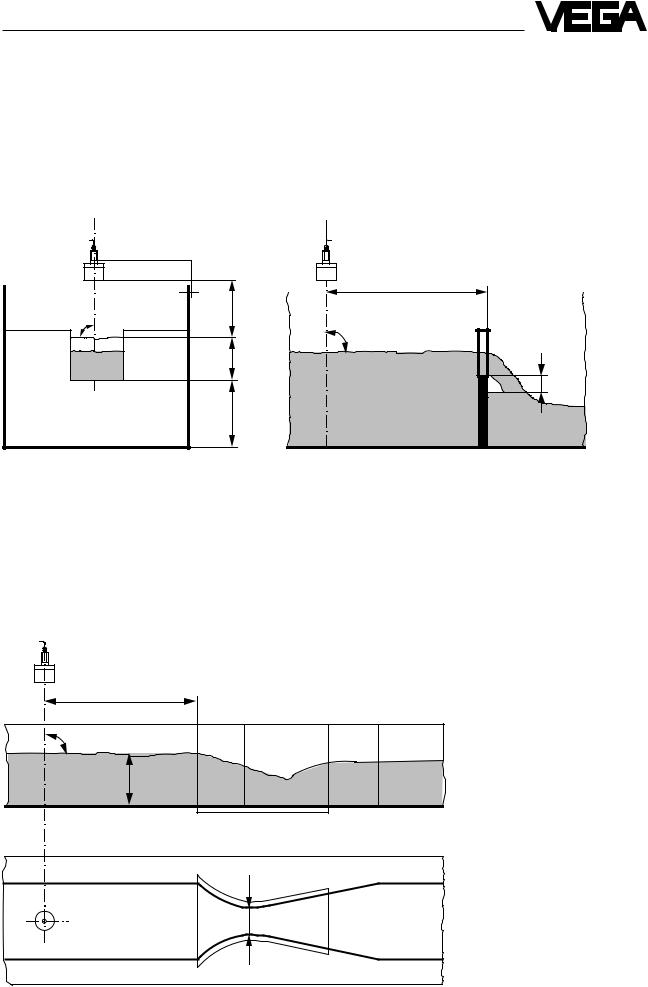

Open flume with weir (e.g. rectangular)

-Installation of the transducer upstream

-Observe distance to the weir (3 … 4 x hmax)

-Installation if possible centered to the flume

-Installation vertical to the surface of the flow product

-Observe min. distance relating to hmax

-Min. distance diaphragm opening to downstream water ³ 5 cm

|

³ Min.- |

distance |

3 - 4 x hmax |

|

90° |

|

|

||

|

|

90° |

|

|

|

|

|

|

|

|

max |

|

|

|

|

h |

|

|

|

|

max |

|

|

³ 5 cm |

|

|

|

|

|

weir |

2 x h |

|

upstream water |

downstream |

|

³ |

|

water |

|

|

|

|

||

|

|

|

|

Open flume with measuring channel (e.g. Khafagi-Venturi flume)

-Installation of the sensor at the inlet

-Observe distance to the Khafagi-Venturi flume (3 … 4 x hmax)

-Installation if possible centered to the flume

-Installation vertically to the surface of the flow product

-Min. distance relating to the height of damping hmax

Note

Otherwise follow the installation guidelines given by the channel manufacturer.

Sensor

3 - 4 x hmax

90° |

hmax |

Sensor

B

VEGASON 71 - D |

9 |

2 Technical Information

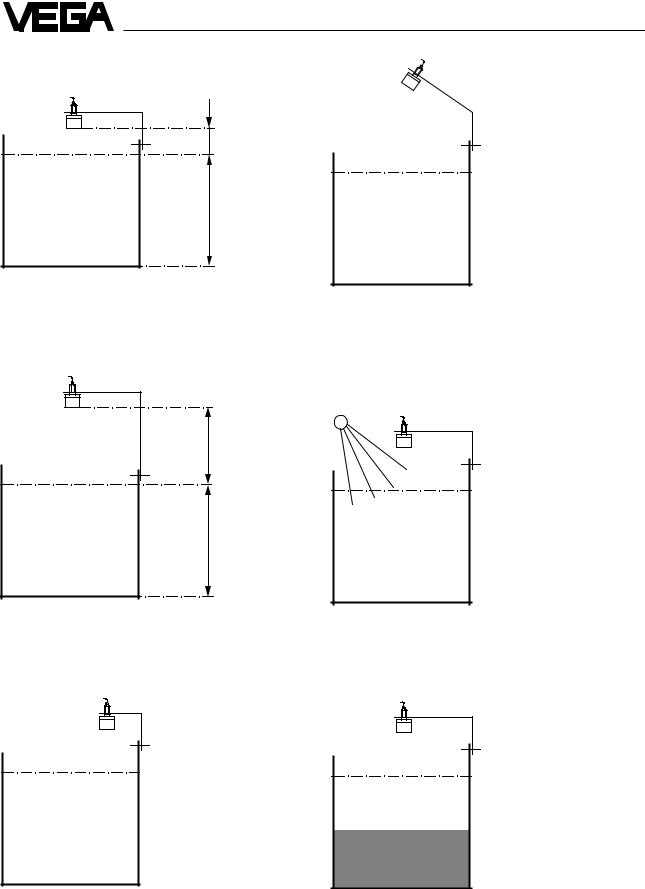

2.6 Installation fault

< 300 mm

h max

Fault: |

Min. distance from sensor to hmax not |

|

maintained. |

Problem: The upper range cannot be measured. Solution: Correct min. distance of the sensor to 0,3 m.

Fault: |

Sensor is not directed vertically to the surface. |

Problem: Sensor receives weak echoes. |

|

Solution: |

Mount sensor vertically. |

> 300 mm

h max

Fault: Distance from sensor to hmax too large. Problem: Unreliable results due to very weak echoes. Solution: Correct min. distance of the sensor to 0,3 m.

Fault: |

Strong heat fluctuations, e.g. sun. |

Problem: The measuring accuracy is not constant. |

|

Solution: Install a sun shield in the respective position.

Fault: |

Sensor too close to the flume wall, i.e. not |

|

mounted in the centre. |

Problem: Build-up and rough flume walls cause |

|

measuring problems.

Solution: Mount sensor in the centre of the flume.

Fault: Surface has foaming problem.

Problem: The surface of the foam is detected as level. The measured value is wrong.

Solution: The used measuring principle is not suitable and must be replaced e.g. by a hydrostatic system (pressure transmitter).

10 |

VEGASON 71 - D |

2 Technical Information

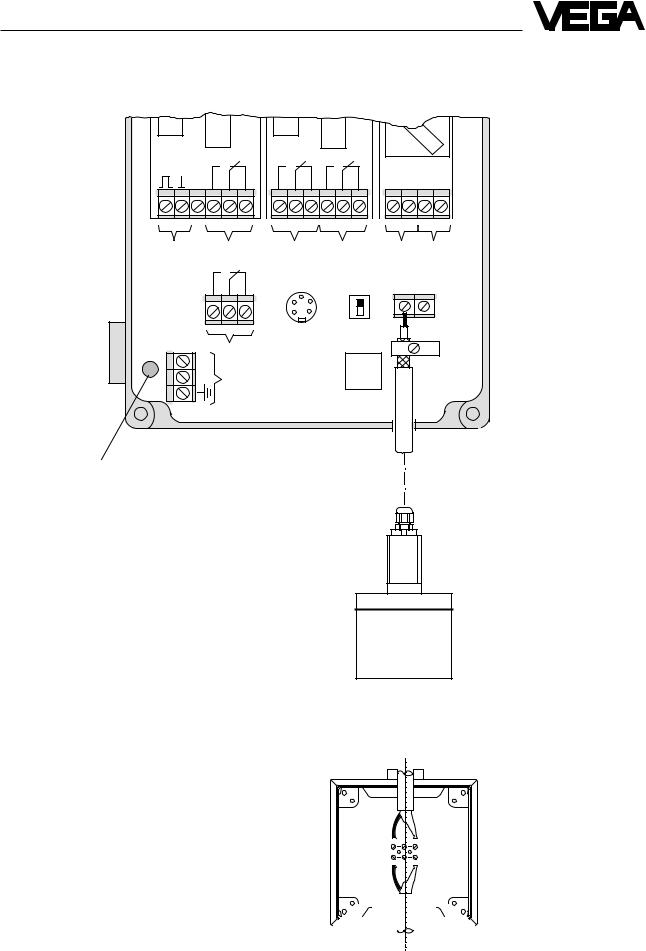

2.7 Electrical connection

Flow module:

-Flow

Terminal 9 and 10

-Sampling Terminal 12 … 14

Flow module |

Level module |

|

Current module |

|||||||||

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

+ |

- |

+ |

- |

9 |

10 |

11 |

12 |

13 14 |

15 16 |

17 18 |

19 |

20 |

21 |

22 |

23 |

24 |

1 |

2 |

1 |

2 |

1 |

2 |

Relay output |

Relay output |

Current output |

|||

|

|

|

Service socket |

|

|

|

|

|

|

|

1 |

6 |

7 |

|

|

|

|

2 |

||

|

|

|

|

|

|

|

|

3 |

4 |

5 |

Service switch |

|

|

- |

|

Failure relay |

|

|

8 |

|

2 |

output |

|

Attention! |

|||

+ |

|

|

|

|

High |

|

1 |

Power supply |

|

voltage |

|

||

|

|

|

|

|

||

Current module:

-flow proportional Terminal 21 and 22

-level proportional Terminal 23 and 24

Fuse type TR5

Manufacturer, e.g. Messrs. Wickmann,

Current value see 2.2 Technical Data

Note

During operation the sensor is clocked with highperformance impulses. It is therefore recommended to provide all electrical connections first and then switch on the power supply.

The connection line to the sensor can be extended as shown. Therefore observe that a max. line length of 300 m is not be exceeded.

standard coax cable

max. cable length = 300 mm

Sensor

standard waterproof distributor box

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VEGASON 71 - D |

11 |

||||||||||||||||

3 Operating surface

3 Operating surface

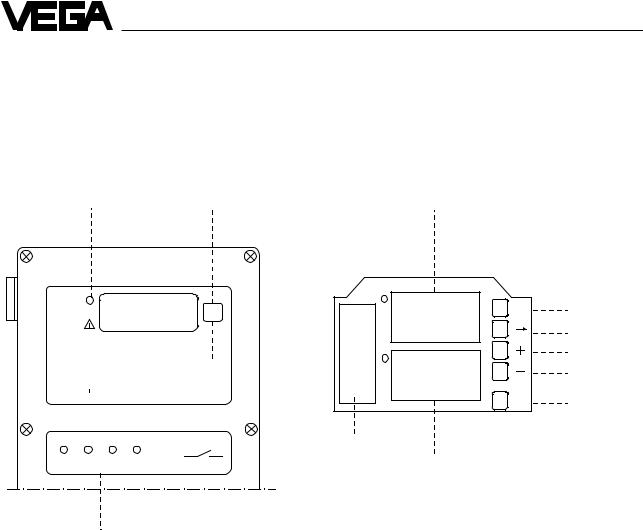

3.1 Indicating and operating elements

Outer view |

|

Inner view |

LED-indication |

Measuring units as label in |

Indication of measured |

Fault signal |

the provided window |

values |

|

|

MODEFIELD |

1 8888

2

1 2 3 4

LED-indication of the relay output 1 … 4

1 |

8888 |

MOD |

|

||

2 |

8888 |

|

|

|

STO |

Scheme of

operation

PARAMETER FIELD

Selection of mode

Cursor position

figures raise

figures lower

Memory

Indication of measured values |

|

|

Mode range |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e.g. flow 00.00 … 75.00 |

11.25 |

m3/h |

General parameter adjustment |

0 - 00 |

|

… |

99 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Optimization |

1 - 01 |

|

… |

27 |

Demonstration after respective programming of |

|

|

|

|

|

|

||

|

|

|

|

|

|

|||

- |

Measuring unit |

|

|

|

|

|

|

|

|

|

|

4.H.01 |

|

|

32 |

||

- Allocation of a multiplication factor |

|

|

Linearization curve 4 |

|

… |

|||

- |

Decimal point e.g. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Flow 0 … 100 % |

50.0 |

% |

Linearization curve 5 |

5.H.01 |

|

… |

32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Level 0 … 100 % |

50.00 |

% |

Linearization curve 6 |

6.H.01 |

|

… |

32 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Distance 0.000 … 5.000 m |

5.000 |

m |

Fault signals |

E2.01 |

|

… |

.04 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

VEGASON 71 - D |

Loading...

Loading...