FANUC SPINDLE MOTOR Alpha i, SPINDLE MOTOR Beta i PARAMETER MANUAL

FANUC AC SPINDLE MOTOR @* series FANUC AC SPINDLE MOTOR #* series FANUC BUILT-IN SPINDLE MOTOR B* series

PARAMETER MANUAL

B-65280EN/06

•No part of this manual may be reproduced in any form.

•All specifications and designs are subject to change without notice.

The products in this manual are controlled based on Japan’s “Foreign Exchange and Foreign Trade Law”. The export from Japan may be subject to an export license by the government of Japan.

Further, re-export to another country may be subject to the license of the government of the country from where the product is re-exported. Furthermore, the product may also be controlled by re-export regulations of the United States government.

Should you wish to export or re-export these products, please contact FANUC for advice.

In this manual we have tried as much as possible to describe all the various matters. However, we cannot describe all the matters which must not be done, or which cannot be done, because there are so many possibilities.

Therefore, matters which are not especially described as possible in this manual should be regarded as ”impossible”.

This manual contains the program names or device names of other companies, some of which are registered trademarks of respective owners. However, these names are not followed by or in the main body.

The parameters described in this manual must be set correctly according to the relevant descriptions. If the parameters are not set correctly, vibrations and unpredictable motions can occur. When setting and updating the parameters, place top priority on safety in operation by taking actions, such as heightening the speed step by step and performing an operation so that an emergency stop can be initiated immediately, until the settings are confirmed to be appropriate.

B-65280EN/06 |

DEFINITION OF WARNING, CAUTION, AND NOTE |

DEFINITION OF WARNING, CAUTION, AND NOTE

This manual includes safety precautions for protecting the user and preventing damage to the machine. Precautions are classified into Warning and Caution according to their bearing on safety. Also, supplementary information is described as a Note. Read the Warning, Caution, and Note thoroughly before attempting to use the machine.

WARNING

WARNING

Applied when there is a danger of the user being injured or when there is a damage of both the user being injured and the equipment being damaged if the approved procedure is not observed.

CAUTION

CAUTION

Applied when there is a danger of the equipment being damaged, if the approved procedure is not observed.

NOTE

The Note is used to indicate supplementary information other than Warning and Caution.

- Read this manual carefully, and store it in a safe place.

s-1

B-65280EN/06 |

PREFACE |

PREFACE

This manual describes the parameters and functions of the FANUC servo amplifier αi/βi series spindle. This manual is divided into four parts and appendix. Part I describes the αi series spindle, Part II describes the βi series spindle, Part III describes the αCi series spindle, and Part IV describes the BiS series spindle.

Unless otherwise noted, the parameter numbers for FANUC Series 16i are used in the text. When using any other model, reference the corresponding parameter numbers.

The table below indicates the abbreviated model names used with the parameter numbers.

Product name |

Abbreviated model |

Abbreviated model |

|

name in text |

name in table |

||

|

|||

FANUC Series 30i |

Series 30i |

30i |

|

FANUC Series 31i |

Series 31i |

||

FANUC Series 32i |

Series 32i |

|

|

FANUC Series 16i |

Series 16i |

|

|

FANUC Series 18i |

Series 18i |

16i |

|

FANUC Series 21i |

Series 21i |

||

|

|||

FANUC Series 0i |

Series 0i |

|

|

FANUC Series 15i |

Series 15i |

15i |

For detailed information indicating which model each function described in this manual can be used with, refer to the manual of each CNC. For the package specifications, in particular, refer to the CNC manual.

The manuals related to the αi/βi series spindle are listed below.

(1)FANUC AC SPINDLE MOTOR αi series DESCRIPTIONS (B-65272EN)

(2)FANUC AC SPINDLE MOTOR αCi series DESCRIPTIONS (B-65372EN)

(3)FANUC AC SPINDLE MOTOR βi series DESCRIPTIONS (B-65312EN)

(4)FANUC SERVO AMPLIFIER αi series DESCRIPTIONS (B-65282EN)

(5)FANUC SERVO AMPLIFIER βi series DESCRIPTIONS (B-65322EN)

(6)FANUC SERVO MOTOR αis/αi series, FANUC SPINDLE MOTOR αi series, FANUC SERVO AMPLIFIER αi series MAINTENANCE MANUAL (B-65285EN)

(7)FANUC SERVO MOTOR βis series, FANUC SPINDLE MOTOR βi series, FANUC SERVO AMPLIFIER βi series MAINTENANCE MANUAL (B-65325EN)

p-1

PREFACE |

B-65280EN/06 |

(8)FANUC AC SPINDLE MOTOR αi/βi series FANUC BUILT-IN SPINDLE MOTOR Bi series PARAMETER MANUAL (B-65280EN)

(9)FANUC AC SPINDLE MOTOR αiB series DESCRIPTIONS (B-65292EN)

(10)FANUC SYNCHRONOUS BUILT-IN SPINDLE MOTOR BiS series DESCRIPTIONS (B-65342 EN)

p-2

B-65280EN/06 |

TABLE OF CONTENTS |

TABLE OF CONTENTS

DEFINITION OF WARNING, CAUTION, AND NOTE ................................. |

s-1 |

PREFACE.................................................................................................... |

p-1 |

I.FANUC AC SPINDLE MOTOR αi series / FANUC BUILT-IN SPINDLE MOTOR BiI series

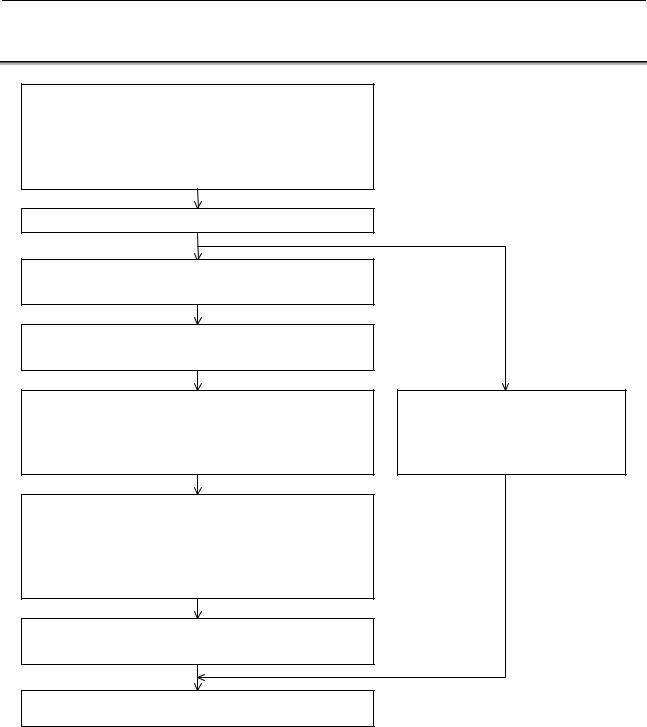

1 START-UP |

............................................................................................... |

3 |

|

1.1 |

START-UP PROCEDURE............................................................................. |

4 |

|

1.2 |

SPINDLE ......................................SERIAL INTERFACE (Optional function) |

5 |

|

|

1.2.1 ...........................................................Parameters Related to Spindle Serial Output |

5 |

|

|

1.2.2 .............................................................Automatic Spindle Parameter Initialization |

6 |

|

|

1.2.3 ................................................................................... |

Diagnosis (Diagnosis Screen) |

7 |

|

1.2.4 ........................................................................................................................ |

Alarm |

8 |

1.3 |

PARAMETERS ..............................................RELATED TO DETECTORS |

10 |

|

|

1.3.1 .............................................................................List of Parameters for Detectors |

10 |

|

|

1.3.2 ........................................................................Details of Parameters for Detectors |

12 |

|

|

1.3.3 ............................................................................ |

Typical Detector Configurations |

21 |

2 EXPLANATION OF OPERATION MODES........................................... |

28 |

|

2.1 VELOCITY CONTROL MODE..................................................................... |

29 |

|

2.1.1 |

Start-up Procedure.................................................................................................. |

29 |

2.1.2 |

Overview ................................................................................................................ |

29 |

2.1.3 |

System Configuration............................................................................................. |

29 |

2.1.4 List of I/O Signals (CNC↔PMC).......................................................................... |

30 |

|

2.1.5 |

Related Parameters ................................................................................................. |

34 |

2.1.6 Details of Related Parameters................................................................................. |

36 |

|

2.1.7 |

Troubleshooting ..................................................................................................... |

47 |

2.2POSITION CODER METHOD SPINDLE ORIENTATION

(Optional function) ....................................................................................... |

51 |

|

2.2.1 |

Start-up Procedure.................................................................................................. |

51 |

2.2.2 |

Overview ................................................................................................................ |

52 |

2.2.3 |

Feature.................................................................................................................... |

52 |

2.2.4 |

System Configuration............................................................................................. |

53 |

2.2.5 |

Stop Position Specification Method ....................................................................... |

55 |

2.2.6 |

I/O Signals (CNC ↔ PMC) ................................................................................... |

56 |

2.2.7 |

Examples of Sequences .......................................................................................... |

60 |

2.2.8 |

Related Parameters ................................................................................................. |

63 |

2.2.9 |

Details of Related Parameters................................................................................. |

64 |

2.2.10 |

Calculating the Position Gain for Orientation ........................................................ |

69 |

2.2.11 |

Adjusting the Orientation Stop Position Shift Parameter....................................... |

70 |

2.2.12 |

Calculating the Orientation Time ........................................................................... |

72 |

2.3 |

RIGID TAPPING (Optional function)............................................................ |

74 |

|

|

2.3.1 |

Start-up Procedure.................................................................................................. |

74 |

|

2.3.2 |

Overview ................................................................................................................ |

74 |

|

|

c-1 |

|

TABLE OF CONTENTS |

B-65280EN/06 |

||

|

2.3.3 |

System Configuration............................................................................................. |

75 |

|

2.3.4 |

List of I/O Signals (CNC ↔ PMC)........................................................................ |

78 |

|

2.3.5 |

Sequence................................................................................................................. |

80 |

|

2.3.6 |

Related Parameters ................................................................................................. |

81 |

|

2.3.7 |

Details of Related Parameters................................................................................. |

83 |

|

2.3.8 |

Parameter Setting Procedure .................................................................................. |

90 |

|

2.3.9 |

Adjustment Procedure ............................................................................................ |

99 |

|

2.3.10 |

Diagnosis (Diagnosis Screen)............................................................................... |

105 |

|

2.3.11 |

Alarm.................................................................................................................... |

107 |

2.4 |

Cs CONTOURING CONTROL (Optional function) .................................... |

110 |

|

|

2.4.1 |

Start-up Procedure................................................................................................ |

110 |

|

2.4.2 |

Overview .............................................................................................................. |

111 |

|

2.4.3 |

System Configuration........................................................................................... |

111 |

|

2.4.4 |

List of I/O Signals (CNC ↔ PMC)...................................................................... |

113 |

|

2.4.5 |

Examples of Sequences ........................................................................................ |

115 |

|

2.4.6 |

Related Parameters ............................................................................................... |

117 |

|

2.4.7 |

Details of Related Parameters............................................................................... |

119 |

|

2.4.8 |

Diagnosis (Diagnosis Screen)............................................................................... |

129 |

|

2.4.9 |

Alarm.................................................................................................................... |

129 |

2.5 |

SPINDLE SYNCHRONOUS CONTROL (Optional function)...................... |

130 |

|

|

2.5.1 |

Start-up Procedure................................................................................................ |

130 |

|

2.5.2 |

Overview .............................................................................................................. |

131 |

|

2.5.3 |

System Configuration........................................................................................... |

132 |

|

2.5.4 |

Explanation of Operation ..................................................................................... |

138 |

|

2.5.5 |

I/O Signals (CNC ↔ PMC) ................................................................................. |

139 |

|

2.5.6 |

Examples of Sequences ........................................................................................ |

143 |

|

2.5.7 |

Related Parameters ............................................................................................... |

148 |

|

2.5.8 |

Details of Related Parameters............................................................................... |

149 |

|

2.5.9 |

Number of Error Pulses in Spindle Synchronous Control.................................... |

158 |

|

2.5.10 |

Specifying a Shift Amount for Spindle Phase Synchronous Control................... |

159 |

|

2.5.11 |

Diagnosis (Diagnosis Screen)............................................................................... |

159 |

|

2.5.12 |

Alarm.................................................................................................................... |

160 |

2.6 |

SPECIFICATIONS COMMON TO ALL OPERATION MODES.................. |

161 |

|

|

2.6.1 |

Overview .............................................................................................................. |

161 |

|

2.6.2 |

List of I/O Signals (CNC ↔ PMC)...................................................................... |

161 |

|

2.6.3 |

Parameters ............................................................................................................ |

166 |

|

2.6.4 |

Details of Parameters............................................................................................ |

169 |

|

2.6.5 |

Diagnosis (Diagnosis Screen)............................................................................... |

179 |

3 I/O SIGNALS (CNC ↔ PMC) .............................................................. |

181 |

||

3.1 |

INPUT SIGNALS (PMC→CNC→SP)......................................................... |

182 |

|

|

3.1.1 |

List of Input Signals ............................................................................................. |

182 |

|

3.1.2 |

Explanation of Input Signals ................................................................................ |

183 |

|

3.1.3 |

Details of Input Signals ........................................................................................ |

185 |

3.2 |

OUTPUT SIGNALS (SP→CNC→PMC)..................................................... |

196 |

|

|

3.2.1 |

List of Output Signals........................................................................................... |

196 |

|

3.2.2 |

Explanation of Output Signals ............................................................................. |

197 |

|

3.2.3 |

Details of Output Signals ..................................................................................... |

199 |

c-2

B-65280EN/06 TABLE OF CONTENTS

4 ADJUSTMENT .................................................................................... |

206 |

||

4.1 |

VELOCITY LOOP GAIN ADJUSTMENT ................................................... |

207 |

|

|

4.1.1 |

Overview .............................................................................................................. |

207 |

|

4.1.2 |

Parameters ............................................................................................................ |

207 |

|

4.1.3 |

Adjustment Procedure .......................................................................................... |

210 |

|

4.1.4 Additional Information (Position Gain Adjustment)............................................ |

211 |

|

4.2 |

MACHINE RESONANCE ELIMINATION................................................... |

212 |

|

|

4.2.1 |

TCMD Filter......................................................................................................... |

212 |

|

4.2.2 |

HRV Filter............................................................................................................ |

213 |

|

4.2.3 |

Disturbance Input Function .................................................................................. |

217 |

4.3AMPLITUDE RATIO/PHASE DIFFERENCE COMPENSATION

FUNCTION ................................................................................................ |

222 |

5 FUNCTION DESCRIPTIONS .............................................................. |

227 |

||

5.1 |

SPEED RANGE SWITCHING CONTROL (Optional function)................... |

228 |

|

|

5.1.1 |

Overview .............................................................................................................. |

228 |

|

5.1.2 Series and Editions of Applicable Spindle Software............................................ |

228 |

|

|

5.1.3 |

Configuration ....................................................................................................... |

228 |

|

5.1.4 I/O Signals (CNC ↔ PMC) ................................................................................. |

229 |

|

|

5.1.5 |

Sequence............................................................................................................... |

233 |

|

5.1.6 List of Related Parameters.................................................................................... |

235 |

|

|

5.1.7 Details of Related Parameters............................................................................... |

236 |

|

5.1.8Parameter-specified Switching between Highand Low-speed Characteristics ..238

5.2 |

SPINDLE SWITCHING CONTROL ........................................................... |

240 |

|

|

5.2.1 |

Overview .............................................................................................................. |

240 |

|

5.2.2 |

Series and Editions of Applicable Spindle Software............................................ |

240 |

|

5.2.3 |

Configuration ....................................................................................................... |

240 |

|

5.2.4 |

Details of Specifications....................................................................................... |

241 |

|

5.2.5 |

Restrictions........................................................................................................... |

241 |

|

5.2.6 |

I/O Signals (CNC↔PMC) ................................................................................... |

242 |

|

5.2.7 |

Sequence............................................................................................................... |

245 |

|

5.2.8 |

List of Related Parameters.................................................................................... |

247 |

|

5.2.9 |

Details of Related Parameters............................................................................... |

247 |

|

5.2.10 |

Parameter Setting Procedure ................................................................................ |

250 |

|

5.2.11 |

Supplementary Descriptions about Parameters .................................................... |

251 |

5.3INCRMENTAL COMMAND TYPE SPINDLE ORIENTATION

(SPINDLE ROTATION SPEED CONTROL) (Optional function)................ |

255 |

|

5.3.1 |

Overview .............................................................................................................. |

255 |

5.3.2 Series and Editions of Applicable Spindle Software............................................ |

255 |

|

5.3.3 |

System Configuration........................................................................................... |

256 |

5.3.4 |

I/O Signals(CNC↔PMC) .................................................................................... |

259 |

5.3.5 |

Examples of Sequences ........................................................................................ |

261 |

5.3.6 List of Related Parameters.................................................................................... |

264 |

|

5.3.7 Details of Related Parameters............................................................................... |

264 |

|

5.4 |

HIGH-SPEED SPINDLE ORIENTATION (Optional function)..................... |

265 |

|

|

5.4.1 |

Overview .............................................................................................................. |

265 |

|

5.4.2 Series and Editions of Applicable Spindle Software............................................ |

265 |

|

|

5.4.3 |

System Configuration........................................................................................... |

265 |

|

|

c-3 |

|

TABLE OF CONTENTS |

B-65280EN/06 |

|

5.4.4 |

I/O Signals (CNC↔PMC) ................................................................................... |

268 |

5.4.5 |

Sequence............................................................................................................... |

270 |

5.4.6 |

List of Related Parameters.................................................................................... |

273 |

5.4.7 |

Details of Related Parameters............................................................................... |

274 |

5.4.8 |

Spindle Data Used in Tuning ............................................................................... |

279 |

5.4.9 |

Tuning Procedure ................................................................................................. |

280 |

5.5SPINDLE ORIENTATION DURING SPINDLE SYNCHRONIZATION

CONTROL (Optional function)................................................................... |

286 |

|

5.5.1 |

Overview .............................................................................................................. |

286 |

5.5.2 |

Series and Editions of Applicable Spindle Software............................................ |

286 |

5.5.3 |

Specification......................................................................................................... |

287 |

5.5.4 |

I/O Signals (CNC ↔ PMC) ................................................................................. |

289 |

5.5.5 |

Sequence............................................................................................................... |

293 |

5.5.6 |

List of Related Parameters.................................................................................... |

295 |

5.5.7 |

Details of Related Parameters............................................................................... |

296 |

5.6 |

SPINDLE FINE ACC./DEC. (FAD) FUNCTION ......................................... |

298 |

|

|

5.6.1 |

Overview .............................................................................................................. |

298 |

|

5.6.2 |

Series and Editions of Applicable Spindle Software............................................ |

298 |

|

5.6.3 |

Block Diagram ..................................................................................................... |

299 |

|

5.6.4 |

Parameters ............................................................................................................ |

299 |

|

5.6.5 |

Diagnosis (Diagnosis Screen)............................................................................... |

301 |

|

5.6.6 |

Status Errors ......................................................................................................... |

301 |

|

5.6.7 |

Cautions................................................................................................................ |

302 |

5.7UNEXPECTED DISTURBANCE TORQUE DETECTION FUNCTION

(Optional function) ..................................................................................... |

304 |

|

5.7.1 |

Overview .............................................................................................................. |

304 |

5.7.2 |

Series and Editions of Applicable Spindle Software............................................ |

304 |

5.7.3 |

I/O Signals (CNC↔PMC) ................................................................................... |

305 |

5.7.4 |

List of Related Parameters.................................................................................... |

306 |

5.7.5 |

Details of Related Parameters............................................................................... |

306 |

5.7.6 |

Parameter Tuning Procedure ................................................................................ |

308 |

5.8SPINDLE EGB (SPINDLE ELECTRONIC GEAR BOX)

(Optional function) ..................................................................................... |

310 |

|

5.8.1 |

Overview .............................................................................................................. |

310 |

5.8.2 |

Series and Editions of Applicable Spindle Software............................................ |

310 |

5.8.3 |

System Configuration........................................................................................... |

311 |

5.8.4 |

Block Diagram ..................................................................................................... |

314 |

5.8.5 |

I/O Signals (CNC ↔ PMC) ................................................................................. |

315 |

5.8.6 |

Examples of Sequences ........................................................................................ |

315 |

5.8.7 |

List of Related Parameters.................................................................................... |

316 |

5.8.8 |

Details of Related Parameters............................................................................... |

317 |

5.8.9 |

Diagnosis Signal Related to Spindle EGB ........................................................... |

321 |

5.8.10 |

Status Errors Related to Spindle EGB.................................................................. |

321 |

5.8.11 |

Alarms .................................................................................................................. |

321 |

5.9 |

DIFFERENTIAL SPINDLE SPEED CONTROL ......................................... |

322 |

|

|

5.9.1 |

Overview .............................................................................................................. |

322 |

|

5.9.2 Series and Editions of Applicable Spindle Software............................................ |

322 |

|

|

5.9.3 |

Configuration ....................................................................................................... |

323 |

|

5.9.4 |

Description ........................................................................................................... |

324 |

|

|

c-4 |

|

B-65280EN/06 |

TABLE OF CONTENTS |

|

5.9.5 |

I/O Signals (CNC↔PMC) ................................................................................... |

324 |

5.9.6 |

Examples of Sequences ........................................................................................ |

325 |

5.9.7 |

List of Related Parameters.................................................................................... |

326 |

5.9.8 |

Details of Related Parameters............................................................................... |

326 |

5.9.9 |

Status Errors on Differential Spindle Speed Control ........................................... |

326 |

5.10 DUAL POSITION FEEDBACK FUNCTION (Optional function) ................. |

327 |

|

5.10.1 |

Overview .............................................................................................................. |

327 |

5.10.2 |

Series and Editions of Applicable Spindle Software............................................ |

327 |

5.10.3 |

Block Diagram ..................................................................................................... |

328 |

5.10.4 |

List of Related Parameters.................................................................................... |

329 |

5.10.5 |

Details of Related Parameters............................................................................... |

329 |

5.10.6 |

Spindle Alarm....................................................................................................... |

333 |

5.11 TORQUE TANDEM CONTROL FUNCTION (Optional function) ............... |

334 |

|

5.11.1 |

Overview .............................................................................................................. |

334 |

5.11.2 |

Series and Editions of Applicable Spindle Software............................................ |

334 |

5.11.3 |

System Configuration........................................................................................... |

335 |

5.11.4 |

I/O Signals (CNC ↔ PMC) ................................................................................. |

337 |

5.11.5 |

Examples of Sequences ........................................................................................ |

340 |

5.11.6 |

Parameters ............................................................................................................ |

344 |

5.11.7 |

Alarm and Status Error......................................................................................... |

347 |

5.12MAGNETIC SENSOR METHOD SPINDLE ORIENTATION

(Optional function) ..................................................................................... |

348 |

|

5.12.1 |

Overview .............................................................................................................. |

348 |

5.12.2 Series and Editions of Applicable Spindle Software............................................ |

348 |

|

5.12.3 |

System Configuration........................................................................................... |

348 |

5.12.4 I/O Signals (CNC ↔ PMC) ................................................................................. |

349 |

|

5.12.5 |

Sequence............................................................................................................... |

349 |

5.12.6 |

Parameters ............................................................................................................ |

350 |

5.13SPINDLE BACKLASH ACCELERATION FUNCTION (Optional function). 355

|

5.13.1 |

Overview .............................................................................................................. |

355 |

|

5.13.2 |

Series and Editions of Applicable Spindle Software ............................................ |

355 |

|

5.13.3 |

Block Diagram ..................................................................................................... |

355 |

|

5.13.4 |

Parameters ............................................................................................................ |

356 |

|

5.13.5 |

Example of Adjustment ........................................................................................ |

357 |

II. FANUC AC SPINDLE MOTOR βi series |

|

||

1 START-UP |

........................................................................................... |

363 |

|

1.1 |

START-UP PROCEDURE......................................................................... |

364 |

|

1.2 |

SPINDLE ..................................SERIAL INTERFACE (Optional function) |

365 |

|

|

1.2.1 ....................................................... |

Parameters Related to Spindle Serial Output |

365 |

|

1.2.2 ......................................................... |

Automatic Spindle Parameter Initialization |

365 |

|

1.2.3 ............................................................................... |

Diagnosis (Diagnosis Screen) |

366 |

|

1.2.4 .................................................................................................................... |

Alarm |

366 |

1.3 |

PARAMETERS ............................................RELATED TO DETECTORS |

367 |

|

|

1.3.1 ........................................................................... |

List of Parameters for Detectors |

367 |

|

1.3.2 ...................................................................... |

Details of Parameters for Detectors |

367 |

|

1.3.3 .......................................................................... |

Typical Detector Configurations |

368 |

c-5

TABLE OF CONTENTS |

B - 65280EN/06 |

|

2 EXPLANATION OF OPERATION MODES |

.........................................372 |

|

2.1 VELOCITY CONTROL MODE................................................................... |

373 |

|

2.1.1 |

Start-up Procedure................................................................................................ |

373 |

2.1.2 |

Overview .............................................................................................................. |

373 |

2.1.3 |

System Configuration........................................................................................... |

373 |

2.1.4 List of I/O Signals (CNC↔PMC)........................................................................ |

373 |

|

2.1.5 |

Related Parameters ............................................................................................... |

373 |

2.1.6 Details of Related Parameters............................................................................... |

373 |

|

2.1.7 |

Troubleshooting ................................................................................................... |

373 |

2.2POSITION CODER METHOD SPINDLE ORIENTATION

(Optional function) ..................................................................................... |

374 |

|

2.2.1 |

Start-up Procedure................................................................................................ |

374 |

2.2.2 |

Overview .............................................................................................................. |

374 |

2.2.3 |

Feature.................................................................................................................. |

374 |

2.2.4 |

System Configuration........................................................................................... |

374 |

2.2.5 |

Stop Position Specification Method ..................................................................... |

376 |

2.2.6 |

I/O Signals (CNC ↔ PMC) ................................................................................. |

376 |

2.2.7 |

Examples of Sequences ........................................................................................ |

376 |

2.2.8 |

Related Parameters ............................................................................................... |

376 |

2.2.9 |

Details of Related Parameters............................................................................... |

376 |

2.2.10 |

Adjusting the Orientation Stop Position Shift Parameter..................................... |

376 |

2.3 |

RIGID TAPPING (Optional function).......................................................... |

377 |

|

|

2.3.1 |

Start-up Procedure................................................................................................ |

377 |

|

2.3.2 |

Overview .............................................................................................................. |

377 |

|

2.3.3 |

System Configuration........................................................................................... |

377 |

|

2.3.4 |

List of I/O Signals (CNC ↔ PMC)...................................................................... |

380 |

|

2.3.5 |

Sequence............................................................................................................... |

380 |

|

2.3.6 |

Related Parameters ............................................................................................... |

380 |

|

2.3.7 |

Details of Related Parameters............................................................................... |

380 |

|

2.3.8 |

Parameter Setting Procedure ................................................................................ |

380 |

|

2.3.9 |

Adjustment Procedure .......................................................................................... |

380 |

|

2.3.10 |

Diagnosis (Diagnosis Screen)............................................................................... |

380 |

|

2.3.11 |

Alarm.................................................................................................................... |

380 |

2.4 |

Cs CONTOURING CONTROL (Optional function) .................................... |

381 |

|

|

2.4.1 |

Start-up Procedure................................................................................................ |

381 |

|

2.4.2 |

Overview .............................................................................................................. |

381 |

|

2.4.3 |

System Configuration........................................................................................... |

381 |

|

2.4.4 |

List of I/O Signals (CNC ↔ PMC)...................................................................... |

382 |

|

2.4.5 |

Examples of Sequences ........................................................................................ |

382 |

|

2.4.6 |

Related Parameters ............................................................................................... |

382 |

|

2.4.7 |

Details of Related Parameters............................................................................... |

383 |

|

2.4.8 |

Diagnosis (Diagnosis Screen)............................................................................... |

384 |

|

2.4.9 |

Alarm.................................................................................................................... |

384 |

2.5 |

SPINDLE SYNCHRONOUS CONTROL (Optional function)...................... |

385 |

|

|

2.5.1 |

Start-up Procedure................................................................................................ |

385 |

|

2.5.2 |

Overview .............................................................................................................. |

385 |

|

2.5.3 |

System Configuration........................................................................................... |

386 |

|

2.5.4 |

Explanation of Operation ..................................................................................... |

389 |

|

2.5.5 I/O Signals (CNC ↔ PMC) ................................................................................. |

389 |

|

|

|

c-6 |

|

B-65280EN/06 |

|

TABLE OF CONTENTS |

||

|

|

2.5.6 |

Examples of Sequences ........................................................................................ |

389 |

|

|

2.5.7 |

Related Parameters ............................................................................................... |

389 |

|

|

2.5.8 |

Details of Related Parameters............................................................................... |

389 |

|

|

2.5.9 |

Number of Error Pulses in Spindle Synchronous Control.................................... |

389 |

|

|

2.5.10 |

Specifying a Shift Amount for Spindle Phase Synchronous Control................... |

389 |

|

|

2.5.11 |

Diagnosis (Diagnosis Screen)............................................................................... |

389 |

|

|

2.5.12 |

Alarm.................................................................................................................... |

389 |

|

2.6 |

SPECIFICATIONS COMMON TO ALL OPERATION MODES.................. |

390 |

|

|

|

2.6.1 |

Overview .............................................................................................................. |

390 |

|

|

2.6.2 |

List of I/O Signals (CNC ↔ PMC)...................................................................... |

390 |

|

|

2.6.3 |

Parameters ............................................................................................................ |

390 |

|

|

2.6.4 |

Details of parameters............................................................................................ |

390 |

|

|

2.6.5 |

Diagnosis (Diagnosis Screen)............................................................................... |

390 |

3 I/O SIGNALS (CNC ↔ PMC) .............................................................. |

391 |

|||

|

3.1 |

INPUT SIGNALS (PMC→CNC→SVSP).................................................... |

392 |

|

|

|

3.1.1 |

List of Input Signals ............................................................................................. |

392 |

|

|

3.1.2 |

Explanation of Input Signals ................................................................................ |

392 |

|

|

3.1.3 |

Details of input signals ......................................................................................... |

392 |

|

3.2 |

OUTPUT SIGNALS (SVSP→CNC→PMC)................................................ |

393 |

|

|

|

3.2.1 |

List of Output Signals........................................................................................... |

393 |

|

|

3.2.2 |

Explanation of Output Signals ............................................................................. |

393 |

|

|

3.2.3 |

Details of Output Signals ..................................................................................... |

393 |

4 |

ADJUSTMENT .................................................................................... |

394 |

||

|

4.1 |

VELOCITY LOOP GAIN ADJUSTMENT ................................................... |

395 |

|

|

|

4.1.1 |

Overview .............................................................................................................. |

395 |

|

|

4.1.2 |

Parameters ............................................................................................................ |

395 |

|

|

4.1.3 |

Adjustment Procedure .......................................................................................... |

395 |

|

|

4.1.4 |

Additional Information (Position Gain Adjustment)............................................ |

395 |

5 |

FUNCTION DESCRIPTIONS .............................................................. |

396 |

||

5.1INCRMENTAL COMMAND TYPE SPINDLE ORIENTATION

(SPINDLE ROTATION SPEED CONTROL) (Optional function)................ |

397 |

|

5.1.1 |

Overview .............................................................................................................. |

397 |

5.1.2 |

System Configuration........................................................................................... |

397 |

5.1.3 |

I/O Signals (CNC↔PMC) ................................................................................... |

399 |

5.1.4 |

Examples of Sequences ........................................................................................ |

399 |

5.1.5 List of Related Parameters.................................................................................... |

400 |

|

5.1.6 Details of Related Parameters............................................................................... |

400 |

|

5.2 |

HIGH-SPEED SPINDLE ORIENTATION (Optional function)..................... |

401 |

|

|

5.2.1 |

Overview .............................................................................................................. |

401 |

|

5.2.2 |

System Configuration........................................................................................... |

401 |

|

5.2.3 |

I/O Signals (CNC↔PMC) ................................................................................... |

402 |

|

5.2.4 |

Sequence............................................................................................................... |

403 |

|

5.2.5 List of Related Parameters.................................................................................... |

404 |

|

|

5.2.6 Details of Related Parameters............................................................................... |

405 |

|

|

5.2.7 Spindle Data Used in Tuning ............................................................................... |

405 |

|

|

5.2.8 |

Tuning Procedure ................................................................................................. |

405 |

c-7

TABLE OF CONTENTS |

B-65280EN/06 |

||

5.3 |

SPINDLE FINE ACC./DEC. (FAD) FUNCTION ......................................... |

406 |

|

|

5.3.1 |

Overview .............................................................................................................. |

406 |

|

5.3.2 Series and Editions of Applicable Spindle Software............................................ |

406 |

|

|

5.3.3 |

Block Diagram ..................................................................................................... |

406 |

|

5.3.4 |

Parameters ............................................................................................................ |

407 |

|

5.3.5 |

Diagnosis (Diagnosis Screen)............................................................................... |

407 |

|

5.3.6 |

Status Errors ......................................................................................................... |

407 |

|

5.3.7 |

Cautions................................................................................................................ |

407 |

5.4UNEXPECTED DISTURBANCE TORQUE DETECTION FUNCTION

(Optional function) ..................................................................................... |

408 |

|

5.4.1 |

Overview .............................................................................................................. |

408 |

5.4.2 Series and Editions of Applicable Spindle Software............................................ |

408 |

|

5.4.3 |

I/O Signals (CNC↔PMC) ................................................................................... |

408 |

5.4.4 List of Related Parameters.................................................................................... |

408 |

|

5.4.5 Details of Related Parameters............................................................................... |

408 |

|

5.4.6 |

Parameter Tuning Procedure ................................................................................ |

408 |

III. FANUC AC SPINDLE MOTOR αCi series |

|

|

1 START-UP |

........................................................................................... |

411 |

|

1.1 |

START-UP PROCEDURE......................................................................... |

412 |

|

1.2 |

SPINDLE ..................................SERIAL INTERFACE (Optional function) |

413 |

|

|

1.2.1 .......................................................Parameters Related to Spindle Serial Output |

413 |

|

|

1.2.2 .........................................................Automatic Spindle Parameter Initialization |

413 |

|

|

1.2.3 ............................................................................... |

Diagnosis (Diagnosis Screen) |

414 |

|

1.2.4 .................................................................................................................... |

Alarm |

414 |

1.3 |

PARAMETERS ............................................RELATED TO DETECTORS |

415 |

|

|

1.3.1 ...........................................................................List of Parameters for Detectors |

415 |

|

|

1.3.2 ......................................................................Details of Parameters for Detectors |

416 |

|

|

1.3.3 .......................................................................... |

Typical Detector Configurations |

420 |

2 EXPLANATION OF OPERATION MODES......................................... |

422 |

|

2.1 VELOCITY CONTROL MODE................................................................... |

423 |

|

2.1.1 |

Start-up Procedure................................................................................................ |

423 |

2.1.2 |

Overview .............................................................................................................. |

423 |

2.1.3 |

System Configuration........................................................................................... |

423 |

2.1.4 List of I/O Signals (CNC↔PMC)........................................................................ |

424 |

|

2.1.5 |

Related Parameters ............................................................................................... |

428 |

2.1.6 Details of Related Parameters............................................................................... |

429 |

|

2.1.7 |

Troubleshooting ................................................................................................... |

434 |

2.2POSITION CODER METHOD SPINDLE ORIENTATION

(Optional function) ..................................................................................... |

438 |

|

2.2.1 |

Start-up Procedure................................................................................................ |

438 |

2.2.2 |

Overview .............................................................................................................. |

439 |

2.2.3 |

Feature.................................................................................................................. |

439 |

2.2.4 |

System Configuration........................................................................................... |

439 |

2.2.5 |

Stop Position Specification Method ..................................................................... |

439 |

2.2.6 |

I/O Signals (CNC↔PMC) ................................................................................... |

440 |

|

c-8 |

|

B-65280EN/06 |

|

TABLE OF CONTENTS |

|

|

2.2.7 |

Examples of Sequences ........................................................................................ |

440 |

|

2.2.8 |

Related Parameters ............................................................................................... |

441 |

|

2.2.9 |

Details of Related Parameters............................................................................... |

442 |

|

2.2.10 |

Adjusting the Orientation Stop Position Shift Parameter..................................... |

446 |

2.3 |

RIGID TAPPING (Optional function).......................................................... |

447 |

|

|

2.3.1 |

Start-up Procedure................................................................................................ |

447 |

|

2.3.2 |

Overview .............................................................................................................. |

447 |

|

2.3.3 |

System Configuration........................................................................................... |

448 |

|

2.3.4 |

List of I/O Signals (CNC ↔ PMC)...................................................................... |

449 |

|

2.3.5 |

Sequence............................................................................................................... |

451 |

|

2.3.6 |

Related Parameters ............................................................................................... |

452 |

|

2.3.7 |

Details of Related Parameters............................................................................... |

453 |

|

2.3.8 |

Parameter Setting Procedure ................................................................................ |

458 |

|

2.3.9 |

Adjustment Procedure .......................................................................................... |

464 |

|

2.3.10 |

Diagnosis (Diagnosis Screen)............................................................................... |

464 |

|

2.3.11 |

Alarm.................................................................................................................... |

464 |

2.4 |

SPINDLE SYNCHRONOUS CONTROL (Optional function)...................... |

465 |

|

|

2.4.1 |

Start-up Procedure................................................................................................ |

465 |

|

2.4.2 |

Overview .............................................................................................................. |

466 |

|

2.4.3 |

System Configuration........................................................................................... |

466 |

|

2.4.4 |

Explanation of Operation ..................................................................................... |

466 |

|

2.4.5 |

I/O Signals (CNC ↔ PMC) ................................................................................. |

467 |

|

2.4.6 |

Examples of Sequences ........................................................................................ |

467 |

|

2.4.7 |

Related Parameters ............................................................................................... |

468 |

|

2.4.8 |

Details of Related Parameters............................................................................... |

469 |

|

2.4.9 |

Number of Error Pulses in Spindle Synchronous Control.................................... |

475 |

|

2.4.10 |

Specifying a Shift Amount for Spindle Phase Synchronous Control................... |

475 |

|

2.4.11 |

Diagnosis (Diagnosis Screen)............................................................................... |

475 |

|

2.4.12 |

Alarm.................................................................................................................... |

475 |

2.5 |

SPECIFICATIONS COMMON TO ALL OPERATION MODES.................. |

476 |

|

|

2.5.1 |

Overview .............................................................................................................. |

476 |

|

2.5.2 |

List of I/O Signals (CNC ↔ PMC)...................................................................... |

476 |

|

2.5.3 |

Parameters ............................................................................................................ |

480 |

|

2.5.4 |

Details of parameters............................................................................................ |

482 |

|

2.5.5 |

Diagnosis (Diagnosis Screen)............................................................................... |

489 |

3 I/O SIGNALS (CNC ↔ PMC) .............................................................. |

490 |

||

3.1 |

INPUT SIGNALS (PMC→CNC→SPMC) ................................................... |

491 |

|

|

3.1.1 |

List of Input Signals ............................................................................................. |

491 |

|

3.1.2 |

Explanation of Input Signals ................................................................................ |

492 |

|

3.1.3 |

Details of Input Signals ........................................................................................ |

493 |

3.2 |

OUTPUT SIGNALS (SPMC→CNC→PMC) ............................................... |

494 |

|

|

3.2.1 |

List of Output Signals........................................................................................... |

494 |

|

3.2.2 |

Explanation of Output Signals ............................................................................. |

494 |

|

3.2.3 |

Details of Output Signals ..................................................................................... |

494 |

4 ADJUSTMENT .................................................................................... |

495 |

||

4.1 |

VELOCITY LOOP GAIN ADJUSTMENT ................................................... |

496 |

|

|

4.1.1 |

Overview .............................................................................................................. |

496 |

|

4.1.2 |

Parameters ............................................................................................................ |

496 |

|

|

c-9 |

|

TABLE OF CONTENTS |

B-65280EN/06 |

||

|

4.1.3 |

Adjustment Procedure .......................................................................................... |

499 |

|

4.1.4 Additional Information (Position Gain Adjustment)............................................ |

500 |

|

IV. FANUC BUILT-IN SPINDLE MOTOR BiS series |

|

||

1 START-UP |

........................................................................................... |

503 |

|

1.1 |

START-UP PROCEDURE......................................................................... |

504 |

|

1.2 |

SPINDLE ..................................SERIAL INTERFACE (Optional function) |

505 |

|

|

1.2.1 .......................................................Parameters Related to Spindle Serial Output |

505 |

|

|

1.2.2 .........................................................Automatic Spindle Parameter Initialization |

505 |

|

|

1.2.3 ............................................................................... |

Diagnosis (Diagnosis Screen) |

505 |

|

1.2.4 .................................................................................................................... |

Alarm |

505 |

1.3 |

PARAMETERS ............................................RELATED TO DETECTORS |

506 |

|

|

1.3.1 ...........................................................................List of Parameters for Detectors |

506 |

|

|

1.3.2 ......................................................................Details of Parameters for Detectors |

506 |

|

|

1.3.3 .......................................................................... |

Typical Detector Configurations |

507 |

1.4 |

SUB MODULE .....................................................................................SM |

508 |

|

|

1.4.1 .............................................................................................................. |

Overview |

508 |

|

1.4.2 ............................................Series and Editions of Applicable Spindle Software |

508 |

|

|

1.4.3 ....................................................................................................... |

Configuration |

508 |

|

1.4.4 ............................................................................................... |

Related Parameters |

509 |

|

1.4.5 ......................................Stop Processing When a Sub Module SM Error Occurs |

511 |

|

|

1.4.6 .........................................................................................Alarm and Status Error |

512 |

|

|

1.4.7 ................................................................................................................. |

Caution |

513 |

1.5 |

MAGNETIC ................................................................POLE DETECTION |

515 |

|

|

1.5.1 .............................................................................................................. |

Overview |

515 |

|

1.5.2 .....................................................................Magnetic Pole Detection Operation |

516 |

|

|

1.5.3 ........................................................................................... |

AMR Offset Function |

518 |

|

1.5.4 .................................................................................I/O Signals (CNC ↔ PMC) |

521 |

|

|

1.5.5 ............................................................................................... |

Related Parameters |

523 |

|

1.5.6 ............................................................................................................... |

Sequence |

529 |

|

1.5.7 .................................................................................Causes of Spindle Alarm 65 |

531 |

|

|

1.5.8 ................................................................................................................ |

Cautions |

531 |

2 EXPLANATION .........................................OF OPERATION MODES |

532 |

||

2.1 |

VELOCITY ...................................................................CONTROL MODE |

533 |

|

|

2.1.1 ................................................................................................ |

Start - up Procedure |

533 |

|

2.1.2 .............................................................................................................. |

Overview |

533 |

|

2.1.3 ........................................................................................... |

System Configuration |

533 |

|

2.1.4 ........................................................................List of I/O Signals (CNC↔PMC) |

533 |

|

|

2.1.5 ............................................................................................... |

Related Parameters |

534 |

|

2.1.6 ...............................................................................Details of Related Parameters |

536 |

|

|

2.1.7 ................................................................................................... |

Troubleshooting |

543 |

2.2POSITION CODER METHOD SPINDLE ORIENTATION

(Optional function) ..................................................................................... |

544 |

|

2.2.1 |

Start-up Procedure................................................................................................ |

544 |

2.2.2 |

Overview .............................................................................................................. |

544 |

2.2.3 |

Feature.................................................................................................................. |

544 |

2.2.4 |

System Configuration........................................................................................... |

544 |

|

|

c-10 |

B-65280EN/06 |

|

TABLE OF CONTENTS |

|

|

2.2.5 |

Stop Position Specification Method ..................................................................... |

544 |

|

2.2.6 |

I/O Signals (CNC ↔ PMC) ................................................................................. |

544 |

|

2.2.7 |

Examples of Sequences ........................................................................................ |

545 |

|

2.2.8 |

Related Parameters ............................................................................................... |

545 |

|

2.2.9 |

Details of Related Parameters............................................................................... |

546 |

|

2.2.10 |

Adjusting the Orientation Stop Position Shift Parameter..................................... |

549 |

2.3 |

RIGID TAPPING (Optional function).......................................................... |

550 |

|

|

2.3.1 |

Start-up Procedure................................................................................................ |

550 |

|

2.3.2 |

Overview .............................................................................................................. |

550 |

|

2.3.3 |

System Configuration........................................................................................... |

550 |

|

2.3.4 |

List of I/O Signals (CNC ↔ PMC)...................................................................... |

550 |

|

2.3.5 |

Sequence............................................................................................................... |

550 |

|

2.3.6 |

Related Parameters ............................................................................................... |

551 |

|

2.3.7 |

Details of Related Parameters............................................................................... |

553 |

|

2.3.8 |

Parameter Setting Procedure ................................................................................ |

557 |

|

2.3.9 |

Adjustment Procedure .......................................................................................... |

557 |

|

2.3.10 |

Diagnosis (Diagnosis Screen)............................................................................... |

562 |

|

2.3.11 |

Alarm.................................................................................................................... |

562 |

2.4 |

Cs CONTOURING CONTROL (Optional function) .................................... |

563 |

|

|

2.4.1 |

Start-up Procedure................................................................................................ |

563 |

|

2.4.2 |

Overview .............................................................................................................. |

563 |

|

2.4.3 |

System Configuration........................................................................................... |

563 |

|

2.4.4 |

List of I/O Signals (CNC ↔ PMC)...................................................................... |

563 |

|

2.4.5 |

Examples of Sequences ........................................................................................ |

563 |

|

2.4.6 |

Related Parameters ............................................................................................... |

564 |

|

2.4.7 |

Details of Related Parameters............................................................................... |

566 |

|

2.4.8 |

Diagnosis (Diagnosis Screen)............................................................................... |

573 |

|

2.4.9 |

Alarm.................................................................................................................... |

573 |

2.5 |

SPINDLE SYNCHRONOUS CONTROL (Optional function)...................... |

574 |

|

|

2.5.1 |

Start-up Procedure................................................................................................ |

574 |

|

2.5.2 |

Overview .............................................................................................................. |

574 |

|

2.5.3 |

System Configuration........................................................................................... |

574 |

|

2.5.4 |

Explanation of Operation ..................................................................................... |

575 |

|

2.5.5 |

I/O Signals (CNC ↔ PMC) ................................................................................. |

575 |

|

2.5.6 |

Examples of Sequences ........................................................................................ |

575 |

|

2.5.7 |

Related Parameters ............................................................................................... |

576 |

|

2.5.8 |

Details of Related Parameters............................................................................... |

577 |

|

2.5.9 |

Number of Error Pulses in Spindle Synchronous Control.................................... |

583 |

|

2.5.10 |

Specifying a Shift Amount for Spindle Phase Synchronous Control................... |

583 |

|

2.5.11 |

Diagnosis (Diagnosis Screen)............................................................................... |

583 |

|

2.5.12 |

Alarm.................................................................................................................... |

583 |

2.6 |

SPECIFICATIONS COMMON TO ALL OPERATION MODES.................. |

584 |

|

|

2.6.1 |

Overview .............................................................................................................. |

584 |

|

2.6.2 |

List of I/O Signals (CNC ↔ PMC)...................................................................... |

584 |

|

2.6.3 |

Parameters ............................................................................................................ |

588 |

|

2.6.4 |