Graco Inc 256856, ti12763a, ti12771a, ti12870a, 257092 User Manual

...

HVLP EDGE™ Gun

Models: 256855, 257092, 256856

Maximum Fluid Working Pressure: 50 psi (0.35 MPa, 3.5 bar) Maximum Air Working Pressure: 10 psi (0.07 MPa, 0.7 bar)

Important Safety Instructions

Refer to your sprayer instruction manual for Pressure Relief and spray instructions. Keep these instructions.

ti12761a |

ti12761a |

ti12870a |

256855 |

257092 |

256856 |

Registered Design No. 001147813-0001 |

313317C |

|

ENG |

- For the application of architectural paints and coatings -

The HVLP Edge gun is not intended to be used on an external compressor

The following Warnings are for the setup, use, grounding, maintenance and repair of this equipment. The exclamation point symbol alerts you to a general warning and hazard symbols refer to procedure-specific risks. Refer back to these Warnings. Additional, product-specific warnings may be found throughout the body of this manual where applicable.

WARNINGS

FIRE AND EXPLOSION HAZARD

Flammable fumes, such as solvent and paint fumes, in work area can ignite or explode. To help prevent fire and explosion:

•Use equipment only in well ventilated area. •Eliminate all ignition sources; such as pilot lights, cigarettes, portable electric lamps, and plastic drop cloths (potential static arc).

•Keep work area free of debris, including solvent, rags and gasoline.

•Do not plug or unplug power cords, or turn power or light switches on or off when flammable fumes are present.

•Ground all equipment in the work area. See Grounding instructions.

•Hold gun firmly to side of grounded pail when triggering into pail.

•If there is static sparking or you feel a shock, stop operation immediately. Do not use equipment until you identify and correct the problem.

•Keep a working fire extinguisher in the work area.

•When flammable liquid is sprayed or used for flushing or cleaning, keep sprayer at least 20 feet (6 meters) away from explosive vapors.

•Do not clean with materials having flash points lower than 70° F (21° C). Use water-based materials or mineral spirits-type material only. For complete information about your fluid, request the MSDS from the fluid distributor or retailer.

EQUIPMENT MISUSE HAZARD

Misuse can cause death or serious injury.

•Do not operate the unit when fatigued or under the influence of drugs or alcohol.

•Do not exceed the maximum working pressure or temperature rating of the lowest rated system component. See Technical Data in all equipment manuals.

•Use fluids and solvents that are compatible with equipment wetted parts. See Technical Data in all equipment manuals. Read fluid and solvent manufacturer’s warnings. For complete information about your material, request MSDS forms from distributor or retailer.

•Check equipment daily. Repair or replace worn or damaged parts immediately with genuine manufacturer’s replacement parts only.

•Do not alter or modify equipment.

•Use equipment only for its intended purpose. Call your distributor for information.

•Route hoses and cables away from traffic areas, sharp edges, moving parts, and hot surfaces.

•Do not kink or over bend hoses or use hoses to pull equipment.

•Keep children and animals away from work area.

•Comply with all applicable safety regulations.

PRESSURIZED ALUMINUM PARTS HAZARD

Do not use 1,1,1-trichloroethane, methylene chloride, other halogenated hydrocarbon solvents or

fluids containing such solvents in pressurized aluminum equipment. Such use can cause serious chemical reaction and equipment rupture, and result in death, serious injury, and property damage.

PERSONAL PROTECTIVE EQUIPMENT

You must wear appropriate protective equipment when operating, servicing, or in the operating

area of the equipment to help protect you from serious injury, including eye injury, inhalation of toxic fumes, burns, and hearing loss. This equipment includes but is not limited to:

•Protective eyewear and Hearing protection

•Gloves, clothing and respirator as recommended by the fluid and solvent manufacturer

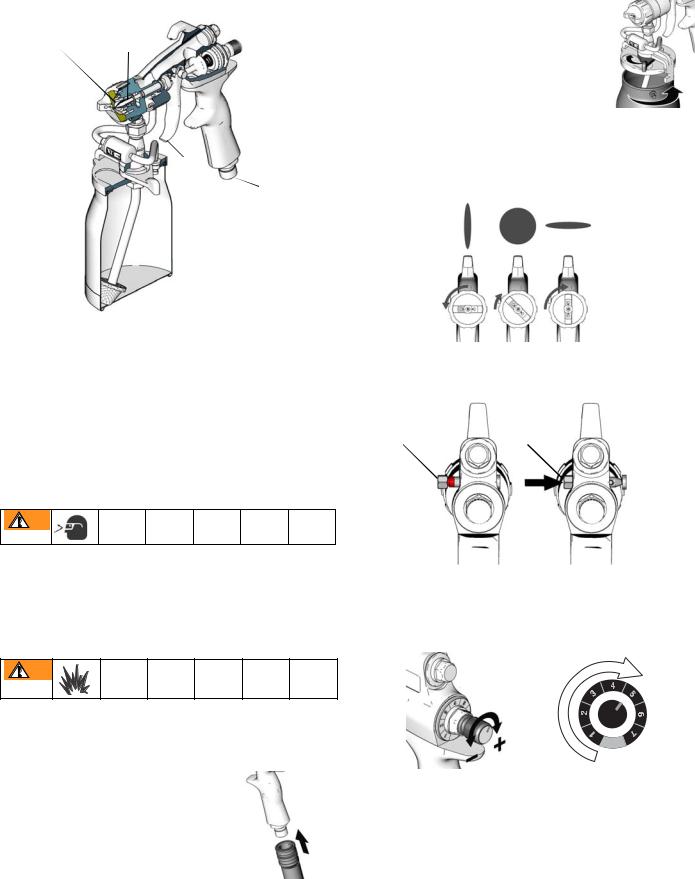

Component Identification

|

D |

E |

|

|

|

|

F |

|||||||

|

|

|

|

|

||||||||||

|

C |

|

|

|

|

|

|

|

|

|

|

|

|

G |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

B |

|

|

|

|

|

|

J |

|

|

|

|||

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

K |

H |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

A |

|

|

|

|

|

|

|

|

|

|

M |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

ti12771a |

|||||

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

N |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

ID |

|

Component |

ID |

Component |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

Siphon Cup |

|

|

|

G |

Trigger Slide |

||||||||

B |

Check Valve |

|

|

|

H |

Air Inlet |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

Air Cap |

|

|

|

J |

EasyGlide™ Trigger |

||||||||

D |

Air Nozzle |

|

|

|

K |

Latch |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

Fluid Needle |

|

|

|

M |

Swivel Tube |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F |

Flow Control Knob |

N |

Strainer |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressure Relief Procedure

Component Identification

2.Fill cup 3/4 full. Install cover. Latch the gun cup cover to secure it to siphon cup.

ti12872a

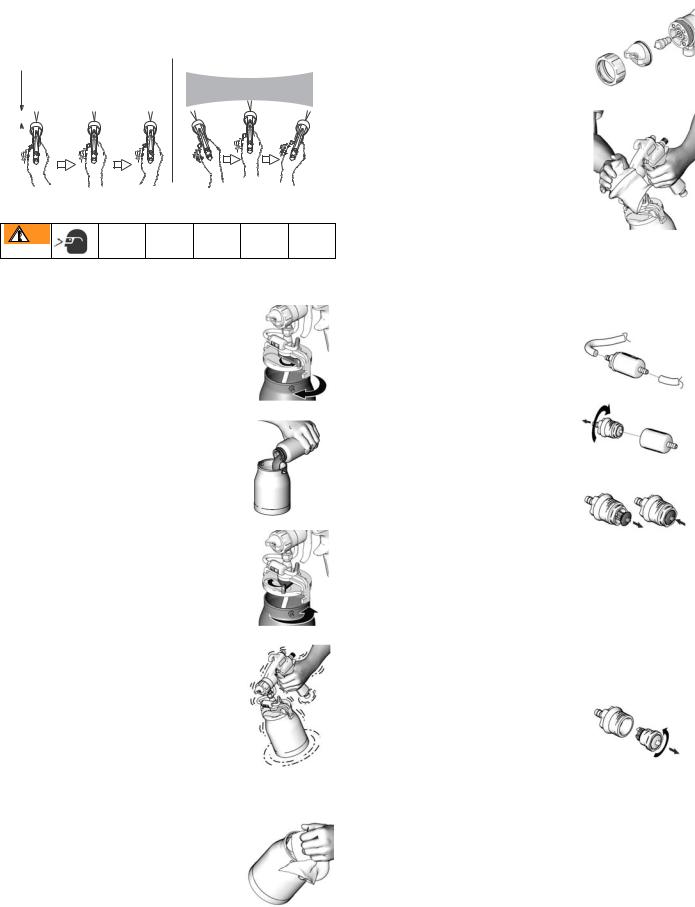

Operation

Adjust Spray Pattern

1. Set air cap to position for spray pattern desired.

ti12763a

2.Verify trigger slide is in SPRAY position (E) and not

NEEDLE REMOVAL position (D).

D E

The spray gun cup is pressurized by the gun air supply. To reduce the risk of serious injury from pressurized fluid or accidental spray from gun, always turn off the air supply to the gun before removing the spray gun cup. Unplug sprayer from outlet

Setup

Make sure sprayer is turned off and unplugged from power source. Refer to your sprayer instruction manual for spray setup.

Connect Gun to Siphon Cup

1.Attach air hose from sprayer to inlet fitting of gun.

ti12797a

ti12795a

Adjust Flow and Pattern Size

Flow and pattern size is determined by the flow control knob. Set knob at 0. Increase flow to attain desired spray pattern.

ti12772a |

ti12823a |

Spray

1.Keep gun perpendicular to surface and at a distance of 6 to 8 in. (150 to 200 mm) from surface.

2 |

313317C |

2.Have spray gun in motion before triggering. Move spray gun in a straight, smooth stroke. Release trigger at end of stroke.

6 to 8 in. (150 to 200 mm)

|

|

|

RIGHT |

|

WRONG |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ti12793a

Cleaning Spray Gun

Before cleaning gun, read all warnings and do Pressure Relief Procedure.

1.Remove siphon cup. Empty spray material from siphon cup.

ti12775a

2.Pour small amount of solvent or water recommended by spray material manufacturer into siphon cup.

ti12775a

3.Latch the gun cup cover to secure it to siphon cup.

ti12872a

4.Swirl solvent or water inside of gun.

5.Spray solvent or water into waste pail until spray appears to be clean.

6. Remove siphon cup. Empty |

ti12906a |

|

|

remaining solvent or water from |

|

siphon cup. |

|

7.Clean inside of siphon cup with a clean rag.

ti12905a

Operation

8.Remove retaining ring, air cap and fluid nozzle. Clean in solvent or water. Clean face of gun with a solvent or water dampened rag.

ti12778a

9.Assemble gun. Wipe gun with solvent or water dampened rag.

ti12780a

Check Valve Troubleshooting

Recommended if fluid is in the check valve.

Poppet Valve Quick Clear

1.Disconnect check valve from siphon cup air hoses.

ti13104a

2. Unscrew check valve.

ti13105a

3.Pull out on nub on poppet valve and release.

ti13106a

4.Assemble check valve. Install on air hoses.

5.Try spraying again to see if spraying is normal.

Check Valve Cleaning

1.Do steps 1 and 2 of Poppet Valve Quick Clean.

2.Unscrew poppet valve from check valve.

3.Clean all parts in solvent rec-

ommended by spray material |

ti13107a |

|

|

manufacturer. |

|

4.After all parts are dry apply a light coat of petroleum jelly all over o-ring.

5.Assemble check valve. Install on air hoses.

313317C |

3 |

Loading...

Loading...