Thomson TS 870 Manual

TS 870

AUTOMATIC TRANSFER SWITCHES

INSTALLATION, OPERATING &

SERVICE MANUAL

PM062 Rev 6 08/08/01

9087A – 198th Street, Langley, BC Canada V1M 3B1 Telephone (604) 888-0110 Telefax (604) 888-3381 E-Mail: info@thomsontechnology.com www.thomsontechnology.com

TS 870 TRANSFER SWITCH

TABLE OF CONTENTS

1. |

PRODUCT REVISION HISTORY |

1 |

|

2. |

EQUIPMENT STORAGE |

1 |

|

|

2.1. |

ENVIRONMENTAL CONDITIONS |

1 |

3. |

NOTES TO INSTALLER |

2 |

|

|

3.1. UPSTREAM CIRCUIT PROTECTIVE DEVICES/ELECTRICAL CONNECTIONS |

2 |

|

|

3.2. TRANSFER SWITCHES WITH INTEGRAL OVER CURRENT PROTECTION |

3 |

|

|

3.3. TRANSFER SWITCHES WITH MULTI-TAP VOLTAGE CAPABILITY |

3 |

|

|

3.4. SYSTEM PHASING-HIGH LEG DELTA SYSTEMS |

4 |

|

|

3.5. REMOTE START CONTACT FIELD WIRING |

5 |

|

|

3.6. |

DIELECTRIC TESTING |

5 |

|

3.7. INSTALLATION OF OPEN TYPE TRANSFER SWITCHES |

5 |

|

4. |

GENERAL DESCRIPTION |

5 |

|

|

4.1. |

PRODUCT MODEL CODE |

7 |

|

4.2. |

TYPICAL COMMISSIONING PROCEDURES |

8 |

5. |

GENERAL THEORY OF OPERATION |

8 |

|

|

5.1. STANDARD AUTOMATIC TRANSFER SWITCH |

8 |

|

|

5.2. SERVICE ENTRANCE AUTOMATIC TRANSFER SWITCH |

9 |

|

|

5.3. |

TEST MODES |

13 |

6. |

OVER CURRENT PROTECTION |

13 |

|

|

6.1. STANDARD TS 870 AUTOMATIC TRANSFER SWITCH |

13 |

|

|

6.2. |

OPTIONAL TS 870 AUTOMATIC TRANSFER SWITCH WITH INTEGRAL OVER |

|

|

|

CURRENT PROTECTION |

14 |

7. |

GENERAL NOTES ON SERVICING TRANSFER SWITCH MECHANISM |

15 |

|

8. |

TRANSFER SWITCH MECHANISM – 100A-800A, S STYLE |

17 |

|

|

8.1. |

MANUAL OPERATION |

17 |

PM062 REV 6 08/08/01 |

Thomson Technology |

|

|

TS 870 TRANSFER SWITCH

9. |

TRANSFER SWITCH MECHANISM –1000A-1200A, T-STYLE |

19 |

|

|

9.1. |

MANUAL OPERATION |

19 |

10. |

RECOMMENDED MAINTENANCE |

21 |

|

11. |

FRONT VIEW (TYPICAL) 3 / 4 POLE 100A-250A S-STYLE TRANSFER |

|

|

MECHANISM |

23 |

||

12. |

FRONT VIEW (TYPICAL) 3 POLE 400A-800A S-STYLE TRANSFER MECHANISM |

||

(MECHANISM FRONT COVER REMOVED) |

24 |

||

13. |

FRONT VIEW (TYPICAL) 3 / 4 POLE 1000A-1200A T-STYLE TRANSFER |

|

|

MECHANISM |

25 |

||

14. |

CONNECTION CONFIGURATION OPTIONS |

26 |

|

15. |

CABLE TERMINAL INFORMATION |

27 |

|

16. |

REQUIREMENTS FOR UPSTREAM CIRCUIT PROTECTIVE DEVICES |

27 |

|

|

16.1. WITHSTAND CURRENT RATINGS (ALL MODELS WITHOUT INTEGRAL |

|

|

|

|

OVERCURRENT PROTECTION OPTION) |

27 |

|

16.2. INTERRUPTING CAPACITY CURRENT RATINGS (ALL MODELS WITH INTEGRAL |

|

|

|

|

OVERCURRENT PROTECTION OPTION) |

28 |

17. |

GROUND FAULT SITE TEST REQUIREMENTS |

28 |

|

|

17.1. |

PERFORMANCE TEST |

28 |

18. |

TROUBLESHOOTING |

30 |

|

19. |

REPLACEMENT PARTS |

32 |

|

20. |

PRODUCT RETURN POLICY |

33 |

|

21. |

NOTES |

34 |

|

22. |

PERFORMANCE TEST FORM |

35 |

|

PM062 REV 6 08/08/01 |

Thomson Technology |

|

|

TS 870 TRANSFER SWITCH

1.PRODUCT REVISION HISTORY

The following information provides an historical summary of changes made to this product since the original release.

Operating & Service Manual Version

Rev 0 04/11/19 |

Original release. |

|

|

Rev 1 05/03/08 |

Changes to incorporate reversing style ATS Motor for 100-250A |

|

transfer switches. |

|

|

Rev 2 05/05/26 |

Revisions to Section 8 and Section 18. |

|

|

Rev 3 06/05/08 |

Revisions to Section 15. |

|

|

Rev 4 07/07/31 |

Changes to Incorporate new S-Style 400A mechanism |

|

|

Rev 5 08/03/05 |

Changes to Incorporate new S-Style mechanism (100A, 150A, |

|

200A, 250A, 600A, 800A) |

|

|

Rev 6 08/08/01 |

Changes to Incorporate optional TSC 80E Transfer Controller |

|

|

Contact Thomson Technology, to obtain applicable instruction manuals or if in doubt about any matter relating to installation, operation or maintenance. Soft copy of the most current version is available at www.thomsontechnology.com.

NOTE: All information contained in this manual is for reference only and is subject

to change without notice.

2.EQUIPMENT STORAGE

The following procedures are required for correct storage of the transfer switch prior to installation.

2.1.ENVIRONMENTAL CONDITIONS

CAUTION!!!

Failure to store and operate equipment under the specified environmental conditions may cause equipment damage and void warranty.

2.1.1. EQUIPMENT STORAGE

The transfer switch shall be stored in an environment with a temperature range not exceeding -4° to +158° Fahrenheit (-20° to +70° Celsius) and a humidity range not exceeding 5%-95% non-condensing. Before storing, unpack sufficiently to check for concealed damage. If concealed damage is found, notify the ATS supplier and the Carrier immediately. Repack with the original, or equivalent packing materials.

PM062 REV 6 08/08/01 |

1 |

Thomson Technology |

TS 870 TRANSFER SWITCH

Protect from physical damage. Do not stack. Store indoors in a clean, dry, well ventilated area free of corrosive agents including fumes, salt and concrete/cement dust. Apply heat as necessary to prevent condensation.

2.1.2. EQUIPMENT OPERATING

The transfer switch shall be operated in an environment with a temperature range not exceeding +5° to +122° Fahrenheit (-15° to +50° Celsius) and a humidity range not exceeding 5%-95% non-condensing.

3.NOTES TO INSTALLER

DANGER!!!!

Arc Flash and Shock Hazard. Will cause severe injury or death.

Do not open equipment until ALL power sources are disconnected

This equipment must be installed and serviced only by qualified electrical personnel utilizing safe work practices and appropriate Personal Protective Equipment (PPE). Failure to do so may cause personal injury or death

3.1.UPSTREAM CIRCUIT PROTECTIVE DEVICES/ELECTRICAL CONNECTIONS

To ensure satisfactory installation of this equipment be sure to observe "Cable Terminal Information” regarding power cable connection tightness and "Requirements for Upstream Circuit Protective Devices" located in this manual.

All mechanical and electrical connections must be checked for tightness prior to placing this equipment in service to ensure proper operation and to validate applicable warranty coverage.

PM062 REV 6 08/08/01 |

2 |

Thomson Technology |

TS 870 TRANSFER SWITCH

3.2. TRANSFER SWITCHES WITH INTEGRAL OVER CURRENT PROTECTION

For models of transfer switch with integral over current protection, the over current protection must be set prior to operation. The equipment will be shipped from the factory with a longtime current setting of 100% (of the equipment rating) and maximum shorttime/instantaneous current and time delay settings.

WARNING!

Do Not Energize this equipment until device settings have been verified to ensure proper system protection & coordination. Failure to do so may result in equipment failure.

Refer to Section 5.2.2 of this manual for additional information on operation of the Transfer switch following an over current trip condition.

Refer to information supplied with the transfer switch documentation package for adjustment procedures on the power switching units over current protection trip unit. Contact the factory if any additional information is required.

3.3.TRANSFER SWITCHES WITH MULTI-TAP VOLTAGE CAPABILITY

If the transfer switch has programmable multi-tap voltage capability (i.e. ATS Model Code with Voltage Code “Y”), confirm the transfer switch has been configured for the correct system voltage prior to installation.

WARNING!

Failure to confirm and match transfer switch voltage with the system voltage could cause serious equipment damage.

The voltage selections and connections are shown on the engineered drawings attached to each transfer switch. The factory default settings will be indicated on the calibration label attached on the inside of the enclosure door (supplied loose on open style models). A blank label is included to record the applicable settings if the configuration is changed from the factory default settings.

PM062 REV 6 08/08/01 |

3 |

Thomson Technology |

TS 870 TRANSFER SWITCH

To change the transfer switch voltage, refer to “INSTRUCTIONS TO CHANGE SYSTEM

VOLTAGE ON TS870 SERIES TRANSFER SWITCHES WITH TSC 80/TSC 80E

CONTROLLER” (attached as “Appendix B). Contact Thomson Technology for further

information as may be required.

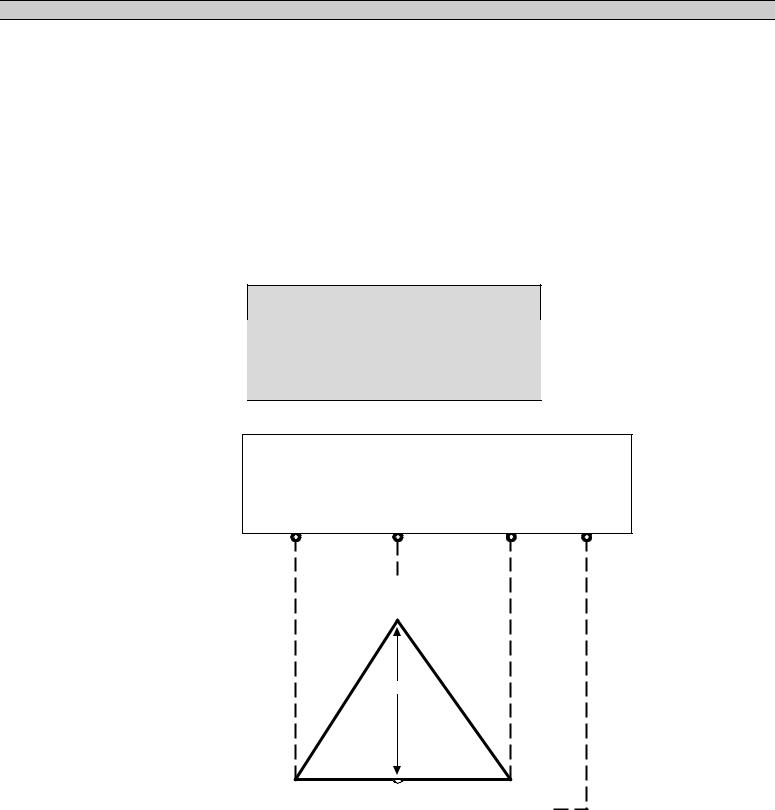

3.4.SYSTEM PHASING-HIGH LEG DELTA SYSTEMS

For systems using high leg delta 240V 3 phase 4 wire systems, connection of supply conductors must have the correct phasing as shown below.

WARNING

Failure to match correct system phasing will result in serious damage to the TSC 80/TSC 80E controller.

Autom atic Transfer

Switch (Utility Supply)

PH A |

PH B |

PH C |

Neural |

(UA) |

(UB) |

(UC) |

(N) |

B

(O range)

(High Leg)

240V |

208V |

240V |

A |

120V |

|

|

|

|

120V |

|

|

|

|

|

C |

||||

|

||||||||||||||||

(Red) |

|

|

|

|

|

|

|

|

|

|

|

|

|

(Yellow) |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N

(W hite)

Where transfer switches are supplied without power isolation transformers (PT1 & PT2) for ATS control logic it is essential that the orientation of phase conductors of

PM062 REV 6 08/08/01 |

4 |

Thomson Technology |

TS 870 TRANSFER SWITCH

the supply source be arranged such that the phase of highest potential with respect to ground is not connected to the power supply inputs to the controller (A Phase for both supplies). Failure to do so will result in equipment damage.

Per NEC Article 384-3 (f) “The B phase shall be that phase having the higher voltage to ground on a 3-phase, 4-wire delta connected systems.”

3.5.REMOTE START CONTACT FIELD WIRING

As a minimum, the remote engine start control field wiring shall conform to the local regulatory authority on electrical installations. Field wiring of a remote start contact from a transfer switch to a control panel should conform to the following guidelines to avoid possible controller malfunction and/or damage.

3.5.1.Minimum #14 AWG (2.5mm2) wire size shall be used for distances up to 100ft (30m)1). For distances exceeding 100 ft. (30m) consult Thomson Technology

3.5.2.Remote start contact wires should be run in a separate conduit.

3.5.3.Avoid wiring near AC power cables to prevent pick-up of induced voltages.

3.5.4.An interposing relay may be required if field-wiring distance is excessively long (i.e. greater than 100 feet (30m)) and/or if a remote contact has a resistance of greater than 5.0 ohms.

3.5.5.The remote start contact must be voltage free (i.e. dry contact). The use of a “powered” contact will damage the transfer controller.

3.6.DIELECTRIC TESTING

Do not perform any high voltage dielectric testing on the transfer switch with the TSC 80/TSC 80E controller connected into the circuit as serious damage will occur to the controller. All AC control fuses and control circuit isolation plugs connected to the TSC 80/TSC 80E must be removed if high voltage dielectric testing is performed on the transfer switch.

3.7.INSTALLATION OF OPEN TYPE TRANSFER SWITCHES

Please refer to the factory for additional information.

4.GENERAL DESCRIPTION

Thomson Technology TS 870 series of Automatic Transfer Switches employ two mechanically interlocked enclosed contact power switching units and a microprocessor based controller to automatically transfer system load to a generator supply in the event of a utility supply failure.

PM062 REV 6 08/08/01 |

5 |

Thomson Technology |

TS 870 TRANSFER SWITCH

System load is then automatically re-transferred back to the utility supply following restoration of the utility power source to within normal operating limits.

The standard TS 870 series Automatic Transfer Switch is rated for 100% system load and requires upstream over current protection. The TS 870 Automatic Transfer Switch may be supplied with optional integral over current protection within the enclosed contact power switching units for applications such as Service Entrance Rated equipment. Refer to Section 6 of this manual for detailed information on over current protection.

The TS 870 series transfer switches use a type TSC 80 standard or optional TSC 80E microprocessor based controller, which provides all necessary control functions for fully automatic operation. The TSC 80/TSC 80E controller is mounted on the door of the transfer switch enclosure and operating status is shown via LED lights. For further information on the TSC 80/TSC 80E Transfer Controller, refer to separate instruction manual PM063.

The power switching devices used for the Utility and Generator sources are operated by an electrically driven motor mechanism in the transfer switch. The transfer switch motor utilizes the power from the source to which the electrical load is being transferred. The mechanism provides a positive mechanical interlock to prevent both power switching units from being closed at the same time, which allows an open transition, “break-before-make” transfer sequence. The TSC 80/TSC 80E transfer controller provides a standard neutral position delay timer to allow adequate voltage decay during transfer operation to prevent out of phase transfers.

Note: For the purpose of this manual, the following standard nomenclature is utilized:

•Utility: to indicate the source of primary power

•Generator: to indicate the source of standby power

•Power switching device: to indicate the transfer switch power switching device

PM062 REV 6 08/08/01 |

6 |

Thomson Technology |

TS 870 TRANSFER SWITCH

4.1.PRODUCT MODEL CODE

The type of TS 870 series transfer switch supplied is identified by way of a 21 digit product code which appears on the equipment rating plate (MODEL) on the door of the transfer switch, and on the transfer switch drawings. The model code structure and definitions are as follows:

1 |

|

2 |

4 |

5 |

6 |

7 |

8 |

|

9 |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

18 |

19 |

20 |

21 |

|

||

|

T |

S |

|

8 |

7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1-3. SERIES |

|

|

|

|

15 . VOLTAGE |

|

|

|

|

|

|

|

|

18. UTILITY SWITCHING DEVICE |

||||||||||

TS - TRANSFER SWITCH |

|

|

|

|

|

1f 3 WIRE |

|

|

|

|

|

|

|

|

|

K - MOLDED CASE SWITCH (100 - 1200 A) |

||||||||

|

|

|

|

|

|

|

|

D - 120/240 |

|

|

|

|

|

|

|

|

|

M - MOLDED CASE SWITCH C/W THER-MAG |

||||||

4 & 5. MODEL |

|

|

|

|

|

3f 4 WIRE (GROUNDED NEUTRAL) |

|

|

|

|

TRIP (100-200A) |

|||||||||||||

87 - 870 SWITCH |

|

|

|

|

|

E - 120/208 1 |

|

|

|

|

|

|

|

|

N - MOLDED CASE SWITCH C/W ELECTRONIC |

|||||||||

|

|

|

|

|

|

|

|

F - 127/220 |

|

|

|

|

|

|

|

|

|

|

TRIP (250-1200A) |

|||||

6. POLES |

|

|

|

|

|

G - 120240 1 (DELTA) |

|

|

|

|

|

|

P - MOLDED CASE SWITCH C/W ELECTRONIC |

|||||||||||

2 - 2 POLE |

|

|

|

|

|

H - 220/380 2 |

|

|

|

|

|

|

|

|

|

& GF TRIP (250-1200A) |

||||||||

3 - 3 POLE |

|

|

|

|

|

J - 240/416 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

4 - 4 POLE |

|

|

|

|

|

K - 254/440 |

|

|

|

|

|

|

|

|

19. GENERATOR SWITCHING DEVICE |

|||||||||

|

|

|

|

|

|

|

|

M - 277/480 1 |

|

|

|

|

|

|

|

|

K - MOLDED CASE SWITCH (100 - 1200 A) |

|||||||

7. CONFIGURATION TYPE |

|

|

|

|

|

N - 347/600 1 |

|

|

|

|

|

|

|

|

M - MOLDED CASE SWITCH C/W THER-MAG |

|||||||||

A - ATS |

|

|

|

|

|

3f 3 WIRE |

|

|

|

|

|

|

|

|

|

|

TRIP (100-200A) |

|||||||

X - SPECIAL |

|

|

|

|

|

P - 208 |

|

|

|

|

|

|

|

|

|

N - MOLDED CASE SWITCH C/W ELECTRONIC |

||||||||

|

|

|

|

|

|

|

|

Q - 220 |

|

|

|

|

|

|

|

|

|

|

TRIP (250-1200A) |

|||||

8 - 11. AMPERAGE |

|

|

|

|

|

R - 240 |

|

|

|

|

|

|

|

|

|

P - MOLDED CASE SWITCH C/W ELECTRONIC |

||||||||

0100 |

|

|

|

|

|

|

|

S - 380 2 |

|

|

|

|

|

|

|

|

|

|

& GF TRIP (250-1200A) |

|||||

0150 |

|

|

|

|

|

|

|

U - 416 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

0200 |

|

|

|

|

|

|

|

V - 480 |

|

|

|

|

|

|

|

|

20. POWER CONNECTIONS |

|||||||

0250 |

|

|

|

|

|

|

|

W - 600 |

|

|

|

|

|

|

|

|

|

A - STANDARD |

||||||

0400 |

|

|

|

|

|

|

|

X - SPECIAL |

|

|

|

|

|

|

|

|

X - SPECIAL |

|

|

|||||

0600 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0800 |

|

|

|

|

|

|

16. CONTROLLER |

|

|

|

|

|

|

|

21. ATS CONNECTION CONFIGURATION |

|||||||||

1000 |

|

|

|

|

|

|

|

1 - TSC80 |

|

|

|

|

|

|

|

|

|

A - STANDARD |

||||||

1200 |

|

|

|

|

|

|

|

3 - TSC 80e |

|

|

|

|

|

|

|

|

B - ALTERNATE B (1000-1200A) |

|||||||

|

|

|

|

|

|

|

|

7 - NONE (MANUAL) |

|

|

|

|

|

|

C - ALTERNATE C (1000-1200A) |

|||||||||

12. APPLICATION |

|

|

|

|

17. ENCLOSURE TYPE |

|

|

|

|

|

|

|

D - ALTERNATE D (1000-1200A) |

|||||||||||

A - STANDARD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

B - SERVICE ENTRANCE |

A - NEMA1, ASA #61 GREY |

X - SPECIAL |

B - NEMA2, ASA #61 GREY |

|

C - NEMA12, ASA #61 GREY |

13. OPERATION TYPE |

D - NEMA3R SD, ASA #61 GREY |

1 - OPEN TRANSITION |

E - NEMA3R/4 DD, ASA #61 GREY 3 |

2 - MANUAL ELEC. OP. |

F - NEMA3RX/4X DD |

X - SPECIAL |

(306 STAINLESS STEEL) 3 |

|

G - NONE (OPEN STYLE) |

14 . SAFETY STANDARDS |

H - NEMA 3RXDD (ALUMINUM) |

A - UL 1008 |

ASA #61 GREY 4 |

B - CSA C22.2 NO 178 |

X - SPECIAL |

X - NOT APPLICABLE |

|

REFER TO DRAWING #870M100

NOTES

1 MULTI-VOLTAGE CAPABLE

2 FOR 50 Hz APPLICATION

3 STANDARD ENCLOSURE RATING IS N3R AT 800A AND ABOVE AND N4 AT 600A AND BELOW

4 ONLY AVAILABLE 800A AND ABOVE

PM062 REV 6 08/08/01 |

7 |

Thomson Technology |

TS 870 TRANSFER SWITCH

4.2.TYPICAL COMMISSIONING PROCEDURES

CAUTION:

Commissioning procedures must be performed by qualified personnel only. Ensure the Automatic Transfer Switch (ATS) Control Circuit Isolation Plug is disconnected prior to energizing the supply sources. Manually place the transfer switch mechanism in the neutral position prior to applying power. Failure to do so may result in equipment failure or personal injury.

Note: The TYPICAL AUTOMATIC TRANSFER SWITCH COMMISSIONING

PROCEDURES MODEL SERIES TS 870 (attached as “Appendix A ”) is provided for general information only pertaining to typical site installations and applications. Contact Thomson Technology for further information as may be required.

Note: An optional hand held, plug-in Service Display Module (SDM) is available for the TSC 80 Transfer Controller. The SDM module provides an LCD screen to display additional detailed information on the operation and settings of the TSC 80 controller for simplified servicing/trouble shooting procedures. For detailed information, refer to the separate SDM module instruction manual (PM065). TSC 80e transfer controllers have a built-in LCD display and therefore do not require the SDM unit.

5.GENERAL THEORY OF OPERATION

5.1. STANDARD AUTOMATIC TRANSFER SWITCH

5.1.1. NORMAL OPERATION

When utility supply voltage drops below a preset nominal value (adjustable from 70% to 100% of nominal) on any phase, an engine start delay circuit is initiated and the transfer to utility supply signal will be removed (i.e. contact opening). Following expiry of the engine start delay period (adjustable from 0 to 60 sec.) an engine start signal (contact closure) will be given.

Once the engine starts, the transfer switch controller will monitor the generator voltage and frequency levels. Once the generator voltage and frequency rises above

PM062 REV 6 08/08/01 |

8 |

Thomson Technology |

TS 870 TRANSFER SWITCH

preset values (adjustable from 70% to 95% of nominal), the engine warm-up timer will be initiated. Once the warm-up timer expires (adjustable from 0 to 60 sec.), the Transfer to Generator Supply signal (contact closure) will be given to the transfer switch mechanism. The load will then transfer from the utility supply to the generator supply via the motor driven mechanism.

The generator will continue to supply the load until the utility supply has returned. The retransfer sequence is completed as follows: when the utility supply voltage is restored to above the preset values (adjustable from 70% to 95% of nominal) on all phases, a transfer return delay circuit will be initiated. Following expiry of the Utility Return Timer (adjustable from 0 to 30 min.), the Transfer to Generator Supply signal will be removed (contact opening), then the Transfer to Utility Supply signal (contact closure) will be given to the transfer switch mechanism. The load will then retransfer the load from the generator supply back to the utility supply. Note: A neutral delay timer circuit will delay the transfer sequence in the neutral position (i.e. both power switching devices open) until the neutral delay time period expires (adjustable from 0 to 60 seconds).

An engine cooldown timer circuit will be initiated once the load is transferred from the generator supply. Following expiry of the cooldown delay period (adjustable from 0 to 30 minutes), the engine start signal will be removed (contact opening) to initiate stopping of the generator set.

5.2. SERVICE ENTRANCE AUTOMATIC TRANSFER SWITCH

Note: This applies only to service entrance transfer switches

5.2.1. NORMAL OPERATION

Under normal conditions, the load is energized from the utility supply through the closed utility transfer power switching device. If the utility power fails, the generator will start and the load will be re-energized via the closed generator transfer power switching device.

In the normal operating mode, the Service Disconnect switch shall be in the “energized” position.

5.2.2. OVER CURRENT TRIP

Should the utility power switching device trip open due to an over current condition, TSC 80/TSC 80E transfer controller will initiate an engine start signal and will permit

PM062 REV 6 08/08/01 |

9 |

Thomson Technology |

TS 870 TRANSFER SWITCH

transfer of the load to the generator supply. The utility source will be locked out and the load will remain on the generator supply until the TSC 80/TSC 80E alarm signal is manually reset.

Refer to the TSC 80/TSC 80E Instruction Manual for further details on Transfer Fail operation.

Should the generator power switching device trip open due to an over current condition, TSC 80/TSC 80E transfer controller will initiate transfer of the load to the utility supply. The generator source will be locked out and the load will remain on the utility supply until the TSC 80/TSC 80E alarm signal is manually reset.

5.2.3. SERVICE DISCONNECT PROCEDURE

To perform a service disconnect (i.e. to disconnect the utility and generator supplies), the following procedure is required:

1.Move the "Service Disconnect" control switch located on the door of the transfer switch to the "Disconnected" position.

2.Verify that the "Service Disconnected" pilot light is illuminated. If the Light is illuminated, the service has been successfully disconnected and it is safe to perform any maintenance procedures as required. In this condition, the transfer switch is in the neutral position, with both utility and generator transfer power switching devices open. The transfer switch will remain in this condition, regardless of condition of the utility and generator supplies (i.e. if the utility power fails, the generator will not receive a start signal, nor will the transfer switch move to the generator position). NOTE: If the Service Disconnect Light is not illuminated, additional procedures are required (refer to the following procedure #5.2.4).

3.Attach safety lockout padlock to the "Service Disconnect" control switch to prevent unauthorized change in operating condition and verify transfer switch door is locked closed. If the door is not locked, turn and remove door key.

WARNING!

Close and lock the transfer switch enclosure door

before connecting power sources.

PM062 REV 6 08/08/01 |

10 |

Thomson Technology |

TS 870 TRANSFER SWITCH

4. To reenergize the load, remove the padlock(s) from the service disconnect control switch, and move the switch to the energized position. The transfer switch will immediately return to the utility or generator supply if within normal operating limits.

5.2.4. ADDITIONAL PROCEDURES

If the "Service Disconnected" pilot light is not illuminated, the service will not have been successfully disconnected and therefore it is not safe to perform any maintenance until the following additional procedures are performed:

DANGER!!!!

Arc Flash and Shock Hazard. Will cause severe injury or death.

Do not open equipment until ALL power sources are disconnected

This equipment must be installed and serviced only by qualified electrical personnel utilizing safe work practices and appropriate Personal Protective Equipment (PPE). Failure to do so may cause personal injury or death

1.Open the door to the transfer switch using a suitable tool and opening the door lock with the key.

2.Visually inspect the actual position of the transfer switch mechanism. If the position of the transfer switch mechanism is clearly in the "neutral position" and the load bus is de-energized on all phases, the service has been successfully disconnected. Proceed to Step. 4.

If the position of the transfer switch mechanism is not in the neutral position or the load bus is energized, further procedures are required.

Note: If the position of the transfer switch mechanism is clearly in the "neutral position, the "service disconnected" pilot light may not have illuminated due to the following reasons:

a)Utility and generator supply voltages are not present (the pilot light requires AC supply voltage to be present).

b)The pilot light may be burnt out. The bulb should be immediately replaced with a suitably rated bulb.

PM062 REV 6 08/08/01 |

11 |

Thomson Technology |

Loading...

Loading...