Renault Premium Service Manual

DT 1/370 AN

english version

GUIDE FOR THE FITTING

OF BODYWORK FOR THE

RENAULT PREMIUM

SERIES

50 21 001 985 - 06/01

édition anglaise

RENAULT V.I.

S.A. au capital de 327 978 500 F.

Siège social : 99, route de Lyon - 69802 Saint-Priest

IMPORTANT

Reading the “Guide for the Fitting of Bodywork for the RENAULT PREMIUM series”

The “Guide for the Fitting of Bodywork for the RENAULT PREMIUM series” ushers in a new

type of presentation for bodywork fitting guides.

This new presentation sets out in one single document all those details which are necessary for

the bodybuilder and equipment manufacturer to have available.

The data given in the “Guide for the Fitting of Bodywork” ref. (DT 6/354) has been included in

the present document under the “General Features” section at the beginning.

You therefore no longer have to refer separately to the “Guide for the Fitting of Bodywork” ref.

(DT 6/354) in order to use and understand this document.

The present document consists of two sections:

A - “General features”:This describes the relevant general principles and basic rules applica-

ble for the conversion and fitting of equipment to vehicles in most cases for the majority of

applications.

B - “RENAULT PREMIUM special bodybuilding features”:This deals in greater detail with

presentation of the vehicle, attachment of the body, electrical pre-arrangements, trade

vehicles and trade packs.

C - “Supplementary information on the RENAULT PREMIUM vehicle”:This deals in greater

detail with power take-offs, air-operated and specific equipment, assembly of equipment to

chassis and cab.

If a topic is dealt with in the three sections, the relative information may be:

- complementary: in this case the “Special features” section provides details or values relat-

ing to the topic dealt with in “General features”.

- partially or fully contradictory: when the RENAULT PREMIUM vehicle is endowed with a

special feature whose characteristics go against general principles.In such case, the ele-

ments regarding this specificity in the “Special features”section supersede those dealing

with the same topic in the “General features” section.

You may need, when looking for information on a specific point, to consult the three “General

features”, “Specific Features” and “Supplementary information on the RENAULT PREMIUM

vehicle” sections, so as to ensure that you have obtained all the relevant details.

RENAULT V.I. - 06/01 - Imprimé en France

DT 1/370 1 RENAULT V .I. 06/01

Page

1. GENERAL FEATURES

1.1 Scope of liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2

1.2 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A2

1.3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A3

1.4 Quality assurance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A4

1.5 Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A4

1.6 General instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A5

1.7 Safety on tilt cabs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A6

1.8 Chassis markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A6

1.9 Adjustments to the vehicle settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.10 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.10.1 Bodywork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.10.2 Chassis/Underbodies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.10.3 Cleaning of the cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.10.4 Cleaning of the instrument panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.11 Safety and protection of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A7

1.12 Summary of definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A8

1.13 Certificate of approval o f th e c onve rs i on o f a vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A9

1.13 . 1 A p p li c at i on fo r ap p roval . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A9

1.13.2 O Body fitting certificate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A9

1.13.3 Responsibility for installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A9

1.14 Painting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A10

1.14.1 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A10

1.14.2 Major units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A10

1.14.3 Chassis frame and accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A11

1.14.4 Recommended products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A12

1.14.5 Marking of polymer components (recycling of plastics) . . . . . . . . . . . . . . . . . . . . . . . . .A13

1.15 Electrical equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A15

1.15.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A15

1.15.2 Wiring Harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A15

1.15.3 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A16

1.15.4 Available power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A16

1.15.5 Flasher units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A16

1.15.6 List of standard power sockets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A17

1.15.7 Additional direction indicator lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A17

1.16 Air-operated equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A20

1.16.1 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A20

1.16.2 Polyamide pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A20

- Identification marking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A20

- Coding used on polyamide pipes (RENAULT V.I. Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . .A20

- Brakes code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A20

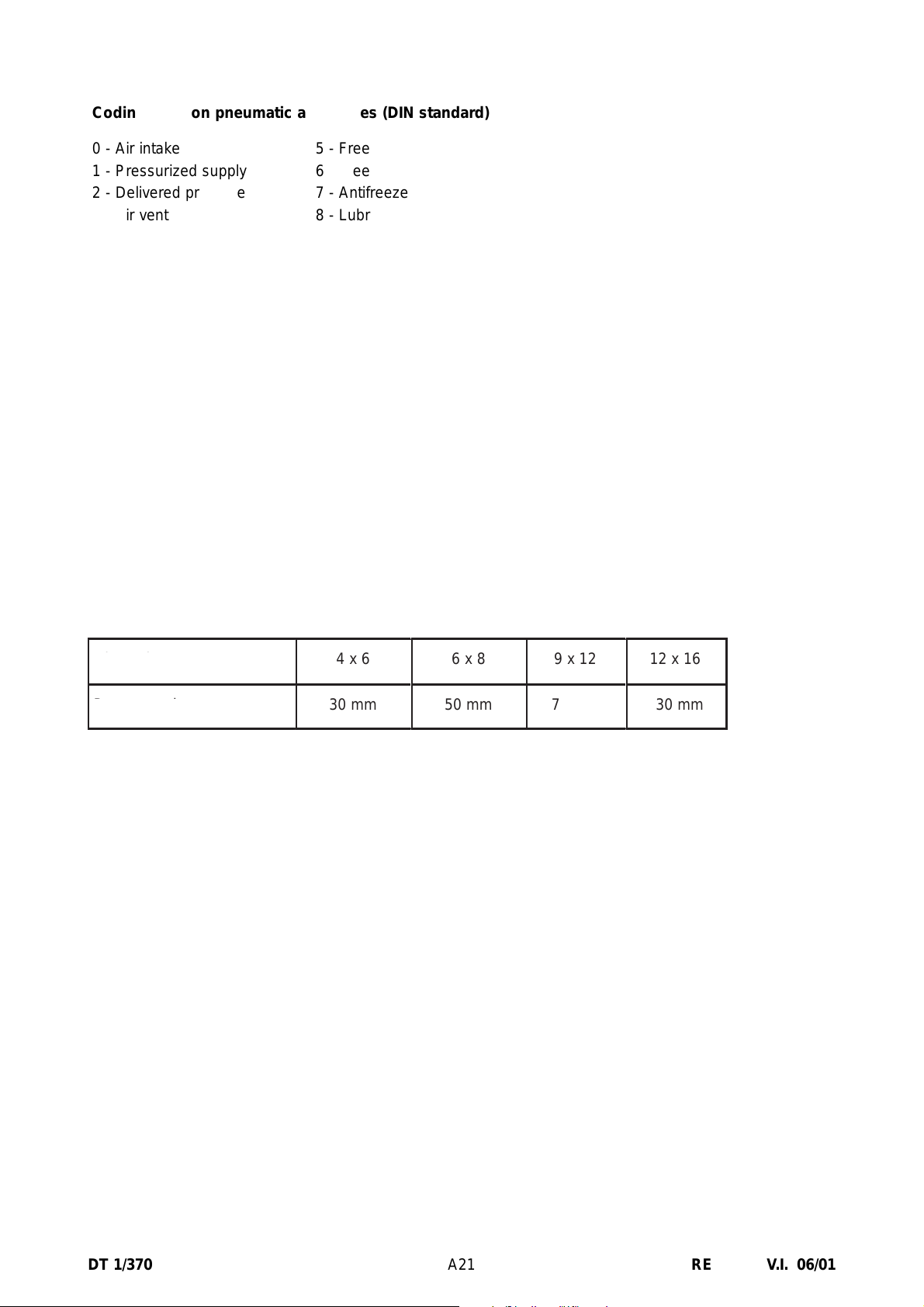

- Coding used on pneumatic appliances (DIN Standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A21

- Replacement of a brake line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A21

- Modification to the length of the chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A21

- Connections for ratchet type pneumatic brake pipes type “RILAX 2000” . . . . . . . . . . . . . . . . . .A21

CONTENTS

GENERAL RULES FOR CONVERSIONS

CHAPTER -A-

GENERAL FEATURES

RENAULT V .I. 06/01 2 DT 1/370

2. GENERAL RULES TO BE OBSERVED WHEN FITTING BODYWORK

2.1 General welding principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A22

2.1.1 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A22

- Protection of the batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A22

- Soundproofing screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A22

- Protection of electrical and mechanical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A22

2.1.2 Preparation of parts for welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A22

- Preparation of specific edges on chassis frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A23

- Method of welding to be specifically used on chassis frames . . . . . . . . . . . . . . . . . . . . . . . . . .A23

- Slave butts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A23

2.1.3 Welding process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A24

- Static or rotary arc welding set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A24

- Relevant standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A24

- MIG or MAG semi-automatic welding set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A24

2.1.4 Equivalent steel grades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A25

2.2 Reinforcement, extension, reduction of sidemembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A26

2.2.1 Bans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A26

2.2.2 Reinforcement of sidemembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A26

- Examples of reinforcements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A26

- Method of joining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A27

- Extension, shortening of sidemembers in the wheelbase . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A28

2.2.3 Modification of the rear overhang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A29

- Attachment of cross-members . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A29

- Towing cross-members . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A29

- Intermediate cross-members . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A29

2.3 Attachment of bodywork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A30

2.3.1. Bans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A30

2.3.2 Protection against exhaust heat radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A30

2.4 Sub-frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A31

2.4.1 Finishing of sub-frames behind the cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A31

2.5 Nuts and bolts, tightening torque for parts in steel and cast iron . . . . . . . . . . . . . . . . . . . . . .A32

2.6 Addition of equipment to the bodywork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A33

2.7 Rear run-under guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A34

3. SPECIFIC EQUIPMENT FEATURES

3.1 Running the engine when vehicle stationary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A34

3.2 Mounting of power take-offs and flanged pumps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A34

3.3 Front power take-offs (crankshaft nose) (except RENAULT PREMIUM / KERAX) . . . . . . . . . . .A35

3.4 Front and rear power take-offs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A35

3.4.1 Propeller shaft alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A35

- Angularity criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A35

- Angular acceleration criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A36

- Transversal stress criteria for prop shaft tubes and bearings . . . . . . . . . . . . . . . . . . . . . . . . . . .A36

3.4.2 Propeller shaft balancing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A37

3.4.3 Maximum permissible length of a prop shaft as a function of the rotating speed . . . . .A37

3.5 Vehicle driveline (powertrain) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A37

3.6 Mounting of handling cranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A38

3.6.1 Mounting on the sub-frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A38

3.6.2 Graph of the moment of inertia of the sub-frame as a function of the lifting torque . . . .A39

3.6.3 Crane in the rear overhang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A40

DT 1/370 3 RENAULT V .I. 06/01

3.7 T ail lifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A41

3.7.1 Sub-frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A41

3.7.2 Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A41

3.7.3 Electrical connections for a tail lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A41

3.7.4 Special recommendations for tail lifts from 1500 to 2000 kg without landing legs . . . . .A41

3.7.5 Graph of the moment of inertia of the sub-frame as a function of the lifting torque . . . .A42

3.8 Sub-frame box sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A43

3.9 Fitting of specific equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A43

3.9.1 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A43

3.9.2 Installation of receivers or generators with a voltage of more than 24 V . . . . . . . . . . . . .A43

3.10 Tapping on the diesel fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A43

3.11 Hitch coupling for drawbar rigid trailers (only on RENAULT MIDLUM) . . . . . . . . . . . . . . . . . .A44

3.11.1 Fitting of an additional cross-member . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A44

3.11.2 Minimum thickness of reinforcing plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A44

3.12 Fifth wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A44

3.12.1 Mounting standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A44

- Kingpin 50 mm (2”) dia. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A44

- Kingpin 90 mm (3.5”) dia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A44

CHAPTER -B-

RENAULT PREMIUM SPECIAL BODYBUILDING FEATURES

1. PRESENTING THE “RENAULT PREMIUM” SERIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B3

1.1 Changes to “RENAULT PREMIUM” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B3

1.2 Make-up of the series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B4

1.3 Electronic management of “RENAULT PREMIUM” vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . .B6

1.3.1 Operating principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B6

1.3.2 Bodybuilders’electrical pre-arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B7

1.4 Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B7

2. GENERAL REMARKS ON THE “RENAULT PREMIUM” SERIES . . . . . . . . . . . . . . . . . . . . . . . . . . .B8

2.1 Identification of the vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B8

2.2 General drilling principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B10

2.2.1 Drilling cab panels for fitting accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B10

2.2.2 Drilling in sidemembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B11

2.3 Precautions prior to welding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B12

2.3.1 Protection of wiring harnesses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B12

2.3.2 Welding on vehicles equipped with an electromagnetic master switch . . . . . . . . . . . . . .B12

2.4 Minimum load on front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B13

2.5 Soundproofing screens and heat shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B13

2.5.1 Instructions for soundproofing screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B13

2.5.2 Instructions for heat shields . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B13

2.6 Side impact beams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B13

3. INSTALLATION OF BODYWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B14

3.1 Use of 1/20th scale drawings and calculation sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B14

3.2 Example of a search . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B14

3.3 Body entrance dimension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B17

3.3.1 Behind-cab surrounds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B17

3.3.2 Body entrances with vertical exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B19

3.3.3 Presentation of the different air intakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B20

3.4 Finishing of sub-frame entrance dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B21

RENAULT V .I. 06/01 4 DT 1/370

3.5 Sub-frame sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B23

3.5.1 Minimum height according to range of suspension movement . . . . . . . . . . . . . . . . . . . .B23

3.5.2 Sub-frame minimum inertia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B23

3.5.3 Discontinuous sub-frames (2-part) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B25

3.5.4 Continuous sub-frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B27

3.6 Attachment of bodywork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B27

3.7 Attachment of sub-frames to brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B28

3.7.1 Day cab guiding and fastening zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B28

3.7.2 Sleeper cab guiding and fastening zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B28

3.7.3 Vertical positioning of brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B30

3.7.4 Transversal positioning of brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B30

3.7.5 Types of bodywork attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B32

3.8 Longitudinal positioning of brackets on chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B36

4. ELECTRICAL PRE-ARRANGEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B52

4.1 Available power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B52

4.2 Electrical pre-arrangements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B52

4.3 Management of engine speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B57

4.3.1 Choice of engine speed by default . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B57

4.3.2 Use of the steering wheel fast idling control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B58

4.3.3 Vehicle fitted with a power take-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B58

4.3.4 Use of the chassis-mounted fast idling control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B59

4.3.5 Use of the chassis-mounted fast idling variable speed control . . . . . . . . . . . . . . . . . . . .B59

4.4 Electrical diagram for available power supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B60

5. REFUSE COLLECTOR VEHICLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B66

5.1 Longitudinal positioning of brackets on chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B66

5.2 Available power supplies at in cab on connection unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B68

5.3 Management of engine speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B69

5.4 Speed limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B69

5.5 Electrical diagram for refuse collector vehicles available power supplies . . . . . . . . . . . . . . . .B70

6. HANDLING CRANES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B74

6.1 Handling crane with lifting torque outside graph limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B74

6.2 Handling crane in rear overhang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B74

6.3 Plate mounting recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B74

6.4 RENAULT PREMIUM behind-cab handling crane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B75

7.TIPPERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B86

8.TANKERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B88

DT 1/370 5 RENAULT V .I. 06/01

CHAPTER -C-

SUPPLEMENTARY INFORMATION ON THE “RENAULT PREMIUM”VEHICLE

1. MOUNTING OF POWER TAKE-OFFS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C3

1.1 Mechanical receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C3

1.1.1 Gearbox-mounted PTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C3

1.2 Instructions for the assembly of auxiliary hydraulic pumps to ZF type “C” PTOs . . . . . . . . . . .C6

1.2.1 Supplementary instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C6

1.2.2 Calculation of the weight torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C6

1.3 Access to gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C7

2. AIR-OPERATED EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C8

2.1 Connection of extra auxiliary equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C8

2.1.1 Coupling for extra auxiliary equipment to chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C8

3. ELECTRICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C11

3.1. Earths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C11

3.1.1 Cab earths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C11

3.1.2 Chassis earths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C12

3.2 Passage of wiring harnesses and compressed air pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C15

4. CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C15

4.1 Steel classes for sidemembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C15

4.2 Sections of sidemembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C15

4.3 Reinforcement, extension, shor tening of sidemembers in the rear overhang . . . . . . . . . . . . .C16

4.3.1 Modification to the rear overhang . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C16

4.4 Intermediate cross-member . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C17

5. CHANGING THE POSITION OF EQUIPMENT ON CHASSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C18

5.1 Rear run-under guard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C18

6. HITCH COUPLING FOR DRAWBAR RIGID TRAILERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C19

6.1 Mounting principle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C20

6.2 Rear bevelling of sidemembers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C21

6.3 Attachment of towing hook to 40-44 tonne and 50-60 tonne cross-member . . . . . . . . . . . . . .C22

7. ASSEMBLY OF EQUIPMENT TO CAB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C24

7.1 Roof catwalk . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C24

7.1.1 Attachment of catwalk to day cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C24

7.1.2 Attachment of catwalk to sleeper cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C25

7.2 Ladder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C26

7.2.1 Attachment of ladder to day cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C26

7.2.2 Attachment of ladder to sleeper cab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C27

7.3 Assembly of accessories on roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C28

7.3.1 Installation of antennae . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C28

7.3.2 Installation of revolving beacons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C28

7.3.3 Installation of air horns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C29

7.3.4 Installation of roof deflector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C30

7.3.5 Installation of frontview mirror . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C31

7.3.6 Installation of sunshade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C32

7.3.7 Installation of gantry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C33

7.4 Fastening of accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C34

8. AIRBAG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C35

8.1 Identification of a vehicle equipped with an airbag system . . . . . . . . . . . . . . . . . . . . . . . . . . .C35

8.2 Work on the vehicle (excluding the airbag) requiring precautions

to be taken to avoid inadvertent deployment of the airbag . . . . . . . . . . . . . . . . . . . . . . . . . . . .C35

RENAULT V .I. 06/01 6 DT 1/370

DT 1/370 A1 RENAUL T V.I. 06/01

CHAPTER -A-

GENERAL FEATURES

RENAULT V .I. 06/01 A2 DT 1/370

1. GENERAL FEATURES

1.1 Scope of liability

RENAULT V.I. vehicles are merchandized at the end of corroborated technical designwork and endurance tes-

ting, taking the various laws, regulations, standards... involved into consideration.

Modifications to a RENAULT V.I. vehicle for the fitting of bodywork and equipment should be carried out in

accordance with the rules and recommendations set out in this bodywork fitting guide and require an

“Agreement in Principle”, issued by the Product Applications Department.

Guarantee and responsibility

Any intervening party is responsible for his services in terms of guarantee and responsibility, including any dam-

age caused by his work and/or the equipment installed on-vehicle or the basic product.

In the event of RENAULT V.I. (or its network) being prime contractor for its own equipment (in relation to the end

customer), the guarantee is considered as being at least that of the warranty offered by RENAULT V.I. to its cus-

tomer.

Unless clearly specified otherwise in the order, the equipment warranty shall be negotiated directly between the

end customer and the equipment manufacturer.

The meeting of recommendations contained in the present document can in no way be considered as relieving

the equipment manufacturer’s responsibility, but simply as complying with the basic rules for professional trade

practice.

Any breach of these recommendations must be considered as shortcoming in respect of the rules and shall relieve

RENAULT V.I. of its liability in the event of damage connected directly or indirectly to such non-compliance.

All the equipment is considered to comply with these recommendations and shall not require any acceptance test-

ing upon delivery to check the conformity.

RENAULT V.I. guarantees non-modified original parts and components.

Interventions, conversions, adaptations of fittings carried out by the intervening par ty involves his responsibility,

even if they are authorized administratively (Conversion appendix II).

Such conversions must not under any circumstance lead to any impairment of the quality or of the primary func-

tions of the component elements of the vehicle (whether these elements are affected directly or not by the inter-

vention).

Any modification, changing of position of constituent vehicle parts or elements must be covered b y an “Ag reement

in Principle”, issued by the RENAULT V.I. Product Applications Department.

For further information or assembly agreement, contact:

TO OBTAIN ANY INFORMATION OR APPROVAL OF MOUNTING, PLEASE CONTACT:

For France:

SERVICE TECHNICO-COMMERCIAL

RENAULT V .I.

API. COM 00A 238

69806 ST PRIEST CEDEX

Tel.: 04 72 96 68 14

Telex: 300 265 UDCF +

Fax:04 72 96 81 93

1.2 Regulations

The bodybuilder must meet:

- the different European and/or destination country laws, regulations and standards governing dr iving and

vehicle building,

- the stipulations of the highway code and its various amendments and appendices,

- the different laws, regulations and standards governing road traffic in force in the country of destination.

For the United Kingdom:

Product Applications Department

RENAULT V.I. UNITED KINGDOM LIMITED

Boscombe Road,

Dunstable

Bedfordshire LU5 4LX

Tel. (Switchboard): (+44) (0)1582 471 122

Fax (Marketing) (+44) (0)1582 479 146

DT 1/370 A3 RENAUL T V.I. 06/01

The scope of this compliance must cover:

- Lighting and signalling,

- Weight and dimensions,

- The field of vision and rear view,

- The regulation protection devices (e.g. side beams, anti-spray, run-under guard),

- The hitch coupling and towing systems, (compliance with standards and regulations),

- Specific clauses concerning the transport of dangerous goods (ADR, COSHH etc.),

- Sun-roofs,

- Pollution control standards,

- Electromagnetic compatibility standards for electronic equipment.

1.3 Safety

All components having an influence on:

- The control of the driver of the trajector y and the ability to stop the vehicle and its trailer,

- The load distribution on the front or the rear, the left or the right,

- The risk of fire,

- and any other risk for the vehicle and its surrounding environment.

Among the components, we would mention, among others:

- The cab tilt mechanism,

- The wheels (tightening of the bolts),

- Seats and seat belts (anchorage points),

- The attachment of bodywork or equipment to be in conformity with the technical instruction document in force,

(i.e. the Guide for the Fitting of Bodywork),

- The hitch coupling and towing systems, (i.e. anchorages),

- Electrical systems (protection of circuitry, the electrical rating, attachment, conformity of the connections with

the technical instruction document, (i.e. the Guide for the Fitting of Bodywork),

- Warning systems and dr iver information systems, (i.e. no interference with the information given by the instru-

ment panel on the dashboard),

- Information for use affixed by the manuf acturer to the vehicle (i.e .decals for tilting of the cab, drilling points, wel-

ding points, batteries, etc.)

- Extension and reduction of the length of the wheelbase and the rear overhang.

- Re-location or replacement of the crossmembers.

- Circuits for ancillary equipment.

In order to guarantee the safety and the satisfactory operation of the vehicle, modification of the follo-

wing components is strictly forbidden:

- Brakes: circuits, controls and anchorages,

- Steering: circuits, controls, anchorages and geometry,

- Axle and axle housing assemblies,

- The air-bag system and pretensioning systems on the seat belts,

- The electronics.

RENAULT V .I. 06/01 A4 DT 1/370

1.4 Quality assurance

Our permanent objective is to give satisfaction to our customers and we must achieve this in full on the final

product consisting of a chassis, bodywork and/or an item of equipment.

In order to achieve this objective, RENAULT V.I. expects from all those co-operating with it in the field of

mounting bodywork and equipment supply to implement a Quality Assurance System.

RENAULT V.I. can demand proof for the execution of all bodywork, the fitting of equipment or modification of

a basic truck, in accordance with Standard ISO 9000, of:

- The conformity with all legislation, EC Directives and national regulations,

- The compliance with the manufacturers’ directions,

- The control of quality of the execution of the work.

This is done with the knowledge that, on the face of it, the vehicle is considered as complying with the

whole of the regulations.

1.5 Documentation

In all cases involving equipment, the installer is obliged to supply a manual covering the use, service, main-

tenance and safety of his installation.

Tension aux bornes de l’accumulateur

’

batterie 6 Volts batterie 12 Volts

D

ens

ité

d

e

l’él

ec

t

ro

l

y

t

e

Et

a

t

d

e c

h

arge

6,3 Volts 12,7 Volts 1,27 100 %

6,2 Volts 12,5 Volts 1,24 80 %

DT 1/370 A5 RENAUL T V.I. 06/01

1.6 General instructions

When building and fitting a body (including such equipment as rear run-under guards), a certain number of

requirements and a certain number of vital requirements specific to each type of vehicle must be taken into

consideration.These various points relate to maintenance, accessibility and the circulation of fluids.

Examples:

- Ease of access to the various maintenance and lubrication points, to the fuel tank and fuel gauge, to the

batteries and the various electrical terminal boxes.

- The ability to easily dismantle the various component par ts of the transmission and the suspension.

- Access to the circuits for air-intake, exhaust, and fuel supply.

- Taking into account the wheel movement detailed on the bodywork drawing (i.e.take care to allow for snow

chains; extra clearance must be provided).

- Ventilation of the brake drums and discs and the batter y compar tment.

- The radiator inlet and outlet areas, which must not be modified.

- Complete compliance with the dimensions and weights specified in our technical documents. Under all cir-

cumstances, the bodybuilder must ensure free movement and safe operation of all the moving component

parts of the chassis (i.e. spr ings, prop shaft, etc.)

- The addition of a body must not affect the vehicle running and driving safety. Take care to ensure that a

balanced distribution of the loads on the right and the left hand sides of the vehicle is obtained.

- For any bodywork installation, a calculation of load distribution must be made for each axle, in order to check

that the weight imbalance between the right and the left hand side is below 4%.

- The flow of the coolant must be maintained at all times. It is, therefore, not allowed to blank off, even par-

tially, the air intakes provided (on the radiator grille or the front end). Orange ADR or similar “Hazardous

Substances” plates should be affixed to solid surfaces (i.e. without vent holes).

On the arrival of a vehicle in your workshop for body fitting, we recommend that you should check one hour

after the arrival of the vehicle, the state of charge of the batteries.

During the period for the fitting of the bodywork, you should particularly check that:

- The vehicle is not run without a batter y.

- Do not move the vehicle on the starter motor.

- Do not use a booster starter.

- Ensure that the tyre pressure is checked and tyres inflated to the correct value where necessary.

- Protect body components or items of trim against all damage.

- Refit the original batteries, where these have been taken off.

IMPORTANT

- Whatever work you are doing on the vehicle, you must switch off the electrical circuit at the master switch or

by disconnecting the batteries in order to avoid any risk of electric shock during work.

- When a vehicle is laid up (i.e.at a standstill for longer than 10 days), disconnect the electrical circuit by remo-

ving the fuse or by the circuit-breaker so as to avoid discharge of the batteries through the tachograph.

Voltage at the battery terminals

Specific gravity

of the electrolyte

State of charge

6 V olt battery 12 V olt battery

6.3

6.2

12.5

12.7

1.24

1.27

RENAULT V .I. 06/01 A6 DT 1/370

The information contained in this manual is only applicable to bodywork in steel. For aluminium bodies, refer

to the Product Applications Department of RENAULT V.I.

It is forbidden to weld, grind, cut up, drill or heat the sidemembers or crossmembers unless the contrar y is

clearly stated. These operations may only be carried out in conformity with the recommendations laid down

in the present document.

Any special case, any bodywork fasteners and fittings not described in this manual must be submitted for our

approval prior to use.

Before commencing the fitting of any bodywork, you must consult:

- The V ehicle Technical Data Sheet,

- The bodybuilders drawing and the relevant calculation sheets which relate to the body to be fitted,

- The vehicle driving and maintenance handbook.

If you do not have these items available, you should obtain them from RENAULT V.I. Dealers or the Product

Applications Department.

In the technical manual and on the bodywork drawing is stated the permitted maximum and minimum length

of body; we would strongly advise you to stay within these limits.

Furthermore, it should be noted that the changing of position of a component such as spare wheel, tank, etc.,

the modification of a chassis without uniform weight distribution or the fitting of an over-cab extension, causes

a modification of the load distribution of a fully equipped chassis in every single case.

Modification to load distribution must be compensated for by an alteration in the permitted length for body-

work. It then becomes necessar y to calculate the new position of the centre of gravity of the bodywork.

The weights specified in our technical data sheets refer to standard vehicles , ready f or the road, without optio-

nal extras.

Furthermore, the weight of chassis cab is given with a tolerance of plus or minus 4%.

Optional equipment such as reinforced springs, power take-offs, different tyre fitments, will cause an increa-

se in weight for the basic chassis.

For these reasons, when weighing the chassis cab, bodybuilders should weigh:

- The front axle(s),

- The rear axle(s),

- The complete vehicle,

without driver, without passenger, but with full fuel tanks and with vehicle on-board tool kit.

For the preparation and attachment of the various types of bodywork, it is pref erab le not to take off the wheels ,

unless absolutely necessary.

Nevertheless, you must take the precautions set out below:

- It is forbidden to paint the bearing surfaces of the wheel rim hubs and the seating for wheel nuts.

- During fitting, make certain that the par ts are perfectly clean prior to fitting.

- Tighten the wheel nuts to the torque recommended (cf. vehicle driving and maintenance handbook)

Installation fitted with keys: the section of such keys must be very different to that used for the vehicle keys.

Indeed, these keys should not be able to be put into the vehicle locks by mistake, thus avoiding any risk of

damage to the barrels of the locks.

1.7 Safety on tilt cabs

After the conversion of standard cabs by the bodybuilders, (i.e. extension, bunk adaptation, over-cab exten-

sion, etc.) because the weight distribution has changed, the tilt system may no longer meet the requirements

of the safety standards.

Under these circumstances, and without prior agreement from the manufacturer, the full and entire responsi-

bility rests with the bodybuilder.

1.8 Chassis markings

The identification number of the vehicle is on the sidemember (refer to the vehicle driving handbook).

The identity markings of the vehicle must remain visible and accessible without having to remove any part of

the body.

DT 1/370 A7 RENAUL T V.I. 06/01

1.9 Adjustments to the vehicle settings

Under no circumstance may bodybuilder or converters make any alteration to the original settings of

RENAULT V.I. vehicles.

1.10 Cleaning

1.10.1 Bodywork

So as not to cause any damage to the condition of the paintwork and the seals:

- Avoid using a high temperature jet of steam.

- Restrict the use of brushes.They must be in good condition and well maintained.

- We advise against the use of brushes, during the first month of vehicle use.

- If you are using a high pressure jet wash unit, limit the pressure to 80 bars maximum.

- Keep the lance well away from the bodywork; do not spray fluidtight joints.

- Use neutral soap based products.

- In order to remove grease spots, use cleaning fluid (not petrol).

- Par ts in aluminium must be cleaned with water to which a non-alkaline washing product has been added,

and rinsed with clean water.

- Spread a coat of Vaseline or talcum powder over the seals.

1.10.2 Chassis/Underbodies

Use a high pressure unit. Limit the pressure of the jet to 80 bars maximum and the time of use to the strict

minimum necessary.

In order to prevent any risk of a problem, do not spray:

- electronic or electrical boxes,

- the seals of link rods,

- hinge pins,

- air inlets for the heater, the engine air intake and air filter,

- pneumatic and electrical apparatus,

- absorbent materials and soundproofing screens,

- the fuel gauge.

1.10.3 Cleaning of the cab

Spray lightly or use a cloth dipped in a cleaning agent (i.e.soapy water, methylated spirits, etc.).Products with

a petroleum and trichlorethylene base are not to be used.

Spread talcum powder lightly onto the door seals and the windows, as well as any link rods.

1.10.4 Cleaning of the instrument panel

Only use soapy water. Any other product is not allowed.

1.11 Safety and protection of components

Before any operation of grinding, drilling, or welding, ensure that the following are effectively protected or

taken off:

- Plastic pipework and tubes,

- Electrical wiring harnesses,

- Suspension springs (particular ly for the protection against corrosion),

- The bags for the air suspension,

- The soundproofing screens,

- Any other component sensitive to heat, to the discharge of incandescent matter, to ultraviolet rays (i.e.elec-

tronic control units, electronic components, items in plastic material, flexible anti-vibration mountings, pain-

ted items, etc.)

- For welding work, comply with the other recommendations described in the chapter entitled “Protection of

electrical and mechanical components”.

RENAULT V .I. 06/01 A8 DT 1/370

1.12 Summary of definitions

Maximum body length (Dimension W on technical data sheets and bodywork drawings).

This is the bracket of lengths for bodies (not including fittings and accessories) worked out in relation to the

extreme positions of a given centre of gravity for a load which is taken to be evenly distributed and taking into

account the space which must be left to the aft of the cab, laid down by the manufacturer, and the maximum

permitted loads per axle on a chassis cab without options.

Body entrance (Dimension B on technical data sheets)

Minimum distance between the front axle centre-line and the front end plane of the body.

Load distribution calculations

Comply with the regulatory constraints for each country and the load limits given per axle for each model by

RENAULT V.I.

We remind you that these values are given for uniformly distributed loads.

The lateral imbalance of the loads should not exceed a maximum of 4% between the LH and RH roadwheel

of each axle.

Chassis rear overhang (Dimension N on technical data sheets)

Horizontal distance between the centre-line of the rear roadwheels and the rear extremity of the body (exclu-

ding fittings and accessories).

In the case of vehicles with 3 or 4 axles: distance between the centre-line of the rearmost axle and the extre-

mity of the chassis.

Body rear overhang (Dimension X on technical data sheets)

Horizontal distance between the centre-line of the rear roadwheels and the rear extremity of the body (exclu-

ding fittings and accessories).

In the case of vehicles with 3 or 4 axles: distance between the technical centre-line of the tandem and the

rear extremity of the body.

Wheelbase (Dimension F or F’ on technical data sheets).

Distance between the centre-lines of the front and rear roadwheels (vehicle laden).

In the case of vehicles with 3 or 4 axles: distance between the centre-line of the front roadwheels and the

centre-line of the foremost rear axle - for calculations take dimension F’ (technical wheelbase).

Tandem

Solely in the case of vehicles with 3 or 4 axles: the 2 rear axles taken together, regardless of whether they

are driving axles or trailing axles.

Maximum axle weight

Carrying weights are stipulated on each axle for each type of vehicle.These values are indicated on the tech-

nical data sheets and on the VIN plate and must be complied with on all v ehicles fitted with bodies when laden

and when empty.

Driver and cab passengers weight

The weight of the driver and passenger (passengers) in the cab is applied to the front axle in the case of a

forward control cab.

For cabs of the semi-forward control type, 2/3 of the weight should be applied to the front axle and 1/3 to the

rear axle.

Weight of driver or each passenger: 75 kg (calculated on the basis of the cab seating capacity), unless sti-

pulated otherwise: i.e. Export, Army, Fire Brigade, etc.

For cabs with a seating capacity of more than 3 persons, calculate the weight distribution of the persons on

the basis of the seats layout.

For equipment intended for the Army or for Civil Administrations, take the specific specifications into account.

DT 1/370 A9 RENAUL T V.I. 06/01

1.13 Certificate of approval of the conversion of a vehicle

1.13.1 Application for approval

1 If the body or the equipment fitted do not modify the weight and dimensional characteristics of the chas-

sis entered in the descriptive sheet, the vehicle can be submitted to the Type Approval Department without

any action by RENAULT V.I. being necessary (within the permitted limits in force).

2 The maximum rear overhang is equal to 60% of the wheelbase.However, for special cases, we can grant

higher percentages - for this, consult us.

3 If the layout requires modification to the wheelbase, it is essential to consult the Product Applications

Department. Each case has to be covered by a specific design.

4 The certificate will be issued in accordance to the legislation in force regarding modifications made by and

under the responsibility of the bodybuilder, within the limits stipulated by the Manufacturer and relative to:

- the wheelbase

- the distribution of loads

- the cab characteristics.

5 For more accuracy in your calculations, we recommend you to introduce into the data the weighed weight

of the chassis cab to be equipped (capable of varying according to manufacturing tolerances and the

various options available). The same applies to equipment for which the manufacturers can accurately

define the weight and the position of the centre of gravity.

1.13.2 Body fitting certificate

This defines the installation of the equipment on the chassis cab and the unladen weight imposed on the axles

and then the weight when fully laden.

It must be attached to all applications relating to the equipment which do not comply with any of the dimen-

sions set out in the descriptive sheet.

1.13.3 Responsibility for installation

The building and fitting of a body on a vehicle is the sole responsibility of the bodybuilder, who must comply

with the recommendations in the present document.

He must ensure that the installation of the body does not affect the functions or the reliability of the compo-

nents or the road behaviour of the vehicle.

RENAULT V .I. 06/01 A10 DT 1/370

1.14 Painting

1.14.1 Precautions

- Protect the RENAULT V.I. equipment (i.e. by using screens, self-adhesive tape, cab cover etc.)

- Never put vehicles into drying ovens at a temperature of more than 80° C.

- The chassis of the vehicle must be electrically earthed to allow static electricity to run away to earth (protec-

tion of electronic boxes).

- The vehicle must be protected against corrosion by paints compatible with those used by our Company and

conforming to RENAULT V.I. Specification No 4702 441 (protection of bodywor k and equipment adapted to

RENAULT V.I. vehicles) available from the Product Applications Department.

- Thinner solvents must never be used on cables and electrical sheaths.

- Protect the identification marking of electrical wires and compressed air pipes.

Never paint bearing surfaces of brake drums and disc wheels, or with twin tyre fitment, the assembly surfaces

between the disc wheels. As a general rule, do not repaint the support surfaces of original fitment nut and bolt

hardware and comply with the specification.

NOTE

Our Product Applications Department holds the reference numbers for paint colour shades for chassis and cabs

at your disposal.These paint colours can be procured as “spare parts” and can be ordered from our dealers.

The cab colour shade is indicated on the front end of the cab.

Since 1994, chassis and accessories are no longer sprayed with the customer’s shade of paint at the time of ori-

ginal fitment.

To preser ve the aspect and original quality, it is essential to observe the following methods after fitting equip-

ment, body, sub-frames and various adaptations to major units or chassis frame:

1.14.2 Major units (gearboxes, drive axles, engines, axles, etc.)

Works paint: GLYCEROPHTHALIC

Retouch (after fitting PTO, charge indicator, etc.)

Retouch method

- Clean with a universal cleaner or using a high-pressure cleaner.

- Wipe down, then apply a primer.

- Let the product cure until mat (about 15 minutes at 20° C), then apply the corresponding polyurethane lacquer.

DT 1/370 A11 RENA UL T V.I. 06/01

1.14.3 Chassis frame and accessories (sidemembers, crossmembers, fittings, lockers,

etc.)

Works paint: POLYURETHANE or POLYESTER powder.

Retouch method:

Superficial scratches (the metal is not affected).

- Clean with a universal cleaning product.

- Wipe down, then apply the corresponding undiluted b ut catalyzed polyurethane lacquer, using a small brush.

Deep and fine scratches (down to the bare metal).

- Clean with a universal cleaning product.

- Wipe down, then apply the primer, using a small brush.

- Let the product cure (about 15 minutes at 20° C), then apply the corresponding undiluted but catalyzed poly-

urethane lacquer.

Deep and wide scratches (down to the bare metal, drilling of sidemembers for attaching tail lifts and acces-

sories) due to drilling.

- Rub down.

- Clean with a universal cleaning product.

- Let the product cure until mat (about 15 minutes at 20° C), then apply the corresponding polyurethane lac-

quer.

Making good after conversion (after converting wheelbase and overhang).

- Grind, rub down; prepare the area in question (bur nt paint, welding scale, etc.).

- Clean with a universal cleaning product or using a high-pressure cleaner.

- Mask with tape (electrical wiring harnesses, air and fuel pipes, labels, etc.)

- Wipe down, then apply the primer.

- Let the product cure until mat (about 15 minutes at 20° C), then apply the corresponding polyurethane lac-

quer.

- After drying, put back the electrical wiring harnesses, air and fuel pipes and accessories.

Spraying chassis and accessories (with customers colour shade).

- The bodybuilder undertakes to preserve the aspect and quality of the original fitment vehicle (except for nut

and bolt hardware).

- Clean with a universal cleaning product or using a high-pressure cleaner.

- Mask with tape (electrical wiring harnesses, air and fuel pipes, labels, etc.)

- Wipe down, then apply the primer.

- Let the product cure until mat (about 15 minutes at 20° C), then apply the corresponding polyurethane lac-

quer.

- After drying, put back the electrical wiring harnesses, air and fuel pipes and accessories.

NOTE

All spray gun operations are to be carried out in a painting booth.

Since August 1999, the chassis are painted grey as replacement for Enduro red. For paint retouches on grey

chassis, use a grey paint aerosol ref. N° 50 01 848 147.

Finish paint

Two-component polyurethane paint and corresponding thinner.

1.14.4 Ingredients

Nettoyage manuel

Nettoyant universel, nettoyant équivalent, solvant.

Produits homologués RENAULT V.I.

Fournisseur Appellation commerciale Réf. RENAULT V.I. Réf. fournisseur

BASF PK 900 50 01 821 758 SV 20023F

ICI AUTOCOLOR Slow Spirit Wipe 50 01 854 983 P850–1402

STANDOX Agent ENTFERNER 50 01 825 985 FA 931 2002

Nettoyage haute pression

Dégraissant, dégraissant phosphatant

Apprêtage

Produits homologués RENAULT V.I.

Fournisseur Appellation commerciale Réf. RENAULT V.I. Réf. fournisseur

STANDOX apprêt “EPOXY”

durcisseur “EPOXY”

diluant “EPOXY”

diluant lent “EPOXY”

diluant 2KS

50 01 826 019

50 01 825 990

50 01 826 005

50 01 829 256

50 01 825 992

FA 931 5203

FA 931 5204

FA 931 5205

FA 931 5213

FA 020 7810

ICI AUTOCOLOR apprêt “EPOXY”

durcisseur “EPOXY”

diluant

50 01 829 477

50 01 829 480

50 01 829 481

P580–2100

P210––833

P850–3091

RENAULT V .I. 06/01 A12 DT 1/370

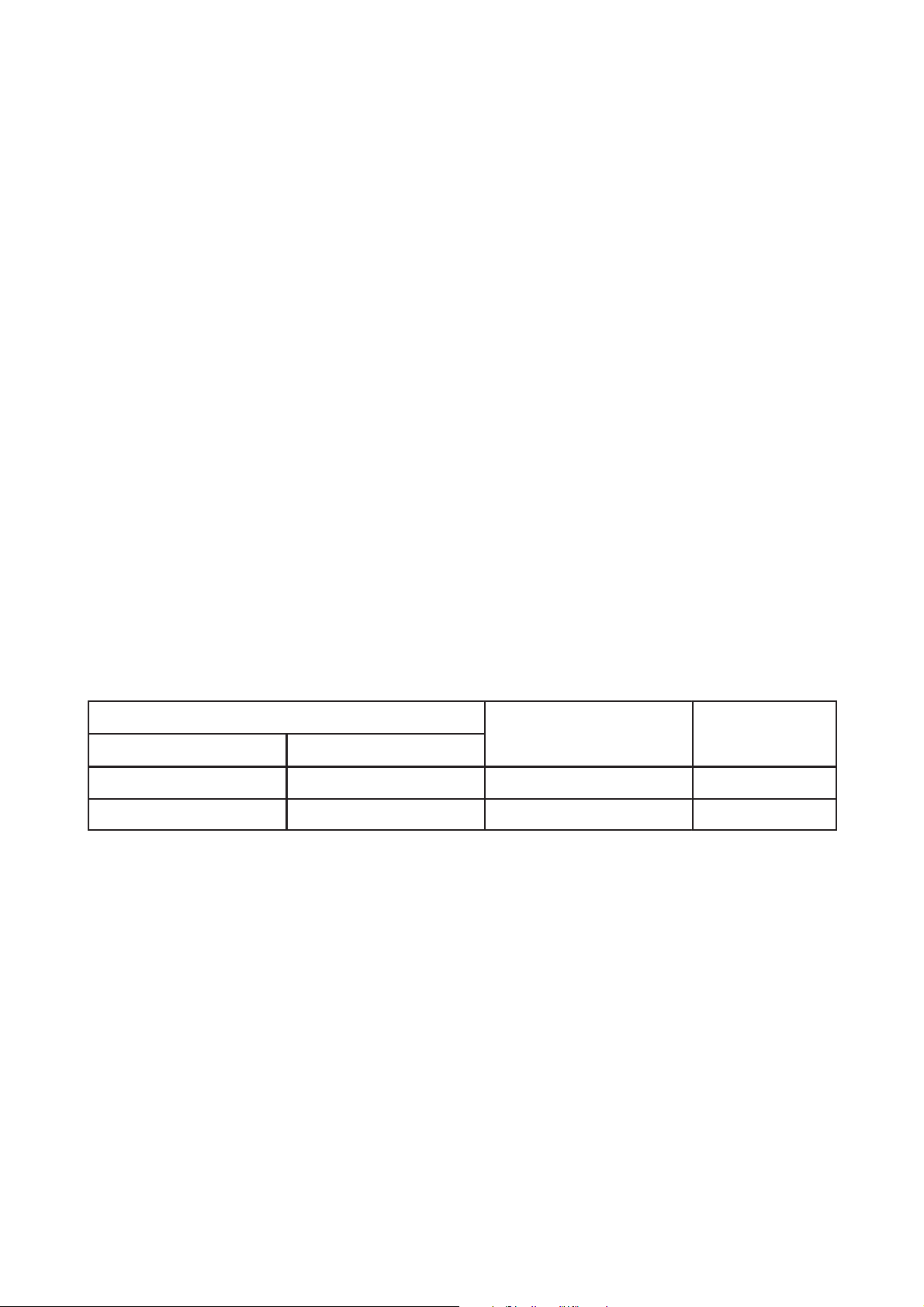

1.14.4 Recommended products

Manual cleaning

Universal cleaning product or equivalent solvent

Products approved by RENAULT V.I.

High-pressure cleaning

Degreaser, phosphater degreaser

Filing and sealing

Products approved by RENAULT V.I.

“EPOXY”filler-sealer

“EPOXY”hardener

“EPOXY”thinner

“EPOXY”slow thinner

thinner 2KS

“EPOXY”filler-sealer

“EPOXY”hardener

thinner

Supplier Commercial name RENAULT V .I. Ref. Supplier Ref.

Supplier Commercial name RENAULT V .I. Ref. Supplier Ref.

ENTFERNER Agent

> A B – C D <

Variante du polymère de base

Séparateur

Désignation des charges et renforts

Pourcentage de charges

Terme abrégé du ou des polymères

DT 1/370 A13 RENA UL T V.I. 06/01

1.14.5 Marking of polymer components (recycling of plastics)

Plastic parts are marked so as to simplify their sor ting dur ing recycling at the time when the vehicle is scrap-

ped at the end of its life.

Marking of the plastic parts is done by placing abbreviated terms for the polymer components between the

symbols “>“ and “<“.The parts are marked on a face which the customers cannot see and when it is possible

the marking is indelible. Marking is done in the following manner:

Marking of single component products

The abbreviated term for the material is enclosed in symbols “>“ and “<“.

For example:“>PP<“ or “PP” indicates polypropylene.

Marking of copolymers

The abbreviated terms for the polymers are separated by a “/”.

For example:“>P/E<” indicates the copolymer propylene ethylene.

Marking of mixtures or blends of polymers

The abbreviated terms are separated by a “+” (heterogeneous structure).

For example:“>PP + EPDM<“ stands for a blend of polypropylene and EPDM.

Marking of polymers with fillers (additives)

The abbreviated term for the polymer is separated from that for the filler by a dash “-”.

The number following the abbreviated term for the filler relates to its percentage in the mixture.

For example:“>PA66 - (GF25 + MD15)<“ indicates polyamide 66 with 25% filler and 15% reinforcement with

mineral fillers (in decreasing order of percentage).

Marking of multi-component products

The abbreviated terms for the components are separated by commas, in order of appearance (firstly the

surface material).

For example:“>PVC, PUR, ABS<“ indicates skin surface PVC on PUR foam with an ABS insert.

Marking of special features

Abbreviated terms for the polymers can be added up to 4 symbols, in order to indicate a modification.

The symbols are put in after the abbreviated terms.

For example:“>PE - C<“ indicates chlorinated polyethylene, “>PE - LLD” stands for linear low density

polyethylene.

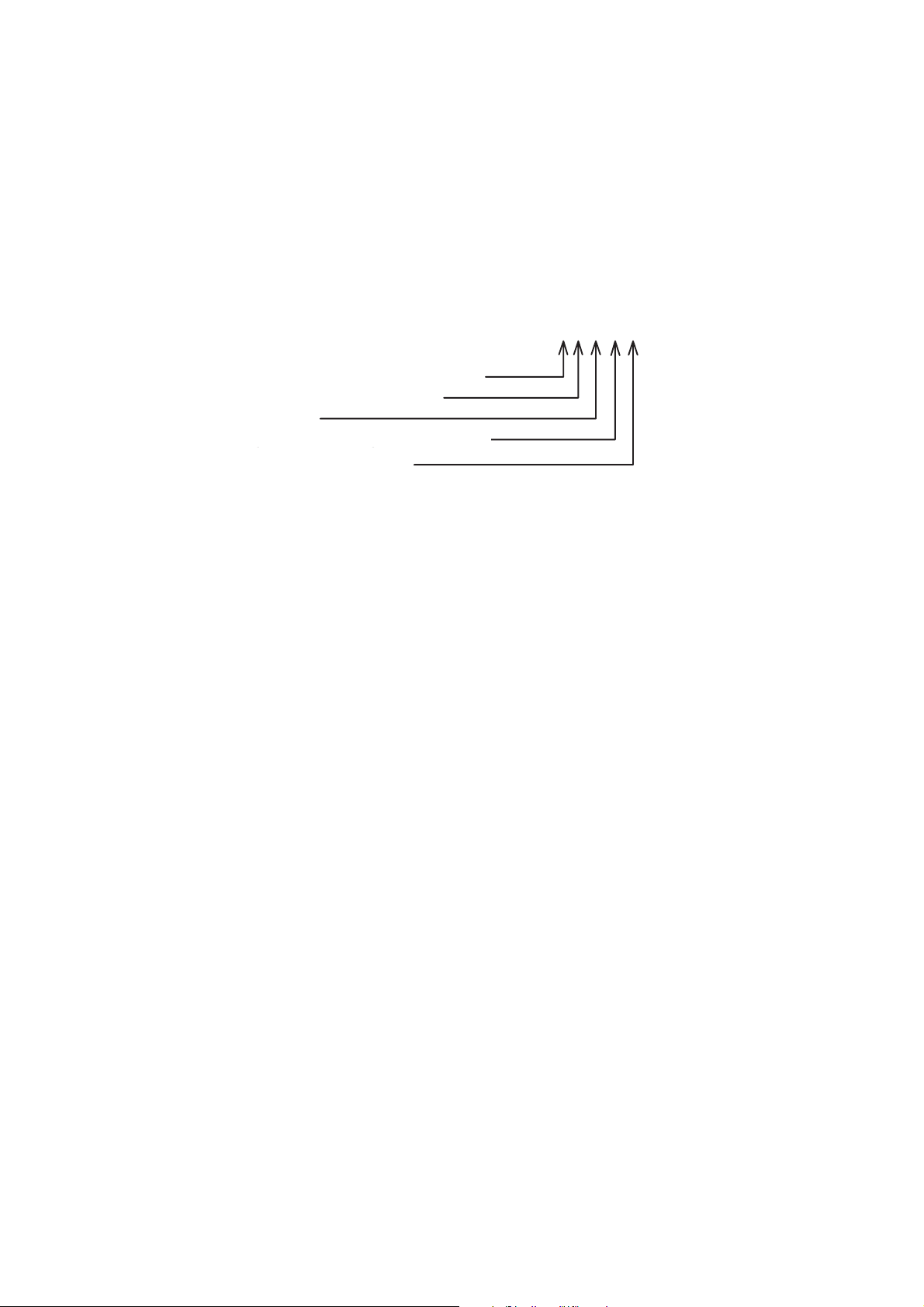

Abbreviation for the polymer(s)

Variant of the base polymer

Separator

Designation of the fillers and additives

Percentage of fillers

Tableau des principaux polymères

Terme abrégé

Variante Matériaux

A.B.S Acrylonitrile/butadiène/styrène

A.S.A Acrylonitrile/styrène/acrylate

E/P Ethylène/propylène

E.P.D.M copolymère éthylène/propylène/diène

P.A Polyamide

P.A 6 Polyamide 6

P.A 66 Polyamide 66

P.C Polycarbonate

P/E Propylène/éthylène

P.E Polyéthylène

P.E – HD Polyéthylène haute densité

P.E – LD Polyéthylène basse densité

P.E – LLD Polyéthylène linéaire basse densité

P.E – X Polyéthylène réticulé

P.M.M.A Poly(méthacrylate de méthyle)

P.O.M Polyoxométhylène

P.P Polypropylène

P.P.E Poly(phénylène éther)

P.P.O.X Poly(oxyde de propylène)

P.S Polystyrène

P.S – HI Polystyrène choc

P.T.F.E Poly(tétrafluorométhylène)

P.U.R Polyuréthanne

P.V.C Polychlorure de vinyle

P.V.C – C Polychlorure de vinyle chloré

P.V.C – P Polychlorure de vinyle plastifié

RENAULT V .I. 06/01 A14 DT 1/370

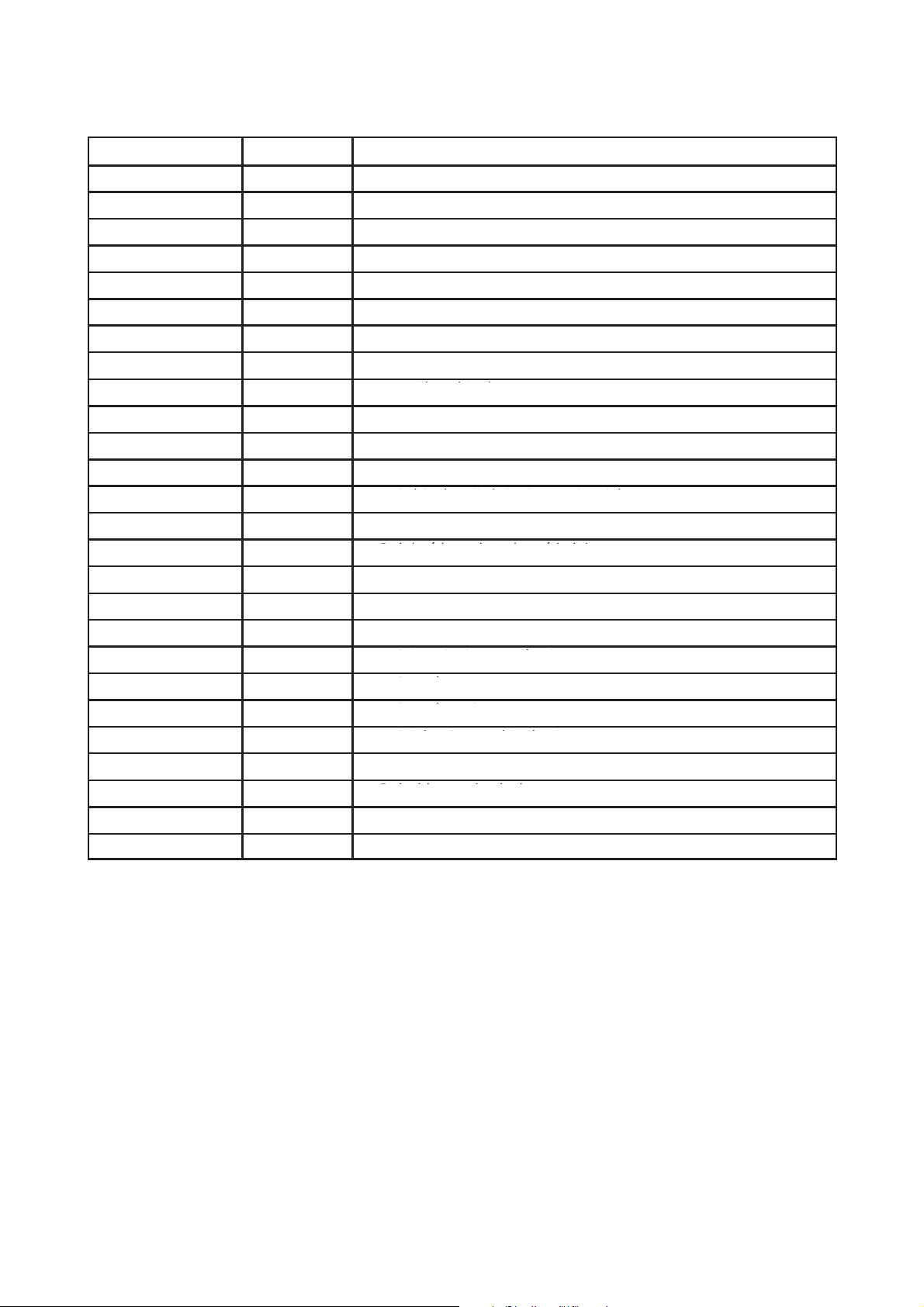

Abbreviated term Variant Materials

Acrylonitrile/butadiene/styrene

Acrylonitrile/styrene/acrylate

Ethylene/propylene

Copolymer ethylene/propylene/diene

Polyamide

Polyamide 6

Polyamide 66

Polycarbonate

Propylene/ethylene

Polyethylene

High density polyethylene

Low density polyethylene

Linear low density polyethylene

Cross-linked polyethylene

Poly(methacrylate of methyl)

Polyoxomethylene

Polypropylene

Poly(phenylene ether)

Poly(oxide of propylene)

Polystyrene

Impact polystyrene

Poly(tetrafluoroethylene)

Polyurethane

Polyvinyl chloride

Chlorinated polyvinyl chloride

Plasticized polyvinyl chloride

Table of the principal polymers

DT 1/370 A15 RENA UL T V.I. 06/01

1.15 Electrical equipment

1.15.1 General

- Any mounting of a specific item of equipment on a commercial vehicle must be in conformity with the recom-

mendations of RENAULT V.I. and the legislation in force. Its execution remains the entire responsibility of the

bodybuilder, both with regard to the suitability for the vehicle being equipped and any possible electromagnetic

interference.

- For reference to wiring diagrams, consult the electrical equipment workshop manual for the vehicle (available

from the Spare Parts Department of RENAULT V.I.).

- Check that the electrical consumption of this equipment is appropriate for the capacity of the batteries and also

the charging current rate of the alternator (if not, refer to the recommendations of the manufacturer CIC 1081).

For the fitting of any particular equipment, consult the Product Applications Department of RENAULT V.I.

- A schematic diagram should be submitted for the approval of RENAULT V.I., when raising any specific question.

- A wiring diagram for the bodybuilder’s or equipment manufacturer’s installation must be incorporated into the

vehicle driving and maintenance handbook.The electrical connection points for the equipment being supplied

should be clearly and precisely indicated on this wiring diagram (even after the agreement of RENAULT V.I. has

been obtained).

- Follow the electrical protection recommendations of RENAULT V.I.; it is forbidden to change the rating of fuses.

- In order to harmonize vehicle equipment, you should use in preference such items as are identical to those fit-

ted in the basic vehicle (i.e.indicator lamps, controls, relays, etc.).

- Assembly of a protective shield on the electric retarder is compulsory for ADR (Transport of Hazardous

Substances) vehicles (refer to regulations in force).

- It is compulsory for the supply voltage for the equipment installed to be equal to the rated v oltage of the vehicle.

The installation of equipment with a 12 volt power rating on our vehicles (24 volt rated voltage) is not permitted

unless a voltage dropper is added.

- Under the circumstances that additional lamps are fitted, the installation must not damage the fluidtight sealing

of the junction boxes.

- Operating without a battery is forbidden.

1.15.2 Wiring harnesses

- Use to the full the wiring runs already set up by the manufacturer (i.e. conduits, tubes, sleeves, etc.) and com-

ply with the limit of their capacity.

- Any wiring harness added by the bodybuilder must be protected by a sealed sheath (smooth and thick or rin-

ged) and can be routed along with the original wiring runs for the vehicle provided that it does not adversely

affect the mechanical mountings for the original harnesses. For vehicles for the transpor t of hazardous goods,

use the protective equipment authorized by the regulations covering the transpor t of hazardous goods.

- If you are obliged to route wires close to a source of heat (i.e.engine, exhaust system, etc.), the minimum clea-

rance to be complied with is 200 mm.

- Never route a wiring harness over projecting angles.

- Never attach a wiring harness to moving parts (even slight movement).

- The section of the cables being used must be suitable for the use in question. Their cross-section should be

selected in accordance with the maximum current on-line (5 amperes per mm2).

- The length of the wiring harnesses should be long enough to allow the electrical appliance which is connected

to be taken off (i.e.principal display unit, tachograph, etc.).

- The numbering of the wires must be in accordance with the manufacturer’s standard.

- The link between the sheath and the connector must be fluidtight.

RENAULT V .I. 06/01 A16 DT 1/370

1.15.3 Electrical connections

- Any additional connection requires protection that is suitable for the use for which it is intended (even if the

power supply provided for the customer by RENAULT V.I. is already protected by a fuse).

- Any electrical connection must be properly wired on the power lines supplied by the manufacturer to the

bodybuilder’s equipment (refer to the servicing and maintenance handbook for the vehicle in question).

- Tapping into the various wiring harnesses supplied by RENAULT V.I. is completely FORBIDDEN (for

example vehicle rear lamps, external marker lamps, contactors, pressure switches, relays, electronic box

inputs and outputs, etc.)

Reminder: a 12 V tapping at the middle point between the two batteries is str ictly FORBIDDEN.

- The electrical connections of the various wiring har nesses of the bodybuilder must be made using a fluid-

tight junction box or otherwise using sealed connectors.If connections have to be made on circuits hooked

up to electronic equipment:

- Ensure that you comply with the polarity recommended.

- No inductance current must pass through the circuits which have been added.

- All the earths must be connected up to the available “EARTH” points provided and not to the bodywork of

the vehicle.

- After work on junction boxes, the seal must always be as integrally effective as the original seal.

- Any power supply requiring a direct connection to the batteries must be capable of being isolated by a bat-

tery cut-out (for example:tail lifts) and protected by a fuse sited as near as possib le to the batteries.Suitable

connection terminals should be used.

- The + power supply is taken from the master switch, or failing this, from the battery terminal for vehicles

without a master switch, but in no case from the alternator or starter motor terminal.

- Power supplies to auxiliary equipment:i.e. telephone, fax, etc.The quality of the installation is the responsi-

bility of the installer (i.e. reception, static, interference, etc.)

- Preferably, you should use connectors approved and distributed by RENAULT V.I. (i.e. type, sealing proper-

ties, rating, number of channels, etc.)

- Connectors for equipment should be positioned near the bottom, whilst avoiding areas subject to splashing

(i.e. wheelarches, etc.).

1.15.4 Available power supplies

All our vehicles are equipped with the available power supply protected by fuses and these are at the dispo-

sal of bodybuilders and equipment manufacturers.

These power supplies are described in the vehicle driving and maintenance handbook (supplied with every

vehicle), in the Workshop Repair Electrical Manual, and in this document (all these documents are available

from the RENAULT V.I. dealer network).

1.15.5 Flasher units

Should the flasher unit become inoperative due to failure to comply with the instructions contained in this

document, the coverage granted by the warranty will be lost.

The flasher units are designed for a maximum rating which is marked on the unit.

Do not exceed this power rating.

Connection

In order to make the connections correctly, consult either the identification mar ks which are located close to

the terminals, or the wiring diagram on the label which is affixed to the flasher unit cover.

1.15.6 Tableaux récapitulatifs des prises de courants normalisees

12 Volts Socle type 12 N

(Norme – BNA.R.43.407 d’Avril 1982

– ISO 1724)

1 – Feux indicateurs de direction gauche

2 – Feu arrière de brouillard

3 – Masse

4 – Feux indicateurs de direction droit

5 – Feux de position arrière et encombrement droit

et éclairage plaque d’immatriculation

6 – Feux de stop

7 – Feux de position arrière et encombrement gauche et

éclairage plaque d’immatriculation

TENSION DESIGNATION ET NORME SCHEMA DU SOCLE

(vue de face)

12 Volts Socle type 12 S

(Norme – BNA.R.43.410 d’Août 1984

– ISO 3732)

C’est un socle supplémentaire qui se monte en plus du

socle 12 N.

1 – Feux de recul

2 – Sans affectation

3 – Masse

4 – Alimentation “+” supplémentaire

5 – Contrôle par mise à la masse

6 – Alimentation “+”

7 – Sans affectation

24 Volts Socle 12 broches

(Norme – BNA.R.43.405 de Mars 1961

– DEFA 1457 b

– DCEA 5.556.

– NATO)

A –Feu de position gauche black–out

B –Feux indicateurs de direction gauche

C –Feu de position droit black–out

D –Masse

E –Feux de position arrière, encombrement et éclairage

plaque d’immatriculattion

F – Feux de stop black–out

H –Sans affectation

J – Feux indicateurs de direction droit

K –Alimentation “+” batterie

L – Masse

M –Feux de stop

N –Sans affectation

DT 1/370 A17 RENA UL T V.I. 06/01

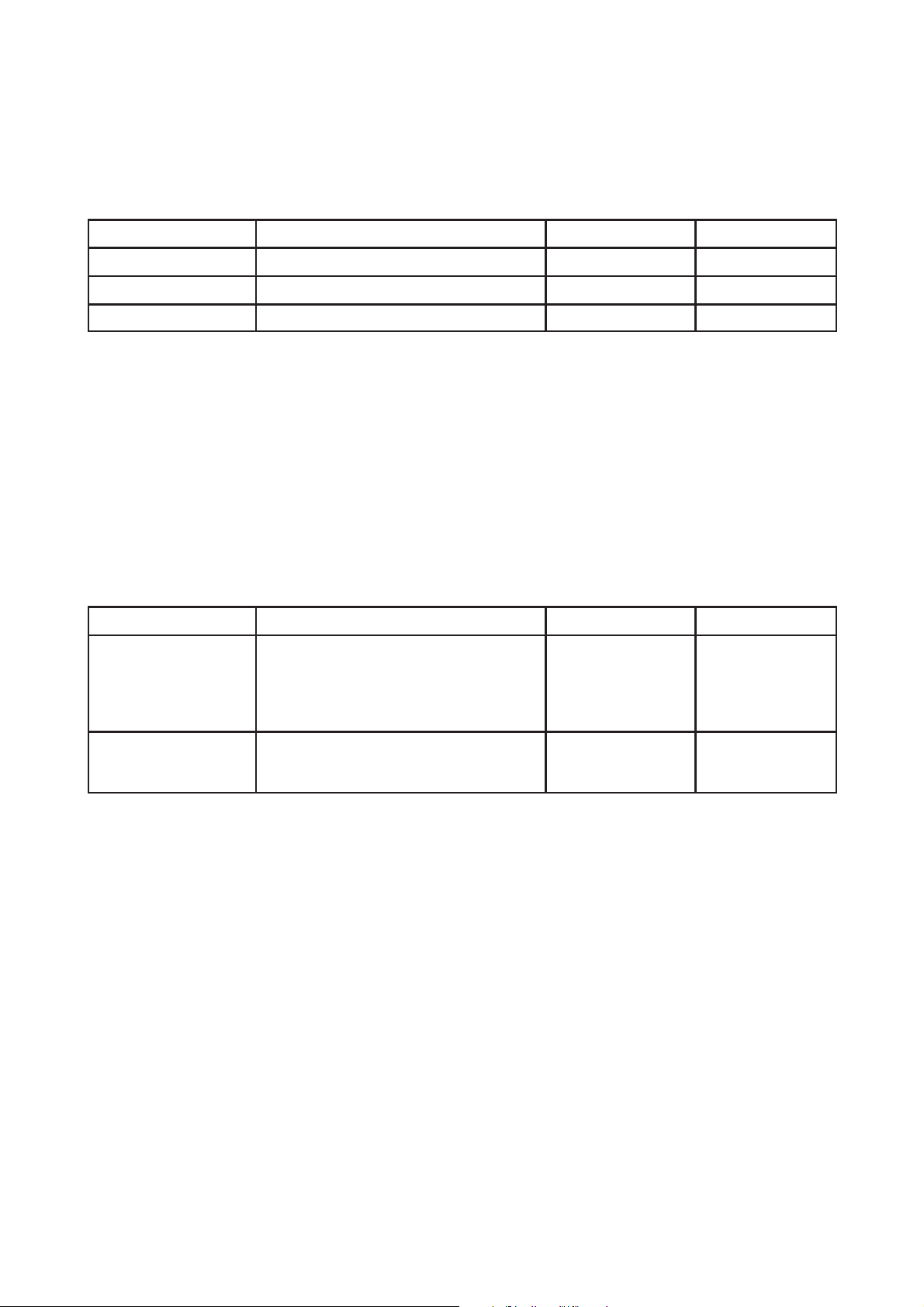

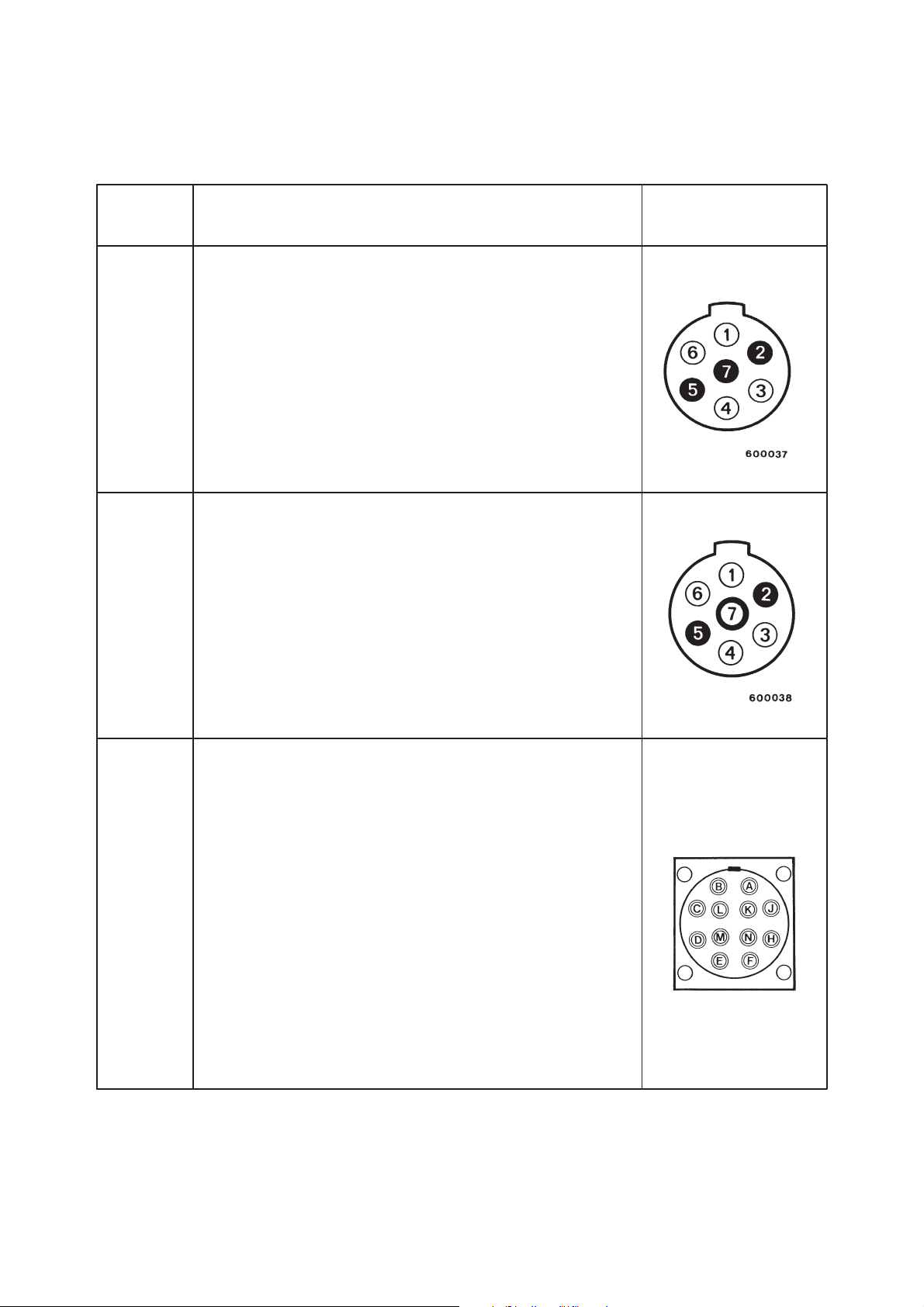

1.15.6 List of standard power sockets

SUPPLY

VOLTAGE

DESCRIPTION AND STANDARDS

12 N type socket

(Standard: - BNA.R.43.407 dated April 1982

- ISO 1724).

1 - LH direction indicator lamp.

2 - Rear fog lamp.

3 - Earth.

4 - RH direction indicator lamp.

5 - RH rear side and marker lamp and number plate

illumination lamp.

6 - Stop lamp.

7 - LH rear side and marker lamp and number plate

illumination lamp.

12 S type socket

(Standard: - BNA.R.43.410 dated August 1982

- ISO 3732).

This is a supplementary socket which is assembled in

addition to the 12 N socket.

1 - Reversing lamp.

2 - Not allocated.

3 - Earth.

4 - Supplementary + power supply.

5 - Earthing monitor.

6 - Positive (+) power supply.

7 - Not allocated.

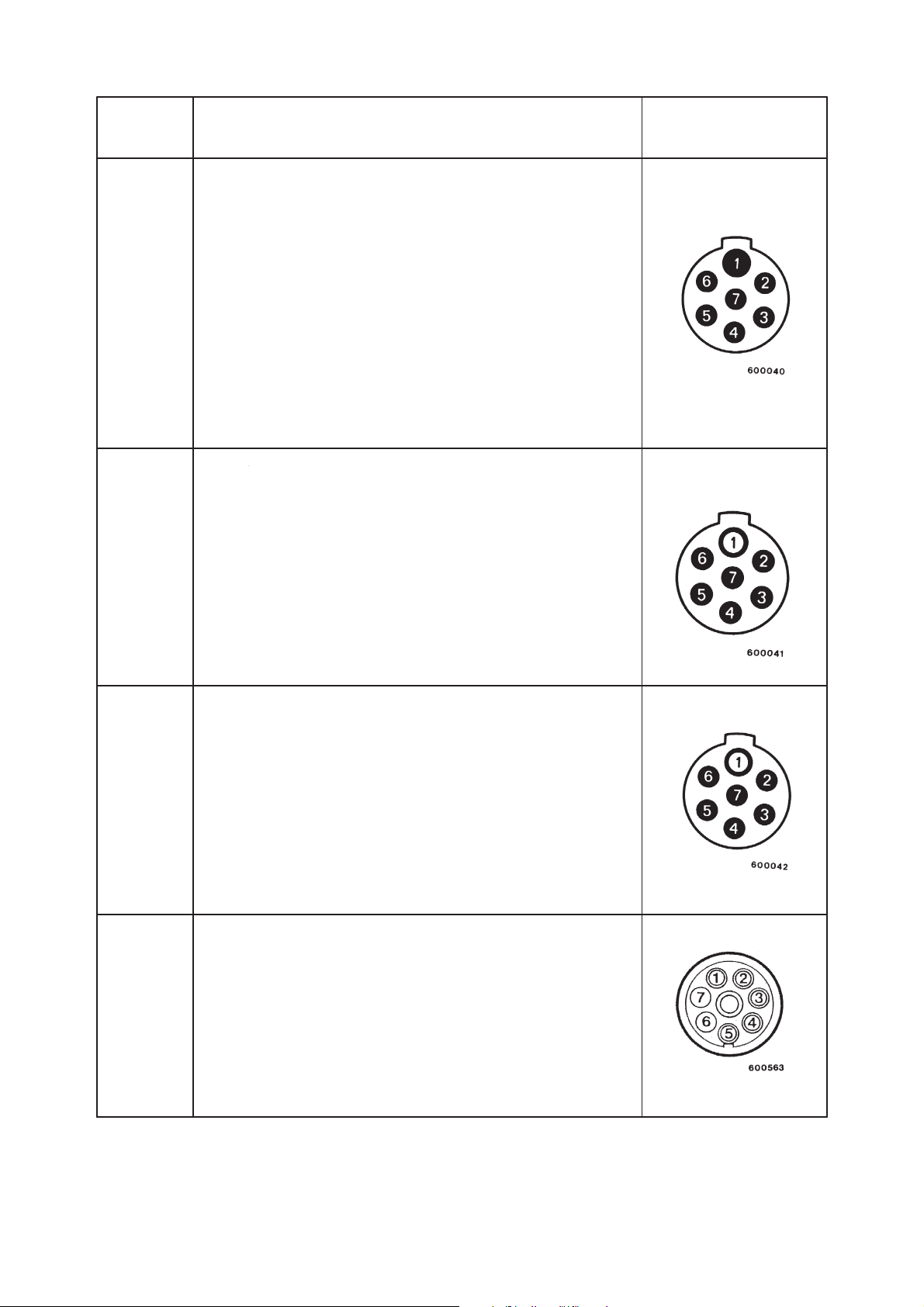

12-pin socket

(Standard: - BNA.R.43.405 dated March 1961

- DEFA 1457 b

- DCEA 5.556

- NATO).

A - LH black-out side lamp.

B - LH direction indicator lamps.

C - RH black-out side lamp.

D - Earth

E - Rear side and marker lamps and number plate illumina-

tion lamp.

F - Black-out stop lamp.

H - Not allocated.

J - RH direction indicator lamps.

K - Battery + power supply.

L - Earth.

M - Stop lamps.

N - Not allocated

SOCKET DIAGRAM

(front view)

TENSION DESIGNATION ET NORME SCHEMA DU SOCLE

(vue de face)

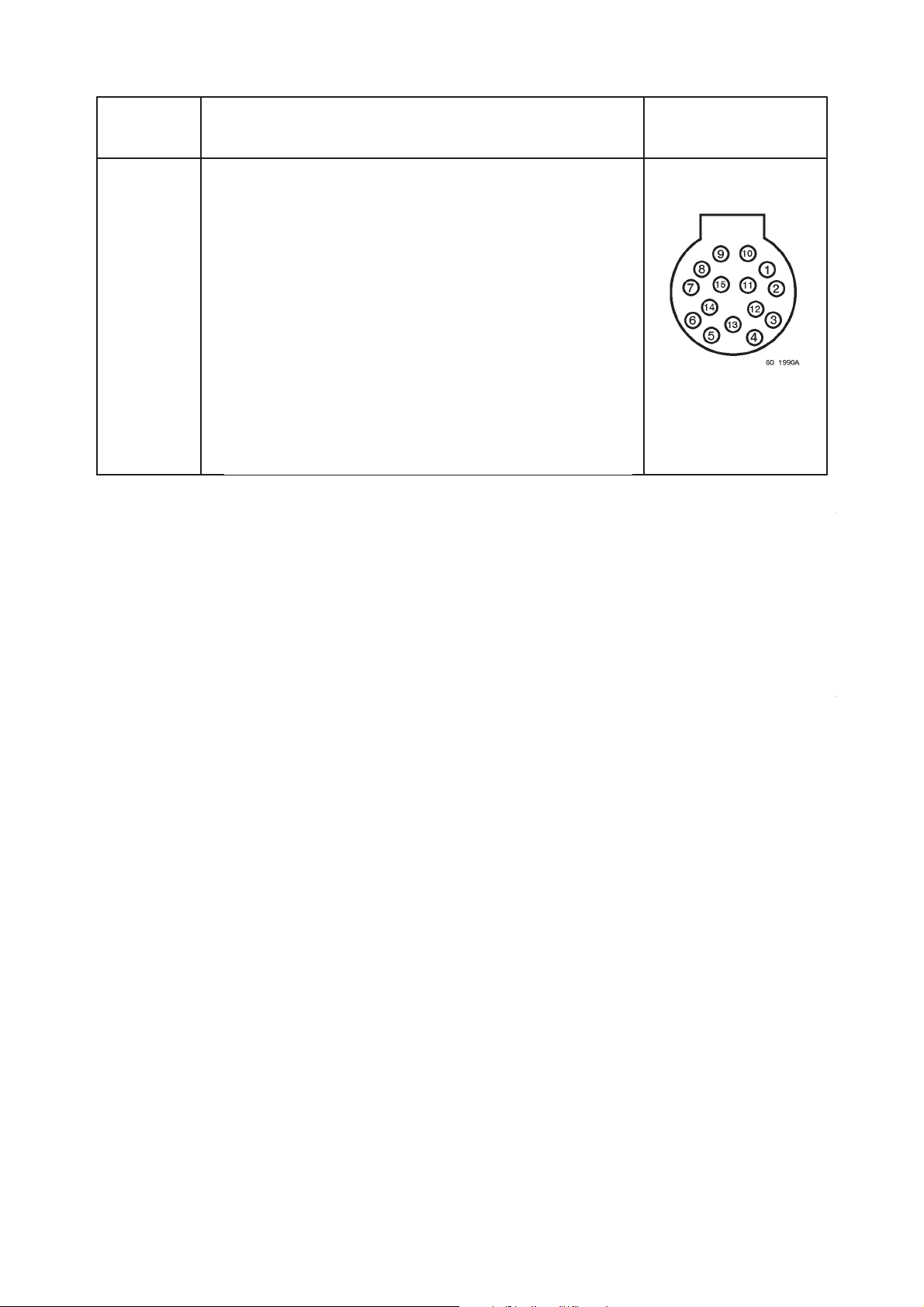

24 Volts Socle type 24 S

(Norme – BNA.R.43.409 d’Avril 1982

– ISO 3731)

C’est un socle supplémentaire qui se monte en plus du

socle 24 N.

1 – Masse

2 – Sans affectation

3 – Feux de recul

4 – Alimentation “+”

5 – Contrôle par mise à la masse

6 – Alimentation “+” supplémentaire

7 – Feu arrière de brouillard

24 Volts Socle 24 P (Pétrolier)

(Norme – BNA.R.10.120 de Juin 1977)

Socle pour véhicules TMD–ADR se monte en

plus du socle 24N.

1 – Masse

2 – Eclairage des vannes

3 – Feux de recul

4 – Alimentation “+”

5 – Masse isolée

6 – Sans affectation

7 – Feu arrière de brouillard

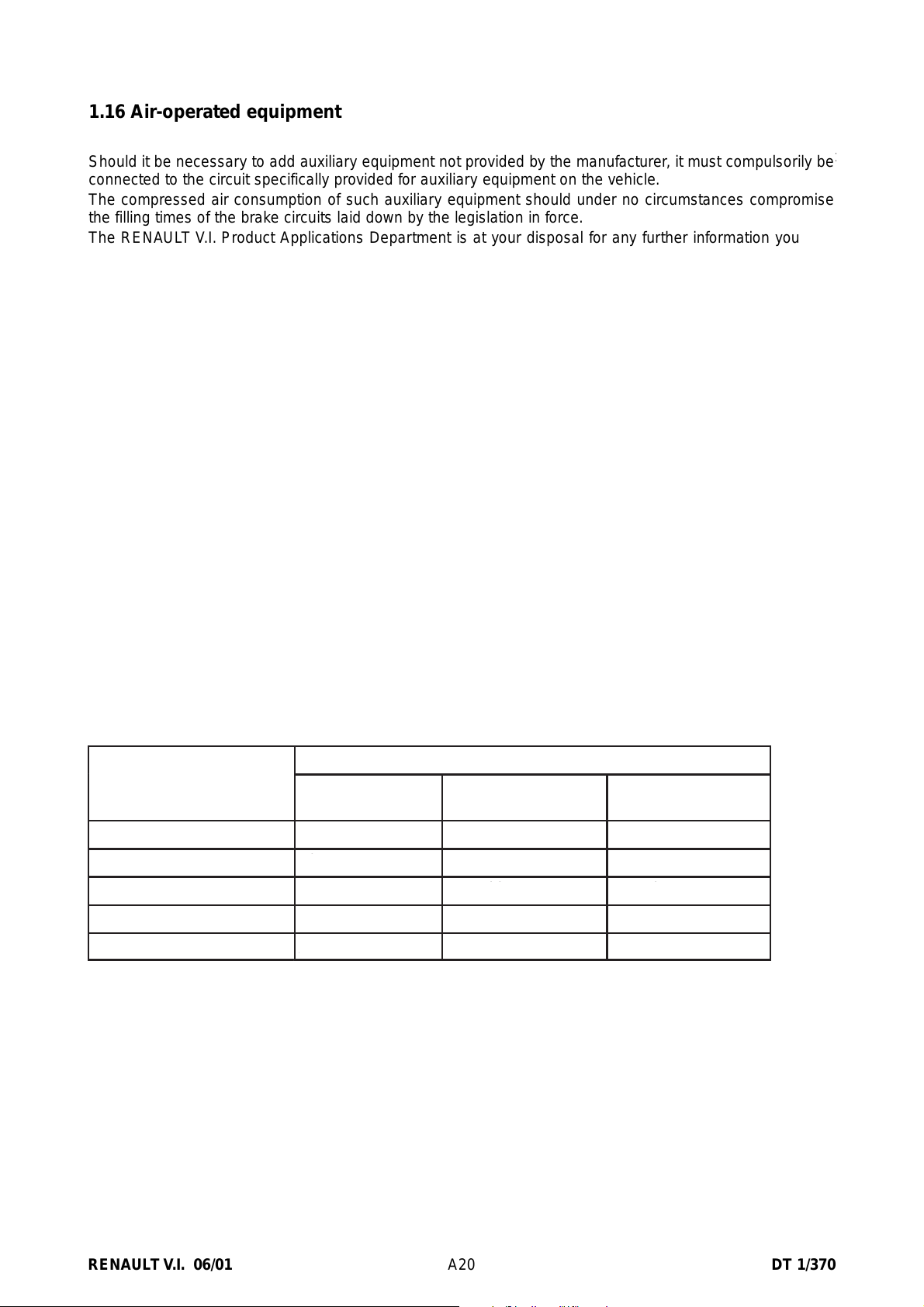

24 Volts Prise ABS spécifique

(Norme ISO 7638)

1 – Alimentation puissance (30A)

2 – Alimentation commande (2A)

3 – Masse commande (2A)

4 – Masse puissance (30A)

5 – Information (2A)

6 – Libre

7 – Libre

24 Volts Socle type 24 N