Makita GA4543C, GA4541C, GA5041C, GA4041C, GA4043C User Manual

...

T |

|

PI / SC / NP |

||

ECHNICAL INFORMATION |

PRODUCT |

|||

|

GA4041C/GA4043C, GA4541C/GA4543C, |

P 1/ 14 |

||

Model No. |

|

|||

|

|

GA5041C/GA5043C |

L |

|

Description Angle Grinders 100mm (4"), 115mm (4-1/2"), |

|

|||

|

|

125mm (5") |

H |

|

CONCEPT AND MAIN APPLICATIONS |

||||

|

||||

1,400W Angle grinder series models; GA4041C/ GA4043C, GA4541C/ GA4543C and GA5041C/ GA5043C are successor models of 9560 series models, featuring:

•"Super Joint System II" developed for effective vibration absorption

•Electronic current limiter, speed control and soft start

•Mechanical brake for powerful braking

•Anti-restart function*1

•Re-designed durable gear housing

•Ergonomically best possible barrel grip

W

Dimensions: mm (")

Model No. |

GA4041C |

|

GA4541C |

|

GA5041C |

GA4043C |

|

GA4543C |

|

GA5043C |

|

|

|

|

|||

Length (L) |

|

325 (12-3/4) |

|

|

|

Width (W) |

117 (4-5/8) |

|

130 (5-1/8) |

|

140 (5-1/2) |

|

|

||||

Height (H) |

117 (4-5/8) |

|

121 (4-3/4) |

||

*1 Anti-restart function is for models, GA4041C, GA4541C, GA5041C only

Specification

Specification

Voltage (V) |

Current (A) |

Cycle (Hz) |

Continuous Rating (W) |

Max. Output (W) |

||

Input |

Output |

|||||

|

|

|

|

|||

110 |

13 |

50/60 |

1,400 |

840 |

1,800 |

|

120 |

12 |

50/60 |

--- |

840 |

2,000 |

|

127 |

12 |

50/60 |

1,400 |

840 |

2,000 |

|

220 |

6.7 |

50/60 |

1,400 |

840 |

2,100 |

|

230 |

6.4 |

50/60 |

1,400 |

840 |

2,100 |

|

240 |

6.1 |

50/60 |

1,400 |

840 |

2,100 |

|

Model No.

Diameter Wheel size: Hole diameter

mm (")

Max. thickness

No load speed: min.ˉ¹=rpm |

|

Shock absorbing system |

|

Electronic |

Constant speed control |

Soft start |

|

|

|

control |

Electronic current limiter |

|

|

|

Anti-restart function |

|

Variable speed control by dial |

GA4041C/ GA4043C |

GA4541C/ GA4543C |

GA5041C/ GA5043C |

100 (4) |

115 (4-1/2) |

125 (5) |

16 (5/8) |

22.23 (7/8) |

|

6 (1/4)

2,800 - 11,000 Super Joint System II Yes

Yes

Yes

GA4041C, GA4541C, GA5041C: Yes/ GA4043C, GA4543C, GA5043C: No

Yes

|

Mechanical brake |

|

|

|

Yes |

|

|

|

Protection against electric shock |

|

|

Double insulation |

|

||

|

Power supply cord: m (ft) |

|

European countries except UK: 4.0 (13.2), Brazil, Australia: 2.0 (6.6) |

||||

|

|

|

Other countries: 2.5 (8.2) |

|

|||

|

|

|

|

|

|||

|

Weight according to |

|

2.6 (5.6) |

|

2.7 (5.9) |

|

2.7 (5.9) |

|

EPTA-Procedure 01/2003*2: kg (") |

|

|

||||

|

|

|

|

|

|

||

|

*2 With Side grip, Wheel cover, Inner flange, Lock nut |

|

|

|

|||

Standard equipment |

|

|

|

|

|

|

|

|

Side grip ............................................... |

|

1 |

|

|

|

|

|

Lock nut wrench .................................. |

|

1 |

|

|

|

|

|

Depressed center wheel ........................ |

|

1 (100mm for GA4041C/ GA4043C, 115mm for GA4541C/ GA4543C, |

||||

|

|

|

125mm for GA5041C/ GA5043C) |

|

|||

|

Note: The standard equipment for the tool shown above may vary by country. |

|

|||||

Optional accessories |

|

|

|

|

|

|

|

|

Depressed center wheels |

Wheel covers for wire cup brush sets |

Abrasive cut off wheels |

|

|||

|

Rubber pads |

Wire bevel brush sets |

Wheel covers |

|

|||

|

Dust collection wheel guards |

Wheel covers for wire bevel brush sets Sanding lock nut |

|

||||

|

Abrasive discs |

Diamond wheels |

etc. |

|

|||

|

Wire cup brush sets |

Dust collecting wheel guards |

|

|

|

||

P 2/ 14

Repair

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. |

Description |

Use for |

|

|

|

1R028 |

Bearing setting pipe 20-12.2 |

mounting Gear housing cover to Armature |

|

|

|

1R045 |

Gear extractor (Large) |

separate Armature from Gear housing cover |

1R232 |

Pipe 30 |

removing Coupling and Ball bearing 6903ZZ from large Spiral bevel gear |

|

|

|

1R258 |

V block |

supporting Armature and Bearing box |

1R268 |

Spring pin extractor M3 |

disassembling Shaft lock mechanism |

|

|

|

1R269 |

Bearing extractor |

removing Ball bearings 627DDW/ 696ZZ from Armature |

|

|

|

1R281 |

Round bar for Arbor 7-50 |

removing Switch knob from Switch lever |

|

|

|

1R286 |

Round bar for Arbor 12-50 |

removing large Spiral bevel gear section from Bearing box |

|

|

|

1R291 |

Retaining ring S & R pliers |

removing Retaining ring S-9 |

|

|

|

1R340 |

Bearing retainer wrench |

removing Bearing retainer 20-33 from Bearing box |

1R350 |

Ring 60 |

supporting Gear housing when disassembling Shaft lock mechanism |

|

|

|

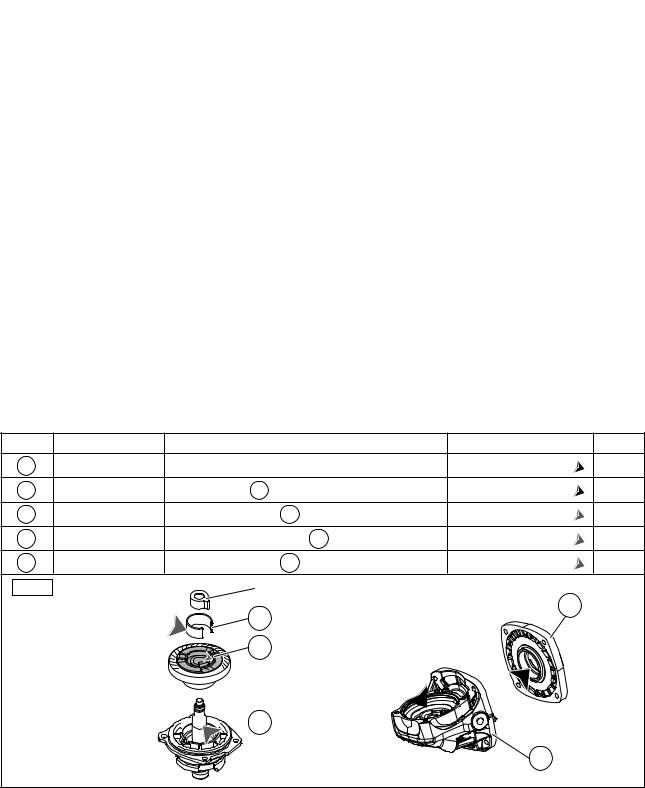

[2] LUBRICATION

Apply Makita grease to the following portions designated with the black triangle and the gray triangle to protect parts and product from unusual abrasion.

Item No. |

Description |

Portion to lubricate |

Lubricant |

Amount |

1 |

Gear housing |

Gear room |

Makita Grease SG No. 0: |

17g |

6 |

Gear housing cover |

O-ring 27.5 of 6 Gear housing cover |

Makita Grease SG No. 0: |

a little |

56 |

C-type plate |

Outer surface where 58 Coupling contacts |

Makita Grease FA No. 2: |

a little |

58 |

Coupling |

Cylindrical portion where 56 C-type plate contacts |

Makita Grease FA No. 2: |

a little |

70 |

Spindle |

Drum portion where 58 Coupling contacts |

Makita Grease FA No. 2: |

a little |

Fig. 1 |

|

Joint sleeve |

6 |

|

|

|

56 |

|

|

|

|

|

|

|

|

|

58 |

|

|

Spiral bevel gear (large)

Spiral bevel gear (large)

Ball bearing 6903ZZ

70

70

1

[3] DISASSEMBLY/ASSEMBLY [3] -1. Note in Disassemble (general)

Note: As listed below, the grinders use different spiral bevel gears, and they are not interchangeable. Referring to this list, therefore, be sure to use correct gears for replacement.

Model No. |

No load |

Smaller spiral bevel gear |

Larger spiral bevel gear |

||

speed: min.ˉ¹ |

(on armature shaft) |

(on spindle) |

|||

|

|

||||

GA4041 |

GA4541C |

|

|

|

|

GA4541 |

GA5041C |

11,000 |

10 teeth |

38 teeth |

|

GA5041 |

GA4543C |

||||

GA4041C GA5043C |

|

|

|

||

GA4043C |

|

|

|

|

|

GA6041 |

|

9,000 |

9 teeth |

41 teeth |

|

P 3/ 14

Repair

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Armature, Spiral bevel gear [small one]

DISASSEMBLING

(1) Remove Spiral bevel gear (small) from the drive end of Armature as drawn in Fig. 2.

Fig. 2

1.Remove Rear cover by unscrewing one 4x18 Tapping screw.

2.Shift Spiral spring from Carbon brush top.

3.Disconnect Carbon brush from commutator by pulling up.

Note: No need to remove Carbon brush in this step.

Rear cover

4x18 Tapping screw

4x18 Tapping screw

4.Unscrew four Tapping screws. Then separate Gear housing cover from Spacer while applying a slotted screwdriver to the notch on Gear housing cover on belly side.

Gear housing cover Gear housing |

4x50 Tapping screw |

Gear housing cover |

|

|

|

|

|

Armature |

Notch on

Gear housing cover

Spacer

5.Remove M6 Hex nut to turn it with Wrench 10 counterclockwise. Then, remove Flat washer 6 and small Spiral bevel gear from Armature.

M6 Hex nut

Flat washer 6

Spiral bevel gear (small)

Wrench 10

Wrench 10

6. Remove Gear housing cover with 1R045. Then, remove Compression spring 33 and Brake shoe holder complete.

Caution: Be careful that the cover and the spring may jump out from Armature side

due to recoil force by the spring.

|

Gear housing |

|

1R045 |

cover |

|

Compression |

||

|

||

|

spring 33 |

Brake shoe

Brake shoe

holder complete

holder complete

Armature

Armature

P 4/ 14

Repair

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Armature, Spiral bevel gear [small one] (cont.)

DISASSEMBLING

(2)Disassemble the commutator end of Armature as drawn in Fig. 3.

Note: This step is required for the models with electronic control system of GA4041C, GA4043C, GA4541C, GA4543C, GA5041C, GA5043C.

Fig. 3

1. Pick up three tabs of |

Tabs |

|

Self lock 6 with tweezers |

||

|

||

to remove it from Armature. |

Self lock 6 |

|

|

Tweezers |

2.Remove Magnet sleeve, Wave washer 6 and Labyrinth rubber ring 22.

Magnet sleeve

Wave washer 6

Labyrinth rubber ring 22

3. Remove Ball bearing 627DDW with 1R269. |

4. Remove Flat washer 7 and |

|

Insulation washer. |

1R269 |

Flat washer 7 |

|

|

Ball bearing 627DDW |

Insulation washer |

|

ASSEMBLING

(1) Assemble the commutator end of Armature as drawn in Fig. 4.

Note: This step is required for the models with electronic control system of GA4041C, GA4043C, GA4541C, GA4543C, GA5041C, GA5043C.

Fig. 4

1. Return tabs of Self lock 6 to their |

2. Press down Self lock 6 until |

3. Magnet sleeve is stabilized |

normal shape before assembling. |

Wave washer 6 gets flat. |

between Self lock 6 and |

Then, mount Wave washer 6 to |

|

Wave washer 6 by the reaction |

|

||

the commutator end of Armature. |

|

force of Wave washer 6. |

Note: Be careful of their directions. |

Self lock 6 |

Refer to the drawings in Fig. 4. |

|

|

Magnet sleeve |

Self lock 6 |

|

Magnet sleeve |

|

Wave washer 6 |

Wave washer 6 |

|

P 5/ 14

Repair

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -2. Armature, Spiral bevel gear [small one] (cont.)

ASSEMBLING

(2) Assemble the drive end of Armature as drawn in Fig. 5.

Fig. 5

1. Set Brake shoe holder |

2. Mount Gear housing cover to |

complete and Compression |

Armature to fit the groove of |

spring 33 to Armature. |

the cover to Compression |

|

spring 33 and Armature shaft |

Compression |

through Ball bearing 6001LLB. |

spring 33 |

Ball bearing |

|

|

Brake shoe |

Groove of Gear |

||

6001LLB |

|||

holder complete |

|

housing cover |

Armature |

Compression |

spring 33 |

3.Supporting Armature section with 2 pcs. of 1R258, press Gear housing cover to Armature section with 1R028.

1R028

1R028

1R258

4.Set Spiral bevel gear (small) and Flat washer 6 to Armature shaft. Then, secure them with M6 Hex nut.

Flat washer 6 |

M6 Hex nut |

|

|

||

Spiral bevel |

Wrench 10 |

|

gear (small) |

||

|

Loading...

Loading...