Makita ER2650LH User Manual

TECHNICAL INFORMATION

PRODUCT P 1/ 14

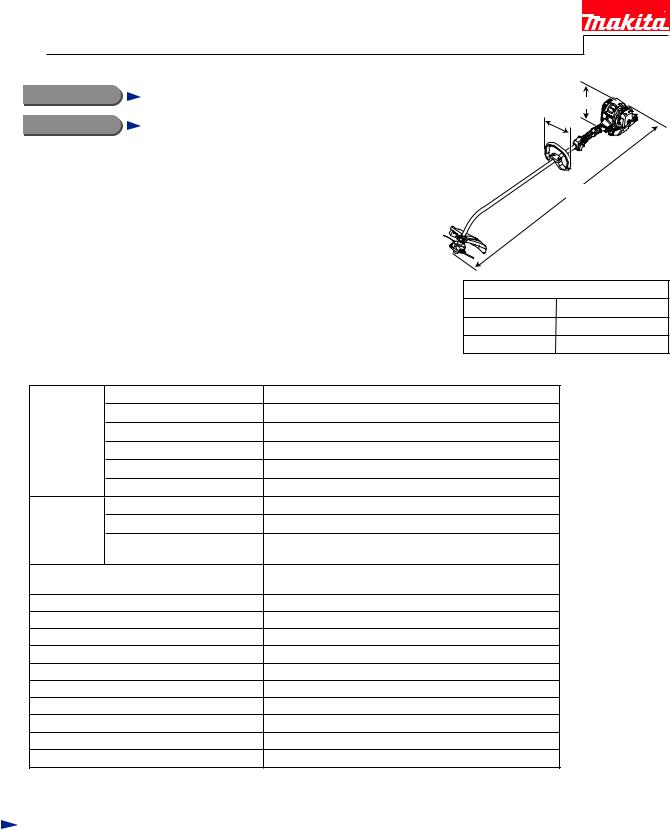

Models No. |

ER2650LH |

H |

|

|

|

Description |

Petrol String Trimmer |

W |

CONCEPT AND MAIN APPLICATIONS

Model ER2650LH is a petrol string trimmer equipped with 25.4cm³ 4-stroke engine in compliance with

all known exhaust emission regulations.

Specification

Specification

L

Dimensions: mm (")

Length (L) |

1,621 (64) |

Width (W) |

310 (12-1/4) |

Height (H) |

479 (18-7/8) |

|

Model |

EH026 |

|

Type |

4-stroke |

|

Displacement: cm³ (cu.in.) |

25.4 (1.5) |

Engine |

|

|

|

Fuel |

Straight unleaded gasoline |

|

Max. output: kW (PS) |

0.77 (1.1) |

|

Max. torque: N.m |

1.1 (at 5,500 min.ˉ¹) |

|

at max. output power |

7,000 |

Speed: |

at no load |

10,000 |

min.ˉ¹=spm |

with nylon cutting head |

7,900 |

|

(nylon cord diameter: mm) |

(2.4) |

|

|

SAE10W-30 oil |

Engine oil |

|

|

|

|

in the Class SF or higher of API classification |

Carburetor |

|

Diaphragm |

Starting system |

Recoil starter, with mechanical decompression |

|

Fuel tank capacity: L (US oz) |

0.6 (20.3) |

|

Primer pump |

|

Yes |

Clutch |

|

Yes |

Spindle size |

|

M8 x 1.25, Right-handed |

Cutting width: mm (") |

412 (16-1/4) |

|

Handle style |

|

Loop handle |

Rapid start |

|

No*1 |

Dry weight*2: kg (lbs) |

4.8 (10) |

|

*1: However, equipped with mechanical decompression |

||

*2: without guard, cutting tool |

|

|

Standard equipment |

|

|

Nylon cutting head .......................................................................................... |

1 |

|

Socket wrench (for 10-16) .............................................................................. |

1 |

|

Hex wrench 4 |

.................................................................................................. |

1 |

Pin 4 ................................................................................................................ |

|

1 |

Accessory bag |

................................................................................................. |

1 |

Oil set (oil bottle containing 80mL engine oil) ............................................... |

1 |

|

Note: The standard equipment for the tool shown may vary by country.

Optional accessories

Optional accessories

Nylon cutting heads [Bump & feed 4, Ultra Auto 4]

P 2/ 14

Repair

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

Code No. |

Description |

Use for |

1R004 |

Retaining ring pliers ST-2 for External ring |

removing/ assembling Retaining rings S-12 and S-24 |

1R127 |

Air density tester |

diagnosing Carburetor |

1R171 |

T-type hex. wrench 4-130 |

removing / assembling M5 Hex socket head bolt |

1R247 |

Round bar for arbor 20-100 |

removing Clutch drum and Ball bearing 6001LLU |

1R286 |

Round bar for arbor 12-50 |

press-fitting Clutch drum |

1R308 |

Spring pin extractor 4.0 |

holding Cutter holder |

1R364 |

Flywheel puller |

removing Flywheel |

1R366 |

Feeler gauge set |

Adjusting Ignition coil, Spark plug and Rocker arm assembly |

--- |

Hex socket bit 13 |

removing / assembling Flywheel |

--- |

Wire brush |

cleaning Spark plug |

[2]GASKET

(1)Replace the removed gasket with the new one.

(2)Clean the matching surface where the gasket is placed to maintain its sealing performance.

[3]LUBRICANT / ADHESIVE APPLICATION

(1)Apply Makita grease N No.2 to Spiral spring in Recoil starter and the spline ends of Shaft.

(2)Apply Liquid gasket; ThreeBond 1215, to the matching surface of Crank case and Cylinder block when assembled. (Fig. 55)

[4]DISASSEMBLY/ASSEMBLY

[4]-1. Attention

Follow the instructions below during repairing.

•Wear glove to avoid injury.

•Cool down the engine enough before repairing to avoid skin burn.

•Remove the remaining fuel in Tank and Carburetor completely. Note; No open flames in the workshop.

•Repair the tool on the stable workbench and keep dust out.

•Record where and how the parts are assembled to avoid mis-assembling. And assort and keep the disassembled parts in the box by section.

•Treat the disassembled parts carefully. Be sure to clean and wash parts before assembling.

•Use Impact driver if bolts and screws can not be loosen.

•Tighten the bolts and the screws to the specific torque as listed in Fig. 59.

•Check the movement and sound of the main parts by manually turning each part once assembled.

•Check the assembled parts by manually turning them if there is any faulty or unusual gap.

P 3/ 14

Repair

Repair

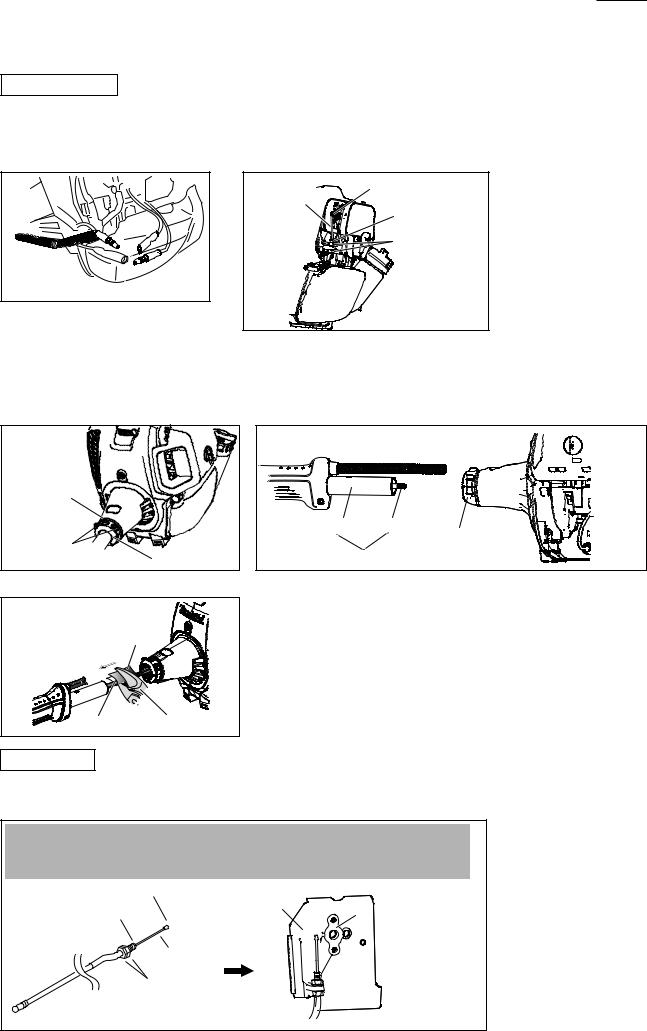

[4] DISASSEMBLY/ASSEMBLY [4]-2. Engine and Shaft

DISASSEMBLING

(1)Disconnect lead wire and grounding wire by removing each connector after Air cleaner cover is removed. (Fig. 1)

(2)Remove Control cable from Insulator by loosening nuts of the adjust screw and disconnecting inner cable from Swivel of Carburetor. (Fig. 2)

Fig. 1 |

Fig. 2 |

Inner cable of Control cable

Cable

holder of

Insulator

Connector (4pcs.)

Swivel

Adjust screw of Control cable

Nuts of Control cable

(3)Loosen two M5x18 Hex socket head bolts on Pipe holder and remove M5x12 Hex socket head bolt. (Fig. 3)

(4)Pull out Shaft pipe complete from Engine (Pipe holder). (Fig. 4)

Note: Cover cloth on a shaft and pull out it by grasping it with Waterpump pliers in case the shaft is stuck at the spline engagement. (Fig. 5).

Fig. 3

M5x13 Hex.  socket head bolt

socket head bolt

M5x18 Hex. |

|

socket head bolt (2pcs.) |

Pipe holder |

Fig. 4

Shaft pipe |

Shaft |

|

Pipe holder |

Shaft pipe complete |

|

Fig. 5

cloth

Shaft Water pump pliers

ASSEMBLING

Take the reverse step of disassembly. Set Control cable in place. (Fig. 2, Fig. 6)

Fig. 6

Hook the tip end of Inner cable in the groove of Swivel on Carburetor and

fix Control cable in the Cable holder of Insulator by tightening Nuts of Control cable. Note: Adjust the tension of the cable to allow the play 1mm to 2mm.

Tip end of Inner cable to be hooked

on Swivel Insulator Swivel Adjust screw

|

Inner cable |

|

Nuts to fix |

|

in Cable holder |

Control cable |

of Insulator |

|

P 4/ 14

Repair

Repair

[4] DISASSEMBLY/ASSEMBLY [4]-3. Shaft pipe complete

DISASSEMBLING

(1)Loosen two M5x25 Hex socket head bolts and remove Clamp cover B and Loop handle. (Fig. 7)

(2)Remove 4x18 Tapping screws (4pcs) and M5x14 Hex socket head bolts, then separate Lever case R and L. (Fig. 8)

Fig. 7 |

|

Fig. 8 |

|

M5x25 Hex. socket |

|

|

head bolt (2pcs.) |

|

|

Shaft pipe |

|

|

complete |

|

|

Loop handle |

socket |

|

head bolt (2pcs.) |

|

|

|

|

Clamp cover B |

|

4x18 Tapping screw |

|

(4pcs) |

(3)Disassemble Shaft pipe complete by following the disassembly step of the chapter [4]-2.

(4)Pull out a shaft from Shaft pipe complete.

ASSEMBLING

Take the disassembling step in reverse.

[4] DISASSEMBLY/ASSEMBLY [4]-4. Head case complete

DISASSEMBLING

(1) Disassemble Protector and Head case complete. (Fig. 9)

Fig. 9

1.Disassemble Protector by removing

Hex bolt (2pcs) and Hex socket bolt (1pc).

2.Insert 1R308 in a hole on Cutter holder to lock shaft and remove Cutter assembly by turning it clockwise.

3.Loosen M5x25 Hex socket head bolt and remove Head case complete.

Shaft pipe |

|

|

|

complete |

|

M5x25 |

Shaft pipe |

Protector |

Hex socket |

complete |

|

|

head bolt |

Hex socket |

|

|

head bolt |

|

|

|

|

|

Head case complete

Hex bolt 1R308

Hex bolt 1R308

Cutter assembly

Cutter holder

P 5/ 14

Repair

Repair

[4] DISASSEMBLY/ASSEMBLY [4]-4. Head case complete (cont.)

DISASSEMBLING

(2) Disaasemble Cutter shaft and Ball bearings from Head case complete. (Fig. 10)

Fig. 10

1.Make Hex wrench 5 square shape by grinding its two diagonal edges and insert it into the square hole of Cutter shaft.

Head case complete

2.Fix Head case with vise and lock Cutter holder with 1R308. Then, turn Wrench 5 counterclockwise and disassemble Cutter holder.

Head case complete |

1R308 |

Hex wrench 5

vise

Square hole of Cutter shaft

Grind these edges. |

Hex wrench 5 |

|

Hex wrench 5 |

||

|

3.Remove Cutter shaft with Arbor press. And then, remove Ball bearing 608DDW by using 1R286.

Arbor press

1R286

Head case complete

Ball bearing 608DDW

ASSEMBLING

(1) Take reverse step of the disassembly. (Fig. 10, 11)

Note: • Pay attention to the assembly direction of Washer and Bearing washer.

•Shaft end can be fitted into the square hole of Cutter shaft by twisting it with pliers to match their angles without disassembling Head case.

Fig. 11

Cutter holder |

Washer |

Head case |

Ball bearing |

Cutter shaft |

Bearing washer |

608DDW |

Spring washer M8 |

|

|

M5x25 |

Collar |

Ball bearing |

|

|

|

Hex socket |

|

608ZZ |

|

|

|

head bolt |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Loading...

Loading...