Lenze 9400 User Manual

9400

Servo Drives 9400 HighLine_ _ _ _ _ _ _ _ _ _ _

E94AxHExxxx

Reference manual |

EN |

|

|

Ä.MvGä 13448538

L

Overview of technical documentation for Servo Drives 9400

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Project planning, selection & order

Hardware manual 9400

Catalogue / electronic catalogue (DSC - Drive Solution Catalogue)

Mounting & wiring

MA - 9400 StateLine/HighLine

MA - communication module

MA - extension module

MA - safety module

MA - accessories

MA - remote maintenance components

Parameter setting

BA - keypad

SW - Lenze software »Engineer«

SW - controller (9400 StateLine/HighLine/PLC)

SW - regenerative power supply module

KHB - communication module

SW - extension module

SW - safety module

SW - Lenze technology application

SW - function library 9400

Configuring & programming

SW - Lenze software »Engineer«

SW - Lenze software »PLC Designer«

SW - controller (9400 HighLine/PLC)

KHB - communication module

SW - extension module

SW - safety module

SW - Lenze technology application

SW - function library 9400

Drive commissioning

Commissioning guide

SW - controller (9400 StateLine/HighLine/PLC)

Chapter "Commissioning" ( 22)

Chapter "Oscilloscope" ( 579)

Chapter "Diagnostics & fault analysis" ( 598)

Remote maintenance manual

Networking structure

KHB - communication medium used

Legend:

Printed documentation

Online documentation (PDF/Engineer online help)

Abbreviations used:

BA Operating instructions

KHB Communication manual

MA Mounting instructions

SW Software Manual

This documentation

This documentation

This documentation

2 |

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 |

About this documentation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

11 |

||||||||

1.1 |

Conventions used |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

12 |

|||||||

1.2 |

Terminology used |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

13 |

|||||||

1.3 |

Definition of notes used _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

14 |

||||||||

2 |

Introduction _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

15 |

||||||||

2.1 |

Parameter setting, configuring, or programming? |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

15 |

|||||||

|

2.1.1 |

Basic functionalities _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

16 |

|||||||

|

2.1.2 |

Technology applications _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

16 |

|||||||

2.2 |

Communicating with the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

17 |

||||||||

|

2.2.1 |

Going online via diagnostic adapter |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

17 |

||||||

|

2.2.2 |

Going online via system bus (CAN on board) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

20 |

|||||||

|

2.2.3 |

Use of other communication interfaces |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

20 |

||||||

2.3 |

Signal types & scaling _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

21 |

||||||||

3 |

Commissioning |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

22 |

|||||||

3.1 |

General information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

23 |

||||||||

3.2 |

Notes on commissioning using the keypad |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

24 |

|||||||

3.3 |

Initial commissioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

25 |

||||||||

3.4 |

Standard set-up |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

26 |

|||||||

3.5 |

Controller replacement |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

27 |

|||||||

3.6 |

Motor replacement |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

27 |

|||||||

4 |

Drive interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

28 |

||||||||

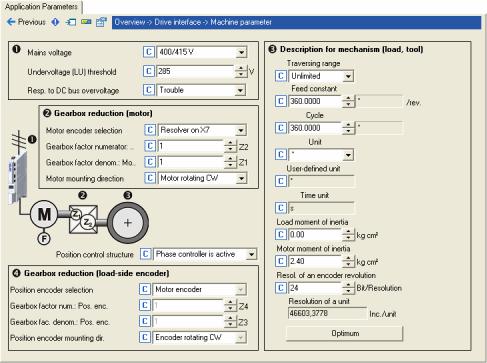

4.1 |

Machine parameters |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

29 |

|||||||

|

4.1.1 |

Mains voltage |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

30 |

||||||

|

4.1.2 |

Gearbox ratio _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

31 |

|||||||

|

4.1.3 |

Motor mounting direction _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

32 |

|||||||

|

4.1.4 |

Feedback configuration _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

32 |

|||||||

|

4.1.5 |

Unit/user-defined unit _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

33 |

|||||||

|

4.1.6 |

Traversing range _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

34 |

|||||||

|

4.1.7 |

Feed constant |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

36 |

||||||

|

4.1.8 |

Resolution of an encoder revolution |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

37 |

||||||

|

4.1.9 |

Max. position, speed, and acceleration that can be displayed internally _ _ _ _ _ _ _ _ _ _ |

40 |

|||||||

4.2 |

Device commands _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

42 |

||||||||

|

4.2.1 |

Load Lenze setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

44 |

|||||||

|

4.2.2 |

Load start parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

45 |

|||||||

|

4.2.3 |

ENP:Load plant data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

46 |

|||||||

|

4.2.4 |

Activate application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

47 |

|||||||

|

4.2.5 |

Save selected application _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

48 |

|||||||

|

4.2.6 |

Save start parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

49 |

|||||||

|

4.2.7 |

Delete logbook _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

51 |

|||||||

|

4.2.8 |

Archive logbook |

|

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

52 |

|||||

|

4.2.9 |

Start application |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

53 |

||||||

|

4.2.10 |

Stop application |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

54 |

||||||

|

4.2.11 |

Reset program |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

55 |

||||||

|

4.2.12 |

Delete program |

|

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

56 |

|||||

|

4.2.13 |

Restart program |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

57 |

||||||

|

4.2.14 |

Reset runtime measurement _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

58 |

|||||||

|

4.2.15 |

Inhibit controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

60 |

|||||||

|

4.2.16 |

Enable controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

61 |

|||||||

|

4.2.17 |

Reset error |

|

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

62 |

|||||

|

4.2.18 |

Activate quick stop _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

63 |

|||||||

|

4.2.19 |

Reset quick stop |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

64 |

||||||

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

3 |

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

|

4.2.20 |

Identify pole position (360°) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

65 |

||||||||

|

4.2.21 |

Identify pole position (min. motion) |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

66 |

|||||||

|

4.2.22 |

Resolver error identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

68 |

||||||||

|

4.2.23 |

Load Lenze INV characteristic |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

69 |

|||||||

|

4.2.24 |

Calculate inv. characteristic |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

70 |

|||||||

|

4.2.25 |

Determine motor parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

71 |

||||||||

|

4.2.26 |

Calculate current controller parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

72 |

||||||||

|

4.2.27 |

Calculate speed controller parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

74 |

||||||||

|

4.2.28 |

CAN on board: Reset Node |

|

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

75 |

||||||

|

4.2.29 |

CAN module: Reset node |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

76 |

|||||||

|

4.2.30 |

CAN on board: Pred.Connect.Set |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

77 |

|||||||

|

4.2.31 |

CAN module: Pred.Connect.Set |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

78 |

|||||||

|

4.2.32 |

CAN on board: Identify node |

|

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

79 |

||||||

|

4.2.33 |

CAN module: Identify node |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

80 |

|||||||

|

4.2.34 |

Unbind/bind Ethernet module MXI1 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

81 |

||||||||

|

4.2.35 |

Unbind/bind Ethernet module MXI2 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

82 |

||||||||

|

4.2.36 |

Activate parameter set 1 ... 4 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

83 |

||||||||

|

4.2.37 |

Activate parameter set 1 ... 4 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

85 |

||||||||

|

4.2.38 |

Load cam data |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

87 |

|||||||

|

4.2.39 |

Save cam data |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

89 |

|||||||

|

4.2.40 |

Calculate cam data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

91 |

||||||||

|

4.2.41 |

Calculate cam data checksum _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

92 |

||||||||

|

4.2.42 |

Format file system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

93 |

||||||||

|

4.2.43 |

Restore file system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

94 |

||||||||

|

4.2.44 |

Prepare firmware update |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

95 |

|||||||

|

4.2.45 |

Restart controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

96 |

||||||||

4.3 |

Device states _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

97 |

|||||||||

|

4.3.1 |

"Initialisation active" state |

|

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

99 |

||||||

|

4.3.2 |

"Safe torque off active" state |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

100 |

|||||||

|

4.3.3 |

"Device is ready to switch on" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

100 |

||||||||

|

4.3.4 |

"Device is switched on" state |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

101 |

|||||||

|

4.3.5 |

"Operation" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

101 |

||||||||

|

4.3.6 |

"Warning active" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

102 |

||||||||

|

4.3.7 |

"Warning locked active" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

102 |

||||||||

|

4.3.8 |

"Quick stop by trouble active" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

102 |

||||||||

|

4.3.9 |

"Trouble active" state |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

103 |

|||||||

|

4.3.10 |

"Fault active" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

103 |

||||||||

|

4.3.11 |

"System fault active" state |

|

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

103 |

||||||

4.4 Automatic restart after mains connection/trouble... |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

104 |

|||||||||

4.5 Behaviour after task overflow |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

106 |

|||||||||

4.6 |

Device output power _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

107 |

|||||||||

|

4.6.1 |

Switching frequency _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

107 |

||||||||

|

4.6.2 |

Monitoring of the device utilisation |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

108 |

|||||||

|

4.6.3 |

Operation with increased continuous power _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

109 |

||||||||

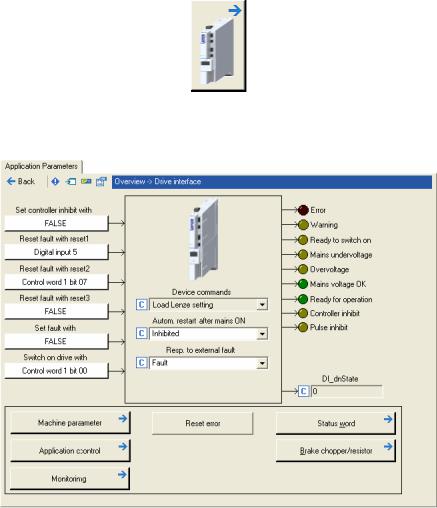

4.7 Internal interfaces | "LS_DriveInterface" system block |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

110 |

|||||||||

|

4.7.1 |

Status signals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

113 |

||||||||

|

4.7.2 |

Monitoring of external events |

|

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

114 |

||||||

4 |

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5 |

Motor interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

115 |

||||||

5.1 |

General information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

117 |

||||||

|

5.1.1 |

Reading out motor data from the controller _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

117 |

|||||

|

5.1.2 |

Selecting a motor from the motor catalogue in the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

118 |

|||||

|

5.1.3 |

Displaying/editing motor data in »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

119 |

|||||

5.2 |

Select motor control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

121 |

||||||

5.3 |

Adjusting motor and controller to each other _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

123 |

||||||

|

5.3.1 |

Accepting/adapting plant parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

124 |

|||||

|

5.3.2 |

Parameterising motor encoder _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

126 |

|||||

|

5.3.3 |

Pole position identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

128 |

|||||

|

5.3.4 |

Optimising the switching performance of the inverter |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

135 |

||||

|

5.3.5 |

Determining the motor parameters |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

138 |

||||

5.4 |

Servo control (SC) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

142 |

||||||

|

5.4.1 |

Optimising the control mode |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

143 |

||||

|

5.4.2 |

Signal flow (servo control for synchronous motor) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

159 |

|||||

|

5.4.3 |

Signal flow (servo control for asynchronous motor) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

161 |

|||||

5.5 |

Sensorless vector control (SLVC) |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

163 |

|||||

|

5.5.1 |

Basic settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

164 |

|||||

|

5.5.2 |

Optimising motor parameters |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

166 |

||||

|

5.5.3 |

Optimising the control mode |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

172 |

||||

|

5.5.4 |

Signal flow |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

180 |

||||

5.6 |

V/f control (VFCplus) |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

181 |

|||||

|

5.6.1 |

Basic settings _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

181 |

|||||

|

5.6.2 |

Optimising the control mode |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

188 |

||||

|

5.6.3 |

Signal flow |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

196 |

||||

5.7 |

V/f control (VFCplus) |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

197 |

|||||

|

5.7.1 |

Signal flow |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

198 |

||||

5.8 |

Parameterisable additional functions |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

200 |

|||||

|

5.8.1 |

Correction of the stator leakage inductance... _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

201 |

|||||

|

5.8.2 |

Field weakening for synchronous machines _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

206 |

|||||

|

5.8.3 |

Flying restart function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

209 |

|||||

|

5.8.4 |

DC-injection braking _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

212 |

|||||

5.9 |

Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

214 |

||||||

|

5.9.1 |

Signal flow |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

214 |

||||

|

5.9.2 |

Motor monitoring (I2xt) |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

215 |

||||

|

5.9.3 |

Motor temperature monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

222 |

|||||

|

5.9.4 |

Motor phase failure monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

226 |

|||||

|

5.9.5 |

Maximum current monitoring |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

230 |

||||

5.10 |

Internal interfaces | "LS_MotorInterface" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

231 |

||||||

6 |

Encoder evaluation |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

236 |

|||||

6.1 |

Internal interfaces | "LS_Feedback" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

237 |

||||||

|

6.1.1 |

Use of an external position encoder |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

239 |

||||

6.2 |

Signal flow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

240 |

||||||

6.3 |

Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

241 |

||||||

|

6.3.1 |

Controller configuration _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

243 |

|||||

|

6.3.2 |

System with motor encoder _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

245 |

|||||

|

6.3.3 |

System with motor encoder and position encoder _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

246 |

|||||

|

6.3.4 |

Position feedback with a linear distance measuring device _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

248 |

|||||

|

6.3.5 |

Adaptation of the resolver evaluation dynamics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

250 |

|||||

|

6.3.6 |

Parameterisation of an unknown Hiperface® encoder |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

251 |

||||

|

6.3.7 |

Parameterisation of a Hiperface® encoder with increased initialisation time _ _ _ _ _ _ _ |

251 |

|||||

|

6.3.8 |

Use of an SSI encoder at X8 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

252 |

|||||

|

6.3.9 |

Rotative encoder with SSI protocol |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

258 |

||||

|

6.3.10 |

Provision of the encoder signal of input X8 _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

260 |

|||||

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

5 |

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

|

6.3.11 |

Resolver error compensation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

263 |

|||

|

6.3.12 |

Encoder angular drift monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

264 |

|||

7 |

Braking operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

266 |

||||

7.1 |

Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

267 |

||||

|

7.1.1 |

Setting the voltage threshold for braking operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

267 |

|||

7.2 |

Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

268 |

||||

|

7.2.1 |

Overcurrent protection |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

268 |

||

|

7.2.2 |

Ixt utilisation - brake transistor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

269 |

|||

|

7.2.3 |

I2t utilisation - brake resistor _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

270 |

|||

|

7.2.4 |

DC bus overvoltage |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

272 |

||

8 |

I/O terminals _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

273 |

||||

8.1 |

Overview _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

273 |

||||

8.2 |

Analog inputs |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

274 |

|||

|

8.2.1 |

Terminal assignment/electrical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

274 |

|||

|

8.2.2 |

Parameter setting |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

275 |

||

|

8.2.3 |

Reconfiguring analog input 1 into current input _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

275 |

|||

|

8.2.4 |

"LS_AnalogInput" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

276 |

|||

8.3 |

Analog outputs |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

277 |

|||

|

8.3.1 |

Terminal assignment/electrical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

277 |

|||

|

8.3.2 |

Parameter setting |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

278 |

||

|

8.3.3 |

"LS_AnalogOutput" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

278 |

|||

8.4 |

Digital inputs |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

279 |

|||

|

8.4.1 |

Terminal assignment/electrical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

279 |

|||

|

8.4.2 |

Parameter setting |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

279 |

||

|

8.4.3 |

"LS_DigitalInput" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

280 |

|||

8.5 |

Digital outputs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

281 |

||||

|

8.5.1 |

Terminal assignment/electrical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

281 |

|||

|

8.5.2 |

Parameter setting |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

281 |

||

|

8.5.3 |

"LS_DigitalOutput" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

282 |

|||

8.6 |

"State bus" monitoring function |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

283 |

|||

|

8.6.1 |

Detecting the current state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

284 |

|||

|

8.6.2 |

Setting the state bus to the "Error" state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

284 |

|||

8.7 |

Touch probe detection _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

285 |

||||

|

8.7.1 |

Actual value interpolation (principle) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

286 |

|||

|

8.7.2 |

Dead time compensation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

287 |

|||

|

8.7.3 |

"LS_TouchProbe1...8" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

288 |

|||

|

8.7.4 |

"LS_TouchProbeMotor" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

289 |

|||

|

8.7.5 |

"LS_TouchProbeLoad" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

289 |

|||

8.8 |

Configure exception handling of the outputs _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

290 |

||||

6 |

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

9 |

"CAN on board" system bus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

292 |

||||||

9.1 |

General information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

293 |

||||||

|

9.1.1 |

General data and application conditions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

294 |

|||||

|

9.1.2 |

Supported protocols _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

294 |

|||||

|

9.1.3 |

Communication time |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

295 |

||||

9.2 |

Possible settings by DIP switch _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

296 |

||||||

|

9.2.1 |

Setting the node address _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

296 |

|||||

|

9.2.2 |

Setting the baud rate |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

297 |

||||

9.3 |

LED status displays for the system bus _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

298 |

||||||

9.4 |

Structure of the CAN data telegram |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

299 |

|||||

|

9.4.1 |

Identifier _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

299 |

|||||

|

9.4.2 |

User data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

301 |

|||||

9.5 |

Communication phases/network management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

302 |

||||||

|

9.5.1 |

State transitions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

303 |

|||||

|

9.5.2 |

Network management telegram (NMT) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

304 |

|||||

|

9.5.3 |

Parameterising the controller as CAN master |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

305 |

||||

9.6 |

Process data transfer |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

306 |

|||||

|

9.6.1 |

Identifiers of the process data objects |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

307 |

||||

|

9.6.2 |

Transmission type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

308 |

|||||

|

9.6.3 |

Masking of the TPDOs for event control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

309 |

|||||

|

9.6.4 |

Monitoring of the RPDOs for data reception _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

309 |

|||||

|

9.6.5 |

Synchronisation of PDOs via sync telegram |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

310 |

||||

9.7 |

Parameter data transfer _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

315 |

||||||

|

9.7.1 |

Identifiers of the parameter data objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

316 |

|||||

|

9.7.2 |

User data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

316 |

|||||

|

9.7.3 |

Parameter data telegram examples |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

322 |

||||

9.8 |

Diagnostics _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

327 |

||||||

9.9 |

Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

328 |

||||||

|

9.9.1 |

Node guarding protocol _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

328 |

|||||

|

9.9.2 |

Heartbeat protocol _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

334 |

|||||

|

9.9.3 |

Emergency telegram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

338 |

|||||

9.10 |

Implemented CANopen objects _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

339 |

||||||

9.11 |

System block "LS_SyncInput" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

364 |

||||||

|

9.11.1 |

Behaviour of the status signal bSyncInsideWindow _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

365 |

|||||

10 |

Safety engineering |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

366 |

|||||

10.1 |

Integration into the application |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

367 |

|||||

10.2 |

Selecting the required safety module |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

368 |

|||||

10.3 |

System block "LS_SafetyModuleInterface" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

368 |

||||||

|

10.3.1 |

Status information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

369 |

|||||

|

10.3.2 |

I/O status information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

370 |

|||||

|

10.3.3 |

Control information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

370 |

|||||

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

7 |

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11 |

Basic drive functions |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

372 |

|||

11.1 |

General information _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

373 |

||||

|

11.1.1 |

Internal state machine _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

373 |

|||

|

11.1.2 |

Function states _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

375 |

|||

|

11.1.3 |

Interrupting/replacing states _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

377 |

|||

|

11.1.4 |

Priorities |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

378 |

||

|

11.1.5 |

Requesting control via a basic function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

379 |

|||

|

11.1.6 |

Start acceleration/acceleration reduction when the basic function changes _ _ _ _ _ _ _ |

380 |

|||

|

11.1.7 |

Setting the S-ramp time _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

382 |

|||

11.2 |

Stop _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

384 |

||||

|

11.2.1 |

Internal interfaces | "LS_Stop" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

385 |

|||

|

11.2.2 |

Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

386 |

|||

|

11.2.3 |

Behaviour of the function (example) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

387 |

|||

11.3 |

Quick stop _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

388 |

||||

|

11.3.1 |

Internal interfaces | "LS_Quickstop" system block" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

388 |

|||

|

11.3.2 |

Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

389 |

|||

|

11.3.3 |

Activate/deactivate quick stop _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

391 |

|||

|

11.3.4 |

DC-injection braking _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

392 |

|||

11.4 |

Manual jog _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

395 |

||||

|

11.4.1 |

Internal interfaces | "LS_ManualJog" system block" _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

396 |

|||

|

11.4.2 |

Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

399 |

|||

|

11.4.3 |

Executing manual jogging _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

401 |

|||

11.5 |

Manual job, encoderless |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

407 |

|||

|

11.5.1 |

Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

408 |

|||

|

11.5.2 |

Carrying out encoderless manual jogging _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

409 |

|||

|

11.5.3 |

Internal interfaces | "LS_ManualJogOpenLoop" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

414 |

|||

11.6 |

Homing _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

416 |

||||

|

11.6.1 |

Internal interfaces | "LS_Homing" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

418 |

|||

|

11.6.2 |

Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

420 |

|||

|

11.6.3 |

Overview of the Lenze homing modes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

427 |

|||

|

11.6.4 |

Overview of DS402 homing modes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

440 |

|||

|

11.6.5 |

Execute homing |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

471 |

||

11.7 |

Positioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

474 |

||||

|

11.7.1 |

Internal interfaces | "LS_Positioner" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

475 |

|||

|

11.7.2 |

Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

480 |

|||

|

11.7.3 |

Carrying out positioning _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

482 |

|||

11.8 |

Position follower _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

485 |

||||

|

11.8.1 |

Internal interfaces | "LS_PositionFollower" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

486 |

|||

|

11.8.2 |

Signal flow |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

487 |

||

|

11.8.3 |

Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

489 |

|||

|

11.8.4 |

Activating setpoint interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

491 |

|||

11.9 |

Speed follower _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

492 |

||||

|

11.9.1 |

Internal interfaces | "LS_SpeedFollower" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

492 |

|||

|

11.9.2 |

Signal flow |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

494 |

||

|

11.9.3 |

Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

495 |

|||

|

11.9.4 |

Activating setpoint interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

496 |

|||

11.10 |

Torque follower |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

497 |

|||

|

11.10.1 Internal interfaces | "LS_TorqueFollower" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

498 |

||||

|

11.10.2 Signal flow |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

499 |

|||

|

11.10.3 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

500 |

||||

|

11.10.4 Activating setpoint interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

501 |

||||

11.11 |

Limiter |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

502 |

|||

|

11.11.1 |

Internal interfaces | "LS_Limiter" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

502 |

|||

|

11.11.2 |

Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

507 |

|||

8 |

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

11.12 |

Brake control _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

517 |

||||

|

11.12.1 Internal interfaces | "LS_Brake" system block |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

519 |

|||

|

11.12.2 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

521 |

||||

|

11.12.3 Mode 0: Brake control is switched off |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

537 |

|||

|

11.12.4 Mode 1/11: Direct control of the brake _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

538 |

||||

|

11.12.5 Mode 2/12: Automatic control of the brake |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

539 |

|||

|

11.12.6 Mode 22: Automatic DC-injection braking _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

544 |

||||

|

11.12.7 Grinding the brake _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

547 |

||||

|

11.12.8 Carrying out brake test |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

549 |

|||

|

11.12.9 Control of two motor holding brakes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

551 |

||||

11.13 |

Cam data management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

552 |

||||

|

11.13.1 "Online" tab for cam data management _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

553 |

||||

|

11.13.2 Internal interfaces | "LS_CamInterface" system block _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

558 |

||||

|

11.13.3 Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

560 |

||||

|

11.13.4 Product/track change-over _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

567 |

||||

|

11.13.5 Invalid cam data due to changed machine parameters _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

568 |

||||

|

11.13.6 Behaviour after mains switching _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

569 |

||||

11.14 |

Pole position identification _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

570 |

||||

|

11.14.1 |

Internal interfaces | System block "LS_PolePositionIdentification" _ _ _ _ _ _ _ _ _ _ _ _ _ |

571 |

|||

|

11.14.2 |

Parameter setting _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

573 |

|||

|

11.14.3 |

Execute pole position identification |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

573 |

||

|

11.14.4 |

Signal characteristics |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

575 |

||

|

11.14.5 Impacts of parameter changes on the signal PPI_bPolePositionAvailable _ _ _ _ _ _ _ _ _ |

577 |

||||

12 |

Oscilloscope _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

579 |

||||

12.1 |

Technical data _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

579 |

||||

12.2 |

Functional description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

580 |

||||

12.3 |

User interface _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

581 |

||||

12.4 |

Operation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

582 |

||||

|

12.4.1 |

Selecting the variables to be recorded |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

582 |

||

|

12.4.2 |

Selecting the recording time/sample rate _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

584 |

|||

|

12.4.3 |

Selecting the trigger condition _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

585 |

|||

|

12.4.4 |

Starting recording _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

586 |

|||

|

12.4.5 |

Adjusting the representation _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

587 |

|||

|

12.4.6 |

Cursor function: Reading individual measured values _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

589 |

|||

12.5 |

Managing oscillograms (measured data records) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

590 |

||||

|

12.5.1 |

Commenting the oscillogram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

590 |

|||

|

12.5.2 |

Saving the oscillogram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

591 |

|||

|

12.5.3 |

Loading an oscillogram |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

592 |

||

|

12.5.4 |

Closing an oscillogram _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

593 |

|||

|

12.5.5 |

Overlay function _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

593 |

|||

|

12.5.6 |

Deleting a data record saved in the project _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

594 |

|||

12.6 |

Variables of the motor control (oscilloscope signals) |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

595 |

|||

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

9 |

Contents

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

13 |

Diagnostics & fault analysis |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

598 |

||

13.1 |

LED status displays _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

598 |

|||

|

13.1.1 LED status displays for the device state _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

599 |

|||

13.2 |

Drive diagnostics with the »Engineer« _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

600 |

|||

13.3 |

Drive diagnostics via keypad/bus system |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

601 |

||

13.4 |

Logbook |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

603 |

||

|

13.4.1 |

Functional description _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

604 |

||

|

13.4.2 |

Filtering logbook entries _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

604 |

||

|

13.4.3 Reading out logbook entries _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

605 |

|||

|

13.4.4 |

Export logbook entries to a file _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

606 |

||

13.5 |

Monitoring _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

607 |

|||

|

13.5.1 |

Setting the error response _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

608 |

||

13.6 |

Maloperation of the drive _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

609 |

|||

13.7 |

Error messages of the operating system _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

610 |

|||

|

13.7.1 |

Structure of the error number (bit coding) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

610 |

||

|

13.7.2 |

Reset error message |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

614 |

|

|

13.7.3 |

Short overview (A-Z) _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

615 |

||

|

13.7.4 |

Cause & possible remedies _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

623 |

||

14 |

Parameter reference _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

713 |

|||

14.1 |

Structure of the parameter descriptions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

714 |

|||

|

14.1.1 |

Data type _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

714 |

||

|

14.1.2 |

Parameters with read-only access |

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

715 |

|

|

14.1.3 |

Parameters with write access _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

715 |

||

|

14.1.4 Parameter attributes _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

719 |

|||

|

14.1.5 |

Abbreviations used in parameter & selection texts _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

719 |

||

14.2 |

Parameter list _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

720 |

|||

14.3 |

Attribute table _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

913 |

|||

|

Index _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

927 |

|||

|

Your opinion is important to us _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ |

952 |

|||

10 |

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

1 About this documentation

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1 |

About this documentation |

Danger!

The controller is a source of danger which may cause death or serious personal injury.

In order to ensure protection against this danger, observe the safety instructions before switching on the controller.

Please read the safety instructions in the mounting instructions and hardware manual of the Servo-Inverter 9400 HighLine. Both instructions are included in the scope of supply.

Target group

This documentation addresses to all persons who want to parameterise, configure, and diagnose the 9400 HighLine controller by means of the engineering software L-force »Engineer« and the keypad.

Validity

The information in this documentation are valid for the following standard devices:

Product series |

Type designation |

from software version |

9400 Servo Drives |

E94AxHExxxx |

1.5 |

|

|

|

Screenshots/application examples

All screenshots in this documentation are application examples. Depending on the firmware version of the 9400 HighLine and the software version of the engineering tools installed (»Engineer« or » Easy Starter«), the screenshots in this documentation may deviate from the screen representation.

Document history

Version |

|

|

Description |

10.0 |

11/2013 |

TD05 |

Error corrections; parameter reference V12.00.xx |

9.0 |

12/2012 |

TD06 |

Extended by new functions for 9400 HighLine V11 |

8.0 |

12/2011 |

TD06 |

Extended by new functions for 9400 HighLine V10 |

7.1 |

10/2010 |

TD06 |

Error corrections & supplements |

7.0 |

04/2010 |

TD06 |

Extended by new functions for 9400 HighLine V8 |

6.1 |

08/2009 |

TD05 |

Error corrections & supplements |

6.0 |

08/2009 |

TD05 |

Extended by new functions for 9400 HighLine V7 |

5.2 |

01/2009 |

TD05 |

Error corrections & supplements |

5.1 |

12/2008 |

TD05 |

Error corrections |

5.0 |

11/2008 |

TD05 |

Extended by new functions for 9400 HighLine V5 |

4.1 |

07/2008 |

TD05 |

New main chapter: "CAN on board" system bus |

4.0 |

06/2008 |

TD05 |

Supplemented with new functions for 9400 HighLine V4 |

3.0 |

11/2007 |

TD05 |

Supplemented with new functions for 9400 HighLine V3 |

2.0 |

05/2007 |

TD05 |

Extended edition |

1.0 |

12/2006 |

TD05 |

First edition for 9400 HighLine V1.5 |

|

|

|

|

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

11 |

1 About this documentation

1.1Conventions used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.1Conventions used

This documentation uses the following conventions to distinguish between different types of information:

Type of information |

Writing |

Examples/notes |

Spelling of numbers |

|

|

Decimal separators |

Point |

The decimal point is generally used. |

|

|

For example: 1234.56 |

Text |

|

|

Version information |

Blue text colour |

Information that is only valid for or from a certain software |

|

|

version of the controller is marked accordingly in this |

|

|

manual. |

|

|

Example: This function extension is available from software |

|

|

version V3.0! |

Program name |

» « |

The Lenze PC software »PLC Designer«... |

Window |

italics |

The Message window ... / The Options dialog box... |

Variable identifier |

|

By setting bEnable to TRUE... |

Control element |

bold |

The OK button... / The Copy command... / The Properties |

|

|

tab... / The Name input field... |

Sequence of menu |

|

If the execution of a function requires several commands, |

commands |

|

the individual commands are separated by an arrow: Select |

|

|

File Open to... |

Shortcut |

<bold> |

Press <F1> to open the online help. |

|

|

|

|

|

If a command requires a combination of keys, a "+" is placed |

|

|

between the key symbols: Use <Shift>+<ESC> to... |

Program code |

Courier |

IF var1 < var2 THEN |

|

|

|

Keyword |

Courier bold |

a = a + 1 |

|

|

END IF |

|

|

|

Hyperlink |

Underlined |

Optically highlighted reference to another topic. In this |

|

|

documentation activated by mouse-click. |

Icons |

|

|

Page reference |

( 12) |

Optically highlighted reference to another page. In this |

|

|

documentation activated by mouse-click. |

Step-by-step instructions |

|

Step-by-step instructions are indicated by a pictograph. |

12 |

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

1 About this documentation

1.2Terminology used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.2Terminology used

Term |

Meaning |

|

Engineering tools |

Software solutions for easy engineering in all project stages |

|

|

|

|

|

|

»EASY Navigator« – provides a good guide to the user |

|

|

• All convenient Lenze engineering tools at a glance |

|

|

• Tools can be selected quickly |

|

|

• The clear structure simplifies the engineering process from the start |

|

|

|

|

|

»EASY Starter« – easy-to-use tool for service technicians |

|

|

• Specially designed for the commissioning and maintenance of Lenze |

|

|

devices |

|

|

• Graphical user interface with just a few buttons |

|

|

• Easy online diagnostics, parameterisation, and commissioning |

|

|

• No risk of an unintended change in applications |

|

|

• Loading of ready-to-use applications to the device |

|

|

|

|

|

»Engineer« – multi-device engineering |

|

|

• For all products in our L-force portfolio |

|

|

• Practical user interface |

|

|

• Graphic interfaces make it easy to navigate |

|

|

• Can be applied in every phase of a project (project planning, |

|

|

commissioning, production) |

|

|

• Parameter setting and configuration |

L-force Controller |

The L-force controller is the central component of the automation system which (by |

|

|

means of the runtime software) controls the Logic and Motion functionalities. |

|

|

The L-force Controller uses the fieldbus to communicate with the field devices. |

|

Engineering PC |

The Engineering PC and the engineering tools installed on it serve to configure and |

|

|

parameterise the system. |

|

|

The Engineering PC uses Ethernet to communicate with the L-force Controller. |

|

Code |

"Container" for one or several parameters used for controller parameter setting or |

|

|

monitoring. |

|

Subcode |

If a code contains several parameters, the individual parameters are stored under |

|

|

"subcodes". |

|

|

This Manual uses a slash "/" as a separator between code and subcode (e.g. "C00118/3"). |

|

Function block editor |

Graphical interconnection tool which is provided for controllers in the MotionControl |

|

|

HighLevel and TopLevel license level in the »Engineer« on the FB editor tab and by means |

|

|

of which the technology applications supplied can also be reconfigured and extended by |

|

|

individual functions. |

|

Function block |

A function block (FB) can be compared with an integrated circuit that contains a specific |

|

|

control logic and delivers one or several values when being executed. |

|

|

• An instance (reproduction, copy) of the function block is always inserted in the circuit. |

|

|

• It is also possible to insert several instances of a function block in a circuit. |

|

|

• Each instance has an unequivocal identifier (the instance name) and a processing |

|

|

number which defines the position at which the function block is calculated during |

|

|

the task cycle. |

|

|

|

|

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

13 |

1 About this documentation

1.3Definition of notes used

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

1.3Definition of notes used

The following signal words and symbols are used in this documentation to indicate dangers and important information:

Safety instructions

Layout of the safety instructions:

Danger!

(characterises the type and severity of danger)

Note

(describes the danger and gives information about how to prevent dangerous situations)

Pictograph |

Signal word |

Meaning |

|

Danger! |

Danger of personal injury through dangerous electrical voltage |

|

Reference to an imminent danger that may result in death or serious personal |

|

|

injury if the corresponding measures are not taken. |

|

|

Danger! |

Danger of personal injury through a general source of danger |

|

Reference to an imminent danger that may result in death or serious personal |

|

|

injury if the corresponding measures are not taken. |

|

|

Stop! |

Danger of property damage |

|

Reference to a possible danger that may result in property damage if the |

|

|

corresponding measures are not taken. |

|

Application notes |

|

|

|

|

|

Pictograph |

Signal word |

Meaning |

|

Note! |

Important note to ensure trouble-free operation |

|

Tip! |

Useful tip for simple handling |

|

|

Reference to other documentation |

|

|

|

14 |

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

2 Introduction

2.1Parameter setting, configuring, or programming?

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2 Introduction

The basis of every L-force application is an easy and quick parameter setting of prepared technology applications and solutions*.

This chapter contains basic information on the runtime software model of L-force and on how you can establish an online connection between the PC and controller for parameter setting with »Engineer« very easily.

At the end of this chapter you will find an overview of the different signal types & scaling which serve to process physical values (e.g. a speed or position) within the application.

*In preparation!

2.1Parameter setting, configuring, or programming?

The graded runtime software model of L-force provides a simple and consistent solution for motion and process tasks as well as for complex machine functions:

Runtime software

PLC level

Freely programmable open and closed loop control functions*

Technology level

Motion Control TopLevel

Additional motion and process control modes for complex drive tasks.

Motion Control HighLevel

Individual extensibility of the basic functions & technology applications by means of the function block editor and the comprehensive function library.

Motion Control StateLevel

Parameterisable basic functions & technology applications.

Programming*

Configuring

The HighLevel and TopLevel licenses enable you to extend the provided technology applications by individual functions using the graphic function block editor of »Engineer«. Here you can access the comprehensive function libraries of Lenze which among other things contain process controllers, arithmetic functions, logic blocks, and ramp generators and integrators.

Parameter setting

The StateLevel license includes a range of technology applications which can be put into operation easily with a keypad or via dialogs in »Engineer«.

* In preparation!

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

15 |

2 Introduction

2.1Parameter setting, configuring, or programming?

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.1.1Basic functionalities

Important basic drive functions and further basic functions are implemented in the firmware of the controller and thus are always provided, irrespective of the runtime software licence available.

Firmware |

|

|

|

||

|

Motion Control basic drive functions |

|

|

Further basic functionalities |

|

|

• Stop |

|

• Drive interface |

||

|

• Quick stop |

|

• Motor interface |

||

|

• Manual jog |

|

• Encoder evaluation |

||

|

• Homing |

|

• I/O terminals |

||

|

• Positioning |

|

• Safety engineering |

||

|

• Position follower |

|

• Logbook |

||

|

• Speed follower |

|

• Oscilloscope |

||

•Torque follower

•Limiter

•Brake control

2.1.2Technology applications

Technology applications (TAs) are applications prepared by Lenze which can serve as a basis for solving typical applications.

•The technology applications available for the Servo Drives 9400 can be selected in »Engineer« from the application catalogue.

Runtime software

Technology level

Motion Control TopLevel

•TA "Positioning sequence control"

•TA "Electronic cam" *

•TA "Register control" *

•TA "Winding technology" *

Motion Control HighLevel

•TA "Electronic gearbox"

•TA "Synchronism with mark synchronisation"

Motion Control StateLevel

•TA "Actuator – speed"

•TA "Actuator – torque"

•TA "Table positioning"

Each higher license contains additional technology applications for further application fields.

* In preparation!

Tip!

Detailed information about the individual technology applications can be found in the corresponding software manuals.

16 |

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

2 Introduction

2.2Communicating with the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

2.2Communicating with the controller

The following interfaces/communication modules can be used to establish communication between the PC and controller:

•Diagnostic interface X6/Going online via diagnostic adapter

•CAN on board interface/Going online via system bus (CAN on board) ( 20)

•Optional interfaces which are provided by corresponding communication modules in the module slots MXI1/MXI2 of the controller.

Note!

For communication with the controller, at least the control electronics of the controller must be supplied with 24 V low voltage via plug X2. For detailed information, please see the Mounting Instructions for the controller.

Stop!

If you change parameters in the »Engineer« while the controller is connected online, the changes will be directly accepted by the controller!

Tip!

Detailed information about the individual interfaces can be found in the corresponding Communication Manuals (KHB).

2.2.1Going online via diagnostic adapter

For initial commissioning of the controller you can for instance use the diagnostic adapter offered by Lenze:

Note!

Please observe the documentation for the diagnostic adapter!

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

17 |

2 Introduction

2.2Communicating with the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Preconditions:

•The diagnostic adapter is connected to the controller at the diagnostic interface X6 and to the PC at a free USB port.

•The driver required for the diagnostic adapter is installed.

•The control electronics of the controller is supplied with 24 V low voltage via plug X2.

How to build up an online connection via the diagnostic adapter:

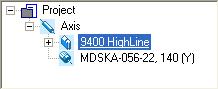

1.Select the 9400 HighLine controller to which you want to build up an online connection in the Project view of the »Engineer«:

2.Click the  icon.

icon.

If the changes you have made on the project have not been accepted yet, first a query on whether an update is to be carried out is effected.

If an update is to be carried out:

•Click on Yes to open the Update project dialog box.

•Press the Create button in the Update project dialog box to update the changed project elements.

•After the update a note is shown, saying whether the update was carried out successfully.

18 |

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

2 Introduction

2.2Communicating with the controller

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

If no communication path was configured yet for the controller selected, the

Communication path dialog box is shown after the update has been carried out:

•The "Diagnostic adapter" bus connection is already preset.

3.Click on Connect.

•The dialog box is closed and the online connection with the controller is built up.

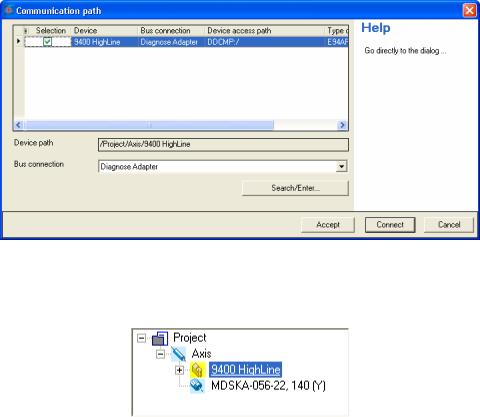

•In the Project view a yellow icon indicates the online connection with the controller:

Now you can use the icons  and

and  to easily build up and end a connection with the controller. The communication settings are only required when communication with a controller is built up for the first time.

to easily build up and end a connection with the controller. The communication settings are only required when communication with a controller is built up for the first time.

•If you want to change the configured communication path, select the command Online Set communication path and go online to open the Communication path dialog box and change the settings.

•When an online connection has been established, the »Engineer« displays the current parameter settings of the controller with a yellow background colour.

Lenze · Servo-Inverter 9400 HighLine · Reference manual · DMS 10.0 EN · 11/2013 · TD05/06 |

19 |

2 Introduction

2.2Communicating with the controller