HP DesignJet T790, DesignJet T1300, DesignJet T2300, DesignJet Z5400ps Service Manual

DESIGNJET T790/T1300/Z5400ps

ePrinter series & T2300 eMFP series

Service manual

For HP Internal Use Only

©Copyright Hewlett-Packard Company

2011

This document contains proprietary

information that is protected by copyright.

All rights are reserved. No part of this

document may be photocopied, reproduced,

or translated to another language without

the prior written consent of Hewlett-Packard

Company.

Edition, December 2013.

Notices

Warranty

The information contained in this

document is subject to change without

notice.

Hewlett-Packard makes no

warranty of any kind with

regard to this material,

including, but not limited to,

the implied warranties of

merchantability and fitness for

a particular purpose.

Hewlett-Packard shall not be liable for

errors contained herein or for

incidental or consequential damages

in connection with the furnishing,

performance, or use of this material.

WARNING

The procedures described in this manual are

to be performed by HP-qualified service

personnel only.

Electrical Shock Hazard

Serious shock hazard leading to death or

injury may result if you do not take the

following precautions:

●

Ensure that the ac power outlet (mains)

has a protective earth (ground)

terminal.

●

Disconnect the product from the power

source prior to performing any

maintenance.

●

Prevent water or any other liquids from

running onto electrical components or

circuits, or through openings in the

enclosure.

Electrostatic Discharge

Refer to the beginning of Chapter 4

Introduction on page 272 of this manual,

for precautions you should take to prevent

damage to the product circuits from

electrostatic discharge.

Safety Symbols

General definitions of safety symbols are

given immediately after the table of

contents.

WARNING

The Warning symbol calls attention to

a procedure, practice, or the like,

which, if not correctly performed or

adhered to, could result in personal

injury. Do not proceed beyond a

Warning symbol until the indicated

conditions are fully understood and

met.

CAUTION

The Caution symbol calls attention to

an operating procedure, practice, or

the like, which, if not correctly

performed or adhered to, could result

in damage to or destruction of part or

all of the product. Do not proceed

beyond a Caution symbol until the

indicated conditions are fully

understood and met.

Content Management Department,

Barcelona Division,

Hewlett-Packard Espanola, S.A.

Avda. Graells, 501

08190 Sant Cugat del Valles

Spain

ENWW iii

iv Notices ENWW

Using this Manual

This Service Manual contains information necessary to test, calibrate, maintain and service the

following:

RTL PostScript

HP Designjet T790 24inch CR647A CR648A

HP Designjet T790 44inch CR649A CR650A

HP Designjet T1300 44inch CR651A CR652A

HP Designjet T2300 eMFP

44inch

CN727A CN728A

HP Designjet T790 24inch

Rev.B

- CR648B

HP Designjet T790 44inch

Rev.B

- CR650B

HP Designjet T1300 44inch

Rev.B

- CR652B

HP Designjet T2300 eMFP

44inch Rev.B

- CN728B

HP Designjet Z5400ps 44inch - E1L21A

HP Designjet Z5400ps 44inch

Rev.B

- E1L21B

When information is only applicable to a specific product, the text will indicate which product it is

applicable to. There are three main areas where this might occur, and at each occurrence an icon will

also be shown:

HP Designjet T2300 Printer

series

HP Designjet T790/T1300/Z5400ps

Printer series

Web Enabled

For information about using these products, refer to the corresponding User and Quick Reference

Guides.

Readership

The procedures described in this Service Manual are to be performed by HP Certified service personnel

only.

Part Numbers

ENWW v

Part Numbers for product service parts are located in Chapter 7 Parts and Diagrams on page 239.

vi Using this Manual ENWW

Table of contents

1 Troubleshooting ................................................................................................................ 1

Using the Touch Control Panel (MFP only) ................................................................................... 2

Using the Touch Control Panel ................................................................................................... 4

Service Key Combinations ......................................................................................................... 6

Product Troubleshooting trees (MFP) ........................................................................................... 7

Paper-handling troubleshooting ................................................................................................ 15

Ink-supplies troubleshooting ..................................................................................................... 16

Print Quality .......................................................................................................................... 37

The Service Image Quality Diagnostic Print ............................................................................... 38

Reading the Diagnostic Print Results .......................................................................................... 40

Advanced Diagnostic Prints ..................................................................................................... 45

Reading the Advanced diagnostic Print Results ........................................................................... 47

Troubleshooting Print Quality Problems ..................................................................................... 53

Connectivity troubleshooting .................................................................................................... 66

2 System Error Codes ......................................................................................................... 71

Introduction ........................................................................................................................... 71

Product logs .......................................................................................................................... 72

What to do if the Touch Control Panel is blank .......................................................................... 72

Troubleshooting system Error 08:11 using LEDs of the Formatter .................................................. 76

Continuable and Non-Continuable Error Codes ......................................................................... 77

System Error Code Brief Descriptions ........................................................................................ 77

System Error Codes—Full Descriptions ...................................................................................... 80

Appendix A: How to troubleshoot SE 79:04 ............................................................................ 109

Appendix B: Emergency firmware upgrade with USB flash drive ................................................ 121

Appendix C: Obtaining the product log and the diagnostics package ........................................ 122

Appendix D: How to check the display list memory for an HP-GL/2 job ...................................... 126

3 Diagnostics Menu ......................................................................................................... 129

Introduction ......................................................................................................................... 129

Diagnostic Tests and Utilities .................................................................................................. 131

ENWW vii

4 Service Menu ................................................................................................................ 173

Introduction ......................................................................................................................... 173

Service Utilities .................................................................................................................... 173

Service Calibrations ............................................................................................................. 214

5 Parts and Diagrams ...................................................................................................... 239

Introduction ......................................................................................................................... 240

Product Support ................................................................................................................... 241

Center Covers Front (1 of 3) .................................................................................................. 242

Center Covers Front (2 of 3) .................................................................................................. 243

Center Covers Front (3 of 3) .................................................................................................. 244

Roll Covers .......................................................................................................................... 245

Center Covers (Rear) ............................................................................................................ 246

Right Cover ......................................................................................................................... 247

Left Cover ........................................................................................................................... 248

Right Hand Assemblies ......................................................................................................... 249

Left Hand Assemblies ............................................................................................................ 250

Carriage Assembly ............................................................................................................... 252

Scan-Axis Assemblies ........................................................................................................... 253

Paper Path Assemblies (Front) ................................................................................................ 254

Paper Path Assemblies (Rear) ................................................................................................. 255

Roll Supports ....................................................................................................................... 256

Scanner Parts (1 of 3) ........................................................................................................... 258

Scanner Parts (2 of 3) ........................................................................................................... 259

Scanner Parts (3 of 3) ........................................................................................................... 260

Tools 1 ............................................................................................................................... 261

Tools 2 ............................................................................................................................... 262

Miscellaneous Parts .............................................................................................................. 263

6 Removal and Installation .............................................................................................. 269

Introduction ......................................................................................................................... 272

Customer Self Repair parts .................................................................................................... 275

Service Calibration Guide to Removal and Installation .............................................................. 277

Belt Assembly ...................................................................................................................... 279

Bin Assembly ....................................................................................................................... 280

Bi-stable Springs .................................................................................................................. 283

Bumpers, Left and Right ......................................................................................................... 289

Engine Cables Kit ................................................................................................................ 293

Interconnect Cables Kit ......................................................................................................... 306

Carriage and Cutter Assembly ............................................................................................... 316

viii ENWW

Carriage Bushing, Rear ........................................................................................................ 325

Carriage Cover and Carriage Latch ....................................................................................... 327

Carriage Rail Oiler .............................................................................................................. 332

Carriage PCA ...................................................................................................................... 334

Cleanout ............................................................................................................................. 339

Center Support .................................................................................................................... 341

Converger ........................................................................................................................... 345

Scanner Piston Gas (MFP only) .............................................................................................. 347

Scanner Bumper (MFP only) ................................................................................................... 350

Right Collar Cover (MFP only) ................................................................................................ 353

Front Cover ......................................................................................................................... 360

Front Top Cover Assembly (MFP only) ..................................................................................... 361

Front Top Cover ................................................................................................................... 363

Drop Detector ...................................................................................................................... 366

Aerosol Fan Assembly .......................................................................................................... 368

EE Box ................................................................................................................................ 370

Encoder Disk and Encoder Sensor .......................................................................................... 375

Encoder Strip ....................................................................................................................... 377

Encoder Strip, spring and attachment nut ................................................................................ 378

Formatter ............................................................................................................................ 381

Freewheel Assembly ............................................................................................................. 383

Right Front Trim .................................................................................................................... 386

Full Bleed Foam ................................................................................................................... 388

Hard Disk Drive ................................................................................................................... 389

Left Ink Cartridge Door ......................................................................................................... 391

Right Ink Cartridge Door ....................................................................................................... 393

Left Ink Supply Station ........................................................................................................... 395

Ink Supply Tubes & Trailing Cable .......................................................................................... 400

Ink Supply Tubes Support Rail ................................................................................................ 409

Interconnect PCA ................................................................................................................. 411

Left Collar Cover (MFP only) .................................................................................................. 413

Left Cover ........................................................................................................................... 414

Left Front Trim ...................................................................................................................... 418

Left Scanner Cover (MFP only) ............................................................................................... 420

Scanner Latch and Hook Assembly (MFP only) ......................................................................... 422

Line Sensor .......................................................................................................................... 424

Media Advance Drive .......................................................................................................... 430

Media Lever ........................................................................................................................ 438

Media Lever Position Sensor .................................................................................................. 440

Media Output Assembly ....................................................................................................... 442

Out-of-paper Sensor ............................................................................................................. 444

ENWW ix

Left Panel ............................................................................................................................ 447

Pen to Paper Space (PPS) Solenoid ......................................................................................... 449

Pinch Arm Assembly ............................................................................................................. 451

Pinchwheel Assembly ........................................................................................................... 454

Print Zone Overdrive ............................................................................................................ 462

Power Supply Unit ................................................................................................................ 466

Real-time Clock Battery ......................................................................................................... 468

Rear Cover (MFP only) .......................................................................................................... 469

Rear Cover .......................................................................................................................... 472

Rear Deflectors .................................................................................................................... 473

Right Cover ......................................................................................................................... 475

Right Scanner Cover (MFP only) ............................................................................................. 479

Roll Cover Bumpers, Lower .................................................................................................... 482

Roll Cover, Lower ................................................................................................................. 485

Roll Cover, Upper ................................................................................................................ 489

Left Roll Guide ..................................................................................................................... 491

Right Roll Guide ................................................................................................................... 492

Roll Support, Lower Left ......................................................................................................... 493

Roll Support, Lower Right ...................................................................................................... 495

Roll Support Sensor, Lower Left .............................................................................................. 497

Roll Support Sensor, Upper Left .............................................................................................. 498

Roll Support, Upper Left ........................................................................................................ 499

Roll Support, Upper Right ...................................................................................................... 501

Scan-axis Motor ................................................................................................................... 503

Service Station ..................................................................................................................... 507

Single-sheet Sensor ............................................................................................................... 512

Spindle ............................................................................................................................... 514

Spittoon, Left ....................................................................................................................... 515

Starwheel Assembly ............................................................................................................. 517

Starwheel Lifter, Left .............................................................................................................. 519

Starwheel Lifter, Right ........................................................................................................... 521

Starwheel Motor .................................................................................................................. 525

Wall Spacers ...................................................................................................................... 527

Scanner Position Sensor (MFP only) ........................................................................................ 530

Torsion Damper (MFP only) ................................................................................................... 535

CIS Element (MFP only) ......................................................................................................... 538

Scanner Exit Media Sensors (MFP only) .................................................................................. 539

Scanner Entry Media Sensors (MFP only) ................................................................................ 540

Pressure Rollers (MFP only) .................................................................................................... 541

Scanner Controller Board (MFP only) ...................................................................................... 542

Scanner Motor Assembly (MFP only) ...................................................................................... 544

x ENWW

Taco Sensor (MFP only) ........................................................................................................ 545

Touch Control Panel ............................................................................................................. 547

Window ............................................................................................................................. 551

Window Position Sensor ....................................................................................................... 555

7 Preventive Maintenance ............................................................................................... 557

Preventive Maintenance ........................................................................................................ 557

Preventive Maintenance Kits .................................................................................................. 565

Appendix A CSR Installation Flyers .................................................................................. 569

Cutter assembly ................................................................................................................... 570

Freewheel assembly ............................................................................................................. 572

Freewheel assembly (screwdriver) .......................................................................................... 574

Left side panel (T1200) ......................................................................................................... 576

Pinch arm assembly .............................................................................................................. 578

Pinch arm assembly (screwdriver) ........................................................................................... 580

Roll cover upper bumpers ...................................................................................................... 582

Roll cover upper bumpers (screwdriver) ................................................................................... 584

Foot Extension ..................................................................................................................... 586

Front Deflector ..................................................................................................................... 587

Rear Deflector Mylar ............................................................................................................ 589

Glass Plate .......................................................................................................................... 591

Latch Handle Cover .............................................................................................................. 593

ENWW xi

xii ENWW

1 Troubleshooting

●

Using the Touch Control Panel (MFP only)

●

Using the Touch Control Panel

●

Service Key Combinations

●

Product Troubleshooting trees (MFP)

●

Paper-handling troubleshooting

●

Ink-supplies troubleshooting

●

Print Quality

●

The Service Image Quality Diagnostic Print

●

Reading the Diagnostic Print Results

●

Advanced Diagnostic Prints

●

Reading the Advanced diagnostic Print Results

●

Troubleshooting Print Quality Problems

●

Connectivity troubleshooting

ENWW 1

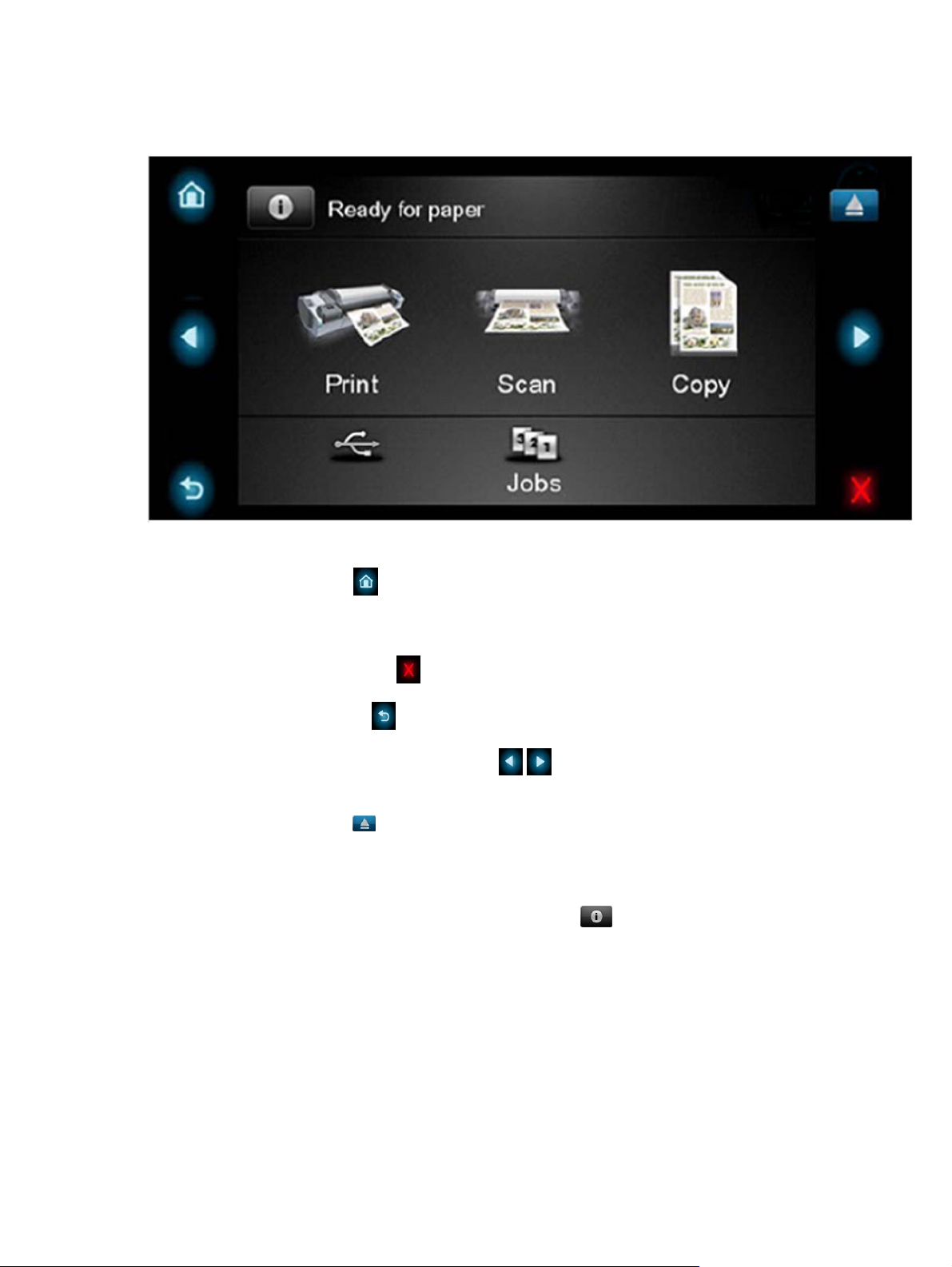

Using the Touch Control Panel (MFP only)

The external frame of the Touch Control Panel contains the following elements:

●

The Home LED (top-left)

is used to return to the Home Screen. When clicked only once, this

same Home Screen is displayed. When pressed for more than 4 seconds, the Accessibility Home

Screen is displayed.

●

The Cancel LED (bottom right)

is used to cancel any action, when it is active.

●

The Back LED (bottom left)

is to go back to the previous screen, when it is active.

●

The Arrow LEDs (in the middle of each side)

enables the user to navigate in both

directions.

●

The Eject LED (top-right)

enables the user to stop the USB connection.

The internal part of the Touch Control Panel is the Home Screen and this is divided into three main

areas:

●

The upper area is for the Product Information (left icon)

and for displaying high priority

alerts (in text) you can press the most critical alert in the home screen and the others (less critical)

will be shown.

The main menu of the product is accessed by clicking on the Product Information icon and then

selecting the last tab (at the right side)

●

The middle area is used to place the three icons for the main work flows of the product, which

are: Print, Scan and Copy.

●

The lower area of the Home Screen is reserved for the contents area. The contents area will

contain all the functionality related with printing content, for example in the Job Queue.

2 Chapter 1 Troubleshooting ENWW

When a USB drive is inserted, a USB icon will also be displayed to the left of this area, and

when a Postscript/PDF job is being printed an Adobe logo

will display in the

bottom right area

ENWW

Using the Touch Control Panel (MFP only)

3

Using the Touch Control Panel

The Touch Control Panel is located on the front right of the printer. It gives you complete control of your

printer: from here you can print, view information about the printer, change printer settings, perform

calibrations and tests, and so on. The Touch Control Panel also displays alerts (warning and error

messages) when needed.

1. A Hi-Speed USB host port, intended for connecting a USB flash drive, which can provide files to

be printed. When a USB flash drive is inserted, a USB icon

is displayed on the Touch Control

Panel's home screen.

2. The Touch Control Panel itself: a touch-sensitive screen with a graphical user interface.

3. The Power key, with which you can turn the printer on or off. The key is illuminated when the

printer is on. It flashes when the printer is in transition between on and off.

The Touch Control Panel has a large central area to display dynamic information and icons. On the left

and right sides you can see up to six fixed icons at different times. Normally they are not all displayed

at the same time.

Left and right fixed icons

●

Press

to return to the home screen.

●

Press

to view help about the current screen.

●

Press

to go to the previous item.

4 Chapter 1 Troubleshooting ENWW

●

Press

to go to the next item.

●

Press

to go back to the previous screen. This does not discard any changes made in the

current screen.

●

Press

to cancel the current process.

Home screen dynamic icons

The following items are displayed only on the home screen.

●

Press

to view information about printer status, change printer settings, or initiate actions such

as loading paper or replacing ink supplies. A smaller warning icon appears if there are actions

that need to be performed.

●

To the right of the above button is a message showing the printer status or the most important

current alert. Press this message to see a list of all current alerts, with an icon indicating the

severity of each alert.

●

Press

to print a file from a USB flash drive, or to print from a computer.

●

Press

to view information about the USB flash drive(s). This icon appears only when one or

more USB flash drives are inserted.

●

Press

to view and manage the job queue. A smaller warning icon appears if there are jobs

on hold.

●

While a PostScript or PDF job is printing (PostScript printers only), the Adobe PDF icon

is

displayed; pressing it has no effect.

If the printer is left idle for some time, it goes into sleep mode and switches off the front-panel display.

To change the time that elapses before sleep mode, press

, then , then Setup > Front

panel options > Sleep mode wait time. You can set a time between 1 and 240 minutes.

The printer wakes from sleep mode and switches on the front-panel display whenever there is some

external interaction with it.

Information about specific uses of the Touch Control Panel can be found throughout this guide.

ENWW

Using the Touch Control Panel

5

Service Key Combinations

Table 1-1 Service Key Combinations

Label Description

Diagnostic mode 1. With the product turned off, press the Power Key

2. When the magic frame LEDs become active, select by

touching one of the following sequences:

●

CANCEL + HOME + EJECT: hp-service-1: For The

Onsite Engineer

●

CANCEL + BACK + EJECT: hp-service-2: For call

center remote support

The LEDs in the frame will blink a response to confirm the

selected sequence.

Service menu (Service Engineers only) With the product is powered on, access main menu – service

menu.

Password is 3174

For tools that require another password, this is 5494

Service menu (for users) With the product powered on, access main menu – service

menu.

Password is 3174. There is an icon in front of the option,

indicating that the tool is protected (which requires a service

password).

6 Chapter 1 Troubleshooting ENWW

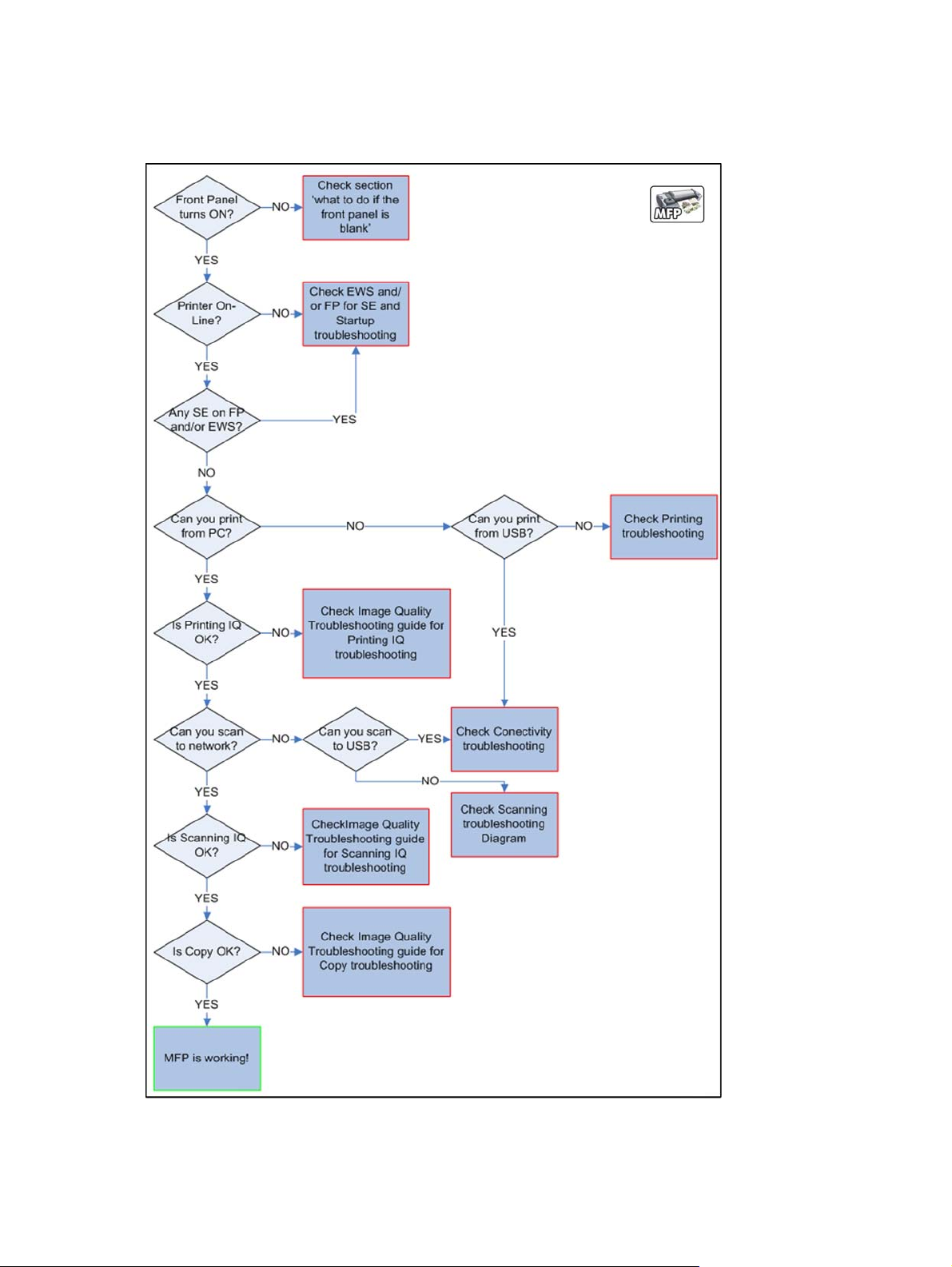

Product Troubleshooting trees (MFP)

Us the following troubleshooting trees to troubleshoot issues with the MFP in the first instance.

ENWW

Product Troubleshooting trees (MFP)

7

Product Troubleshooting Tree

Figure 1-1 Troubleshooting

8 Chapter 1 Troubleshooting ENWW

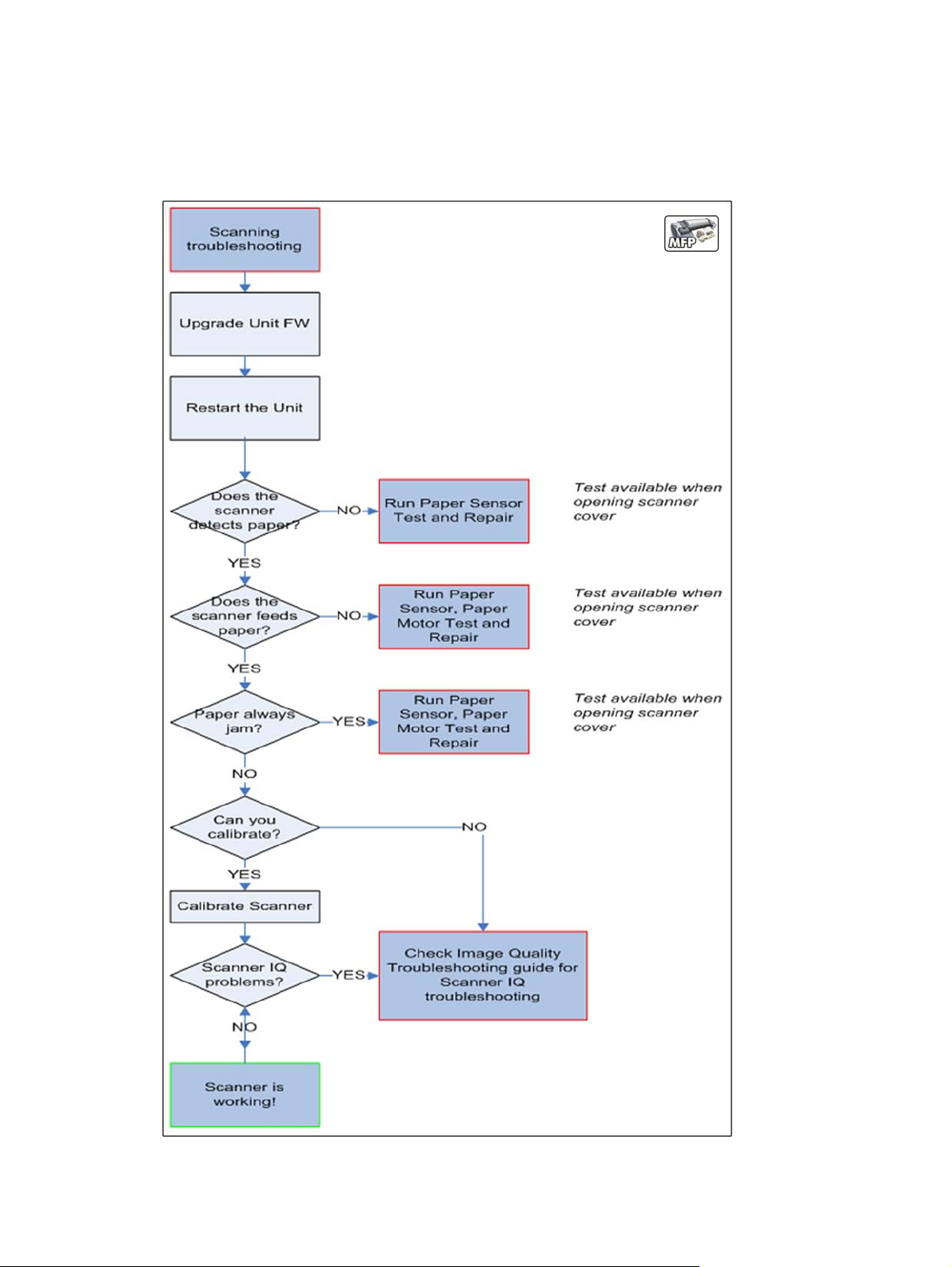

Scanner Troubleshooting Tree

Use this tree to troubleshoot the scanner in the MFP.

Figure 1-2 Scanner Troubleshooting

ENWW

Product Troubleshooting trees (MFP)

9

Scanner CIS Troubleshooting

Use this tree to troubleshoot the CIS of the scanner in the MFP.

Figure 1-3 Scanner Troubleshooting

Troubleshooting system error codes

System Error Codes on page 71 contains a list of system error codes and their respective descriptions

and recommended corrective actions. Try only one recommended action at a time and check whether

the error code has disappeared.

If you have an error code which is not documented in this Service Manual or you have an error which

you cannot resolve, then report the error to the HP Response Center or the nearest HP Support Office.

When reporting the error, have the information ready, refer to

Reporting a system error to HP support

on page 71:

10 Chapter 1 Troubleshooting ENWW

Performing a service test on a failed assembly

If possible, always perform a Service Test on the component/assembly that you are about to replace,

just to make sure that is the component/assembly that has failed.

Shown below is a list of the Service tests and the component(s) tested:

●

Scan Axis Test

◦

Star Wheel Lifter

◦

PRS

◦

Scan Axis Servosystem

◦

Cutter

●

Paper Drive Test

◦

Components of the Paper Axis Subsystem

●

Electronics Module Test

◦

Formatter

●

Carriage assembly test

◦

Carriage Assembly

●

Sensors Test

◦

Scanner Position Sensor (MFP only)

◦

Media Lever Position sensor

◦

Media sensor

◦

Upper or lower roll cover sensor

◦

Single-sheet sensor

●

Rewinder test

◦

Right Roll Support.

●

Ink Delivery System Test

◦

Ink Supply Station

◦

Ink supplies

●

Service Station test

◦

Service Station.

◦

Primer Motor

ENWW

Product Troubleshooting trees (MFP)

11

NOTE: If the test on that component/assembly passes, you should not replace it.

For information on the Service Tests and how to use them see

Diagnostics Menu on page 129.

Performing the necessary service calibrations

Is the product calibrated correctly after replacing a component? For information on the Service

Calibrations and how to use them see

Service Menu on page 173.

NOTE: Remember that certain Calibrations are required even if an Assembly has been disassembled

to gain access to another Assembly or Component.

Solving scan/print-quality problems

Refer to the Image Quality Troubleshooting Guide (in the EWS-Support Tab or in the CD).

The Touch Control Panel is blank

See What to do if the Touch Control Panel is blank on page 72.

The product does not power on

See What to do if the Touch Control Panel is blank on page 72.

The product continuously rejects printheads

▲

Clean the flex contacts on the Printhead and in the Carriage Assembly using the Carriage

Interconnect Wiper and try again.

Cover sensors are not working

1. Perform the Sensors Test. See Sensors Test on page 149.

2. Check that the cable for the faulty sensor is not damaged and is connected correctly.

3. Replace the faulty Sensor.

The line sensor has problems detecting paper

1. Check the type of paper that is being used since the Line sensor may have problems detecting

transparent paper or some types of Non-HP paper. Try loading white HP paper in to the product

and check that the Line sensor detects it.

2. The Line Sensor is not calibrated correctly. Perform the Line Sensor Calibration. See

Line Sensor

Calibration on page 228.

3. The Line Sensor is damaged or faulty. Replace the Line Sensor. See

Line Sensor on page 424.

12 Chapter 1 Troubleshooting ENWW

Troubleshooting Printer paper jams and printhead crashes

The failure modes "paper jam" and "head crash" are grouped together because in many cases a

paper jam causes the paper to lift up into the Carriage path and cause a Printhead crash, thus causing

many paper jam failures to be reported as head crashes.

1. Did the paper jam occur when loading paper?

●

If the client has had paper jams, it is common for pieces of paper to get stuck in the paper

path. Clear the paper path.

NOTE: When clearing a paper jam, sometimes paper is stuck in the paper path. To clear this,

you must lift the Media Lever and insert thicker paper into the paper path to push out the paper

that is still stuck there.

2. Is the customer using non-HP paper?

●

The use of non-HP paper can easily be the cause of paper jams and head crashes (especially

head crashes because HP paper is specially formulated to avoid cockle, one of the primary

causes of head crashes). If the paper is not HP approved, advise the customer to use HP

paper and check to see whether the problem is now solved.

Troubleshooting Scanner paper jams (MFP only)

1. If while feeding paper into the Scanner a jam occurs, use the eject button on the Touch

Control Panel to clear the jam.

2. Unlatch the CIS Cover.

ENWW

Product Troubleshooting trees (MFP)

13

3. Open the CIS and clear the area of any paper.

The basket was damaged during the product setup

1. There are three plastic parts that could break during product installation and need replacing.

2. Check the parts table and graphics in Parts and Diagrams to identify what service parts you must

order. See

Product Support on page 241.

3. Replace the component. See

Bin Assembly on page 280.

14 Chapter 1 Troubleshooting ENWW

Paper-handling troubleshooting

Roll paper The Touch Control Panel of the product indicates that paper is misaligned or incorrectly positioned

●

The roll may be loaded the wrong way. The paper should load over the roll toward you.

●

Check that the paper is correctly loaded onto the spindle.

●

The paper may be loaded at an angle. The right-hand edge must be aligned with the blue line on the

Print Platen.

●

Check that the Right Roll Support is properly attached and screwed to the product.

●

The Rewinder, located on the Right Roll Support, should maintain proper back tension. If the Right Roll

Support is misaligned or not properly attached to the product, the Rewinder will not function properly.

●

To further diagnose problems with the Rewinder, see

Rewinder Test on page 151.

●

If the customer is experiencing problems with paper jams, check that the Overdrive is not obstructed by

paper or that the Turn Drive Roller Service Utility is being used. See

Turn Drive Roller on page 177

●

While attempting to load roll media, if the Touch Control Panel prompts you to remove paper, although

no paper is loaded, calibrate the sheet sensor, refer to

Calibrate Sheet Sensor on page 232

Sheet paper

●

The sheet must be loaded with the right-hand edge against the white line on the upper roll cover.

●

The paper may be crumpled or warped or may have irregular edges.

●

If the printer incorrectly detects the presence of a sheet of paper, perform the Calibrate Sheet Sensor,

refer to

Calibrate Sheet Sensor on page 232.

●

If hand-cut paper is used, the edges may not form a right-angle or they may be rough. If possible,

hand-cut paper should not be used. Only purchased sheet paper should be used in the product.

●

If you have problems with paper jams, check that the Overdrive is not obstructed by bits of paper or

using the Turn Drive Roller Service Utility. See

Turn Drive Roller on page 177.

●

When attempting to load sheet paper from Front Panel, if the printer displays a media skew message

repeatedly, and sheet cannot be loaded, calibrate sheet sensor. refer to

Calibrate Sheet Sensor

on page 232

ENWW

Paper-handling troubleshooting

15

Ink-supplies troubleshooting

●

Introduction to ink supplies

●

Ink cartridge levels, information and replacement

●

Printhead information, replacement and alignment

●

Ink cartridge and printhead status messages

●

Solving ink-supply problems

●

Maintaining and cleaning the printheads

Introduction to ink supplies

Introduction to ink supplies

What are ink supplies?

For each of the ink colors used in the product, there are two components, the Printhead and Ink

Cartridge. These components are called Ink Supplies.

Ink cartridges

The product's six Ink Cartridges provide matte black, magenta, yeloow, cyan, gray and photo black ink

to the Printheads. The color Ink Cartridges supplied with the product have a capacity of 69ml but

optional 130 ml are also available.

All these Ink cartridges are physically the same size. Only the internal capacity varies.

16 Chapter 1 Troubleshooting ENWW

The Ink Cartridges for the T product series require no maintenance or cleaning. As long as each Ink

Cartridge is inserted correctly into its slot, the ink will flow to the Printheads. Because the Printheads

control the amount of ink transferred to the page, you will continue to see high-quality printing results

even when the ink levels are getting low.

The Touch Control Panel displays the status of the Ink Cartridge. Using the Touch Control Panel,

detailed information can be checked on the Ink Cartridges.

Table 1-2 Available Ink Cartridges

Ink cartridge Product Model Part number

HP 72 69 ml Photo Black Ink Cartridge T series models C9397A

HP 72 69 ml Cyan Ink Cartridge T series models C9398A

HP 72 69 ml Magenta Ink Cartridge T series models C9399A

HP 72 69 ml Yellow Ink Cartridge T series models C9400A

HP 72 69 ml Gray Ink Cartridge T series models C9401A

HP 72 130 ml Matte Black Ink Cartridge T series models C9403A

HP 72 130 ml Photo Black Ink Cartridge T series models C9370A

HP 72 130 ml Cyan Ink Cartridge T series models C9371A

HP 72 130 ml Magenta Ink Cartridge T series models C9372A

HP 72 130 ml Yellow Ink Cartridge T series models C9373A

HP 72 130 ml Gray Ink Cartridge T series models C9374A

HP 726 300 ml Matte Black Ink Cartridge T1300 series only CH575A

HP 70 Matte Black 130 ml Ink Cartridge Z5400 series models C9448A

HP 70 Photo Black 130 ml Ink Cartridge Z5400 series models C9449A

HP 70 Light Gray 130 ml Ink Cartridge Z5400 series models C9451A

HP 70 Cyan 130 ml Ink Cartridge Z5400 series models C9452A

HP 70 Magenta 130 ml Ink Cartridge Z5400 series models C9453A

HP 70 Yellow 130 ml Ink Cartridge Z5400 series models C9454A

ENWW

Ink-supplies troubleshooting

17

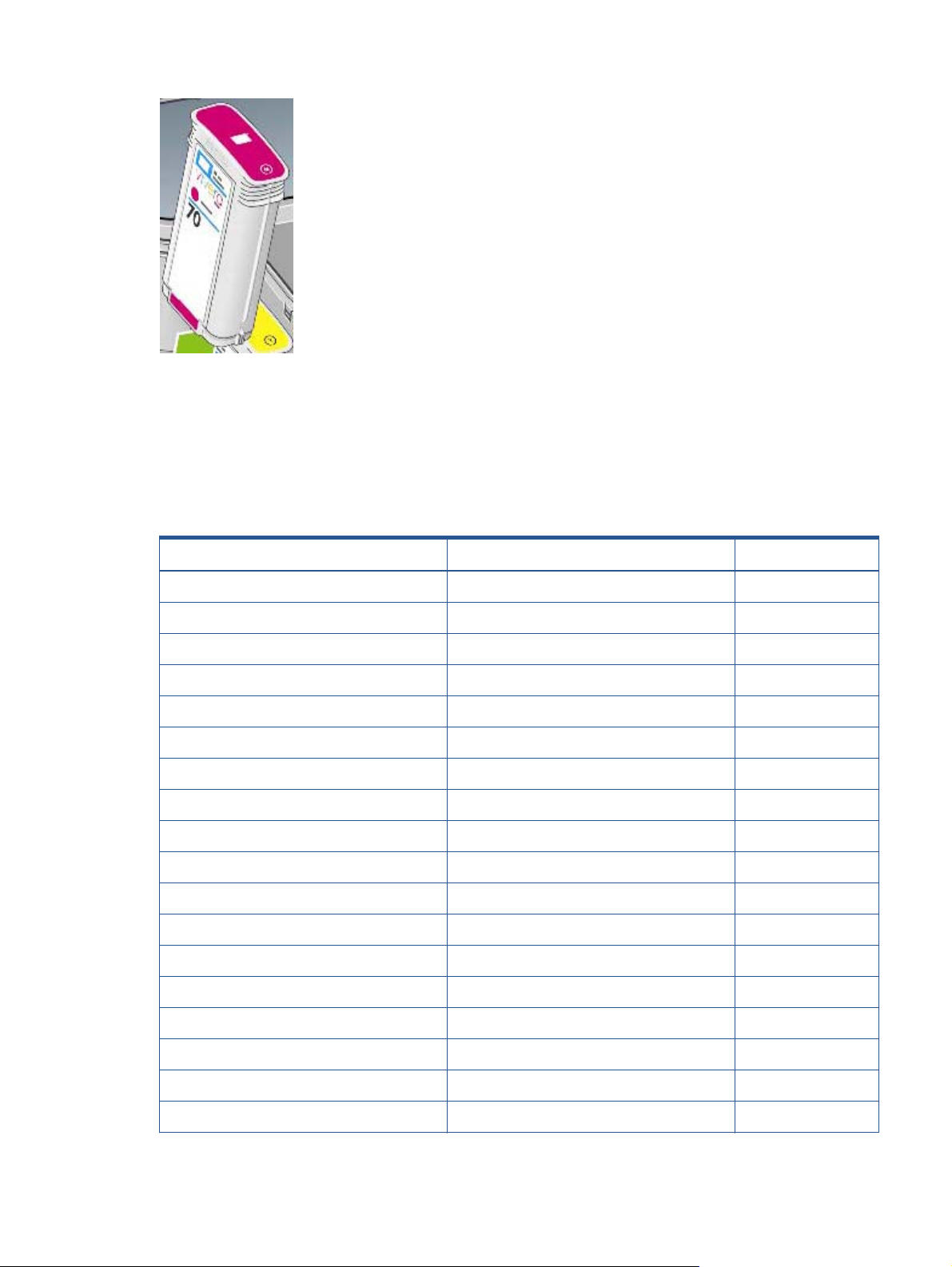

Table 1-2 Available Ink Cartridges (continued)

Ink cartridge Product Model Part number

HP 70 Matte Black 130 ml Ink Cartridge Twin

Pack

Z5400 series models CB339A

HP 70 Photo Black 130 ml Ink Cartridge Twin

Pack

Z5400 series models CB340A

HP 70 Light Gray 130 ml Ink Cartridge Twin

Pack

Z5400 series models CB342A

HP 70 Cyan 130 ml Ink Cartridge Twin Pack Z5400 series models CB343A

HP 70 Magenta 130 ml Ink Cartridge Twin Pack Z5400 series models CB344A

HP 70 Yellow 130 ml Ink Cartridge Twin Pack Z5400 series models CB345A

HP 772 300 ml Magenta Designjet Ink Cartridge Z5400 series models CN629A

HP 772 300 ml Yellow Designjet Ink Cartridge Z5400 series models CN630A

HP 772 300 ml Photo Black Designjet Ink

Cartridge

Z5400 series models CN633A

HP 772 300 ml Light Gray Designjet Ink

Cartridge

Z5400 series models CN634A

HP 772 300 ml Matte Black Designjet Ink

Cartridge

Z5400 series models CN635A

HP 772 300 ml Cyan Designjet Ink Cartridge Z5400 series models CN636A

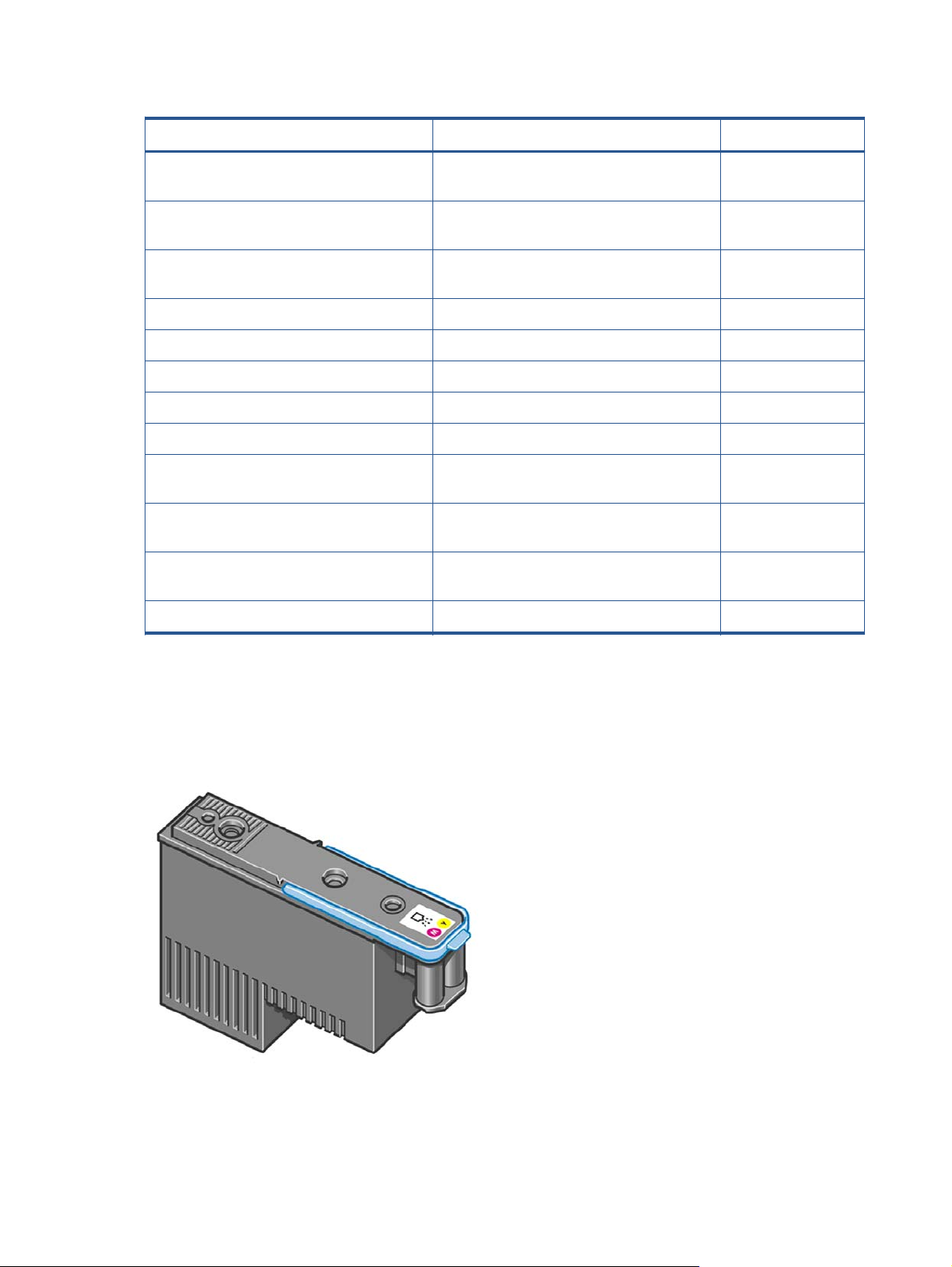

Printheads

The Printheads are extremely durable and do not need to be replaced every time an Ink Cartridge is

replaced. They are independent of the Ink Cartridges and will continue giving excellent image-quality

results even if the Ink Cartridges are low on ink.

18 Chapter 1 Troubleshooting ENWW

Loading...

Loading...